Durability Assessment of Eco-Friendly Intumescent Coatings Based on Cork and Waste Glass Fillers for Naval Fire Safety

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials and Coatings Preparation

2.2. UV Aging Test

2.3. Coatings Characterization

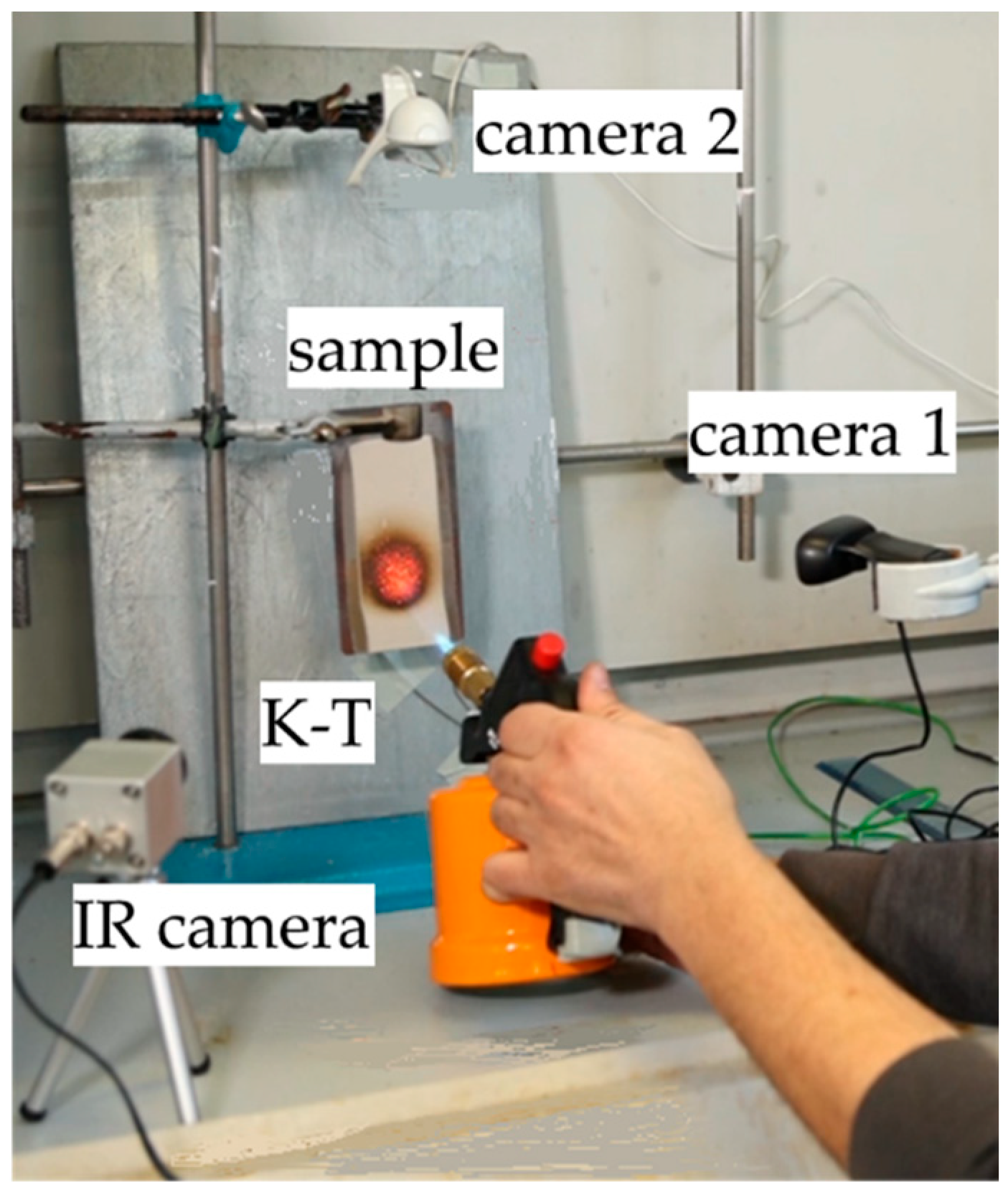

2.4. Intumescent Layer Growth Test

3. Results and Discussion

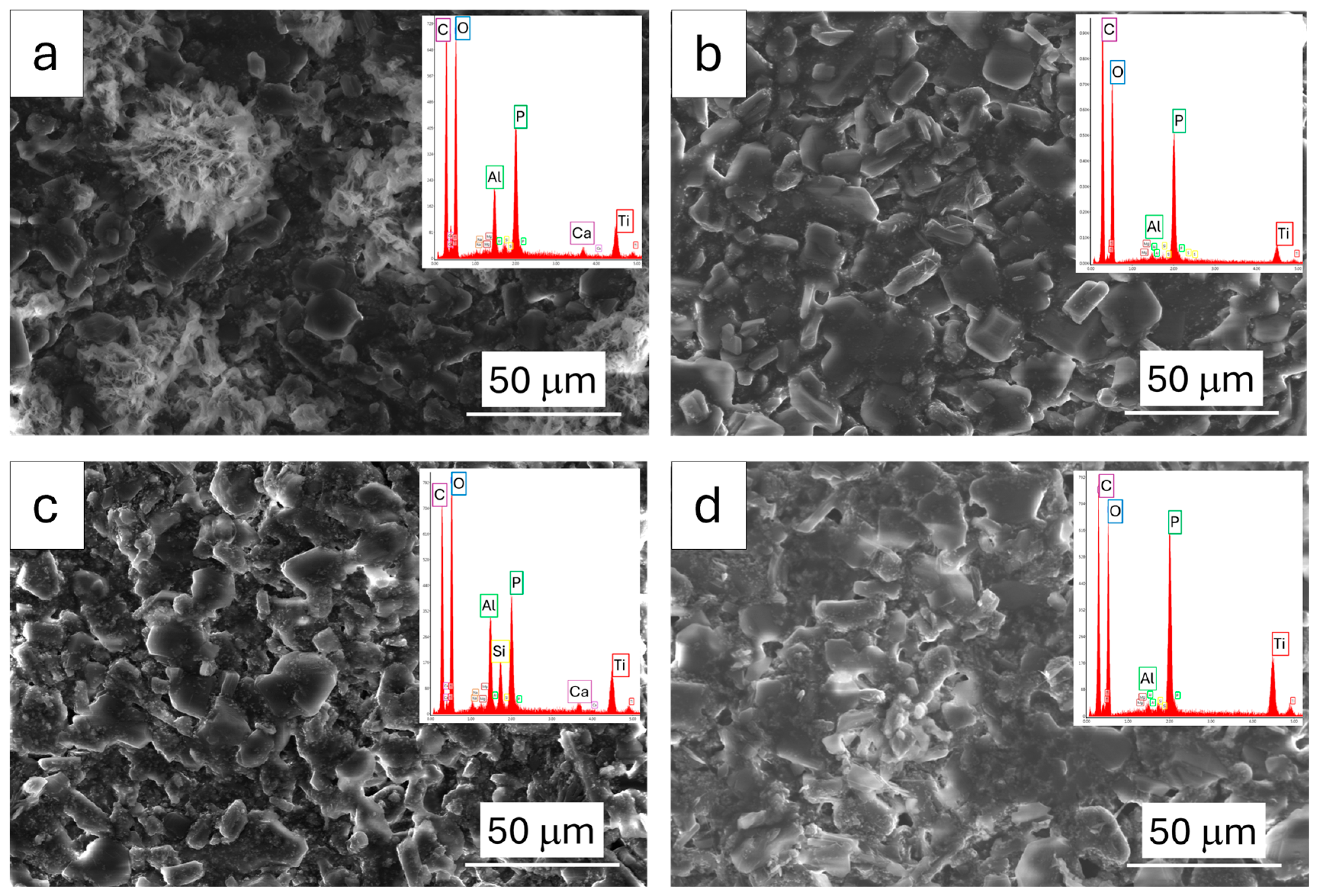

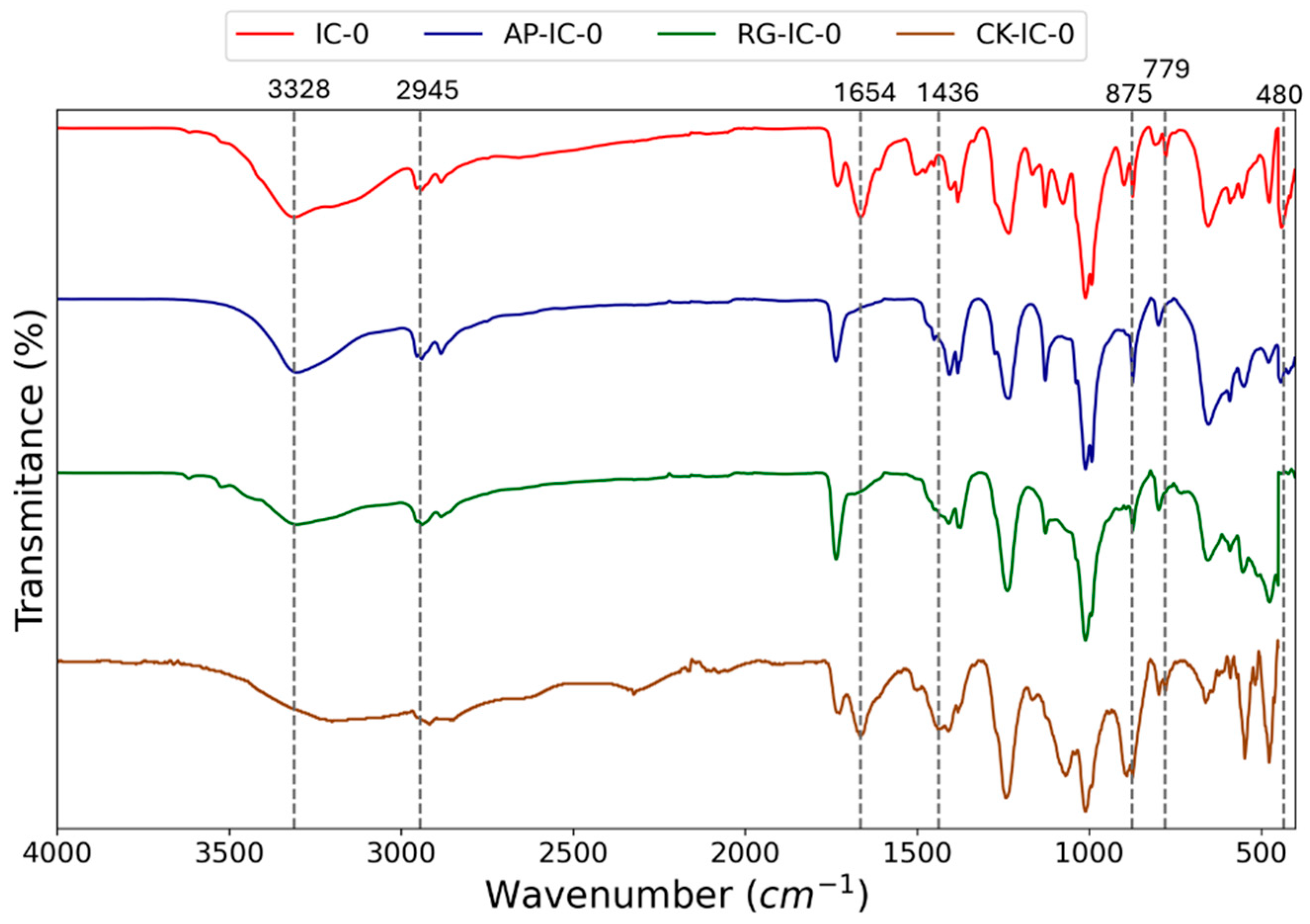

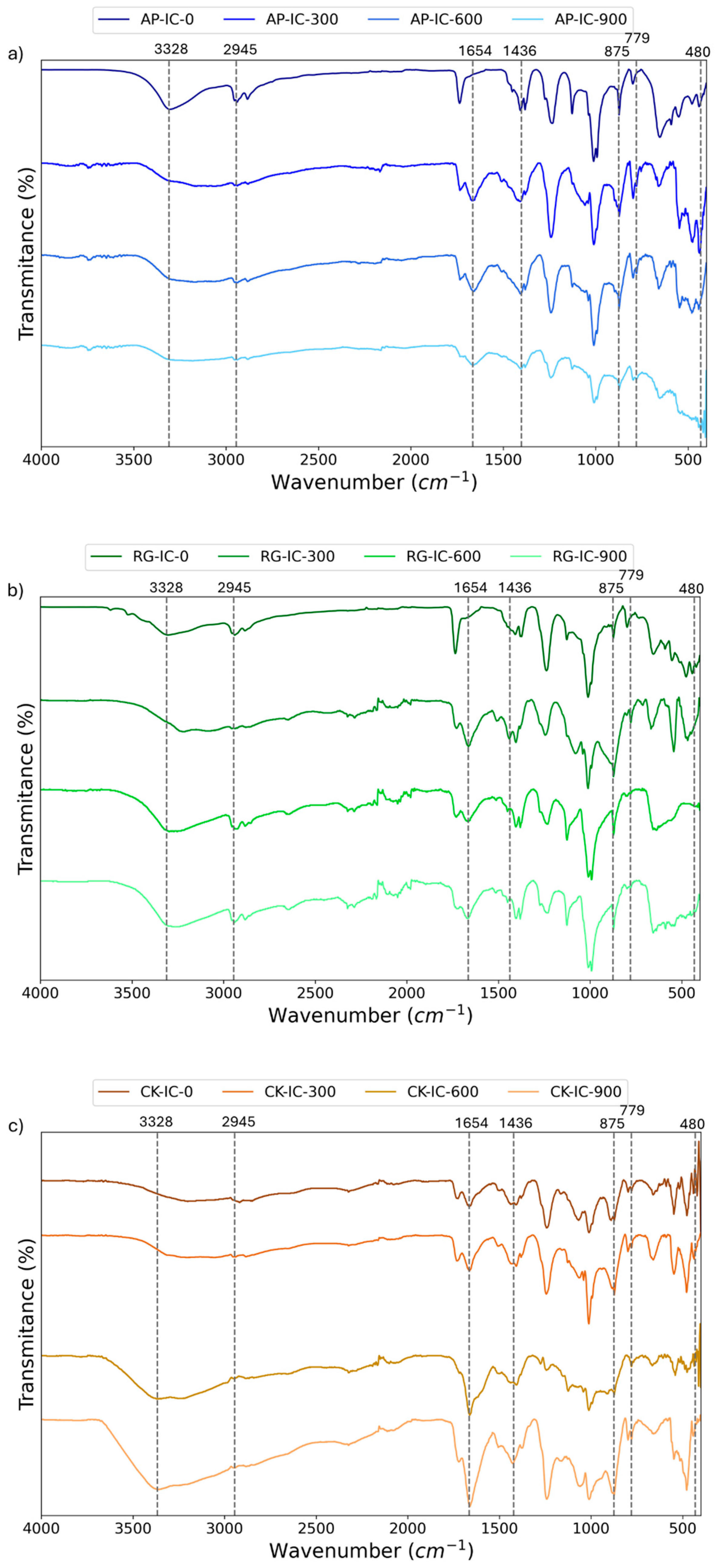

3.1. Chemo-Physical Characterization

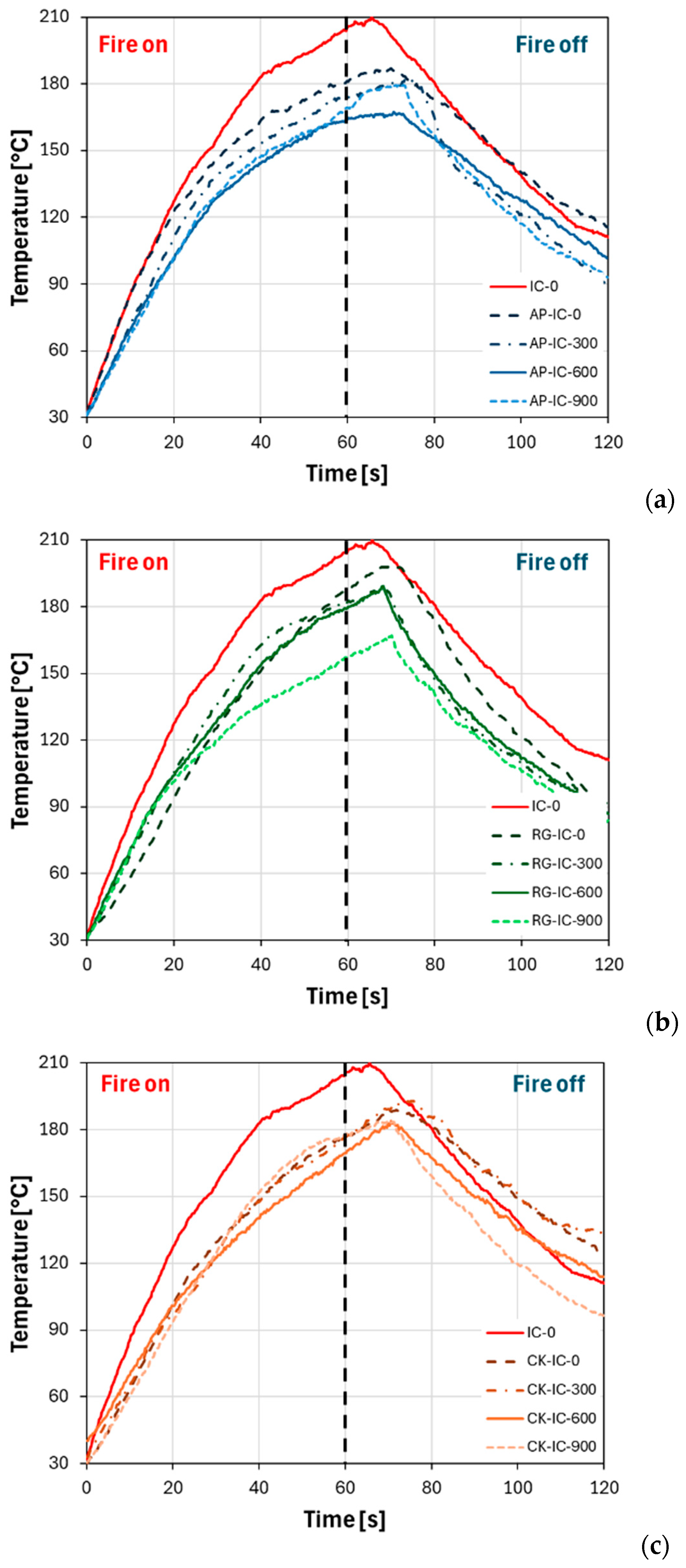

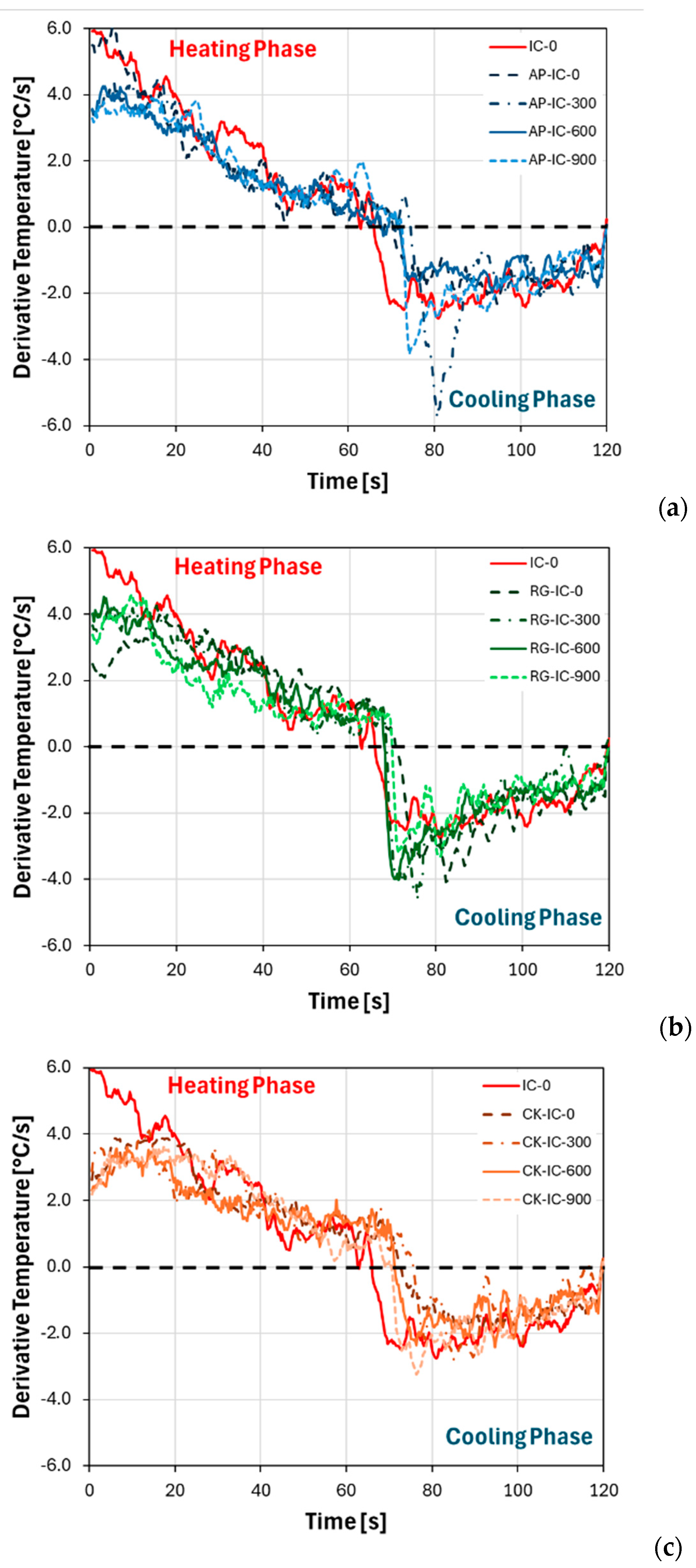

3.2. Fire Resistance Test of the Intumescent Coatings

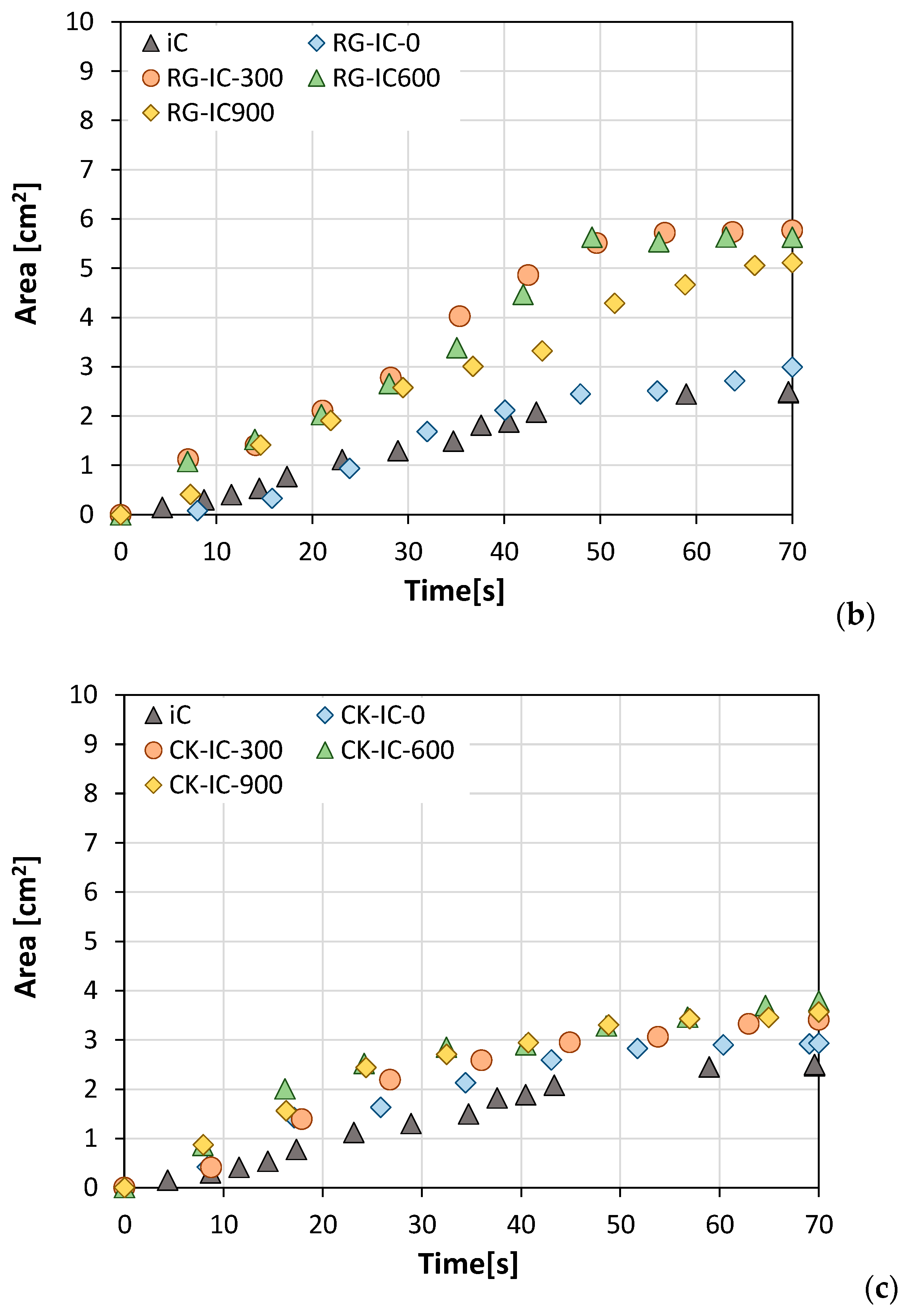

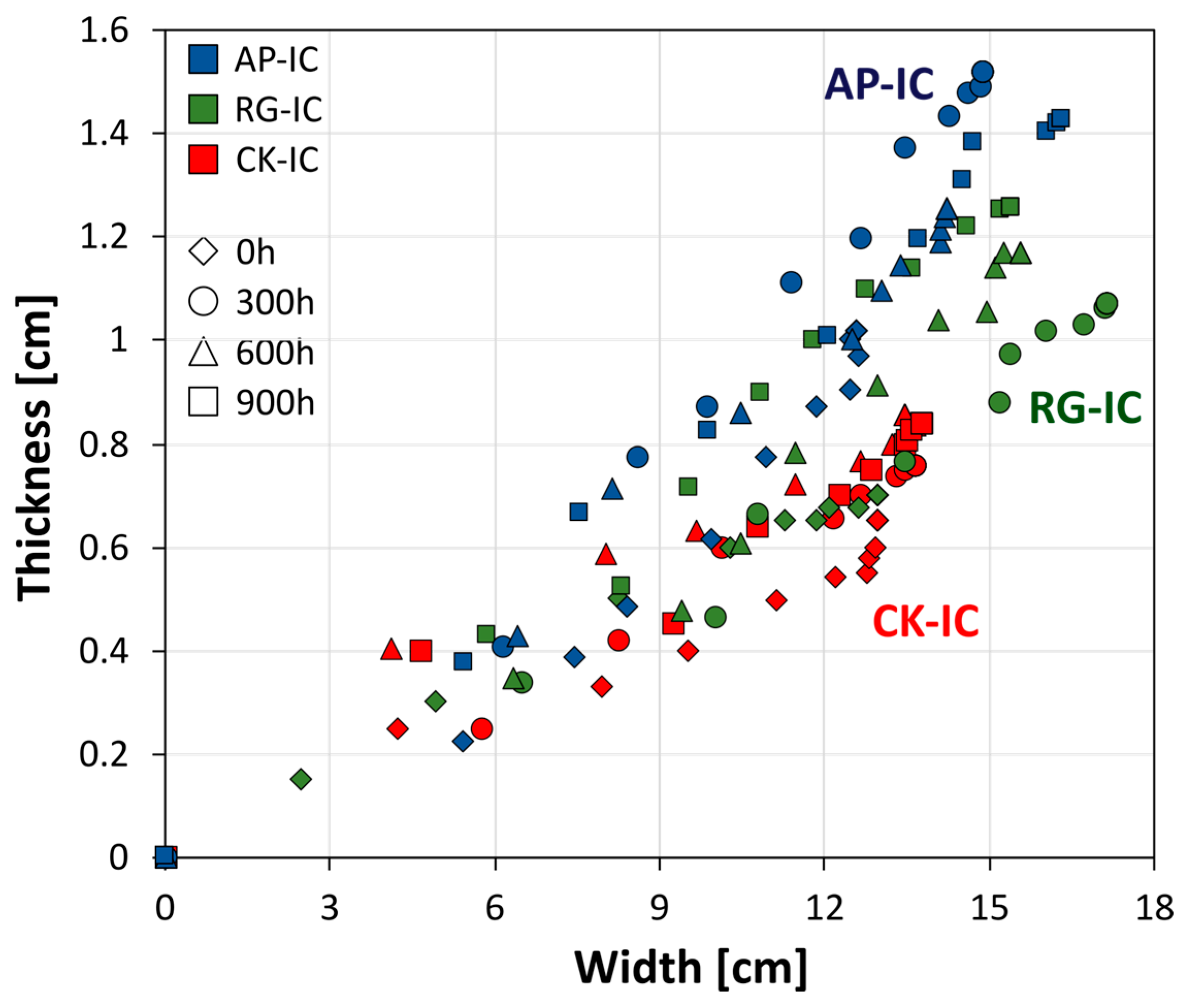

- The CK-IC (cork-filled) batch showed a rapid stabilization of its intumescent area, indicating the saturation of its foaming process. Notably, its performance experienced a slight increase due to UV aging exposure. For instance, the intumescent area for CK-IC-0 (unaged) was approximately 3.0 cm2, while CK-IC-900 (900 h UV aged) reached 3.7 cm2, representing a 23% increase. This unexpected enhancement in intumescence after UV aging for the cork-filled coating may be attributed to coupled sensitive photo-oxidation of the cork particles and the resin matrix [31]. This could lead to the formation of new functional groups [32] that serve as additional gas sources or charring agents when exposed to fire, thereby promoting a more robust or stable char structure [33]. Additionally, UV exposure may induce chemical modifications (e.g., cross-linking or oxidation) in the polymer matrix [34,35], which, upon heating, could enhance char formation and contribute to a more rigid and mechanically stable char.

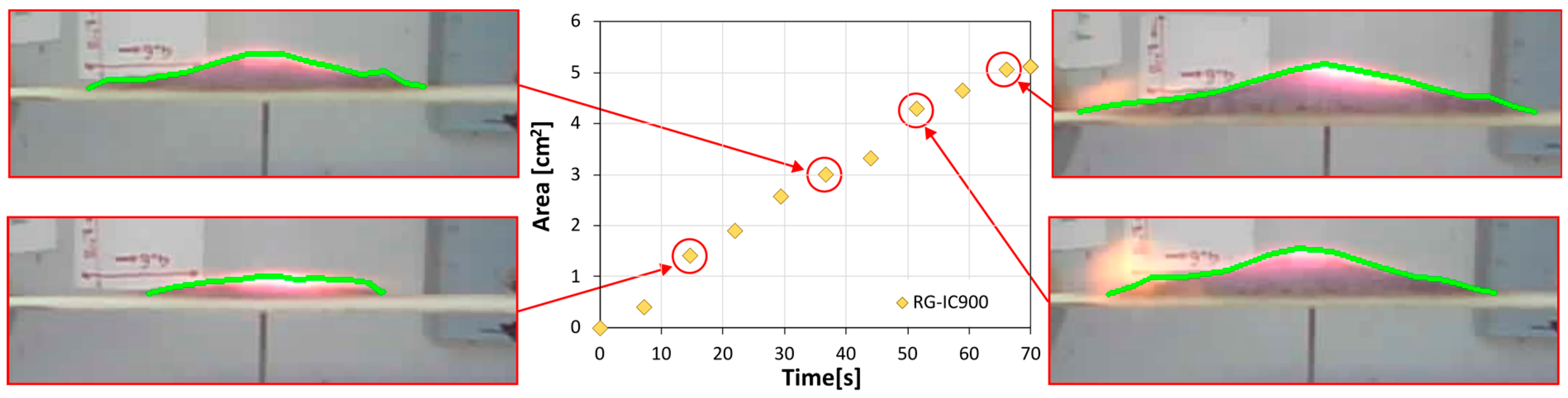

- Conversely, the RG-IC (recycled glass-filled) batch also exhibited rapid stabilization but demonstrated a notably better foaming action, evidenced by an approximately 40% higher intumescence than the CK-IC batch. Unlike the cork-based samples, the recycled glass batch showed a significant dependence on UV aging exposure. Its intumescent behavior increased substantially, as confirmed by the foamed cross-sectional area that doubled in the UV-aged samples. However, no large differences were identified among the various UV-aged RG-IC samples. The increased intumescence with UV aging in the recycled glass-filled coatings could be ascribed to some synergistic factors. Coupled with resin modification as previously indicated, UV radiation might induce surface modifications on the glass particles, added as filler, potentially creating more reactive sites or altering their interaction with the polymer matrix and intumescent agents [36]. This could facilitate more efficient gas release or improve the mechanical integrity of the char, leading to enhanced expansion. The lack of significant difference between the UV-aged samples suggests that the primary UV-induced effect reaches saturation relatively early in the aging process.

- Meanwhile, the AP-IC (ammonium polyphosphate-filled) batch demonstrated an improved intumescence profile. Around 30–40 s, their area curves sharply increased due to the efficient foaming action supplied primarily by the ammonium polyphosphate (APP) within the formulation, significantly amplifying the intumescent action. After 70 s, the AP-IC samples achieved cross-sectional intumescent areas ranging from 7.0 to 9.1 cm2. These results confirm the superior performance of the APP-filled coating, exhibiting an intumescent area approximately two times larger than the traditional IC (unfilled) formulation. The pronounced increase in intumescence for the ammonium polyphosphate (APP)-filled coating is primarily attributed to APP’s role as a potent acid source and gas-generating agent within the intumescent system. Upon heating, APP decomposes to release phosphoric acid, which then promotes the charring of carbonific agents (like pentaerythritol) and generates non-flammable gases (e.g., ammonia). This coordinated action drives the rapid and extensive foaming of the coating, creating a highly effective insulating char layer that significantly amplifies the intumescent action.

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Zhan, W.; Li, L.; Chen, L.; Kong, Q.; Chen, M.; Chen, C.; Zhang, Q.; Jiang, J. Biomaterials in Intumescent Fire-Retardant Coatings: A Review. Prog. Org. Coat. 2024, 192, 108483. [Google Scholar] [CrossRef]

- Li, Y.; Cao, C.-F.; Chen, Z.-Y.; Liu, S.-C.; Bae, J.; Tang, L.-C.; Li, Y.; Cao, C.-F.; Chen, Z.-Y.; Liu, S.-C.; et al. Waterborne Intumescent Fire-Retardant Polymer Composite Coatings: A Review. Polymers 2024, 16, 2353. [Google Scholar] [CrossRef] [PubMed]

- Soares, I.; Ferreira, J.L.; Silva, H.; Rodrigues, M.P. Fire-Retardant and Fire-Resistant Coatings: From Industry to the Potential Use on Cultural Heritage. J. Cult. Herit. 2024, 68, 316–327. [Google Scholar] [CrossRef]

- Piperopoulos, E.; Grifò, G.; Scionti, G.; Atria, M.; Calabrese, L.; Consolo, G.; Proverbio, E. Study of Intumescent Coatings Growth for Fire Retardant Systems in Naval Applications: Experimental Test and Mathematical Model. Coatings 2022, 12, 1180. [Google Scholar] [CrossRef]

- Vakhitova, L.; Kalafat, K.; Vakhitov, R.; Drizhd, V. Improving the Fire-Retardant Performance of Industrial Reactive Coatings for Steel Building Structures. Heliyon 2024, 10, e34729. [Google Scholar] [CrossRef] [PubMed]

- Piperopoulos, E.; Scionti, G.; Atria, M.; Calabrese, L.; Valenza, A.; Proverbio, E. Optimizing Ammonium Polyphosphate–Acrylic Intumescent Coatings with Sustainable Fillers for Naval Fire Safety. Materials 2024, 17, 5222. [Google Scholar] [CrossRef]

- Zhao, W.; Kumar Kundu, C.; Li, Z.; Li, X.; Zhang, Z. Flame Retardant Treatments for Polypropylene: Strategies and Recent Advances. Compos. Part. A Appl. Sci. Manuf. 2021, 145, 106382. [Google Scholar] [CrossRef]

- Huang, Y.; Li, L.; Qian, L. Synergistic Effect Between Oxides and Flame Retardants to Construct Multilayer Char in Intumescent Coatings for Steel Structure. Fire Technol. 2024, 61, 2189–2215. [Google Scholar] [CrossRef]

- Wang, L.L.; Wang, Y.C.; Li, G.Q.; Zhang, Q.Q. An Experimental Study of the Effects of Topcoat on Aging and Fire Protection Properties of Intumescent Coatings for Steel Elements. Fire Saf. J. 2020, 111, 102931. [Google Scholar] [CrossRef]

- Wang, X.; Weinell, C.E.; Ring, L.; Kiil, S. Thermal Insulation Performance and Char Formation and Degradation Mechanisms of Boron-Containing Hydrocarbon Intumescent Coatings. Fire Saf. J. 2021, 123, 103369. [Google Scholar] [CrossRef]

- Zhang, L.; Hu, Y.; Li, M. Combined Heat Transfer Mechanisms in the Porous Char Layer Formed from the Intumescent Coatings under Fire. Coatings 2021, 11, 200. [Google Scholar] [CrossRef]

- Lim, K.-S.; Bee, S.-T.; Sin, L.T.; Tee, T.-T.; Ratnam, C.T.; Hui, D.; Rahmat, A.R. A Review of Application of Ammonium Polyphosphate as Intumescent Flame Retardant in Thermoplastic Composites. Compos. B Eng. 2016, 84, 155–174. [Google Scholar] [CrossRef]

- Zybina, O.; Gravit, M. Basic Ingredients of Intumescent Compositions. In Intumescent Coatings for Fire Protection of Building Structures and Materials; Zybina, O., Gravit, M., Eds.; Springer International Publishing: Cham, Switzerland, 2020; pp. 1–51. ISBN 978-3-030-59422-0. [Google Scholar]

- Kowalczyk, K.; Kowalczyk, A. Intumescent Coatings Modified with Cocoa Shells as a Bio-Substitute for Pentaerythritol. Prog. Org. Coat. 2024, 186, 108046. [Google Scholar] [CrossRef]

- Ng, Y.H.; Dasari, A.; Tan, K.H.; Qian, L. Intumescent Fire-Retardant Acrylic Coatings: Effects of Additive Loading Ratio and Scale of Testing. Prog. Org. Coat. 2021, 150, 105985. [Google Scholar] [CrossRef]

- Kang, J.; Takahashi, F.; T’ien, J.S. In Situ Thermal-Conductivity Measurements and Morphological Characterization of Intumescent Coatings for Fire Protection. J. Fire Sci. 2018, 36, 419–437. [Google Scholar] [CrossRef]

- Andrzejewski, J.; Kemnitz, Ł.; Sałasińska, K. The Development of a New Type of Sustainable Flame Retarded Polyamide 6 (PA6)-Based Composites, Modified with Biocarbon/Phosphorus Flame Retardant/Basalt Fiber System (BC/OP/BF). The Evaluation of the Material Performance and Flammability. Polym. Degrad. Stab. 2024, 229, 111002. [Google Scholar] [CrossRef]

- Wang, F.; Liu, H.; Yan, L.; Feng, Y. Comparative Study of Fire Resistance and Anti-Ageing Properties of Intumescent Fire-Retardant Coatings Reinforced with Conch Shell Bio-Filler. Polymers 2021, 13, 2620. [Google Scholar] [CrossRef] [PubMed]

- Kuyyakanont, A.; Iwata, M. Study of Different Degradation Effects in UV-Sensitive Polymers Using Xenon Lamp and Deuterium Lamp to Simulate UV Irradiation in Space Environment. Nucl. Instrum. Methods Phys. Res. B 2024, 549, 165267. [Google Scholar] [CrossRef]

- Zhang, T.; Huang, H.; Ge, X.; Zhang, Z.; Li, P. Experimental Study of UV/Water-Spray Coupled Hydrothermal Accelerated Aging on Fire Resistive of Intumescent Coatings for Steel Structures. J. Phys. Conf. Ser. 2021, 2044, 012036. [Google Scholar] [CrossRef]

- Zaki, A.; Elkady, R.M.; Khalaf, T.M.; Elkady, M.A.; Shebl, S. Impact of Accelerated Weathering on Fire Resistance Performance of Intumescent Materials. Mater. Sci. Forum 2023, 1089, 175–182. [Google Scholar] [CrossRef]

- Häßler, D.; Mund, M.; Daus, L.H.; Hothan, S.; Schaumann, P.; Schartel, B. Durability of Intumescent Coatings and Recommendations for Test Concepts for a Working Life of More than 10 Years. Fire Saf. J. 2024, 146, 104173. [Google Scholar] [CrossRef]

- Troitzsch, J.H. Fire Performance Durability of Flame Retardants in Polymers and Coatings. Adv. Ind. Eng. Polym. Res. 2024, 7, 263–272. [Google Scholar] [CrossRef]

- Sandinge, A.; Blomqvist, P.; Dederichs, A.; Markert, F. The Necessity of Accelerated Ageing in Fire Performance Assessments of Composite Materials. Saf. Sci. 2021, 141, 105358. [Google Scholar] [CrossRef]

- Luo, Y.; Liu, Y.; Wang, D.; Liu, L.; Gao, X.; Zhang, Q.; Zhang, J. Research on UV Aging Evolution Mechanism of Metakaolin Base Geopolymer Coatings. Constr. Build. Mater. 2024, 416, 134935. [Google Scholar] [CrossRef]

- Wang, L.L.; Wang, Y.C.; Li, G.Q. Experimental Study of Hydrothermal Aging Effects on Insulative Properties of Intumescent Coating for Steel Elements. Fire Saf. J. 2013, 55, 168–181. [Google Scholar] [CrossRef]

- Alvarez-Gayosso, C.; Canseco, M.A.; Estrada, R.; Palacios-Alquisira, J.; Hinojosa, J.; Castaño, V.M. Preparation and Microstructure of Cobalt(III) Poly (Acrylate) Hybrid Materials. Int. J. Basic. Appl. Sci. 2015, 4, 255–263. [Google Scholar] [CrossRef]

- Deng, C.L.; Deng, C.; Zhao, J.; Li, R.M.; Fang, W.H.; Wang, Y.Z. Simultaneous Improvement in the Flame Retardancy and Water Resistance of PP/APP through Coating UV-Curable Pentaerythritol Triacrylate onto APP. Chin. J. Polym. Sci. 2015, 33, 203–214. [Google Scholar] [CrossRef]

- Wang, J.; Zhao, M. Study on the Effects of Aging by Accelerated Weathering on the Intumescent Fire Retardant Coating for Steel Elements. Eng. Fail. Anal. 2020, 118, 104920. [Google Scholar] [CrossRef]

- de Sá, S.C.; de Souza, M.M.; Peres, R.S.; Zmozinski, A.V.; Braga, R.M.; de Araújo Melo, D.M.; Ferreira, C.A. Environmentally Friendly Intumescent Coatings Formulated with Vegetable Compounds. Prog. Org. Coat. 2017, 113, 47–59. [Google Scholar] [CrossRef]

- Sergi, C.; Sarasini, F.; Felici, A.C.; Bracciale, M.P.; Tirillò, J. Effects of Accelerated Aging on Compressive Response of Natural and Synthetic Core Materials: Freeze-Thaw Cycles and UV Radiation. Wood Mater. Sci. Eng. 2024, 19, 253–263. [Google Scholar] [CrossRef]

- Mostefaoui, O.; Iannuzzi, Z.; Lopez, D.; Mignot, E.; Lipeme-Kouyi, G.; Bayard, R.; Massardier-Nageotte, V.; Mourier, B. Quantitative Study of Microplastic Degradation in Urban Hydrosystems: Comparing in Situ Environmentally Aged Microplastics vs. Artificially Aged Materials Generated via Accelerated Photo-Oxidation. J. Hazard. Mater. 2025, 486, 137087. [Google Scholar] [CrossRef] [PubMed]

- Cai, S.X.; Kanskar, M.; Wybourne, M.N.; Keana, J.F.W. Introduction of Functional Groups into Polymer Films via Deep-UV Photolysis or Electron-Beam Lithography: Modification of Polystyrene and Poly(3-Octylthiophene) by a Functionalized Perfluorophenyl Azide. Chem. Mater. 1992, 4, 879–884. [Google Scholar] [CrossRef]

- Kim, H.J.; Czech, Z.; Bartkowiak, M.; Shim, G.S.; Kabatc, J.; Licbarski, A. Study of UV-Initiated Polymerization and UV Crosslinking of Acrylic Monomers Mixture for the Production of Solvent-Free Pressure-Sensitive Adhesive Films. Polym. Test. 2022, 105, 107424. [Google Scholar] [CrossRef]

- Fu, Y.W.; Sun, W.F.; Wang, X. UV-Initiated Crosslinking Reaction Mechanism and Electrical Breakdown Performance of Crosslinked Polyethylene. Polymers 2020, 12, 420. [Google Scholar] [CrossRef]

- Beil, S.; Horn, H.; Windisch, A.; Hilgers, C.; Pochner, K. Photochemical Functionalization of Polymer Surfaces for Subsequent Metallization. Surf. Coat. Technol. 1999, 116–119, 1195–1203. [Google Scholar] [CrossRef]

| Code | Characteristics |

|---|---|

| IC | Standard intumescent coating |

| AP-IC | Intumescent coating with increased ammonium polyphosphate |

| RG-IC | Intumescent coating with recycled glass microparticles |

| CK-IC | Intumescent coating with cork particulates |

| Sample Code | Max Temperature [°C] | Max Heating Rate [°C/s] | Cross-Over Point [s] |

|---|---|---|---|

| SS | 430.8 ± 37.9 | 9.9 ± 0.9 | 82.9 ± 7.4 |

| IC | 210.0 ± 19.1 | 5.9 ± 0.5 | 62.6 ± 6.0 |

| AP-IC-0 | 187.0 ± 15.9 | 6.0 ± 0.5 | 67.0 ± 6.4 |

| AP-IC-300 | 182.1 ± 15.1 | 4.5 ± 0.4 | 70.4 ± 6.5 |

| AP-IC-600 | 167.3 ± 16.4 | 4.3 ± 0.4 | 67.3 ± 6.3 |

| AP-IC-900 | 179.5 ± 18.0 | 3.9 ± 0.4 | 72.4 ± 7.2 |

| RG-IC-0 | 198.7 ± 19.9 | 4.0 ± 0.4 | 70.4 ± 6.5 |

| RG-IC-300 | 190.1 ± 18.1 | 4.3 ± 0.4 | 68.3 ± 5.9 |

| RG-IC-600 | 188.9 ± 16.6 | 4.5 ± 0.5 | 67.8 ± 5.5 |

| RG-IC-900 | 166.9 ± 14.0 | 4.6 ± 0.4 | 69.8 ± 6.2 |

| CK-IC-0 | 188.7 ± 17.0 | 4.0 ± 0.4 | 72.3 ± 6.8 |

| CK-IC-300 | 193.0 ± 16.6 | 3.9 ± 0.4 | 75.5 ± 7.0 |

| CK-IC-600 | 183.9 ± 16.9 | 3.6 ± 0.4 | 71.1 ± 6.8 |

| CK-IC-900 | 183.6 ± 17.1 | 3.6 ± 0.4 | 68.8 ± 6.7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Piperopoulos, E.; Scionti, G.; Atria, M.; Calabrese, L.; Valenza, A.; Proverbio, E. Durability Assessment of Eco-Friendly Intumescent Coatings Based on Cork and Waste Glass Fillers for Naval Fire Safety. Polymers 2025, 17, 1659. https://doi.org/10.3390/polym17121659

Piperopoulos E, Scionti G, Atria M, Calabrese L, Valenza A, Proverbio E. Durability Assessment of Eco-Friendly Intumescent Coatings Based on Cork and Waste Glass Fillers for Naval Fire Safety. Polymers. 2025; 17(12):1659. https://doi.org/10.3390/polym17121659

Chicago/Turabian StylePiperopoulos, Elpida, Giuseppe Scionti, Mario Atria, Luigi Calabrese, Antonino Valenza, and Edoardo Proverbio. 2025. "Durability Assessment of Eco-Friendly Intumescent Coatings Based on Cork and Waste Glass Fillers for Naval Fire Safety" Polymers 17, no. 12: 1659. https://doi.org/10.3390/polym17121659

APA StylePiperopoulos, E., Scionti, G., Atria, M., Calabrese, L., Valenza, A., & Proverbio, E. (2025). Durability Assessment of Eco-Friendly Intumescent Coatings Based on Cork and Waste Glass Fillers for Naval Fire Safety. Polymers, 17(12), 1659. https://doi.org/10.3390/polym17121659