Advances in the Applications and Studies of Polyurethane Foam for Flexible Strain Sensors

Abstract

1. Introduction

2. Fundamental Composition of PU Foam-Based Sensor

2.1. PU Foam Substrates

2.1.1. Commercially Available PU Foams

2.1.2. Laboratory Preparation of PU Foams

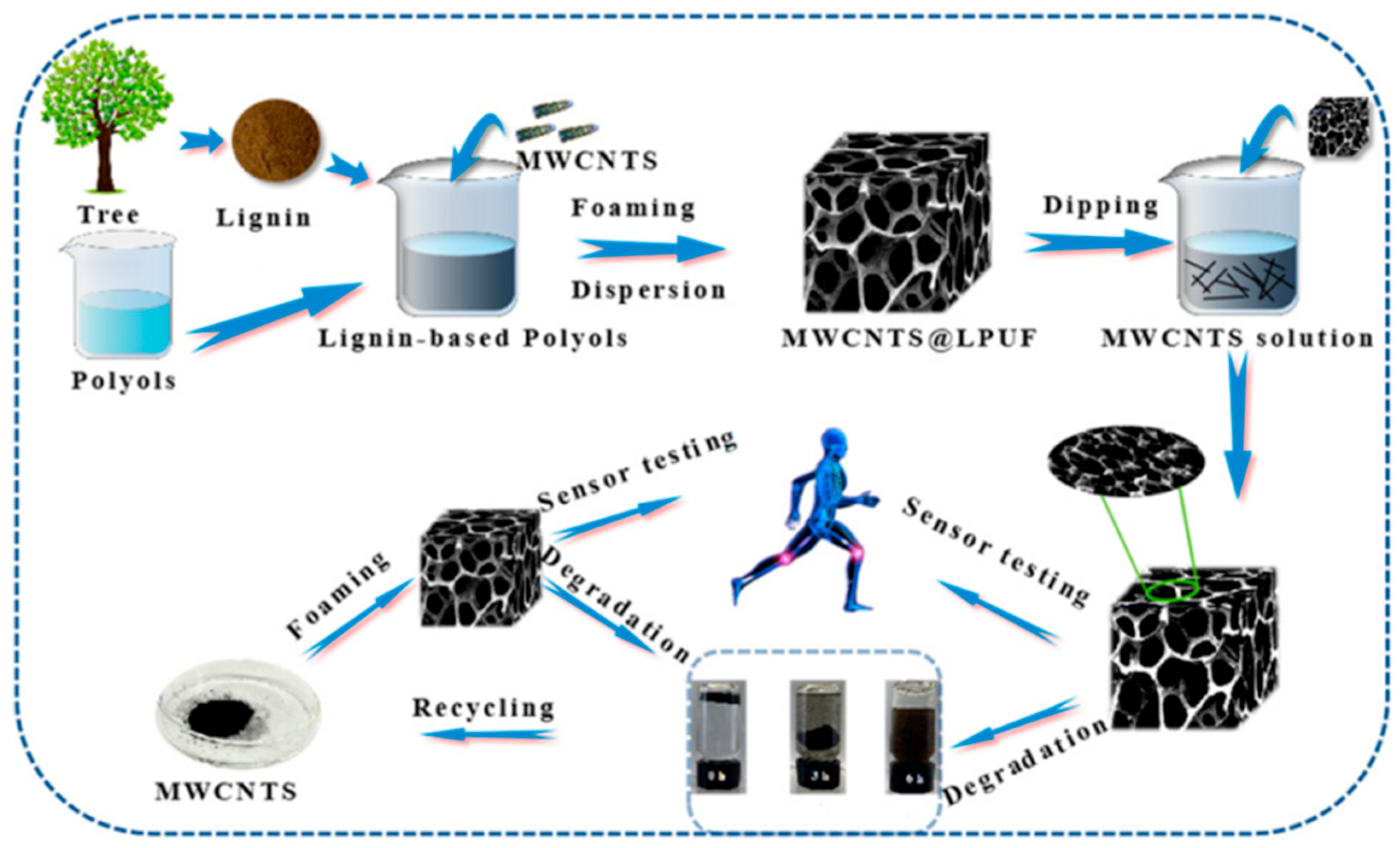

- Direct Foaming from Isocyanates and Polyols

- 2.

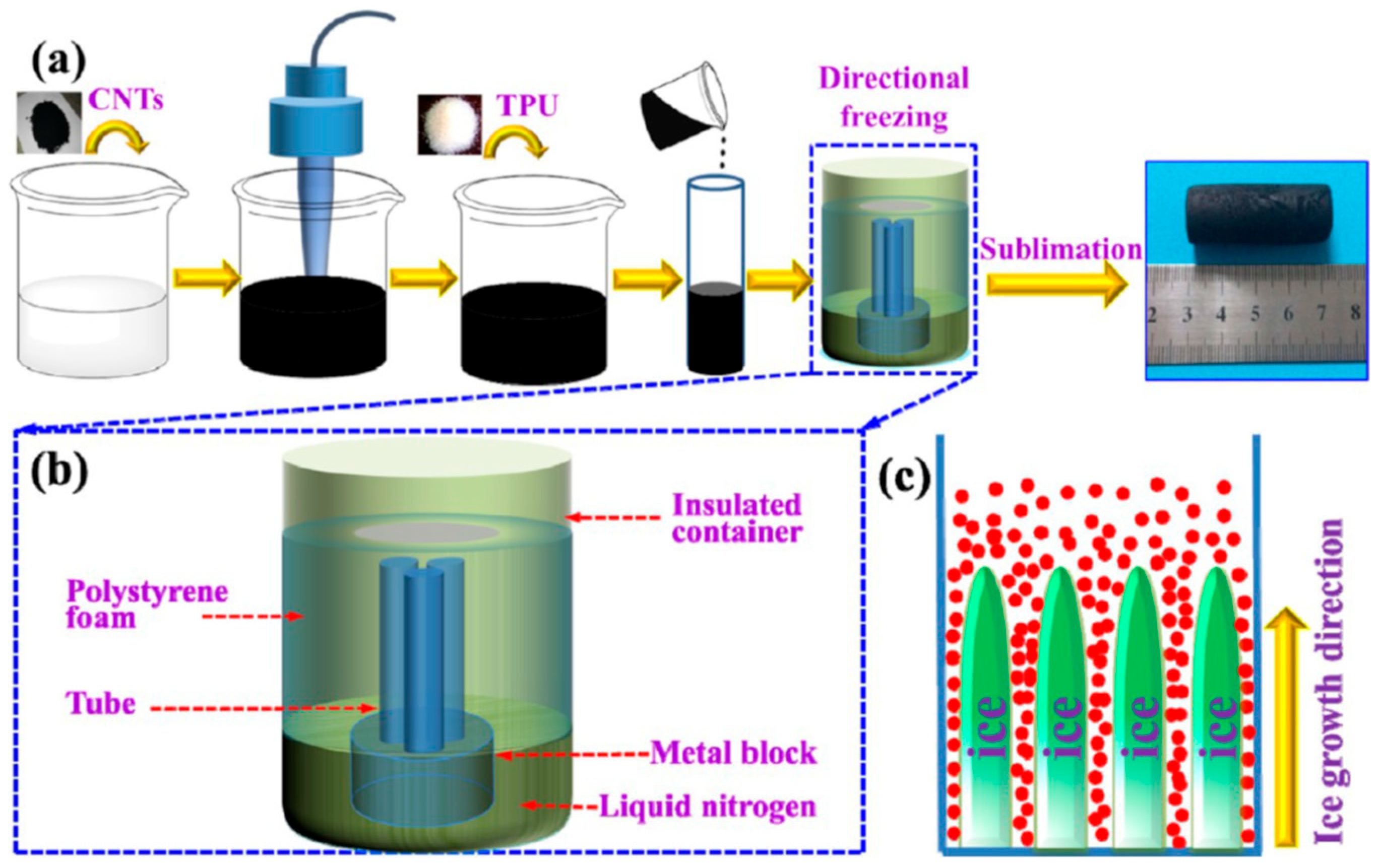

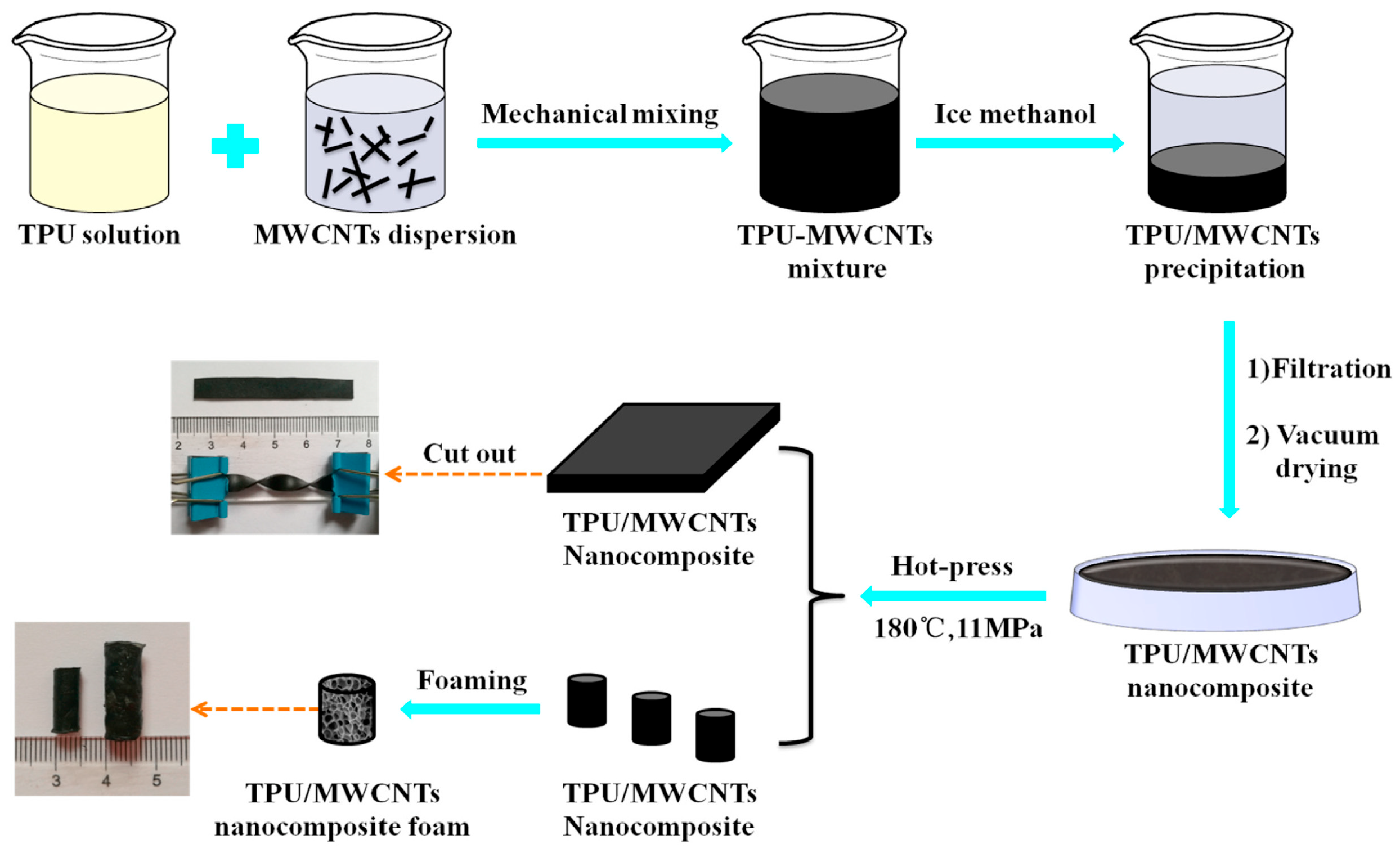

- Thermoplastic Polyurethane (TPU) Foams

- Template-Assisted Method:

- b.

- Phase Separation Techniques:

2.2. Conductive Filler

2.2.1. Carbon Nanotubes

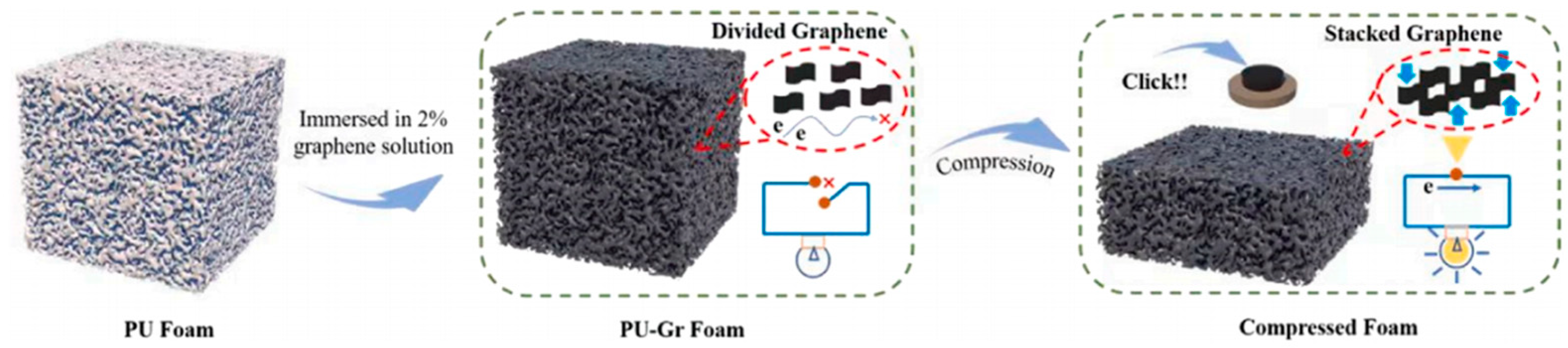

2.2.2. Graphene

2.2.3. MXenes

2.2.4. Liquid Metals (LMs)

2.2.5. Intrinsically Conductive Polymers (ICPs)

2.2.6. Ionic Liquids (ILs)

3. Fabrication of a Stain Sensor Based on PU Foam

3.1. Dip-Coating Method

3.2. In Situ Polymerization

3.3. Direct Foaming Method

3.4. Two-Step Template Method

4. Sensing Mechanisms

4.1. Piezoresistive Sensing Mechanism

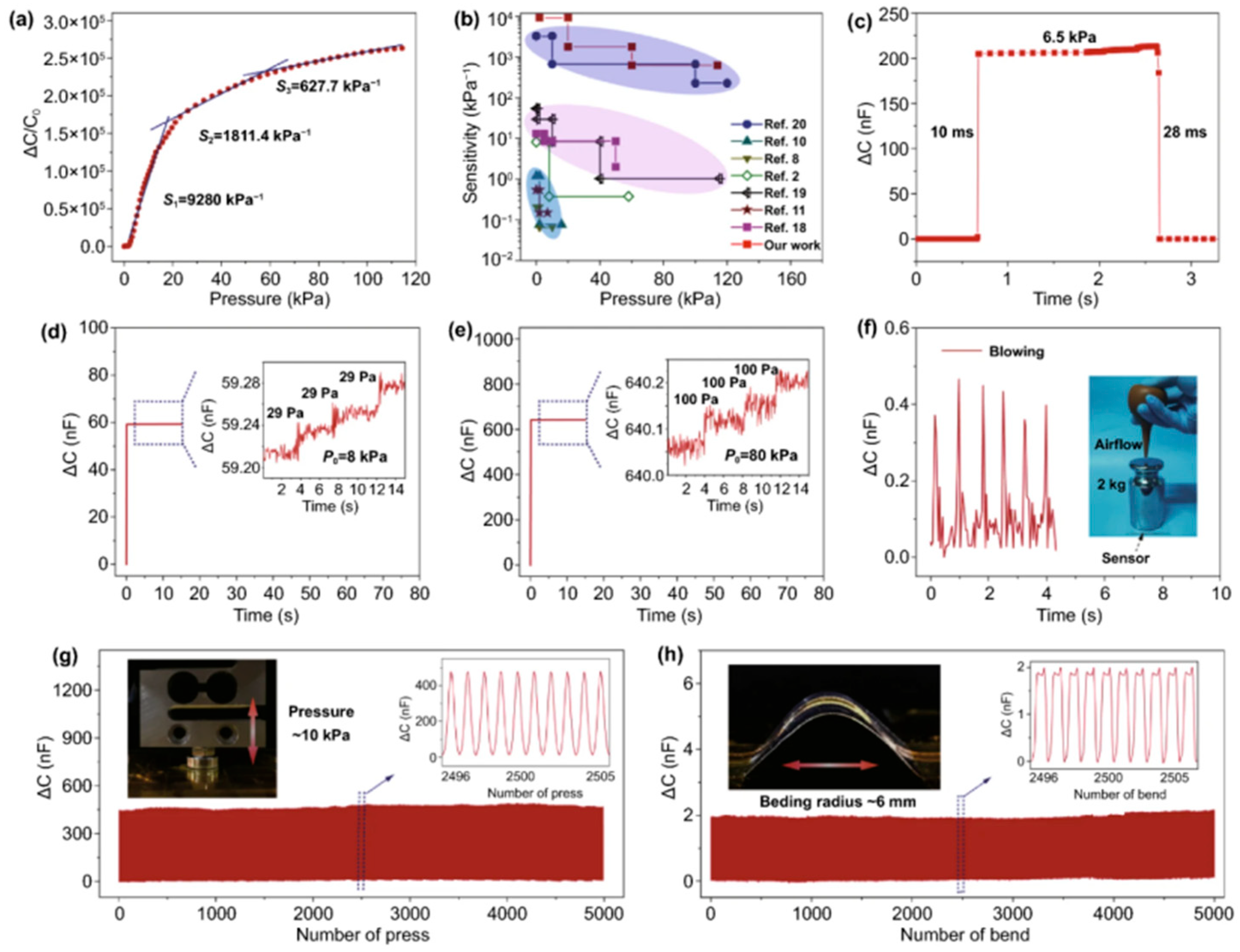

4.2. Capacitive Sensing Mechanism

4.3. Piezoelectric Sensing Mechanism

5. Applications of PU Foam Strain Sensor

5.1. Human Motion Monitoring

5.2. Medical and Healthcare Applications

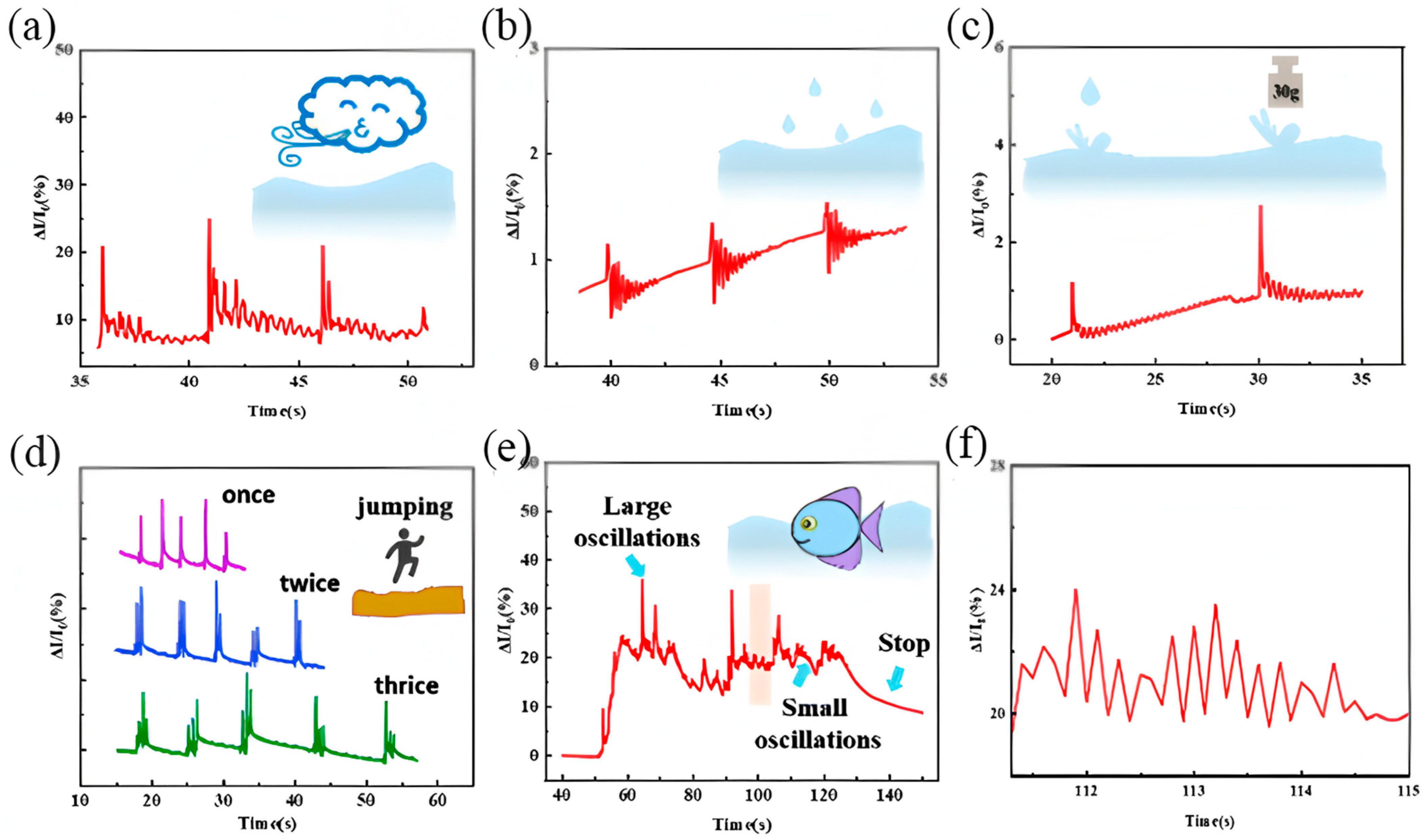

5.3. Industrial and Environmental Sensing

6. Summary and Outlook

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| 3D | Three-dimensional |

| Ag NPs | Silver nanoparticles |

| Ag NWs | Silver nanowires |

| ANOC | Array narrow orifice configuration |

| Au NPs | Gold nanoparticles |

| Au NWs | Gold nanowires |

| CNTs | Carbon Nanotubes |

| CS | Chitosan |

| ECG | Electrocardiogram |

| FAS-f-rGONR | (heptadecafluoro-1, 1, 2, 2-tetradecyl) trimethoxysilane functionalized rGONR |

| GF | Gauge Factor |

| GM | Multilayered graphene |

| GO | Graphene Oxide |

| Gr | Graphene |

| Gr-LPUF | Graphene-Lignin PU foam |

| ICPs | Intrinsically conductive polymers |

| IL | Ionic Liquid |

| IR | Infrared Spectroscopy |

| LM | Liquid Metal |

| MWCNTs | Multiwalled Carbon Nanotubes |

| MWCNTs-C | Carboxylic Multiwalled Carbon Nanotubes |

| PANI | Polyaniline |

| PDA | Polydopamine |

| PDMS | Polydimethylsiloxane |

| PEDOT | Poly(3,4-ethylene dioxythiophene) |

| PPI | Pores per inch |

| PPy | Polypyrrole |

| PTh | Polythiophene |

| PU | Polyurethane |

| rGO | Reduced Graphene Oxide |

| rGONR | Reduced Graphene Oxide Nanoribbons |

| RTVSR | Room temperature vulcanized silicone rubber |

| SA | Sodium alginate |

| ScCO2 | Supercritical Carbon Dioxide |

| semi-IPN | Semi-interpenetrating network |

| TIPS | Thermally Induced Phase Separation |

| TMOS-f-rGONR | Trimethoxyoctadecylsilane functionalized rGONR |

| TPU | Thermoplastic Polyurethane |

| WVIPS | Water-Vapor-Induced Phase Separation |

References

- Trung, T.Q.; Lee, N.E. Flexible and Stretchable Physical Sensor Integrated Platforms for Wearable Human-Activity Monitoring and Personal Healthcare. Adv. Mater. 2016, 28, 4338–4372. [Google Scholar] [CrossRef] [PubMed]

- Hwang, T.; Tsogbayar, D.; Vanessa; Choi, H.H.; Lee, H.S. Next-generation wearable sensors: Toward multi-directional strain sensing in sensory integration platforms. J. Mater. Chem. C 2024, 12, 15310–15338. [Google Scholar] [CrossRef]

- Chen, F.; Qiu, F.; Li, X.; Song, Y.; Liu, X.; Jiang, H.; Liu, H.; Xiao, Y.; Gao, M.; Liu, Y.; et al. The importance of interface interactions in flexible sensing materials: Classification, effect, and application. Chem. Eng. J. 2025, 511, 162276. [Google Scholar] [CrossRef]

- Van Nguyen, D.; Song, P.; Manshaii, F.; Bell, J.; Chen, J.; Dinh, T. Advances in Soft Strain and Pressure Sensors. ACS Nano 2025, 19, 6663–6704. [Google Scholar] [CrossRef]

- Yi, F.; Guo, Y.; Wu, S.; Zhu, Y.; Cui, Z.; Huang, A. 3D Porous Thermoplastic Polyurethane/Carbon Nanotube@Silver Nanoparticle Foam with Multidimensional Conductive Networks for Flexible Electronic Sensing. ACS Appl. Polym. Mater. 2025, 7, 3564–3575. [Google Scholar] [CrossRef]

- Adepu, V.; Mattela, V.; Sahatiya, P. A remarkably ultra-sensitive large area matrix of MXene based multifunctional physical sensors (pressure, strain, and temperature) for mimicking human skin. J. Mater. Chem. B 2021, 9, 4523–4534. [Google Scholar] [CrossRef]

- Shi, L.; Li, Z.; Chen, M.; Qin, Y.; Jiang, Y.; Wu, L. Quantum effect-based flexible and transparent pressure sensors with ultrahigh sensitivity and sensing density. Nat. Commun. 2020, 11, 3529. [Google Scholar] [CrossRef]

- Tadakaluru, S.; Thongsuwan, W.; Singjai, P. Stretchable and flexible high-strain sensors made using carbon nanotubes and graphite films on natural rubber. Sensors 2014, 14, 868–876. [Google Scholar] [CrossRef]

- Zhou, Z.; Tang, W.; Xu, T.; Zhao, W.; Zhang, J.; Bai, C. Flexible Strain Sensors Based on Thermoplastic Polyurethane Fabricated by Electrospinning: A Review. Sensors 2024, 24, 4793. [Google Scholar] [CrossRef]

- Maamoun, A.A.; Arafa, M.; Esawi, A.M.K. Flexible polyurethane foam: Materials, synthesis, recycling, and applications in energy harvesting—A review. Mater. Adv. 2025, 6, 1842–1858. [Google Scholar] [CrossRef]

- Akindoyo, J.O.; Beg, M.D.H.; Ghazali, S.; Islam, M.R.; Jeyaratnam, N.; Yuvaraj, A.R. Polyurethane types, synthesis and applications—A review. RSC Adv. 2016, 6, 114453–114482. [Google Scholar] [CrossRef]

- Wu, S.; Ma, S.; Zhang, Q.; Yang, C. A comprehensive review of polyurethane: Properties, applications and future perspectives. Polymer 2025, 327, 128361. [Google Scholar] [CrossRef]

- Wen, L.; Fan, W.; Kang, J.; Huang, H. Porous pressure sensors from mechanisms to application: A review. Sens. Actuators A 2025, 387, 116461. [Google Scholar] [CrossRef]

- Dong, W.; Wang, Y.; Zhou, Y.; Bai, Y.; Ju, Z.; Guo, J.; Gu, G.; Bai, K.; Ouyang, G.; Chen, S.; et al. Soft human–machine interfaces: Design, sensing and stimulation. Int. J. Intell. Rob. Appl. 2018, 2, 313–338. [Google Scholar] [CrossRef]

- Han, F.; Chen, S.; Wang, F.; Liu, M.; Li, J.; Liu, H.; Yang, Y.; Zhang, H.; Liu, D.; He, R.; et al. High-Conductivity, Self-Healing, and Adhesive Ionic Hydrogels for Health Monitoring and Human-Machine Interactions Under Extreme Cold Conditions. Adv. Sci. 2025, 12, e2412726. [Google Scholar] [CrossRef]

- Jiao, Z.; Zhuang, Z.; Cheng, Y.; Deng, X.; Sun, C.; Yu, Y.; Li, F. Lightweight Dual-Mode Soft Actuator Fabricated from Bellows and Foam Material. Actuators 2022, 11, 245. [Google Scholar] [CrossRef]

- Alqaderi, A.I.J.; Ramakrishnan, N. Carbon-based flexible strain sensors: Recent advances and performance insights in human motion detection. Chem. Eng. J. 2025, 513, 162609. [Google Scholar] [CrossRef]

- Liu, Q.; Liu, Y.; Shi, J.; Liu, Z.; Wang, Q.; Guo, C.F. High-Porosity Foam-Based Iontronic Pressure Sensor with Superhigh Sensitivity of 9280 kPa(-1). Nano Micro Lett. 2021, 14, 21. [Google Scholar] [CrossRef]

- Li, H.; Chen, J.; Chang, X.; Xu, Y.; Zhao, G.; Zhu, Y.; Li, Y. A highly stretchable strain sensor with both an ultralow detection limit and an ultrawide sensing range. J. Mater. Chem. A 2021, 9, 1795–1802. [Google Scholar] [CrossRef]

- Brady, S.; Diamond, D.; Lau, K.-T. Inherently conducting polymer modified polyurethane smart foam for pressure sensing. Sens. Actuators A 2005, 119, 398–404. [Google Scholar] [CrossRef]

- Chen, Q.; Gao, Q.; Wang, X.; Schubert, D.W.; Liu, X. Flexible, conductive, and anisotropic thermoplastic polyurethane/polydopamine/MXene foam for piezoresistive sensors and motion monitoring. Compos. Part A 2022, 155, 106838. [Google Scholar] [CrossRef]

- Ma, Z.; Wei, A.; Ma, J.; Shao, L.; Jiang, H.; Dong, D.; Ji, Z.; Wang, Q.; Kang, S. Lightweight, compressible and electrically conductive polyurethane sponges coated with synergistic multiwalled carbon nanotubes and graphene for piezoresistive sensors. Nanoscale 2018, 10, 7116–7126. [Google Scholar] [CrossRef]

- Eghbalinia, S.; Katbab, A.; Nazockdast, H.; Katbab, P. Highly compressible piezoresistive strain sensor with a semi-IPN structure based on PU sponge/RTV silicone rubber/MWCNTs. J. Polym. Res. 2022, 29, 471. [Google Scholar] [CrossRef]

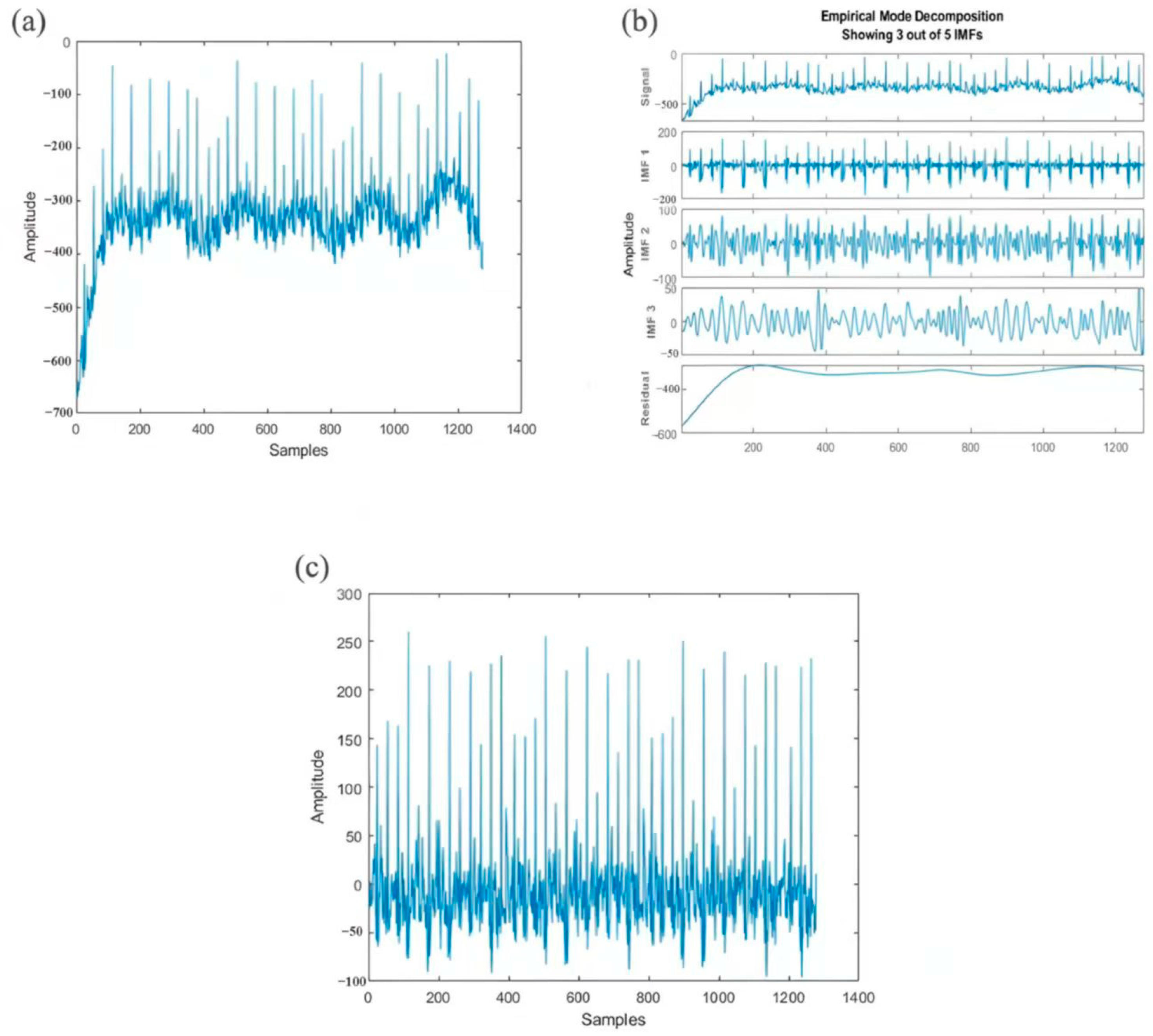

- Rajeev, P.K.; Suchetha, M.; Subramanian, J.; Vijayan, A. Flexible Conductive Polymer Reinforced Polyurethane Foam for Real-Time Human Body Electrical Signal Sensing and ECG Peaks. IEEE Sens. J. 2025, 25, 4127–4134. [Google Scholar] [CrossRef]

- Delavarde, A.; Savin, G.; Derkenne, P.; Boursier, M.; Morales-Cerrada, R.; Nottelet, B.; Pinaud, J.; Caillol, S. Sustainable polyurethanes: Toward new cutting-edge opportunities. Prog. Polym. Sci. 2024, 151, 101805. [Google Scholar] [CrossRef]

- Ates, M.; Karadag, S.; Eker, A.A.; Eker, B. Polyurethane foam materials and their industrial applications. Polym. Int. 2022, 71, 1157–1163. [Google Scholar] [CrossRef]

- Wang, S.; Chen, Z.; Zhou, H.; Fu, X.; Chen, B.; Wang, F.; Liu, A.; Guo, W.; Ye, M. Microporous MXene/Polyurethane Gels Derived from Iron Foam Templates for Ultra-High Stable Pressure Sensors and Triboelectric Nanogenerators. ACS Appl. Electron. Mater. 2024, 6, 3491–3500. [Google Scholar] [CrossRef]

- Wang, F.; Ma, X.; Wu, J.; Chao, Y.; Xiao, P.; Zhu, J.; Chen, J. Flexible, recyclable and sensitive piezoresistive sensors enabled by lignin polyurethane-based conductive foam. Mater. Adv. 2023, 4, 586–595. [Google Scholar] [CrossRef]

- Huang, W.; Dai, K.; Zhai, Y.; Liu, H.; Zhan, P.; Gao, J.; Zheng, G.; Liu, C.; Shen, C. Flexible and Lightweight Pressure Sensor Based on Carbon Nanotube/Thermoplastic Polyurethane-Aligned Conductive Foam with Superior Compressibility and Stability. ACS Appl. Mater. Interfaces 2017, 9, 42266–42277. [Google Scholar] [CrossRef]

- Liu, H.; Dong, M.; Huang, W.; Gao, J.; Dai, K.; Guo, J.; Zheng, G.; Liu, C.; Shen, C.; Guo, Z. Lightweight conductive graphene/thermoplastic polyurethane foams with ultrahigh compressibility for piezoresistive sensing. J. Mater. Chem. C 2017, 5, 73–83. [Google Scholar] [CrossRef]

- Liu, H.; Huang, W.; Gao, J.; Dai, K.; Zheng, G.; Liu, C.; Shen, C.; Yan, X.; Guo, J.; Guo, Z. Piezoresistive behavior of porous carbon nanotube-thermoplastic polyurethane conductive nanocomposites with ultrahigh compressibility. Appl. Phys. Lett. 2016, 108, 011904. [Google Scholar] [CrossRef]

- Zhang, X.; Chen, J.; Chen, X.; Yao, J.; Zheng, W.; Shen, B. Recyclable and leakage-suppressed microcellular liquid–metal composite foams for stretchable electromagnetic shielding. Chem. Eng. J. 2024, 493, 152478. [Google Scholar] [CrossRef]

- Fei, Y.; Chen, F.; Fang, W.; Xu, L.; Ruan, S.; Liu, X.; Zhong, M.; Kuang, T. High-strength, flexible and cycling-stable piezo-resistive polymeric foams derived from thermoplastic polyurethane and multi-wall carbon nanotubes. Compos. Part B 2020, 199, 108279. [Google Scholar] [CrossRef]

- Yan, X.; Chen, Y.; Tan, J.; Zhang, C.; Xie, Z.; Zheng, S.Y.; Wang, Q.; Zhou, Z.; Yang, J. Tough and stretchable ionic polyurethane foam for use in wearable devices. Soft Matter 2024, 20, 8136–8143. [Google Scholar] [CrossRef]

- Han, F.; Li, J.; Zhao, S.; Zhang, Y.; Huang, W.; Zhang, G.; Sun, R.; Wong, C.-P. A crack-based nickel@graphene-wrapped polyurethane sponge ternary hybrid obtained by electrodeposition for highly sensitive wearable strain sensors. J. Mater. Chem. C 2017, 5, 10167–10175. [Google Scholar] [CrossRef]

- Li, J.; Zhang, E.; Ren, X. Ultrahigh strain-response conductive polyurethane foam for strain sensor and pressure control switches. Mater. Today Commun. 2024, 38, 108016. [Google Scholar] [CrossRef]

- Madbouly, A.I.; Hassanien, W.S.; Morsy, M. Tailoring the polyurethane foam/rGO/BaTiO3 pressure sensor for human activities. Diam. Relat. Mater. 2023, 136, 109940. [Google Scholar] [CrossRef]

- Shi, Z.; Li, A.; Zhang, C.; Zhang, Y.-F. Reduced graphene oxide coated polyurethane composite foams as flexible strain sensors for large deformation. Mater. Sci. Eng. B 2021, 272, 115360. [Google Scholar] [CrossRef]

- Yao, H.B.; Ge, J.; Wang, C.F.; Wang, X.; Hu, W.; Zheng, Z.J.; Ni, Y.; Yu, S.H. A flexible and highly pressure-sensitive graphene-polyurethane sponge based on fractured microstructure design. Adv. Mater. 2013, 25, 6692–6698. [Google Scholar] [CrossRef]

- Li, X.P.; Li, Y.; Li, X.; Song, D.; Min, P.; Hu, C.; Zhang, H.B.; Koratkar, N.; Yu, Z.Z. Highly sensitive, reliable and flexible piezoresistive pressure sensors featuring polyurethane sponge coated with MXene sheets. J. Colloid Interface Sci. 2019, 542, 54–62. [Google Scholar] [CrossRef]

- Zheng, Z.; Fang, X.; Pan, Y.; Song, S.; Xue, H.; Li, J.; Li, Y.; Li, J. A liquid metal-embedded 3D interconnected-porous TPU/MXene composite with improved capacitive sensitivity and pressure detection range. RSC Adv. 2024, 14, 15730–15741. [Google Scholar] [CrossRef]

- Peng, Y.; Liu, H.; Li, T.; Zhang, J. Hybrid Metallic Foam with Superior Elasticity, High Electrical Conductivity, and Pressure Sensitivity. ACS Appl. Mater. Interfaces 2020, 12, 6489–6495. [Google Scholar] [CrossRef] [PubMed]

- Cai, S.; Allioux, F.-M.; Tang, J.; Han, J.; Zhang, J.; He, Y.; Merhebi, S.; Christoe, M.J.; Mayyas, M.; Wong, E.H.H.; et al. Soft Liquid Metal Infused Conductive Sponges. Adv. Mater. Technol. 2022, 7, 2101500. [Google Scholar] [CrossRef]

- Hu, Z.; Xin, Y.; Fu, Q. Ultrahigh sensitivity and wide strain range of porous pressure sensor based on binary conductive fillers by in-situ polymerization. J. Polym. Res. 2021, 28, 134. [Google Scholar] [CrossRef]

- Luo, Y.; Zhao, G.; Chen, J.; Chang, X.; Huang, J.; Zhu, Y. Lightweight and highly compressible/stretchable ionogel foams for designing pressure and strain sensors. Polymer 2024, 293, 126616. [Google Scholar] [CrossRef]

- Gai, B.; Li, S.; Zhang, J.; Jiang, Z.; Xie, G.; Zhang, J.; Xing, S.; Yao, M. Multifunctional and high-stability RGO/PANI wrapped polyurethane foam for flexible piezoresistive sensor applications. J. Appl. Polym. Sci. 2024, 141, e55761. [Google Scholar] [CrossRef]

- Ren, X.; Tian, Q.; Zhu, X.; Mi, H.-Y.; Jing, X.; Dong, B.; Liu, C.; Shen, C. Multi-scale closure piezoresistive sensor with high sensitivity derived from polyurethane foam and polypyrrole nanofibers. Chem. Eng. J. 2023, 474, 145926. [Google Scholar] [CrossRef]

- Beccatelli, M.; Villani, M.; Gentile, F.; Bruno, L.; Seletti, D.; Nikolaidou, D.M.; Culiolo, M.; Zappettini, A.; Coppedè, N. All-Polymeric Pressure Sensors Based on PEDOT:PSS-Modified Polyurethane Foam. ACS Appl. Polym. Mater. 2021, 3, 1563–1572. [Google Scholar] [CrossRef]

- Hong, S.Y.; Oh, J.H.; Park, H.; Yun, J.Y.; Jin, S.W.; Sun, L.; Zi, G.; Ha, J.S. Polyurethane foam coated with a multi-walled carbon nanotube/polyaniline nanocomposite for a skin-like stretchable array of multi-functional sensors. NPG Asia Mater. 2017, 9, e448. [Google Scholar] [CrossRef]

- Selvaraj, V.K.; Subramanian, J.; Krishna Rajeev, P.; Rajendran, V.; Raja, S. Optimization of conductive nanofillers in bio-based polyurethane foams for ammonia-sensing application. Polym. Eng. Sci. 2025, 65, 14–28. [Google Scholar] [CrossRef]

- Wang, X.; Gao, Q.; Schubert, D.W.; Liu, X. Review on Electrospun Conductive Polymer Composites Strain Sensors. Adv. Mater. Technol. 2023, 8, 2300293. [Google Scholar] [CrossRef]

- Ju, M.; Dou, Z.; Li, J.W.; Qiu, X.; Shen, B.; Zhang, D.; Yao, F.Z.; Gong, W.; Wang, K. Piezoelectric Materials and Sensors for Structural Health Monitoring: Fundamental Aspects, Current Status, and Future Perspectives. Sensors 2023, 23, 543. [Google Scholar] [CrossRef] [PubMed]

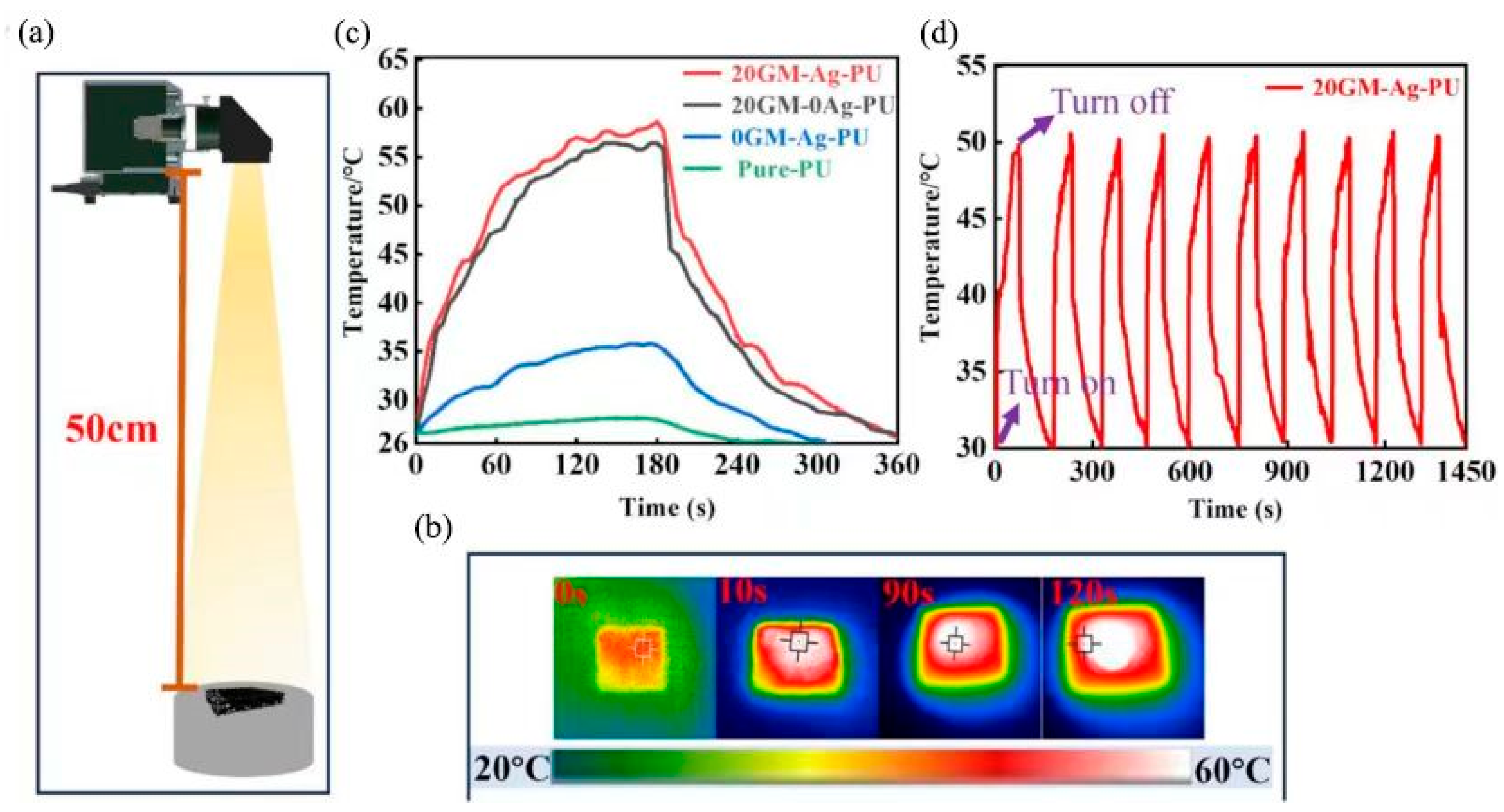

- Huang, M.; Du, X. Synergistic effect of Ag nanoparticle and graphene on improving antimicrobial and photothermal conversion performances of their polyurethane foam sensor. Chem. Eng. J. 2025, 507, 160836. [Google Scholar] [CrossRef]

- Ugarte, L.; Gómez-Fernández, S.; Tercjak, A.; Martínez-Amesti, A.; Corcuera, M.A.; Eceiza, A. Strain sensitive conductive polyurethane foam/graphene nanocomposites prepared by impregnation method. Eur. Polym. J. 2017, 90, 323–333. [Google Scholar] [CrossRef]

- Zhong, W.; Ding, X.; Li, W.; Shen, C.; Yadav, A.; Chen, Y.; Bao, M.; Jiang, H.; Wang, D. Facile Fabrication of Conductive Graphene/Polyurethane Foam Composite and Its Application on Flexible Piezo-Resistive Sensors. Polymers 2019, 11, 1289. [Google Scholar] [CrossRef]

- Qiang, F.; Hu, L.-L.; Gong, L.-X.; Zhao, L.; Li, S.-N.; Tang, L.-C. Facile synthesis of super-hydrophobic, electrically conductive and mechanically flexible functionalized graphene nanoribbon/polyurethane sponge for efficient oil/water separation at static and dynamic states. Chem. Eng. J. 2018, 334, 2154–2166. [Google Scholar] [CrossRef]

- Huang, Y.; Yu, B.; Zhang, L.; Ning, N.; Tian, M. Highly Stretchable Conductor by Self-Assembling and Mechanical Sintering of a 2D Liquid Metal on a 3D Polydopamine-Modified Polyurethane Sponge. ACS Appl. Mater. Interfaces 2019, 11, 48321–48330. [Google Scholar] [CrossRef]

- Lv, B.; Chen, X.; Liu, C. A Highly Sensitive Piezoresistive Pressure Sensor Based on Graphene Oxide/Polypyrrole@Polyurethane Sponge. Sensors 2020, 20, 1219. [Google Scholar] [CrossRef]

- Zhao, H.; Ma, X.; Xu, X.; Cui, M.; Stott, N.E.; Zhu, J.; Chen, J. Lightweight, superhydrophobic, lignin-based polyurethane foam composites for underwater pressure sensing. J. Mater. Chem. C 2024, 12, 3203–3209. [Google Scholar] [CrossRef]

- Ren, X.; Li, R.; Mi, H.-Y.; Zhang, M.; Tian, Q.; Jing, X.; Zhu, X.; Han, J.; Ren, Y.; Dong, B.; et al. Scorpion-inspired multi-scale contact enabled multifunctional piezoresistive pressure sensor based on hybrid nanofiber decoration. Chem. Eng. J. 2024, 499, 156496. [Google Scholar] [CrossRef]

- Tewari, A.; Gandla, S.; Bohm, S.; McNeill, C.R.; Gupta, D. Highly Exfoliated MWNT-rGO Ink-Wrapped Polyurethane Foam for Piezoresistive Pressure Sensor Applications. ACS Appl. Mater. Interfaces 2018, 10, 5185–5195. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Zhou, R.; Li, D.; Zhang, L.; Ren, G.; Wang, L.; Liu, J.; Wang, D.; Tang, Z.; Lu, G.; et al. High-Performance Foam-Shaped Strain Sensor Based on Carbon Nanotubes and Ti(3)C(2)T(x) MXene for the Monitoring of Human Activities. ACS Nano 2021, 15, 9690–9700. [Google Scholar] [CrossRef] [PubMed]

- Souri, H.; Banerjee, H.; Jusufi, A.; Radacsi, N.; Stokes, A.A.; Park, I.; Sitti, M.; Amjadi, M. Wearable and Stretchable Strain Sensors: Materials, Sensing Mechanisms, and Applications. Adv. Intell. Syst. 2020, 2, 2000039. [Google Scholar] [CrossRef]

| Conductive Material | Materials | Fabrication Method | Sensitivity/GF (at Strain %) | Sensing Range | Response/Recovery Time (ms) | Durability (Cycles at Strain %) | Ref. |

|---|---|---|---|---|---|---|---|

| CNTs | MWCNTs/PU | dip-coating | 3.51 (70%) | 0–90% | / | 20 (50%) | [23] |

| MWCNTs-C/TPU | template-assisted method and dip-coating | 5.38 (0–30%) | 0–782% | 200 | 40 (30%) | [34] | |

| MWCNTs/TPU | template-assisted method | 1.22 (0–77%) | 0–77% | / | 2000 (30%) | [29] | |

| MWCNTs/TPU | solution-blending and ScCO2 foaming | 1.88 (35%) | 0–50% | / | 1000 (30%) | [33] | |

| CNTs/TPU | electrospinning and dip-coating | 0.101 (400%) | 0.05–600% | 75 | 2000 (50%) | [19] | |

| MWCNTs/Ag/TPU | salt-template-assisted method and dip-coating | 1.4 (0–55%) | 0–70% | 20/20 | 500 (50%) | [5] | |

| CNTs/TPU | solution-blending and TIPS | / | 0–90% | / | 50 (90%) | [31] | |

| MXenes | MXenes/PU | dip-coating | 323.59 (5–20%) | 0–20% | 510/65 | 2500 (10%) | [6] |

| MXene/PU | iron foam template and dip-coating | 0.96144 kPa−1 | 0–454.7 kPa | 140/152 | 15,000 (130 kPa) | [27] | |

| MXenes/PDA/TPU | directional freezing and dip-coating | 2.36 (2.5–20%) | 0–80% | 40 | 5000 (50%) | [21] | |

| MXenes/CS/PU | dip-coating | 3 (45–85%) | 0–85% | 19 | 5000 (20%) | [40] | |

| Gr | Gr/TPU | TIPS | 12.24 (60–90%) | 0–99% | / | 50 | [30] |

| rGO/PU | dip-coating | / | 0–100% | 100/740 | / | [38] | |

| rGO/BaTiO3/PU | dip-coating | 2.64 kPa−1 | 0–60 kPa | 560 | / | [37] | |

| rGO/SA/PU | direct foaming method | / | 0–40% | 100/100 | 100 (50%) | [36] | |

| GO/Ag/PU | dip-coating and chemical reduction of Ag | 66.3 (45–60%) | 0–60 kPa | / | 100 (15%) | [53] | |

| Gr/PU | dip-coating | / | 0–70% | / | / | [54] | |

| rGO/PU | dip-coating | 0.26 kPa−1 | 0–10 kPa | / | 10,000 (2 kPa) | [39] | |

| rGO/PU | dip-coating | 0.17 kPa−1 | 0–25 kPa | 300/300 | 50(3.125 kPa) | [55] | |

| rGO/PU | dip-coating | / | 0–80% | / | 100 (80%) | [56] | |

| Ni/GO/PU | dip-coating and electrodeposition of Ni | 3360.09 (20–65%) | 0–65% | 100 | 1000 (30%) | [35] | |

| IL | IL/PU | dip-coating | 9280 kPa−1 | 0–120 kPa | 10/28 | 5000(10 kPa) | [18] |

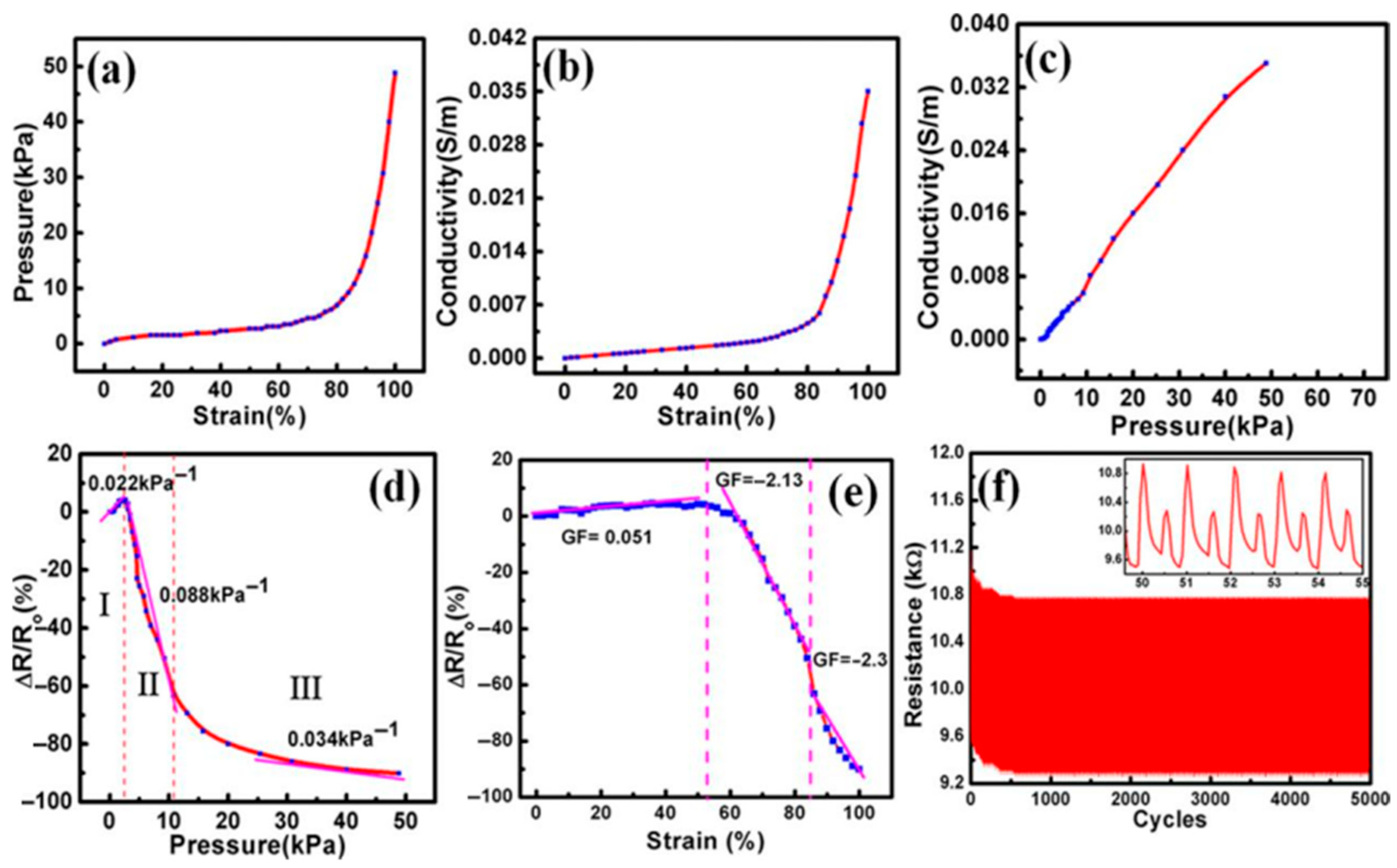

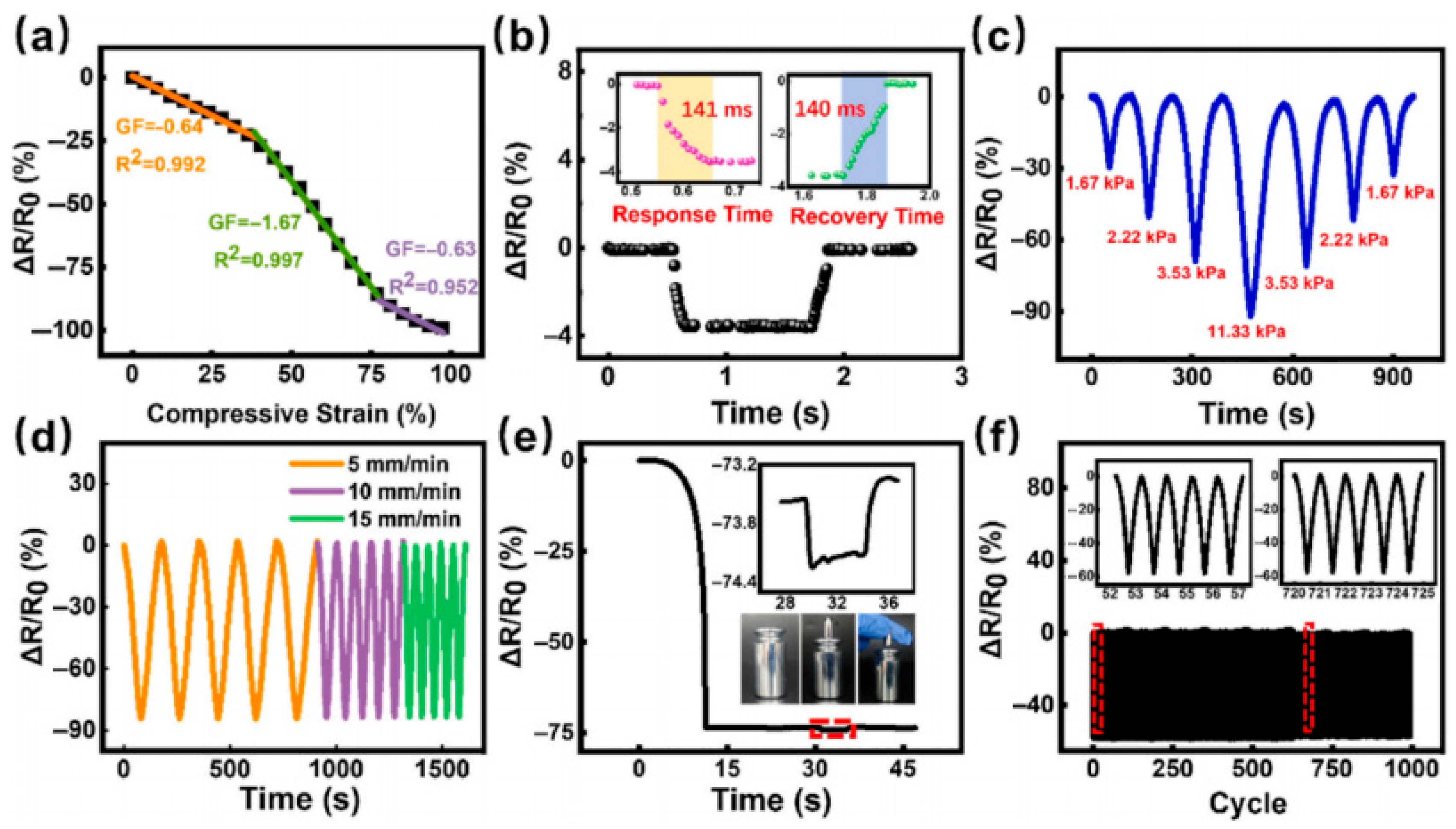

| IL/PU | dip-coating | 2.82 (150–275%) | 0–275% | 141/140 | 1000 (40%) | [45] | |

| ICP | PPy/PU | in situ polymerization | / | 0–100% | 50,000 | / | [20] |

| PPy/PDA/PU | in situ polymerization | 6.66 (0–20%) | 0–70% | 120/100 | 1000 | [47] | |

| PEDOT-PSS/PU | dip-coating | 0.3 kPa−1 (0–30 kPa) | 0–50 kPa | / | / | [48] | |

| PTh-Ag/PU | in situ polymerization | 152.24 (60–80%) | 0–80% | / | 1000 (30%) | [44] | |

| LMs | Ga/PU | dip-coating | / | 64.5–386.8 kPa | / | 1000 (174.5 kPa) | [43] |

| LMs/PU | direct foaming method | 35.8 (19–22%) | 0–100% | 202 | 800 (10%) | [42] | |

| LMs/PDA/PU | dip-coating | / | 0–150% | / | 1000 | [57] | |

| LMs/TPU | WVIPS | / | 0–741% | / | 250 (200%) | [32] | |

| Multiple conductive fillers | GO/PPy/PU | dip-coating and in situ polymerization | 2.1 (0–40) | 0–80% | 70 | 10,000 (45%) | [58] |

| PPy/GO/PU | dip-coating and in situ polymerization | 13.89 (70–90%) | 0–90% | 100 | 2000 (50%) | [59] | |

| PPy/CNT/PU | dip-coating and in situ polymerization | 1.8 kPa−1 (0–1.5 kPa) | 10–70% | 120/90 | 1000 (40%) | [60] | |

| LM/MXene/TPU | template-assisted method and dip-coating | 1.91 kPa−1 | 0–260 kPa | 60/110 | 4000 (50%) | [41] | |

| MWCNT/PANI/PU | dip-coating | 2.1 kPa−1 | 0.05–30 kPa | 20 | 10,000 (1 kPa) | [49] | |

| MWCNTs/rGO/PU | dip-coating | 2.3 (100%) | 0–100% | 30 | 5000 (50%) | [61] | |

| MWCNTs/rGO/PU | dip-coating | 1.75 (50–75%) | 0–75% | / | / | [22] | |

| MXenes/MWCNTs/TPU | salt-template-assisted method and dip-coating | 363 (80–101%) | 0–101% | / | 200 (80%) | [62] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, S.; Liu, G.; Sun, Y.; Zhang, X. Advances in the Applications and Studies of Polyurethane Foam for Flexible Strain Sensors. Polymers 2025, 17, 1851. https://doi.org/10.3390/polym17131851

Huang S, Liu G, Sun Y, Zhang X. Advances in the Applications and Studies of Polyurethane Foam for Flexible Strain Sensors. Polymers. 2025; 17(13):1851. https://doi.org/10.3390/polym17131851

Chicago/Turabian StyleHuang, Shuai, Guanbing Liu, Ying Sun, and Xiacong Zhang. 2025. "Advances in the Applications and Studies of Polyurethane Foam for Flexible Strain Sensors" Polymers 17, no. 13: 1851. https://doi.org/10.3390/polym17131851

APA StyleHuang, S., Liu, G., Sun, Y., & Zhang, X. (2025). Advances in the Applications and Studies of Polyurethane Foam for Flexible Strain Sensors. Polymers, 17(13), 1851. https://doi.org/10.3390/polym17131851