Biocomposites Based on Biopolyamide with Reduced Water Absorption and Increased Fatigue Strength

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods of Testing

- —water absorption (%);

- —weight of the sample after incubation in water (g);

- —initial sample weight (g)

- —the maximum moisture content (g);

- —sample thickness (mm);

- —initial slope of curve as a function of as shown in Equation (3):

- —moisture content (g);

- —saturation moisture content (g);

- and —constant parameters.

3. Results and Discussion

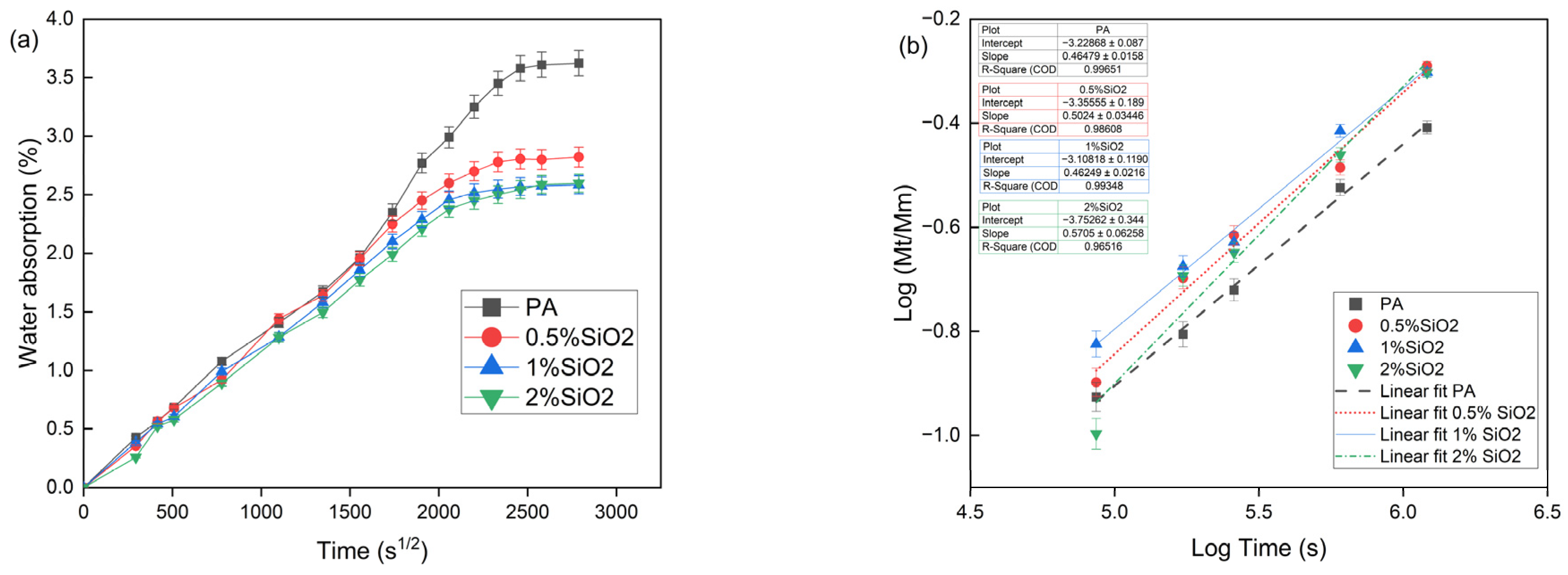

3.1. The Influence of Microsilica on the Water Absorption and Diffusion Coefficient of Biopolyamides

3.2. Hybrid Composites Modified with Microsilica and Short Aramid, Basalt, and Carbon Fibers

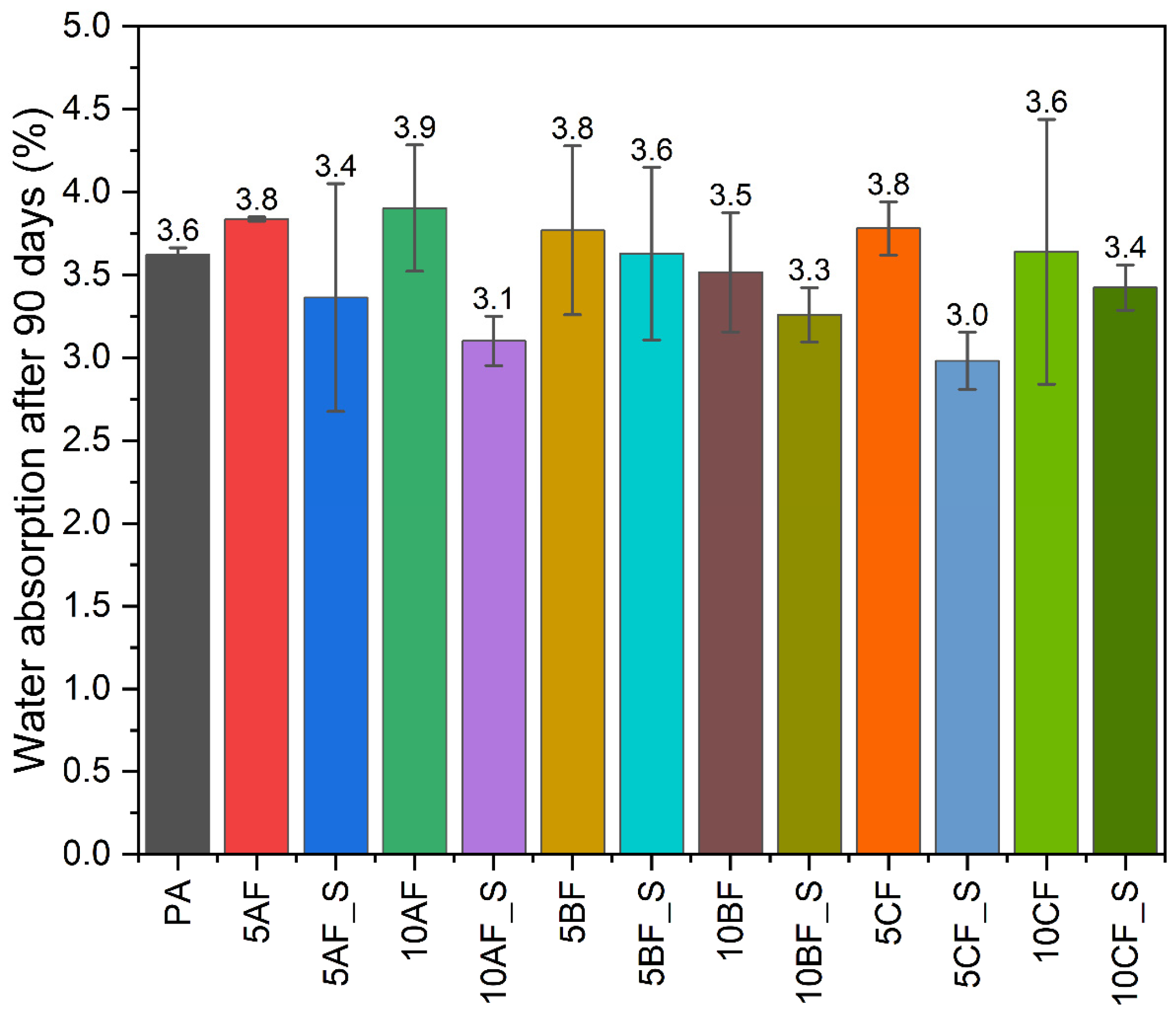

3.2.1. Water Absorption of Hybrid Composites

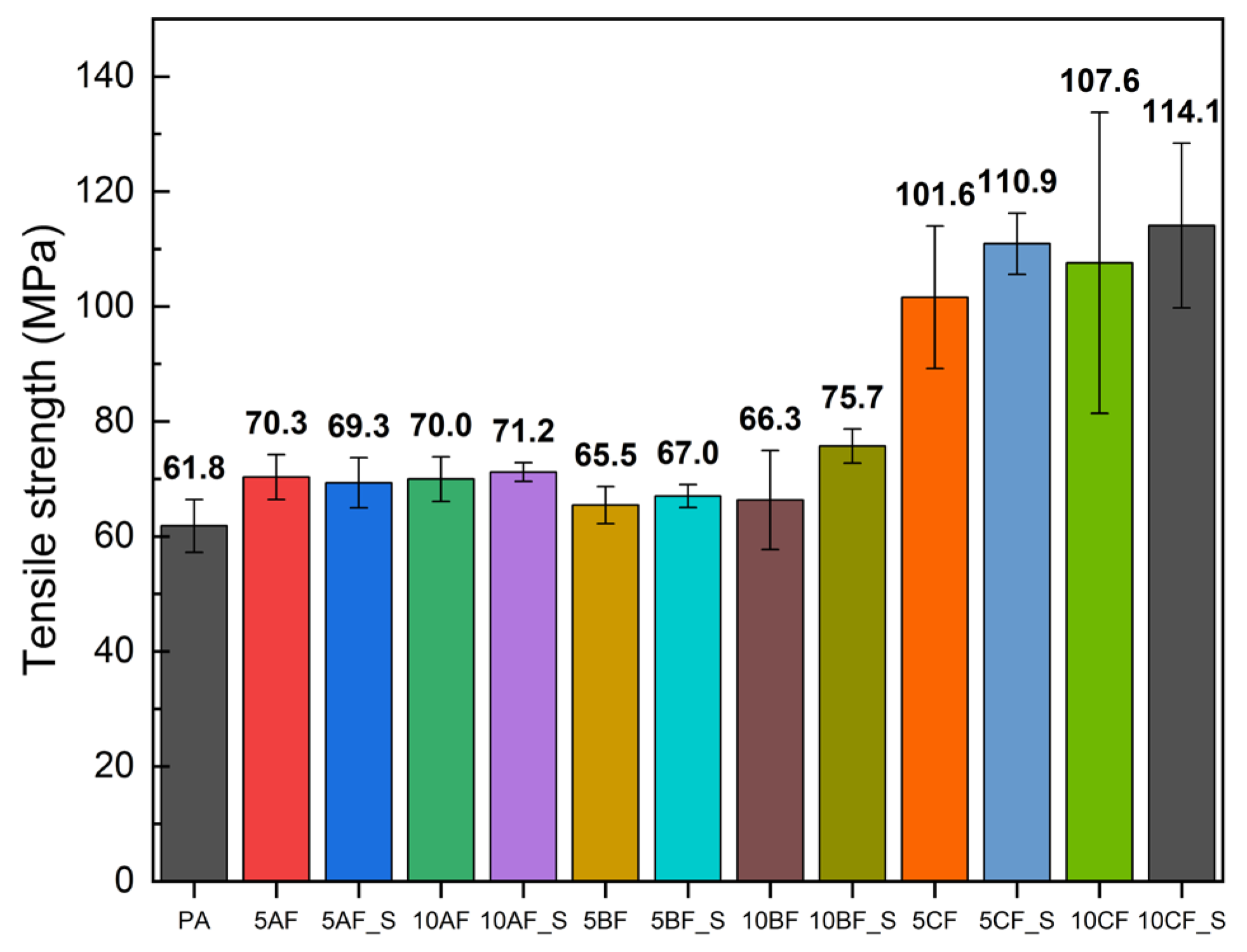

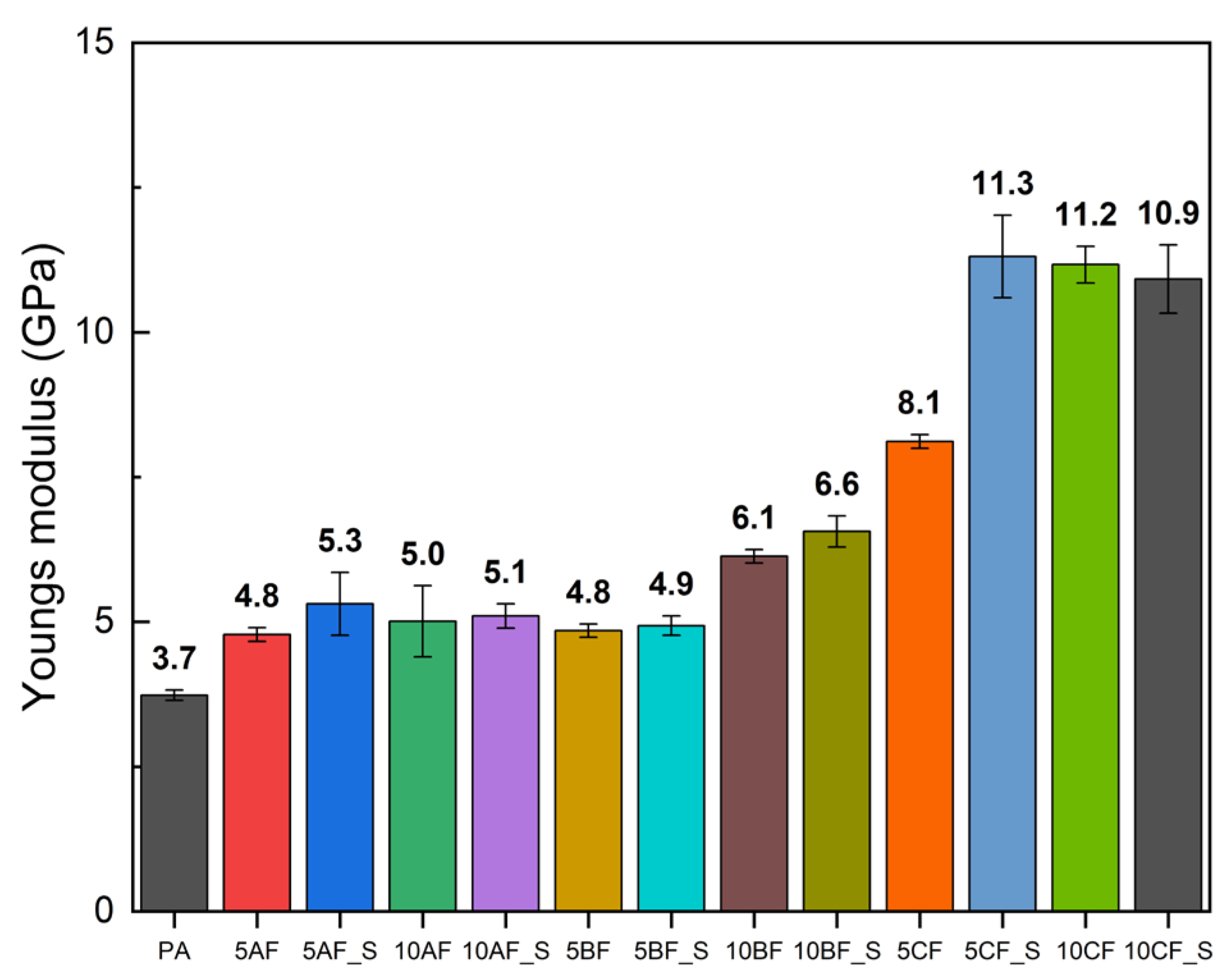

3.2.2. Basic Mechanical Properties

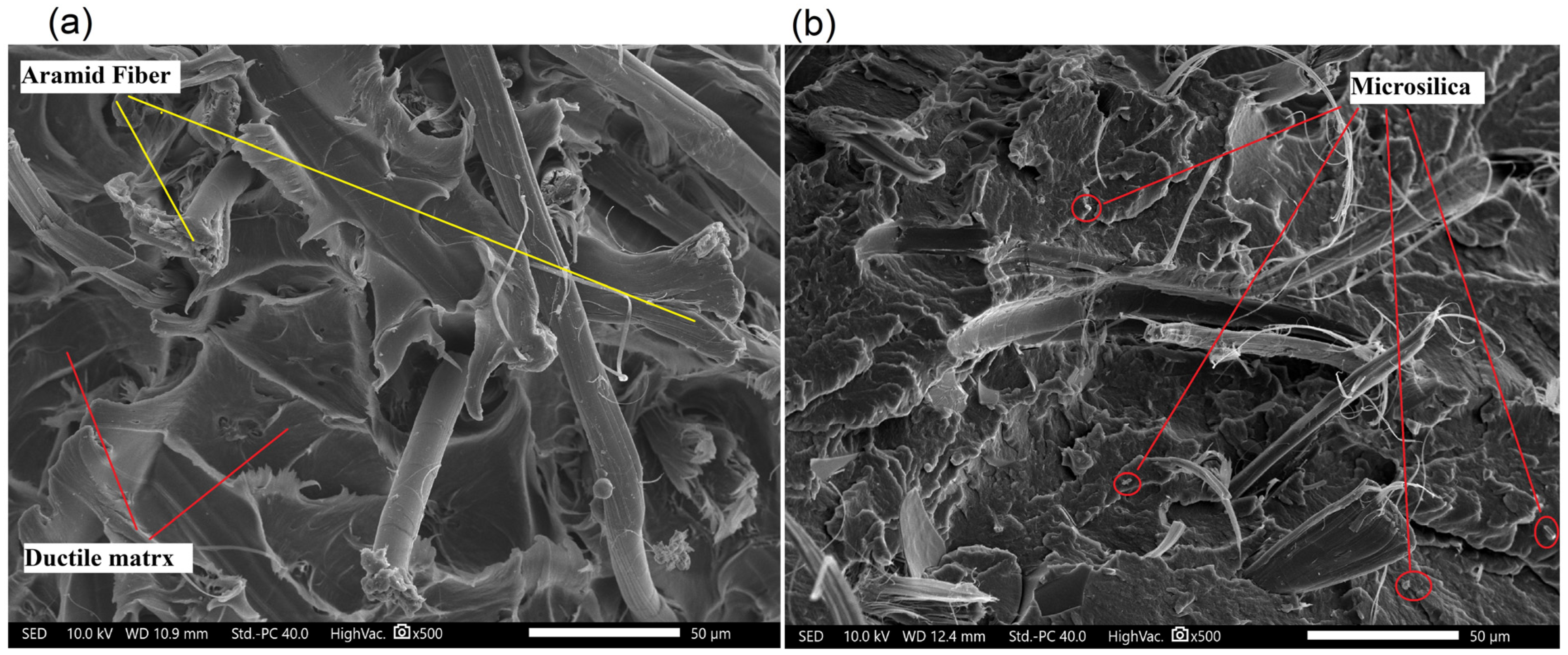

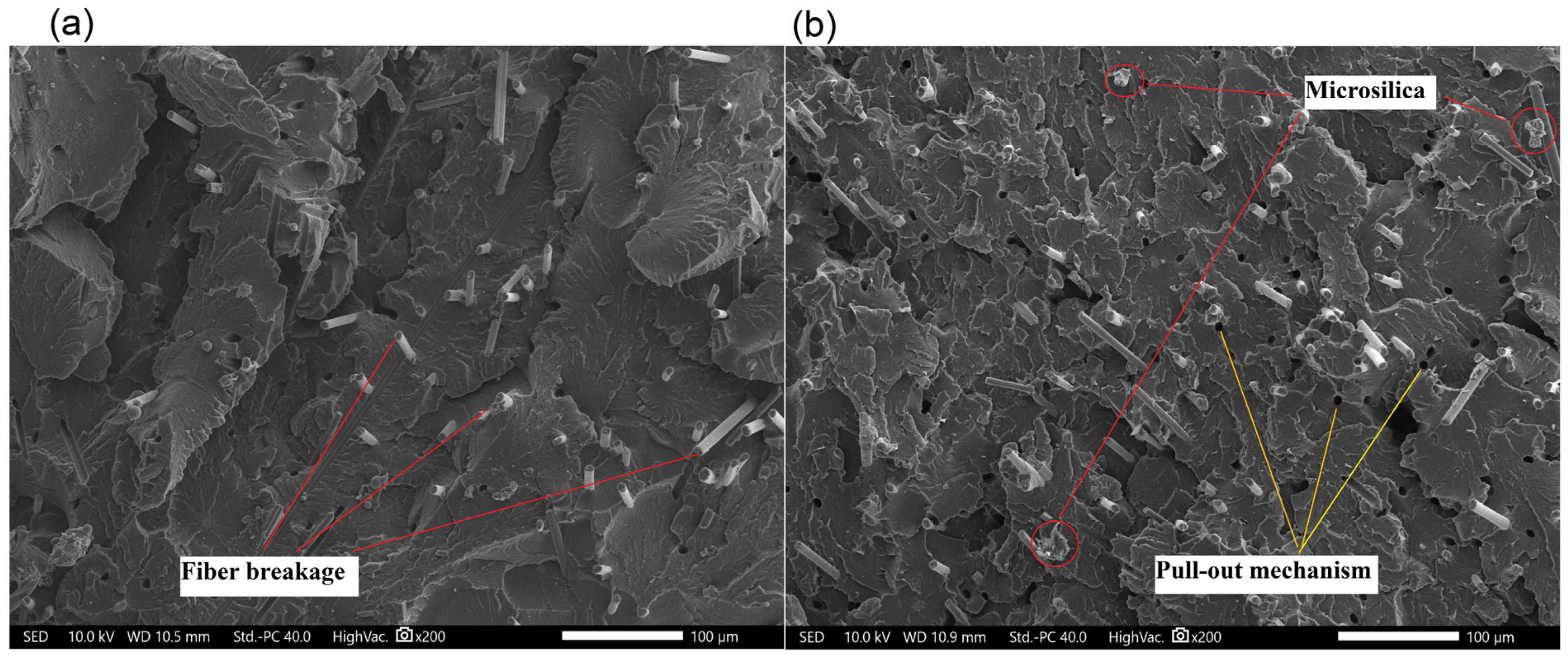

3.2.3. Microstructure of Manufactured Composites

- The effectiveness of microsilica reinforcement depends on uniform dispersion and processing quality—without prior compounding, agglomerates appear, which weaken mechanical properties;

- The best adhesion and effective load transfer were observed in composites with carbon fibers, which correlates with their microstructure and the dominance of the fiber fracture mechanism;

- Basalt fibers combined with microsilica improved mechanical properties, but their poor adhesion in the microstructure may limit long-term durability.

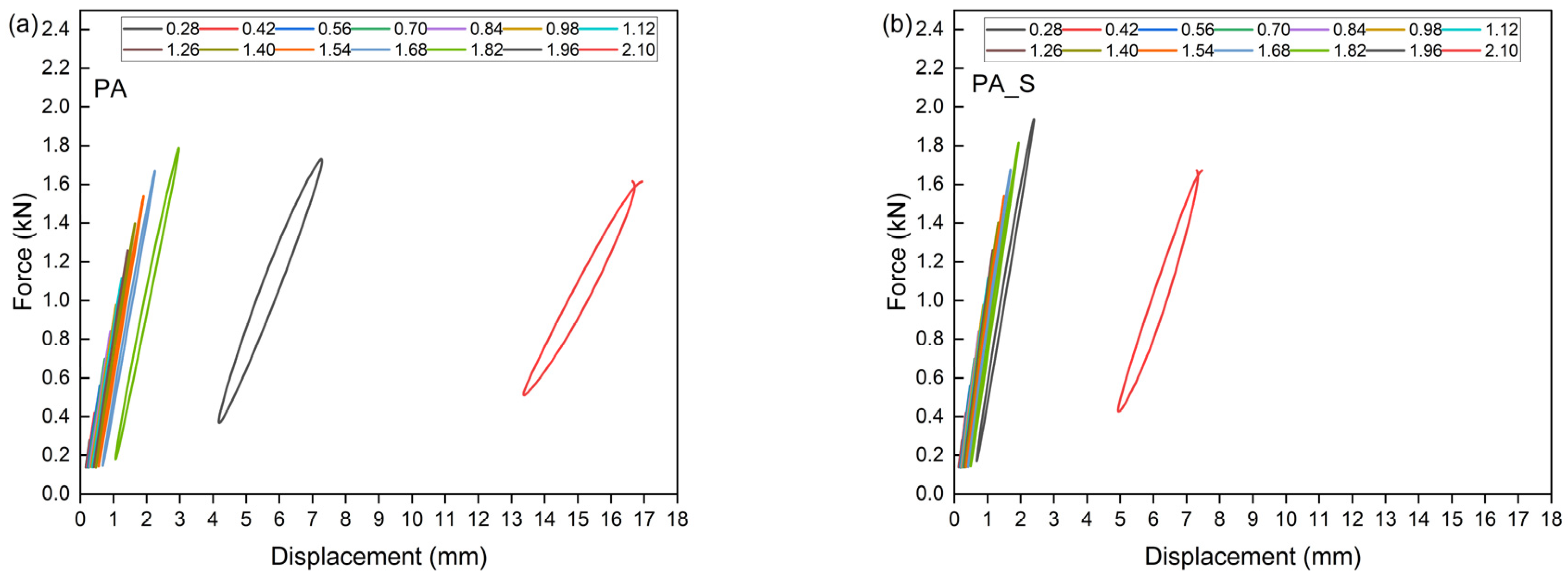

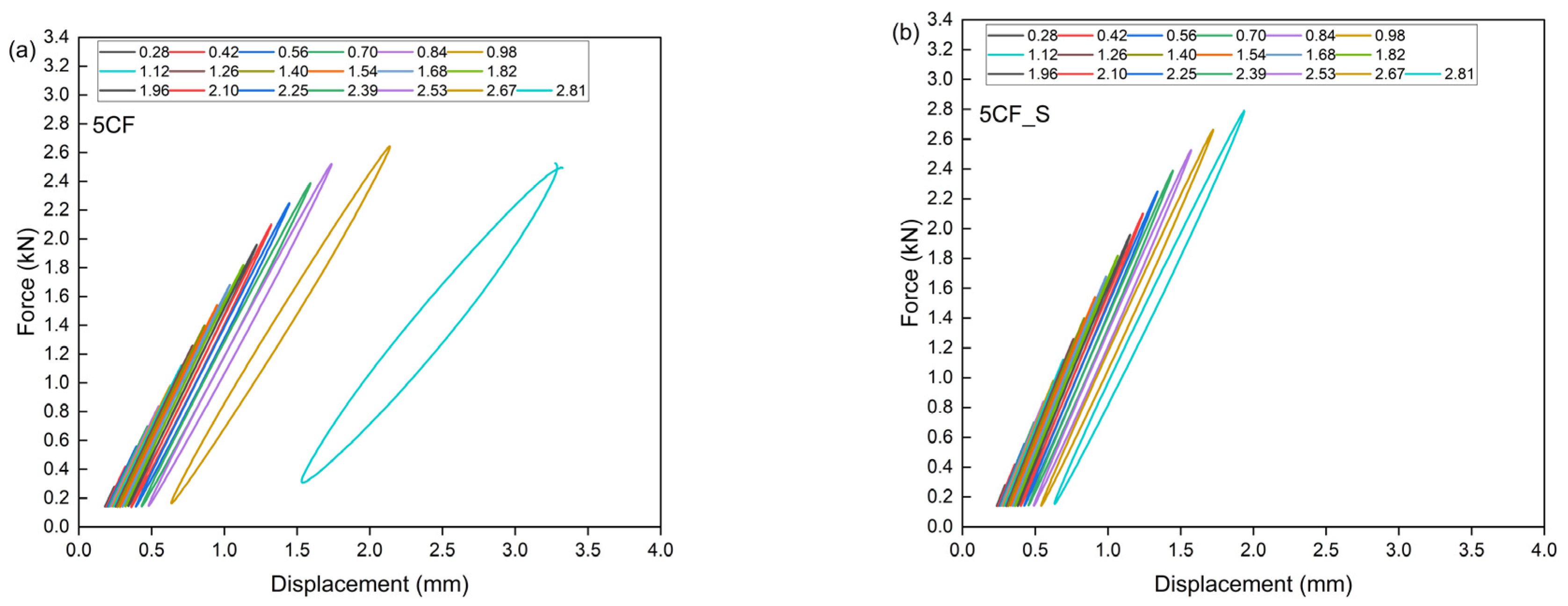

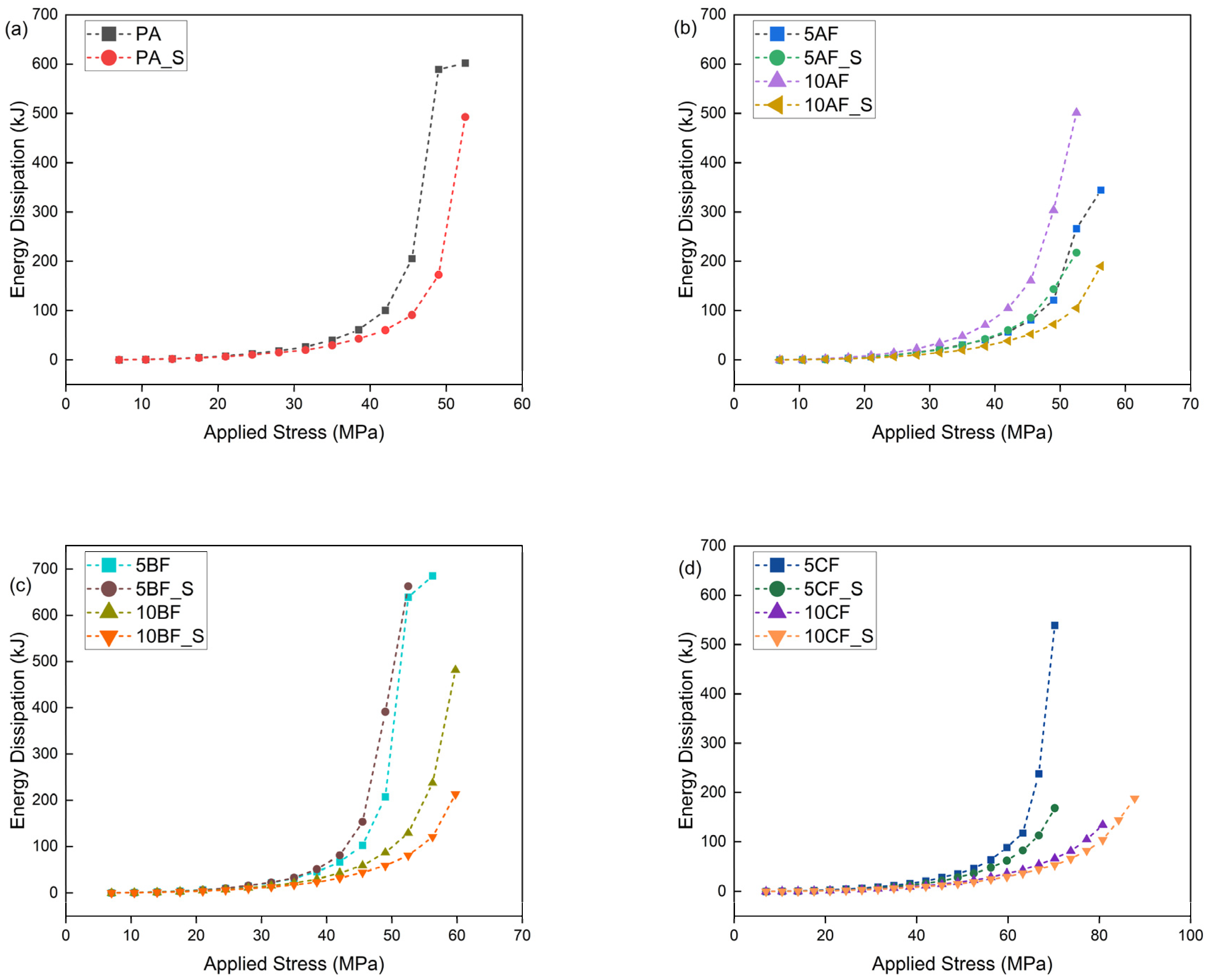

3.2.4. Accelerated Fatigue Testing

- —the stress at which the material has withstood a full load cycle without being destroyed, (MPa);

- —stress at which the material was destroyed, (MPa).

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Winnacker, M.; Rieger, B. Biobased Polyamides: Recent Advances in Basic and Applied Research. Macromol. Rapid Commun. 2016, 37, 1391–1413. [Google Scholar] [CrossRef] [PubMed]

- Armioun, S.; Panthapulakkal, S.; Scheel, J.; Tjong, J.; Sain, M. Sustainable and Lightweight Biopolyamide Hybrid Composites for Greener Auto Parts. Can. J. Chem. Eng. 2016, 94, 2052–2060. [Google Scholar] [CrossRef]

- Bazan, P.; Wierzbicka-Miernik, A. A Novel Hybrid Composites Based on Biopolyamide 10. 10 with Basalt/Aramid Fibers: Mechanical and Thermal Investigation. Compos. B Eng. 2021, 223, 109125. [Google Scholar] [CrossRef]

- Kyulavska, M.; Toncheva-moncheva, N.; Rydz, J. Biobased Polyamide Ecomaterials and Their Susceptibility to Biodegradation. In Handbook of Ecomaterials; Springer: Cham, Switzerland, 2017; ISBN 9783319482811. [Google Scholar]

- Nikiforov, A.A.; Volfson, S.I.; Rinberg, R.; Okhotina, N.A.; Fayzullin, I.Z. Effect of Lubricants on Fiber Length Distribution and Properties of Glass Fiber Reinforced Composites Based on Polyamide 1010. Key Eng. Mater. 2019, 816, 202–207. [Google Scholar] [CrossRef]

- Rinberg, R.; Hartmann, T.; Nikiforov, A.; Doynikov, A.; Volfson, S.; Kroll, L. Investigation of Bio-Based Polyamide with Short Fibers for Lightweight Structures. Technol. Lightweight Struct. (TLS) 2018, 1, 147–156. [Google Scholar] [CrossRef]

- Armioun, S.; Panthapulakkal, S.; Scheel, J.; Tjong, J.; Sain, M. Biopolyamide Hybrid Composites for High Performance Applications. J. Appl. Polym. Sci. 2016, 133, 43595. [Google Scholar] [CrossRef]

- Li, T.; Wang, Z.; Yu, J.; Wang, Y.; Zhu, J.; Hu, Z. Cu (II) Coordination Modification of Aramid Fiber and Effect on Interfacial Adhesion of Composites. High. Perform. Polym. 2019, 31, 1054–1061. [Google Scholar] [CrossRef]

- Gore, P.M.; Kandasubramanian, B. Functionalized Aramid Fibers and Composites for Protective Applications: A Review. Ind. Eng. Chem. Res. 2018, 57, 16537–16563. [Google Scholar] [CrossRef]

- Yuan, Y.; Song, S.; Deng, S.; Wang, Q.; Feng, Q.; Xiong, C.; Dong, L. Scatheless Active Functionalized Poly(p-Phenylene Terephthalamide) Fibres and Their Outstanding Potential in Enhancing Interface Adhesion with Polymer Matrix. J. Appl. Polym. Sci. 2016, 133, 43018. [Google Scholar] [CrossRef]

- Korniejenko, K.; Figiela, B.; Miernik, K.; Ziejewska, C.; Marczyk, J.; Hebda, M.; Cheng, A.; Lin, W.T. Mechanical and Fracture Properties of Long Fiber Reinforced Geopolymer Composites. Materials 2021, 14, 5183. [Google Scholar] [CrossRef]

- Chi, M.; Cai, C.; Liu, Y.; Zhang, S.; Liu, T.; Du, G.; Meng, X.; Luo, B.; Wang, J.; Shao, Y.; et al. Aramid Triboelectric Materials: Opportunities for Self-Powered Wearable Personal Protective Electronics. Adv. Funct. Mater. 2024, 34, 2411020. [Google Scholar] [CrossRef]

- Kalajahi, P.F.; Shahbazi, A.; Shelesh-Nezhad, K.; Arsalani, N. The Effects of Aramid Short Fiber and CaCO3 Nanoparticles Inclusions on the Elastic, Damping, and Thermal Behavior of Polypropylene Composite. J. Thermoplast. Compos. Mater. 2020, 33, 1707–1720. [Google Scholar] [CrossRef]

- Akhil, K.T.; Blaise, S.; Davis, G.; Shunmugesh, K.; Genuvin, C.; Bins, P. The Study of the Mechanical Properties of Aramid Fiber Reinforced Epoxy Resin Composite. Appl. Mech. Mater. 2016, 852, 36–42. [Google Scholar] [CrossRef]

- Xu, Y.; Liu, Y.; Chen, S.; Ni, Y. Current overview of carbon fiber: Toward green sustainable raw materials. Bioresources 2020, 15, 7234–7259. [Google Scholar] [CrossRef]

- Forintos, N.; Czigany, T. Multifunctional Application of Carbon Fiber Reinforced Polymer Composites: Electrical Properties of the Reinforcing Carbon Fibers—A Short Review. Compos. B Eng. 2019, 162, 331–343. [Google Scholar] [CrossRef]

- Luo, Y. Study on Three Major Carbon Fiber Composites. Appl. Comput. Eng. 2023, 7, 240–246. [Google Scholar] [CrossRef]

- Bashmal, S.; Siddiqui, M.; Arif, A.F. Experimental and Numerical Investigations on the Mechanical Characteristics of Carbon Fiber Sensors. Sensors 2017, 17, 2026. [Google Scholar] [CrossRef]

- Luan, C.; Yao, X.; Shen, H.; Fu, J. Self-Sensing of Position-Related Loads in Continuous Carbon Fibers-Embedded 3D-Printed Polymer Structures Using Electrical Resistance Measurement. Sensors 2018, 18, 994. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, M.; Liu, H.; Tian, L.; Liu, J.; Fu, C.; Fu, X. Properties of Basalt Fiber Core Rods and Their Application in Composite Cross Arms of a Power Distribution Network. Polymers 2022, 14, 2443. [Google Scholar] [CrossRef]

- Deak, T.; Czigany, T.; Tamas, P.; Nemeth, C. Enhancement of Interfacial Properties of Basalt Fiber Reinforced Nylon 6 Matrix Composites with Silane Coupling Agents. Express Polym. Lett. 2010, 4, 590–598. [Google Scholar] [CrossRef]

- Zhiming, Y.; Jinxu, L.; Xinya, F.; Shukui, L.; Yuxin, X.; Jie, R. Investigation on Mechanical Properties and Failure Mechanisms of Basalt Fiber Reinforced Aluminum Matrix Composites under Different Loading Conditions. J. Compos. Mater. 2018, 52, 1907–1914. [Google Scholar] [CrossRef]

- Prajapati, R.S.; Jain, S.; Shit, S.C. Development of Basalt Fiber-reinforced Thermoplastic Composites and Effect of PE-g-MA on Composites. Polym. Compos. 2017, 38, 2798–2805. [Google Scholar] [CrossRef]

- Radzik, P.; Leszczyńska, A.; Pielichowski, K. Modern Biopolyamide-Based Materials: Synthesis and Modification. Polym. Bull. 2020, 77, 501–528. [Google Scholar] [CrossRef]

- Bednarowski, D.; Bazan, P.; Kuciel, S. Enhancing Strength and Sustainability: Evaluating Glass and Basalt Fiber-Reinforced Biopolyamide as Alternatives for Petroleum-Based Polyamide Composite. Polymers 2023, 15, 3400. [Google Scholar] [CrossRef]

- Vosáhlo, J.; Ryvolová, M. Basalt Reinforced Plastic—Development and Modeling of Part. Mater. Sci. Forum 2020, 994, 115–124. [Google Scholar] [CrossRef]

- Lesti, M.; Ng, S.; Plank, J. Mediated Interaction Between Microsilica and Polycarboxylate Comb Polymers in a Model Cement Pore Solution. J. Am. Ceram. Soc. 2010, 93, 3493–3498. [Google Scholar] [CrossRef]

- Li, Y.; Xiang, R.; Xu, N.; Wang, Q.; Li, S.; Wu, M.; Yang, C. Fabrication of Calcium Hexaluminate-based Porous Ceramic with Microsilica Addition. Int. J. Appl. Ceram. Technol. 2018, 15, 1054–1059. [Google Scholar] [CrossRef]

- Tian, H.; Cheng, S.; Zhen, J.; Lei, Z. Superabsorbent Polymer with Excellent Water/Salt Absorbency and Water Retention, and Fast Swelling Properties for Preventing Soil Water Evaporation. J. Polym. Environ. 2023, 31, 812–824. [Google Scholar] [CrossRef]

- International Standard PN-EN ISO 62:2008; Plastics—Determination of Water Absorption. ISO: Geneva, Switzerland, 2008.

- Cavasin, M.; Sangermano, M.; Thomson, B.; Giannis, S. Exposure of Glass Fiber Reinforced Polymer Composites in Seawater and the Effect on Their Physical Performance. Materials 2019, 12, 807. [Google Scholar] [CrossRef]

- Espert, A.; Vilaplana, F.; Karlsson, S. Comparison of Water Absorption in Natural Cellulosic Fibres from Wood and One-Year Crops in Polypropylene Composites and Its Influence on Their Mechanical Properties. Compos. Part A Appl. Sci. Manuf. 2004, 35, 1267–1276. [Google Scholar] [CrossRef]

- International Standard PN-EN ISO 527-1:2010; Plastics—Determination of Tensile Properties. ISO: Geneva, Switzerland, 2010.

- International Standard EN ISO 178:2011; Plastics—Determination of Flexural Properties. ISO: Geneva, Switzerland, 2011.

- International Standard PN-EN ISO 179-1:2010; Plastics—Determination of Charpy Impact Properties. ISO: Geneva, Switzerland, 2010.

- International Standard PN-EN ISO 3167:2003; Plastics—Multipurpose test specimens. ISO: Geneva, Switzerland, 2003.

- Vitovec, F.H.; Lazan, B.J. Strength, Damping, and Elasticity of Materials under Increasing Reversed Stress with Reference to Accelerated Fatigue Testing. Proc. Am. Soc. Test. Mater. 1955, 55, 844. [Google Scholar]

- Liber-Kneć, A.; Kuźniar, P.; Kuciel, S. Accelerated Fatigue Testing of Biodegradable Composites with Flax Fibers. J. Polym. Environ. 2015, 23, 400–406. [Google Scholar] [CrossRef]

- Eljufout, T.; Toutanji, H.; Al-Qaralleh, M. Fatigue Stress-Life Model of RC Beams Based on an Accelerated Fatigue Method. Infrastructures 2019, 4, 16. [Google Scholar] [CrossRef]

- Wang, F.; Zheng, J.; Liu, K.; Tong, M.; Zhou, J. Numerical Analysis of Crack Propagation in an Aluminum Alloy under Random Load Spectra. Modelling 2024, 5, 424–437. [Google Scholar] [CrossRef]

- Duncan, B.C.; Broughton, W.R. Measurement Good Practice Guide No. 102 Absorption and Diffusion of Moisture In Polymeric Materials. In Measurement Good Practice Guide; National Physical Laboratory: Teddington, UK, 2023. [Google Scholar]

- Walczak, M.; Szala, M.; Pieniak, D. Effect of Water Absorption on Tribological Properties of Thermoplastics Matrix Composites Reinforced with Glass Fibres. Adv. Sci. Technol. Res. J. 2022, 16, 232–239. [Google Scholar] [CrossRef]

- Preda, F.; Alegría, Á.; Bocahut, A.; Fillot, L.; Long, D.; Sotta, P. Investigation of water diffusion mechanisms in relation to polymer relaxations in polyamides. Macromolecules 2015, 48, 5730–5741. [Google Scholar] [CrossRef]

- Rajeesh, K.; Gnanamoorthy, R.; Ramachandran, R. The effect of moisture content on the tensile behaviour of polyamide 6 nanocomposites. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2010, 224, 173–176. [Google Scholar] [CrossRef]

- Wu, B.; Yang, Y.; Li, M.; Zhu, K.; Iqbal, Z.; Li, Y. Enhanced thermal conductivity of polyamide-66 composites with mesocarbon microbeads through simple melt blending. Polym. Eng. Sci. 2021, 62, 530–536. [Google Scholar] [CrossRef]

- Maubane, L.; Ray, S.; Jalama, K. Influence of silica size on properties of poly[(butylene succinate)-co-adipate]/butyl-etherified high-amylose starch blend composites. Starch-Stärke 2018, 70, 1700181. [Google Scholar] [CrossRef]

- Kokayeva, G.; Niyazbekova, R.; Serekpayeva, M.; Ibzhanova, A.; Bekeshev, A. Using of microsilica for improvement of physical and mechanical properties of epoxide-based composite material. East.-Eur. J. Enterp. Technol. 2023, 4, 18–25. [Google Scholar] [CrossRef]

- Sharifov, D.; Niyazbekova, R.; Mirzo, A.; Shansharova, L.; Serekpayeva, M.; Aldabergenova, S.; Bembenek, M. The study of composite materials properties based on polymers and nano-additives from industrial wastes from Kazakhstan. Materials 2024, 17, 2959. [Google Scholar] [CrossRef] [PubMed]

- Melo, R.Q.C.; Santos, W.R.G.; Barbosa de Lima, A.G.; Lima, W.M.P.B.; Silva, J.V.; Farias, R.P. Water Absorption Process in Polymer Composites: Theory Analysis and Applications; Delgado, J.M.P.Q., Barbosa de Lima, A., Eds.; Advanced S. Springer: Cham, Switzerland, 2018. [Google Scholar]

- Azizan, A.; Johar, M.; Karam Singh, S.S.; Abdullah, S.; Koloor, S.S.R.; Petrů, M.; Wong, K.J.; Tamin, M.N. An Extended Thickness-Dependent Moisture Absorption Model for Unidirectional Carbon/Epoxy Composites. Polymers 2021, 13, 440. [Google Scholar] [CrossRef] [PubMed]

- Chen, L.W.; Khairun, M.; Uyup, A. Effect of Treatment on Water Absorption Behavior of Natural Fiber–Reinforced Polymer Composites; Elsevier Ltd.: Amsterdam, The Netherlands, 2019; ISBN 9780081022924. [Google Scholar]

- Halip, J.A.; Hua, L.S.; Ashaari, Z.; Tahir, P.M.; Chen, L.W.; Anwar Uyup, M.K. Effect of Treatment on Water Absorption Behavior of Natural Fiber–Reinforced Polymer Composites. In Mechanical and Physical Testing of Biocomposites, Fibre-Reinforced Composites and Hybrid Composites; Elsevier: Amsterdam, The Netherlands, 2019; pp. 141–156. [Google Scholar]

- Dhakal, H.N.; Zhang, Z.Y.; Richardson, M.O.W. Effect of Water Absorption on the Mechanical Properties of Hemp Fibre Reinforced Unsaturated Polyester Composites. Compos. Sci. Technol. 2007, 67, 1674–1683. [Google Scholar] [CrossRef]

- Ishida, H.; Koenig, J.L. The Reinforcement Mechanism of Fiber-glass Reinforced Plastics under Wet Conditions: A Review. Polym. Eng. Sci. 1978, 18, 128–145. [Google Scholar] [CrossRef]

- Thomason, J.L. The Interface Region in Glass Fibre-Reinforced Epoxy Resin Composites: 2. Water Absorption, Voids and the Interface. Composites 1995, 26, 477–485. [Google Scholar] [CrossRef]

- Silva, L.; Tognana, S.; Salgueiro, W. Study of the Water Absorption and Its Influence on the Young’s Modulus in a Commercial Polyamide. Polym. Test. 2013, 32, 158–164. [Google Scholar] [CrossRef]

- Bian, X.S.; Ambrosio, L.; Kenny, J.M.; Nicolas, L. Effect of Water Absorption on the Behavior of E-glass Fiber/Nylon-6 Composites. Polym. Compos. 1991, 12, 333–337. [Google Scholar] [CrossRef]

- Ishak, Z.A.M.; Lim, N.C. Effect of Moisture Absorption on the Tensile Properties of Short Glass Fiber Reinforced Poly(Butylene Terephthalate). Polym. Eng. Sci. 1994, 34, 1645–1655. [Google Scholar] [CrossRef]

- Alexis, F.; Castagnet, S.; Nadot-Martin, C.; Robert, G.; Havet, P. Effect of Severe Thermo-Oxidative Aging on the Mechanical Behavior and Fatigue Durability of Short Glass Fiber Reinforced PA6/6.6. Int. J. Fatigue 2023, 166, 107280. [Google Scholar] [CrossRef]

- Mochane, M.J.; Mokhena, T.C.; Mokhothu, T.H.; Mtibe, A.; Sadiku, E.R.; Ray, S.S.; Ibrahim, I.D.; Daramola, O.O. Recent Progress on Natural Fiber Hybrid Composites for Advanced Applications: A Review. Express Polym. Lett. 2019, 13, 159–198. [Google Scholar] [CrossRef]

- Singha, K. A Short Review on Basalt Fiber. Int. J. Text. Sci. 2012, 1, 19–28. [Google Scholar]

- Mansor, M.; Sapuan, S.; Zainudin, E.; Aziz, N.; Hambali, A. Rigidity analysis of kenaf thermoplastic composites using halpin-tsai equation. Appl. Mech. Mater. 2014, 548–549, 29–33. [Google Scholar] [CrossRef]

- Etcheverry, M.; Barbosa, S. Glass fiber reinforced polypropylene mechanical properties enhancement by adhesion improvement. Materials 2012, 5, 1084–1113. [Google Scholar] [CrossRef] [PubMed]

- Xu, A.; Bao, L.; Nishida, M.; Yamanaka, A. Molding of pbo fabric reinforced thermoplastic composite to achieve high fiber volume fraction. Polym. Compos. 2013, 34, 953–958. [Google Scholar] [CrossRef]

- Won, J.; Lim, S.; Park, J.; Hahm, W.; Park, J.; Lee, S.; Jeong, Y. Microstructures and mechanical properties of thermoplastic composites based on polyarylate/nylon6 islands-in-sea fibers. Polym. Compos. 2018, 40 (Suppl. S1), E484–E492. [Google Scholar] [CrossRef]

- Saba, N.; Tahir, P.; Jawaid, M. A review on potentiality of nano filler/natural fiber filled polymer hybrid composites. Polymers 2014, 6, 2247–2273. [Google Scholar] [CrossRef]

- Dong, Y.X.; Wang, Q.; Yang, C.Y.; Xu, W.Z.; Zhou, S.; Liu, D.S.; Tian, J.H. Effect of Process Parameters on Mechanical Properties of Carbon Fiber Reinforced ABS Composites. Key Eng. Mater. 2019, 815, 145–150. [Google Scholar] [CrossRef]

- Hwang, D.; Lee, S.G.; Cho, D. Dual-Sizing Effects of Carbon Fiber on the Thermal, Mechanical, and Impact Properties of Carbon Fiber/ABS Composites. Polymers 2021, 13, 2298. [Google Scholar] [CrossRef]

- Ghanbari, A.; Jalali, A.; Nofar, M.; Mamun, A.; Arjmand, M. Extrinsic Toughening of Recycled Carbon Fibers in Polypropylene Composites in the Absence of Plasticity Penalty. J. Compos. Mater. 2022, 56, 941–950. [Google Scholar] [CrossRef]

- Ahmad, H.; Stiller, J.; Päßler, E.; Nestler, D.; Kroll, L.; Wagner, G. Properties of C/C-SiC Composites Produced via Transfer Moulding and Inner Siliconization. Int. J. Appl. Ceram. Technol. 2020, 17, 2137–2146. [Google Scholar] [CrossRef]

- Badura, K. Effect of Nano and Micro Size of Copper Oxide on the Properties of Thermoplastic Elastomer. Adv. Sci. Technol. Res. J. 2024, 18, 78–91. [Google Scholar] [CrossRef] [PubMed]

- Badura, K.; Bazan, P. Biodegradable Polylactic Acid/Polyhydroxybutyrate-Co-Hydroxyvalerate Blend Composites with Microcrystalline Cellulose—Mechanical, Rheological and Thermal Investigation. Adv. Sci. Technol. Res. J. 2025, 19, 184–201. [Google Scholar] [CrossRef] [PubMed]

- Jeon, S.-H.; Choi, W.C.; Park, T.-H.; Kim, H.-M.; Jung, I.-E.; Baek, C.-K.; Seo, K.-J.; Choi, B.-H. Development of a New Light-Weight Car Audio Using Polycarbonate/Acrylonitrile-Butadiene-Styrene Copolymer Composite Based Hybrid Material. Int. J. Precis. Eng. Manuf. 2012, 13, 85–96. [Google Scholar] [CrossRef]

- Mortazavian, S.; Fatemi, A. Effects of Fiber Orientation and Anisotropy on Tensile Strength and Elastic Modulus of Short Fiber Reinforced Polymer Composites. Compos. Part B Eng. 2015, 72, 116–129. [Google Scholar] [CrossRef]

- Castro, V.R.; Filho, A.S.; Guimara, R.C.L.; Roma, W.; Silva, A.L.N.; Teixeira, S.C.S.; De Paoli, M.; De Sena, G.L.; Santo, E.; Ferrari, A.F.; et al. Ageing of Polyamide 11 Used in the Manufacture of Flexible Piping. J. Appl. Polym. Sci. 2009, 114, 1777–1783. [Google Scholar] [CrossRef]

- Starkova, O.; Gagani, A.I.; Karl, C.W.; Rocha, I.B.C.M.; Burlakovs, J.; Krauklis, A.E. Modelling of Environmental Ageing of Polymers and Polymer Composites—Durability Prediction Methods. Polymers 2022, 14, 907. [Google Scholar] [CrossRef]

- Wang, B.; Ci, S.; Zhou, M.; Di, C.; Yu, J.; Zhu, B.; Qiao, K. Effects of Hygrothermal and Salt Mist Ageing on the Properties of Epoxy Resins and Their Composites. Polymers 2023, 15, 725. [Google Scholar] [CrossRef]

- Kocańda, S.; Szala, J. Podstawy Obliczeń Zmęczeniowych (Basics of Fatigue Calculations), 3rd ed.; Wydawnictwo Naukowe PWN: Warszawa, Poland, 1997; Volume 1. [Google Scholar]

- Mazurkiewicz, S.; Porębska, R. Energia Dyssypacji w Kompozytach Polimerowych. Czas. Tech. Mech.-WPK 2009, 106, 245–248. [Google Scholar]

- Mortazavian, S.; Fatemi, A. Fatigue Behavior and Modeling of Short Fiber Reinforced Polymer Composites: A Literature Review. Int. J. Fatigue 2015, 70, 297–321. [Google Scholar] [CrossRef]

- Zhang, W.; Zhou, Z.; Scarpa, F.; Zhao, S. A Fatigue Damage Meso-Model for Fiber-Reinforced Composites with Stress Ratio Effect. Mater. Des. 2016, 107, 212–220. [Google Scholar] [CrossRef]

- Mostovoy, A.S.; Kadykova, Y.A.; Bekeshev, A.Z.; Tastanova, L.K. Epoxy Composites Modified with Microfibers of Potassium Polytitanates. J. Appl. Polym. Sci. 2018, 135, 46651. [Google Scholar] [CrossRef]

- Rosfadzlin Hanna, Z.A.; Taufik, T.; Sivaraos, S.; Mohd Ghazali, S.; Rosidah, J.; Mohd Amran, M.A. Design Simulation on Fatigue Life of Fiber Reinforced Polymer Composites. Appl. Mech. Mater. 2015, 761, 47–51. [Google Scholar] [CrossRef]

- Sayyidmousavi, A. Investigation of Creep and Fatigue in High Temperature Polymer Matrix Composites Using a Micromechanical Approach. Ph.D. Thesis, Toronto Metropolitan University, Toronto, ON, Canada, 2014. [Google Scholar]

- Mortazavian, S.; Fatemi, A. Tensile and Fatigue Behaviors of Polymers for Automotive Applications. Materwiss Werksttech 2015, 46, 204–213. [Google Scholar] [CrossRef]

- Niemczyk, A.; Dziubek, K.; Czaja, K.; Frączek, D.; Piasecki, R.; Rabiej, S.; Dutkiewicz, M. Study and Evaluation of Dispersion of Polyhedral Oligomeric Silsesquioxane and Silica Filler in Polypropylene Composites. Polym. Compos. 2019, 40, 1354–1364. [Google Scholar] [CrossRef]

- Farhadinejad, Z.; Ehsani, M.; Moemen-Bellah, S. Dynamic Mechanical and Thermal Behavior Evaluation of an Epoxy/Anhydride/Nano-Aluminum Oxide Composite System. High Perform. Polym. 2013, 25, 518–525. [Google Scholar] [CrossRef]

| Temperature (°C) | Injection Pressure (bar) | Compression Pressure (bar) | Press Time (s) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Feed Zone | Zone 1 | Zone 2 | Zone 3 | Zone 4 | Nozzle | Mold | |||

| 40 | 190 | 265 | 265 | 275 | 280 | 60 | 1200 | 600 | 8 |

| Screw speed (RPM) | Back pressure (bar) | Injection speed (mm/s) | Gate design and location | ||||||

| 100 | 40 | 20 | Edge gate | ||||||

| Index | Description |

|---|---|

| PA | Bio-based polyamide 100% |

| 0.5%SiO2 | PA + 0.5 wt.% microsilica |

| 1%SiO2 | PA + 1 wt.% microsilica |

| 2%SiO2 | PA + 2 wt.% microsilica |

| 5AF | PA + 5 wt.% aramid fiber |

| 5AF_S | PA + 5 wt.% aramid fiber + 2 wt.% microsilica |

| 10AF | PA + 10 wt.% aramid fiber |

| 10AF_S | PA + 10 wt.% aramid fiber + 2 wt.% microsilica |

| 5BF | PA + 5 wt.% basalt fiber |

| 5BF_S | PA + 5 wt.% basalt fiber + 2 wt.% microsilica |

| 10BF | PA + 10 wt.% basalt fiber |

| 10BF_S | PA + 10 wt.% basalt fiber + 2 wt.% microsilica |

| 5CF | PA + 5 wt.% carbon fiber |

| 5CF_S | PA + 5 wt.% carbon fiber + 2 wt.% microsilica |

| 10CF | PA + 10 wt.% carbon fiber |

| 10CF_S | PA + 10 wt.% carbon fiber + 2 wt.% microsilica |

| Index | Density (g/cm3) | Impact Strength (kJ/m2) | (s) | ||

|---|---|---|---|---|---|

| PA | 1.08 0.01 | - | 3.58 × 10−13 | 0.00122 | 0.4648 |

| 0.5%SiO2 | 1.09 0.01 | 24.7 1.8 | 7.24 × 10−13 | 0.00135 | 0.5024 |

| 1%SiO2 | 1.10 0.01 | 22.7 1.1 | 5.88 × 10−13 | 0.00111 | 0.4625 |

| 2%SiO2 | 1.14 0.01 | 23.0 1.0 | 7.63 × 10−13 | 0.00127 | 0.5705 |

| Index | Density (g/cm3) | Impact Strength (kJ/m) | (s) | ||

|---|---|---|---|---|---|

| PA | 0.01 | - | 3.58 × 10−13 | 0.001220 | 0.4648 |

| 5AF | 0.01 | 1.8 | 4.22 × 10−13 | 0.001403 | 0.5169 |

| 5AF_S | 0.01 | 0.2 | 5.03 × 10−13 | 0.001343 | 0.4958 |

| 10AF | 0.01 | 2.4 | 4.52 × 10−13 | 0.001426 | 0.5710 |

| 10AF_S | 0.01 | 0.9 | 4.03 × 10−13 | 0.001296 | 0.5188 |

| 5BF | 0.01 | 6.2 | 3.56 × 10−13 | 0.001270 | 0.5446 |

| 5BF_S | 0.01 | 1.0 | 6.09 × 10−13 | 0.001313 | 0.6888 |

| 10BF | 0.01 | 2.4 | 5.17 × 10−13 | 0.001584 | 0.7208 |

| 10BF_S | 0.01 | 2.8 | 6.18 × 10−13 | 0.001375 | 1.0140 |

| 5CF | 0.04 | 1.0 | 4.09 × 10−13 | 0.001267 | 0.4919 |

| 5CF_S | 0.04 | 2.1 | 4.42 × 10−13 | 0.001221 | 0.5082 |

| 10CF | 0.03 | 1.0 | 6.77 × 10−13 | 0.001689 | 0.8122 |

| 10CF_S | 0.01 | 3.1 | 5.64 × 10−13 | 0.001451 | 0.7303 |

| State | Conditioned | After Water Absorption | ||

|---|---|---|---|---|

| Material | Flexural Strength (MPa) | Flexural Modulus (GPa) | Flexural Strength (MPa) | Flexural Modulus (GPa) |

| PA | 2.2 | 0.1 | 0.6 | 0.02 |

| PA_S | 4.8 | 0.1 | 0.5 | 0.01 |

| 5AF | 0.8 | 0.1 | 0.9 | 0.05 |

| 5AF_S | 1.1 | 0.5 | 2.0 | 0.06 |

| 5BF | 2.4 | 0.3 | 3.2 | 0.09 |

| 5BF_S | 5.4 | 0.4 | 0.6 | 0.10 |

| 5CF | 4.9 | 2.6 | 1.7 | 0.07 |

| 5CF_S | 4.6 | 1.4 | 1.1 | 0.06 |

| Index | Max Strength, (kN) | Number of Cycles to Break | (MPa) | (MPa) | (MPa) | (MPa) | (MPa) |

|---|---|---|---|---|---|---|---|

| PA | 2.10 | 13,590 | 49.0 | 52.5 | 45.5 | 27.5 | 61.8 |

| PA_S | 2.10 | 13,790 | 49.0 | 52.5 | 45.5 | 31.5 | 62.2 |

| 5AF | 2.25 | 14,400 | 52.5 | 56.3 | 48.7 | 29.9 | 70.4 |

| 5AF_S | 2.10 | 13,600 | 49.0 | 52.5 | 45.5 | 31.5 | 69.3 |

| 10AF | 2.10 | 13,800 | 49.0 | 52.5 | 45.5 | 28.0 | 70.0 |

| 10AF_S | 2.39 | 15,460 | 56.3 | 59.8 | 52.8 | 31.5 | 71.2 |

| 5BF | 2.25 | 14,480 | 52.5 | 56.3 | 48.7 | 38.5 | 65.5 |

| 5BF_S | 2.10 | 13,690 | 49.0 | 52.5 | 45.5 | 35.0 | 67.0 |

| 10BF | 2.39 | 15,780 | 56.3 | 59.8 | 52.8 | 41.3 | 66.4 |

| 10BF_S | 2.39 | 16,000 | 56.3 | 59.8 | 52.8 | 45.0 | 75.7 |

| 5CF | 2.81 | 18,490 | 66.8 | 70.3 | 63.3 | 42.5 | 101.6 |

| 5CF_S | 2.81 | 18,790 | 66.8 | 70.3 | 63.3 | 46.8 | 110.9 |

| 10CF | 3.23 | 21,770 | 77.3 | 81.3 | 73.3 | 49.0 | 107.6 |

| 10CF_S | 3.51 | 23,530 | 84.3 | 87.8 | 80.8 | 56.3 | 114.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bazan, P.; Jacobsen, E.E.; Olsen, A.; Paso, K.G. Biocomposites Based on Biopolyamide with Reduced Water Absorption and Increased Fatigue Strength. Polymers 2025, 17, 1559. https://doi.org/10.3390/polym17111559

Bazan P, Jacobsen EE, Olsen A, Paso KG. Biocomposites Based on Biopolyamide with Reduced Water Absorption and Increased Fatigue Strength. Polymers. 2025; 17(11):1559. https://doi.org/10.3390/polym17111559

Chicago/Turabian StyleBazan, Patrycja, Elisabeth Egholm Jacobsen, Anna Olsen, and Kristofer Gunnar Paso. 2025. "Biocomposites Based on Biopolyamide with Reduced Water Absorption and Increased Fatigue Strength" Polymers 17, no. 11: 1559. https://doi.org/10.3390/polym17111559

APA StyleBazan, P., Jacobsen, E. E., Olsen, A., & Paso, K. G. (2025). Biocomposites Based on Biopolyamide with Reduced Water Absorption and Increased Fatigue Strength. Polymers, 17(11), 1559. https://doi.org/10.3390/polym17111559