Optimizing Mechanical and Microstructural Properties of Sandy Clayey Silt Stabilized with Lignin Fiber and Cement Synergy

Abstract

1. Introduction

2. Materials and Methods

2.1. Experimental Materials

- (1)

- Sandy clayey silt

- (1)

- Dry the air-dried and crushed powdered clay through a sieve.

- (2)

- Turn on the computer and laser particle size analyzer and run the program.

- (3)

- After the instrument absorbs water and removes air bubbles, use a small spoon to add the appropriate amount of dispersal sodium phosphate to a small amount of the sample.

- (4)

- Record the test data and analyze the test results. The grain gradation of sandy clayey silt is shown in Table 2, and its particle size distribution is shown in Figure 1b. In Table 2, d90, d60, d30, and d10 are particle diameters of the soil mass, which are less than the particle sizes of 0.09 mm, 0.06 mm, 0.03 mm, and 0.01 mm accounting for the total soil mass, respectively. Cu and Cc are the nonuniform coefficient and curvature coefficient, respectively.

- (2)

- Treated sandy clayey silt

2.2. Experimental Measurements and Curing

- (1)

- Unconfined Compressive Test

- (1)

- The masses of lignin fiber, cement, sandy clayey silt, and water are weighed according to the ratio designed in the test scheme.

- (2)

- Mix the lignin fiber, cement, and sandy clayey silt in dry condition manually for 1 min to make each material contact evenly. Then, add an appropriate amount of water to the dried-mixed material, and use an electric mixer to mix for 3–5 min with a moisture content of 24%.

- (3)

- Each sample was compacted in three equal layers, with each layer subjected to 25 blows using a standardized rammer (2.5 kg mass, 300 mm drop height). The final density of all samples was maintained within ±1.5% of the target value (1.66 g/cm3).

- (4)

- Prepare the samples with a size of 39.1 × 80 mm (diameter × height) by using a triaxial sampler. Then put the samples into the standard constant temperature and humidity curing box for the specified curing period. The prepared soil samples and standard curing box are shown in Figure 3.

- (5)

- When the sample reaches the curing period (1 d, 7 d, 14 d, or 30 d), the YYW-2 strain-controlled unconfined compressor is utilized with an axial strain rate of 1%/min. The finally loaded axial strain is controlled at 3–5% when the axial stress reaches the peak or the stable state. During loading, the axial stress and axial strain are measured and recorded.

- (6)

- Samples cured for 30 d are selected for SEM-EDX analysis to evaluate the stabilized microstructure at hydration equilibrium, ensuring representative insights into long-term performance. This aligns with ASTM C192 guidelines and prior studies on cementitious stabilization. It is conducted in Section 3.

- (2)

- SEM-EDX analysis

2.3. UCS Tests and Data Analysis

3. Results and Discussions

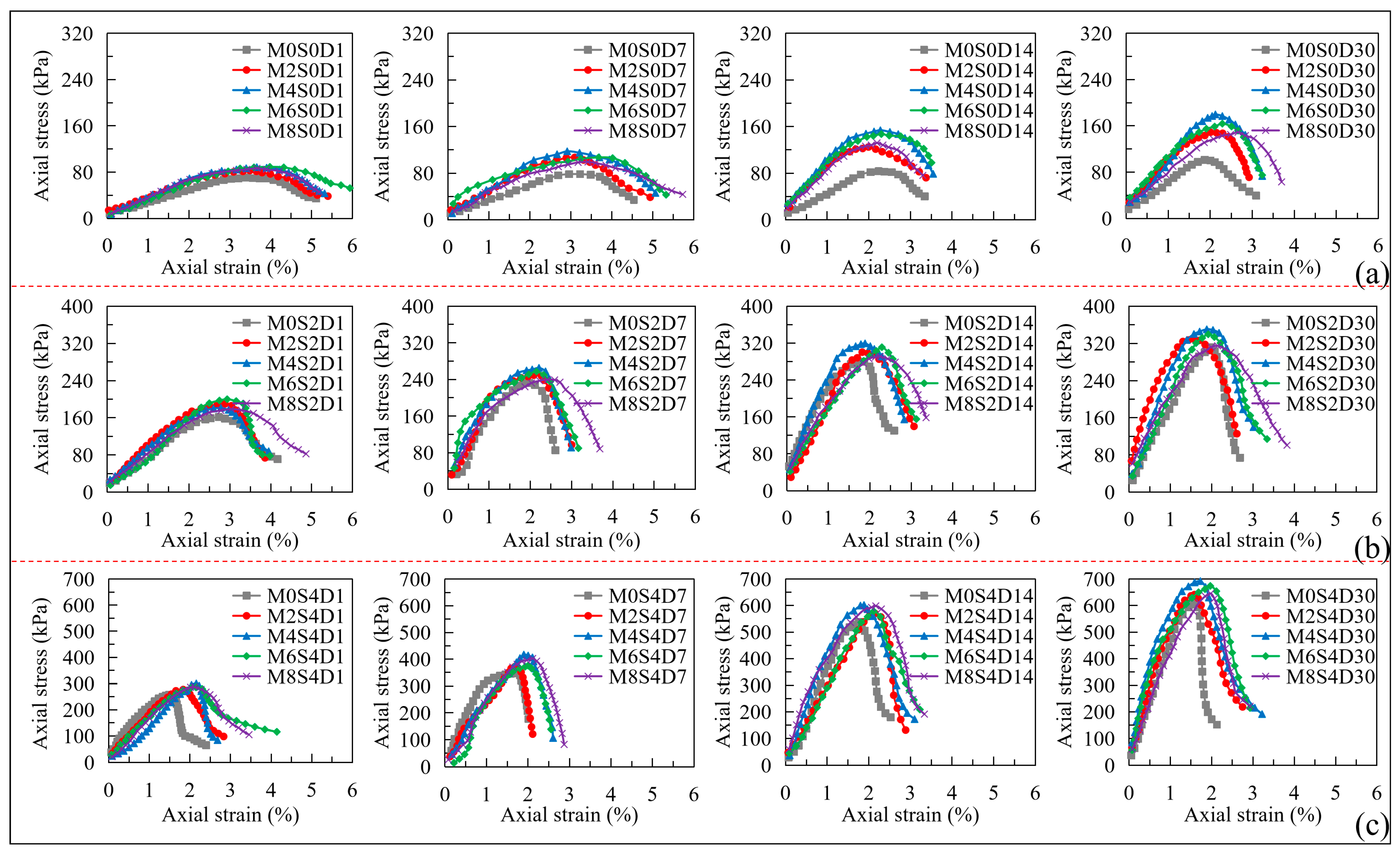

3.1. Mechanical Behavior Under Combined Fiber-Cement Stabilization

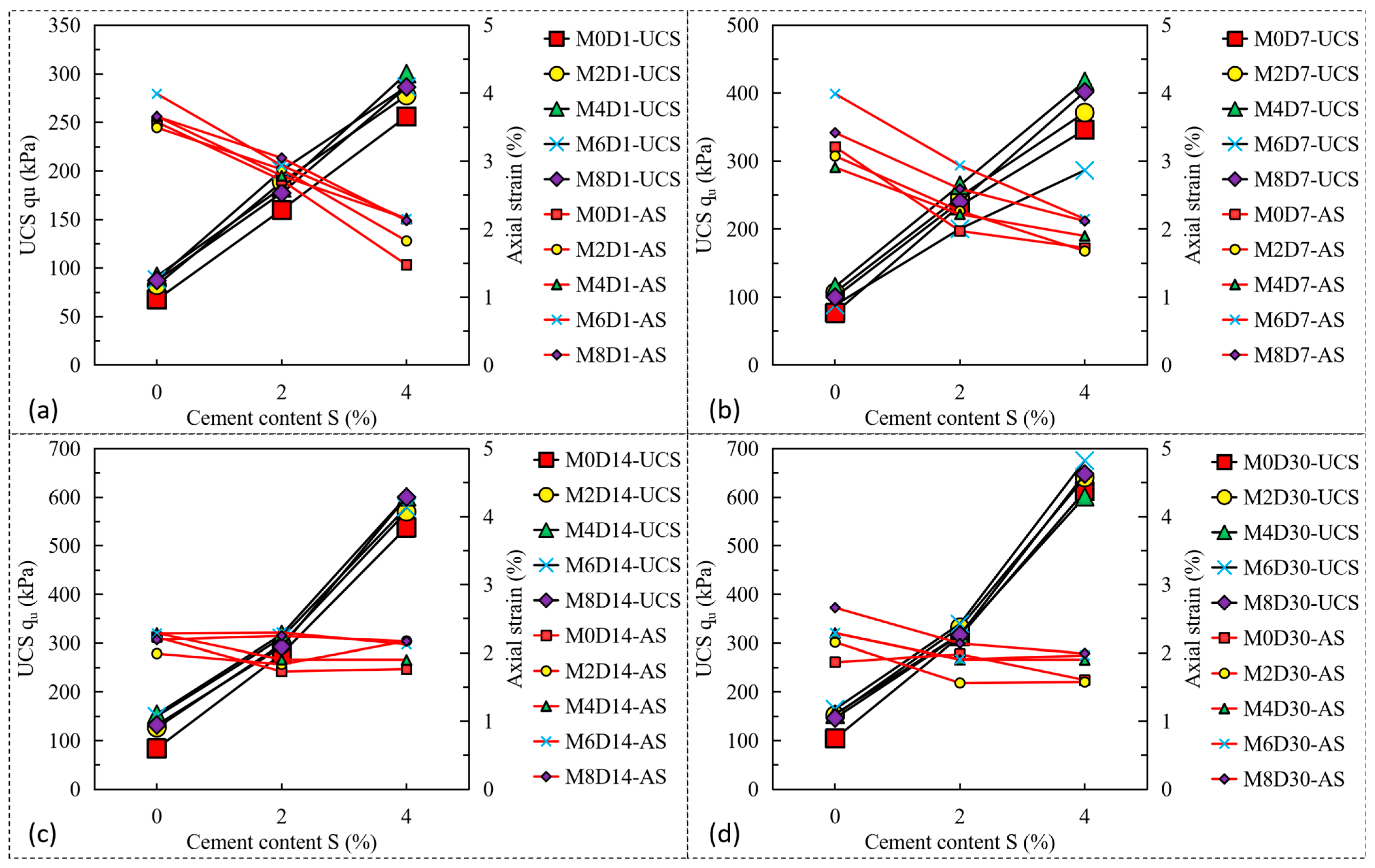

3.2. Role of Curing Time on Strength-Ductility Transition

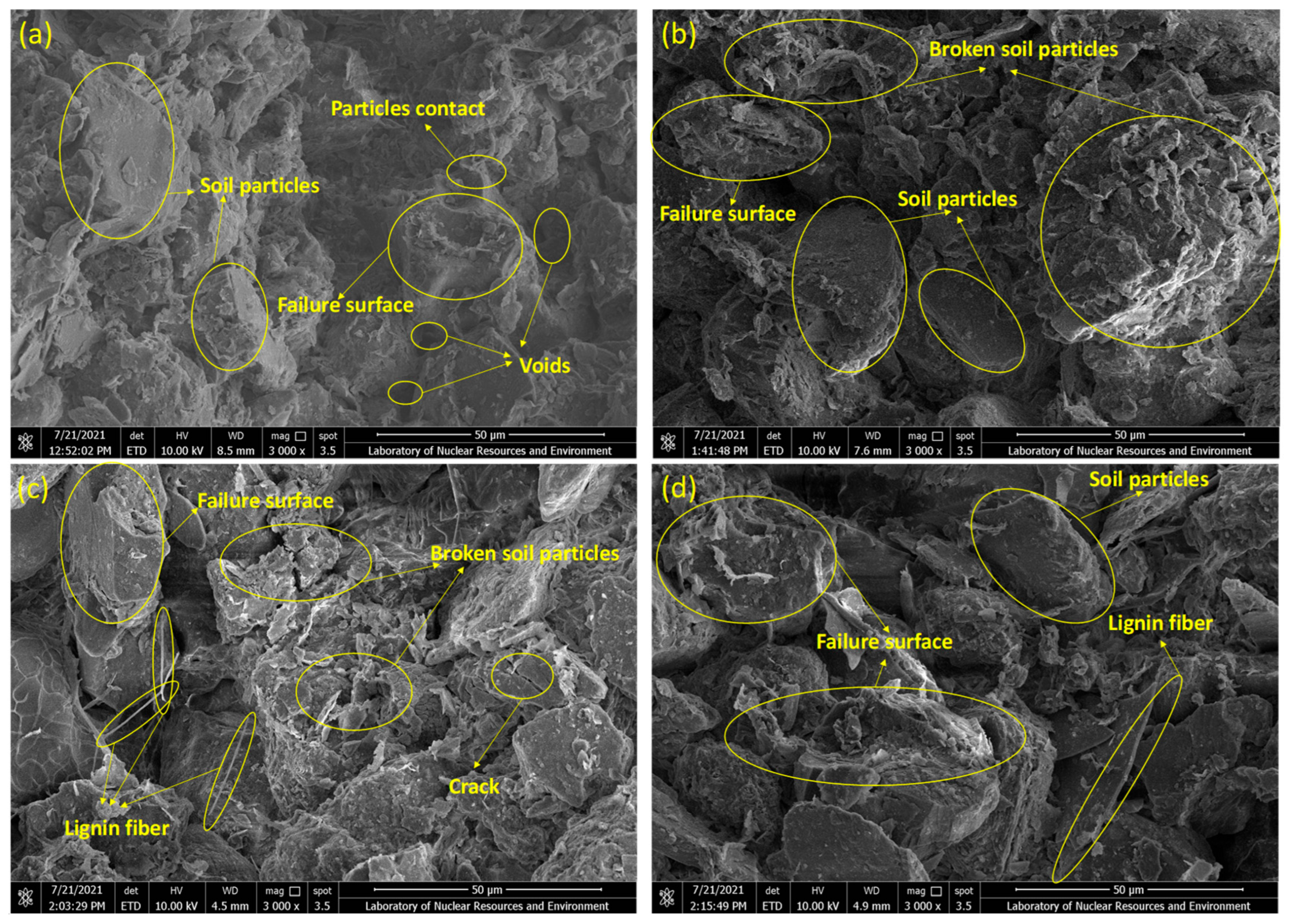

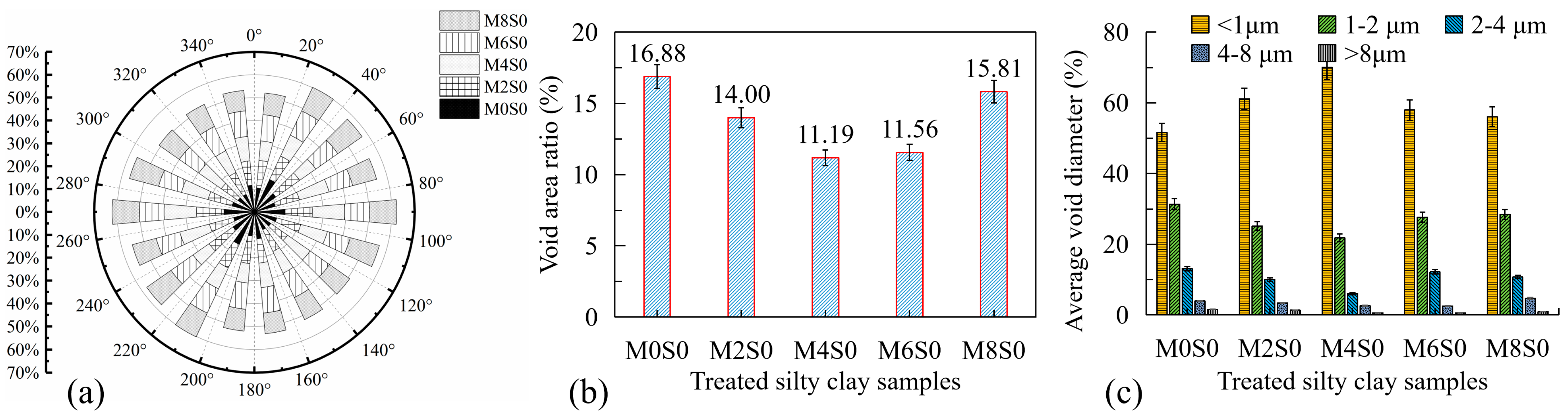

3.3. Synergistic Microstructural Mechanisms

4. Conclusions

- (1)

- The mechanical properties of treated sandy clayey silt transitioned from strain-softening to strain-hardening during curing, highlighting the synergistic role of lignin fiber (enhancing ductility) and cement (improving stiffness) in stabilizing waste soils. This dual stabilization approach aligns with sustainable construction goals by repurposing engineering waste soils into viable backfill materials, reducing reliance on virgin aggregates and lowering carbon-intensive cement usage.

- (2)

- Lignin fiber content exhibited a threshold value of 4% for optimal strength enhancement. Beyond this limit, increased void ratios (up to 15.8%) weakened the soil matrix, underscoring the need for balanced fiber incorporation to maximize resource efficiency. This finding supports sustainable practices by demonstrating how low-cost, biodegradable fibers can partially replace cement (up to 4% in this study) while maintaining performance, thereby lowering material costs and embodied carbon.

- (3)

- Cement content linearly improved UCS (by 96–139% over 30 days) but reduced axial failure strain (by 37–91%), emphasizing the trade-off between strength and brittleness. For sustainable infrastructure, this suggests that cement dosage should be minimized where ductility is critical (e.g., seismic zones), with lignin fiber compensating for strength loss, a strategy that extends the service life of waste soil applications while mitigating brittle failure risks.

- (4)

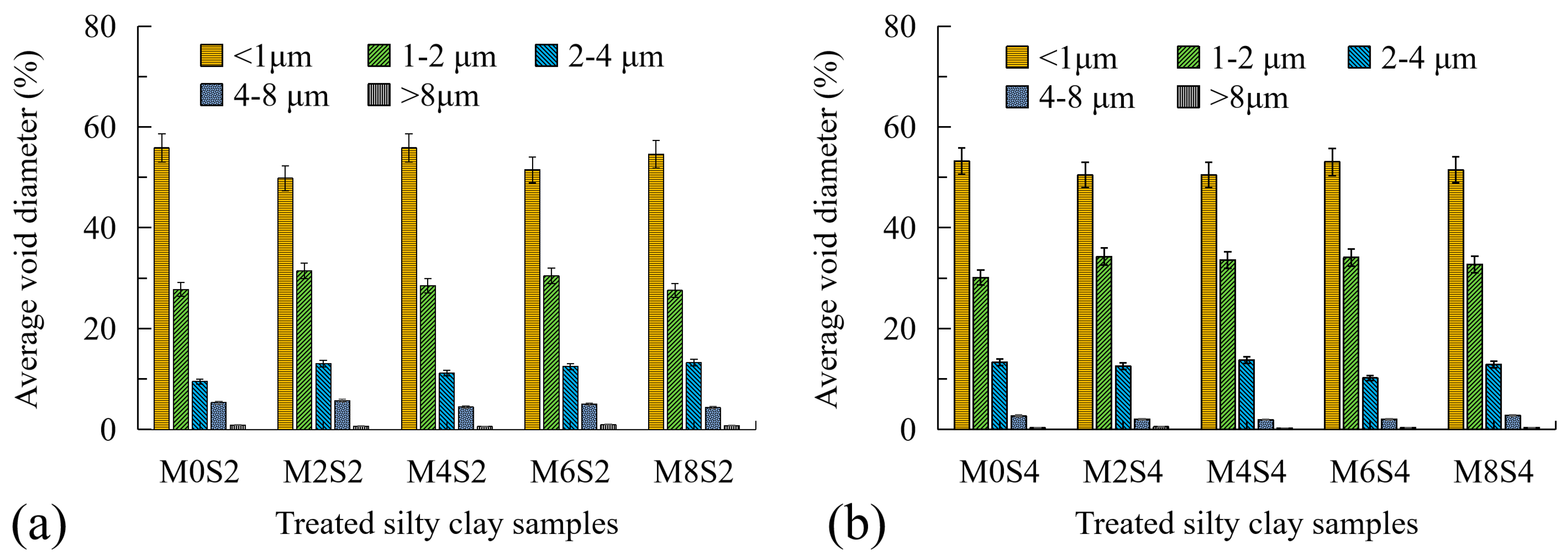

- Microstructural analysis revealed that lignin fiber-cement matrices formed interlocking networks, reducing particle detachment and homogenizing void distributions (e.g., <1 μm voids increased by 22% at 4% fiber). This micro-to-macro behavior validates the viability of lignin-fiber stabilization as a scalable, eco-friendly technique for repurposing silty waste soils in subgrades or embankments.

- (5)

- While this study demonstrates the short-term efficacy of lignin fiber-cement stabilization, long-term durability under field conditions (e.g., cyclic loading, freeze-thaw, and chemical leaching) remains unverified. Future research should investigate (i) the biodegradation kinetics of lignin fibers in soil-cement systems, (ii) lifecycle carbon footprint analysis comparing this method to conventional stabilization, and (iii) field trials to assess scalability in diverse geoenvironments. Additionally, exploring alternative biofibers (e.g., rice husk, cellulose) could further advance sustainable waste soil reuse.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Santa, G.D.; Cola, S.; Secco, M.; Tateo, F.; Sassi, R.; Galgaro, A. Multiscale analysis of freeze-thaw effects induced by ground heat exchangers on permeability of silty clays. Géotechnique 2019, 69, 95–105. [Google Scholar] [CrossRef]

- Tao, Z.F.; Tao, Y.; Chen, X.R.; Chen, X.M. Effects of freeze-thaw cycles on the mechanical properties of cement-fiber composite treated silty clay. Constr. Build. Mater. 2022, 316, 125867. [Google Scholar] [CrossRef]

- Wan, Y.; Hui, X.M.N.; He, X.X.; Li, J.S.; Xue, J.F.; Feng, D.Z.; Liu, X.L.; Wang, S.Q. Performance of green binder developed from flue gas desulfurization gypsum incorporating Portland cement and large-volume fly ash. Constr. Build. Mater. 2022, 348, 128679. [Google Scholar] [CrossRef]

- Monaldo, E.; F Nerilli, G. Vairo, Basalt-based fiber-reinforced materials and structural applications in civil engineering. Compos. Struct. 2019, 214, 246–263. [Google Scholar] [CrossRef]

- Xu, M.; Liu, L.; Deng, Y.F.; Zhou, A.N.; Gu, S.T.; Gu, J.W. Influence of sand incorporation on unconfined compression strength of cement-based stabilized soft clay. Soils Found. 2021, 61, 1132–1141. [Google Scholar] [CrossRef]

- Lang, L.; Li, F.D.; Chen, B. Small-strain dynamic properties of silty clay stabilized by cement and fly ash. Constr. Build. Mater. 2020, 237, 117646. [Google Scholar] [CrossRef]

- Khodaparast, M.; Rajabi, A.M.; Mohammadi, M. Mechanical properties of silty clay soil treated with a mixture of lime and zinc oxide nanoparticles. Constr. Build. Mater. 2021, 281, 122548. [Google Scholar] [CrossRef]

- Liu, L.; Deng, T.T.; Deng, Y.F.; Zhan, L.T.; Horpibulsuk, S.; Wang, Q. Stabilization nature and unified strength characterization for cement-based stabilized soils. Constr. Build. Mater. 2022, 336, 127544. [Google Scholar] [CrossRef]

- Shi, J.; Wang, S.N.; Cao, W.Z.; Su, J.; Zhang, X.J. Mechanical Properties and Strengthening Mechanism of Dredged Silty Clay Stabilized by Cement and Steel Slag. Materials 2022, 15, 3823. [Google Scholar] [CrossRef]

- Plé, O.; Lê, T.N.H. Effect of polypropylene fiber-reinforcement on the mechanical behavior of silty clay. Geotext. Geomembr. 2012, 32, 111–116. [Google Scholar] [CrossRef]

- Mirzababaei, M.; Arulraja, A.; Haque, A.; Nimbalkar, S.; Mohajerani, A. Effect of fiber reinforcement on shear strength and void ratio of soft clay. Geosynth. Int. 2018, 25, 471–480. [Google Scholar] [CrossRef]

- Zhang, J.; Deng, A.; Jaksa, M. Enhancing mechanical behavior of micaceous soil with jute fibers and lime additives. J. Rock Mech. Geotech. Eng. 2021, 13, 1093–1100. [Google Scholar] [CrossRef]

- Fan, K.; Yan, J.; Liu, L.; Pei, Q.; Zou, W. Study on strength characteristics and microstructure of expansive soil treated with lignin fibers in seasonal frozen area. J. Cent. South Univ. (Sci. Technol.) 2022, 53, 326–334. (In Chinese) [Google Scholar] [CrossRef]

- Chen, C.; Guo, W.; Ren, Y. Properties and microscopic analysis of lignin fiber-reinforced soils under freeze-thaw cycles. Chin. J. Geotech. Eng. 2020, 42, 135–140. (In Chinese) [Google Scholar] [CrossRef]

- Vakili, A.H.; Salimi, M.; Lu, Y.; Shamsi, M.; Nazari, Z. Strength and post-freeze-thaw behavior of a marl soil modified by lignosulfonate and polypropylene fiber: An environmentally friendly approach. Constr. Build. Mater. 2022, 332, 127364. [Google Scholar] [CrossRef]

- Lin, L. Triaxial Experimental Study on Improved Soil Mixed with Lignin Fiber and Fly Ash; Beijing Jiaotong University: Beijing, China, 2016; pp. 9–10. [Google Scholar]

- Thanushan, K.; Sathiparan, N. Mechanical performance and durability of banana fibre and coconut coir reinforced cement stabilized soil blocks. Materialia 2022, 21, 101309. [Google Scholar] [CrossRef]

- Mohan, T.P.; Kanny, K. Compressive characteristics of unmodified and nanoclay treated banana fiber reinforced epoxy composite cylinders. Compos. Part B Eng. 2019, 169, 118–125. [Google Scholar] [CrossRef]

- Boobalan, S.C.; Sivakami Devi, M. Investigational study on the influence of lime and coir fiber in the stabilization of expansive soil. Mater. Today Proc. 2022, 60, 311–314. [Google Scholar] [CrossRef]

- Duong, N.T.; Satomi, T.; Takahashi, H. Potential of corn husk fiber for reinforcing cemented soil with high water content. Constr. Build. Mater. 2021, 271, 121848. [Google Scholar] [CrossRef]

- Song, H.W.; Liu, J.; He, K.Y.; Ahmad, W. A comprehensive overview of jute fiber reinforced cementitious composites. Case Stud. Constr. Mater. 2021, 15, e00724. [Google Scholar] [CrossRef]

- Peng, L.Y.; Wang, D.Y.; Qi, J.L. Study on anti-corrosion of PVA-treated wheat straw and its application in reinforcement of a silty soil. Constr. Build. Mater. 2021, 291, 123305. [Google Scholar] [CrossRef]

- Nguyen, C.V.; Mangat, P.S. Properties of rice straw reinforced alkali activated cementitious composites. Constr. Build. Mater. 2020, 261, 120536. [Google Scholar] [CrossRef]

- Consoli, N.C.; Prietto, P.D.M.; Ulbrich, L.A. Influence of fiber and cement addition on behavior of sandy soil. J. Geotech. Geoenviron. Eng. 1998, 124, 1211–1214. [Google Scholar] [CrossRef]

- Correia, A.A.S.; Oliveira, P.J.V.; Custodio, D.G. Effect of polypropylene fibres on the compressive and tensile strength of a soft soil, artificially stabilised with binders. Geotext. Geomembr. 2015, 43, 97–106. [Google Scholar] [CrossRef]

- Takahashi, H.; Omori, S.; Asada, H.; Fukawa, H.; Gotoh, Y.; Morikawa, Y. Mechanical Properties of Cement-Treated Soil Mixed with Cellulose Nanofibre. Appl. Sci. 2021, 11, 6425. [Google Scholar] [CrossRef]

- Monfared, A.M.D.; Shaikh, F.U.A. Anisotropy and bond behaviour of recycled Polyethylene terephthalate (PET) fibre as concrete reinforcement. Constr. Build. Mater. 2020, 265, 120331. [Google Scholar] [CrossRef]

- Anagnostopoulos, C.; Tzetzis, D.; Berketis, K. Shear strength behaviour of polypropylene fibre reinforced cohesive soils. Géoméch. Geoengin. 2013, 9, 241–251. [Google Scholar] [CrossRef]

- Li, L.H.; Zang, T.B.; Xiao, H.L.; Feng, W.Q.; Liu, Y.L. Experimental study of polypropylene fibre-reinforced clay soil mixed with municipal solid waste incineration bottom ash. Eur. J. Environ. Civ. Eng. 2020, 27, 2700–2716. [Google Scholar] [CrossRef]

- Komal, K.; Bawa, S.; KantSharma, S. Laboratory investigation on the effect of polypropylene and nylon fiber on silt stabilized clay. Mater. Today Proc. 2021, 52, 1368–1376. [Google Scholar] [CrossRef]

- Kholghifard, M.; Behbahani, B.A. Shear strength of clayey sand treated by nanoclay mixed with recycled polyester fiber. J. Cent. South Univ. 2022, 29, 259–269. [Google Scholar] [CrossRef]

- Yuan, B.X.; Li, Z.H.; Chen, Y.M.; Ni, H.; Zhao, Z.Q.; Chen, W.J.; Zhao, J. Mechanical and microstructural properties of recycling granite residual soil reinforced with glass fiber and liquid-modified polyvinyl alcohol polymer. Chemosphere 2022, 286, 131652. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Y.Y.; Yang, Y.; Ling, X.Z.; Gong, W.M.; Li, G.Y.; Su, L. Dynamic behavior of natural sand soils and fiber reinforced soils in heavy-haul railway embankment under multistage cyclic loading. Transp. Geotech. 2021, 28, 100507. [Google Scholar] [CrossRef]

- Syed, M.; GuhaRay, A. Effect of natural fiber reinforcement on strength response of alkali activated binder treated expansive soil: Experimental investigation and reliability analysis. Constr. Build. Mater. 2021, 273, 121743. [Google Scholar] [CrossRef]

- Guo, X.; Li, H.; Chen, Y. Chemically modified lignin polymers for sustainable soil stabilization: Mechanical performance and life-cycle assessment. J. Clean. Prod. 2023, 412, 137256. [Google Scholar] [CrossRef]

- Kumar, R.; Sharma, P.; Thomas, S. Hybrid lignin sulfonate-fly ash binder for low-carbon soil stabilization. Resour. Conserv. Recycl. 2025, 198, 107203. [Google Scholar]

- Hoque, M.; Kamal, S.; Raghunath, S.; Foster, E.J. Unraveling lignin degradation in fibre cement via multidimensional fluorometry. Sci. Rep. 2023, 13, 8385. [Google Scholar] [CrossRef]

- Song, W.; Cui, Z.; Wu, H.; Sun, B. Lignin fiber reinforced gypsum-cement composite materials: Investigation of fracture properties and freeze-thaw behaviors. Theor. Appl. Fract. Mech. 2024, 134, 104738. [Google Scholar] [CrossRef]

- Lee, S.; Park, J.; Kim, H. Lignin-epoxy hybrid composites for sustainable infrastructure: Mechanical enhancement and life-cycle analysis. Compos. Part B Eng. 2023, 265, 110945. [Google Scholar]

- Zhang, R.; Wang, T.; Nguyen, L. Recycled PET-silica nanocomposites for soil stabilization: Performance and environmental benefits. J. Clean. Prod. 2024, 434, 139876. [Google Scholar]

- Smith, A.; Johnson, B.; Green, K. Biodegradable PLA-lignin blends for eco-friendly soil stabilization: Mechanisms and field applications. Constr. Build. Mater. 2025, 409, 133105. [Google Scholar]

- Elinwa, A.U.; Umar, M. X-ray diffraction and microstructure studies of gum Arabic-cement concrete. Constr. Build. Mater. 2017, 156, 632–638. [Google Scholar] [CrossRef]

- EN ISO 14688-2: 2018; Geotechnical Investigation and testing-Identification and Classification of Soil-Part 2: Principles for a Classification. Comité Européen de Normalisation: Brussels, Belgium, 2018.

- ASTM D2166/D2166M-16; Standard Test Method for Unconfined Compressive Strength of Cohesive Soil. ASTM: West Conshohocken, PA, USA, 2016.

- Wang, Y.C.; Liu, S.S.; Wang, Q.; Ji, X.X.; Yang, G.H.; Chen, J.C.; Fatehi, P. Strong, ductile and biodegradable polylactic acid/lignin-containing cellulose nanofibril composites with improved thermal and barrier properties. Ind. Crop. Prod. 2021, 171, 113898. [Google Scholar] [CrossRef]

- Zhu, F.; Li, J.Y.; Dong, W.Z.; Zhang, S. Geotechnical properties and microstructure of lignin-treated silty clay in seasonally frozen regions. Bull. Eng. Geol. Environ. 2021, 80, 5645–5656. [Google Scholar] [CrossRef]

- Fan, K.; Pei, Q.; Liu, L.; Han, Z.; Zou, W. Strength and microstructure of a lignin fiber-reinforced expansive soil in cold regions. Geosynth. Int. 2022, 29, 622–629. [Google Scholar] [CrossRef]

- Jia, J.; Wei, H.; Yang, D.; Wu, Y. The Impact of Freeze–Thaw Cycles on the Shear and Microstructural Characteristics of Compacted Silty Clay. Buildings 2023, 13, 2308. [Google Scholar] [CrossRef]

| Density (g/cm3) | Moisture Content (%) | Gravity | Liquid Limit (%) | Plastic Limit (%) | Plasticity Index |

|---|---|---|---|---|---|

| 1.66 | 24.02 | 2.69 | 34.00 | 20.10 | 13.9 |

| ) | Cu | Cc | ||||||

| 0.075–2 | 0.005–0.075 | <0.005 | d10 | d30 | d60 | d90 | ||

| 6.4% | 83.97% | 9.63% | 7.472 | 16.01 | 39.75 | 65.75 | 7.8 | 1.31 |

| Moisture Content (%) | Lignin Fiber Content M(%) | Cement Content S(%) | Curing Time (D) |

|---|---|---|---|

| W24 | M0 | S0 | D30 |

| S2 | |||

| S4 | |||

| M2 | S0 | ||

| S2 | |||

| S4 | |||

| M4 | S0 | ||

| S2 | |||

| S4 | |||

| M6 | S0 | ||

| S2 | |||

| S4 | |||

| M8 | S0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, S.; Jiang, X.; Zhang, Z.; Lu, Q.; Wang, Z.; Zhao, K. Optimizing Mechanical and Microstructural Properties of Sandy Clayey Silt Stabilized with Lignin Fiber and Cement Synergy. Polymers 2025, 17, 1584. https://doi.org/10.3390/polym17111584

Guo S, Jiang X, Zhang Z, Lu Q, Wang Z, Zhao K. Optimizing Mechanical and Microstructural Properties of Sandy Clayey Silt Stabilized with Lignin Fiber and Cement Synergy. Polymers. 2025; 17(11):1584. https://doi.org/10.3390/polym17111584

Chicago/Turabian StyleGuo, Shuangfeng, Xiaoyi Jiang, Zhihua Zhang, Qingrui Lu, Zhe Wang, and Kai Zhao. 2025. "Optimizing Mechanical and Microstructural Properties of Sandy Clayey Silt Stabilized with Lignin Fiber and Cement Synergy" Polymers 17, no. 11: 1584. https://doi.org/10.3390/polym17111584

APA StyleGuo, S., Jiang, X., Zhang, Z., Lu, Q., Wang, Z., & Zhao, K. (2025). Optimizing Mechanical and Microstructural Properties of Sandy Clayey Silt Stabilized with Lignin Fiber and Cement Synergy. Polymers, 17(11), 1584. https://doi.org/10.3390/polym17111584