Abstract

Global concerns about environmental pollution, poor waste management, and the rise in antimicrobial resistance due to uncontrolled antibiotic use have driven researchers to seek alternative, multifaceted solutions. Plants, animals, microorganisms, and their processing wastes serve as valuable sources of natural biopolymers and bioactive compounds. Through nanotechnology, these can be assembled into formulations with enhanced antimicrobial properties, high safety, and low toxicity. This review explores polysaccharides, including chitosan, alginate, starch, pectin, cellulose, hemicellulose, gums, carrageenan, dextran, pullulan, and hyaluronic acid, used in nanotechnology, highlighting their advantages and limitations as nanocarriers. Addressing the global urgency for alternative antimicrobials, we examined natural compounds derived from plants, microorganisms, and animals, such as phytochemicals, bacteriocins, animal antimicrobial peptides, and proteins. Focusing on their protection and retained activity, this review discusses polysaccharide-based nanoformulations with natural antimicrobials, including nanoparticles, nanoemulsions, nanocapsules, nanoplexes, and nanogels. Special emphasis is placed on strategies and formulations for the encapsulation, entrapment, and conjugation of natural compounds using polysaccharides as protective carriers and delivery systems, including a brief discussion on their future applications, prospects, and challenges in scaling up.

Keywords:

chitosan; alginate; cellulose; gum; dextran; complexation; conjugation; essential oil; bacteriocins; AMP 1. Introduction

Antimicrobial resistance (AMR) has emerged as a critical challenge to modern healthcare systems worldwide. The uncontrolled use of antibiotics has been identified as a principal causative factor in the emergence of this critical public health challenge. Innovative antibacterial agents with unique modes of action are urgently needed to overcome current resistance challenges. Nanomaterials, natural antimicrobial compounds, and particularly their synergistic combinations offer promising solutions to address antimicrobial resistance [1,2,3,4].

Nanomaterials can be categorized into three primary classes based on composition: organic, carbon-based, and inorganic [5]. The key advantages of nanoparticles as carriers include their ultra-small and tunable size, protective encapsulation of payloads, controllable release kinetics, reduced systemic side effects, and capacity for combinatorial loading of therapeutic agents [6]. The utilization of nanocarriers as delivery systems enhances bioactive molecules’ therapeutic potential by improving their absorption, bioavailability, and stability while reducing toxicity and optimizing pharmacokinetic profiles [4].

Organic nanoparticles (NPs) fabricated from biopolymers exhibit favorable biocompatibility, biodegradability, and flexible loading capacity for various bioactive molecules [7,8]. Biopolymers are classified by origin as (1) synthetic polymers from bio-derived monomers (e.g., polylactic acid [PLA] and other polyesters), (2) natural animal- and plant-derived polymers (e.g., chitin, cellulose, collagen, and zein), and (3) microbial polymers (e.g., polyhydroxyalkanoates [PHA], bacterial cellulose, xanthan, and pullulan) [9]. Biopolymers directly extracted from biomass represent the most abundant category of natural polymers. This group encompasses polysaccharides (starch, cellulose derivatives, gums, alginates, pectins, and chitin/chitosan), animal proteins (casein, collagen, gelatin, and whey), and plant proteins (soy, pumpkin, wheat, and zein) [9,10,11,12,13], demonstrating significant potential for developing organic-based delivery systems [14]. Synthetic polymers, including those fabricated from bio-derived monomers, demonstrate several challenges in their application. The main limitations include potential toxicity, a complicated and expensive synthesis process, hydrophobicity, as well as poor biocompatibility and biodegradability of some synthetic polymers [15]. However, a group of synthetic polymers such as PLA, poly(lactide-co-glycolide) (PLGA), poly(caprolactone) (PCL), etc., are biocompatible and biodegradable [15,16]. PLA-based carriers have low drug loading capacity and encapsulation efficiency [17], while PLGA may develop biocompatibility problems [18].

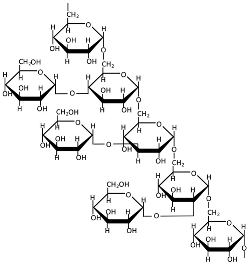

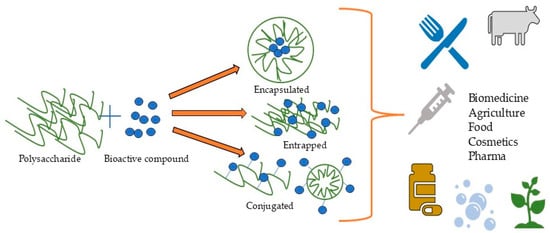

The combined factors of potential toxicity and immunogenicity aligned with the limited biocompatibility and accumulation risks of synthetic polymers combined with commercial interests have shifted focus toward biomass-derived biopolymers, which offer natural abundance and sustainable sourcing. Polysaccharides offer low immunogenicity and toxicity and excellent biocompatibility and biodegradability [19,20,21], and they are extensively utilized in biopolymeric nanoparticle fabrication [22,23], exhibiting not only superior mechanical and physicochemical properties but also intrinsic biological activity [24] that is often enhanced in nanoform. Bioactive compounds could be simply trapped, encapsulated, or conjugated with polysaccharides (Figure 1) [25]. Their nanoformulations as polysaccharide-based NPs can extend drug half-life, reduce cytotoxicity, and control release [26,27]. Polysaccharide-based nanoformulations serve as versatile delivery systems, material-reinforcing agents, and Pickering emulsion stabilizers for diverse applications including drug and gene delivery; antibacterial platforms; tissue engineering; cancer therapy; cosmetics; food fortification, preservation, and packaging; etc. [22,28,29,30,31].

Figure 1.

Formation of polysaccharide-based nanoformulations and their applications.

Natural antimicrobials represent a diverse group of compounds derived from various sources, including plants, animals, and microorganisms [14]. These encompass phytochemicals (in either isolated forms or complex mixtures such as essential oils and extracts), peptides, proteins, polymers, etc. [32], and exhibit low toxicity, targeted antimicrobial activity (including against antibiotic-resistant strains), and high bioavailability [4,33,34]. Natural antimicrobial compounds face significant application challenges due to rapid degradation and volatility—issues that can be effectively addressed through encapsulation strategies [14].

This review systematically consolidates current knowledge on prevalent polysaccharides employed in nanocarrier synthesis, fabrication methodologies, and established nanomaterial technologies incorporating plant-, microbial-, and animal-derived antimicrobial compounds.

2. Natural Polysaccharides for Nanocarrier Fabrication

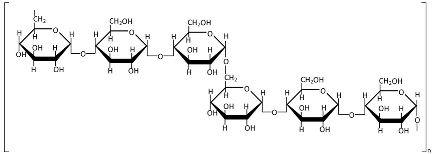

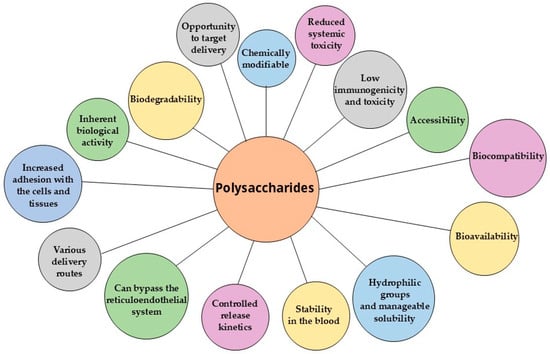

Polysaccharides are widely utilized in nanocarrier fabrication, either individually or in complex/conjugated forms [22,35,36,37,38,39,40]. Among natural polysaccharides, chitosan, alginate, and cellulose have been most extensively studied and implemented in nanoformulations [8,41,42]. Polysaccharide-based nanocarriers synergistically combine the advantageous properties of biopolymers, including low immunogenicity and toxicity, biodegradability, biocompatibility, and bioavailability, with the benefits of nanoformulations, such as enhanced drug bioavailability, prolonged drug half-life, reduced systemic toxicity, and controlled release kinetics [19,20,21,26,27,43]. Figure 2 illustrates the main common benefits of polysaccharides.

Figure 2.

Benefits of polysaccharides as nanocarriers.

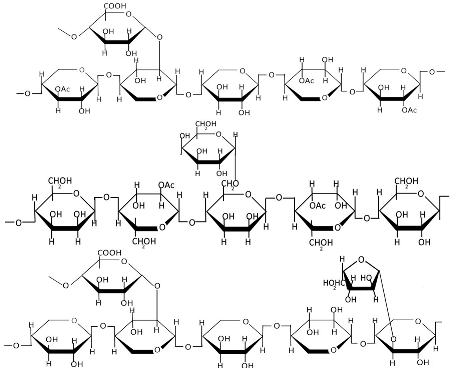

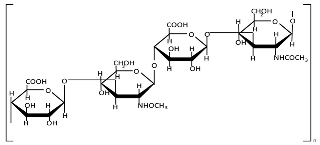

However, the toxicity and side effects of polysaccharide-based nanoformulations remain insufficiently characterized, necessitating further systematic studies to evaluate their potential adverse effects. Moreover, their properties could be influenced by a heterogeneous chemical structure, molecular weight, and modifications [44]. Table 1 presents the chemical structures of polysaccharides, and Table 2 systematically summarizes the non-common advantages and limitations of certain polysaccharides as nanocarriers.

Table 1.

Chemical structures of polysaccharides.

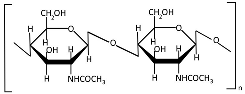

Chitin (Table 1), a linear polysaccharide of poly(β-(1→4)-N-acetyl-D-glucosamine, is abundantly distributed in nature as crystalline microfibrils that constitute the structural framework of arthropod exoskeletons and fungal cell walls [45]. Industrially, chitin is sourced primarily from exoskeletons obtained as byproducts of global seafood processing [46,47]. Its extraction involves sequential treatments: (1) acid hydrolysis for demineralization (removing calcium carbonate), (2) alkaline solution for deproteinization, and (3) oxidative decolorization to yield a purified, colorless polymer [48,49].

Chitosan (Table 1), the principal chitin derivative, is produced via alkaline deacetylation [50]. Its physicochemical and biological properties are critically dependent on the molecular weight (50–2000 kDa), degree of deacetylation (54–100%), and functional group modifications (including nitration, sulfonation, graft copolymerization, and cross-linking) [51]. The deacetylation process constitutes a two-stage nucleophilic substitution reaction, typically achieved through thermal treatment in alkali at elevated temperatures [52,53]. Chitosan processing employs chemical, physical, and enzymatic techniques to achieve lower molecular weights, with physical methods being increasingly favored due to their ability to mitigate key limitations of alternative approaches—including random chain cleavage, high costs, and environmental concerns [54]. The most prevalent chitosan NP morphologies include nanospheres, nanocapsules, and nanofibers [55]. In recent decades, chitosan and its nanoforms have garnered significant research interest owing to their exceptional properties, particularly their biological activities: mucoadhesion, anti-inflammatory effects, antioxidant capacity, antimicrobial/antifungal action, antihyperglycemic activity, antitumor potential, and wound-healing promotion [55,56,57,58]. However, these materials may also exhibit cytotoxicity [51], which correlates with both acetylation degree and molecular mass [59].

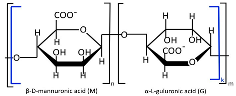

Alginate, a highly abundant natural polysaccharide, exhibits unique cation-binding properties that enable the formation of stable and tunable hydrogels [60]. Alginate is primarily extracted from brown seaweed species and can also be produced through bacterial biosynthesis [61]. Alginate (Table 1) is composed of linear copolymer chains containing β-D-mannuronate (M) and α-L-guluronate (G) residues interconnected via 1→4 glycosidic linkages [62,63]. These monomers assemble into three distinct block configurations, poly-M homopolymers, poly-G homopolymers, and alternating MG heteropolymers, whose relative proportions dictate the polymer’s structural diversity, molecular weight distribution, and ultimately its functional physicochemical properties [64]. The molecular weight (32–400 kDa) and M/G composition of alginates are source-dependent, showing distinct variations across harvest locations and seasons [64,65]. Commercial alginate production employs both acidic and non-acidic extraction methods to isolate polysaccharides from brown seaweed biomass [65]. The classical acidic extraction method sequentially involves mineral acid treatment, alkaline conversion to sodium alginate, precipitation (CaCl2 or ethanol), and purification (acidification/Ca2⁺/ethanol) [64]. Novel extraction techniques are now being actively researched and implemented, including microwave-assisted extraction, ultrasound treatment, high-pressure processing, pressurized fluid extraction, and enzymatic hydrolysis methods [66]. Alginate-based nanocarriers (e.g., nanoparticles, nanofibers, nanoemulsions, nanocomplexes, and nanohydrogels) are extensively fabricated to encapsulate diverse bioactive payloads such as therapeutic drugs, proteins, and even whole cells [67,68]. Alginate nanomaterials exhibit advantageous physicochemical and biological properties, biocompatibility, pH sensitivity, mucoadhesiveness, and controlled biodegradability along with excellent safety profiles, though their performance is critically dependent on structural parameters (molecular weight, M/G ratio, and chemical modifications) [69,70].

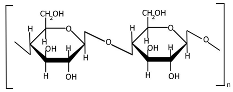

Cellulose (Table 1) is a linear homopolysaccharide composed of D-glucoses connected by β(1→4) glycosidic bonds [71,72]. Cellulose is the most abundant renewable biopolymer on Earth, biosynthesized across multiple biological kingdoms including bacteria, plants, and even some animals [72]. The molecular weight of cellulose and its derivatives varies significantly with the degree of polymerization [73], which directly affects polymer solubility. Native cellulose is insoluble in conventional solvents due to its robust network of intermolecular and intramolecular hydrogen bonds, coupled with hydrophobic interactions [74]. Cellulose extraction can be performed across multiple scales (nano, micro, and macro) using chemical, mechanical, chemo-mechanical, or green techniques [75,76,77]. Both the mechanical and physicochemical properties of cellulose can be tailored through chemical modifications [78], though these processes typically require reagent application and subsequent purification steps to remove residual chemicals. Nanocellulose is broadly categorized into three principal types: cellulose nanocrystals (CNCs), cellulose nanofibrils (CNFs), and bacterial nanocellulose (BNC) [79]. The mechanical properties of cellulose-based materials critically determine their suitability for diverse applications [80]. Despite possessing unique advantages (high surface area, tunable surface chemistry, and exceptional mechanical strength), recent studies indicate that nanocellulose may exhibit complex toxicity profiles, necessitating further investigation into its biological safety [42].

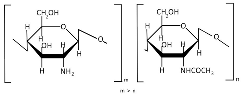

Alongside cellulose, lignin and hemicellulose constitute fundamental components of plant cell walls, exhibiting remarkable properties. However, their inherent structural heterogeneity profoundly impacts all downstream processes, from extraction and purification to the final characteristics of derived nanomaterials [81,82]. Hemicellulose (Table 1) is a branched heteropolysaccharide composed of a sugar backbone with substituted side chains [83,84]. Hemicellulose comprises pentoses, hexoses, and uronic acids, including arabinose, xylose, glucose, mannose, galactose, glucuronic acid, and galacturonic acid, with minor constituents like fucose and rhamnose [85,86,87]. These form relatively short, branched chains of 500–3000 sugar units. In contrast, cellulose consists exclusively of linear β(1→4)-linked glucose polymers with higher degrees of polymerization (7000–15,000 units) [88,89]. The composition of this biopolymer varies significantly by species, with mannose-rich hemicellulose dominating softwoods and xylose-rich forms prevalent in hardwoods [90]. Hemicellulose is extracted from various plant sources and, while water-insoluble, can be isolated through alkaline treatment or mild acid hydrolysis [83,91]. Thus, conventional methods for hemicellulose extraction involve chemical treatments using alkali and organic solvents, while newer approaches employing H2O2, steam explosion, microwave, and ultrasonic techniques are also being investigated [92]. The mechanical, physical, chemical, and biological properties of hemicellulose vary significantly due to its structural heterogeneity and can be precisely manipulated through targeted modifications [93,94]. Current research indicates that nano-hemicellulose exhibits low toxicity and immunogenicity, though these properties remain insufficiently characterized in the literature [95].

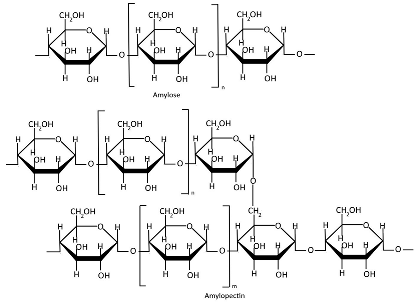

Starch (Table 1), a plant-derived polysaccharide composed of amylose and amylopectin, is extracted from various agricultural crops [96]. Amylose is a linear α-glucan connected by α(1→4) glycosidic linkages, typically comprising 1000–20,000 glucose units with an average molecular weight of ~100 kDa [39,97,98]. Amylopectin is a highly branched macromolecule with a molecular weight of 1000–10,000 kDa, significantly larger than amylose. Its structure consists of α(1→4)-linked glucose chains with 5% α(1→6) branch points, creating a dendritic architecture [39,97,98]. Amylose typically comprises 5–35% of native starch, whereas genetically modified starches can achieve elevated amylose contents of 50–80% [99,100]. The amylose-to-amylopectin ratio significantly influences the physicochemical and functional properties of starch, with variations dependent on botanical origin [100,101,102]. Starch is stored in various plant organs, including seeds, fruits, roots, tubers, stems, and leaves [103,104]. Starch is primarily extracted through traditional methods involving washing, grinding, filtration, and sedimentation, typically via wet or dry processing pathways. Mechanical extraction methods additionally employ crushing, pressing, and centrifugation for higher yields [105]. Starch extraction is also accomplished through chemical methods (alkaline or surfactant-based treatments) and enzymatic approaches [106,107,108], with emerging green techniques gaining increasing application [109,110]. Native starch typically exhibits limited mechanical strength and poor water barrier properties [111,112]. Starch modification is crucial for enhancing functional properties and overcoming the inherent limitations of native starches [113]. Starch modification techniques include physical, enzymatic, and genetic methods [114]. Nanostarches are primarily categorized into two types: starch nanocrystals (SNCs) and starch nanoparticles (SNPs), which differ in their crystallinity and preparation methods [115,116]. Although starch nanoforms demonstrate enhanced mechanical strength, barrier performance, and thermal stability, these properties are strongly influenced by amylose/amylopectin ratios and often require modification to achieve optimal functionality [115,116,117,118,119].

Table 2.

Benefits and drawbacks of polysaccharides as nanocarriers.

Table 2.

Benefits and drawbacks of polysaccharides as nanocarriers.

| Biopolymer | Advantages | Disadvantages | Ref. and Pub. Year |

|---|---|---|---|

| Chitosan |

|

| [51,55,58,59,120,121] 2023, 2023, 2023, 2024, 2022, 2025 |

| Alginate |

|

| [60,62,67,69,122,123] 2021, 2012, 2022, 2024, 2022, 2022 |

| Cellulose |

|

| [42,78,79,80,124,125] 2020, 2021, 2015, 2023, 2022, 2022 |

| Hemicellulose and xylan |

|

| [86,92,93,95,126,127] 2024, 2020, 2021, 2023, 2021, 2024 |

| Starch |

|

| [115,116,117,118,119] 2020, 2023, 2022, 2015, 2024 |

| Pectin |

|

| [128,129,130,131,132,133] 2023, 2015, 2008, 2021, 2023, 2022 |

| Gums |

|

| [134,135,136,137] 2020, 2023, 2019, 2025 |

| Carrageenan |

|

| [138,139,140,141,142,143,144,145,146] 2021, 2022, 2021, 2017, 2017 2001, 2023, 2013, 2017 |

| Dextran |

|

| [43,147,148,149,150,151] 2023, 2022, 2016, 2022, 2023, 2020 |

| Pullulan |

|

| [152,153,154,155,156,157,158,159,160] 2022, 2021, 2021, 2016, 2016, 2013, 2023, 2023, 2025 |

| Hyaluronic acid |

|

| [161,162,163,164,165,166] 2020, 2022, 2024, 2024, 2021, 2022 |

Notes: MW—molecular weight; DA—deacetylation degree; DE/DA—degree of esterification and amidation (DA).

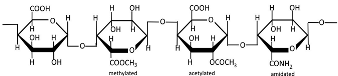

Pectins are hydrophilic polymers naturally present in plant cell walls [167]. Their functional properties are determined by the degree of esterification (DE) and degree of amidation (DA) [130]. Pectins consist of a covalently linked, galacturonic acid-rich polysaccharide backbone (up to 70%, α-1,4-linked) and are classified into the following main types: homogalacturonan (HG, Table 1) as the major component, and rhamnogalacturonan I (RGI), rhamnogalacturonan II (RGII), xylogalacturonan (XGA), and apiogalacturonan (AGA) as the minor components [168,169,170]. The backbone of RGI contains L-rhamnose, while the branched structures of pectins (RGI, RGII, and XG) include L-rhamnose, L-arabinose, D-apiose, D-glucuronic acid, D- and L-galactose, D-xylose, L-fucose, and L-aceric acid [171]. Pectin is commercially extracted from sugar beet pulp, citrus peel, and apple pomace through conditional extraction with mild acids, as well as enzyme-, microwave-, and ultrasound-assisted extraction, subcritical water extraction, pressurized CO2 and deionized water methods, deep eutectic solvents, and ohmic heating [171,172]. Pectin exhibits poor mechanical properties and moisture resistance [133]. Pectin-based nanostructures, including nanoparticles, nanoemulsions, nanocapsules, and nanogels, have attracted significant interest due to their outstanding properties, such as physical sensitivity (to light, temperature, and electricity), chemical sensitivity (to pH, redox reactions, and glucose), and biological sensitivity (to enzymes) [173,174].

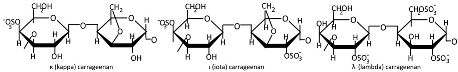

Plant gums are polysaccharides composed of covalently bound sugar monomers [134]. The most extensively studied varieties include arabic gum, carrageenan, xanthan gum, and tragacanth [136]. Their structural backbones typically contain galactose, arabinose, rhamnose, uronic acids, galacturonic acid, proteins, calcium, and magnesium [175]. These biopolymers exhibit unique structural and biological properties—including water retention capacity, thermal stability, and hydrophilicity, along with antibacterial, antioxidant, and immunomodulatory activities—making them promising candidates for drug delivery applications [137]. While less studied than other biopolymers, gum-based nanostructures such as nanoemulsions, nanoparticles, nanocomplexes, and nanofibers have shown particular promise for colorectal therapy due to their selective digestibility properties [134,135,136]. Carrageenan (Table 1) is extracted from specific red seaweed species through alkaline processing [176]. This sulfated polysaccharide consists of alternating galactose and anhydrogalactose units linked by glycosidic bonds [177], with an average molecular mass exceeding 100 kDa. The major types of carrageenans are ι (iota), κ (kappa), and λ (lambda), which differ in their sulfate group content [178,179]. Carrageenan exhibits significant antioxidant, immunomodulatory, and disease-preventive properties, making it a promising candidate for pharmaceutical development [144]. Its chain conformation and gelation behavior are strongly influenced by temperature and the electrolyte concentration [139], but when carrageenan is used as an individual matrix material, zero-order kinetics and pH-independent release profiles cannot be achieved [146]. Toxicological studies indicate excellent biocompatibility with no observed teratogenic effects [145].

Dextran (Table 1) is a neutral bacterial exopolysaccharide produced by lactic acid bacteria or their enzymes in sucrose-rich environments, featuring α-(1→6)-linked glucose backbones with potential α-(1→2), α-(1→3), or α-(1→4) branches, and exhibiting molecular weights ranging from <40 kDa (low) to >40 kDa (high) [148,180,181]. The solubility and rheological properties of dextran depend on its molecular weight (up to 440 MDa) and branching structure [180]. Dextran’s alcohol insolubility enables ethanol/methanol precipitation (the conventional isolation method), with contemporary approaches employing membrane filtration or deep eutectic solvents [182,183]. The polymer’s molecular weight determines the functionality of dextran-coated NPs and bioconjugates [184,185]. While comprehensive toxicity profiles remain scarce [149], dextran’s optimal biocompatibility and tunable properties [150] have established it as a premier nanocarrier material [186], adaptable to nanoparticle, nanogel, microsphere, and micelle formulations [151].

Pullulan (Table 1) is a natural, neutral exopolysaccharide primarily composed of maltotriose units, produced through aerobic fermentation by black yeasts [152,187]. Maltotriose units consist of three glucose molecules linked by α-1,4 glycosidic bonds, which are further connected to each other via α-1,6 glycosidic bonds [188,189]. The molecular weight of pullulan ranges from 45 to 600 kDa depending on the culture conditions and the strain of A. pullulans [190], and it significantly influences its rheological and mechanical properties [191]. The production of pullulan involves microbe harvesting, the elimination of unwanted substances (mainly melanin), precipitation, membrane purification, and freeze drying [164]. Pullulan is virtually insoluble in organic solvents; thus, ethanol and isopropanol are the most commonly used solvents for its purification. However, chromatographic techniques or aqueous two-phase systems may also be employed [192]. Pullulan exhibits high chemical versatility, enabling facile modification through carboxymethylation, oxidation, amination, sulfation, acetylation, and esterification [153,158]. Hydrophobic modifications, in particular, facilitate the spontaneous self-assembly of nanocarriers, which exhibit high drug-loading capacity and a low critical micellar concentration, making them promising for targeted delivery systems [153,158]. Pullulan-based nanostructures can be engineered into diverse forms, including nanoparticles, nanogels, and nanoplexes, leveraging the enhanced permeability and retention effect [154]. Despite its advantages, pullulan’s poor mechanical strength, extreme hydrophilicity, and lack of inherent antibacterial properties restrict its applications [193].

Hyaluronic acid (HA, Table 1) is an anionic polysaccharide consisting of D-glucuronic acid and N-acetyl-D-glucosamine linked by β-1,3- or β-1,4-glycosidic bonds [37]. It is produced by membrane-bound HA synthases and can be obtained through extraction from animal tissues, microbial production, or cell-free enzymatic synthesis [166], with membrane technologies being the preferred purification technique [194]. The molecular weight of HA, which can exceed 500 kDa, significantly influences its structural, biological, physical, physicochemical, and degradation characteristics [163,195]. HA functions as an endogenous ligand for cell surface receptors, with high affinity for CD44. This receptor-specific binding enables HA-based systems to selectively target and deliver therapeutic agents to pathological tissues [165]. Despite its outstanding properties, HA has several substantial limitations. These include rapid biodegradation, poor stability and mechanical strength, extreme hydrophilicity, limited ability to encapsulate and deliver hydrophobic drugs, molecular weight-dependent tissue penetration, and potential immunogenicity, particularly for chemically modified forms. Many of these limitations can be addressed through strategic chemical modifications [161,164].

Polysaccharides are renewable, widely accessible, biodegradable, and biocompatible materials that confer low toxicity and allergenicity to polysaccharide-based nanomaterials. Due to their unique physical and chemical properties, polysaccharide-based nanocarriers exhibit all advantageous characteristics of organic nanocarriers, including an extended drug half-life, enhanced solubility, and controlled release profiles. Furthermore, these nanocarriers can be readily modified to achieve tailored properties while inherently possessing various beneficial biological activities. The main limitation in applying polysaccharides for nanoformulation is their variable chemical structure, which affects physicochemical properties and water absorption capacity, along with poorly characterized cytotoxic effects that may arise from structural variations, modifications, impurities, or NP characteristics (size, shape, and biological barrier penetration ability) [37].

3. Methods of Synthesis for Polysaccharide-Based Nanocarriers

Polysaccharide nanocarriers can be synthesized through various methods including self-assembly, ionic gelation, cross-linking, complex coacervation, emulsification, ultrasonication, desolvation, supercritical fluid technology, and nanoprecipitation or solvent displacement, with the choice of method depending on the desired nanoparticle characteristics and polysaccharide properties [36,196].

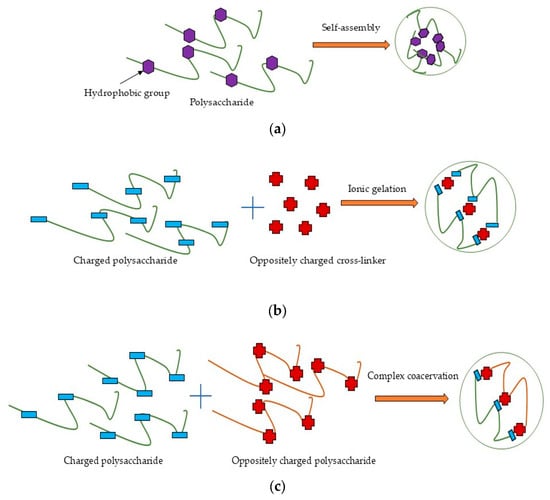

Self-assembly (Figure 3a) is one of the most promising techniques for nanoparticle synthesis due to its environmental friendliness, biocompatibility, process simplicity, and low toxicity [40]. This method involves the spontaneous organization of amphiphilic polysaccharides into ordered nanostructures with a hydrophobic core (for drug encapsulation) and a hydrophilic shell (for aqueous stability). The driving forces include non-covalent interactions such as hydrophobic effects, electrostatic forces, van der Waals interactions, and π–π stacking (in aromatic-modified systems) [36,40,197]. Chemical modification (e.g., grafting hydrophobic chains) can convert naturally hydrophilic polysaccharides into amphiphilic polymers, enabling controlled self-assembly [36]. Conversely, chemical modification involves the application of harmful reagents and could be inefficient and wasteful [198], therefore requiring subsequent purification steps, and it limits the potential of self-assembly for the industrial scale.

Figure 3.

Schematic illustration of preparation process for polysaccharide nanoformulations: (a) self-assembly; (b) ionic gelation; (c) complex coacervation; (d) cross-linking.

Ionic gelation (Figure 3b) is a widely used method to form nanostructures from charged polysaccharides through electrostatic interactions with oppositely charged cross-linkers in dilute aqueous solutions [22]. Chitosan and other cationic polysaccharides can be cross-linked with polyanions like tripolyphosphate (TPP), whereas anionic polysaccharides such as alginate are typically cross-linked with cations like Ca2⁺ from CaCl2 [199,200,201]. Ionic gelation is a widely used nanoparticle synthesis method characterized by its simplicity and convenience. Furthermore, this controllable process avoids organic solvents and exhibits no toxicity [36] and can thus be used for industrial scale-up by optimizing the polymer and cross-linker concentration and mixing speed or by using droplet-producing devices [202,203].

Complex coacervation (Figure 3c) occurs through electrostatic interactions between oppositely charged species, typically involving two oppositely charged polysaccharides [36,204]. Electrostatic complexation induces phase separation, forming a biopolymer-rich coacervate phase and a solvent-rich phase [205]. Ionic strength, pH, temperature, charge density, and polyelectrolyte molar mass critically influence coacervate particle stability and formation, while these systems also exhibit excellent biocompatibility and low toxicity [22]. The simplicity and safety of this method made it attractive for scaling up, but it requires careful consideration of numerous factors like mixing systems, polymer ratios and concentrations, temperature, pH, and balance in ionic strength [206].

Covalent cross-linking (Figure 3d) in the nanoformulations created irreversible cross-linking points, yielding highly stable nanostructures [22]. Glutaraldehyde, compounds with PO43− groups, enzymes, carbodiimide, genipin, epoxy, acrylamide, citric acid, formaldehyde, etc., are the most common synthetic and natural cross-linkers applied for polysaccharides [207]. The application of toxic reagents in covalent cross-linking has limited its industrial scalability. To address this challenge, green alternatives including citric acid, tannic acid, vanillin, gallic acid, ferulic acid, proanthocyanidins, phytic acid, squaric acid, and epigallocatechin have been investigated for developing polysaccharide-based nanoformulations [208].

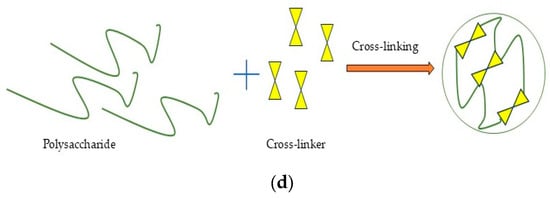

Emulsification (Figure 4) can be performed in either oil-in-water or water-in-oil systems through mechanical stirring or ultrasonication [36]. More complex systems, such as double emulsions (oil-in-water-in-oil or water-in-oil-in-water), may also be employed for specialized applications [22]. Ultrasound treatment can depolymerize biopolymers, modify their physical properties (e.g., viscosity and molecular weight), and promote structural reorganization of polysaccharide molecules [209,210]. Nanoparticles can be obtained from emulsions through various methods including internal/external gelation, solvent evaporation/diffusion, and reverse salting out [22]. Despite enabling the production of controllable, spherical nanoparticles, emulsification remains a more complex technique that requires significantly greater energy input and larger quantities of organic solvents compared to alternative methods [25,36,56]. These requirements make scale-up more complicated and energy-intensive, and consequently more expensive. Additionally, the technique requires the optimization of numerous parameters, including ones for internal/external gelation, solvent evaporation/diffusion, and reverse salting out [25].

Figure 4.

Schematic illustration of emulsification followed by ionic gelation.

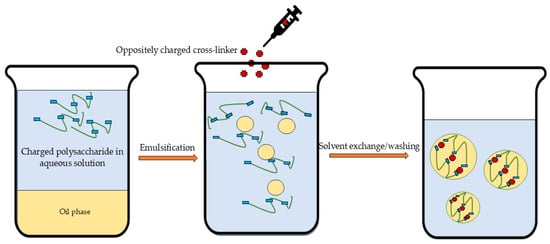

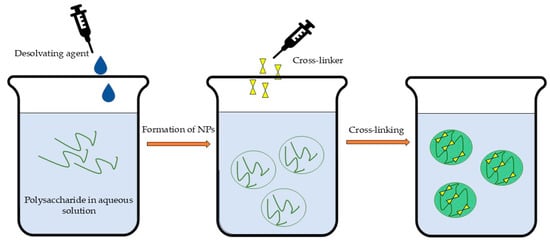

The desolvation technique (Figure 5) involves the coacervation or precipitation of dissolved polysaccharides through the gradual addition of desolvating agents (e.g., salts and alcohols). This process is typically followed by cross-linking to stabilize the formed nanoparticles [38,211]. The selection of desolvating agents depends on the encapsulated substance’s properties [22] but may require a subsequent purification step due to the potential toxicity of residual molecules [36], which could limit its scaling-up ability. The desolvation method is typically used for protein nanoparticle preparation, but there is a lack of systematic studies on this approach for polysaccharides, particularly regarding physical stability [212]. However, the desolvation technique followed by cross-linking could be successfully applied for the fabrication of polysaccharide NPs [213].

Figure 5.

Schematic illustration of desolvation followed by cross-linking.

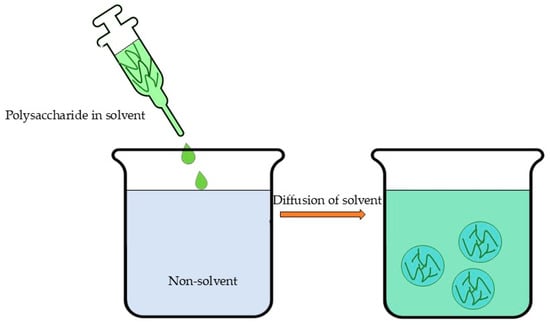

Nanoprecipitation or solvent displacement (Figure 6) is an easy, less complex, less energy-consuming, widely applicable method that involve the following steps: (1) the dissolution of the polymer in a fully or partly water-miscible solvent, (2) the transfer of the solution to another non-solvent which may contain a surfactant, and (3) nanoprecipitation due to the rapid diffusion of solvent provided that aggregation is limited [214,215,216]. The excess solvent is typically eliminated through evaporation, dialysis, or lyophilization [22]. However, this method’s primary limitations involve both the requirement for organic solvents and their substantial dilution to prevent particle aggregation during precipitation [36]. Furthermore, studies indicate that nanoprecipitation demonstrates optimal efficacy for hydrophobic drugs [217]. These limitations, coupled with the demanding optimization requirements, present significant challenges in scaling up nanoprecipitation and solvent displacement methods for industrial applications.

Figure 6.

Schematic illustration of nanoprecipitation or solvent displacement.

Equipment-based methods such as electrospinning enable the fabrication of polysaccharide nanomaterials with enhanced specific surface area and porosity [218]. However, challenges in electrospinning polysaccharides include poor solubility (e.g., cellulose), high viscosity, and elevated surface tension [219]. These limitations can be addressed through optimized solvent selection, material modification, and tailored structural design [220].

Target substances can be incorporated into nanostructures either through covalent conjugation via surface functional groups or via physical encapsulation during fabrication, mediated by electrostatic interactions, hydrogen bonding, or other entrapment mechanisms [196,221,222].

Safety concerns associated with toxic or potentially toxic reagents and challenges in process parameter optimization represent major barriers to industrial-scale implementation. The primary obstacles in scaling up nanoformulation production include (1) developing safe and effective nanoformulations through green nanotechnology approaches, (2) ensuring batch-to-batch reproducibility and controlled manufacturing processes, (3) achieving target-specific delivery while maintaining functionality, (4) guaranteeing long-term stability and structural properties, and (5) understanding nanoparticle exposure effects, including systemic toxicity, and characterizing in vivo behavior [25].

4. Polysaccharide-Based Nanocarriers for Plant-Derived Antimicrobials

Plant antimicrobials comprise a broad group of bioactive compounds demonstrating antioxidant, antibacterial, and antifungal activities [223]. Essential oils (EOs) and plant extracts (PEs) represent complex mixtures containing diverse phytochemicals, including monoterpenes, phenylpropanoids, monoterpenoids, phenolic compounds, and other major substance classes that serve as effective antimicrobial agents [4,35,224,225]. Notable examples of these plant-derived antimicrobials include curcumin, quercetin, saponin, resveratrol, gallic acid, magnoflorin, sulforaphane, naringenin, honokiol, glycyrrhetinic acid, rutin, luteolin, carotene, α-tocopherol, zoledronic acid, kaempferol, carvacrol, thymol, linalool, and menthol, among others—all exhibiting superior antimicrobial and antifungal properties [4,14,221,222].

Chitosan is extensively utilized in nanoparticle (NP) formulation (Table 3) due to its intrinsic antimicrobial properties [121,226,227]. The formulation of nanoparticles (NPs) with plant essential oils (EOs) typically requires emulsification [228], followed by biopolymer-specific techniques such as ionic gelation or coacervation for chitosan and alginate [229,230,231,232]. Chitosan-based NPs incorporating tea water extract effectively inhibited P. grisea and X. oryzae [233], while those with grape pomace extract demonstrated significant antimicrobial efficacy: a 6-log reduction in C. albicans, 5-log reduction in methicillin-susceptible S. aureus (MSSA), 3-log reduction in L. monocytogenes and P. aeruginosa, and 1-log reduction in E. coli and S. enteritidis [234]. Similarly, chitosan NPs containing Lavandula angustifolia water extract suppressed biofilm formation in P. aeruginosa, S. aureus, and C. albicans [235], and those with Martynia annua leaf ethanol extract showed strong antibacterial activity (in descending order): B. fragilis > S. oralis > P. acnes > P. aeruginosa > S. aureus > E. coli > B. cereus > S. mutans > A. hydrophila > S. faecalis [236]. Clove and guava leaf essential oils (EOs) were successfully incorporated into chitosan NPs through oil-in-water emulsification followed by ionic gelation. The resulting NPs exhibited significant antimicrobial activity against L. monocytogenes, S. aureus, S. typhi, E. coli [229], and K. pneumoniae [230]. Resveratrol, a potent polyphenolic antioxidant, demonstrates broad-spectrum antimicrobial properties against diverse bacteria, viruses, and fungi [237]. When encapsulated in chitosan NPs, resveratrol showed enhanced activity against H. pylori [238].

Chitosan is synergistically combined with alginate, pectin, or gums through electrostatic interactions to form complex nanostructures with enhanced stability and broad-spectrum antimicrobial activity [239,240,241,242]. These hybrid systems employ techniques like pre-ionic gelation (for chitosan/alginate or chitosan/pectin NPs) and complex coacervation [240,243,244], as demonstrated by oregano EO- and Ocimum sanctum-loaded chitosan/alginate NPs effective against S. aureus [243], E. coli, P. aeruginosa, and B. cereus [244]. Anthocyanins, a class of bioactive water-soluble flavonoid pigments [245], exhibit broad-spectrum antimicrobial activity with particularly pronounced efficacy against Gram-positive bacteria [246]. These compounds have been successfully encapsulated into hybrid chitosan/pectin NPs [241].

Table 3.

Representative polysaccharide-based nanoformulations incorporating plant-derived antimicrobial compounds.

Table 3.

Representative polysaccharide-based nanoformulations incorporating plant-derived antimicrobial compounds.

| Active Component | Nanocarrier | Composition | Formulation Method | Antimicrobial Activity | Ref. and Pub. Year |

|---|---|---|---|---|---|

| Tea water extract (TPS) | Chitosan | Chitosan (85% DA, MW 27 kDa, 250 mg/100 mL) TPS (2.5 mg/mL) | Complex coacervation | Against P. grisea, X. oryzae | [233] 2024 |

| Lavendula angustifolia water extract | Chitosan (1% w/v) Ratio to extract (1:1) | Self-assembling | Suppressed P. aeruginosa, S. aureus, and C. albicans biofilm formation | [235] 2023 | |

| Martynia annua leaves ethanol extract | Chitosan (1% w/v) Ratio to extract (1:1) | Considerable antibacterial activity in order of B. fragilis > S. oralis > P. acnes > P. aeruginosa > S. aureus > E. coli > B. cereus > S. mutans > A. hydrophila > S. faecalis | [236] 2022 | ||

| Clove essential oil (CEO) | Chitosan (75–85% DA, MW 50–190 kDa, 1% w/v) Ratios to CEO (1:0, 1:0.25, 1:0.5, and 1:1) Sodium tripolyphosphate (TPP) | Oil-in-water emulsification followed by ionic gelation | Against L. monocytogenes, S. aureus, S. typhi, and E. coli | [229] 2020 | |

| Guava leaves essential oil (GLEO) | Chitosan (75% DA, MW 50 kDa, 1% w/v) Ratio to GLEO (1:1) TPP | Against K. pneumoniae | [230] 2020 | ||

| Curcumin | Chitosan (1 mg/mL) Curcumin stock (1 mg/mL) in ethanol TPP (1 mg/mL) | Ionic gelation | Against S. aureus and P. aeruginosa | [247] 2014 | |

| Resveratrol | Chitosan (75–85% DA, MW 50–190 kDa, 2 mg/mL) Resveratrol stock (5 mg/mL) in ethanol Ratio (1:5) TPP (1 mg/mL) | Against H. pylori | [238] 2024 | ||

| Grape pomace extract | Chitosan (low molecular weight) Grape pomace extract TPP (1 mg/mL) | 6-log reduction in C. albicans, 5-log reduction in MSSA, a 3-log reduction in L. monocytogenes and P. aeruginosa, and a 1-log reduction in E. coli and S. enteritidis | [234] 2021 | ||

| Grape pomace extract | Alginate | Sodium alginate Grape pomace extract Calcium chloride (2 mg/mL) | Ionic gelation | 6-log reduction in C. albicans, 3-log reduction in MSSA, a 2-log reduction in L. monocytogenes, P. aeruginosa, and S. enteritidis, and 1-log reduction in E. coli | [234] 2021 |

| Cuminum cyminum and Zataria multiflora EOs | Alginate solution (0.25% w/v) EO (0.25% w/v) Calcium chloride (0.04–0.05%) | Oil-in-water emulsification followed by ionic gelation | Superior efficacy for NPs containing Z. multiflora EO against E.coli, P.aeruginosa, and S. aureus | [231] 2024 | |

| Lemon EO | Alginate Myristic acid Ethylene carbo-di-imide hydrochloride (EDC) N-hydroxysuccinimide (NHS) Addition of EO in drop-wise manner | Emulsification and cross-linking | Inhibit multidrug-resistant (MDR) isolates of Acinetobacter baumannii | [232] 2025 | |

| Oregano EO | Chitosan Alginate | Chitosan (MW 110–150 kDa) Alginate (very low viscosity) Calcium chloride Oregano EO | Oil-in-water emulsification followed by pre-ionic gelation of alginate and coacervation with chitosan | Against S. aureus | [243] 2022 |

| O. sanctum methanolic extract | Sodium alginate solution (0.06%, w/v) Calcium chloride (18 mM) Chitosan solution (0.05%, w/v) Methanolic extract of O. sanctum | Pre-ionic gelation of alginate followed by chitosan coacervation | Against E. coli, P. aeruginosa, B. cereus, and S. aureus | [244] 2013 | |

| Curcumin | Sodium alginate (3%) Chitosan (75–85% DA, low MW) Ratio (5:4) Curcumin dissolved in ethanol | Coacervation | Mild activity against S. aureus, B. subtilis, and E. aerogenes | [248] 2024 | |

| Terminalia arjuna (arjuna), Azadirachta indica (neem), Withania somnifera (ashwagandha), Tinospora cordifolia (giloy), Murraya koenigii (curry leaves) extracts | Bacterial Nanocellulose (BNC) | BNC Extracts (20% w/v in water) | Ex situ modification of BNC by simple dipping method | Against E. coli and A. viridans | [249] 2020 |

| Curcumin | BNC Curcumin and curcumin degradation products (0.05, 0.1, and 0.5 mg/mL) | Loaded from aqueous solution during autoclaving | Against S. epidermidis and E. coli | [250] 2020 | |

| Cell cultures of Chelidonium majus | BNC C. majus cells | C. majus cells were cultured in vitro on BNC matrices in liquid media, followed by enzymatic digestion and purification | Against S.aureus, P. aeruginosa, and C. albicans | [251] 2022 | |

| Peppermint (PM), Cinnamon (CN) and lemongrass (LG) EOs | Cellulose Acetate (CA) | CA (acetyl content of 39.8%, MW 30 kDa, 1% w/v) EO in acetone (0.5% v/v) | Nanoprecipitation by solvent/anti-solvent technique EOs were grafted on cellulose acetate molecules | CA/CN significantly inhibited growth of S. aureus, E. coli, P. aeruginosa, and C. albicans | [252] 2018 |

| Thymol | Cellulose Nanofibrils (CNFs) | CNFs Thymol (200 mg) | Impregnation with thymol in scCO2 | Against E. coli, S. epidermidis, and C. albicans | [253] 2020 |

| Curcumin | Xylan | Xylan (0.132 g, 1 mmol) Curc-monosuccinate (0.864 g, 2 mmol) DMSO N, N’-dicyclohexylcarbodiimide (DCC, 0.412 g, 2 mmol) 4-Dimethylaminopyridine (DMAP, 0.116 g, 1 mmol) Precipitation in ethanol/ethyl ether (1:1 v/v) | Conjugation followed by precipitation | No data | [254] 2018 |

| Menthone, oregano, cinnamon, lavender, and citral EOs | Starch | Debranched starch (1% w/v in water) EOs (250 µL dissolved in 20 mL hot ethanol) | Precipitation and freeze drying | Better antimicrobial activity against S. aureus than E. coli | [255] 2017 |

| Triphala Churna (TC) extract | Heating soluble starch (5 g) in 0.4 M NaOH Addition of 0.3% of TC and acetone | Precipitation and graft copolymerization | Antibacterial activity against S. typhi and S. dysenteriae; antibiofilm activity against ATCC MRSA 33591 and clinical strain N7 | [256] 2020 | |

| Linalyl acetate | Corn starch (2 wt%) Mixture of 1 M sodium hydroxide and 1 M urea, volume ratio 1:2 Linalyl acetate (1.5 wt%) Tween 80 Ethanol was used as anti-solvent (1:15 ratio to solvent) | Nanoprecipitation by solvent/anti-solvent technique | Promote wound healing | [257] 2025 | |

| Curcumin | Cinnamic acid-esterified debranched starch Curcumin | Additional π-π interactions provided from cinnamic acid | Biofilm scavenging ability, superior antibacterial effects | [258] 2022 | |

| Quercetin | Pea, corn and potato starches (20 mg/mL) and quercetin (2 mg/mL) dissolved in NaOH/urea/H2O Ratio (0.8:1:98.2 by weight) 0.1 M HCl | Nanoprecipitation | No data | [259] 2018 | |

| Rutin | Quinoa and maize starch suspensions (1.5%) preheated (80 °C) in 0.1 M NaOH solution Rutin (1.5%) dissolved in ethanol Ratio (1:10) | Ultrasonication | [260] 2021 | ||

| Flavonoids of citrus peel extracts (CPE) | Pectin | Pectin water solution CPE ethanol extract Calcium chloride | Ionic gelation | No data | [261] 2017 |

| Quercetin | Pectin Chitosan | Chitosan (80% DA, MW 190–300 kDa, 1% w/v) TPP Quercetin dehydrate Pectin Calcium chloride | [240] 2022 | ||

| Anthocyanins (ANCs) | Chitosan (95% DA, MW 300 kDa, 1% w/v) ANCs (1–4% w/v) Pectin (MD 30%, 5% w/v) Mass ratio of chitosan/pectin/anthocyanin (1:1:3) | Coacervation | [241] 2020 | ||

| Lippia sidoides EO | Chitosan Cashew Gum | Gum (MW 110 kDa, 5%) Chitosan (75% DA, MW 180 kDa) Ratio (1:1) Polymer matrix/EO (10:2) | Complex coacervation | Against St. Aegypti larvae | [242] 2012 |

| Saffron extract | Chitosan Arabic Gum | Chitosan (DA > 75%, MW 50–180 kDa, 1–10 mg/mL) Gum arabic (MW 295–1860 kDa, 1–5 mg/mL) Saffron (5–15 mg/mL) | No data | [262] 2019 | |

| L. sidoide EO | Alginic Acid Sodium Salt Cashew Gum | Alginate (low viscosity, MW 54 kDa) Cashew gum (MW 110 kDa) Relative ratios of alginate/gum (1:3, 1:1, and 3:1) Blend/oil ratio (10:1, w/w) Calcium chloride (0.5%, w/w) | Ionic gelation followed by spray drying | [263] 2014 | |

| Curcumin | Prunus armeniaca Gum (PAGE) | PAGE solution in water Ethanolic solution of curcumin (400 μL, 10 mg/mL) Calcium chloride-to-mixture ratio (1:1) | Ionic gelation | Against S. aureus and E. coli | [264] 2021 |

| Quercetin | PAGE Quercetin Calcium chloride | Significant decline in bacterial load | [265] 2024 | ||

| D-limonene (DL, R-(+)-Limonene) | Carrageenan | Carrageenan (sulfate content around 27% w/w, MW 672 ± 32 kDa) DL | Electrospray | No data | [266] 2022 |

| Curcumin | Carrageenan (0.15% and 0.44% in 0.5 mL/L NaCl aqueous solution) Curcumin ethanolic solution (100 mg/mL and 10 mg/mL) | Self-assembling | [139] 2022 | ||

| Grapefruit seed extract and cinnamon oil (GCN) | Chitosan Carrageenan | Chitosan Carrageenan GCN | Complex coacervation | Against Streptococcus mutans and sobrinus | [267] 2023 |

| Quercetin | Modified Dextran | Grafted dextran with L-cysteine and octadecylamine onto carboxymethyl dextran Quercetin | Self-assembling | No data | [268] 2023 |

| Eucalyptus staigeriana EO | Dextran Sulfate Chitosan | Dextran sulfate Chitosan Aloe Vera Eucalyptus staigeriana EO | Formation of hydrogel | Inhibited bacteria growth | [269] 2023 |

| α-Tocopherol | Dextran sulfate (MW 15 kDa) Chitosan (95%DA) α-Tocopherol Lecithin | Multi-layer nanoemulsions | No data | [270] 2024 | |

| Curcumin | Dextran sulfate (MW > 500 kDa, 0.1 wt%) Chitosan (DA > 75%, low MW, 0.1 wt%) Volume ratio of 3:2 Curcumin (2 mg) was loaded into NPs in 5 wt% of polymer | Complex coacervation | [271] 2011 | ||

| Naringenin | Dextran sulfate (MW 500 kDa, 0.1 wt%) Chitosan (DA > 75%, 0.1 wt%) Volume ratio (3:2) Naringenin (2 mg/mL) was equal to 5% weight of polymers | [272] 2021 | |||

| Clove extract | Pullulan Whey | Pullulan (20% w/w) Whey (20% w/w) Pullulan: whey protein ratios (100:0 w/w, 50:50 w/w, and 25:75 w/w) Clove extract (5% w/w) | Electrospinning | Against S. aureus and M. luteus | [273] 2022 |

| Resveratrol | Pullulan | Pullulan Resveratrol | Surface-functionalized with the ligand n-acetyl glucosamine | No data | [274] 2025 |

| Tannic acid | Pullulan Chitosan | Pullulan (18 wt%) Chitosan (DA 75–85%, MW 50–190 kDa, 3 wt%) Tannic acid (1 wt%) | Force-spinning | Against E.coli | [275] 2015 |

| Curcumin | Pullulan Hyaluronic Acid (HA) | Succinylated pullulan (SPu, 200 kDa, 400 mg) HA (5.4 kDa, 0.528 mmol disaccharide repeat unit) DMAP (0.106 mmol) EDC (0.528 mmol) Formamide Curcumin Mass ratios Cur/HA-SPu (1/5, 1/10, 1/15) | Conjugation | Against E. coli and S. aureus | [276] 2020 |

| Olive leaf extract (OLE) | Hyaluronic Acid Silk Fibroin (SF) | SF (15% w/v in formic acid) HA (0.5% w/v in distilled water) OLE (12 and 15% w/v) | Electrospinning | Perfect antibacterial activities against both Gram-negative and Gram-positive bacteria, while antifungal activity against C. albicans was rather poor | [277] 2016 |

| Curcumin | Pluronic Chitosan Hyaluronic Acid | Pluronic Chitosan (DA 97%, MW 1–3 kDa) HA Triethanolamine (TEA) DMAP | Conjugation and nebulisation | No data | [278] 2021 |

| Curcumin (CUR) and resveratrol (REV) | Hyaluronic Acid Chitosan | Chitosan (0.1% w/v) 1 mg of each CUR and REV is dissolved into 70:30 ratio of ethanol and water TPP (0.1% v/v) HA (0.01–0.05% w/v) | Ionic gelation followed coacervation | [279] 2020 | |

| Quercetin | Hyaluronic Acid | HA sodium salt solution (0.5% w/v, MW 200 kDa) DMSO (1:1 v/v ratio) Glutaraldehyde (5% v/v) HCl Quercetin (34 µmol) in phosphate buffer containing 10% v/v of ethanol | Nanoprecipitation with solvent–non solvent method and cross-linking | [280,281] 2017 2018 | |

| Tannic acid (TA) | Sodium Hyaluronate (HA) | HA (MW 44 KDa (low), 375 kDa (medium) and 737 kDa (high), 10 mg/mL) 4-(4,6-dimethoxy-1,3,5-triazin-2-yl)-4-methylmorpholinium chloride (DMTMM, 404 μmol) 3-aminophenylboronic acid hydrochloride (3-APBA∙HCl, 91 μmol) HA-APBA (2 mg/mL) TA water solution (28, 56, 112, 224, or 448 μg/mL) | Cross-linking (Catechol/Boronate complexation) | Against E. coli, MSSA, and MRSA | [282] 2016 |

Notes: TPS—tea water extract; DA—deacetylation degree; MW—molecular weight; CEO—cove essential oil; GLEO—guava leaf essential oil; TPP—sodium tripolyphosphate; MSSA—methicillin-susceptible S. aureus; EDC—ethylene carbo-di-imide hydrochloride; NHS—N-hydroxysuccinimide; MDR—multidrug-resistant; EO—essential oil; BNC—bacterial nanocellulose; CA—cellulose acetate; PM—peppermint; CN—cinnamon; LG—lemongrass; CNFs—cellulose nanofibrils; DCC—N, N’-dicyclohexylcarbodiimide; DMAP—4-Dimethylaminopyridine; TC—Triphala Churna; MRSA—methicillin-resistant S. aureus; CPE—citrus peel extract; ANCs—anthocyanins; MD—methylation degree; PAGE—Prunus armeniaca gum exudate; DL—D-limonene; GCN—grapefruit seed extract and cinnamon oil; SPu—succinylated pullulan; HA—hyaluronic acid; OLE—olive leaf extract; SF—silk fibroin; TEA—triethanolamine; DMTMM—4-(4,6-dimethoxy-1,3,5-triazin-2-yl)-4-methylmorpholinium chloride; 3-APBA∙HCl—3-aminophenylboronic acid hydrochloride.

Lippia sidoides essential oil and saffron extract were effectively loaded into chitosan/gum NPs via complex coacervation [242,262], while chitosan/carrageenan NPs containing grapefruit seed extract and cinnamon oil demonstrated strong activity against St. mutans and S. sobrinus [267]. Alginate NPs with grape pomace extract exhibited dose-dependent antimicrobial effects, achieving a 6-log reduction in C. albicans; 3-log reduction in MSSA; 2-log reduction in L. monocytogenes, P. aeruginosa, and S. enteritidis; and 1-log reduction in E. coli [234]. Furthermore, alginate NPs encapsulating Cuminum cyminum, Zataria multiflora, or lemon essential oils (prepared by oil-in-water emulsification with ionic gelation/cross-linking) showed species-specific activity: Z. multiflora-loaded NPs were effective against E. coli, P. aeruginosa, and S. aureus [231], whereas lemon oil NPs targeted multidrug-resistant A. baumannii [232]. Additionally, citrus peel flavonoids were successfully incorporated into pectin NPs through ionic gelation [261], further expanding the repertoire of plant-polysaccharide antimicrobial delivery systems.

Curcumin and quercetin exhibit strong antimicrobial potential, though their therapeutic applications are limited by poor water solubility and low bioavailability [283,284]. These challenges have been addressed through advanced nanoformulations: (1) curcumin-loaded NPs using Prunus armeniaca gum, chitosan, and chitosan/alginate composites demonstrated efficacy against S. aureus [247,248,264], E. coli [264], P. aeruginosa [247], B. subtilis, and E. aerogenes [248]; (2) quercetin was successfully encapsulated in Prunus armeniaca gum and chitosan/pectin NPs via ionic gelation [240,265], as well as in hyaluronic acid nanostructures through nanoprecipitation with solvent–non-solvent methods and cross-linking [280,281]. Additional curcumin delivery systems include BNC loading during autoclaving, carrageenan encapsulation, and xylan conjugation [139,250,254]. Furthermore, formulations like succinylated pullulan/hyaluronic acid and pluronic/chitosan/hyaluronic acid NPs have enhanced curcumin’s activity against E. coli and S. aureus [276,278], demonstrating the versatility of polysaccharide-based nanocarriers for these bioactive compounds.

Nanocellulose possesses exceptional physicochemical properties, including high surface area, porosity, and modifiable surface chemistry, making it a suitable platform for antimicrobial agent encapsulation and immobilization [285]. BNC can incorporate natural antimicrobials or living cell cultures through various approaches: physical adsorption, in situ incorporation, immersion techniques, chemical fixation, or electrostatic self-assembly [251,286]. Hemicelluloses (xylans, mannans, and β-glucans) demonstrate synergistic effects with polyphenolic compounds and can be functionalized through either physical adsorption or covalent conjugation, while nanoparticles are typically prepared via precipitation or dialysis methods [127,287]. BNC composites incorporating traditional medicinal plant extracts (Terminalia arjuna, Azadirachta indica, Withania somnifera, Tinospora cordifolia, and Murraya koenigii) or Chelidonium majus cell cultures was prepared by dipping or cultivation with subsequent enzymatic digestion and exhibited broad-spectrum antimicrobial activity against E. coli, A. viridans [249], S.aureus, P. aeruginosa, and C. albicans [251]. Notably, cinnamon essential oil encapsulated in cellulose acetate nanoparticles shows potent inhibitory effects against clinically relevant pathogens including S. aureus, E. coli, P. aeruginosa, and C. albicans [252]. Thymol, a bioactive monoterpenoid phenol abundant in essential oils, demonstrates particularly strong antimicrobial properties [288] when impregnated into cellulose nanofibrils using supercritical CO2 technology, showing efficacy against E. coli, S. epidermidis, and C. albicans [253].

Starch NPs are typically prepared via precipitation [115] and effectively encapsulate diverse bioactive compounds including phytochemicals, essential oils (EOs), and plant extracts [255,256,257,258,259,260], often requiring debranching pretreatment for optimal formulation [255,258]. These NPs with EO-loaded systems (menthone, oregano, cinnamon, lavender, and citral) showed greater efficacy against S. aureus than E. coli [255]. Triphala Churna extract-loaded starch NPs exhibit dual activity: antibacterial action against S. typhi and S. dysenteriae, plus antibiofilm effects against methicillin-resistant S. aureus (MRSA) ATCC 33591 and clinical strain N7 [256]. The platform also successfully encapsulates linalyl acetate, curcumin, quercetin, and rutin [257,258,259,260].

Dextran derivatives and their NPs demonstrate antimicrobial properties [289,290]. Quercetin has been successfully encapsulated into self-assembled NPs prepared from dextran grafted with L-cysteine and octadecylamine [268]. Dextran sulfate and chitosan were combined to incorporate Eucalyptus staigeriana essential oil (EO), α-tocopherol, curcumin, and naringenin through three fabrication methods: complex coacervation [271,272], multilayer nanoemulsions [270], and antibacterial hydrogels [269]. Resveratrol, a bioactive polyphenol with demonstrated antibacterial and antibiofilm properties [291], has been effectively encapsulated in both pullulan-based structures [274] and hybrid hyaluronic acid/chitosan systems via ionic gelation–coacervation, with the latter showing synergistic effects when combined with curcumin [279].

Equipment-based spinning techniques were employed to fabricate nanoformulations of pullulan/whey, pullulan/chitosan, and hyaluronic acid/silk fibroin. These systems incorporated clove extract, olive leaf extract, and tannic acid, demonstrating antimicrobial activity against S. aureus and M. luteus [273], E. coli [275,277], and MRSA [277]. Tannic acid, a natural polyphenolic tannin, exhibits broad-spectrum antimicrobial and antiviral properties [292]. Sodium hyaluronate NPs containing tannic acid showed significant efficacy against E. coli, MSSA, and MRSA [282].

Plants represent a rich source of diverse secondary metabolites, such as tannins, terpenoids, alkaloids, and flavonoids, which exhibit broad-spectrum bioactive properties, particularly antimicrobial activity [293]. These phytochemicals can be effectively encapsulated within polysaccharide nanomatrices in various forms (essential oils, crude extracts, or purified compounds), serving as potent antimicrobial agents with sustained release profiles [294,295].

5. Polysaccharide-Based Nanocarriers for Microbial-Derived Antimicrobials

Microorganisms produce diverse antimicrobial agents, including peptides, spirotetronates, polyketides, alkaloids, organic acids, and sesquiterpene derivatives [296]. Among these, bacteriocins represent one of the most promising and intensively studied groups of microbial-derived antimicrobials [4,297,298,299,300]. Bacteriocins are classified into three main categories based on their chemical structure, molecular weight, biochemical properties, spectrum of antimicrobial activity, and mechanism of antimicrobial action: (1) Class I—heat-stable lanthionine-containing peptides (lantibiotics, thiopeptides, sactibiotics, lasso peptides, and cyclic bacteriocins); (2) Class II—small heat-stable non-lanthionine peptides; and (3) Class III—large heat-labile proteins [224,301,302,303]. Class I bacteriocins include lantibiotics, lipolantins, thiopeptides, botromycins, linear azole-containing peptides, sactibiotics (sactipeptides), lasso peptides, and cyclic bacteriocins [303]. Class II bacteriocins are divided into three subclasses and include pediocin, enterocin, sakacins, leucocin, carnobacteriocins, etc. [304]. Class III bacteriocins include megacins, klebicin, helveticin I, and enterolysin [305].

While bacteriocins show promise as antimicrobial agents, they face several application challenges that limit their clinical and industrial utilization. Thus, bacteriocins have a limited spectrum of activity against closely related bacterial strains [306,307]. The intensive application of bacteriocins could lead to the potential development of bacterial resistance. Thus, some species of B. cereus and P. polymyxa produce nisinase, while Listeria species demonstrate alterations in the surface charge of their cell walls due to gene mutations that disrupt bacteriocin binding, and some C. botulinum strains also show cross-resistance to Class II bacteriocins [308]. Low production yield, purification challenges, and formulation stability issues hinder the widespread adoption of bacteriocins as biopreservatives [309,310]. Due to their peptide nature, bacteriocins are sensitive to proteases, possess poor pharmacokinetic profiles, and may act as host sensitizers or allergens [311]. These limitations may be partially overcome through nanoencapsulation strategies.

Nisin is a widely recognized Class I bacteriocin with Generally Recognized as Safe (GRAS) status [312,313]. Composed of 34 amino acids, it is produced by Lactococcus lactis ssp. [314] and exhibits potent inhibitory activity against spore-forming bacteria such as Bacillus and Clostridium. Additionally, nisin demonstrates efficacy against Listeria, Micrococcus, Staphylococcus, Streptococcus, Lactobacillus, Lactococcus, Leuconostoc, Mycobacterium, and Pediococcus. However, it shows minimal to no activity against Gram-negative bacteria [315]. Nisin-incorporated nanoparticles (NPs) were successfully developed using various biopolymers, each demonstrating distinct antimicrobial properties. Nisin was encapsulated into chitosan NPs via ionic gelation (Table 4), exhibiting antimicrobial activity against S. aureus, L. monocytogenes, and E. coli [316,317]. Additionally, nisin-loaded NPs were fabricated using chitosan combined with alginate [318,319], pectin [320], or carrageenan [321] through electrostatic coacervation. These NPs effectively suppressed the growth of L. monocytogenes, S. aureus, E. coli, S. enterica, M. luteus, P. aeruginosa, and E. aerogenes. Bacterial cellulose nanocrystals, carboxymethylcellulose, and nanofibrillated cellulose can form nanocomposites with nisin through complexation. These nanocomposites exhibit microbial inactivation and demonstrate activity against S. aureus and B. subtilis [322,323,324]. Co-culturing Enterobacter sp. FY-07 (a bacterial nanocellulose producer) with Lactococcus lactis N8 (a nisin producer) resulted in the formation of a nanomaterial with strong inhibitory effects against Gram-positive bacteria [325]. Nisin-functionalized cellulose nanofibers exhibit inhibitory activity against B. thermosphacta and L. innocua [326], while holocellulose nanofibrils conjugated with nisin demonstrate antimicrobial efficacy, particularly against Gram-positive bacteria including S. aureus and L. monocytogenes [327].

Table 4.

Polysaccharide-based nanostructures incorporating microbial-derived antimicrobial agents.

Alginate–nisin and alginate–starch–nisin NPs, prepared by emulsification followed by ionic gelation showed effective activity against L.monocytogenes [328]. Nisin-incorporated pectin NPs exhibited spectrum-specific antimicrobial activity that varied with the esterification degree, showing efficacy against Arthrobacter sp., B. subtilis, E. coli, and Klebsiella sp. [329]. Notably, high-methoxyl pectin nanoparticles demonstrated inhibition against S. aureus and E. coli [330]. Similarly, gellan gum- and dextran-based nisin nanoparticles showed potent activity against S. aureus [295]. Similarly, gellan gum- and dextran-based NPs with nisin were active against S. aureus [331], and radiation-synthesized dextran-nisin conjugates showed broader spectrum activity against E. coli, P. fluorescence, S. aureus, and B. cereus [332]. Electrospun NPs fabricated from pullulan, amaranth protein isolate, and nisin demonstrated antimicrobial effects against L. mesenteroides, L. monocytogenes, and S. Typhimurium [333]. Hyaluronic acid-based formulations showed promising results: HA–nisin nanoformulations prepared by electrostatic complexation exhibited superior inhibition against hyaluronidase-producing S. aureus compared to B. cereus [334], while HA–nisin conjugates were also effective against S. epidermidis, S. aureus, and P. aeruginosa [335].

Pediocin-like bacteriocins are small (<5 kDa) peptides characterized by the conserved sequence -Y-G-N-G-V-X1-C-X2-K/N-X3-X4-C- [349], produced primarily by some Pediococcus spp. [350]. They exhibit broad-spectrum activity against Gram-positive bacteria, with particularly strong inhibition of L. monocytogenes, as well as efficacy against E. faecalis, S. aureus, and C. perfringens [350,351,352]. When encapsulated in alginate–guar gum via complex coacervation, pediocin demonstrated significant activity against L. innocua [336]. Plantaricins, bacteriocins derived from L. plantarum [353], include variants such as plantaricin E/F, which inhibit Gram-positive bacteria. Alginate-encapsulated plantaricin E/F showed antimicrobial effects against the sensitive indicator strain L. plantarum NCIMB 700965 (LP965) [337]. Enterocins, produced by Enterococcus spp. [354,355], display potent activity against foodborne pathogens, including S. aureus, L. monocytogenes, and S. enterica et al. [356]. Alginate and bacterial cellulose nanomaterials were successfully fabricated through simple ball milling [338] or soaking methods [339], demonstrating effective antimicrobial activity against C. perfringens and L. monocytogenes. In parallel, sakacins—a group of bacteriocins produced by specific L. sakei strains with a narrow antibacterial spectrum [357]—showed activity when conjugated with bacterial cellulose nanocrystals, particularly against L. innocua [340]. Further developments in bacteriocin delivery systems include chitosan nanoparticles produced by ionic gelation encapsulation of Levilactobacillus brevis and Lactococcus lactis subsp lactis bacteriocins. These nanoparticles exhibited superior antibacterial effects against Gram-positive pathogens (especially under acidic conditions) compared to Gram-negative bacteria [341] and demonstrated activity against S. typhimurium, E. coli, B. cereus, and S. aureus [342]. Similarly, cellulose nanocrystals functionalized with bacteriocins from P. acidilactici and E. faecium effectively inhibited the growth of multiple pathogens including S. aureus, L. monocytogenes, E. coli, E. herbicola, B. subtilis, B. cereus, and P. aeruginosa [343].

Natamycin, a natural antifungal compound produced by Streptomyces species, is widely approved as a food preservative [358,359]. While ineffective against bacteria, it demonstrates broad-spectrum activity against fungi and yeasts including Candida spp., Aspergillus spp., Cephalosporium spp., Fusarium spp., and Penicillium spp. [360]. Various nanoformulations have been developed to enhance its efficacy: chitosan-based nanoparticles (either alone or combined with zein or lecithin) showed strong activity against C. albicans [347], completely inhibiting spore germination and suppressing mycelial growth by 64.4% [344], with additional activity against A. fumigates [345]. Similarly, carboxymethylcellulose-gliadin NPs inhibited P. expansum [346], and alginate nanoparticles prepared by emulsification–ion gelation achieved a 2-log reduction in A. flavus populations [348].

Bacteriocins exhibit low toxicity to eukaryotic cells and demonstrate minimal inhibitory concentrations against numerous bacterial strains, along with high-temperature stability. However, they are sensitive to proteases, possess poor pharmacokinetic profiles, and may act as host sensitizers or allergens [311]. These limitations can be partially mitigated through nanoencapsulation, which enhances their stability and antimicrobial functionality [361].

6. Polysaccharide-Based Nanocarriers for Animal-Derived Antimicrobial Proteins and Peptides

Animal-derived antimicrobials include enzymes (e.g., lysozyme and lactoperoxidase), glycoproteins (lactoferrin, ovotransferrin, and avidin), histones, and antimicrobial peptides (arenicins, magainins, seroins, pleurocidins, cecropins, cathelicidins, protegrins, and defensins) [4,224,303,362].

Despite their potential as antimicrobial agents, animal-derived peptides and proteins face significant translational challenges that restrict their widespread clinical and industrial application, including a lack of selectivity, off-target effects, proteolytic instability, potential toxicity, and immunogenicity [363]. Low production yields and purification difficulties could also limit the application of animal-derived antimicrobial peptides and proteins [364]. Thus, studies have demonstrated that bacteria can develop resistance to AMPs under in vitro conditions [365]. Furthermore, certain antimicrobial peptides (AMPs) exhibit low specificity, targeting both pathogenic microbes and host cells. This non-selective activity can induce cytotoxic effects in human cells, resulting in adverse side effects that limit their therapeutic application [363,366]. Their proteinaceous nature renders animal-derived peptides and proteins susceptible to proteolytic degradation and results in suboptimal pharmacokinetic properties [367]. These limitations can be partially mitigated through nanoencapsulation.

Lysozyme, a 14.3 kDa secretory enzyme composed of 129 amino acids [368,369,370], is most abundant in egg white but also present in milk, cauliflower, cabbage, papaya juice, spleen, thymus, pancreas, and mucus [370], or it can be produced recombinantly [371]. Its antimicrobial activity primarily targets Gram-positive bacteria through the cleavage of β-(1,4)-glycosidic bonds in peptidoglycan, while it exhibits limited or negligible effects against Gram-negative bacteria [370,372]. Chitosan-based NPs incorporating lysozyme demonstrate broad-spectrum antimicrobial activity against both Gram-positive and Gram-negative bacteria through the synergistic action of chitosan and lysozyme (Table 5). Ionic gelation-fabricated chitosan-lysozyme NPs effectively inhibited the growth of E. coli and B. subtilis [373], while nanoprecipitated formulations significantly reduced A. parasiticus viability and strongly suppressed spore germination [374]. Lysozyme-conjugated chitosan NPs showed potent activity against S. aureus, E. coli, P. aeruginosa, and K. pneumoniae [375]. Nanogels fabricated from carboxymethyl chitosan, lysozyme, and amorphous calcium phosphate demonstrated activity against S. mutans [376]. Researchers have developed various innovative delivery systems for lysozyme, including chitosan/alginate NPs prepared via alginate pre-ionic gelation followed by chitosan coacervation [377], and complexes combining chitosan, CNCs, and lysozyme that exhibited antimicrobial effects against E. coli and L. innocua [378]. Additionally, lysozyme has been successfully encapsulated in depolymerized chitosan/dextran sulfate NPs through polyelectrolyte complexation [379] and in alginate formulations via ionic gelation [380], further expanding its potential applications in antimicrobial therapies. CNCs enable both nonspecific and covalent immobilization of lysozyme. The resulting nanomaterials exhibited antimicrobial activity against M. deykticus [381], Corynebacterium sp., E. coli, and Ps. mendocina [382].

Table 5.

Polysaccharide-based nanostructures incorporating animal-derived antimicrobial agents.

In a separate formulation, cellulose acetate (CA) nanofibers were functionalized with pectin and lysozyme via electrostatic layer-by-layer assembly, yielding a nanomaterial with inhibitory effects against E. coli and S. aureus [383]. Starch-based formulations incorporating lysozyme have been successfully developed through cross-linking techniques [384,385], demonstrating potent antimicrobial activity against various bacterial strains including B. licheniformis 7558, B. licheniformis 6993, B. subtilis 168, L. monocytogenes LR991, and L. monocytogenes 001 [384]. Lysozyme-loaded NPs of pectin, κ-carrageenan, and xanthan gum were prepared through ionic gelation (retaining activity against M. lysodeikticus) [386] and complex coacervation via electrostatic polysaccharide–protein interactions [387,389,390], followed by either alkaline gelatinization [391,392] or high-pressure homogenization-assisted electrostatic complexation [393]. Gum arabic NPs incorporating lysozyme were fabricated through complex coacervation via electrostatic interactions, followed by Maillard reaction-induced conjugation, demonstrating antimicrobial activity against E. coli and S. aureus [388]. Similarly, lysozyme–dextran and lysozyme–pullulan conjugates prepared via Maillard dry heat processing [394,395,396,397] exhibited broad-spectrum inhibition against multiple pathogens, including M. Lysodeikticus, V. parahaemolyticus IFO 13286, E. coli IFO 12713, A. hydrophila IFO 13286, P. mirabilis IFO 12668, K. pneumoniae IFO 14438, B. cereus IFO 13690, S. aureus IFO 14462 [395], E. coli, S. enterica, and S. aureus [396]. Electrospun pullulan fibers cross-linked with lysozyme also showed efficacy against E. coli and S. aureus [397]. Additionally, hyaluronic acid–lysozyme complex coacervates [398,399] were developed with demonstrated wound-healing properties [399].

Lactoperoxidase (LPO) is an 80 kDa calcium- and iron-containing enzyme [432] predominantly found in mammalian secretions, particularly milk, where it constitutes ~1% (w/w) of whey proteins [433,434]. The LPO antimicrobial system, composed of lactoperoxidase (LPO), thiocyanate, and hydrogen peroxide, is naturally occurring and exhibits both bacteriostatic and bactericidal activity against diverse Gram-positive and Gram-negative microorganisms [435]. Lactoferrin (LF), a cationic glycosylated protein [436], is similarly abundant in milk (~1% of whey proteins) and colostrum, and it is also present in tears, saliva, gastric mucosa, spleen, lymph nodes, skin, and white blood cells [437]. While its primary role is iron binding, LF demonstrates broad-spectrum antibacterial activity [438], with reported efficacy against E. coli, S. typhi, Streptococcus, L. pneumophila, and S. aureus [439]. The LPO can be incorporated into NPs through complex coacervation, either with chitosan and gum tragacanth or in combination with LF, chitosan, and dextran [400,401,402,403]. Chitosan–LF NPs prepared by ionic gelation demonstrated antimicrobial activity against S. aureus [404]. Similarly, LF was successfully encapsulated in alginate formulations using ionic gelation [407,408], while pectin–LF NPs fabricated through complex coacervation [411,412] inhibited P. aeruginosa growth [411]. LF has also been conjugated with hyaluronic acid (either non-covalently or covalently) [413] or BNC, exhibiting antimicrobial effects against S. aureus and E. coli [409]. Additionally, the electrostatic complexation of LF with gellan gum formed NPs active against both S. aureus and E. coli [410]. Ovotransferrin (OVT), a 76 kDa glycoprotein constituting approximately 12% of total egg white protein [440], exhibits broad-spectrum antimicrobial activity against pathogens including S. aureus, B. cereus, L. monocytogenes, E. coli, and H. pylori [441]. Research has demonstrated OVT’s ability to form nanoformulations through polysaccharide–protein complexation with carboxymethyl chitosan, pectin, and various gums [414,415,416,417,418].

Antimicrobial peptides (AMPs), conserved across nearly all species, serve as components of innate host defense systems [362]. The Antimicrobial Peptide Database (APD) catalogs 2580 animal-derived AMPs, including 154 human host defense peptides, 397 from mammals, and 1110 active peptides from amphibians [442]. Their activity is largely attributed to cationic and amphipathic structural features [443], which enable broad-spectrum antimicrobial effects [444] through cell membrane disruption, the inhibition of cell wall synthesis, and interference with nucleic acid and protein production [445]. Chitosan is widely employed for encapsulating AMPs through ionic gelation, leveraging both the technique’s simplicity and chitosan’s inherent antimicrobial properties. This approach was proven successful with various AMPs. Cryptdin-2 from Paneth cells, when encapsulated in chitosan nanoparticles, reduced Salmonella Typhimurium loads in murine tissues by 2 log units [419]. Similarly, chitosan NPs incorporating frog skin-derived temporin B demonstrated efficacy against S. epidermidis [420], while those containing insect-derived cecropin-B showed activity against multidrug-resistant K. pneumoniae [421]. The encapsulation of human neutrophil defensin (HNP-1) in chitosan yielded NPs with broad-spectrum antibacterial activity against S. aureus ATCC 25923, E. coli NCTC 9001, P. aeruginosa ATCC 10145, K. aerogenes NCTC 10006, and MRSA [422]. Human cathelicidin peptide LL-37 encapsulated in chitosan NPs exhibited potent effects against MRSA [423]. Pleurocidin-like AMPs, identified across multiple flounder species, include NRC-07, which was successfully complexed with chitosan to form NPs exhibiting antimicrobial activity against P. aeruginosa [424].

AMPs have been successfully conjugated and immobilized into CNFs and modified starch matrices. These fabricated materials, incorporating either cecropin CA(1–7)M(2–9) or the LL-37 antimicrobial motif (KR-12), demonstrated growth inhibition against B. subtilis [425], E. coli, S. aureus [426,428], and even MRSA [428]. Electrospun pullulan fibers functionalized with the minimal bovine lactoferricin motif (LfcinB) (20–25)Pal showed potent activity against E. coli [427]. Microfluidic chip technology enabled the fabrication of nanogels from octenyl succinic anhydride-modified hyaluronic acid conjugated with snake cathelicidin Ab-Cath. These nanogels demonstrated antimicrobial activity, inhibiting the growth S. aureus, A. baumannii, and E. coli in biological fluids while significantly reducing S. aureus and A. baumannii biofilms [429]. Cecropin B exhibited electrostatic interactions with hyaluronic acid in aqueous solutions [431]. Hyaluronic acid/PLGA complex coacervates incorporating insect thanatin from Podisus maculiventri thanatin [446] effectively mitigated sepsis caused by metallo-β-lactamases-1 (NDM-1) producing E. coli [430].