Abstract

High-density polyethylene (HDPE) is a widely used thermoplastic known for its chemical resistance and ease of processing, but it has limited wear performance and moderate mechanical properties. In this study, recycled polyvinyl butyral (rPVB) was incorporated into HDPE at 5, 10, 15, and 20 wt.% to evaluate its effect on tribological performance. Pin-on-disk wear tests were conducted at 12, 15, and 18 N to assess the coefficient of friction (CoF) and wear resistance. Mean CoF values decreased by up to 40% with rPVB addition, with the best performance observed at 15 wt.% rPVB, although some variation was observed across replicates. SEM analysis revealed that rPVB promotes finer debris and transfer film formation, explaining the CoF reduction. However, wear resistance exhibited a complex trend: while rPVB improved adhesion and reduced material loss at lower loads, volume loss increased at higher loads, likely due to rPVB’s lower hardness. Mechanical testing showed an increase in elastic modulus at low rPVB contents due to higher crystallinity, confirmed by DSC; however, tensile strength and impact resistance decreased with rPVB. The results suggest that incorporating 10–15 wt.% of rPVB into HDPE can enhance frictional performance without severely compromising mechanical integrity, offering a sustainable way to valorize rPVB.

1. Introduction

The growing concern about sustainability has highlighted the need for recycling plastics, particularly those used in the automotive sector. Unlike commodity plastics, many of the polymers employed in vehicles, such as polyvinyl butyral (PVB), are engineering or high-performance materials with unique characteristics. PVB is predominantly used in laminated glass for automotive windshields, contributing approximately 1.5 to 2 kg of material per vehicle [1,2]. Given the significant volume of end-of-life vehicles worldwide, this represents an immense opportunity to recycle and repurpose PVB into high-value applications.

Despite its excellent mechanical and thermal properties [3], recycled PVB (rPVB)—whether obtained from end-of-life windshields or as residual scrap from production lines—has largely been underutilized or not effectively used [4]. Current applications for this material include its incorporation into flooring and carpet backing [5] and other low-performance products, which fail to exploit its potential as a high-performance polymer. Recent investigations have explored advanced uses for rPVB, including its role as a toughener for polymers such as polyamide [3,4,6,7] and polyvinyl chloride [8]. In these blends, rPVB has demonstrated the ability to enhance impact resistance when appropriately compatibilized. More recently, use of rPVB as a UV-protective textile coating has also been investigated [9], and it was reported that rPVB coating not only improved the tensile strength of the textile materials but also showed a great improvement in its ultraviolet protection factor. Finally, rPVB has been investigated as a solid lubricant for neat and glass-fiber-reinforced polyamide [10,11,12] and polyoxymethylene [13] due to its good adhesion and low shear strength. In those studies, rPVB has significantly reduced the coefficient of friction (CoF) of the blends.

This study focuses on the potential use of rPVB as a solid lubricant in high-density polyethylene (HDPE) blends. In previous studies, a wide range of modifiers have been explored to enhance the wear resistance and tribological behavior of HDPE. These include inorganic nanoparticles such as fumed silica (SiO2), titanium nitride (TiN), and halloysite nanotubes (HNTs), which have shown notable improvements when modified with silane coupling agents to enhance interfacial bonding [14]. Graphite nanoplatelets (GNPs), both untreated and organosilane-modified, have demonstrated solid-lubricating effects, achieving significant increases in wear resistance and reductions in friction at low contents [15,16]. Molybdenum disulfide (MoS2) has also been incorporated effectively into HDPE, promoting transfer film formation and frictional heat dissipation [17]. Blending with ultra-high-molecular-weight polyethylene (UHMWPE) has similarly been shown to improve abrasion resistance through plastic deformation and fibrillation mechanisms [18].

While these approaches offer significant tribological performance enhancements, there is growing interest in integrating sustainability principles through green tribology. For example, a recent study [19] demonstrated that incorporating recycled silicon particles recovered from wafer cutting waste into a PTFE matrix significantly reduced both the coefficient of friction and specific wear rate, showcasing the potential of recycled industrial materials as effective solid lubricants in polymer composites. Because tribological behavior is known to be highly system-specific, dependent not only on bulk properties but also on surface interactions and operating conditions [20], even if recycled polymers experience some degradation that limits their use in structural applications, they may still perform well in tribological systems. For example, recycled polycarbonate has shown good sliding performance in components like skateboard wheels, while reprocessed HDPE has exhibited wear resistance comparable to that of virgin UHMWPE, even after multiple extrusion cycles [20,21]. These examples highlight the potential of recycled materials in tribological applications and support further investigation into alternative, circular strategies for performance enhancement.

HDPE is a more promising candidate for blending with rPVB compared to previously studied polymers like PA. While PA has excellent mechanical resistance (e.g., higher elastic modulus and ultimate tensile strength), it is thermally dissimilar to rPVB, raising concerns about degradation during processing. Furthermore, rPVB was found to significantly reduce the mechanical properties of PA blends [11], limiting their practical applications. In contrast, HDPE shares greater thermal compatibility with rPVB, potentially enabling better integration and improved material properties.

Additionally, previous work by the authors [22] has demonstrated the biocompatibility and safety of HDPE/rPVB blends in preclinical in vitro models, paving the way for their use in biomedical applications where wear resistance and low friction coefficients are critical. These findings highlight the importance of mechanical and tribological characterization to evaluate the suitability of HDPE/rPVB blends for such applications. The present study aims to address this need by investigating the mechanical and tribological performance of HDPE/rPVB blends, exploring their potential for innovative, high-value uses of rPVB. This research seeks to contribute to a circular economy and reduce the environmental impact of polymer waste while advancing sustainable materials for engineering applications.

2. Materials and Methods

2.1. Materials

Polymer blends were produced using a commercial high-density polyethylene (HDPE), under the tradename Alathon H5520 from LyondellBasell (Rotterdam, The Netherlands), and recycled polyvinyl butyral (rPVB) donated by Saint-Gobain Mexico (Morelos, Mexico) from its windshield production line. Maleic anhydride (MA) with a molecular weight of 98.06 g/mol from Meyer (Ciudad de Mexico, Mexico) was used as a coupling agent.

2.2. Blends Preparation

HDPE/rPVB/MA blends were produced by mixing HDPE with an initial rPVB/MA blend. rPVB/MA blends were prepared by extruding rPVB with 1 wt.% of MA in a Beutelspacher SB-19 single screw extruder at 120 °C and 90 rpm. The extruded material strands were cooled in a water bath and pelletized. Prior to extrusion, the mixtures of rPVB with MA were dried at 60 °C for 24 h. MA was selected for its role as a reactive compatibilizer in the rPVB/MA blend. By reacting with the hydroxyl groups in rPVB, MA introduces polar reactive sites that enhance interfacial adhesion with nonpolar HDPE, improving overall blend compatibility [23,24,25]. Then, HDPE/rPVB/MA blends were prepared by extruding HDPE with 5, 10, 15, and 20 wt.% of the different rPVB/MA blends at temperatures between 140 and 150 °C and 90 rpm. The extruded material strands were cooled in a water bath and pelletized. The mixtures of HDPE/rPVB/MA were also dried in a fan oven at 60 °C for 24 h before extrusion. The obtained blends were extruded one more time (two in total) to promote a good dispersion of the rPVB/MA blend into the HDPE matrix. To maintain an equal thermal history, the same extrusion process was performed twice on the HDPE matrix used as a control. Blends and their compositions are summarized in Table 1.

Table 1.

Composition of HDPE/rPVB/MA blends.

Specimens for tensile, impact, and wear tests were injection-molded in a Belken SSF500-k5 machine (Belken, Taichung, Taiwan) at an injection temperature of 180 °C and injection and packing pressures of 35–45 MPa and 20–36 MPa, respectively. The mold was kept at room temperature.

2.3. Morphology Analysis

Injection-molded wear specimens (Section 2.8) were cryogenically fractured using liquid nitrogen and etched with ethanol for 9 h to selectively dissolve the rPVB phase as described in ref. [6]. This etching step was necessary to evaluate the dispersion of rPVB within the HDPE matrix, as it enables indirect observation of its distribution through the voids remaining in the matrix, which are not visible in unetched fractured surfaces.

2.4. Differential Scanning Calorimetry (DSC)

DSC tests were performed using a Shimadzu DSC-60 device (Shimadzu Corporation, Kyoto, Japan). Specimens were first heated from 25 °C to 200 °C at 10 °C/min under nitrogen flow and then kept at 200 °C for 5 min. The specimens were then cooled to 25 °C at the same rate and held at 25 °C for 5 min. Then, the specimens were reheated to 200 °C at the same rate and finally cooled down to room temperature at 20 °C/min.

2.5. Melt Flow Index (MFI)

MFI tests were performed on a Dynisco 5000 Melt Flow Indexer (Dynisco, MA, USA) following the ASTM D1238 standard [26] at 190 °C with a 2.16 kg load. The blends were dried in a fan oven at 60 °C for 24 h prior to testing. Three replicate samples were used.

2.6. Shore D Hardness

Hardness measurements were performed on a Shore SI-TV desktop device (Shore Instruments & MFG Co., New York, NY, USA) following the ASTM D2240 standard [27] using a 4 kg load. Sanded wear specimens (Section 2.8) were used. Ten measurements per blend were made.

2.7. Tensile Tests

Tensile tests were performed in a Shimadzu AG-I equipment (Shimadzu Corporation, Kyoto, Japan) according to the ASTM D638 standard [28]. Type V specimens were used with a gauge length of 7.62 mm, a narrow section width of 3.18 mm, and thickness of 3.30 mm. Tests were performed at room temperature with a crosshead speed of 10 mm/min. Three replicate samples of each blend were used.

2.8. Charpy Impact Tests

Impact tests were performed according to the ASTM D6110 standard [29] on an MT 3016 Charpy impact tester (Hung Ta Instrument Co., Taichung, Taiwan) with a hammer arm length of 358 mm and a mass of 2.25 kg. Notched specimens (12.7 mm × 4.2 mm × 125 mm) with a 2.5 mm deep 45° V-groove were tested. Five replicate samples per blend were used.

2.9. Wear Tests

Injection-molded disk specimens with a diameter of 38 mm and a thickness of 3 mm were used for wear tests. Before testing, each specimen was sanded until obtaining a roughness of 0.3 ± 0.03 μm. Pin-on-disk wear tests were performed according to the ASTM G99-17 standard [30] in a CSM tribometer (Anton Paar, Peseux, Switzerland) using 6 mm steel balls (AISI 52100); normal loads of 12, 15, and 18 N; a sliding speed of 1 m/s; a 100 mm track radius; and a sliding distance of 1000 m. Three replicates per blend were used.

2.10. Scanning Electron Microscopy (SEM)

Cryogenically fractured etched surfaces, wear tracks, and counterpart steel balls were analyzed in a JSM6360LV scanning electron microscope (JEOL Ltd., Tokyo, Japan). Specimens were sputter-coated with a thin layer of gold prior to observation to eliminate charging.

3. Results and Discussion

3.1. Morphology Analysis

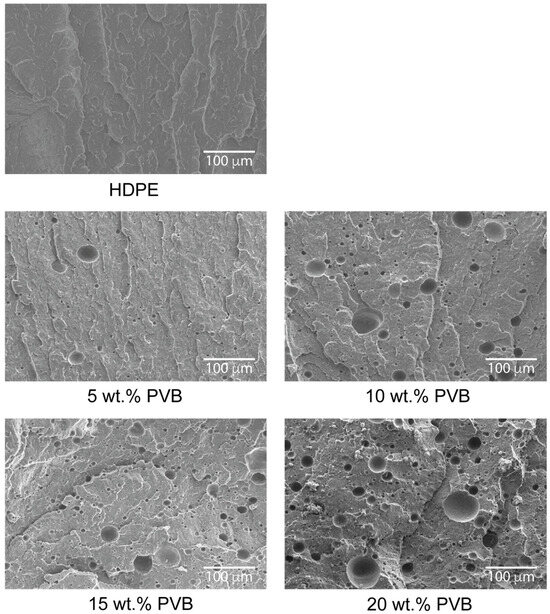

In Figure 1, the morphology of the blends is shown. rPVB was dissolved in ethanol, so the remaining voids observed in the micrographs represent the size and dispersion of rPVB particles. Particle size was measured using ImageJ software (version 1.54 g), and the results are summarized in Table 2. As observed, particle size increases with rPVB content, as reported for other rPVB blends [11,13], although for 10 wt.% and 15 wt.%, the size is very similar. Also note that the standard deviation is very high, as the size of rPVB particles varies significantly in every sample.

Figure 1.

Cryogenically fractured surfaces after etching with ethanol.

Table 2.

Results for particle diameter, melt and crystallization temperatures, crystallinity, and melt flow index for HDPE/rPVB/MA blends.

3.2. Dynamic Scanning Calorimetry (DSC)

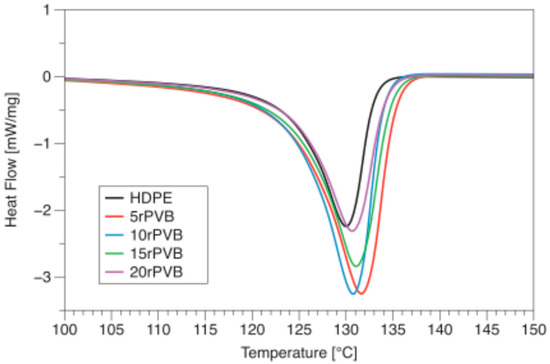

The DSC curves of the HDPE/rPVB/MA blends are shown in Figure 2 and summarized in Table 2. The crystallinity of the blends was estimated with Equation (1):

where is the melting enthalpy of the blends, the melting enthalpy of 100% crystallized HDPE (293 J/g [31]), and the weight fraction of HDPE in the samples.

Figure 2.

DSC curves of HDPE/PVB/MA blends during the second heating cycle.

As observed from Table 2, the addition of rPVB increases the crystallinity of HDPE from 30.7 to 57.5% when 5 wt.% of rPVB is used. This represents an increase of 87% in crystallinity. As rPVB content increases further, crystallinity decreases down to 46.9%. Similar results have been reported for PP [25], in which rPVB particles acted as nucleating agents for crystallization.

3.3. Melt Flow Index (MFI)

As observed in Table 2, the addition of 5 wt.% of rPVB slightly increases the MFI of pure HDPE. However, further increases in rPVB linearly decrease (R2 = 0.988) the MFI of the blends. For the 20rPVB blend, the MFI decreases down to 16.5 g/10 min, which represents a decrease of 11.8% with respect to HDPE. This agrees with similar works in which rPVB was blended with other polymers such as POM [13] and PA [11,12]. Although rPVB from laminated glasses usually has up to 30 wt.% of plasticizers [3], which may reduce viscosity and thus increase the MFI, rPVB alone typically has a higher molecular weight and lower chain mobility than HDPE. This results in a lower MFI for rPVB (1.71 ± 0.02 and 18.7 ± 0.1 g/10 min for rPVB and HDPE, respectively), which explains the decrease in MFI for blends with 10, 15, and 20 wt.% of rPVB: as the rPVB content increases, the overall viscosity of the blend rises because the polymer matrix is progressively diluted with a component that has less flowability.

3.4. Shore D Hardness

The Shore D hardness results are shown in Table 3. Although hardness is slightly lower for blends containing rPVB, the difference is not significant. The values remained between 61.6 ± 1.1 (20 wt.%) and 65.7 ± 0.6 (HDPE), which represents a maximum reduction of 6.2%. Similar results have been reported for PA/rPVB and POM/rPVB blends, in which the hardness of the matrix is usually maintained despite rPVB having a significantly lower hardness (25.6 Shore D [13]) than the matrix (in this case, 65.7 for HDPE according to Table 3). Because Shore D hardness evaluates the resistance of the material to localized deformation, it is primarily determined by the properties of the continuous matrix phase (HDPE), diminishing the effect of rPVB.

Table 3.

Results for Shore D hardness, tensile, and impact tests for HDPE/rPVB/MA blends.

3.5. Tensile Tests

Elastic modulus (E), ultimate tensile strength (UTS), and strain at UTS results are summarized in Table 3. Contrary to other rPVB blends with PA and POM matrices, the addition of small amounts of rPVB (5–10 wt.%) increases E. Although the standard deviation for the 5rPVB blend is higher than 10%, the results indicate that at 5 and 10 wt.% content of rPVB, the stiffness of the matrix prevails with a certain level of enhancement. It has been reported that PVB has an E of 6.4 MPa [3], whereas HDPE, according to Table 2, has an E = 353 MPa. This does not seem possible according to the rule of mixtures, which predicts an E of 335 MPa for HDPE with 5 wt.% of rPVB. However, this enhancement might be due to rPVB particles acting as nucleating agents for HDPE and thus increasing its crystallinity, as reported in Section 3.2. However, at higher rPVB contents, the effect of rPVB’s low stiffness is more dominant than that of increased crystallinity.

Contrary to E values, UTS values decrease with rPVB content: UTS decreases 6.5% when 5 wt.% of rPVB is used, and 30% when 20 wt.% is added. This decoupling between E and UTS behavior is likely due to the presence of large and non-uniform rPVB particles (as observed in Figure 1), which acted as stress concentrators under tensile loading, and thus promoted earlier failure. This also agrees with the reduction in strain at UTS with rPVB addition. Furthermore, the increase in crystallinity can also contribute to the embrittlement of the blend.

3.6. Charpy Impact Tests

Charpy impact resistance decreases with rPVB content as shown in Table 3. For samples with 20 wt.% of rPVB, a reduction of ~47% was found. This is opposite to the toughening effect that has been reported for rPVB blends in other investigations [4,6]. However, in those studies, compatibilizers such as POE-g-MA were used, in which their toughening effect contributes to the toughening of the system. The reduction in impact resistance can be attributed to similar factors to UTS, including poor stress transfer at the HDPE/rPVB interface, the presence of large and irregular rPVB particles acting as stress concentrators, and the increased crystallinity of the matrix that led to a more brittle behavior.

3.7. Wear Tests

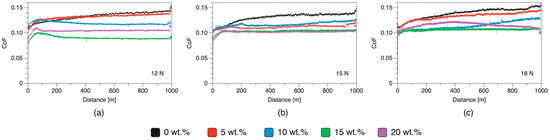

The tribological performance of HDPE/rPVB/MA blends was investigated using pin-on-disk wear tests under different loads (12, 15, and 18 N). In Figure 3, CoF curves obtained from the pin-on-disk wear tests are shown. In general, the curves follow the same pattern: there is a sudden increase in CoF due to the application of the load, followed by a running-in period in which the tribological pairs are coupled. It has been reported that at this stage, asperities at the surfaces might be knocked off and as a result, surfaces mate better. After that stage, the CoF stabilizes into a steady-state sliding.

Figure 3.

Coefficient of friction (CoF) curves of HDPE/rPVB/MA blends during pin-on-disk wear tests at (a) 12, (b) 15, and (c) 18 N.

CoF results are summarized in Table 4. As observed, pure HDPE presents the highest CoF at all loads. The addition of rPVB to HDPE reduced the CoF across all tested loads. This reduction was more pronounced at higher rPVB content (20 wt.%), except for blends tested at 12 N and 18 N, where the 15 wt.% PVB blend outperformed others, including samples with 20 wt.% of rPVB. This has been previously reported for PAGF/rPVB and POM/rPVB blends [11,12,13], in which recycled rPVB acts as a solid lubricant, which has been attributed to the formation of a transfer film on the steel counterpart. Although some of the error bars in the CoF results overlap, the mean values show a general decreasing trend with increasing rPVB content. This trend aligns with the expected behavior of rPVB as a solid lubricant and is supported by similar observations in the literature [10,11,13]. However, further statistical analysis (e.g., ANOVA) and additional repetitions could be performed in future work to confirm the significance of these differences and reduce experimental variability.

Table 4.

Coefficient of friction and volume loss for HDPE/rPVB/MA blends with 1 wt.% of maleic anhydride (MA) during pin-on-disk wear tests at 12, 15, and 18 N.

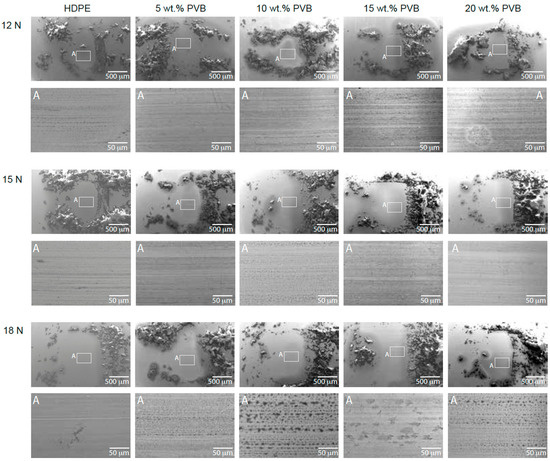

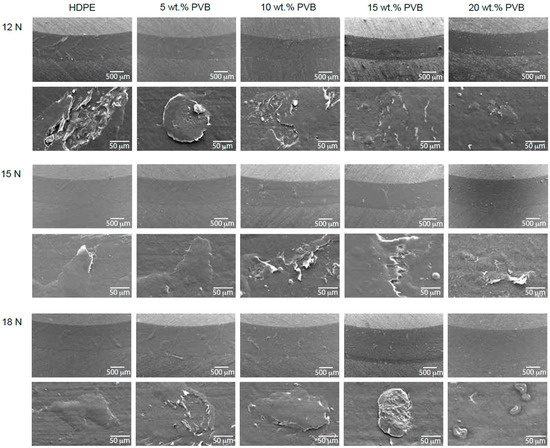

In Figure 4, SEM images of the steel balls are shown. Debris is accumulated in all the balls regardless of their composition or load. However, it can be noticed that debris from HDPE samples is bulkier, whereas with rPVB content, the debris becomes finer. Larger debris particles can remain trapped between the contact surfaces, acting as third-body abrasives that increase roughness and therefore the CoF, whereas finer debris particles are less likely to interlock and more prone to act as lubricants, reducing the CoF. Also, finer debris might be acting as third-body rolling elements [32,33], which can decrease friction and increase wear resistance of the polymer matrix acting as micro-bearings. Due to rPVB adhesive properties, it might be harder for large particles to break off from the surface, leading to finer debris and progressive removal, layer by layer, rather than large detachments of material as in the HDPE blend. A closer look into these micrographs is also shown in Figure 4, in which the transfer film located at the middle of the balls is observed in more detail.

Figure 4.

SEM micrographs of steel balls (counterparts) after pin-on-disk wear tests of HDPE/rPVB/MA blends at 12, 15, and 18 N.

At 12 N, the transfer films were uniform across all rPVB contents, supporting the hypothesis that rPVB promotes film retention. For the 15 wt.% sample, the darker color indicates that the material was transferred and accumulated into the valleys of the counterpart, leaving the surface smoother and hence reducing the CoF. No signs of detachment are observed. Similar surfaces are observed at 15 N, although for 10 wt.%, the transfer film appears patchy and non-uniform, indicating that the film was being formed and removed under higher loads. Bahadur [34] concluded that the lack of a continuous transfer film suggests that adhesion between the polymeric transfer film and the steel surface was weak. At higher loads, the wear mechanism might change, so the adhesion effect of rPVB might not be enough to prevent material removal. Also, the transfer film might break down, releasing debris and increasing wear. This is also observed at 18 N (10 and 20 wt.% PVB) and agrees with the higher wear rate of these samples, which will be analyzed next. For the 15 wt.% rPVB blend at 18 N, roll-like debris [34] is observed on the steel counterpart, further suggesting partial removal of the transfer film under higher loads. Note, however, that further characterization of the adhered material using X-ray photoelectron spectroscopy (XPS) or energy-dispersive X-ray spectroscopy (EDX) would be highly valuable to precisely determine the elemental composition and chemical changes occurring at the contact surfaces. Complementary techniques such as confocal Raman microscopy or FTIR could also help to identify organic species present in the transfer film and provide insights into potential tribochemical reactions.

The resulting wear tracks after the pin-on-disk tests are shown in Figure 5. Their width was measured to estimate the disk volume loss as proposed by the ASTM G99 standard [30] with Equation (2), assuming no significant wear on the steel balls.

where and represent the wear track radius and width, and is the radius of the pin. The results are summarized in Table 4. The volume loss results indicate a complex interaction between rPVB content, applied load, and the competing mechanisms of adhesion and hardness. At 12 N, blends with rPVB exhibited lower volume loss compared to pure HDPE, although no consistent trend was observed across all concentrations. This reduction (up to 16%, or 13% when accounting for experimental variability) suggests that rPVB may initially improve wear behavior by promoting adhesion and transfer film formation, thereby reducing material detachment from the wear track. The authors acknowledge that the relatively modest improvement and overlap in error bars across replicates make it difficult to draw strong conclusions about the magnitude of this effect. Higher magnification SEM images of the wear tracks, shown in Figure 5, support this hypothesis, showing significant detachment of adhered material in pure HDPE and blends with 5 wt.% rPVB, while detachment is progressively minimized in blends with 10, 15, and 20 wt.% rPVB. Note the blister-like features present at 0 and 5 wt.% of rPVB. It seems like material in those regions is not completely adhered and is ready to be detached with further sliding contact. At 15 N, volume loss was very similar for blends with 0 to 15 wt.% of rPVB, but it increased a little bit further for 20 wt.%. At 18 N, however, volume loss increased for all blends containing rPVB. The higher contact force likely overcomes the adhesive effect of rPVB, leading to the removal of the transfer film and greater material detachment from the wear track. SEM images corroborate this, showing that detachment becomes more severe in HDPE/rPVB/MA blends at higher loads. This agrees with [12], in which it was concluded that rPVB initially acts as a binder or adhesive that hinders debris release, decreasing mass loss; however, at higher contact loads, this binding effect is overcome by the lower hardness effect of rPVB, which facilitates material detachment and thus increases volume loss.

Figure 5.

SEM micrographs of the wear tracks after pin-on-disk wear tests of HDPE/rPVB/MA blends at 12, 15, and 18 N.

4. Conclusions

This study investigated the effects of rPVB on the properties of HDPE, focusing on morphological, mechanical, rheological, and tribological behaviors. The incorporation of rPVB led to non-uniform morphologies with increasing particle size at higher concentrations. Melt flow index (MFI) exhibited a decreasing trend with increasing rPVB content, attributed to the higher molecular weight and lower chain mobility of rPVB. Mechanical characterization showed that Shore D hardness remained relatively unchanged across all blends, as this property is mainly governed by the HDPE matrix. Interestingly, the elastic modulus of the blends increased at low rPVB concentrations (5–10 wt.%), a behavior that deviates from other studies in which 5 to 10 wt.% of rPVB decreased the stiffness of PA and POM. DSC analysis indicated that rPVB acted as a nucleating agent, increasing the crystallinity of the HDPE matrix, which explains the stiffening effect. In contrast, both UTS and impact resistance decreased with increasing rPVB content. This reduction in strength and toughness is attributed to the presence of large, non-uniform rPVB particles acting as stress concentrators, as well as the increased crystallinity, which contributes to embrittlement of the matrix, promoting premature failure. Tribological analysis showed that the addition of rPVB led to a general decrease in the CoF of HDPE, particularly at higher rPVB contents. Although some variability was observed among replicates, the mean trend supports the lubricating role of rPVB, attributed to the formation of a more stable transfer film on the steel counterpart and the generation of finer debris, as confirmed by SEM analysis. At lower contact loads, rPVB’s adhesive nature promoted better film retention and minimized wear by preventing large-scale material detachment. However, at higher loads, this beneficial effect was overcome, likely due to the lower hardness of rPVB, leading to increased volume loss. The wear performance of the blends thus exhibited a complex dependence on both rPVB content and applied load: with rPVB acting as a binder at low stresses but contributing to material removal at higher stresses. Although the improvements in tribological performance were moderate and presented variability across replicates, the observed trends are consistent with the expected behavior of rPVB as a solid lubricant. Note, however, that these findings must be weighed against the reduction in mechanical strength, especially for 15–20 wt.%, and the limited effect of rPVB on the thermal transitions of HDPE. Nevertheless, this study contributes to a better understanding of how recycled materials, despite certain trade-offs, can be functionally integrated into tribological systems.

Author Contributions

Investigation, S.A.-M.; supervision, U.F.-L.; methodology, U.F.-L. and A.G.-M.; writing—review and editing, A.G.-M.; funding acquisition, U.F.-L. and A.G.-M. All authors have read and agreed to the published version of the manuscript.

Funding

This work was financially supported by the Tecnologico de Monterrey Challenge-Based Research Funding Program, Proposal E065-EIC-GI03-A-T11-D.

Institutional Review Board Statement

Not applicable.

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by the authors on request.

Acknowledgments

The authors thankfully acknowledge the donation of residual PVB from Saint-Gobain Mexico.

Conflicts of Interest

The authors declare no conflicts of interest. The funder had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

References

- Šooš, L.U.; Matúš, M.; Pokusová, M.; Čačko, V.; Bábics, J. The recycling of waste laminated glass through decomposition technologies. Recycling 2021, 6, 26. [Google Scholar] [CrossRef]

- Swain, B.; Ryang Park, J.; Yoon Shin, D.; Park, K.S.; Hwan Hong, M.; Gi Lee, C. Recycling of waste automotive laminated glass and valorization of polyvinyl butyral through mechanochemical separation. Environ. Res. 2015, 142, 615–623. [Google Scholar] [CrossRef] [PubMed]

- Valera, T.S.; Demarquette, N.R. Polymer toughening using residue of recycled windshields: PVB film as impact modifier. Eur. Polym. J. 2008, 44, 755–768. [Google Scholar] [CrossRef]

- Wei, Z.; Wang, R.; Wang, J.; Yang, Y.; Liu, Y.; Wang, W.; Cao, Y. Highly toughened PA6 using residue of plasticized PVB film via two-step reactive melt blending. Polymer 2020, 186, 122052. [Google Scholar] [CrossRef]

- Tupý, M.; Měřínská, D.; Tesaříková-Svobodová, A.; Carrot, C.; Pillon, C.; Petránek, V. Mechanical properties of recycled plasticized PVB/PVC blends. Int. J. Chem. Mol. Eng. 2014, 8, 981–986. [Google Scholar]

- Wei, Z.; Wang, R.; Zhang, C.; Wang, J.; Yang, Y.; Wang, W.; Cao, Y. Preparation and characterization of super-toughened PA6/r-PVB blends with “transplanted” multicore morphology by reactive compatibilization. Eur. Polym. J. 2021, 143, 110173. [Google Scholar] [CrossRef]

- Zanjanijam, A.R.; Hakim, S.; Azizi, H. Rheological, mechanical and thermal properties of the PA/PVB blends and their nanocomposites: Structure-property relationships. Polym. Test. 2018, 66, 48–63. [Google Scholar] [CrossRef]

- Peng, Y.; Sui, Y. Compatibility research on PVC/PVB blended membranes. Desalination 2006, 196, 13–21. [Google Scholar] [CrossRef]

- Cei, N.; Canesi, I.; Nejrotti, S.; Montalbano, G.; Darjazi, H.; Piovano, A.; Bonomo, M.; Fina, A.; Yecora, B.; Perez, A.; et al. A UV-Protective Textile Coating Based on Recycled Poly(vinyl butyral) (PVB): A New Life for a Waste Polymer. Polymers 2024, 16, 3439. [Google Scholar] [CrossRef]

- Hernández-Peña, A.; Guevara-Morales, A.; Figueroa-López, U.; Carmona-Cervantes, A.; Farfan-Cabrera, L.I. Tribological properties of recycled polyvinyl butyral (rPVB) and glass fiber reinforced polyamide blends in dry and micro-abrasive contacts. Tribol. Trans. 2024, 67, 805–816. [Google Scholar] [CrossRef]

- Carmona-Cervantes, I.A.; Campos-Silva, I.; Figueroa-López, U.; Guevara-Morales, A. Effect of Recycled Polyvinyl Butyral (rPVB) Addition on the Tribological Performance of Glass–Fiber Reinforced Polyamide (PAGF) during Reciprocating Sliding Wear Conditions. Polymers 2023, 15, 2580. [Google Scholar] [CrossRef] [PubMed]

- Carmona-Cervantes, I.A.; Paredes-Mogica, E.A.; López-Cabrera, H.R.; Figueroa-López, U.; Vieyra-Ruíz, H.; Guevara-Morales, A. Tribological behavior of glass fiber reinforced polyamide (PA-GF) and recycled polyvinyl butyral (r-PVB) blends. Mater. Lett. 2022, 319, 132261. [Google Scholar] [CrossRef]

- Cardona-Ramírez, J.; Paredes-Mogica, E.A.; Guevara-Morales, A.; Figueroa-López, U. Recycling automotive plastic waste: Residual polyvinyl butyral (rPVB) as solid lubricant in polyoxymethylene (POM) blends. Tribol. Trans. 2024, 67, 359–369. [Google Scholar] [CrossRef]

- Pelto, J.; Heino, V.; Karttunen, M.; Rytöluoto, I.; Ronkainen, H. Tribological performance of high density polyethylene (HDPE) composites with low nanofiller loading. Wear 2020, 460, 203451. [Google Scholar] [CrossRef]

- Liu, T.; Li, B.; Lively, B.; Eyler, A.; Zhong, W.-H. Enhanced wear resistance of high-density polyethylene composites reinforced by organosilane-graphitic nanoplatelets. Wear 2014, 309, 43–51. [Google Scholar] [CrossRef]

- Xu, S.; Tangpong, X. Tribological behavior of polyethylene-based nanocomposites. J. Mater. Sci. 2013, 48, 578–597. [Google Scholar] [CrossRef]

- Pettarin, V.; Churruca, M.J.; Felhös, D.; Karger-Kocsis, J.; Frontini, P.M. Changes in tribological performance of high molecular weight high density polyethylene induced by the addition of molybdenum disulphide particles. Wear 2010, 269, 31–45. [Google Scholar] [CrossRef]

- Aderikha, V.; Feipeng, C.; Koval, V.; Xiaoyu, L.; Shapovalov, V.; Makarenko, O.; Yongguang, X. Increasing the resistance of HDPE to abrasive wear with small additions of UHMWPE. J. Frict. Wear 2022, 43, 1–7. [Google Scholar] [CrossRef]

- Vishal, K.; Rajkumar, K.; Sabarinathan, P. Effect of recovered silicon filler inclusion on mechanical and tribological properties of polytetrafluoroethylene (PTFE) composite. Silicon 2022, 14, 4601–4610. [Google Scholar] [CrossRef]

- Raghuram, H.; Roitner, J.; Jones, M.P.; Archodoulaki, V.-M. Recycling of polyethylene: Tribology assessment. Resour. Conserv. Recycl. 2023, 192, 106925. [Google Scholar] [CrossRef]

- Tzanakis, I.; Hadfield, M.; Thomas, B.; Noya, S.; Henshaw, I.; Austen, S. Future perspectives on sustainable tribology. Renew. Sustain. Energy Rev. 2012, 16, 4126–4140. [Google Scholar] [CrossRef]

- Vieyra, H.; Juárez, E.; Figueroa-López, U.; Alejo-Martínez, S.; Aguilar-Méndez, M.A.; San Martin-Martínez, E.; Guevara-Morales, A. Cytotoxicity and biocompatibility of a material based in recycled polyvinyl butyral PVB and high-density polyethylene HDPE determined in human peripheral leukocytes. Mater. Res. Express 2024, 11, 105402. [Google Scholar] [CrossRef]

- Hofmann, G.H.; Lee, W.C. Modification of polymers by using poly(vinyl butyral)-based additives. J. Vinyl Addit. Technol. 2006, 12, 33–36. [Google Scholar] [CrossRef]

- Trivedi, B. Maleic Anhydride; Springer Science & Business Media: New York, NY, USA, 2013. [Google Scholar]

- Zanjanijam, A.R.; Hakim, S.; Azizi, H. Morphological, dynamic mechanical, rheological and impact strength properties of the PP/PVB blends: The effect of waste PVB as a toughener. RSC Adv. 2016, 6, 44673–44686. [Google Scholar] [CrossRef]

- ASTM 1238; Standard Test Method for Melt Flow Rates of Thermoplastics by Extrusion Plastometer. ASTM International: West Conshohocken, PA, USA, 2013.

- ASTM D2240; Standard Test Method for Rubber Property—Durometer Hardness. ASTM International: West Conshohocken, PA, USA, 2010.

- ASTM D638; Standard Test Method for Tensile Properties of Plastics. ASTM International: West Conshohocken, PA, USA, 2008.

- ASTM D6110; Determining the Charpy Impact Resistance of Notched Specimens of Plastics. ASTM International: West Conshohocken, PA, USA, 2008.

- ASTM G99; Standard Test Method for Wear Testing with a Pin-on-Disk Apparatus. ASTM International: West Conshohocken, PA, USA, 2005.

- Tarani, E.; Arvanitidis, I.; Christofilos, D.; Bikiaris, D.N.; Chrissafis, K.; Vourlias, G. Calculation of the degree of crystallinity of HDPE/GNPs nanocomposites by using various experimental techniques: A comparative study. J. Mater. Sci. 2023, 58, 1621–1639. [Google Scholar] [CrossRef]

- Opia, A.C.; Abdollah, M.F.B.; Mamah, S.C.; Hamid, M.K.B.A.; Syahrullail, S.; Audu, I.A.; Johnson, C.; Basiron, J. Lubricity effectiveness of bio-lubricant modified with multi-wall carbon nanotube and organic polymer. Wear 2023, 528, 204974. [Google Scholar] [CrossRef]

- Wang, Q.; Pei, X. The influence of nanoparticle fillers on the friction and wear behavior of polymer matrices. In Tribology of Polymeric Nanocomposites—Friction and Wear of Bulk Materials and Coatings; Tribology and Interface Engineering Series; Elsevier: Amsterdam, The Netherlands, 2008; pp. 62–81. [Google Scholar]

- Bahadur, S. The development of transfer layers and their role in polymer tribology. Wear 2000, 245, 92–99. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).