Antioxidant Biocomposite Films Based on Grape Stalk Lignocellulosic Fractions and Biodegradable Polyesters

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Obtention of Fillers

2.3. Preparation and Characterization of Biocomposites

2.3.1. Microstructure, X-Ray Analysis, and FTIR of Films

2.3.2. Mechanical, Barrier, and Optical Properties of Films

2.3.3. Thermal Behaviour of Films

2.3.4. Antioxidant Properties of Films

2.4. Statistical Analyses

3. Results and Discussion

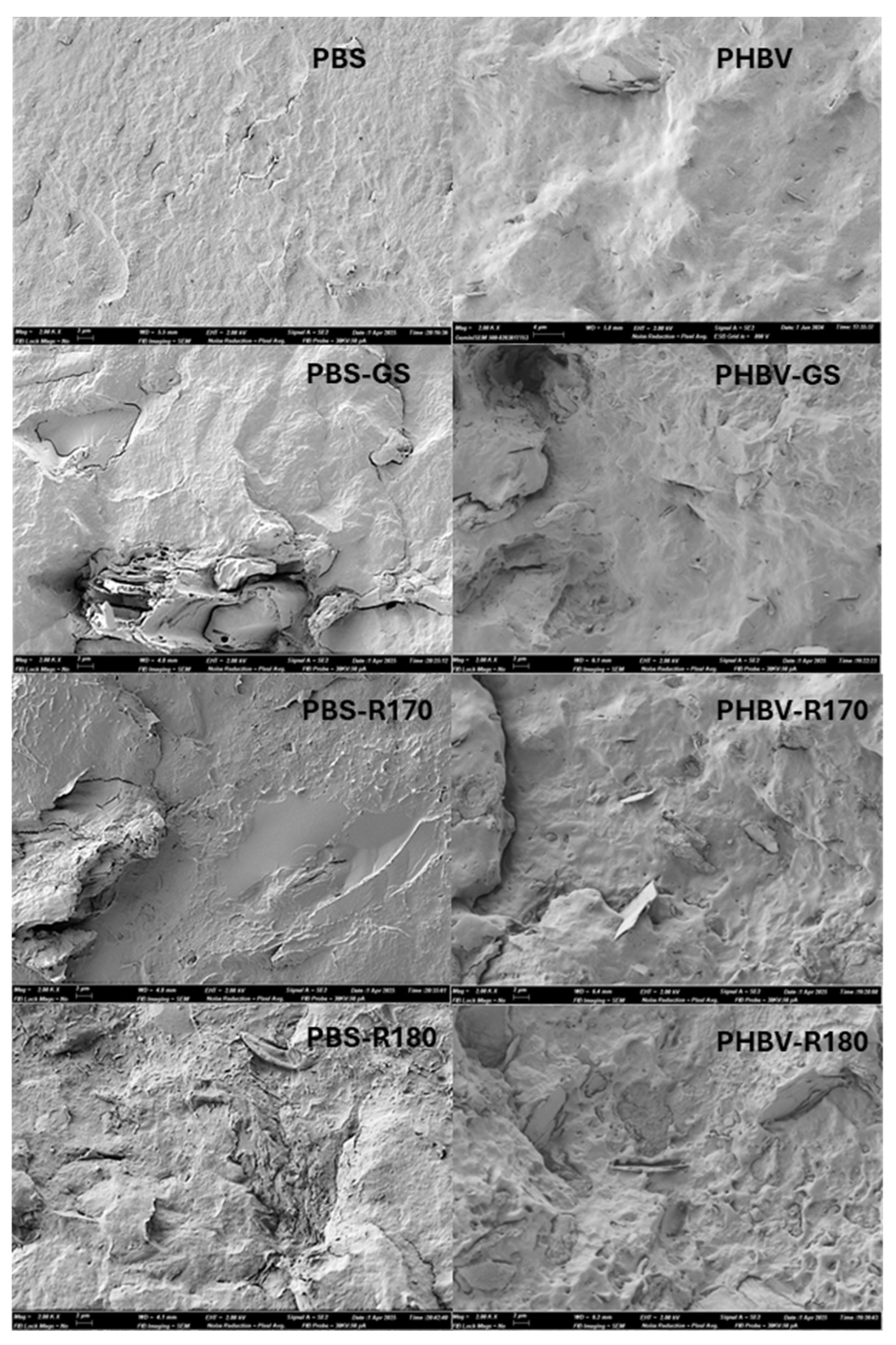

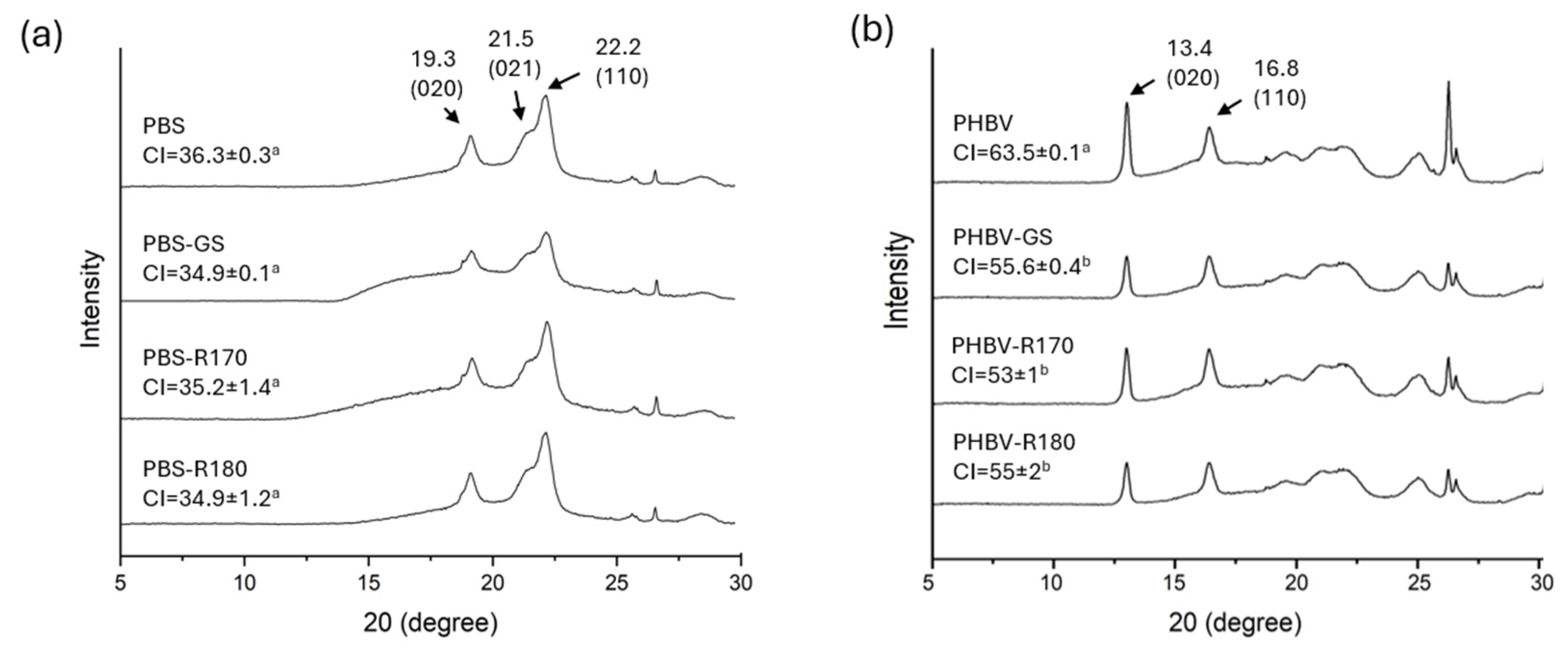

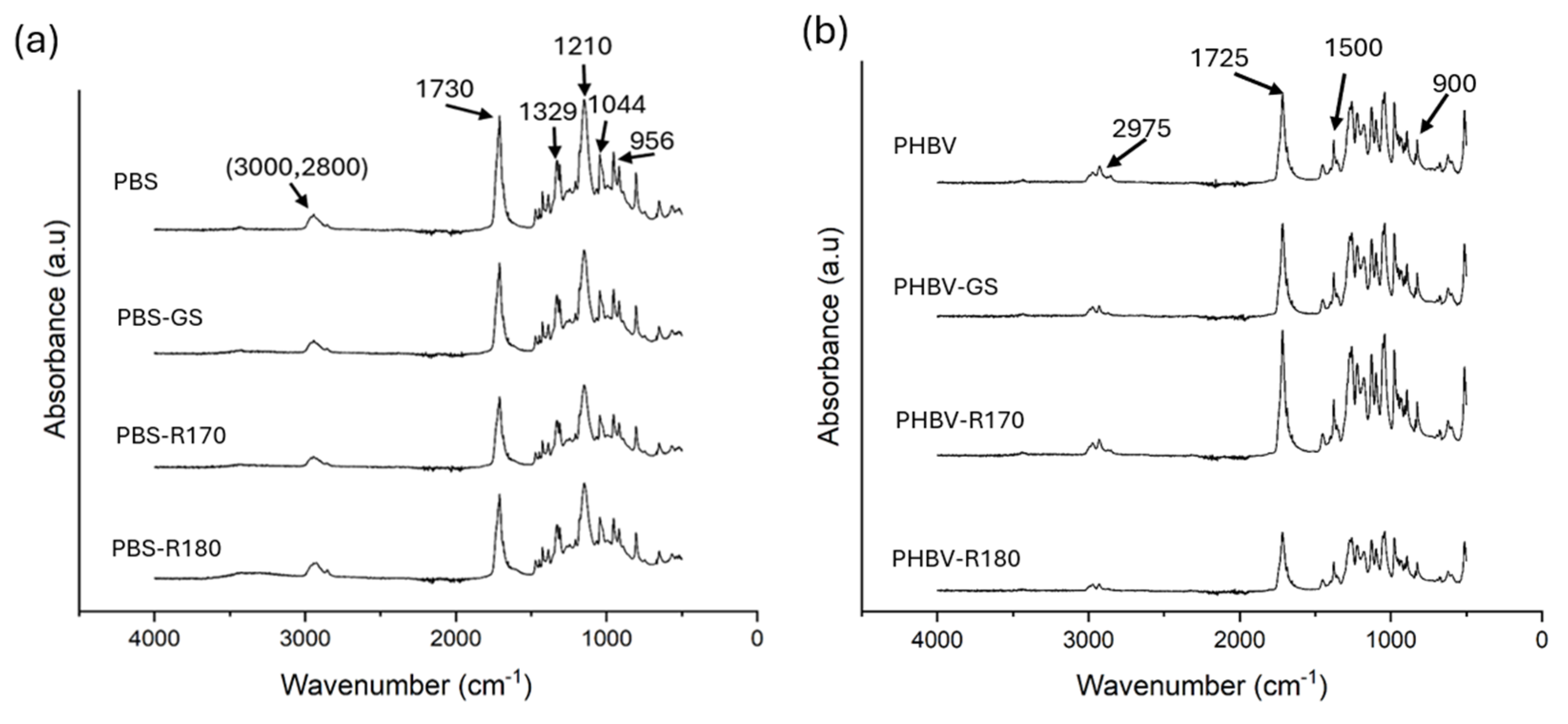

3.1. Microstructural and Spectral Analysis

3.2. Mechanical, Barrier, and Optical Properties

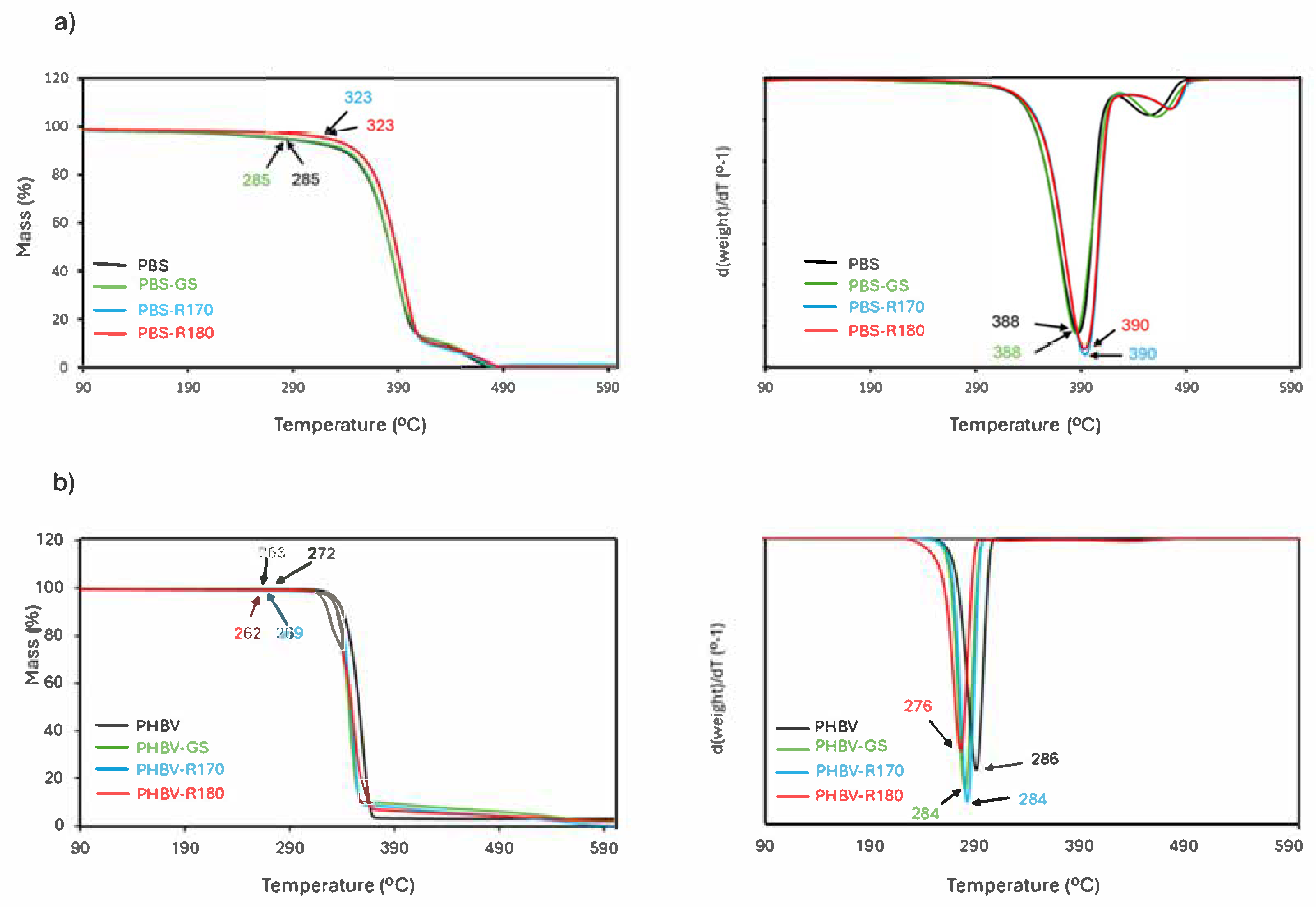

3.3. Thermal Behaviour of Films

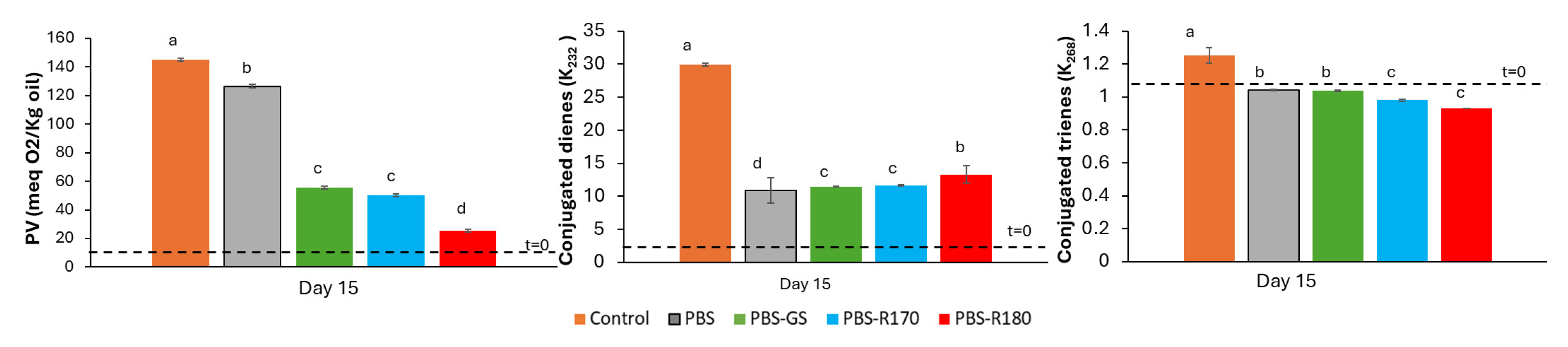

3.4. Antioxidant Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Ingle, A.P.; Saxena, S.; Moharil, M.P.; Rivaldi, J.D.; Ramos, L.; Chandel, A.K. Production of biomaterials and biochemicals from lignocellulosic biomass through sustainable approaches: Current scenario and future perspectives. Biotechnol. Sustain. Mater. 2025, 2, 3. [Google Scholar] [CrossRef]

- Laycock, B.; Pratt, S.; Halley, P. A perspective on biodegradable polymer biocomposites—From processing to degradation. Funct. Compos. Mater. 2023, 4, 10. [Google Scholar] [CrossRef]

- Mochane, M.J.; Magagula, S.I.; Sefadi, J.S.; Mokhena, T.C. A Review on Green Composites Based on Natural Fiber-Reinforced Polybutylene Succinate (PBS). Polymers 2021, 13, 1200. [Google Scholar] [CrossRef] [PubMed]

- Ilsouk, M.; Raihane, M.; Rhouta, B.; Meri, R.M.; Zicans, J.; Vecstaudža, J.; Lahcini, M. The relationship of structure, thermal and water vapor permeability barrier properties of poly(butylene succinate)/organomodified beidellite clay bionanocomposites prepared by in situ polycondensation. RSC Adv. 2020, 10, 37314–37326. [Google Scholar] [CrossRef]

- Gowman, A.; Wang, T.; Rodriguez-Uribe, A.; Mohanty, A.K.; Misra, M. Bio-poly(butylene succinate) and Its Composites with Grape Pomace: Mechanical Performance and Thermal Properties. ACS Omega 2018, 3, 15205–15216. [Google Scholar] [CrossRef]

- Rafiqah, S.A.; Khalina, A.; Harmaen, A.S.; Tawakkal, I.A.; Zaman, K.; Asim, M.; Nurrazi, M.; Lee, C.H. A Review on Properties and Application of Bio-Based Poly(Butylene Succinate). Polymers 2021, 13, 1436. [Google Scholar] [CrossRef]

- Barletta, M.; Aversa, C.; Ayyoob, M.; Gisario, A.; Hamad, K.; Mehrpouya, M.; Vahabi, H. Poly(butylene succinate) (PBS): Materials, processing, and industrial applications. Prog. Polym. Sci. 2022, 132, 101579. [Google Scholar] [CrossRef]

- Shaiju, P.; Dorian, B.; Senthamaraikannan, R.; Padamati, R.B. Biodegradation of Poly (Butylene Succinate) (PBS)/Stearate Modified Magnesium-Aluminium Layered Double Hydroxide Composites under Marine Conditions Prepared via Melt Compounding. Molecules 2020, 25, 5766. [Google Scholar] [CrossRef]

- Chen, R.; Zou, W.; Zhang, H.; Zhang, G.; Yang, Z.; Jin, G.; Qu, J. Thermal behavior, dynamic mechanical properties and rheological properties of poly(butylene succinate) composites filled with nanometer calcium carbonate. Polym. Test. 2015, 42, 160–167. [Google Scholar] [CrossRef]

- Laycock, B.; Halley, P.; Pratt, S.; Werker, A.; Lant, P. The chemomechanical properties of microbial polyhydroxyalkanoates. Prog. Polym. Sci. 2012, 38, 536–583. [Google Scholar] [CrossRef]

- Policastro, G.; Luongo, V.; Fabbricino, M. Biohydrogen and poly-β-hydroxybutyrate production by winery wastewater photofermentation: Effect of substrate concentration and nitrogen source. J. Environ. Manag. 2020, 271, 111006. [Google Scholar] [CrossRef] [PubMed]

- Ibrahim, M.I.; Alsafadi, D.; Alamry, K.A.; Hussein, M.A. Properties and Applications of Poly(3-hydroxybutyrate-co-3-hydroxyvalerate) Biocomposites. J. Polym. Environ. 2021, 29, 1010–1030. [Google Scholar] [CrossRef]

- Samaniego-Aguilar, K.; Sánchez-Safont, E.; Rodríguez, A.; Marín, A.; Candal, M.V.; Cabedo, L.; Gamez-Perez, J. Valorization of agricultural waste lignocellulosic fibers for Poly(3-Hydroxybutyrate-Co-Valerate)-Based composites in short Shelf-Life applications. Polymers 2023, 15, 4507. [Google Scholar] [CrossRef] [PubMed]

- David, G.; Vannini, M.; Sisti, L.; Marchese, P.; Celli, A.; Gontard, N.; Angellier-Coussy, H. Eco-Conversion of Two Winery Lignocellulosic Wastes into Fillers for Biocomposites: Vine Shoots and Wine Pomaces. Polymers 2020, 12, 1530. [Google Scholar] [CrossRef]

- Olivas-Alonso, C.; Freitas Pa, V.; Torres-Giner, S.; Chiralt, A. Thermo-Compressed Films of Poly(butylene succinate) Reinforced with Cellulose Fibers Obtained from Rice Straw by Green Extraction Methods. Macromol. Mater. Eng. 2024, 309, 2400094. [Google Scholar] [CrossRef]

- Nanni, A.; Cancelli, U.; Montevecchi, G.; Masino, F.; Messori, M.; Antonelli, A. Functionalization and use of grape stalks as poly(butylene succinate) (PBS) reinforcing fillers. Waste Manag. 2021, 126, 538–548. [Google Scholar] [CrossRef]

- Galanakis, C.M. (Ed.) Handbook of Grape Processing By-Products: Sustainable Solutions; Elsevier: Amsterdam, The Netherlands, 2017; Available online: https://www.sciencedirect.com/book/9780128098707/handbook-of-grape-processing-by-products (accessed on 20 May 2025).

- International Organisation of Vine and Wine. State of the World Vine and Wine Sector in 2023; International Organisation of Vine and Wine: Paris, France, 2024; Available online: https://www.oiv.int/sites/default/files/2024-04/OIV_STATE_OF_THE_WORLD_VINE_AND_WINE_SECTOR_IN_2023.pdf (accessed on 20 May 2025).

- Souquet, J.; Labarbe, B.; Guernevé, C.L.; Cheynier, V.; Moutounet, M. Phenolic composition of grape stems. J. Agric. Food Chem. 2000, 48, 1076–1080. [Google Scholar] [CrossRef]

- Prozil, S.O.; Evtuguin, D.V.; Silva, A.M.; Lopes, L.P. Structural characterisation of lignin from grape stalks (Vitis vinifera L.). J. Agric. Food Chem. 2014, 62, 5420–5428. [Google Scholar] [CrossRef]

- Spigno, G.; Maggi, L.; Amendola, D.; Dragoni, M.; De Faveri, D.M. Influence of cultivar on the lignocellulosic fractionation of grape stalks. Ind. Crops Prod. 2013, 46, 283–289. [Google Scholar] [CrossRef]

- Maté, I.; Vargas, M.; Atarés, L.; Chiralt, A. Fractionation of winemaking grape stalks by subcritical water extraction to obtain Added-Value products. Foods 2024, 13, 3566. [Google Scholar] [CrossRef]

- Freitas, P.A.; Santana, L.G.; González-Martínez, C.; Chiralt, A. Combining subcritical water extraction and bleaching with hydrogen peroxide to obtain cellulose fibres from rice straw. Carbohydr. Polym. Technol. Appl. 2024, 7, 100491. [Google Scholar] [CrossRef]

- Requena, R.; Jiménez-Quero, A.; Vargas, M.; Moriana, R.; Chiralt, A.; Vilaplana, F. Integral Fractionation of Rice Husks into Bioactive Arabinoxylans, Cellulose Nanocrystals, and Silica Particles. ACS Sustain. Chem. Eng. 2019, 7, 6275–6286. [Google Scholar] [CrossRef]

- Cheng, Y.; Xue, F.; Yu, S.; Du, S.; Yang, Y. Subcritical Water Extraction of Natural Products. Molecules 2021, 26, 4004. [Google Scholar] [CrossRef] [PubMed]

- ASTM D882-12; Standard Test Method for Tensile Properties of Thin Plastic Sheeting. American Society for Testing and Materials: West Conshohocken, PA, USA, 2012.

- ASTM E96/E96M-05; Standard Test Methods for Water Vapor Transmission of Materials. American Society for Testing and Materials: West Conshohocken, PA, USA, 2005.

- ASTM D3985-05; Oxygen Gas Transmission Rate Through Plastic Film and Sheeting Using a Coulometric Sensor. Annual Book of ASTM Standards, C, 1–7. American Society for Testing and Materials: West Conshohocken, PA, USA, 2010.

- Hutchings, J.B. (Ed.) Food Colour and Appearance; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2011. [Google Scholar]

- Moll, E.; Chiralt, A. Polyhydroxybutyrate-co-hydroxyvalerate (PHBV) with Phenolic Acids for Active Food Packaging. Polymers 2023, 15, 4222. [Google Scholar] [CrossRef]

- Talón, E.; Vargas, M.; Chiralt, A.; González-Martínez, C. Antioxidant starch-based films with encapsulated eugenol. Application to sunflower oil preservation. LWT 2019, 113, 108290. [Google Scholar] [CrossRef]

- La Fuente Arias, C.I.; González-Martínez, C.; Chiralt, A. Active Poly(3-hydroxybutyrate-co-3-hydroxyvalerate) (PHBV) Films Containing Phenolic Compounds with Different Molecular Structures. Polymers 2024, 16, 1574. [Google Scholar] [CrossRef]

- David, G.; Michel, J.; Gastaldi, E.; Gontard, N.; Angellier-Coussy, H. How vine shoots as fillers impact the biodegradation of PHBV-Based composites. Int. J. Mol. Sci. 2019, 21, 228. [Google Scholar] [CrossRef]

- Wang, X.; Zhou, J.; Li, L. Multiple Melting Behavior of Poly(butylene succinate). Eur. Polym. J. 2007, 43, 3163–3170. [Google Scholar] [CrossRef]

- Zhao, Q.; Tang, H.; Ren, L.; Wei, J. In Vitro Apatite Mineralization, Degradability, Cytocompatibility and In Vivo New Bone Formation and Vascularization of Bioactive Scaffold of Polybutylene Succinate/Magnesium Phosphate/Wheat Protein Ternary Composite. Int. J. Nanomed. 2020, 15, 7279–7295. [Google Scholar] [CrossRef]

- Liu, G.; Zhang, W.; Zhou, S.; Wang, X.; Wang, Y. Improving Crystallization and Processability of PBS via Slight Cross-Linking. RSC Adv. 2016, 6, 68942–68951. [Google Scholar] [CrossRef]

- Yoo, E.S.; Im, S.S. Melting Behavior of Poly(butylene succinate) during Heating Scan by DSC. J. Appl. Polym. Sci. 1999, 37, 1357–1366. [Google Scholar] [CrossRef]

- Väisänen, T.; Das, O.; Tomppo, L.A. Review on New Bio-Based Constituents for Natural Fiber-Polymer Composites. J. Clean. Prod. 2017, 149, 582–596. [Google Scholar] [CrossRef]

- Renstad, R.; Karlsson, S.; Albertsson, A.C. The Influence of Processing Induced Differences in Molecular Structure on the Biological and Non-Biological Degradation of Poly(3-hydroxybutyrate-co-3-hydroxyvalerate), P (3-HB-co-3-HV). Polym. Degrad. Stab. 1999, 63, 201–211. [Google Scholar] [CrossRef]

- Kai, W.; He, Y.; Inoue, Y. Fast Crystallization of Poly(3-hydroxybutyrate) and Poly(3-hydroxybutyrate-co-3-hydroxyvalerate) with Talc and Boron Nitride as Nucleating Agents. Polym. Int. 2005, 54, 780–789. [Google Scholar] [CrossRef]

- Zhou, Y.; Zhao, M.; Guo, H.; Li, Y.; Liu, Q.; Deng, B. Morphology and Crystallization Behavior of Poly(3-hydroxybutyrate-co-3-hydroxyvalerate)/Polyhedral Oligomeric Silsesquioxane Hybrids. RSC Adv. 2019, 9, 8146–8158. [Google Scholar] [CrossRef]

- David, G.; Heux, L.; Pradeau, S.; Gontard, N.; Angellier-Coussy, H. Upcycling of Vine Shoots: Production of Fillers for PHBV-Based Biocomposite Applications. J. Polym. Environ. 2021, 29, 404–417. [Google Scholar] [CrossRef]

- Matos Costa, A.R.; Crocitti, A.; De Carvalho, L.H.; Carroccio, S.C.; Cerruti, P.; Santagata, G. Properties of Biodegradable Films Based on Poly(butylene Succinate) (PBS) and Poly(butylene Adipate-co-Terephthalate) (PBAT) Blends. Polymers 2020, 12, 2317. [Google Scholar] [CrossRef]

- Sasimowski, E.; Majewski, Ł.; Grochowicz, M. Artificial Ageing, Chemical Resistance, and Biodegradation of Biocomposites from Poly(Butylene Succinate) and Wheat Bran. Materials 2021, 14, 7580. [Google Scholar] [CrossRef]

- Barrino, F.; De La Rosa-Ramírez, H.; Schiraldi, C.; López-Martínez, J.; Samper, M.D. Preparation and Characterization of New Bioplastics Based on Polybutylene Succinate (PBS). Polymers 2023, 15, 1212. [Google Scholar] [CrossRef]

- Yao, S.; Chen, X.; Ye, H. Investigation of Structure and Crystallization Behavior of Poly(butylene succinate) by Fourier Transform Infrared Spectroscopy. J. Phys. Chem. B 2017, 121, 9476–9485. [Google Scholar] [CrossRef]

- Kennouche, S.; Moigne, N.L.; Kaci, M.; Quantin, J.; Caro-Bretelle, A.; Delaite, C.; Lopez-Cuesta, J. Morphological Characterization and Thermal Properties of Compatibilized Poly(3-hydroxybutyrate-co-3-hydroxyvalerate) (PHBV)/Poly(butylene succinate) (PBS)/Halloysite Ternary Nanocomposites. Eur. Polym. J. 2015, 75, 142–162. [Google Scholar] [CrossRef]

- Montanheiro, T.L.D.A.; Passador, F.R.; De Oliveira, M.P.; Durán, N.; Lemes, A.P. Preparation and Characterization of Maleic Anhydride Grafted Poly(Hydroxybutyrate-co-Hydroxyvalerate)—PHBV-G-MA. Mater. Res. 2016, 19, 229–235. [Google Scholar] [CrossRef]

- Xu, J.; Guo, B. Poly(butylene succinate) and Its Copolymers: Research, Development and Industrialization. Biotechnol. J. 2010, 5, 1149–1163. [Google Scholar] [CrossRef] [PubMed]

- Bledzki, A.; Jaszkiewicz, A. Mechanical Performance of Biocomposites Based on PLA and PHBV Reinforced with Natural Fibres—A Comparative Study to PP. Compos. Sci. Technol. 2010, 70, 1687–1696. [Google Scholar] [CrossRef]

- Lagazzo, A.; Moliner, C.; Bosio, B.; Botter, R.; Arato, E. Evaluation of the Mechanical and Thermal Properties Decay of PHBV/Sisal and PLA/Sisal Biocomposites at Different Recycle Steps. Polymers 2019, 11, 1477. [Google Scholar] [CrossRef]

- Noh, S.; Kim, D.; Jeong, G.; Koo, J.M.; Koo, J. Highly Dispersed Biochar as a Sustainable Filler for Enhancing Mechanical Performance and Biodegradation of Polybutylene Succinate. J. Appl. Polym. Sci. 2024, 141, 25. [Google Scholar] [CrossRef]

- Singh, S.; Mohanty, A.K.; Sugie, T.; Takai, Y.; Hamada, H. Renewable Resource Based Biocomposites from Natural Fiber and Polyhydroxybutyrate-Co-Valerate (PHBV) Bioplastic. Compos. Part A Appl. Sci. Manuf. 2008, 39, 875–886. [Google Scholar] [CrossRef]

- Frącz, W.; Janowski, G.; Smusz, R.; Szumski, M. The Influence of Chosen Plant Fillers in PHBV Composites on the Processing Conditions, Mechanical Properties and Quality of Molded Pieces. Polymers 2021, 13, 3934. [Google Scholar] [CrossRef]

- Moll, E.; Freitas, P.A.; Chiralt, A. Effect of Active Rice Straw Extracts on the Properties and Migration of PHBV Films. Food Packag. Shelf Life 2025, 48, 101454. [Google Scholar] [CrossRef]

- Hernández-García, E.; Pacheco-Romeralo, M.; Zomeño, P.; Viscusi, G.; Malvano, F.; Gorrasi, G.; Torres-Giner, S. Development and Characterization of Thermoformed Bilayer Trays of Paper and Renewable Succinic Acid Derived Biopolyester Blends and Their Application to Preserve Fresh Pasta. Materials 2023, 16, 3872. [Google Scholar] [CrossRef]

- Quiles-Carrillo, L.; Montanes, N.; Lagaron, J.M.; Balart, R.; Torres-Giner, S. In Situ Compatibilization of Biopolymer Ternary Blends by Reactive Extrusion with Low-Functionality Epoxy-Based Styrene–Acrylic Oligomer. J. Polym. Environ. 2018, 27, 84–96. [Google Scholar] [CrossRef]

- Fortunati, E.; Luzi, F.; Jiménez, A.; Gopakumar, D.; Puglia, D.; Thomas, S.; Kenny, J.; Chiralt, A.; Torre, L. Revalorization of Sunflower Stalks as Novel Sources of Cellulose Nanofibrils and Nanocrystals and Their Effect on Wheat Gluten Bionanocomposite Properties. Carbohydr. Polym. 2016, 149, 357–368. [Google Scholar] [CrossRef] [PubMed]

- Bonilla, J.; Atarés, L.; Vargas, M.; Chiralt, A. Edible Films and Coatings to Prevent the Detrimental Effect of Oxygen on Food Quality: Possibilities and Limitations. J. Food Eng. 2011, 110, 208–213. [Google Scholar] [CrossRef]

- Kovalcik, A.; Machovsky, M.; Kozakova, Z.; Koller, M. Designing Packaging Materials with Viscoelastic and Gas Barrier Properties by Optimized Processing of Poly(3-hydroxybutyrate-co-3-hydroxyvalerate) with Lignin. React. Funct. Polym. 2015, 94, 25–34. [Google Scholar] [CrossRef]

- Freitas, P.A.; González-Martínez, C.; Chiralt, A. Antioxidant Starch Composite Films Containing Rice Straw Extract and Cellulose Fibres. Food Chem. 2023, 400, 134073. [Google Scholar] [CrossRef]

- Plaza, M.; Amigo-Benavent, M.; Del Castillo, M.D.; Ibáñez, E.; Herrero, M. Facts about the Formation of New Antioxidants in Natural Samples after Subcritical Water Extraction. Food Res. Int. 2010, 43, 2341–2348. [Google Scholar] [CrossRef]

- Lv, Z.; Zhang, M.C.; Zhang, Y.; Guo, B.; Xu, J. Study on melting and recrystallization of poly(butylene succinate) lamellar crystals via step heating differential scanning calorimetry. Chin. J. Polym. Sci. 2017, 35, 1552–1560. [Google Scholar] [CrossRef]

- Montanheiro, T.L.D.A.; Cristóvan, F.H.; Machado, J.P.B.; Tada, D.B.; Durán, N.; Lemes, A.P. Effect of MWCNT functionalization on thermal and electrical properties of PHBV/MWCNT nanocomposites. J. Mater. Res. 2015, 30, 55–65. [Google Scholar] [CrossRef]

| Sample | Water Extractives (g/100 g) | Cellulose (g/100 g) | Hemicellulose (g/100 g) | Lignin (g/100 g) | Ashes (g/100 g) | TPC (g GAE/100 g) | EC 50 (mg/mg DPPH) |

|---|---|---|---|---|---|---|---|

| GS | 52.2 ± 0.0 a | 22 ± 4 a | 7.0 ± 4 a | 14.7 ± 1.3 a | 7.6 ± 0.1 a | 9.3 ± 0.6 c | 0.64 ± 0.07 a |

| R170 | 25.9 ± 0.0 b | 32 ± 4 b | 1.6 ± 0.1 b | 41.3 ± 1.6 b | 2.9 ± 0.1 b | 17.8 ± 0.3 b | 0.38 ± 0.05 b |

| R180 | 21.2 ± 0.1 b | 34 ± 1.8 b | 0.4 ± 0.1 b | 40.0 ± 0.2 b | 2.9 ± 0.1 b | 19.7 ± 0.3 a | 0.38 ± 0.01 b |

| Sample | EM (MPa) | σ (MPa) | ε (%) | OP × 1014 (cm3 m−1 s−1 Pa−1) | WVP × 1012 (g m−1 s−1 Pa−1) |

|---|---|---|---|---|---|

| PBS | 448 ± 21 c | 40.8 ± 1.7 a | 9.0 ± 0.6 a | 86.0 ± 3.0 a | 18.0 ± 2.0 b |

| PBS-GS | 504 ± 49 b | 31.3 ± 1.9 b | 6.1 ± 0.9 b | 73.2 ± 0.3 b | 36.0 ± 5.0 a |

| PBS-R170 | 634 ± 23 a | 27.0 ± 2.0 c | 4.5 ± 0.6 c | 74.0 ± 2.0 b | 39.0 ± 6.0 a |

| PBS-R180 | 664 ± 55 a | 29.5 ± 1.9 bc | 4.6 ± 0.6 c | 65.4 ± 1.7 c | 38.0 ± 8.0 a |

| PHBV | 2500 ± 180 a | 33.0 ± 2.0 a | 1.7 ± 0.2 b | 39.0 ± 2.0 a | 6.0 ± 0.2 a |

| PHBV-GS | 1100 ± 120 b | 27.0 ± 3.0 c | 1.8 ± 0.1 b | 26.0 ± 2.0 b | 5.1 ± 1.2 a |

| PHBV-R170 | 1200 ± 200 b | 32.0 ± 4.0 ab | 2.2 ± 0.1 a | 26.0 ± 6.0 b | 4.5 ± 0.4 b |

| PHBV-R180 | 1200 ± 120 b | 30.0 ± 3.0 bc | 1.9 ± 0.1 ab | 23.0 ± 5.0 b | 4.2 ± 0.2 b |

| Sample | L* | Cab* | hab* | ∆E* |

|---|---|---|---|---|

| PBS | 93 ± 0 a | 5.40 ± 0.10 b | 69.3 ± 0.3 a | - |

| PBS-GS | 41.0 ± 1.0 b | 21.5 ± 0.2 a | 57.9 ± 1.1 b | 58.3 ± 0.8 b |

| PBS-R170 | 23.9 ± 0.2 c | 1.80 ± 0.10 c | 31.0 ± 2.0 c | 69.4 ± 0.2 a |

| PBS-R180 | 24.0 ± 0.0 c | 1.20 ± 0.10 d | 30.0 ± 4.0 c | 69.7 ± 0.0 a |

| PHBV | 75.0 ± 0.1 a | 18.6 ± 0.2 a | 80.5 ± 0.0 a | - |

| PHBV-GS | 37.1 ± 0.0 b | 13.4 ± 0.1 b | 51.1 ± 0.1 b | 39.1 ± 0.1 c |

| PHBV-R170 | 27.4 ± 0.0 c | 2.3 ± 0.1 c | 41.8 ± 0.1 c | 50.2 ± 0.1 b |

| PHBV-R180 | 27.7 ± 0.0 d | 2.5 ± 0.0 d | 41.7 ± 0.1 c | 50.6 ± 0.0 a |

| 1st Heating | 2nd Heating | |||

|---|---|---|---|---|

| Sample | ∆Hm (J/g Polymer) | Xc (%) | ∆Hm (J/g Polymer) | Xc (%) |

| PBS | 67.0 ± 3.0 a | 33.2 ± 1.3 a | 60.0 ± 6.0 a | 29.7 ± 2.8 a |

| PBS-GS | 66.6 ± 0.6 a | 32.7 ± 0.2 a | 57.8 ± 0.5 a | 28.6 ± 0.5 a |

| PBS-R170 | 69.6 ± 1.14 a | 34.5 ± 0.6 a | 58.0 ± 3.0 a | 28.7 ± 0.2 a |

| PBS-R180 | 69.0 ± 6.0 a | 34.0 ± 3.0 a | 57.7 ± 1.6 a | 28.6 ± 0.4 a |

| PHBV | 86.9 ± 0.4 a | 65.8 ± 0.3 a | 86.0 ± 2.0 a | 65.0 ± 2.0 a |

| PHBV-GS | 65.0 ± 2.0 b | 49.0 ± 2.0 b | 67.0 ± 3.0 b | 51.0 ± 2.0 b |

| PHBV-R170 | 69.0 ± 8.0 b | 52.2 ± 0.3 b | 70.3 ± 1.1 b | 53.2 ± 0.8 b |

| PHBV-R180 | 66.0 ± 1.7 b | 50.0 ± 1.3 b | 71.6 ± 0.3 b | 54.5 ± 0.3 b |

| Samples | Time (Days) | PV (meq O2/Kg Oil) | Conjugated Dienes (K232) | Conjugated Trienes (K268) |

|---|---|---|---|---|

| 0 | 5.36 ± 0.04 | 3.34 ± 0.01 | 1.07 ± 0.01 | |

| Control | 15 | 145.0 ± 12.0 a | 29.93 ± 0.2 c | 1.25 ± 0.05 ab |

| PBS | 124.4 ± 11.2 a | 29.2 ± 1.2 b | 1.47 ± 0.08 ab | |

| PBS-GS | 119.0 ± 20.0 a | 29.8 ± 0.8 b | 1.36 ± 0.03 ab | |

| PBS-R170 | 122.6 ± 11.3 a | 29.3 ± 1.7 ab | 1.25 ± 0.03 ab | |

| PBS-R180 | 124.0 ± 3.0 a | 29.3 ± 0.2 b | 1.40 ± 0.20 b | |

| PHBV | 128.0 ± 18.0 a | 29.4 ±0.7 ab | 1.20 ± 0.16 ab | |

| PHBV-GS | 84.0 ± 22.0 b | 25.6 ± 1.4 a | 1.70 ± 0.40 b | |

| PHBV-R170 | 79.6 ± 0.2 b | 26.0 ± 2.0 ab | 1.18 ± 0.05 ab | |

| PHBV-R180 | 86.0 ± 9.0 b | 28.2 ± 1.5 ab | 1.13 ± 0.05 a |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Maté, I.; Atarés, L.; Vargas, M.; Chiralt, A. Antioxidant Biocomposite Films Based on Grape Stalk Lignocellulosic Fractions and Biodegradable Polyesters. Polymers 2025, 17, 1525. https://doi.org/10.3390/polym17111525

Maté I, Atarés L, Vargas M, Chiralt A. Antioxidant Biocomposite Films Based on Grape Stalk Lignocellulosic Fractions and Biodegradable Polyesters. Polymers. 2025; 17(11):1525. https://doi.org/10.3390/polym17111525

Chicago/Turabian StyleMaté, Irene, Lorena Atarés, Maria Vargas, and Amparo Chiralt. 2025. "Antioxidant Biocomposite Films Based on Grape Stalk Lignocellulosic Fractions and Biodegradable Polyesters" Polymers 17, no. 11: 1525. https://doi.org/10.3390/polym17111525

APA StyleMaté, I., Atarés, L., Vargas, M., & Chiralt, A. (2025). Antioxidant Biocomposite Films Based on Grape Stalk Lignocellulosic Fractions and Biodegradable Polyesters. Polymers, 17(11), 1525. https://doi.org/10.3390/polym17111525