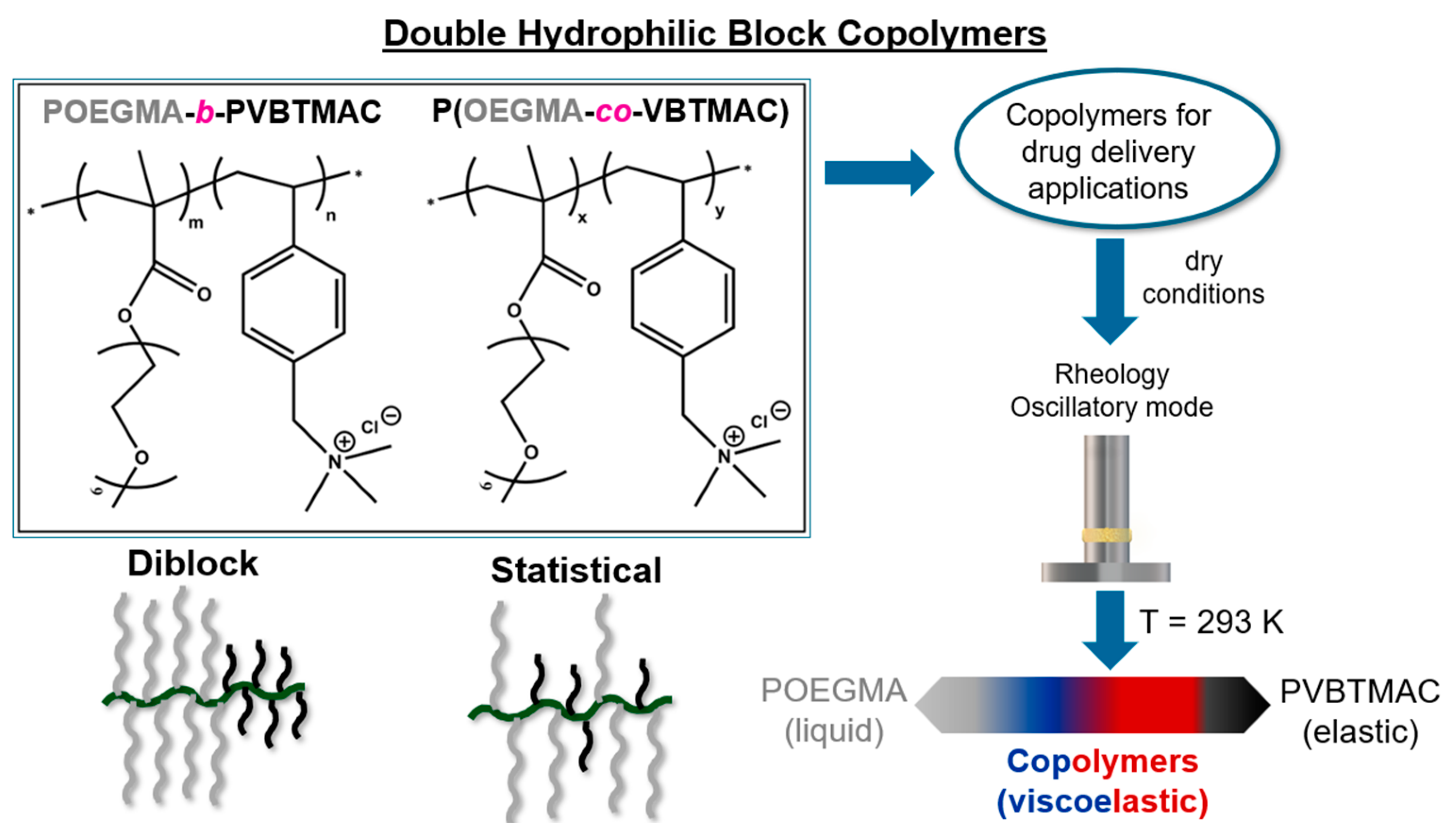

Viscoelastic Response of Double Hydrophilic Block Copolymers for Drug Delivery Applications

Abstract

1. Introduction

2. Materials and Methods

2.1. Synthesis

2.2. Rheology

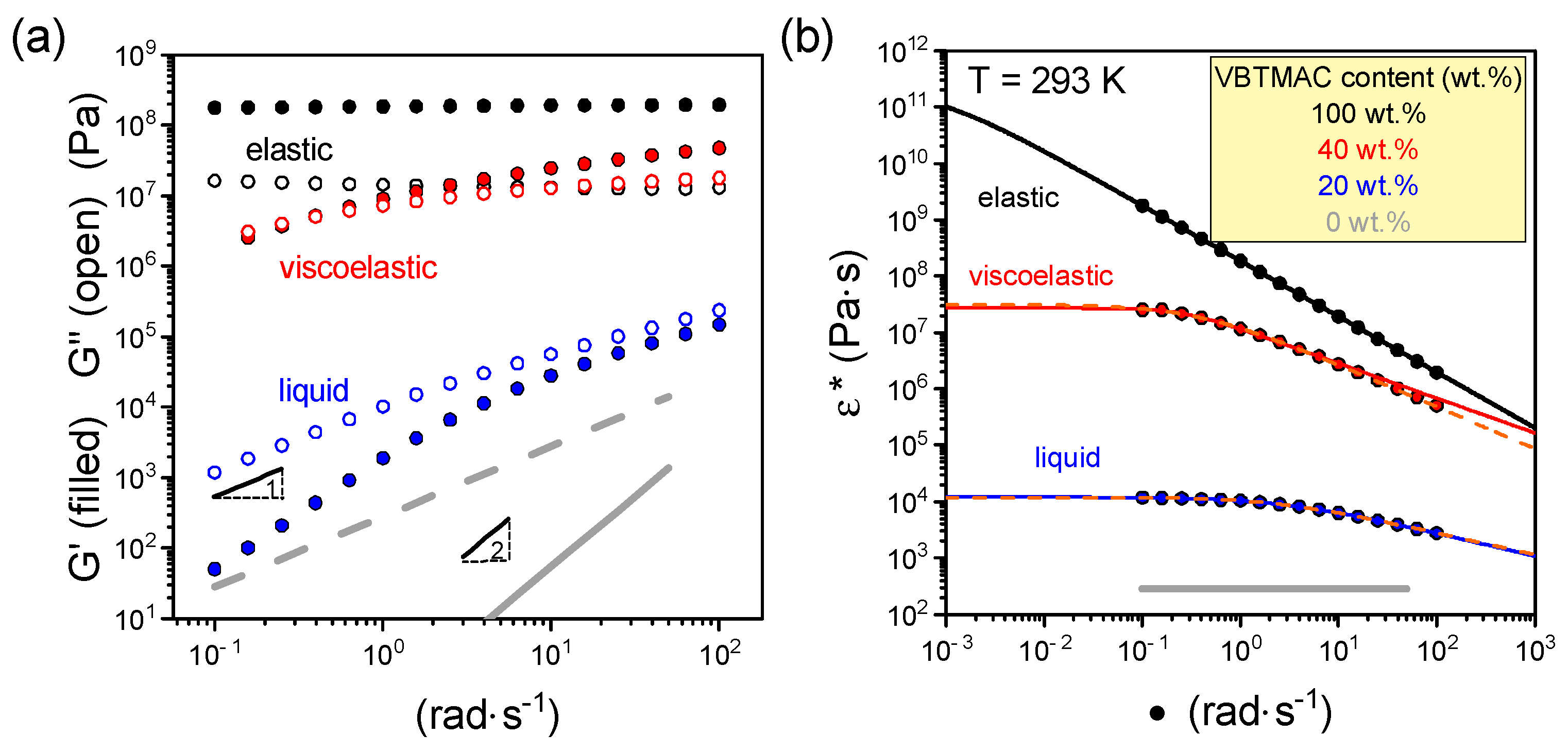

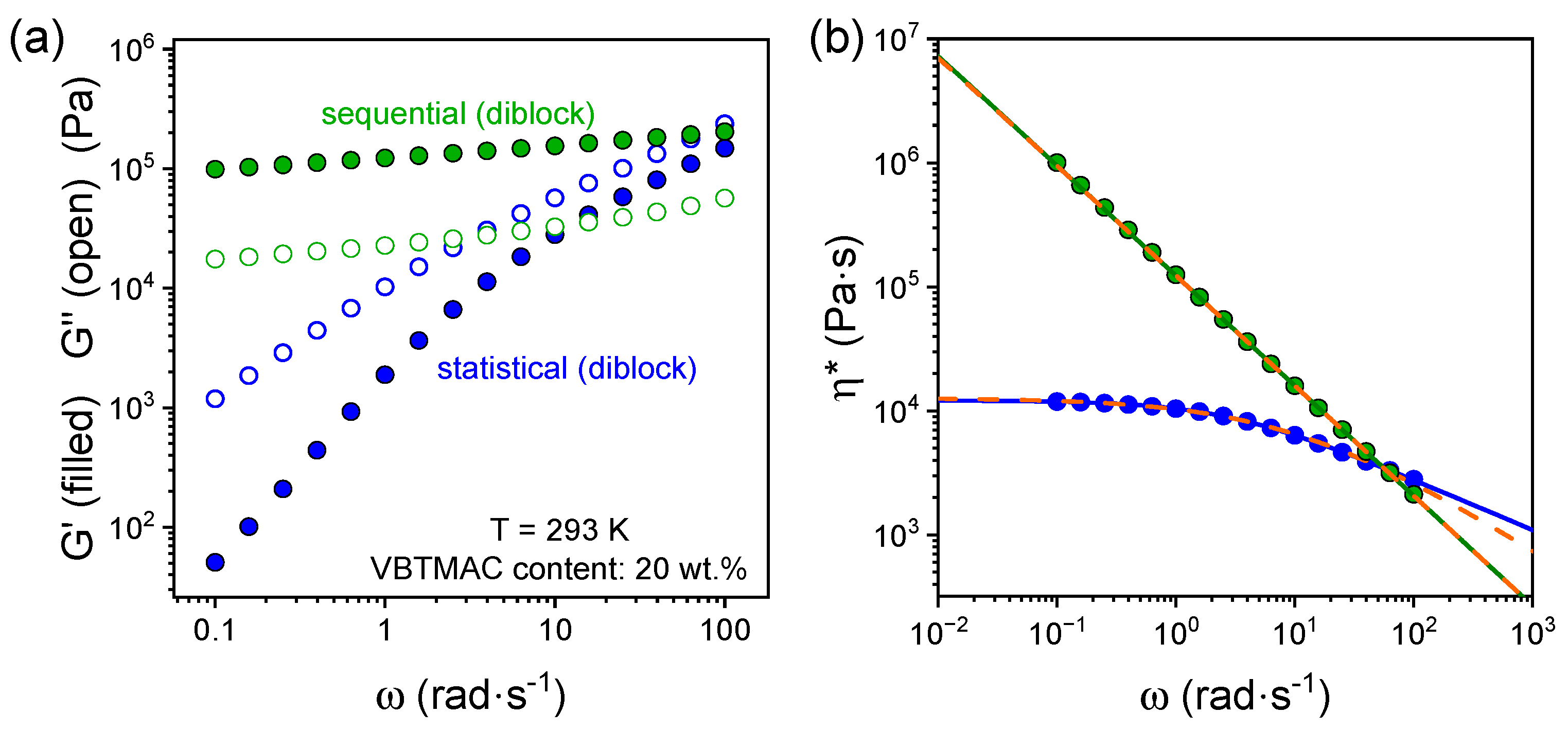

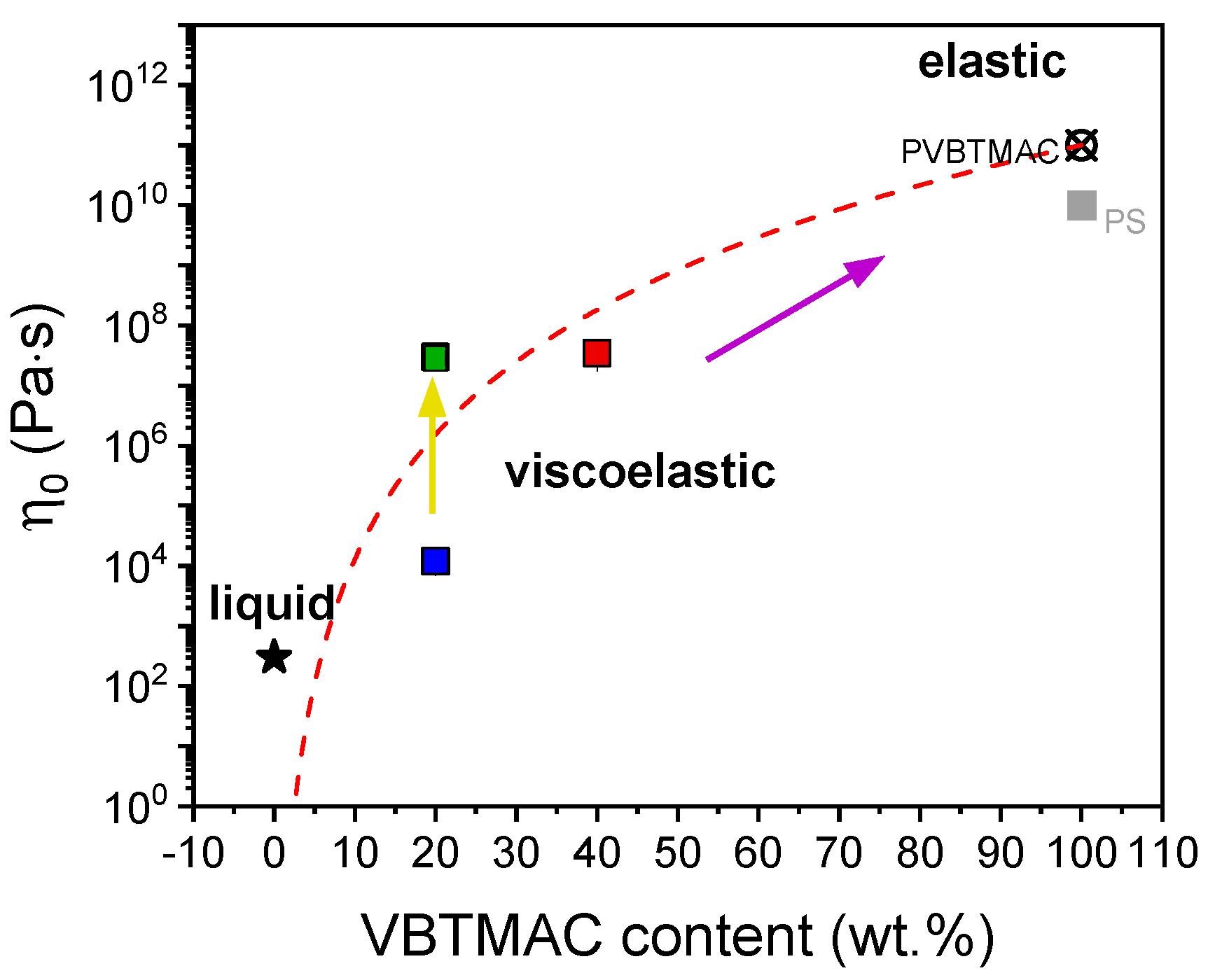

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| DHBCs | double hydrophilic block copolymers |

| POEGMA | poly[oligo(ethylene glycol) methacrylate] |

| PVBTMAC | poly(vinyl benzyl trimethylammonium chloride) |

| SAOS | small amplitude oscillatory shear |

| Tginter | interfacial glass transition temperature |

| RAFT | reversible addition–fragmentation chain transfer |

| Tg | glass transition temperature |

| LVR | linear viscoelastic regime |

| CY | Carreau–Yasuda model |

| MC | modified Cross model |

| |G*| | complex shear moduli |

| G′ | shear storage moduli |

| G″ | shear loss moduli |

| η0 | zero shear viscosity |

| tTs | time–temperature superposition |

| WLF | Williamas–Landel–Ferry |

| αT | horizontal shift factor |

| f(Tg) | fractional free volume at Tg |

| αf | thermal expansion coefficient of free volume at Tg |

| m* | fragility |

| Eg | apparent activation energy |

| PS | polystyrene |

References

- Bates, F.S.; Fredrickson, G.H. Block copolymers—Designer soft materials. Phys. Today 1999, 52, 32–38. [Google Scholar] [CrossRef]

- Hadjichristidis, N.; Pispas, S.; Floudas, G. Block Copolymers: Synthetic Strategies, Physical Properties, and Applications; John Wiley & Sons: Hoboken, NJ, USA, 2003. [Google Scholar]

- Tsukahara, Y.; Kohjiya, S.; Tsutsumi, K.; Okamoto, Y. On the intrinsic viscosity of poly (macromonomer) s. Macromolecules 1994, 27, 1662–1664. [Google Scholar] [CrossRef]

- Neugebauer, D.; Zhang, Y.; Pakula, T.; Sheiko, S.S.; Matyjaszewski, K. Densely-grafted and double-grafted PEO brushes via ATRP. A route to soft elastomers. Macromolecules 2003, 36, 6746–6755. [Google Scholar] [CrossRef]

- Vlassopoulos, D.; Fytas, G.; Loppinet, B.; Isel, F.; Lutz, P.; Benoit, H. Polymacromonomers: Structure and dynamics in nondilute solutions, melts, and mixtures. Macromolecules 2000, 33, 5960–5969. [Google Scholar] [CrossRef]

- Kapnistos, M.; Vlassopoulos, D.; Roovers, J.; Leal, L. Linear rheology of architecturally complex macromolecules: Comb polymers with linear backbones. Macromolecules 2005, 38, 7852–7862. [Google Scholar] [CrossRef]

- Hu, M.; Xia, Y.; McKenna, G.B.; Kornfield, J.A.; Grubbs, R.H. Linear rheological response of a series of densely branched brush polymers. Macromolecules 2011, 44, 6935–6943. [Google Scholar] [CrossRef]

- Daniel, W.F.; Burdyńska, J.; Vatankhah-Varnoosfaderani, M.; Matyjaszewski, K.; Paturej, J.; Rubinstein, M.; Dobrynin, A.V.; Sheiko, S.S. Solvent-free, supersoft and superelastic bottlebrush melts and networks. Nat. Mater. 2016, 15, 183–189. [Google Scholar] [CrossRef]

- Qian, Z.; Chen, D.; McKenna, G.B. Re-visiting the “consequences of grafting density on the linear viscoelastic behavior of graft polymers”. Polymer 2020, 186, 121992. [Google Scholar] [CrossRef]

- Jang, J.; Leo, C.M.; Santiago, P.; Kennemur, J.G. Unraveling the Linear-to-Bottlebrush Transition by Linear Viscoelastic Response to Increasing Side Chain Length. Macromolecules 2025, 58, 2437–2449. [Google Scholar] [CrossRef]

- Daniels, D.; McLeish, T.; Crosby, B.; Young, R.; Fernyhough, C. Molecular rheology of comb polymer melts. 1. Linear viscoelastic response. Macromolecules 2001, 34, 7025–7033. [Google Scholar] [CrossRef]

- Lee, J.H.; Fetters, L.J.; Archer, L.A. Stress relaxation of branched polymers. Macromolecules 2005, 38, 10763–10771. [Google Scholar] [CrossRef]

- Roovers, J.; Graessley, W. Melt rheology of some model comb polystyrenes. Macromolecules 1981, 14, 766–773. [Google Scholar] [CrossRef]

- Saha, D.; Witt, C.L.; Fatima, R.; Uchiyama, T.; Pande, V.; Song, D.-P.; Fei, H.-F.; Yavitt, B.M.; Watkins, J.J. Opportunities in Bottlebrush Block Copolymers for Advanced Materials. ACS Nano 2024, 19, 1884–1910. [Google Scholar] [CrossRef]

- Cui, S.; Zhang, B.; Shen, L.; Bates, F.S.; Lodge, T.P. Core–shell gyroid in ABC bottlebrush block terpolymers. J. Am. Chem. Soc. 2022, 144, 21719–21727. [Google Scholar] [CrossRef]

- Song, Q.; Dong, Q.; Liang, R.; Xue, Y.; Zhong, M.; Li, W. Hierarchical self-assembly of ABC-type bottlebrush copolymers. Macromolecules 2023, 56, 5470–5481. [Google Scholar] [CrossRef]

- Detappe, A.; Nguyen, H.V.-T.; Jiang, Y.; Agius, M.P.; Wang, W.; Mathieu, C.; Su, N.K.; Kristufek, S.L.; Lundberg, D.J.; Bhagchandani, S.; et al. Molecular bottlebrush prodrugs as mono-and triplex combination therapies for multiple myeloma. Nat. Nanotechnol. 2023, 18, 184–192. [Google Scholar] [CrossRef] [PubMed]

- Pan, T.; Dutta, S.; Kamble, Y.; Patel, B.B.; Wade, M.A.; Rogers, S.A.; Diao, Y.; Guironnet, D.; Sing, C.E. Materials design of highly branched bottlebrush polymers at the intersection of modeling, synthesis, processing, and characterization. Chem. Mater. 2022, 34, 1990–2024. [Google Scholar] [CrossRef]

- Lapkriengkri, I.; Albanese, K.R.; Rhode, A.; Cunniff, A.; Pitenis, A.A.; Chabinyc, M.L.; Bates, C.M. Chemical Botany: Bottlebrush Polymers in Materials Science. Annu. Rev. Mater. Res. 2024, 54, 27–46. [Google Scholar] [CrossRef]

- Tu, S.; Choudhury, C.K.; Luzinov, I.; Kuksenok, O. Recent advances towards applications of molecular bottlebrushes and their conjugates. Curr. Opin. Solid State Mater. Sci. 2019, 23, 50–61. [Google Scholar] [CrossRef]

- Zardalidis, G.; Pipertzis, A.; Mountrichas, G.; Pispas, S.; Mezger, M.; Floudas, G. Effect of polymer architecture on the ionic conductivity. Densely grafted poly (ethylene oxide) brushes doped with LiTf. Macromolecules 2016, 49, 2679–2687. [Google Scholar] [CrossRef]

- Pipertzis, A.; Kafetzi, M.; Giaouzi, D.; Pispas, S.; Floudas, G.A. Grafted Copolymer Electrolytes Based on the Poly (acrylic acid-co-oligo ethylene glycol acrylate) (P (AA-co-OEGA)) Ion-Conducting and Mechanically Robust Block. ACS Appl. Polym. Mater. 2022, 4, 7070–7080. [Google Scholar] [CrossRef]

- Rolland, J.; Brassinne, J.; Bourgeois, J.-P.; Poggi, E.; Vlad, A.; Gohy, J.-F. Chemically anchored liquid-PEO based block copolymer electrolytes for solid-state lithium-ion batteries. J. Mater. Chem. A 2014, 2, 11839–11846. [Google Scholar] [CrossRef]

- Shim, J.; Bates, F.S.; Lodge, T.P. Superlattice by charged block copolymer self-assembly. Nat. Commun. 2019, 10, 2108. [Google Scholar] [CrossRef] [PubMed]

- Zhang, B.; Zheng, C.; Sims, M.B.; Bates, F.S.; Lodge, T.P. Influence of charge fraction on the phase behavior of symmetric single-ion conducting diblock copolymers. ACS Macro Lett. 2021, 10, 1035–1040. [Google Scholar] [CrossRef]

- Kataoka, K.; Harada, A.; Nagasaki, Y. Block copolymer micelles for drug delivery: Design, characterization and biological significance. Adv. Drug Deliv. Rev. 2012, 64, 37–48. [Google Scholar] [CrossRef]

- Thang, N.H.; Chien, T.B.; Cuong, D.X. Polymer-based hydrogels applied in drug delivery: An overview. Gels 2023, 9, 523. [Google Scholar] [CrossRef]

- Mai, Y.; Eisenberg, A. Self-assembly of block copolymers. Chem. Soc. Rev. 2012, 41, 5969–5985. [Google Scholar] [CrossRef]

- Yan, C.; Altunbas, A.; Yucel, T.; Nagarkar, R.P.; Schneider, J.P.; Pochan, D.J. Injectable solid hydrogel: Mechanism of shear-thinning and immediate recovery of injectable β-hairpin peptide hydrogels. Soft Matter 2010, 6, 5143–5156. [Google Scholar] [CrossRef]

- Chen, M.H.; Wang, L.L.; Chung, J.J.; Kim, Y.-H.; Atluri, P.; Burdick, J.A. Methods to assess shear-thinning hydrogels for application as injectable biomaterials. ACS Biomater. Sci. Eng. 2017, 3, 3146–3160. [Google Scholar] [CrossRef]

- Altunbas, A.; Lee, S.J.; Rajasekaran, S.A.; Schneider, J.P.; Pochan, D.J. Encapsulation of curcumin in self-assembling peptide hydrogels as injectable drug delivery vehicles. Biomaterials 2011, 32, 5906–5914. [Google Scholar] [CrossRef]

- Prince, D.A.; Villamagna, I.J.; Hopkins, C.C.; de Bruyn, J.R.; Gillies, E.R. Effect of drug loading on the properties of temperature-responsive polyester–poly (ethylene glycol)–polyester hydrogels. Polym. Int. 2019, 68, 1074–1083. [Google Scholar] [CrossRef]

- Singh, A.; Dowdall, N.; Hoare, T. Poly (Oligo (Ethylene Glycol) Methacrylate)-Based Polymers in Biomedical Applications: Preparation and Applications. Biomacromolecules 2025. [Google Scholar] [CrossRef] [PubMed]

- Taneja, H.; Salodkar, S.M.; Parmar, A.S.; Chaudhary, S. Hydrogel based 3D printing: Bio ink for tissue engineering. J. Mol. Liq. 2022, 367, 120390. [Google Scholar] [CrossRef]

- Pispas, S. Double hydrophilic block copolymers of sodium (2-sulfamate-3-carboxylate) isoprene and ethylene oxide. J. Polym. Sci. A Polym. Chem. 2006, 44, 606–613. [Google Scholar] [CrossRef]

- Mountrichas, G.; Pispas, S. Novel double hydrophilic block copolymers based on poly (p-hydroxystyrene) derivatives and poly (ethylene oxide). J. Polym. Sci. A Polym. Chem. 2007, 45, 5790–5799. [Google Scholar] [CrossRef]

- Chroni, A.; Forys, A.; Sentoukas, T.; Trzebicka, B.; Pispas, S. Poly [(vinyl benzyl trimethylammonium chloride)]-based nanoparticulate copolymer structures encapsulating insulin. Eur. Polym. J. 2022, 169, 111158. [Google Scholar] [CrossRef]

- Chroni, A.; Forys, A.; Trzebicka, B.; Alemayehu, A.; Tyrpekl, V.; Pispas, S. Poly [oligo (ethylene glycol) methacrylate]-b-poly [(vinyl benzyl trimethylammonium chloride)] Based Multifunctional Hybrid Nanostructures Encapsulating Magnetic Nanoparticles and DNA. Polymers 2020, 12, 1283. [Google Scholar] [CrossRef]

- Al-Tahami, K.; Singh, J. Smart polymer based delivery systems for peptides and proteins. Recent Pat. Drug Deliv. Formul. 2007, 1, 65–71. [Google Scholar] [CrossRef]

- Pipertzis, A.; Chroni, A.; Pispas, S.; Swenson, J. Molecular Dynamics and Self-Assembly in Double Hydrophilic Block and Random Copolymers. J. Phys. Chem. B 2024, 128, 11267–11276. [Google Scholar] [CrossRef]

- Moad, G.; Rizzardo, E.; Thang, S.H. Radical addition–fragmentation chemistry in polymer synthesis. Polymer 2008, 49, 1079–1131. [Google Scholar] [CrossRef]

- Skandalis, A.; Sentoukas, T.; Selianitis, D.; Balafouti, A.; Pispas, S. Using RAFT Polymerization Methodologies to Create Branched and Nanogel-Type Copolymers. Materials 2024, 17, 1947. [Google Scholar] [CrossRef]

- Ferry, J.D. Viscoelastic Properties of Polymers; John Wiley & Sons: Hoboken, NJ, USA, 1980. [Google Scholar]

- Carreau, P.J. Rheological equations from molecular network theories. Trans. Soc. Rheol. 1972, 16, 99–127. [Google Scholar] [CrossRef]

- Yasuda, K. Investigation of the Analogies Between Viscometric and Linear Viscoelastic Properties of Polystyrene Fluids. Ph.D. Thesis, Massachusetts Institute of Technology, Cambridge, MA, USA, 1979. [Google Scholar]

- Cross, M.M. Rheology of non-Newtonian fluids: A new flow equation for pseudoplastic systems. J. Colloid Sci. 1965, 20, 417–437. [Google Scholar] [CrossRef]

- Wagner, M.H.; Narimissa, E.; Poh, L.; Shahid, T. Modeling elongational viscosity and brittle fracture of polystyrene solutions. Rheol. Acta 2021, 60, 385–396. [Google Scholar] [CrossRef]

- Plazek, D.J.; Ngai, K.L. Correlation of polymer segmental chain dynamics with temperature-dependent time-scale shifts. Macromolecules 1991, 24, 1222–1224. [Google Scholar] [CrossRef]

- Qin, Q.; McKenna, G.B. Correlation between dynamic fragility and glass transition temperature for different classes of glass forming liquids. J. Non Cryst. Solids 2006, 352, 2977–2985. [Google Scholar] [CrossRef]

- Angell, C. Spectroscopy simulation and scattering, and the medium range order problem in glass. J. Non Cryst. Solids 1985, 73, 1–17. [Google Scholar] [CrossRef]

- Pipertzis, A.; Hossain, M.D.; Monteiro, M.J.; Floudas, G. Segmental dynamics in multicyclic polystyrenes. Macromolecules 2018, 51, 1488–1497. [Google Scholar] [CrossRef]

- Huang, D.; McKenna, G.B. New insights into the fragility dilemma in liquids. J. Chem. Phys. 2001, 114, 5621–5630. [Google Scholar] [CrossRef]

- Böhmer, R.; Ngai, K.L.; Angell, C.A.; Plazek, D.J. Nonexponential relaxations in strong and fragile glass formers. J. Chem. Phys. 1993, 99, 4201–4209. [Google Scholar] [CrossRef]

- Kunal, K.; Robertson, C.G.; Pawlus, S.; Hahn, S.F.; Sokolov, A.P. Role of chemical structure in fragility of polymers: A qualitative picture. Macromolecules 2008, 41, 7232–7238. [Google Scholar] [CrossRef]

- Floudas, G.; Štepánek, P. Structure and dynamics of poly (n-decyl methacrylate) below and above the glass transition. Macromolecules 1998, 31, 6951–6957. [Google Scholar] [CrossRef]

- Pipertzis, A.; Hess, A.; Weis, P.; Papamokos, G.; Koynov, K.; Wu, S.; Floudas, G. Multiple segmental processes in polymers with cis and trans stereoregular configurations. ACS Macro Lett. 2018, 7, 11–15. [Google Scholar] [CrossRef] [PubMed]

- Pipertzis, A.; Skandalis, A.; Pispas, S.; Floudas, G. Nanophase Segregation Drives Heterogeneous Dynamics in Amphiphilic PLMA-b-POEGMA Block-Copolymers with Densely Grafted Architecture. Macromol. Chem. Phys. 2024, 225, 2400180. [Google Scholar] [CrossRef]

- Mierzwa, M.; Floudas, G.; Neidhöfer, M.; Graf, R.; Spiess, H.W.; Meyer, W.H.; Wegner, G. Constrained dynamics in supramolecular structures of poly (p-phenylenes) with ethylene oxide side chains: A combined dielectric and nuclear magnetic resonance investigation. J. Chem. Phys. 2002, 117, 6289–6299. [Google Scholar] [CrossRef]

| VBTMAC (wt.%) | η0 (Pa·s) | λ (s) | n | α |

|---|---|---|---|---|

| Carreau–Yasuda (CY) model | ||||

| 20 (sequential) | 107 | 580 ± 10 | 0.11 ± 0.02 | 2 (fixed) |

| 20 (statistical) | 11,970 ± 30 | 0.43 ± 0.01 | 0.59 ± 0.01 | 0.91 ± 0.03 |

| 40 (statistical) | 107 | 3.8 ± 0.3 | 0.38 ± 0.02 | 2.0 ± 0.4 |

| 100 | 1011 | 2000 ± 1000 | 0.015 ± 0.002 | 0.99 ± 0.2 |

| Modified Cross (MC) model | ||||

| 20 (sequential) | 107 | 1800 ± 900 | 0.11 ± 0.02 | - |

| 20 (statistical) | 11,970 ± 30 | 0.43 ± 0.01 | 0.61 ± 0.01 | - |

| 40 (statistical) | 107 | 2.65 ± 0.4 | 0.25 ± 0.04 | - |

| 100 | 1011 | 1490 ± 60 | 0.015 ± 0.002 | - |

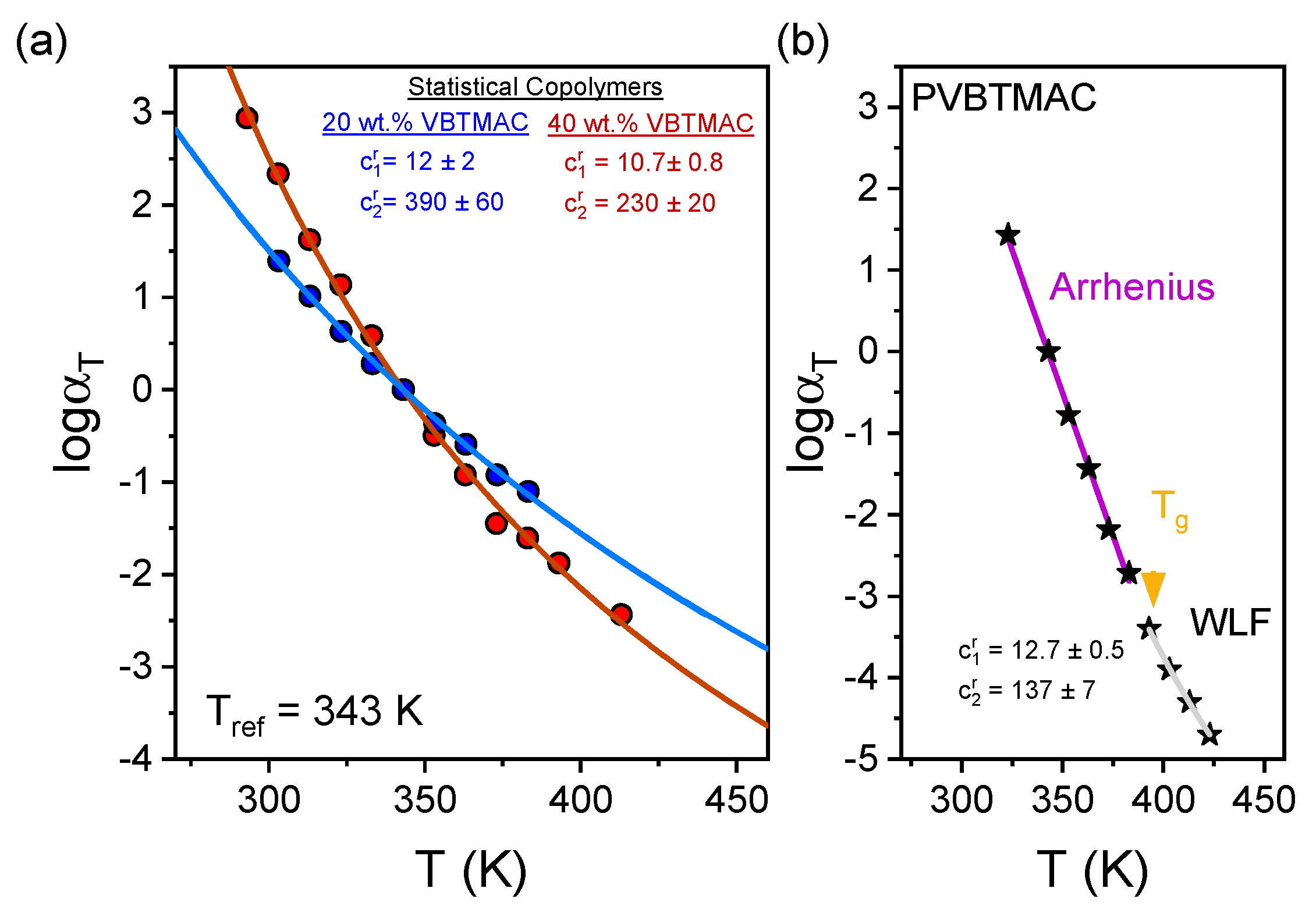

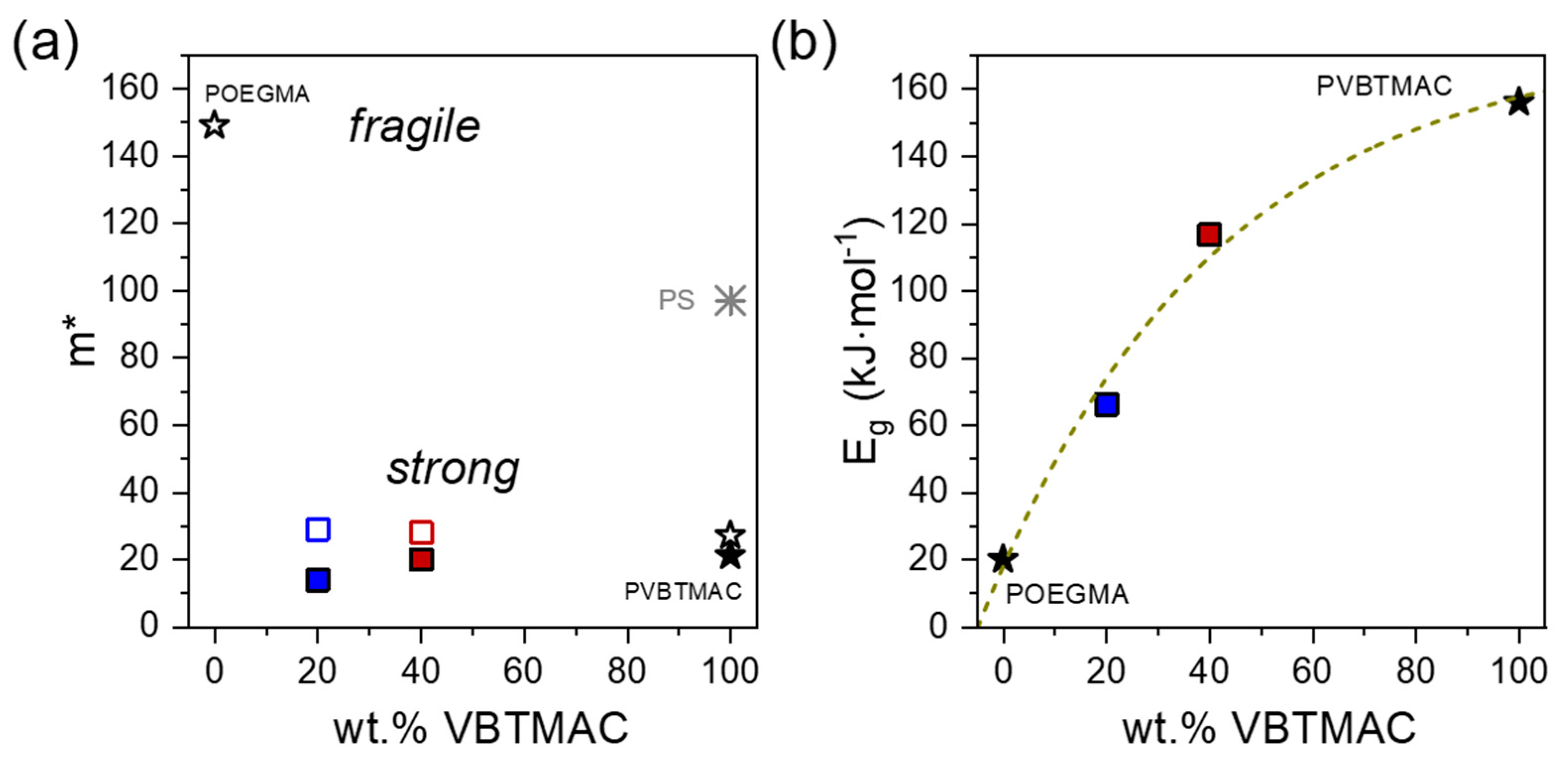

| Sample Code | Tg (K) * | c1g | c2g (K) | f(Tg) | αf (K−1) | m* | Eg (kJ·mol−1) |

|---|---|---|---|---|---|---|---|

| P(OEGMA80-co-VBTMAC20) | 290 | 13.89 | 337 | 0.0313 | 10−5 | 12 | 66.4 |

| P(OEGMA60-co-VBTMAC40) | 310 | 12.49 | 197 | 0.0348 | 10−4 | 20 | 116.7 |

| PVBTMAC | 383 | 9.83 | 177 | 0.044 | 10−4 | 21 | 156.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pipertzis, A.; Chroni, A.; Pispas, S.; Swenson, J. Viscoelastic Response of Double Hydrophilic Block Copolymers for Drug Delivery Applications. Polymers 2025, 17, 1857. https://doi.org/10.3390/polym17131857

Pipertzis A, Chroni A, Pispas S, Swenson J. Viscoelastic Response of Double Hydrophilic Block Copolymers for Drug Delivery Applications. Polymers. 2025; 17(13):1857. https://doi.org/10.3390/polym17131857

Chicago/Turabian StylePipertzis, Achilleas, Angeliki Chroni, Stergios Pispas, and Jan Swenson. 2025. "Viscoelastic Response of Double Hydrophilic Block Copolymers for Drug Delivery Applications" Polymers 17, no. 13: 1857. https://doi.org/10.3390/polym17131857

APA StylePipertzis, A., Chroni, A., Pispas, S., & Swenson, J. (2025). Viscoelastic Response of Double Hydrophilic Block Copolymers for Drug Delivery Applications. Polymers, 17(13), 1857. https://doi.org/10.3390/polym17131857