Effects of Void Characteristics on the Mechanical Properties of Carbon Fiber Reinforced Polyetheretherketone Composites: Micromechanical Modeling and Analysis

Abstract

1. Introduction

2. Statistical Analysis of CF/PEEK Porosity Characteristics

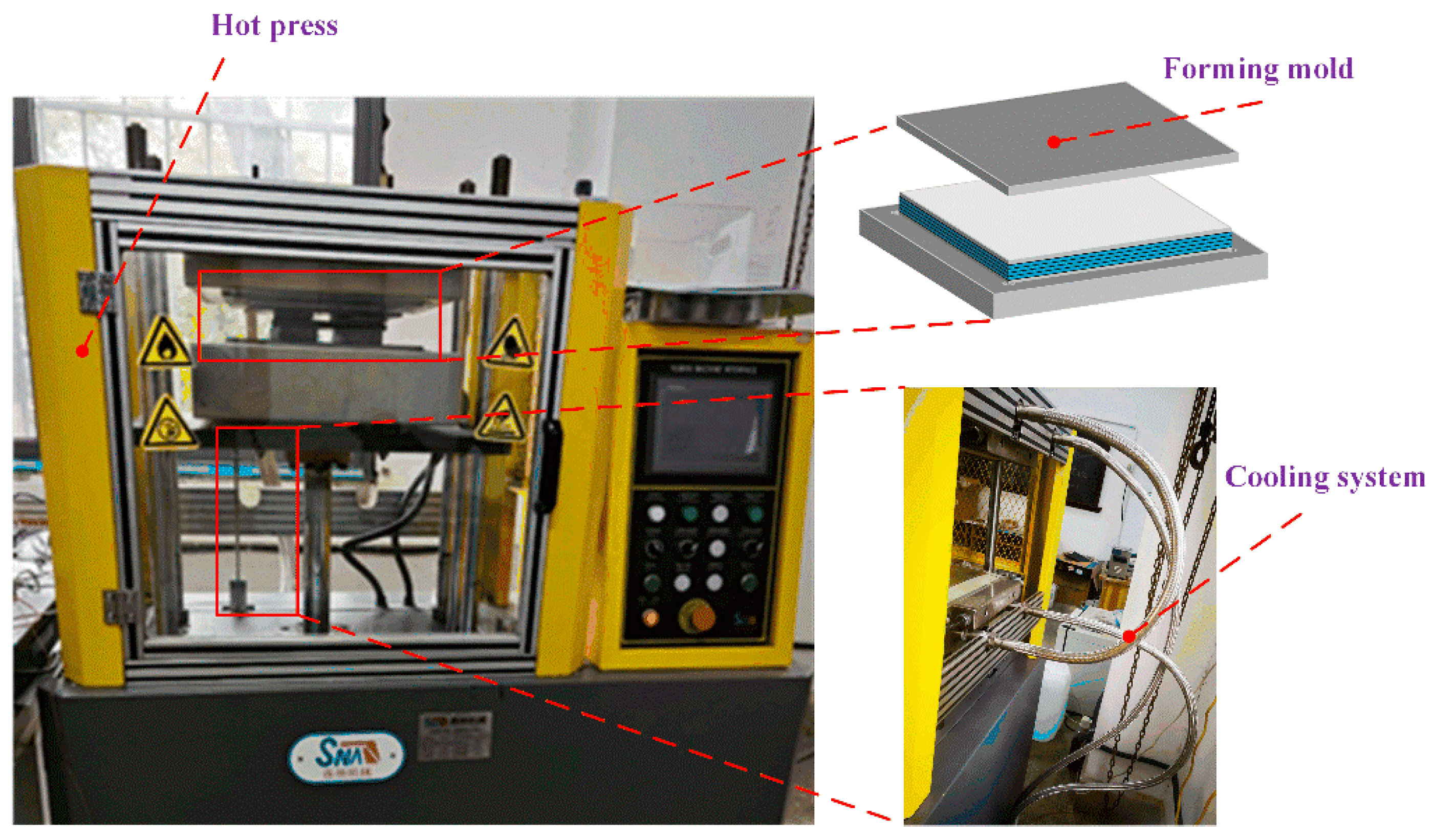

2.1. Material and Specimen Preparation

- (1)

- The hot press system is heated from room temperature to the molding temperature at a rate of 10 °C/min, with a pre-pressure of 0.1 MPa applied.

- (2)

- Once the molding temperature is reached, the pressure is increased to the target molding pressure and maintained for 30 min to ensure proper consolidation and bonding of the prepreg layers.

- (3)

- Finally, the system is cooled to room temperature under constant pressure to prevent defects and ensure dimensional stability.

2.2. Micro-Computed Tomography (Micro-CT) Scanning

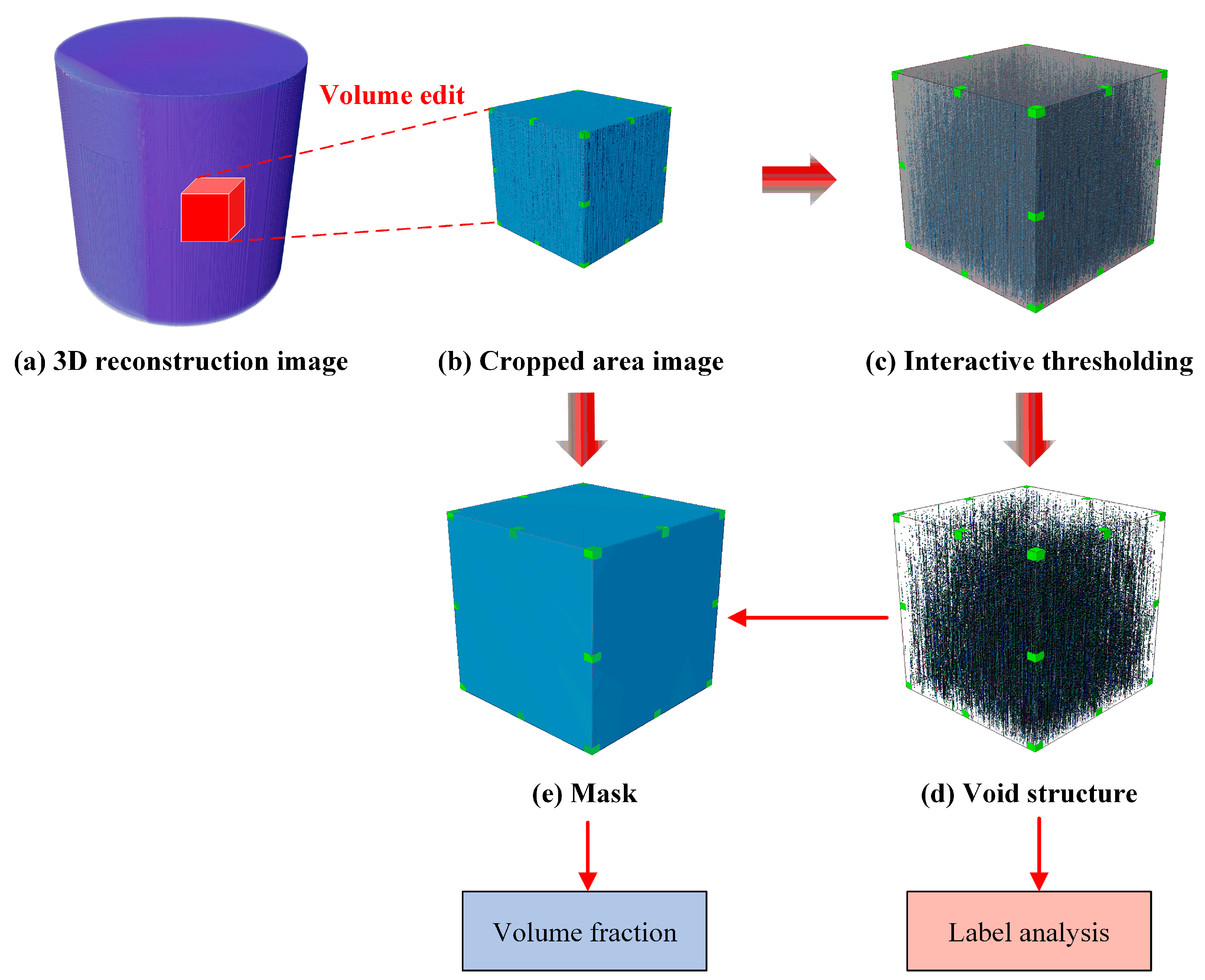

2.3. Extraction of Void Characteristics

- (1)

- The raw data are processed and reconstructed into a detailed three-dimensional (3D) model.

- (2)

- Core data within the targeted area are precisely cropped from the model to remove unnecessary portions.

- (3)

- Grayscale values are carefully adjusted to define the contours and features of the voids, thereby improving recognition efficiency and analysis accuracy.

- (4)

- Based on optimized grayscale range, thresholding and image segmentation are performed to accurately identify void regions. Through extensive comparative analysis, the optimal grayscale threshold range for accurate void identification is determined to be 0–4852 under 16-bit grayscale conditions.

- (5)

- To address pore stacking issues, a watershed algorithm is applied to separate connected voids and extract detailed void morphologies.

- (6)

- The label analysis tool is used to perform a thorough statistical evaluation of various void characteristics.

- (7)

- Finally, VC is calculated as the ratio of the total void volume to the volume of the study area.

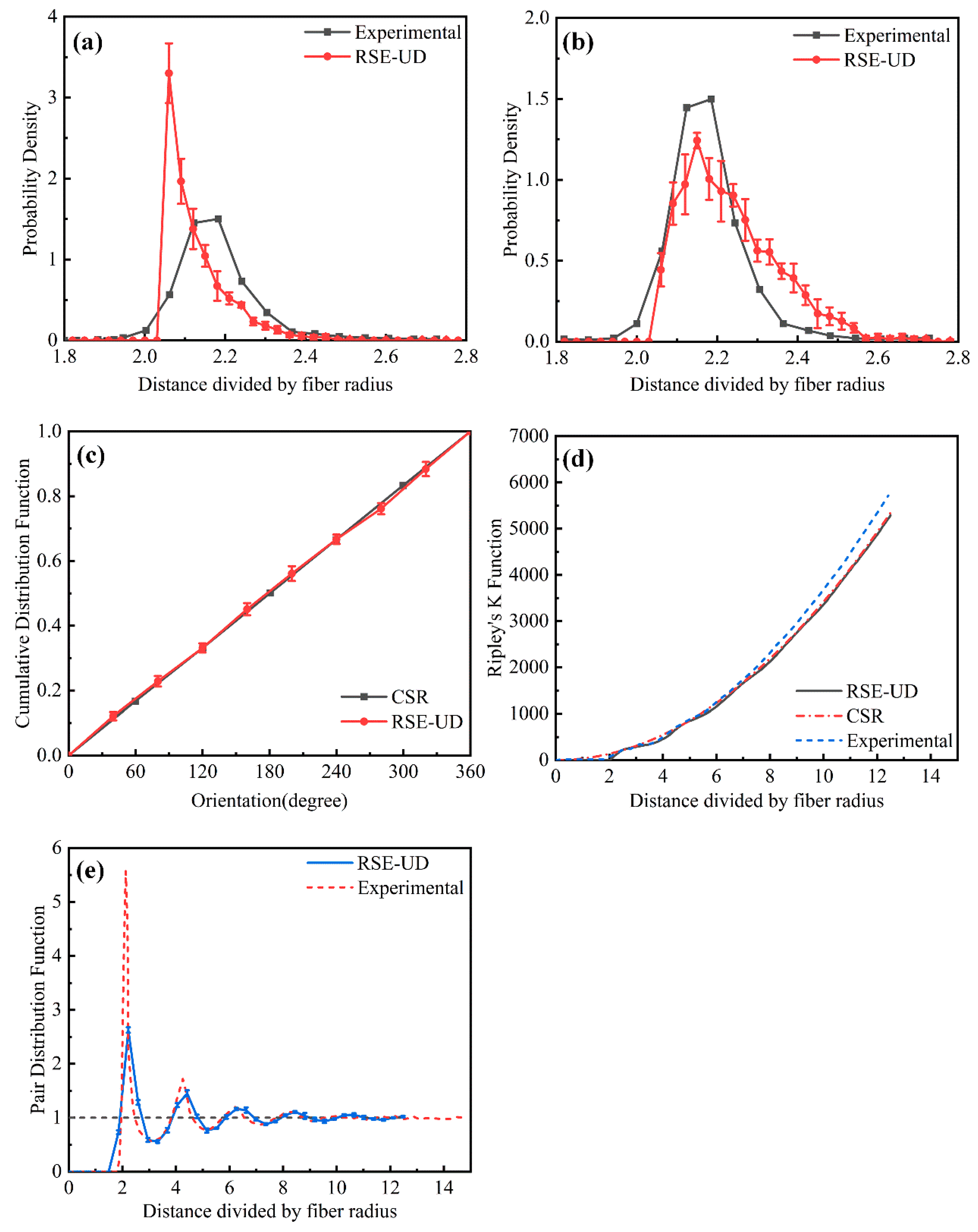

2.4. Quantitative Characterization of Pore Models

3. Generation of RVE Units with Embedded Pore Characteristics

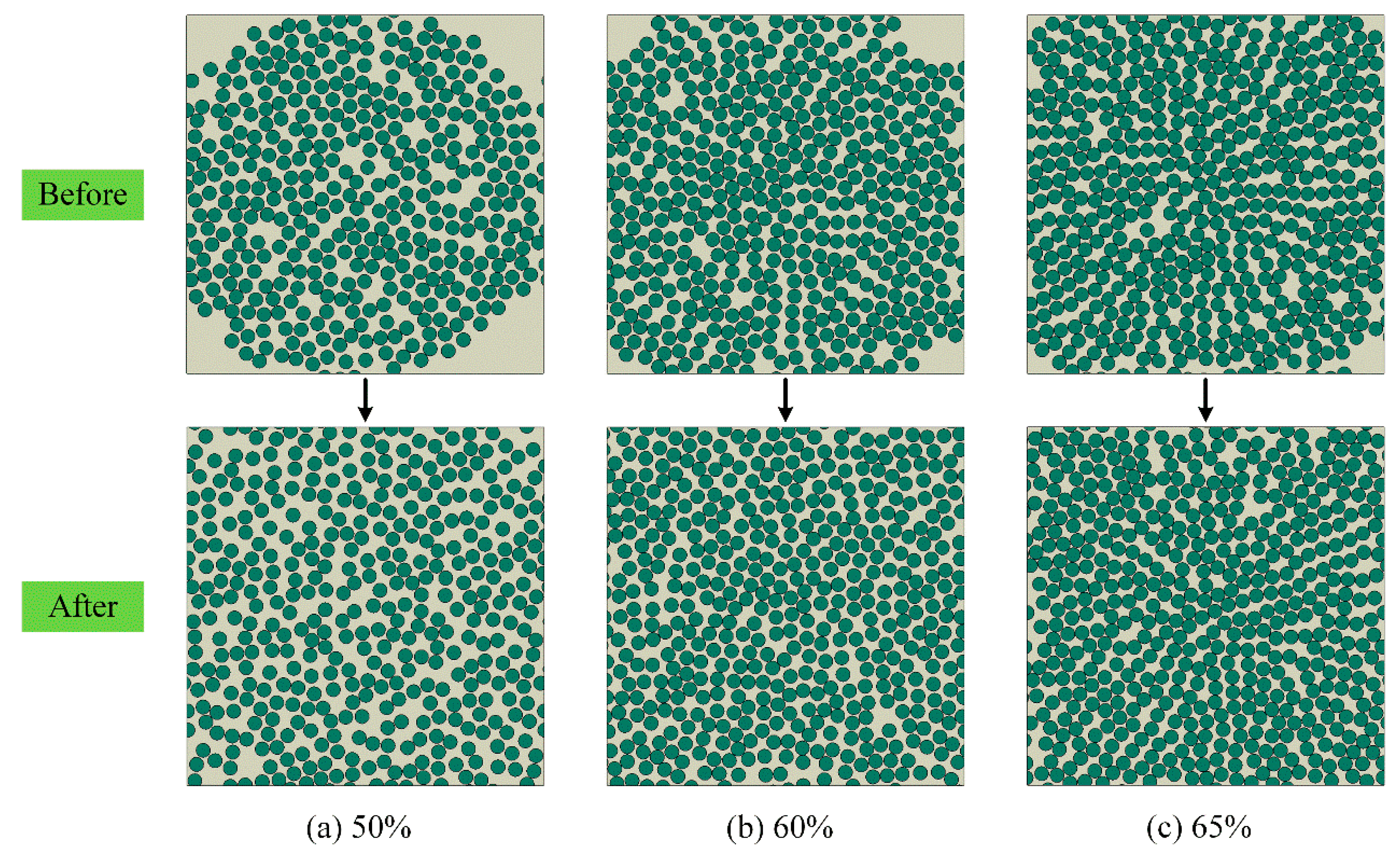

3.1. RVE Construction Method for Composites with High Fiber Volume Fraction

- (1)

- Initial fiber layout generation: Fibers are first generated based on the specified fiber volume fraction using the RSE algorithm.

- (2)

- Simulation of particle interactions: A force model combined with a stochastic perturbation mechanism is applied to simulate fiber interactions, which gradually eliminate local structural irregularities.

- (3)

- Fiber removal: Excess fibers are randomly removed to achieve the target fiber distribution and produce the final RVE.

3.2. Void Distribution Model

- (1)

- The fiber–resin RVE serves as the base model, with the void diameter range and probability density distribution obtained from statistical analysis used as input parameters.

- (2)

- Voids are randomly generated within the RVE domain according to the probability density distribution of void diameters. Each void is assigned a diameter and a random spatial position.

- (3)

- The generated voids are checked for overlap or interference with existing fibers or other voids. If interference occurs, the voids are regenerated until all conditions are satisfied.

- (4)

- The total porosity of the generated voids is calculated. If the porosity does not meet the target value, steps 2 and 3 are repeated until the desired porosity is achieved, thereby completing the generation process.

4. Simulation of Mechanical Properties of Composite Materials Using RVE Models

4.1. Mechanical Modeling of Fibers

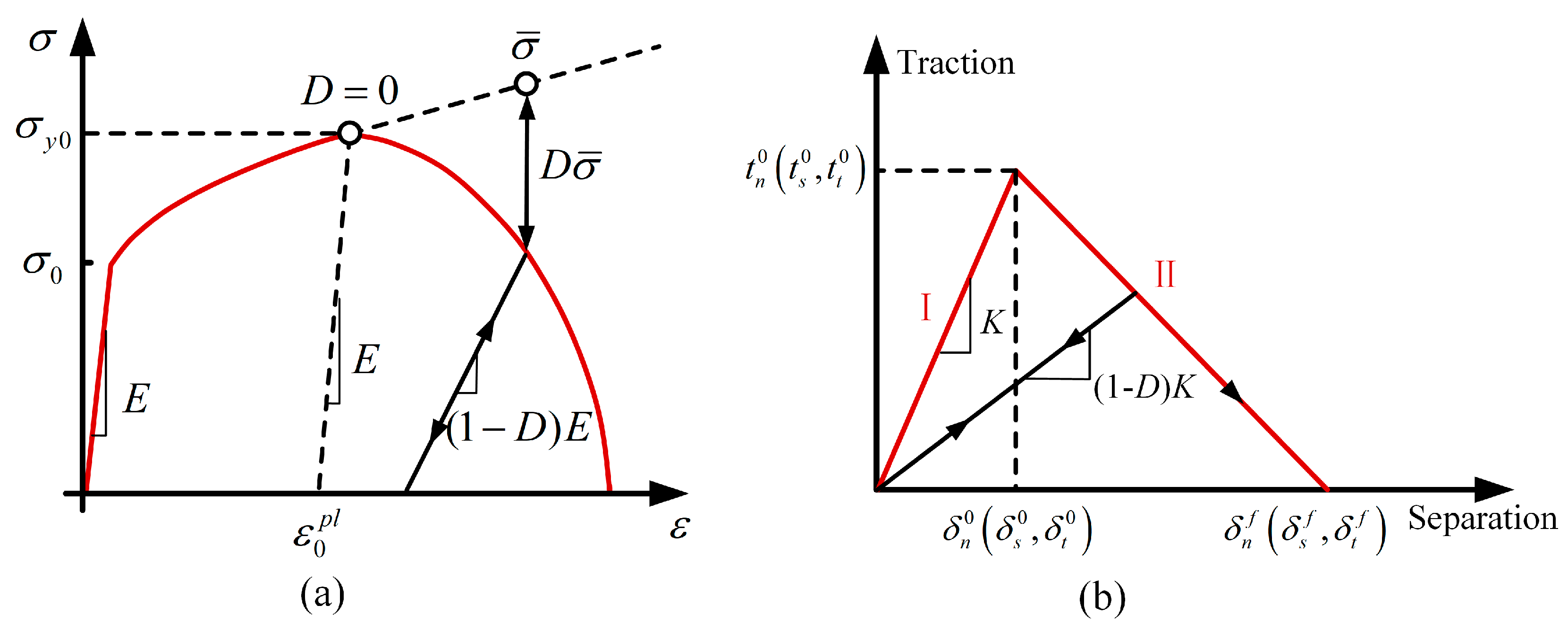

4.2. Elasto-Plastic Modeling of the Resin

4.3. Cohesive Zone Model

4.4. Prediction and Verification of Mechanical Properties

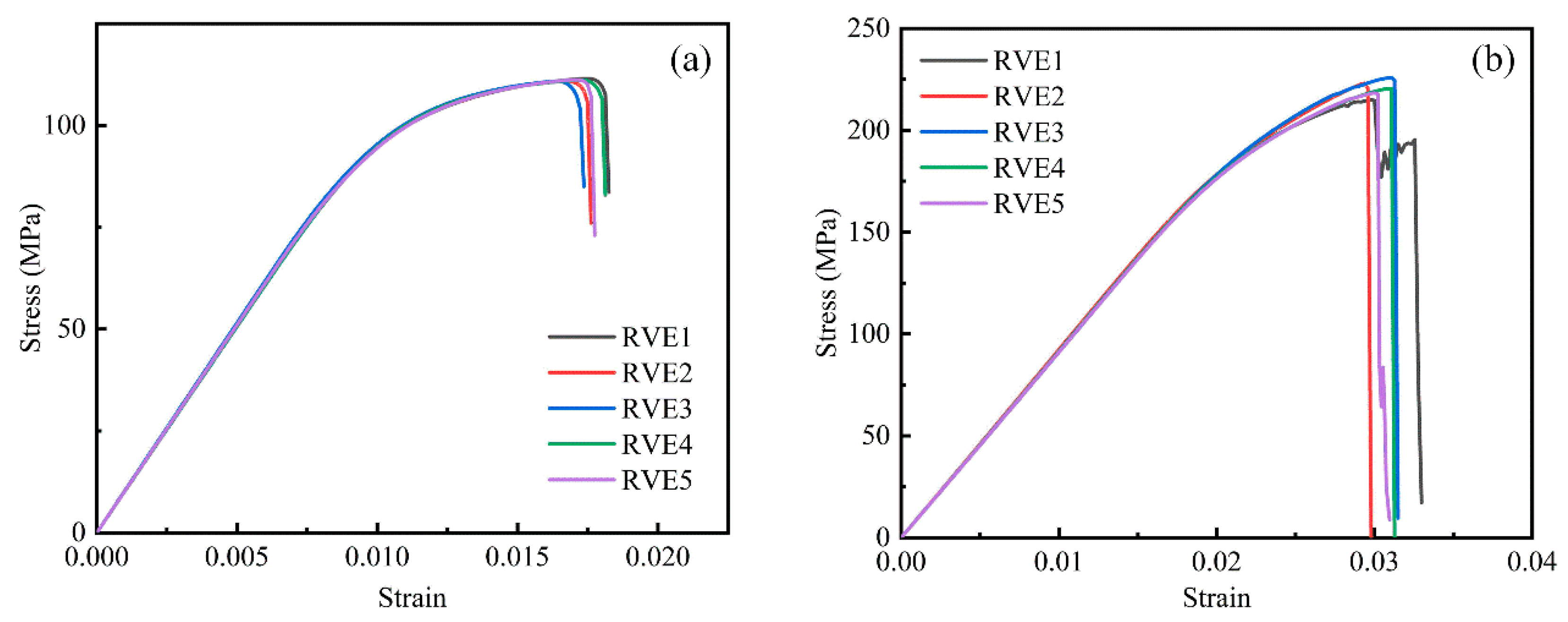

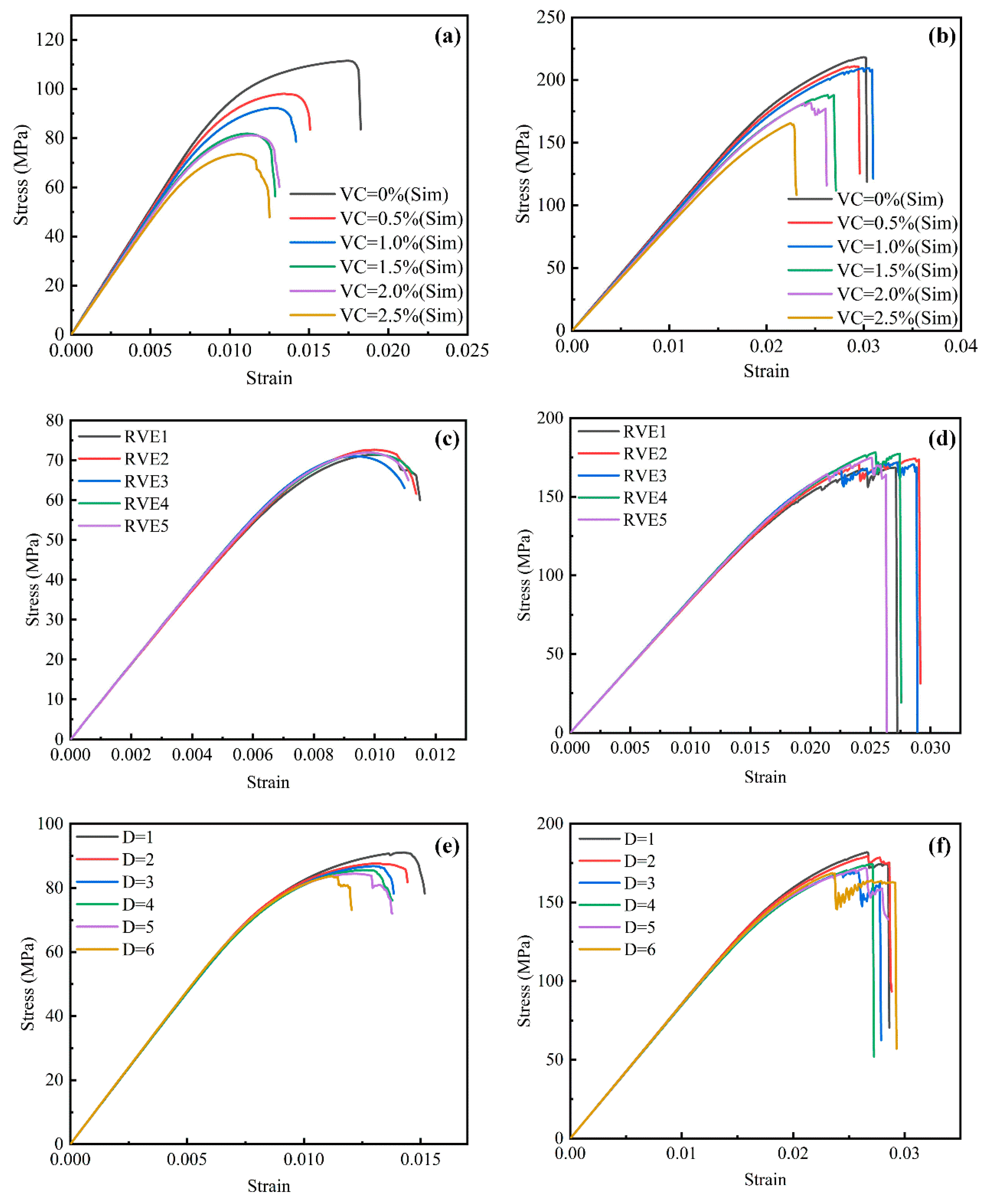

4.4.1. Mesh Sensitivity Analysis

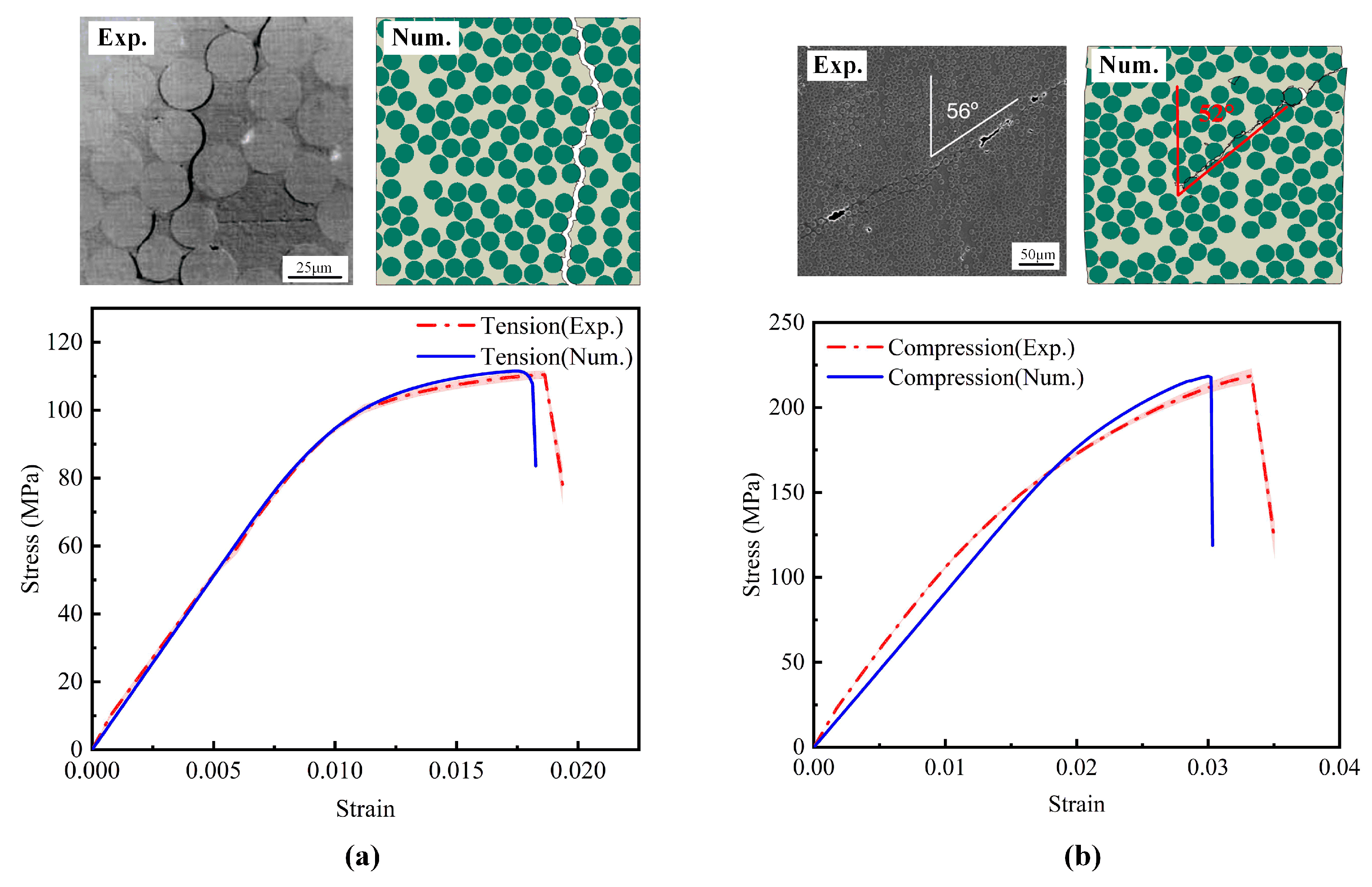

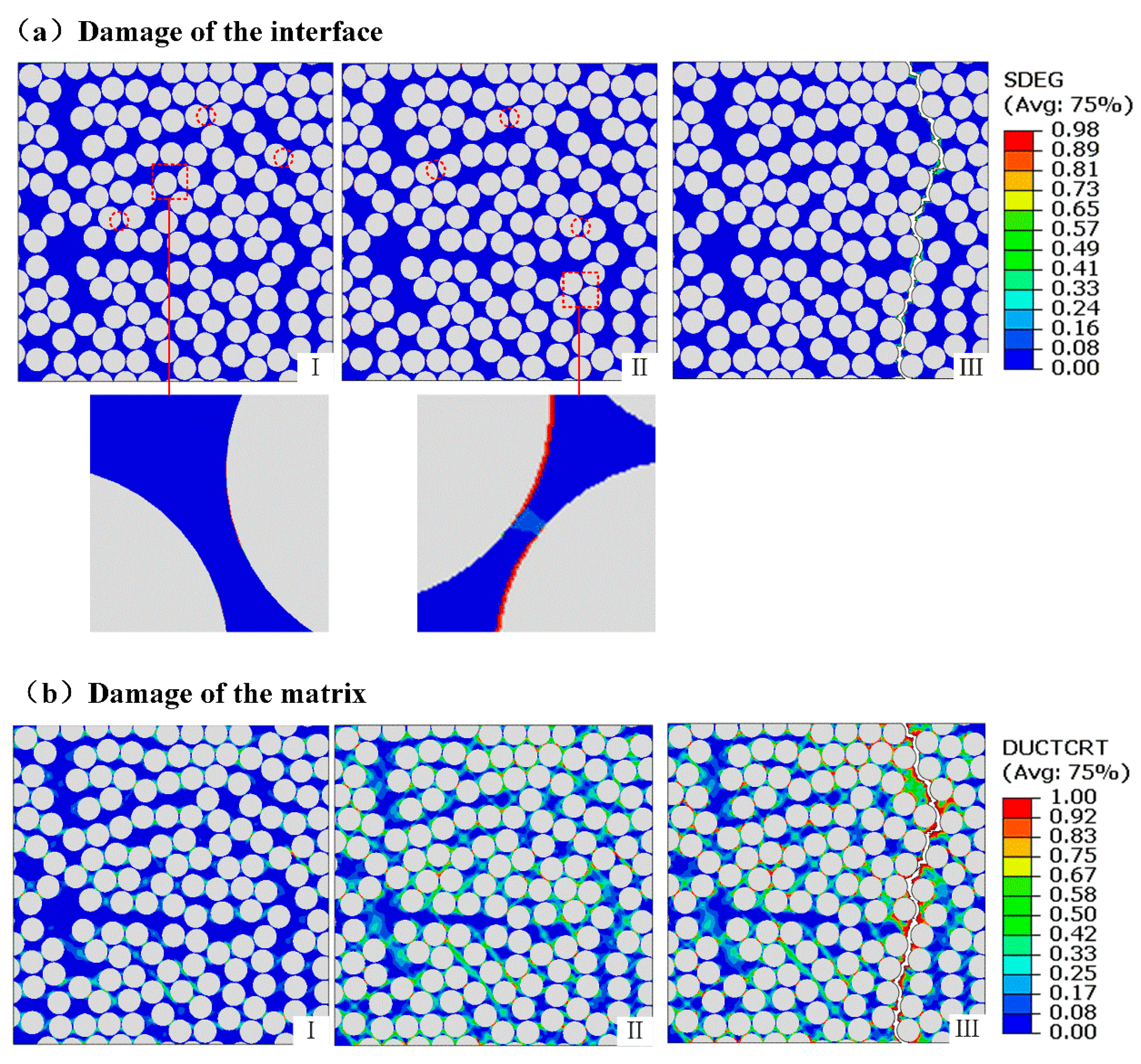

4.4.2. Stress–Strain Curves and Damage Evolution Pathway at Zero Porosity

4.4.3. Stress–Strain Curves at Different Void Levels

5. Effect of Void Characteristics on the Mechanical Properties of Composite Materials

5.1. Effect of Void Content

5.2. Effect of Void Spatial Distribution

5.3. Effect of Void Size

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Karaş, B.; Smith, P.J.; Fairclough, J.P.A.; Mumtaz, K. Additive manufacturing of high density carbon fibre reinforced polymer composites. Addit. Manuf. 2022, 58, 103044. [Google Scholar] [CrossRef]

- Seo, J.; Kim, D.C.; Park, H.; Kang, Y.S.; Park, H.W. Advancements and challenges in the carbon fiber-reinforced polymer (CFRP) trimming process. Int. J. Precis. Eng. Manuf.-Green Technol. 2024, 11, 1341–1360. [Google Scholar] [CrossRef]

- Zhao, C.; Zhong, J.; Wang, H.; Liu, C.; Li, M.; Liu, H. Impact behaviour and protection performance of a CFRP NPR skeleton filled with aluminum foam. Mater. Des. 2024, 246, 113295. [Google Scholar] [CrossRef]

- Li, M.; Li, S.; Tian, Y.; Zhang, H.; Zhu, W.; Ke, Y. Bottom-up stochastic multiscale model for the mechanical behavior of multidirectional composite laminates with microvoids. Compos. Part A Appl. Sci. Manuf. 2024, 181, 108144. [Google Scholar] [CrossRef]

- Zhou, W.; Zhu, W.; Xu, Q.; Ke, Y. Out-of-plane tensile failure behavior of fiber reinforced composites due to lay-up temperature induced intra-ply and inter-ply voids. Compos. Struct. 2021, 271, 114150. [Google Scholar] [CrossRef]

- Zheng, Y.; Hu, W.; van Asch, T.; Li, Y.; Fan, Y. Experimental study on the failure mechanisms of non-cohesive soil landslide dams with different scales. Eng. Geol. 2024, 333, 107489. [Google Scholar] [CrossRef]

- Wan, L.; Millen, S.L.J. Multiscale modelling of CFRP composites exposed to thermo-mechanical loading from fire. Compos. Part A Appl. Sci. Manuf. 2024, 187, 108481. [Google Scholar] [CrossRef]

- Balasubramani, N.K.; Zhang, B.; Chowdhury, N.T.; Mukkavilli, A.; Suter, M.; Pearce, G. Micro-mechanical analysis on random RVE size and shape in multiscale finite element modelling of unidirectional FRP composites. Compos. Struct. 2022, 282, 115081. [Google Scholar] [CrossRef]

- Trias, D.; Costa, J.; Mayugo, J.A.; Hurtado, J. Random models versus periodic models for fibre reinforced composites. Comput. Mater. Sci. 2006, 38, 316–324. [Google Scholar] [CrossRef]

- Brockenbrough, J.R.; Suresh, S.; Wienecke, H.A. Deformation of metal-matrix composites with continuous fibers: Geometrical effects of fiber distribution and shape. Acta Metall. Mater. 1991, 39, 735–752. [Google Scholar] [CrossRef]

- Gusev, A.A.; Hine, P.J.; Ward, I.M. Fiber packing and elastic properties of a transversely random unidirectional glass/epoxy composite. Compos. Sci. Technol. 2000, 60, 535–541. [Google Scholar] [CrossRef]

- Pyrz, R. Quantitative description of the microstructure of composites. Part I: Morphology of unidirectional composite systems. Compos. Sci. Technol. 1994, 50, 197–208. [Google Scholar] [CrossRef]

- Oh, J.H.; Jin, K.K.; Ha, S.K. Interfacial strain distribution of a unidirectional composite with randomly distributed fibers under transverse loading. J. Compos. Mater. 2006, 40, 759–778. [Google Scholar] [CrossRef]

- Vaughan, T.J.; McCarthy, C.T. A combined experimental–numerical approach for generating statistically equivalent fibre distributions for high strength laminated composite materials. Compos. Sci. Technol. 2010, 70, 291–297. [Google Scholar] [CrossRef]

- Yang, L.; Yan, Y.; Ran, Z.; Liu, Y. A new method for generating random fibre distributions for fibre reinforced composites. Compos. Sci. Technol. 2013, 76, 14–20. [Google Scholar] [CrossRef]

- Chen, J.; Wan, L.; Ismail, Y.; Ye, J.; Yang, D. A micromechanics and machine learning coupled approach for failure prediction of unidirectional CFRP composites under triaxial loading: A preliminary study. Compos. Struct. 2021, 267, 113876. [Google Scholar] [CrossRef]

- Zhou, G.; Sun, Q.; Li, D.; Meng, Z.; Peng, Y.; Chen, Z.; Zeng, D.; Su, X. Meso-scale modeling and damage analysis of carbon/epoxy woven fabric composite under in-plane tension and compression loadings. Int. J. Mech. Sci. 2021, 190, 105980. [Google Scholar] [CrossRef] [PubMed]

- He, C.; Ge, J.; Cao, X.; Chen, Y.; Chen, H.; Fang, D. The effects of fiber radius and fiber shape deviations and of matrix void content on the strengths and failure mechanisms of UD composites by computational micromechanics. Compos. Sci. Technol. 2022, 218, 109139. [Google Scholar] [CrossRef]

- Vajari, D.A. A micromechanical study of porous composites under longitudinal shear and transverse normal loading. Compos. Struct. 2015, 125, 266–276. [Google Scholar] [CrossRef]

- Sharp, N.D.; Goodsell, J.E.; Favaloro, A.J. Measuring fiber orientation of elliptical fibers from optical microscopy. J. Compos. Sci. 2019, 3, 23. [Google Scholar] [CrossRef]

- Wang, W.; Dai, Y.; Zhang, C.; Gao, X.; Zhao, M. Micromechanical modeling of fiber-reinforced composites with statistically equivalent random fiber distribution. Materials 2016, 9, 624. [Google Scholar] [CrossRef]

- Babuška, I.; Andersson, B.; Smith, P.J.; Levin, K. Damage analysis of fiber composites Part I: Statistical analysis on fiber scale. Comput. Methods Appl. Mech. Eng. 1999, 172, 27–77. [Google Scholar] [CrossRef]

- Saenz-Castillo, D.; Martín, M.I.; Calvo, S.; Rodriguez-Lence, F.; Güemes, A. Effect of processing parameters and void content on mechanical properties and NDI of thermoplastic composites. Compos. Part A Appl. Sci. Manuf. 2019, 121, 308–320. [Google Scholar] [CrossRef]

- Chanteli, A.; Bandaru, A.K.; Peeters, D.; O’HIggins, R.M.; Weaver, P.M. Influence of repass treatment on carbon fibre-reinforced PEEK composites manufactured using laser-assisted automatic tape placement. Compos. Struct. 2020, 248, 112539. [Google Scholar] [CrossRef]

- Chen, J.; Fu, K.; Li, Y. Understanding processing parameter effects for carbon fibre reinforced thermoplastic composites manufactured by laser-assisted automated fibre placement (AFP). Compos. Part A Appl. Sci. Manuf. 2021, 140, 106160. [Google Scholar] [CrossRef]

- Comer, A.J.; Ray, D.; Obande, W.O.; Jones, D.; Lyons, J.; Rosca, I.; O’Higgins, R.M.; McCarthy, M.A. Mechanical characterisation of carbon fibre–PEEK manufactured by laser-assisted automated-tape-placement and autoclave. Compos. Part A Appl. Sci. Manuf. 2015, 69, 10–20. [Google Scholar] [CrossRef]

- Almeida, J.H.S., Jr.; Miettinen, A.; Léonard, F.; Falzon, B.G.; Withers, P.J. Microstructure and damage evolution in short carbon fibre 3D-printed composites during tensile straining. Compos. Part B Eng. 2025, 292, 112073. [Google Scholar] [CrossRef]

- Eliasson, S.; Karlsson Hagnell, M.; Wennhage, P.; Barsoum, Z. An experimentally based micromechanical framework exploring effects of void shape on macromechanical properties. Materials 2022, 15, 4361. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, H.; Luo, L. Comparison analysis of the calculation methods for particle diameter. Crystals 2022, 12, 1107. [Google Scholar] [CrossRef]

- Zdilla, M.J.; Hatfield, S.A.; McLean, K.A.; Cyrus, L.M.; Laslo, J.M.; Lambert, H.W. Circularity, solidity, axes of a best fit ellipse, aspect ratio, and roundness of the foramen ovale: A morphometric analysis with neurosurgical considerations. J. Craniofacial Surg. 2016, 27, 222–228. [Google Scholar] [CrossRef]

- Zhang, D. Void Consolidation of Thermoplastic Composites via Non-Autoclave Processing. Ph.D. Thesis, University of Delaware, Newark, DE, USA, 2017. [Google Scholar]

- Liu, J.; Li, Y.; Huang, M.; Zeng, L.; Lu, Y. Generation of unidirectional fiber random distribution structures based on an artificial fish swarm algorithm with random deletion after fiber filling. J. Compos. Mater. 2023, 57, 2353–2365. [Google Scholar] [CrossRef]

- Yang, L.; Yan, Y.; Liu, Y.; Ran, Z. Microscopic failure mechanisms of fiber-reinforced polymer composites under transverse tension and compression. Compos. Sci. Technol. 2012, 72, 1818–1825. [Google Scholar] [CrossRef]

- Wang, B.; Li, M.; Fang, G.; Hu, J.; Ye, J.; Meng, S. A novel FFT framework with coupled non-local elastic-plastic damage model for the thermomechanical failure analysis of UD-CF/PEEK composites. Compos. Sci. Technol. 2024, 251, 110540. [Google Scholar] [CrossRef]

- Li, N.; Zhou, Y.D. Failure mechanism analysis of fiber-reinforced polymer composites based on multi-scale fracture plane angles. Thin-Walled Struct. 2021, 158, 107195. [Google Scholar] [CrossRef]

- Fiedler, B.; Hojo, M.; Ochiai, S.; Schulte, K.; Ando, M. Failure behavior of an epoxy matrix under different kinds of static loading. Compos. Sci. Technol. 2001, 61, 1615–1624. [Google Scholar] [CrossRef]

- He, C.; Ge, J.; Zhang, B.; Gao, J.; Zhong, S.; Liu, W.K.; Fang, D. A hierarchical multiscale model for the elastic-plastic damage behavior of 3D braided composites at high temperature. Compos. Sci. Technol. 2020, 196, 108230. [Google Scholar] [CrossRef]

- Parıs, F.; Correa, E.; Cañas, J. Micromechanical view of failure of the matrix in fibrous composite materials. Compos. Sci. Technol. 2003, 63, 1041–1052. [Google Scholar] [CrossRef]

- González, C.; LLorca, J. Mechanical behavior of unidirectional fiber-reinforced polymers under transverse compression: Microscopic mechanisms and modeling. Compos. Sci. Technol. 2007, 67, 2795–2806. [Google Scholar] [CrossRef]

- Christoff, B.G.; Almeida, J.H.S., Jr.; Ribeiro, M.L.; Maciel, M.M.; Guedes, R.M.; Tita, V. Multiscale modelling of composite laminates with voids through the direct FE2 method. Theor. Appl. Fract. Mech. 2024, 131, 104424. [Google Scholar] [CrossRef]

| Unit | Value | Standard | |

|---|---|---|---|

| Fiber volume fraction | % | 60 | EN2559 |

| Fiber weight fraction | % | 67 | EN2559 |

| Tape density | g/cm3 | 1.58 | ISO1183 |

| Tape thickness | mm | 0.14 | —— |

| Mechanical Properties | Experiment | Predicted | Error(%) | |

|---|---|---|---|---|

| Average | SD | |||

| (GPa) | 138 | 137.740 | 0.002 | 0.188 |

| 0.28 | 0.287 | 0.001 | 2.507 | |

| (GPa) | 11 | 9.465 | 0.027 | 13.952 |

| 0.4 | 0.427 | 0.002 | 6.711 | |

| In-plane shear modulus, (GPa) | 5.5 | 4.918 | 4.918 | 10.586 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Li, Y.; Luan, X.; Meng, B.; Liu, J.; Lu, Y. Effects of Void Characteristics on the Mechanical Properties of Carbon Fiber Reinforced Polyetheretherketone Composites: Micromechanical Modeling and Analysis. Polymers 2025, 17, 1721. https://doi.org/10.3390/polym17131721

Zhang Y, Li Y, Luan X, Meng B, Liu J, Lu Y. Effects of Void Characteristics on the Mechanical Properties of Carbon Fiber Reinforced Polyetheretherketone Composites: Micromechanical Modeling and Analysis. Polymers. 2025; 17(13):1721. https://doi.org/10.3390/polym17131721

Chicago/Turabian StyleZhang, Yong, Yibo Li, Xi Luan, Bin Meng, Jinsong Liu, and Yan Lu. 2025. "Effects of Void Characteristics on the Mechanical Properties of Carbon Fiber Reinforced Polyetheretherketone Composites: Micromechanical Modeling and Analysis" Polymers 17, no. 13: 1721. https://doi.org/10.3390/polym17131721

APA StyleZhang, Y., Li, Y., Luan, X., Meng, B., Liu, J., & Lu, Y. (2025). Effects of Void Characteristics on the Mechanical Properties of Carbon Fiber Reinforced Polyetheretherketone Composites: Micromechanical Modeling and Analysis. Polymers, 17(13), 1721. https://doi.org/10.3390/polym17131721