Overcoming Low-Polarity Limitations in Polyphenylene Oxide Electrospinning: Chemical Functionalization and Polymer Hybridization for Interlaminar Toughening of Carbon Fiber Composites

Abstract

1. Introduction

2. Experimental Section

2.1. Materials

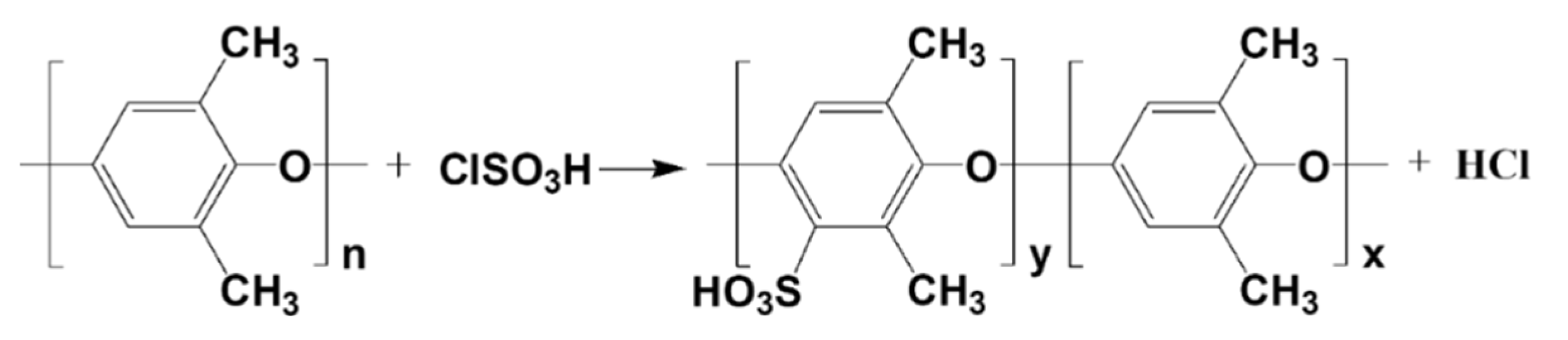

2.2. Preparation of SPPO

2.3. Preparation of Modified-PPO Electrospun Veils

2.4. Preparation of Composite Laminates

2.5. Testing and Characterization

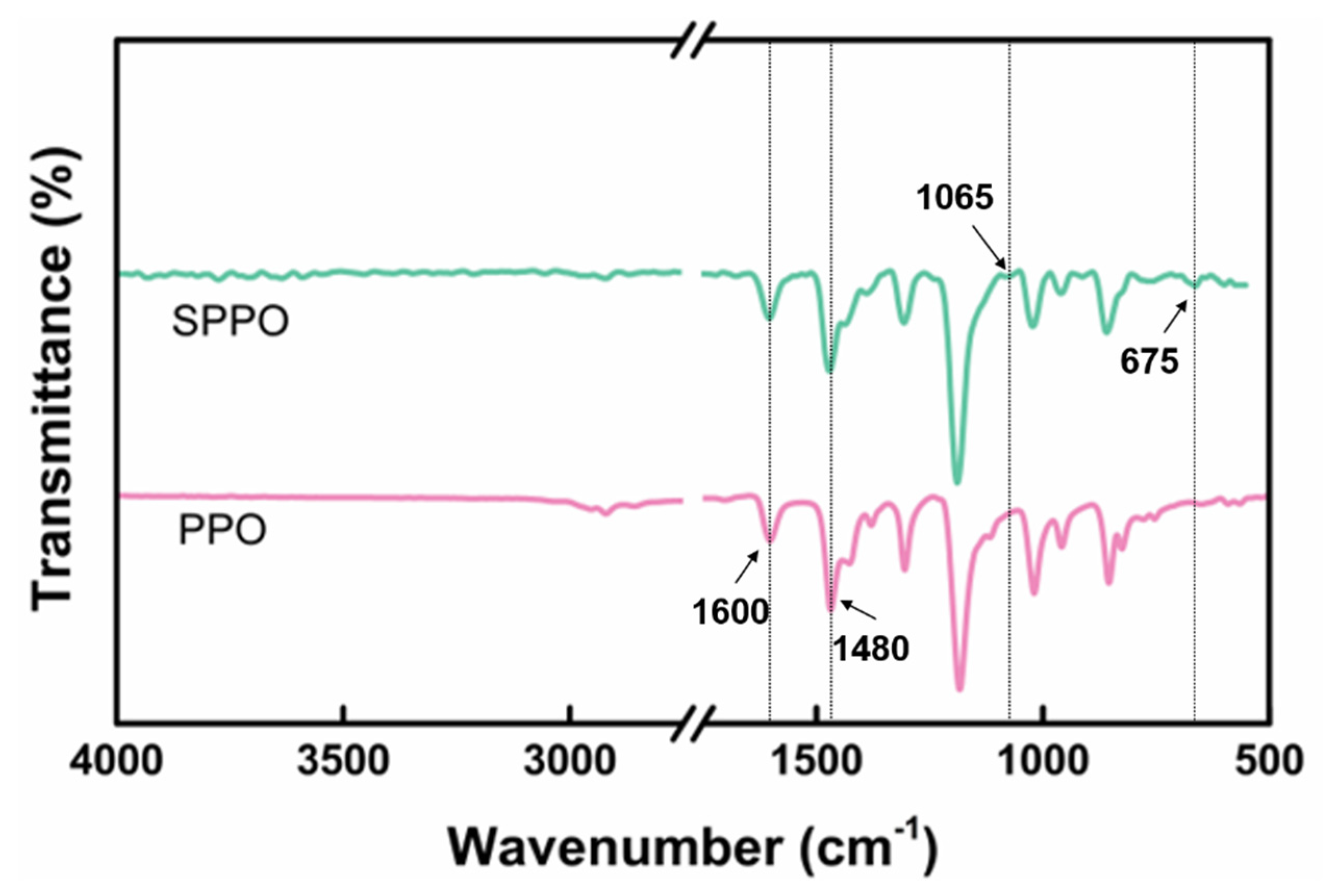

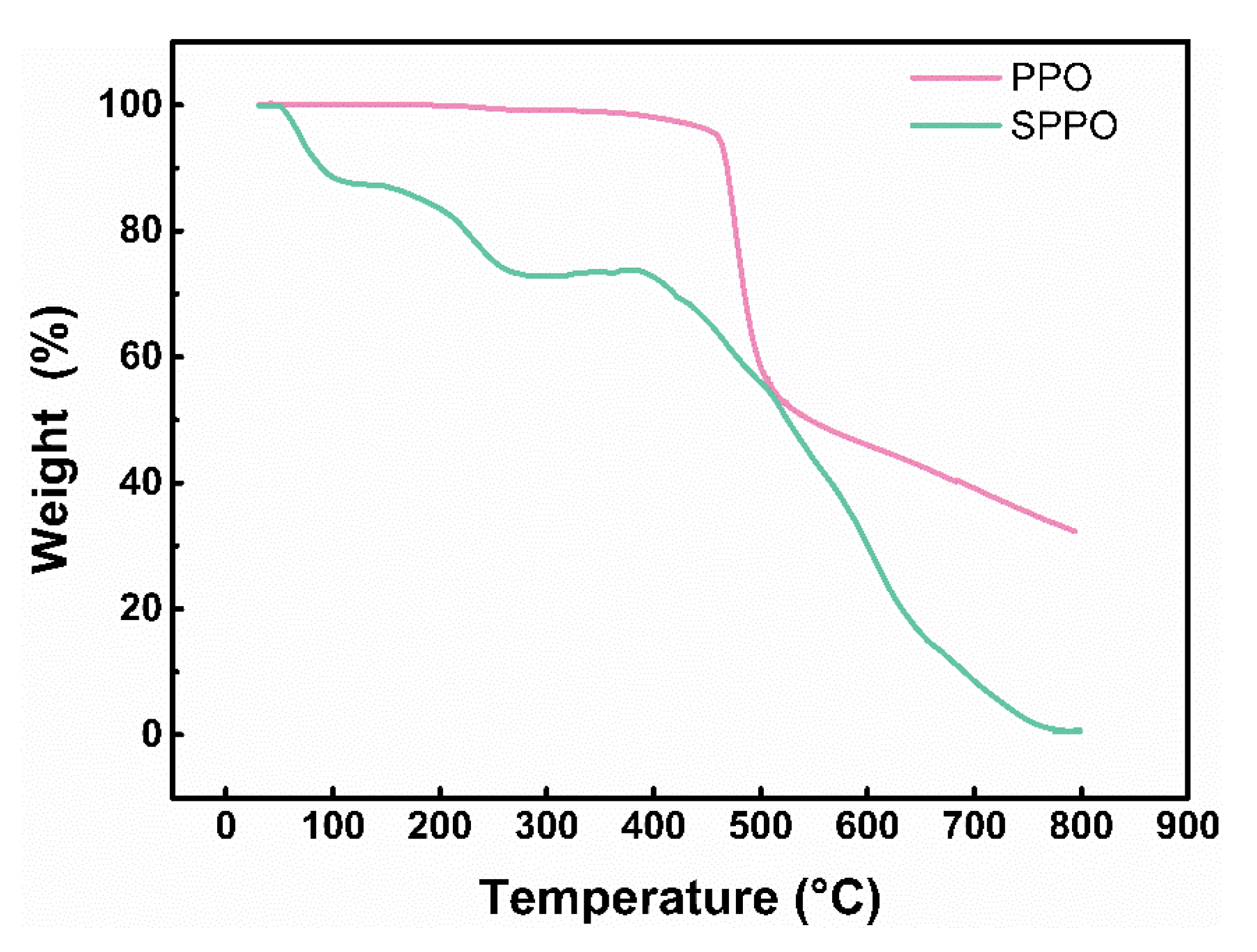

2.5.1. Characterization of SPPO

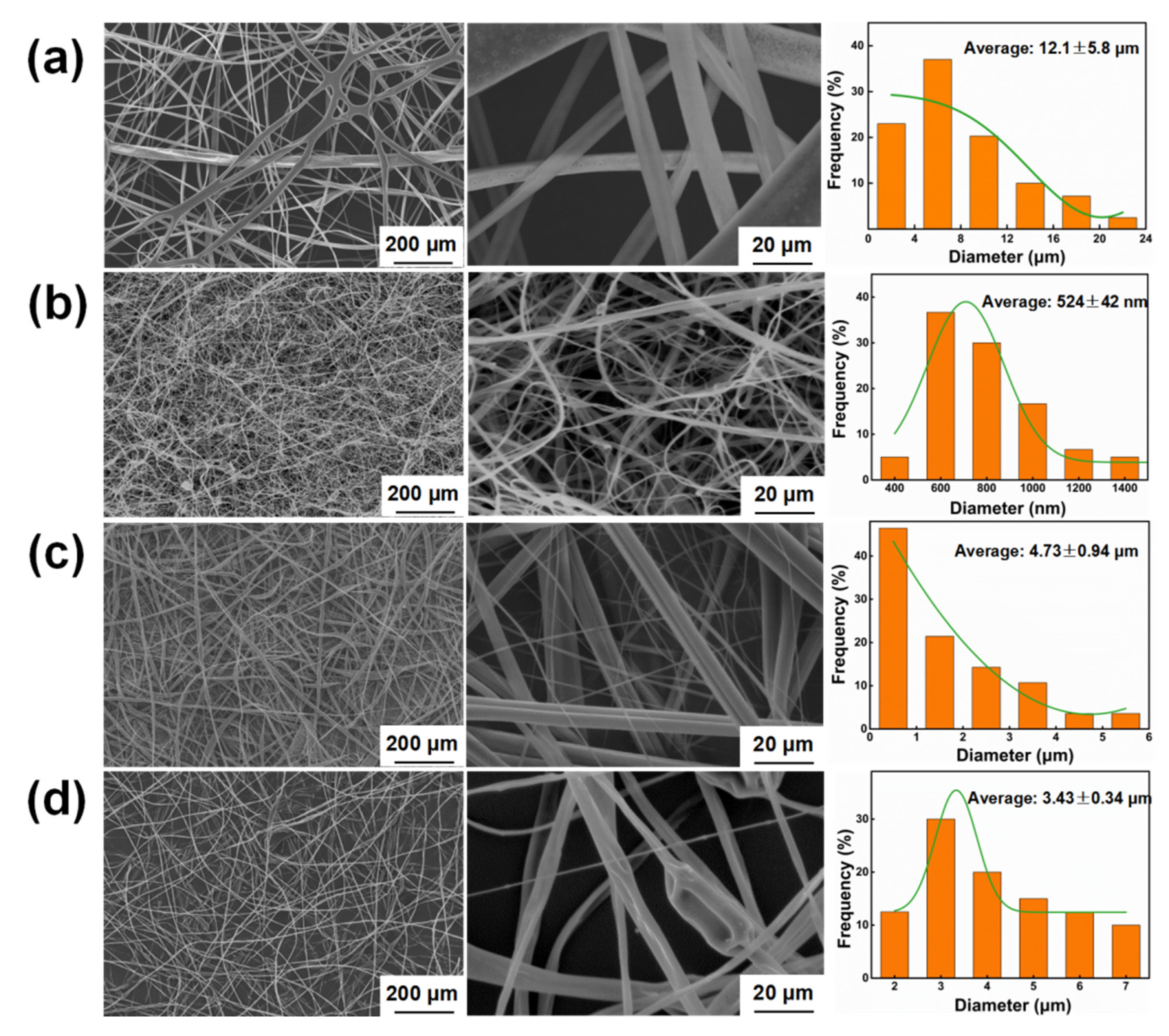

2.5.2. SEM Characterization

2.5.3. Fracture Toughness Evaluation

3. Results and Discussion

3.1. Characterization Results of SPPO

3.2. Morphology Characterization of the Electrospun Veils

3.3. Results of Fracture Toughness Testing

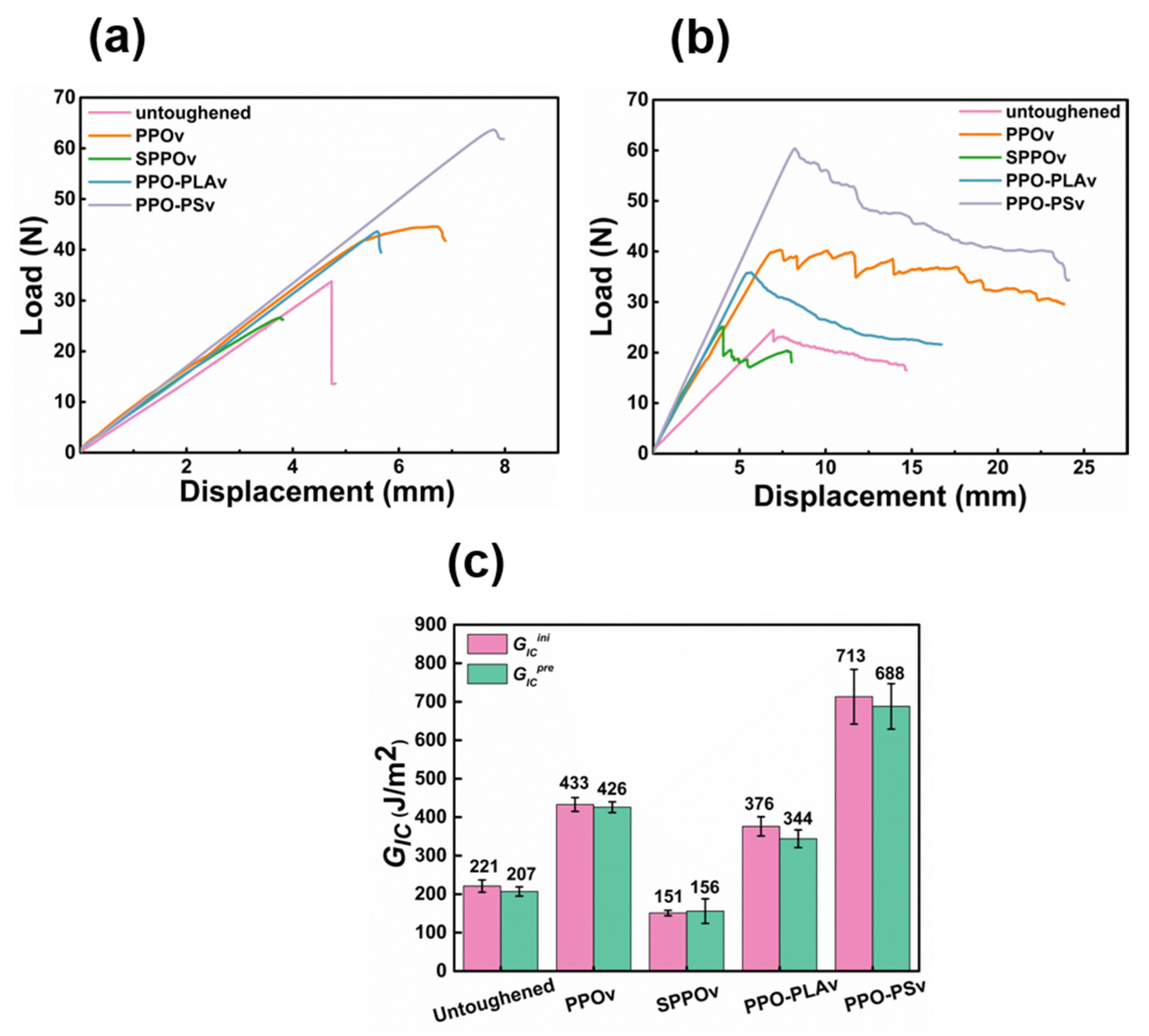

3.3.1. Mode I Interlaminar Fracture Toughness

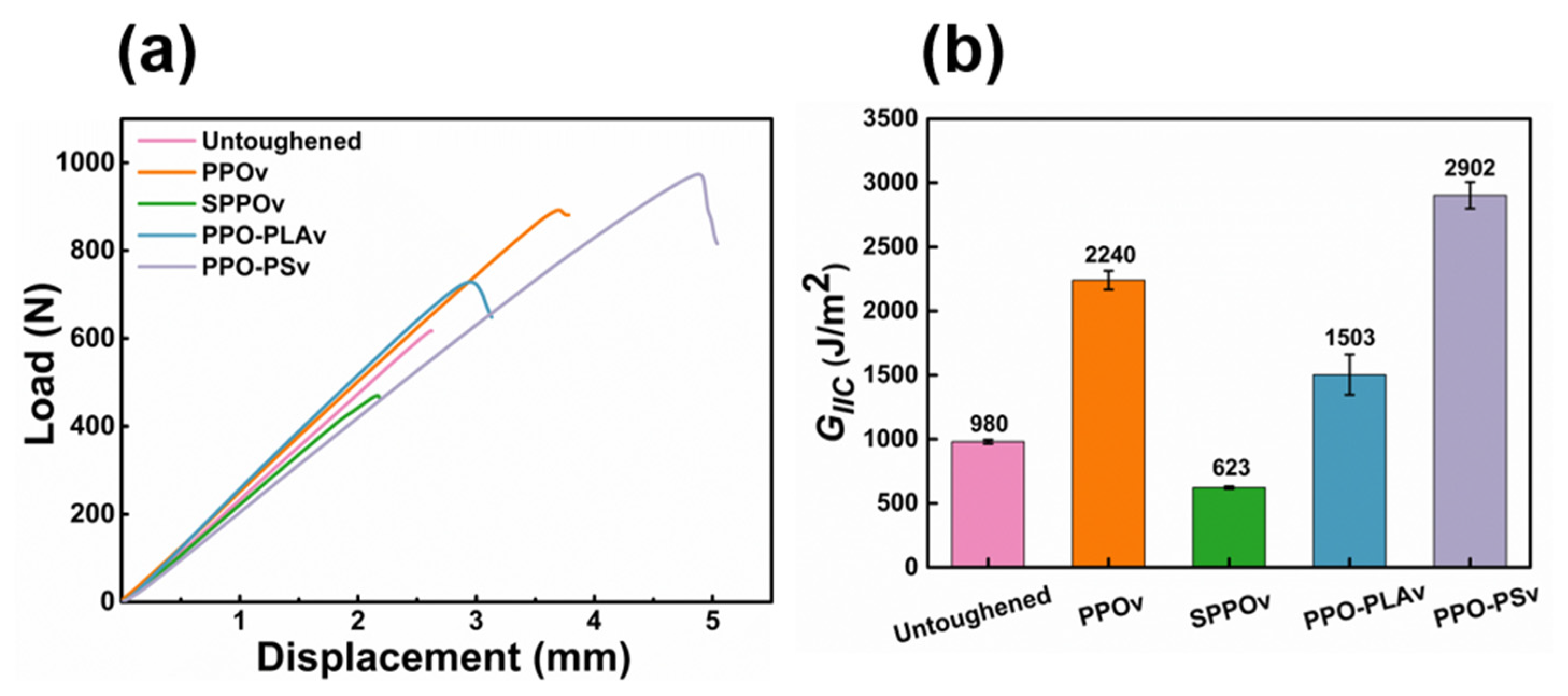

3.3.2. Mode II Interlaminar Fracture Toughness

3.4. Toughening Mechanism Investigation

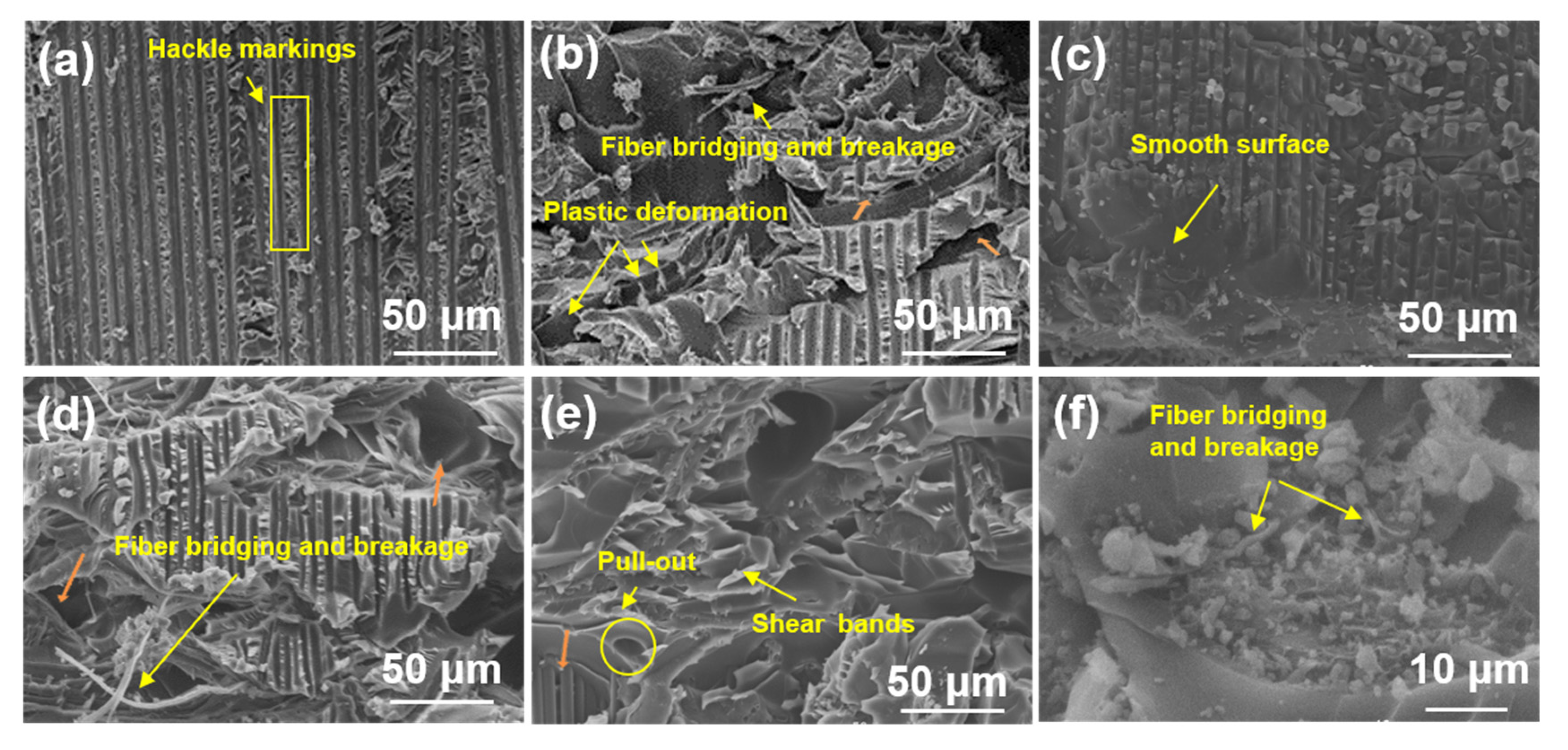

3.4.1. SEM of Mode I Fracture Surfaces

3.4.2. SEM of Mode II Fracture Surfaces

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Group, R.P. Boeing opts for composites for 7E7. Reinf. Plast. 2003, 47, 10. [Google Scholar]

- Liu, Z.; Li, P.F. Effect of fiber orientation of adjacent plies on the mode I delamination fracture of carbon fiber reinforced polymer multidirectional laminates. Polym. Compos. 2025, 46, 2560–2572. [Google Scholar] [CrossRef]

- Johnsen, B.B.; Kinloch, A.J.; Mohammed, R.D.; Taylor, A.C.; Sprenger, S. Toughening mechanisms of nanoparticle-modified epoxy polymers. Polymer 2007, 48, 530–541. [Google Scholar] [CrossRef]

- Chandrasekaran, S.; Sato, N.; Tölle, F.; Mülhaupt, R.; Fiedler, B.; Schulte, K. Fracture toughness and failure mechanism of graphene based epoxy composites. Compos. Sci. Technol. 2014, 97, 90–99. [Google Scholar] [CrossRef]

- Mahato, B.; Lomov, S.V.; Shiverskii, A.; Owais, M.; Abaimov, S.G. A Review of Electrospun Nanofiber Interleaves for Interlaminar Toughening of Composite Laminates. Polymers 2023, 15, 1380. [Google Scholar] [CrossRef]

- Wang, C.; Li, H.; Peng, Z.; Zhang, H.; Liu, L.; Wang, H. Study on the dielectric properties of the epoxy resin toughened with different molecular weight HTBN. In Proceedings of the 2015 IEEE 11th International Conference on the Properties and Applications of Dielectric Materials (ICPADM), Sydney, NSW, Australia, 19–22 July 2015; pp. 852–855. [Google Scholar]

- Maccaferri, E.; Mazzocchetti, L.; Benelli, T.; Brugo, T.M.; Zucchelli, A.; Giorgini, L. Rubbery-Modified CFRPs with Improved Mode I Fracture Toughness: Effect of Nanofibrous Mat Grammage and Positioning on Tanδ Behaviour. Polymers 2021, 13, 1918. [Google Scholar] [CrossRef]

- Zheng, N.; Sun, W.; Liu, H.Y.; Huang, Y.; Gao, J.; Mai, Y.W. Effects of carboxylated carbon nanotubes on the phase separation behaviour and fracture-mechanical properties of an epoxy/polysulfone blend. Compos. Sci. Technol. 2018, 159, 180–188. [Google Scholar] [CrossRef]

- Li, H.; Gan, W.; Zhao, L.; Li, S. Studies on the Phase Separation of a Polyetherimide Modified Epoxy Resin. VI. Effect of Surface Energy on Reaction-Induced Phase Separation of Epoxy Resin Modified with Polyetherimide. J. Macromol. Sci. Part A 2003, 40, 833–846. [Google Scholar] [CrossRef]

- Bakar, M.; Okulska-Bo, M.; Zygmunt, M. Effect of poly(amic acid) and polyimide on the adhesive strength and fracture toughness of epoxy resin. Mater. Sci. 2011, 47, 355–362. [Google Scholar] [CrossRef]

- Wang, S.; Akbolat, M.C.; Katnam, K.B.; Zou, Z.; Potluri, P.; Taylor, J. On the interlaminar fracture behavior of carbon/epoxy laminates interleaved with fiber-hybrid non-woven veils. Polym. Compos. 2024, 45, 3315–3326. [Google Scholar] [CrossRef]

- Wang, M.; Cai, W.; Wang, X.; Guo, P.; Chen, Q. Carbon Fiber Prepreg Comprises Resin Matrix and Carbon Fiber Layer, Where Resin Base Body Covers Carbon Fiber Layer and Fills Gap in Carbon Fiber Layer, Resin Matrix Further Includes First Toughening Particle Layer; Zhongfu Shenying Shanghai Technology Co.: Shanghai, China, 2024. [Google Scholar]

- Ke, H.; Lai, J.M.; Li, Y.L.; Xue, X.M.; Liu, X.; Cao, J. Interlayer toughening of mode I unidirectional CFRP laminates under the synergistic effect of a modified MWCNTs interpenetrating network. Compos. Commun. 2025, 53, 102198. [Google Scholar] [CrossRef]

- Wang, X.; Jiang, W.; He, Q.; Chen, C.; Zhang, M.; Huang, Z.; Zhou, H. Enhanced interlaminar fracture toughness of CF/PEEK laminates by interleaving CNT-decorated PEEK films. Polym. Test. 2023, 126, 108159. [Google Scholar] [CrossRef]

- Ou, Y.; Wu, L.; Yi, X.; Mao, D. Understanding Mode I interlaminar toughening of unidirectional CFRP laminates interleaved with aligned ultrathin CNT fiber veils: Thickness and orientation effects. Compos. Part B Eng. 2023, 254, 110578. [Google Scholar] [CrossRef]

- Guo, F.L.; Hu, J.M.; Guan, T.; Peng, C.Y.; Fu, Y.T.; Qu, D.Y.; Hou, W.D.; Zhang, Y.C.; Li, Y.Q.; Liu, S.T.; et al. Enhancing interlaminar mechanical performance and cryo-thermal cycling resistance of carbon fiber reinforced epoxy composite laminates with discrete short carbon fiber method. Compos. Commun. 2025, 53, 102253. [Google Scholar] [CrossRef]

- Mahato, B.; Lomov, S.V.; Jafarypouria, M.; Owais, M.; Abaimov, S.G. Hierarchical toughening and self-diagnostic interleave for composite laminates manufactured from industrial carbon nanotube masterbatch. Compos. Sci. Technol. 2023, 243, 110241. [Google Scholar] [CrossRef]

- Gupta, S.; Sohail, T.; Checa, M.; Rohewal, S.S.; Toomey, M.D.; Kanbargi, N.; Damron, J.T.; Collins, L.; Kearney, L.T.; Naskar, A.K.; et al. Enhancing Composite Toughness Through Hierarchical Interphase Formation. Adv. Sci. 2024, 11, 2470036. [Google Scholar] [CrossRef]

- Huang, Y.Z.; Lv, X.J.; Huo, H.Y.; Zhang, B.Y.; Peng, G.Q.; Ge, J.; Guo, H.; Liu, Y. Interlaminar reinforced carbon fiber/epoxy composites by electrospun ultrafine hybrid fibers. Compos. Part B Eng. 2024, 281, 111578. [Google Scholar] [CrossRef]

- Yu, B.S.; Wang, W.T.; Zhou, G.D.; Song, Y.H.; Peng, M. Rapid and scalable synthesis of novel carboxylated aramid nanofibers for simultaneously improving the strength and toughness of carbon fiber/epoxy laminates. Compos. Sci. Technol. 2024, 245, 110320. [Google Scholar] [CrossRef]

- Yang, C.; Liu, L.; Huang, Y.; Dong, J.; Li, N. Anion-conductive poly(2,6-dimethyl-1,4-phenylene oxide) grafted with tailored polystyrene chains for alkaline fuel cells. J. Membr. Sci. 2018, 573, 247–256. [Google Scholar] [CrossRef]

- Wang, J.; Tsou, A.H.; Passino, H.L.; Favis, B.D. PPE-g-HDPE in high-performance Poly(p-Phenylene Ether)/Polyethylene Blends: Synthesis and compatibilization effects. Polymer 2018, 138, 92–102. [Google Scholar] [CrossRef]

- Du, Y.; Wang, D.; Wang, W.; Fu, J.; Chen, X.; Wang, L.; Yang, W.; Zhang, X. Electrospun Nanofibrous Polyphenylene Oxide Membranes for High-Salinity Water Desalination by Direct Contact Membrane Distillation. ACS Sustain. Chem. Eng. 2019, 7, 20060–20069. [Google Scholar] [CrossRef]

- Huang, Y.; Ning, N.; Qiu, Y.; Wei, Y. Composite Interlaminar Fracture Toughness Enhancement Using Electrospun PPO Fiber Veils Regulated by Functionalized CNTs. Polymers 2023, 15, 3152. [Google Scholar] [CrossRef] [PubMed]

- Smitha, B. Synthesis and characterization of proton conducting polymer membranes for fuel cells. J. Membr. Sci. 2003, 225, 63–76. [Google Scholar] [CrossRef]

- Huang, Y.; Qiu, Y.; Wei, Y. Composite interlaminar fracture toughness imparted by electrospun PPO veils and interleaf particles: A mechanistical comparison. Compos. Struct. 2023, 312, 116865. [Google Scholar] [CrossRef]

- Russell, A.J.; Street, K.N. Delamination and debonding of materials: ASTM STP 876, American Society for Testing and Materials, 1985 (£64). Int. J. Adhes. Adhes. 1987, 7, 349–370. [Google Scholar] [CrossRef]

- Liu, Y.H. Synthesis and Solution Properties of Sulfonated Polyphenylene Oxide Polymers. Guangzhou Chem. 1990, 8, 17–24. [Google Scholar] [CrossRef]

- Blinov, I.A.; Mukhortov, D.A.; Yampolskii, Y.P.; Belov, N.A.; Alentiev, A.Y.; Chirkov, S.V.; Bondarenko, G.N.; Kostina, Y.V.; Legkov, S.A.; Perepuchov, A.M.; et al. Direct fluorination of poly-2,6-dimethyl-1,4-phenylene oxide in perfluorinated liquid medium. J. Fluor. Chem. 2020, 234, 109526. [Google Scholar] [CrossRef]

- Yan, H.; Zhang, J.; Zhang, M.; Du, X.; Ma, S.; Xu, B. Synergistic Flame-Retardant Effect of IFR and PPO in Improving Flame Retardancy of Polystyrene. Adv. Polym. Technol. 2015, 35, 208–214. [Google Scholar] [CrossRef]

- Petreanu, I.; Ebrasu, D.; Sisu, C.; Varlam, M. Thermal analysis of sulfonated polymers tested as polymer electrolyte membrane for PEM fuel cells. J. Therm. Anal. Calorim. 2012, 110, 335–339. [Google Scholar] [CrossRef]

- Niu, G.; Tao, Y.; Zhang, R.; Feng, X.; Deng, H.; Ren, M.; Sun, J.; Peijs, T. Toughening of self-reinforced PLA films using PLA nanofiber mats and oriented PLA tapes as interlayers. Compos. Part A Appl. Sci. Manuf. 2024, 185, 108267. [Google Scholar] [CrossRef]

- Daelemans, L.; van der Heijden, S.; De Baere, I.; Rahier, H.; Van Paepegem, W.; De Clerck, K. Damage-Resistant Composites Using Electrospun Nanofibers: A Multiscale Analysis of the Toughening Mechanisms. ACS Appl. Mater. Interfaces 2016, 8, 11806–11818. [Google Scholar] [CrossRef] [PubMed]

- Greenhalgh, E.S. Failure Analysis and Fractography of Polymer Composites; Elsevier: Amsterdam, The Netherlands, 2009. [Google Scholar]

- Zhang, D.; Chen, J.; Bao, J.; Zhong, X.; Chen, X. Effects of thermoplastic resin content on mode-Ⅱinterlaminar fracture toughness of carbon fiber reinforced epoxy composite. J. Mater. Eng. 2021, 49, 178–184. [Google Scholar]

- Nagi, C.S.; Ogin, S.L.; Mohagheghian, I.; Crean, C.; Foreman, A.D. Spray deposition of graphene nano-platelets for modifying interleaves in carbon fibre reinforced polymer laminates. Mater. Des. 2020, 193, 108831. [Google Scholar] [CrossRef]

- Palazzetti, R.; Zucchelli, A. Electrospun nanofibers as reinforcement for composite laminates materials—A review. Compos. Struct. 2017, 182, 711–727. [Google Scholar] [CrossRef]

| Types of Veils | Polymer/Solvent (% w/w) | Voltage (kV) | Tip to Collector Distance (cm) | Flow Rate (mL/h) |

|---|---|---|---|---|

| PPO | 18% PPO + 82% CHCl3 | 18 | 18 | 0.5 |

| SPPO | 12% SPPO + 88% CHCl3 | 16 | 25 | 1 |

| PPO-PLA | 6% PPO + 6% PLA + 88% CHCl3 | 16 | 20 | 1 |

| PPO-PS | 8.5% PPO + 8.5% PS + 83% CHCl3 | 16 | 20 | 1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, Y.; Wei, Y.; Huang, C.; Qiu, Y.; Gu, B.; Yang, B. Overcoming Low-Polarity Limitations in Polyphenylene Oxide Electrospinning: Chemical Functionalization and Polymer Hybridization for Interlaminar Toughening of Carbon Fiber Composites. Polymers 2025, 17, 1480. https://doi.org/10.3390/polym17111480

Huang Y, Wei Y, Huang C, Qiu Y, Gu B, Yang B. Overcoming Low-Polarity Limitations in Polyphenylene Oxide Electrospinning: Chemical Functionalization and Polymer Hybridization for Interlaminar Toughening of Carbon Fiber Composites. Polymers. 2025; 17(11):1480. https://doi.org/10.3390/polym17111480

Chicago/Turabian StyleHuang, Yuan, Yi Wei, Canyi Huang, Yiping Qiu, Bohong Gu, and Bo Yang. 2025. "Overcoming Low-Polarity Limitations in Polyphenylene Oxide Electrospinning: Chemical Functionalization and Polymer Hybridization for Interlaminar Toughening of Carbon Fiber Composites" Polymers 17, no. 11: 1480. https://doi.org/10.3390/polym17111480

APA StyleHuang, Y., Wei, Y., Huang, C., Qiu, Y., Gu, B., & Yang, B. (2025). Overcoming Low-Polarity Limitations in Polyphenylene Oxide Electrospinning: Chemical Functionalization and Polymer Hybridization for Interlaminar Toughening of Carbon Fiber Composites. Polymers, 17(11), 1480. https://doi.org/10.3390/polym17111480