Effect of Recycling and UV Ageing on the Properties of PLA-Based Materials Used in Additive Manufacturing

Abstract

1. Introduction

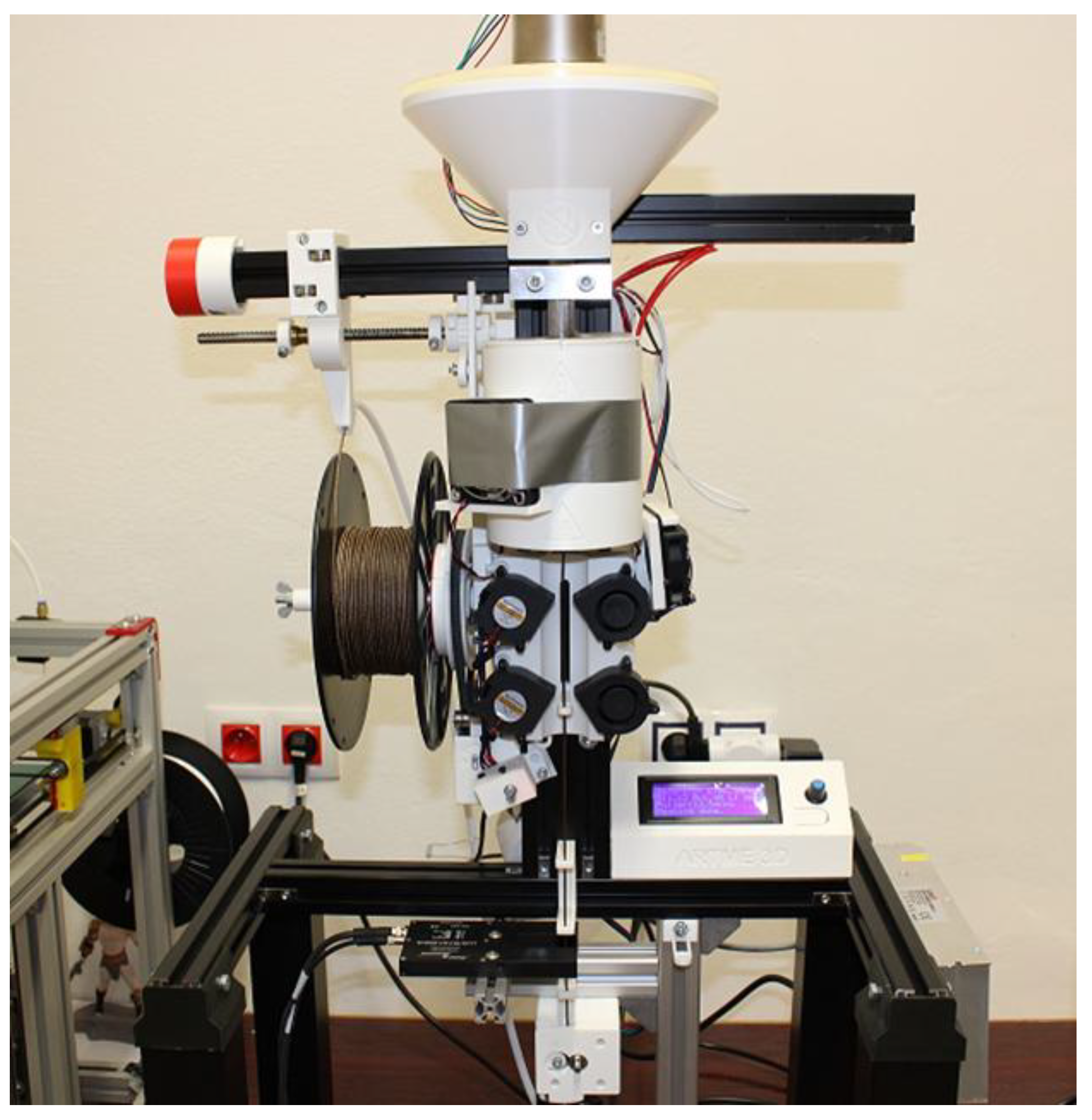

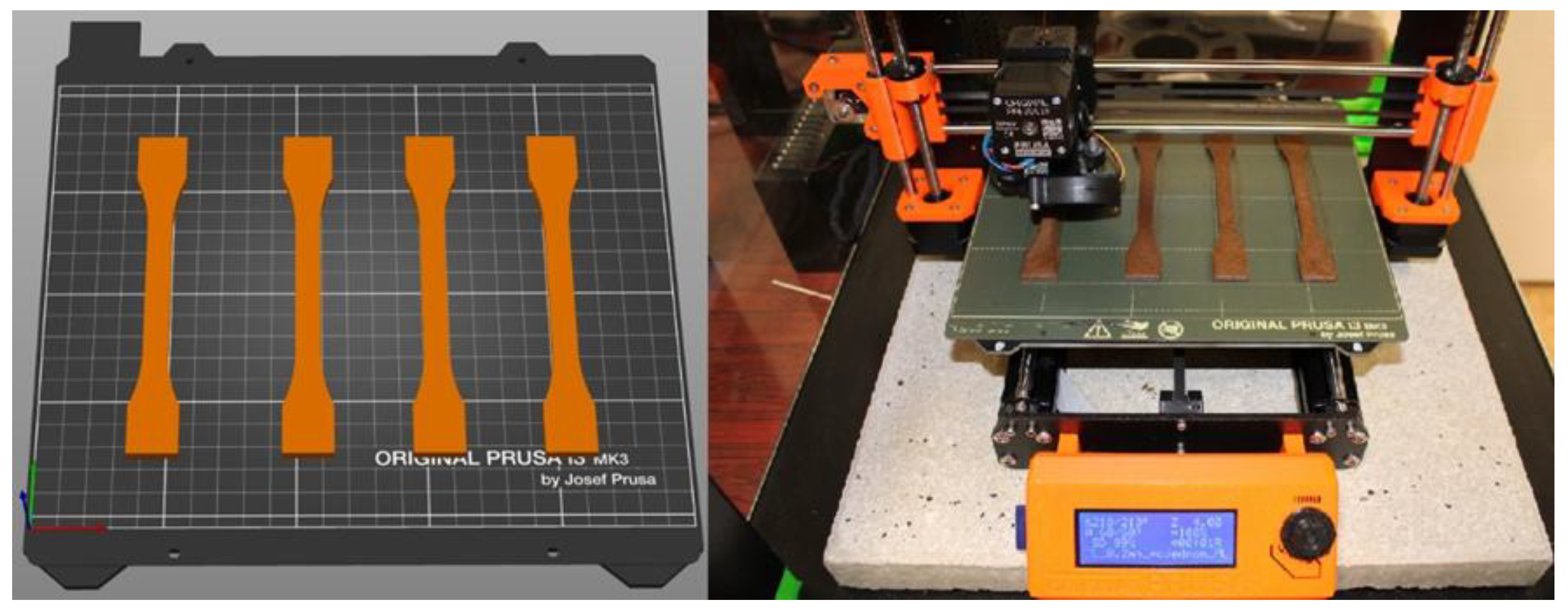

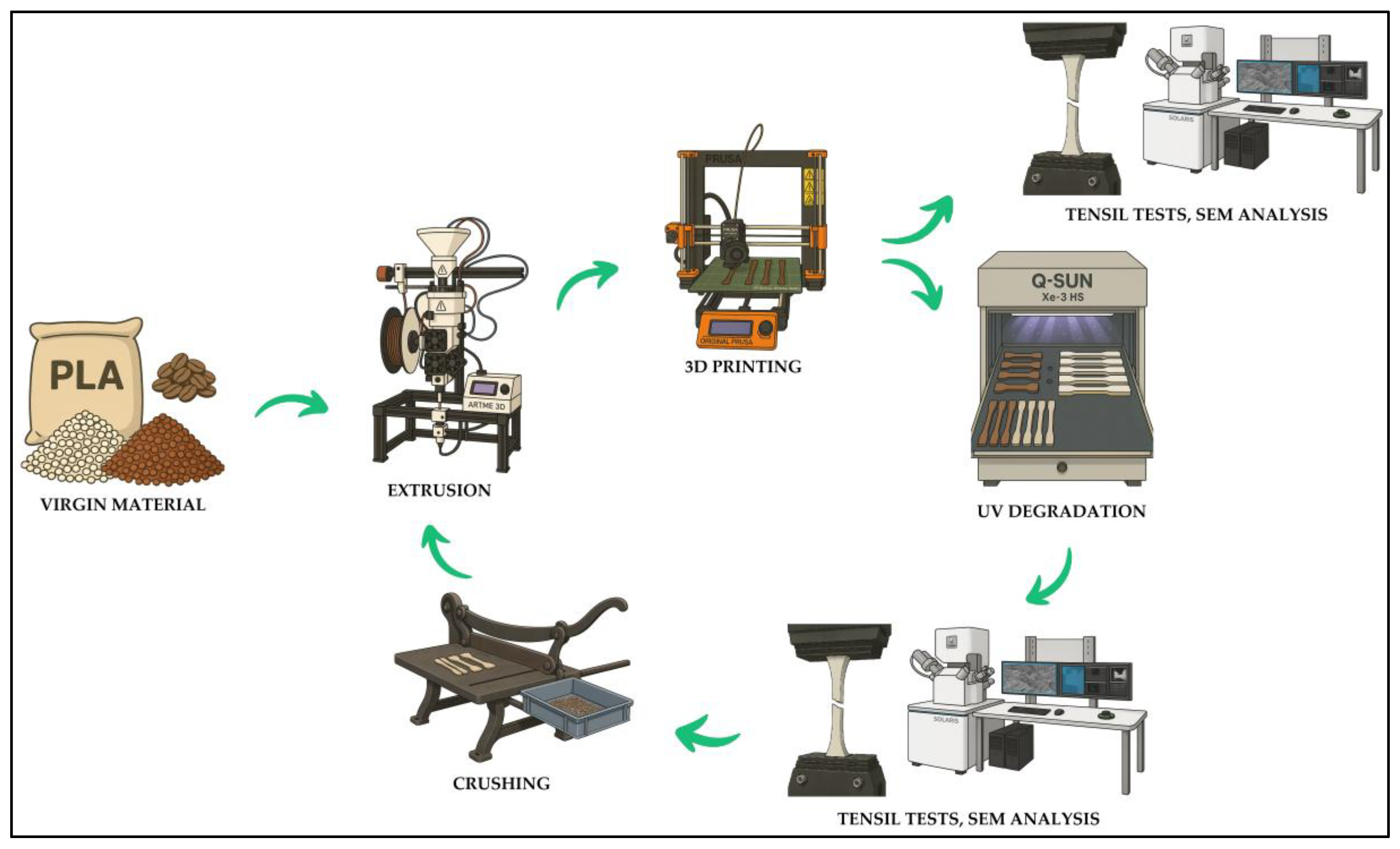

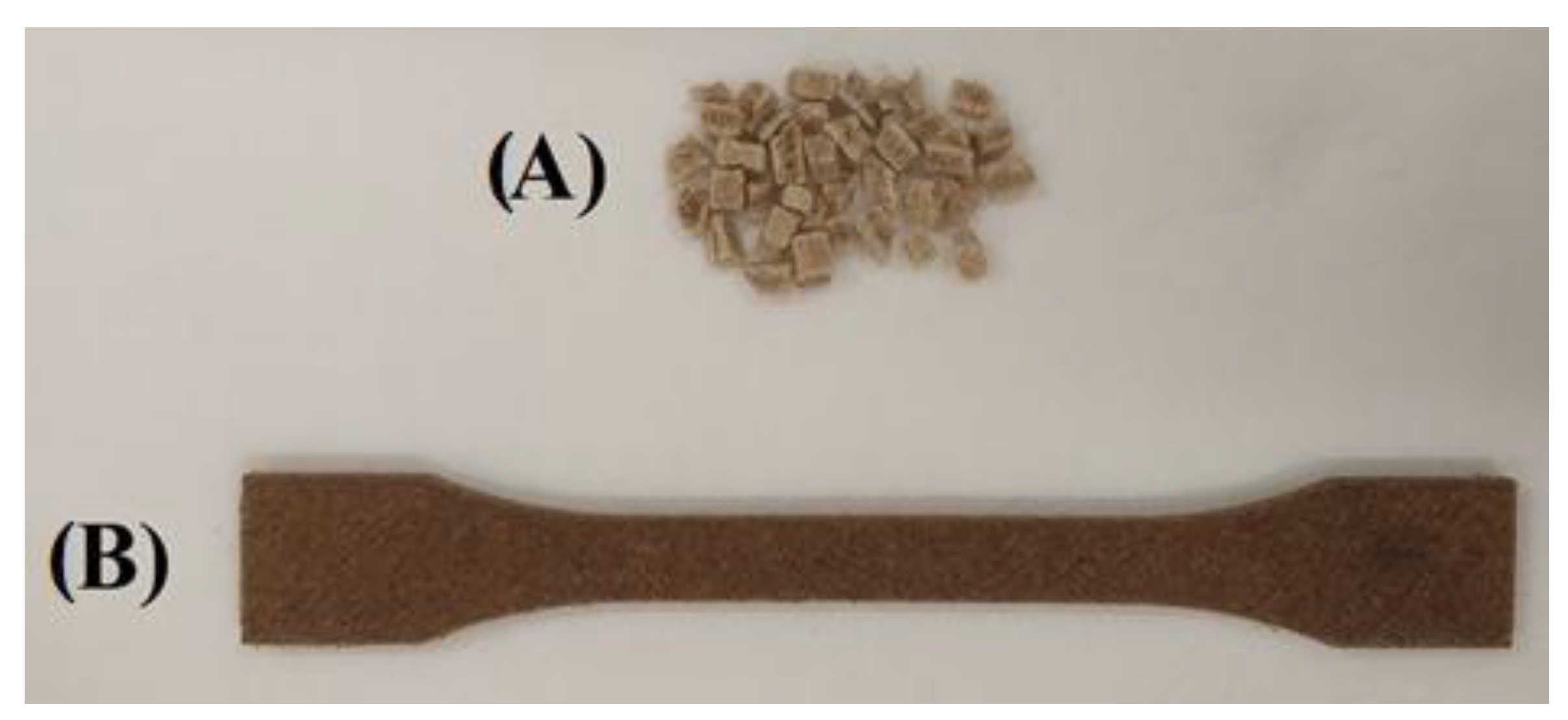

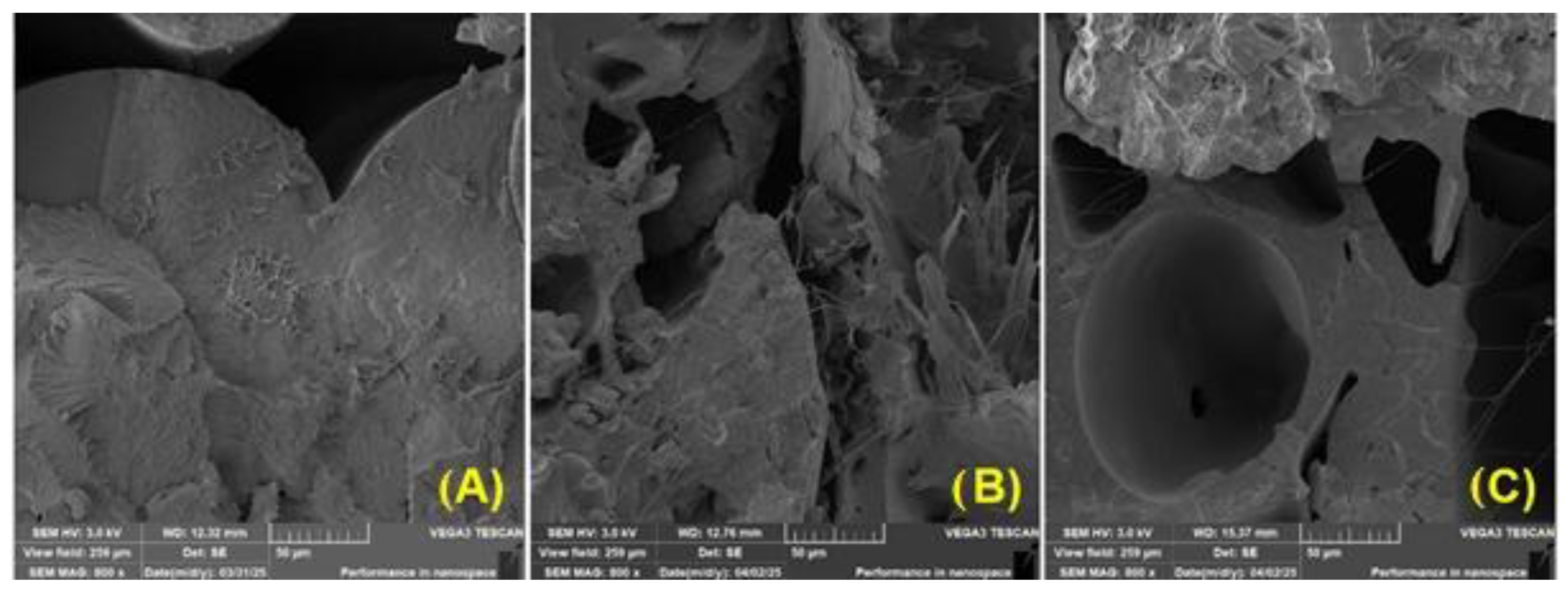

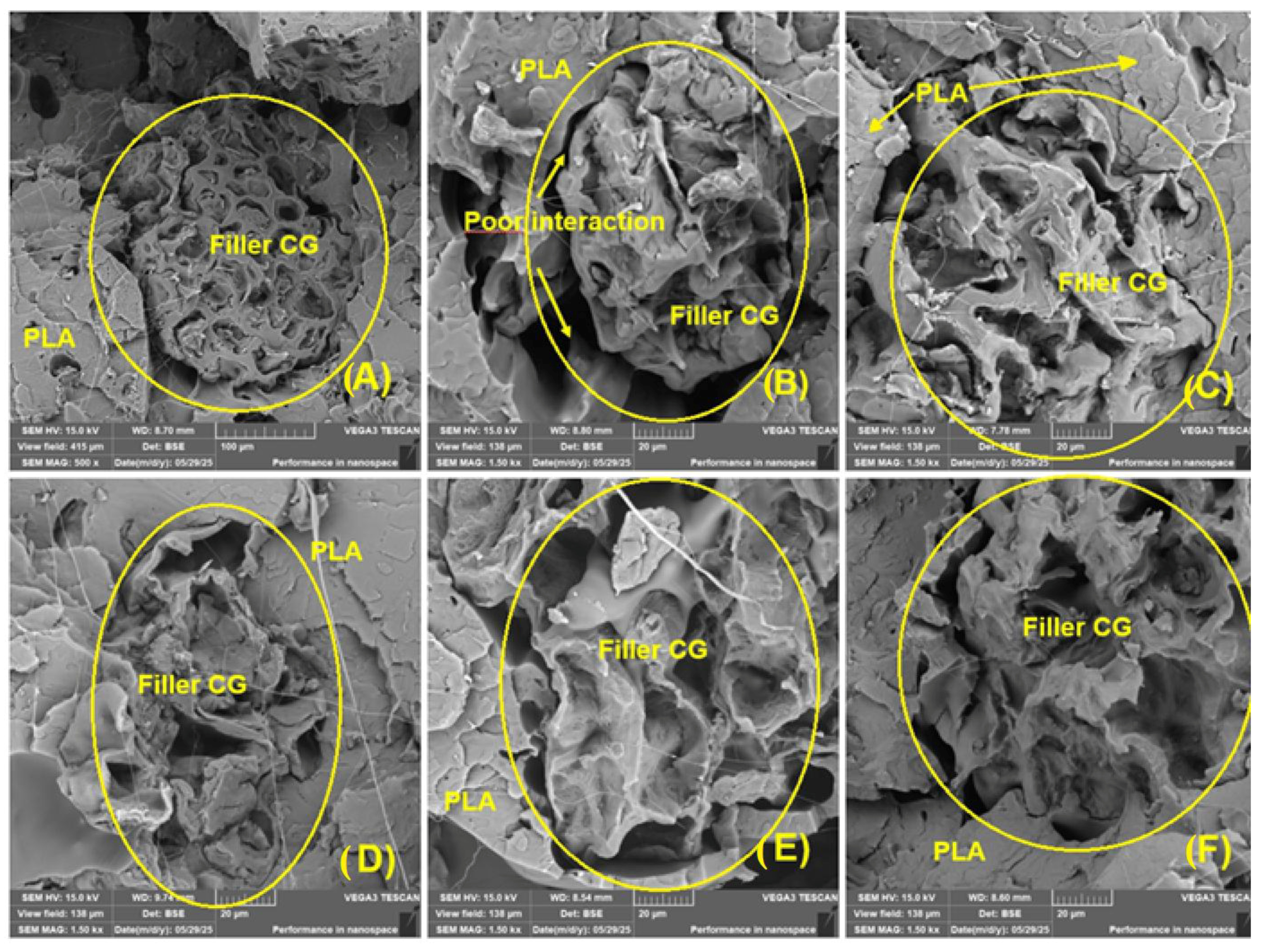

2. Materials and Methods

3. Results and Discussion

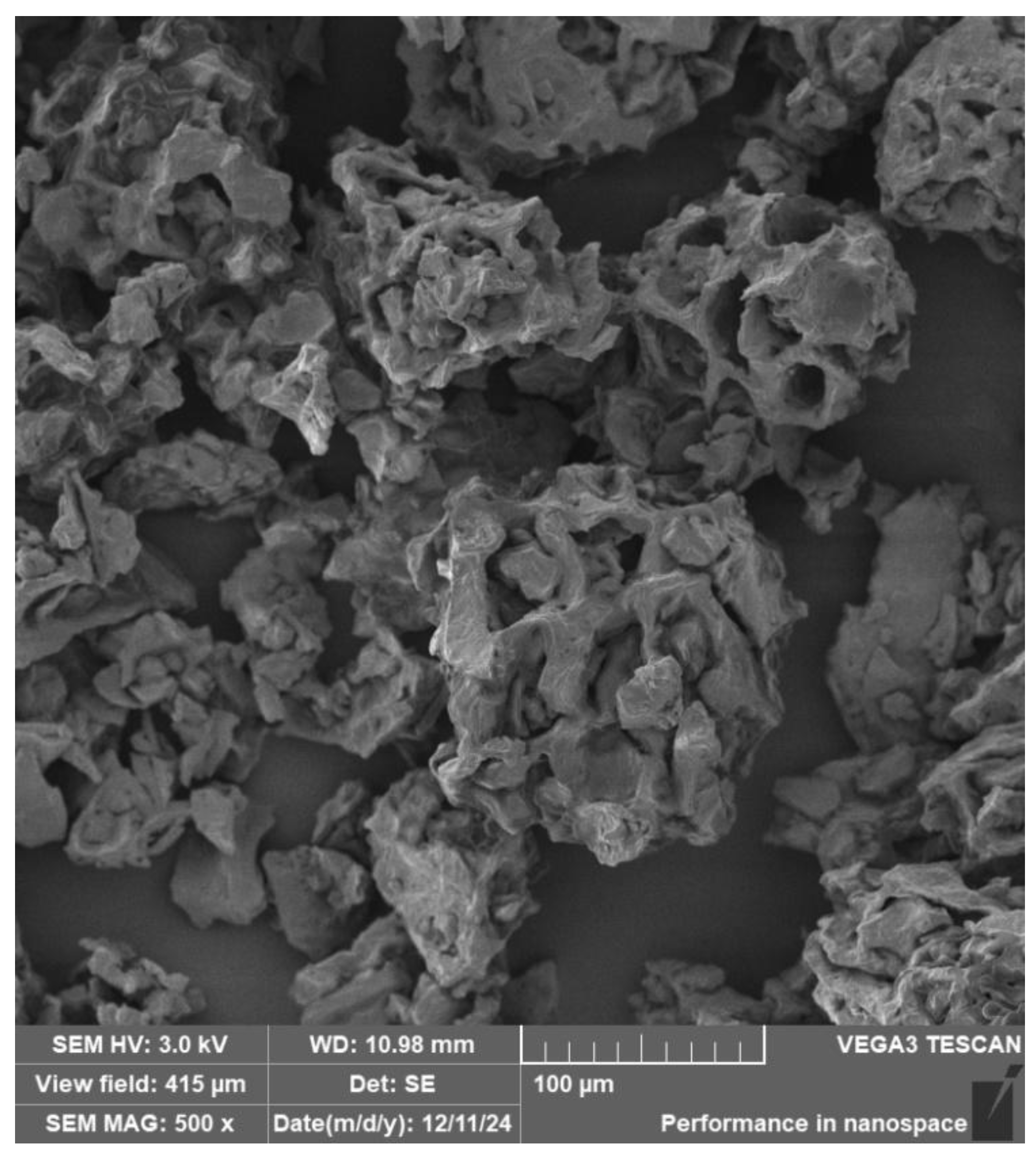

- Material degradation

- Recycling after degradation

4. Conclusions

- Neat PLA exhibited an initial tensile strength of ≈28 MPa (mean value for the as-printed specimens; see Table 3). After 12 weeks of exposure to simulated solar UV (λ = 280–400 nm, irradiance 0.68 W m−2), the tensile strength fell below 10 MPa, confirming severe photo-oxidative degradation.

- The PLA_CG composite (PLA + 10 wt. % coffee grounds) started at a lower tensile strength (≈25–27 MPa) but maintained this level after the 12-week UV regime, demonstrating markedly higher UV resistance and structural integrity.

- Recycling performance diverged strongly: neat PLA could not be re-processed after prolonged UV ageing. The melting process failed during filament extrusion, and the re-printed parts were mechanically unstable, whereas PLA_CG was successfully recycled and re-printed without a significant loss of tensile strength.

- The Young’s modulus of neat PLA dropped by ≈20% within the first 4 weeks of UV exposure, and its coefficient of variation increased to ~35%. Although the CG filler lowers the absolute modulus, it stabilises the data scatter (2.6–13.2%) and preserves the long-term stability.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Dasgupta, A.; Dutta, P. A Comprehensive Review on 3D Printing Technology: Current Applications and Challenges. Jordan J. Mech. Ind. Eng. 2022, 16, 529–542. [Google Scholar]

- Tabassum, T.; Ahmad Mir, A. A Review of 3d Printing Technology-the Future of Sustainable Construction. Mater. Today Proc. 2023, 93, 408–414. [Google Scholar] [CrossRef]

- Hajare, D.M.; Gajbhiye, T.S. Additive Manufacturing (3D Printing): Recent Progress on Advancement of Materials and Challenges. Mater. Today Proc. 2022, 58, 736–743. [Google Scholar] [CrossRef]

- Alarifi, I.M. Revolutionising Fabrication Advances and Applications of 3D Printing with Composite Materials: A Review. Virtual Phys. Prototyp. 2024, 19, e2390504. [Google Scholar] [CrossRef]

- Slim, R.; Houssin, R.; Coulibaly, A.; Hanifi, M.; Chibane, H. Framework for Resolving Problems Resulting from Lean Integration from the Early Design Phases of Production 3D Printing Machine. FME Trans. 2021, 49, 279–290. [Google Scholar] [CrossRef]

- Coruzzolo, A.M.; Balugani, E.; Gamberini, R. Spare Parts Management with Additive Manufacturing (AM): A Critical Review. IFAC-PapersOnLine 2022, 55, 1159–1164. [Google Scholar] [CrossRef]

- Hällgren, S.; Pejryd, L.; Ekengren, J. Additive Manufacturing and High Speed Machining-Cost Comparison of Short Lead Time Manufacturing Methods. Procedia CIRP 2016, 50, 384–389. [Google Scholar] [CrossRef]

- Nugroho, W.T.; Dong, Y.; Pramanik, A. 3D Printing Composite Materials: A Comprehensive Review. Compos. Mater. Manuf. Prop. Appl. 2021, 65–115. [Google Scholar] [CrossRef]

- Zhu, Y.; Tang, T.; Zhao, S.; Joralmon, D.; Poit, Z.; Ahire, B.; Keshav, S.; Raje, A.R.; Blair, J.; Zhang, Z.; et al. Recent Advancements and Applications in 3D Printing of Functional Optics. Addit. Manuf. 2022, 52, 102682. [Google Scholar] [CrossRef]

- Hassan, T.; Jamshaid, H.; Mishra, R.; Khan, M.Q.; Petru, M.; Tichy, M.; Muller, M. Factors Affecting Acoustic Properties of Natural-Fiber-Based Materials and Composites: A Review. Textiles 2021, 1, 55–85. [Google Scholar] [CrossRef]

- Yang, T.; Xiong, X.; Venkataraman, M.; Mishra, R.; Novák, J.; Militký, J. Investigation on sound absorption properties of aerogel/polymer nonwovens. J. Text. Inst. 2019, 110, 196–201. [Google Scholar] [CrossRef]

- Valino, A.D.; Dizon, J.R.C.; Espera, A.H.; Chen, Q.; Messman, J.; Advincula, R.C. Advances in 3D Printing of Thermoplastic Polymer Composites and Nanocomposites. Prog. Polym. Sci. 2019, 98, 101162. [Google Scholar] [CrossRef]

- Sai Saran, O.; Prudhvidhar Reddy, A.; Chaturya, L.; Pavan Kumar, M. 3D Printing of Composite Materials: A Short Review. Mater. Today Proc. 2022, 64, 615–619. [Google Scholar] [CrossRef]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.Q.; Hui, D. Additive Manufacturing (3D Printing): A Review of Materials, Methods, Applications and Challenges. Compos. Part B Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Lee, J.Y.; An, J.; Chua, C.K. Fundamentals and Applications of 3D Printing for Novel Materials. Appl. Mater. Today 2017, 7, 120–133. [Google Scholar] [CrossRef]

- Wang, X.; Jiang, M.; Zhou, Z.; Gou, J.; Hui, D. 3D Printing of Polymer Matrix Composites: A Review and Prospective. Compos. Part B Eng. 2017, 110, 442–458. [Google Scholar] [CrossRef]

- Memarzadeh, A.; Safaei, B.; Tabak, A.; Sahmani, S.; Kizilors, C. Advancements in Additive Manufacturing of Polymer Matrix Composites: A Systematic Review of Techniques and Properties. Mater. Today Commun. 2023, 36, 106449. [Google Scholar] [CrossRef]

- Regulation—2023/2055—EN—EUR-Lex. Available online: https://eur-lex.europa.eu/eli/reg/2023/2055/oj (accessed on 1 June 2025).

- Oh, J.; Park, S.B.; Cha, C.; Hwang, D.K.; Park, S.A.; Park, J.; Oh, D.X.; Jeon, H.; Koo, J.M. Structural Evaluation of Poly(Lactic Acid) Degradation at Standardized Composting Temperature of 58 Degrees. Chemosphere 2024, 354, 141729. [Google Scholar] [CrossRef]

- Olawumi, M.A.; Oladapo, B.I.; Ikumapayi, O.M.; Akinyoola, J.O. Waste to Wonder to Explore Possibilities with Recycled Materials in 3D Printing. Sci. Total Environ. 2023, 905, 167109. [Google Scholar] [CrossRef]

- Budin, S.; Jaafar, M. Comparative Study on Mechanical Properties of Virgin and Recycled Polylactic Acid Aging in Natural Weathering and Seawater Environment. Polym. Bull. 2022, 79, 4841–4858. [Google Scholar] [CrossRef]

- Fico, D.; Rizzo, D.; De Carolis, V.; Montagna, F.; Palumbo, E.; Corcione, C.E. Development and Characterization of Sustainable PLA/Olive Wood Waste Composites for Rehabilitation Applications Using Fused Filament Fabrication (FFF). J. Build. Eng. 2022, 56, 104673. [Google Scholar] [CrossRef]

- Di, L.; Yang, Y. Towards Closed-Loop Material Flow in Additive Manufacturing: Recyclability Analysis of Thermoplastic Waste. J. Clean. Prod. 2022, 362, 132427. [Google Scholar] [CrossRef]

- Kassab, A.; Al Nabhani, D.; Mohanty, P.; Pannier, C.; Ayoub, G.Y. Advancing Plastic Recycling: Challenges and Opportunities in the Integration of 3D Printing and Distributed Recycling for a Circular Economy. Polymers 2023, 15, 3881. [Google Scholar] [CrossRef] [PubMed]

- Mishra, V.; Negi, S.; Kar, S. FDM-Based Additive Manufacturing of Recycled Thermoplastics and Associated Composites. J. Mater. Cycles Waste Manag. 2023, 25, 758–784. [Google Scholar] [CrossRef]

- Hong, J.H.; Yu, T.; Park, S.J.; Kim, Y.H. Repetitive Recycling of 3D Printing PLA Filament as Renewable Resources on Mechanical and Thermal Loads. Int. J. Mod. Phys. B 2020, 34, 2040147. [Google Scholar] [CrossRef]

- Lanzotti, A.; Martorelli, M.; Maietta, S.; Gerbino, S.; Penta, F.; Gloria, A. A Comparison between Mechanical Properties of Specimens 3D Printed with Virgin and Recycled PLA. Procedia CIRP 2019, 79, 143–146. [Google Scholar] [CrossRef]

- Mikula, K.; Skrzypczak, D.; Izydorczyk, G.; Warchoł, J.; Moustakas, K.; Chojnacka, K.; Witek-Krowiak, A. 3D Printing Filament as a Second Life of Waste Plastics—A Review. Environ. Sci. Pollut. Res. 2021, 28, 12321–12333. [Google Scholar] [CrossRef]

- Alami, A.H.; Olabi, A.G.; Ayoub, M.; Aljaghoub, H.; Alasad, S.; Abdelkareem, M.A. 3D Concrete Printing: Recent Progress, Applications, Challenges, and Role in Achieving Sustainable Development Goals. Buildings 2023, 13, 924. [Google Scholar] [CrossRef]

- Chong, S.; Pan, G.T.; Khalid, M.; Yang, T.C.K.; Hung, S.T.; Huang, C.M. Physical Characterization and Pre-Assessment of Recycled High-Density Polyethylene as 3D Printing Material. J. Polym. Environ. 2017, 25, 136–145. [Google Scholar] [CrossRef]

- Yousaf, A.; Al Rashid, A.; Polat, R.; Koç, M. Potential and Challenges of Recycled Polymer Plastics and Natural Waste Materials for Additive Manufacturing. Sustain. Mater. Technol. 2024, 41, e01103. [Google Scholar] [CrossRef]

- Su, J.; Ng, W.L.; An, J.; Yeong, W.Y.; Chua, C.K.; Sing, S.L. Achieving Sustainability by Additive Manufacturing: A State-of-the-Art Review and Perspectives. Virtual Phys. Prototyp. 2024, 19, e2438899. [Google Scholar] [CrossRef]

- Shanmugam, V.; Das, O.; Neisiany, R.E.; Babu, K.; Singh, S.; Hedenqvist, M.S.; Berto, F.; Ramakrishna, S. Polymer Recycling in Additive Manufacturing: An Opportunity for the Circular Economy. Mater. Circ. Econ. 2020, 2, 11. [Google Scholar] [CrossRef]

- Kothandaraman, L.; Balasubramanian, N.K. Optimization of FDM Printing Parameters for Square Lattice Structures: Improving Mechanical Characteristics. Mater. Today Proc. 2024. [Google Scholar] [CrossRef]

- Kechagias, J.D. 3D Printing Parametric Optimization Using the Power of Taguchi Design: An Expository Paradigm. Mater. Manuf. Process. 2024, 39, 797–803. [Google Scholar] [CrossRef]

- Chen, K.; Yu, L.; Cui, Y.; Jia, M.; Pan, K. Optimization of Printing Parameters of 3D-Printed Continuous Glass Fiber Reinforced Polylactic Acid Composites. Thin-Walled Struct. 2021, 164, 107717. [Google Scholar] [CrossRef]

- Cisneros-López, E.O.; Pal, A.K.; Rodriguez, A.U.; Wu, F.; Misra, M.; Mielewski, D.F.; Kiziltas, A.; Mohanty, A.K. Recycled Poly(Lactic Acid)–Based 3D Printed Sustainable Biocomposites: A Comparative Study with Injection Molding. Mater. Today Sustain. 2020, 7–8, 100027. [Google Scholar] [CrossRef]

- Giorgini, L.; Benelli, T.; Brancolini, G.; Mazzocchetti, L. Recycling of Carbon Fiber Reinforced Composite Waste to Close Their Life Cycle in a Cradle-to-Cradle Approach. Curr. Opin. Green Sustain. Chem. 2020, 26, 100368. [Google Scholar] [CrossRef]

- Al Rashid, A.; Koç, M. Additive Manufacturing for Sustainability, Circularity and Zero-Waste: 3DP Products from Waste Plastic Bottles. Compos. Part C Open Access 2024, 14, 100463. [Google Scholar] [CrossRef]

- Bilal, E.; Glazer, Y.R.; Sassaman, D.M.; Seepersad, C.C.; Webber, M.E. Circularity: Understanding the Environmental Tradeoffs of Additive Manufacturing with Waste Plastics. Recycling 2024, 9, 72. [Google Scholar] [CrossRef]

- Khosravani, M.R.; Reinicke, T. On the Environmental Impacts of 3D Printing Technology. Appl. Mater. Today 2020, 20, 100689. [Google Scholar] [CrossRef]

- Kaur, G.; Uisan, K.; Ong, K.L.; Ki Lin, C.S. Recent Trends in Green and Sustainable Chemistry & Waste Valorisation: Rethinking Plastics in a Circular Economy. Curr. Opin. Green Sustain. Chem. 2018, 9, 30–39. [Google Scholar] [CrossRef]

- Sardon, H.; Long, T.; Le Ferrand, H. Sustainable Additive Manufacturing of Plastics. ACS Sustain. Chem. Eng. 2022, 10, 1983–1985. [Google Scholar] [CrossRef]

- Pujol, D.; Liu, C.; Gominho, J.; Olivella, M.À.; Fiol, N.; Villaescusa, I.; Pereira, H. The Chemical Composition of Exhausted Coffee Waste. Ind. Crops Prod. 2013, 50, 423–429. [Google Scholar] [CrossRef]

- Kechagias, J.; Zaoutsos, S. Effects of 3D-Printing Processing Parameters on FFF Parts’ Porosity: Outlook and Trends. Mater. Manuf. Process. 2024, 39, 804–814. [Google Scholar] [CrossRef]

- EN ISO 527-2; Plastics—Determination of Tensile Properties. Part 2: Test Conditions for Moulding and Extrusion Plastics. ISO—International Organization for Standardization: Geneva, Switzerland, 2025.

- Fu, L.; Gong, Y.; Zhou, Q.; Ou, Z.; Rao, X.; Wang, S.; Huo, C.; Du, X. Antioxidant and Ultraviolet Shielding Performance of Lignin-Polysaccharide Complex Isolated from Spent Coffee Ground. Int. J. Biol. Macromol. 2023, 230, 123245. [Google Scholar] [CrossRef]

- Giang, H.N.; Tran, C.C.; Huynh, T.N.A.; Doan, P.T.M. Spent Coffee Grounds Utilization for Green Ultraviolet Filter and Nanocomposite Fabrication. Express Polym. Lett. 2023, 17, 900–912. [Google Scholar] [CrossRef]

- Sasse, J.; Pelzer, L.; Schön, M.; Ghaddar, T.; Hopmann, C. Investigation of Recycled and Coextruded PLA Filament for Additive Manufacturing. Polymers 2022, 14, 2407. [Google Scholar] [CrossRef]

- Nagengast, N.; Bay, C.; Döpper, F.; Schmidt, H.W.; Neuber, C. Thermo-Mechanical Recyclability of Additively Manufactured Polypropylene and Polylactic Acid Parts and Polypropylene Support Structures. Polymers 2023, 15, 2291. [Google Scholar] [CrossRef]

- Sharma, A.; Kumar, M.; Sharma, A. Sustainable Additive Manufacturing: Challenges and Opportunities of Recycling Plastic Waste for 3D Printing Filaments. Sādhanā 2025, 50, 14. [Google Scholar] [CrossRef]

- Yu, W.; Yuan, T.; Yao, Y.; Deng, Y.; Wang, X. PLA/Coffee Grounds Composite for 3D Printing and Its Properties. Forests 2023, 14, 367. [Google Scholar] [CrossRef]

- Boughanmi, O.; Allegue, L.; Marouani, H.; Koubaa, A.; Fouad, Y. Repetitive Recycling Effects on Mechanical Characteristics of Poly-Lactic Acid and PLA/Spent Coffee Grounds Composite Used for 3D Printing Filament. Polym. Eng. Sci. 2024, 64, 5613–5626. [Google Scholar] [CrossRef]

- de Bomfim, A.S.C.; de Oliveira, D.M.; de Carvalho Benini, K.C.C.; Cioffi, M.O.H.; Voorwald, H.J.C.; Rodrigue, D. Effect of Spent Coffee Grounds on the Crystallinity and Viscoelastic Behavior of Polylactic Acid Composites. Polymers 2023, 15, 2719. [Google Scholar] [CrossRef]

- Saccani, A.; Fiorini, M.; Burzotta, G. Sustainable Bio-Composites Obtained from Recycling Post-Industrial PLA and Fillers Derived from Coffee Production. Recycling 2022, 7, 89. [Google Scholar] [CrossRef]

- Waisarikit, A.; Suadaung, N.; Khantho, B.; Hadad, B.; Ross, G.M.; Topham, P.D.; Ross, S.; Mahasaranon, S. Extracted Spent Coffee Grounds as a Performance-Enhancing Additive for Poly(Lactic Acid) Biodegradable Nursery Bags in Agriculture. Polymers 2025, 17, 561. [Google Scholar] [CrossRef]

- Petaloti, A.-I.; Achilias, D.S.; Petaloti, A.-I.; Achilias, D.S. The Development of Sustainable Biocomposite Materials Based on Poly(Lactic Acid) and Silverskin, a Coffee Industry By-Product, for Food Packaging Applications. Sustainability 2024, 16, 5075. [Google Scholar] [CrossRef]

- Marșavina, L.; Vălean, C.; Mărghitaș, M.; Linul, E.; Razavi, N.; Berto, F.; Brighenti, R. Effect of the Manufacturing Parameters on the Tensile and Fracture Properties of FDM 3D-Printed PLA Specimens. Eng. Fract. Mech. 2022, 274, 108766. [Google Scholar] [CrossRef]

- Hsueh, M.H.; Lai, C.J.; Chung, C.F.; Wang, S.H.; Huang, W.C.; Pan, C.Y.; Zeng, Y.S.; Hsieh, C.H. Effect of Printing Parameters on the Tensile Properties of 3D-Printed Polylactic Acid (PLA) Based on Fused Deposition Modeling. Polymers 2021, 13, 2387. [Google Scholar] [CrossRef]

- Zhao, Y.; Chen, Y.; Zhou, Y. Novel Mechanical Models of Tensile Strength and Elastic Property of FDM AM PLA Materials: Experimental and Theoretical Analyses. Mater. Des. 2019, 181, 108089. [Google Scholar] [CrossRef]

- Coppola, B.; Cappetti, N.; Di Maio, L.; Scarfato, P.; Incarnato, L. 3D Printing of PLA/Clay Nanocomposites: Influence of Printing Temperature on Printed Samples Properties. Materials 2018, 11, 1947. [Google Scholar] [CrossRef]

- Baptista, R.; Guedes, M. Morphological and Mechanical Characterization of 3D Printed PLA Scaffolds with Controlled Porosity for Trabecular Bone Tissue Replacement. Mater. Sci. Eng. C 2021, 118, 111528. [Google Scholar] [CrossRef]

- Sit, M.; Dashatan, S.; Zhang, Z.; Dhakal, H.N.; Khalfallah, M.; Gamer, N.; Ling, J. Inorganic Fillers and Their Effects on the Properties of Flax/PLA Composites after UV Degradation. Polymers 2023, 15, 3221. [Google Scholar] [CrossRef] [PubMed]

- Gunti, R.; Prasad, A.R.; Gupta, A. Mechanical and Degradation Properties of Natural Fiber-Reinforced PLA Composites: Jute, Sisal, and Elephant Grass. Polym. Compos. 2018, 39, 1125–1136. [Google Scholar] [CrossRef]

- Shang, H.; Xu, K.; Li, X.; Lu, S.; Ke, L.; Yang, H.R.; Gao, J.; Tang, D.; Huang, D.; He, X.; et al. UV-Protective and High-Transparency Poly(Lactic Acid) Biocomposites for Ecofriendly Packaging of Perishable Fruits. Int. J. Biol. Macromol. 2022, 222, 927–937. [Google Scholar] [CrossRef] [PubMed]

- González-López, M.E.; Martín del Campo, A.S.; Robledo-Ortíz, J.R.; Arellano, M.; Pérez-Fonseca, A.A. Accelerated Weathering of Poly(Lactic Acid) and Its Biocomposites: A Review. Polym. Degrad. Stab. 2020, 179, 109290. [Google Scholar] [CrossRef]

- Bocchini, S.; Fukushima, K.; Di Blasio, A.; Fina, A.; Frache, A.; Geobaldo, F. Polylactic Acid and Polylactic Acid-Based Nanocomposite Photooxidation. Biomacromolecules 2010, 11, 2919–2926. [Google Scholar] [CrossRef]

- Zhao, X.; Copenhaver, K.; Wang, L.; Korey, M.; Gardner, D.J.; Li, K.; Lamm, M.E.; Kishore, V.; Bhagia, S.; Tajvidi, M.; et al. Recycling of Natural Fiber Composites: Challenges and Opportunities. Resour. Conserv. Recycl. 2022, 177, 105962. [Google Scholar] [CrossRef]

- Drumright, R.E.; Gruber, P.R.; Henton, D.E. Polylactic Acid Technology. Adv. Mater. 2000, 12, 1841–1846. [Google Scholar] [CrossRef]

- Tsuji, H.; Suzuyoshi, K. Environmental Degradation of Biodegradable Polyesters 1. Poly(ε-Caprolactone), Poly[(R)-3-Hydroxybutyrate], and Poly(L-Lactide) Films in Controlled Static Seawater. Polym. Degrad. Stab. 2002, 75, 347–355. [Google Scholar] [CrossRef]

- Pérez-Fonseca, A.A.; González-López, M.E.; Robledo-Ortíz, J.R. Reprocessing and Recycling of Poly(Lactic Acid): A Review. J. Polym. Environ. 2023, 31, 4143–4159. [Google Scholar] [CrossRef]

- Lomakin, S.; Mikheev, Y.; Usachev, S.; Rogovina, S.; Zhorina, L.; Perepelitsina, E.; Levina, I.; Kuznetsova, O.; Shilkina, N.; Iordanskii, A.; et al. Evaluation and Modeling of Polylactide Photodegradation under Ultraviolet Irradiation: Bio-Based Polyester Photolysis Mechanism. Polymers 2024, 16, 985. [Google Scholar] [CrossRef]

- Tsuji, H.; Echizen, Y.; Nishimura, Y. Photodegradation of Biodegradable Polyesters: A Comprehensive Study on Poly(l-Lactide) and Poly(ɛ-Caprolactone). Polym. Degrad. Stab. 2006, 91, 1128–1137. [Google Scholar] [CrossRef]

- Wang, W.; Ye, G.; Fan, D.; Lu, Y.; Shi, P.; Wang, X.; Bateer, B. Photo-Oxidative Resistance and Adjustable Degradation of Poly-Lactic Acid (PLA) Obtained by Biomass Addition and Interfacial Construction. Polym. Degrad. Stab. 2021, 194, 109762. [Google Scholar] [CrossRef]

- Rizzarelli, P.; Piredda, G.; La Carta, S.; Mirabella, E.F.; Valenti, G.; Bernet, R.; Impallomeni, G. Characterization and Laser-Induced Degradation of a Medical Grade Polylactide. Polym. Degrad. Stab. 2019, 169, 108991. [Google Scholar] [CrossRef]

- Masssijaya, S.Y.; Lubis, M.A.R.; Nissa, R.C.; Nurhamiyah, Y.; Nugroho, P.; Antov, P.; Lee, S.H.; Papadopoulos, A.N.; Kusumah, S.S.; Karlinasari, L. Utilization of Spent Coffee Grounds as a Sustainable Resource for the Synthesis of Bioplastic Composites with Polylactic Acid, Starch, and Sucrose. J. Compos. Sci. 2023, 7, 512. [Google Scholar] [CrossRef]

- Chen, F.; Xu, Q.; Huang, F.; Xie, Z.; Fang, H. Effect of Nozzle Vibration at Different Frequencies on Surface Structures and Tensile Properties of PLA Parts Printed by FDM. Mater. Lett. 2022, 325, 132612. [Google Scholar] [CrossRef]

- Lage-Rivera, S.; Ares-Pernas, A.; Dopico-García, M.S.; Covas, J.; Abad, M.J. Comparing Lignin and Spent Coffee Grounds as Bio-Fillers in PLA 3D-Printable Filaments. Polym. Compos. 2024, 45, 14566–14579. [Google Scholar] [CrossRef]

- Tabassum, Z.; Girdhar, M.; Anand, A.; Kumari, N.; Sood, B.; Malik, T.; Kumar, A.; Mohan, A. Trash to Treasure: Advancing Resource Efficiency Using Waste-Derived Fillers as Sustainable Reinforcing Agents in Bioplastics. Mater. Adv. 2025, 6, 527–546. [Google Scholar] [CrossRef]

- Mallegni, N.; Cicogna, F.; Passaglia, E.; Gigante, V.; Coltelli, M.B.; Coiai, S. Natural Antioxidants: Advancing Stability and Performance in Sustainable Biobased and Biodegradable Plastics. Compounds 2025, 5, 4. [Google Scholar] [CrossRef]

- Szadkowski, B.; Śliwka-Kaszyńska, M.; Marzec, A. Improving Compatibility between Coffee or Black Tea Ground Wastes and Polymer Matrix via Silane Treatment for Production Sustainable Biofillers. Sci. Rep. 2025, 15, 13554. [Google Scholar] [CrossRef]

- Mendoza, A.; Kortaberria, G.; Carrero, D.; Latorre, A.; Basurko, O.C.; Peña-Rodríguez, C. Industrial Optical Sorting for Marine Plastic Litter Management. Waste Manag. Bull. 2024, 2, 102–107. [Google Scholar] [CrossRef]

- Osadolor, A.; Showole, A.; Eze, T.; Ajayi, V.; Owulo, R. Design and Analysis of the Impact of Ultraviolet Aging on the Mechanical Properties and Durability of PLA Lattice Structures. J. Mater. Sci. Res. Rev. 2024, 7, 287–301. [Google Scholar]

- Guo, Z.; Song, W.; Wei, X.; Feng, Y.; Song, Y.; Cheng, W. Effect of Ultraviolet Irradiation on Strength and Toughness of Composites of Poly(Lactic Acid) and Poly(Butylene Adipate-Co-Terephthalate) with Different Mass Ratio. J. Polym. Res. 2024, 31, 2. [Google Scholar] [CrossRef]

- Li, D.; Leng, Z.; Yao, L.; Cao, R.; Zou, F.; Li, G.; Wang, H.; Wang, H. Mechanical, Economic, and Environmental Assessment of Recycling Reclaimed Asphalt Rubber Pavement Using Different Rejuvenation Schemes. Resour. Conserv. Recycl. 2024, 204, 107534. [Google Scholar] [CrossRef]

- Ballesteros, L.F.; Ramirez, M.J.; Orrego, C.E.; Teixeira, J.A.; Mussatto, S.I. Optimization of Autohydrolysis Conditions to Extract Antioxidant Phenolic Compounds from Spent Coffee Grounds. J. Food Eng. 2017, 199, 1–8. [Google Scholar] [CrossRef]

- Müller, M.; Valášek, P.; Rudawska, A.; Chotěborský, R. Effect of Active Rubber Powder on Structural Two-Component Epoxy Resin and Its Mechanical Properties. J. Adhes. Sci. Technol. 2018, 32, 1531–1547. [Google Scholar] [CrossRef]

- Letcher, T.; Waytashek, M. Material Property Testing of 3D-Printed Specimen in PLA on an Entry-Level 3D Printer. In Proceedings of the ASME 2014 International Mechanical Engineering Congress and Exposition, Montreal, QC, Canada, 14–20 November 2014; pp. 1–8. [Google Scholar] [CrossRef]

- Dave, H.K.; Patadiya, N.H.; Prajapati, A.R.; Rajpurohit, S.R. Effect of Infill Pattern and Infill Density at Varying Part Orientation on Tensile Properties of Fused Deposition Modeling-Printed Poly-Lactic Acid Part. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2021, 235, 1811–1827. [Google Scholar] [CrossRef]

- Lee, D.; Lee, Y.; Kim, I.; Hwang, K.; Kim, N. Thermal and Mechanical Degradation of Recycled Polylactic Acid Filaments for Three-Dimensional Printing Applications. Polymers 2022, 14, 5385. [Google Scholar] [CrossRef]

- Dash, A.; Kabra, S.; Misra, S.; Hrishikeshan, G.; Singh, R.P.; Patterson, A.E.; Chadha, U.; Rajan, A.J.; Hirpha, B.B. Comparative Property Analysis of Fused Filament Fabrication PLA Using Fresh and Recycled Feedstocks. Mater. Res. Express 2022, 9, 115303. [Google Scholar] [CrossRef]

- Bergaliyeva, S.; Sales, D.L.; Delgado, F.J.; Bolegenova, S.; Molina, S.I. Manufacture and Characterization of Polylactic Acid Filaments Recycled from Real Waste for 3D Printing. Polymers 2023, 15, 2165. [Google Scholar] [CrossRef]

- Muthurathinam, S.G.; Perumal, A.V. Synthesis, Characterization and Tribological Investigation of Vegetable Oil Methyl Esters Based Bio-Lubricants. Ind. Crops Prod. 2023, 203, 117098. [Google Scholar] [CrossRef]

| Option | UV Degradation (Number of Weeks) | Recycled 2 | Material |

|---|---|---|---|

| 1 | 0 | No | PLA |

| 2 | 0 | No | PLA_CG 1 |

| 3 | 4 | No | PLA |

| 4 | 4 | No | PLA_CG 1 |

| 5 | 4 | Yes | PLA |

| 6 | 4 | Yes | PLA_CG 1 |

| 7 | 12 | No | PLA |

| 8 | 12 | No | PLA_CG 1 |

| 9 | 12 | Yes | PLA |

| 10 | 12 | Yes | PLA_CG 1 |

| Nozzle size | 0.4 mm |

| Layer height | 0.2 mm |

| Infill density | 100% |

| Infill pattern | Rectilinear |

| Angle of filling | 45° |

| Number of perimeters | 2 |

| Type of Sample | Option | UV Degradation [Number of Weeks] | Recycled 1 | σm [MPa] | ΔL [mm] | E [MPa] |

|---|---|---|---|---|---|---|

| PLA | 1 | 0 | No | 27.73 ± 3.91 | 5.28 ± 1.32 | 1797.12 ± 120.70 |

| PLA_CG | 2 | 0 | No | 27.41 ± 0.53 | 4.09 ± 0.23 | 1124.45 ± 50.96 |

| PLA | 3 | 4 | No | 27.75 ± 5.38 | 3.37 ± 0.65 | 1421.86 ± 106.89 |

| PLA_CG | 4 | 4 | No | 25.36 ± 2.22 | 3.16 ± 0.25 | 1088.96 ± 129.04 |

| PLA | 5 | 4 | Yes | 30.90 ± 1.28 | 10.74 ± 0.73 | 1723.64 ± 132.99 |

| PLA_CG | 6 | 4 | Yes | 25.56 ± 2.38 | 2.69 ± 0.09 | 1084.99 ± 143.12 |

| PLA | 7 | 12 | No | 7.34 ± 1.41 | 0.50 ± 0.13 | 1570.65 ± 531.29 |

| PLA_CG | 8 | 12 | No | 26.95 ± 1.23 | 2.37 ± 0.18 | 1254.47 ± 71.36 |

| PLA | 9 | 12 | - | - | - | - |

| PLA_CG | 10 | 12 | Yes | 25.82 ± 1.01 | 2.42 ± 0.20 | 1096.55 ± 28.25 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jirků, P.; Muller, M.; Mishra, R.K.; Svobodová, J. Effect of Recycling and UV Ageing on the Properties of PLA-Based Materials Used in Additive Manufacturing. Polymers 2025, 17, 1862. https://doi.org/10.3390/polym17131862

Jirků P, Muller M, Mishra RK, Svobodová J. Effect of Recycling and UV Ageing on the Properties of PLA-Based Materials Used in Additive Manufacturing. Polymers. 2025; 17(13):1862. https://doi.org/10.3390/polym17131862

Chicago/Turabian StyleJirků, Petr, Miroslav Muller, Rajesh Kumar Mishra, and Jaroslava Svobodová. 2025. "Effect of Recycling and UV Ageing on the Properties of PLA-Based Materials Used in Additive Manufacturing" Polymers 17, no. 13: 1862. https://doi.org/10.3390/polym17131862

APA StyleJirků, P., Muller, M., Mishra, R. K., & Svobodová, J. (2025). Effect of Recycling and UV Ageing on the Properties of PLA-Based Materials Used in Additive Manufacturing. Polymers, 17(13), 1862. https://doi.org/10.3390/polym17131862