The Application of Montmorillonite (MMT), Halloysite (HNT), and Carbon Nanotubes (CNT) in Toughened Polyethylene Terephthalate Glycol/Polycarbonate (PETG/PC) Blends: The Critical View on the Use of Nanosized Fillers as Phase Structure Modifiers

Abstract

1. Introduction

2. Experimental

2.1. Materials

- -

- Unmodified polycarbonate resin Macrolon PC 2205 (BASF, Ludwigshafen, Germany, supplied by Albis Polska(Poznan, Poland)), with a melt flow rate (MFR) of 37 g/10 min (1.2 kg/300 °C)

- -

- Poly(ethylene terephthalate)-glycol PETG resin Eastar 6763 (Eastman Chemicals, Kingsport, TN, USA), inherent viscosity (IV) = 0.70 dL/g;

- -

- Ethylene–butyl acrylate copolymer grafted with glycidyl methacrylate EBA-g-GMA toughening agent Elvaloy PTW (Du Pont, Wilmington, DE, USA), MFR = 12 g/10 min (2.16 kg/190 °C), 28% acrylate comonomer content;

- -

- Multi-walled carbon nanotubes CARBON4nano (Institute of Carbon Technology, Poland), with lengths of 1–2 μm (CNT-short) and 5–20 μm (CNT-long);

- -

- Halloysite nanoclay (Sigma-Aldrich, Burlington, MA, USA)—kaolin clay in the form of nanotubes with lengths of 1–3 μm;

- -

- CLOISITE-20 A montmorillonite (BYK, Wesel, Germany)—a nanoclay with a structure of Lamellar;

- -

- Joncryl 4368C (BASF, Ludwigshafen, Germany)—chain extender, poly(styrene-acrylic-co-glycidyl methacrylate), supplied in the white powdered form.

2.2. Sample Preparation

2.3. Characterization Methods

3. Results

3.1. Structural Appearance—Optical Analysis/Scanning Electron Microscopy

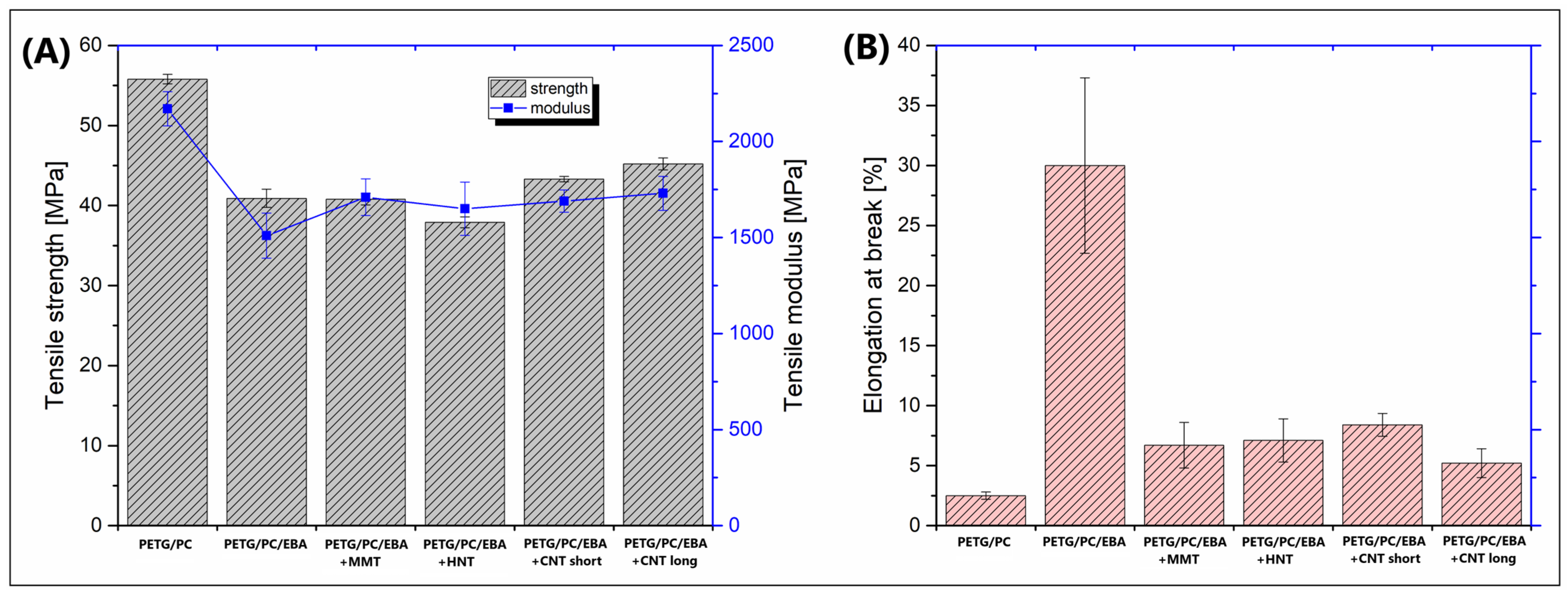

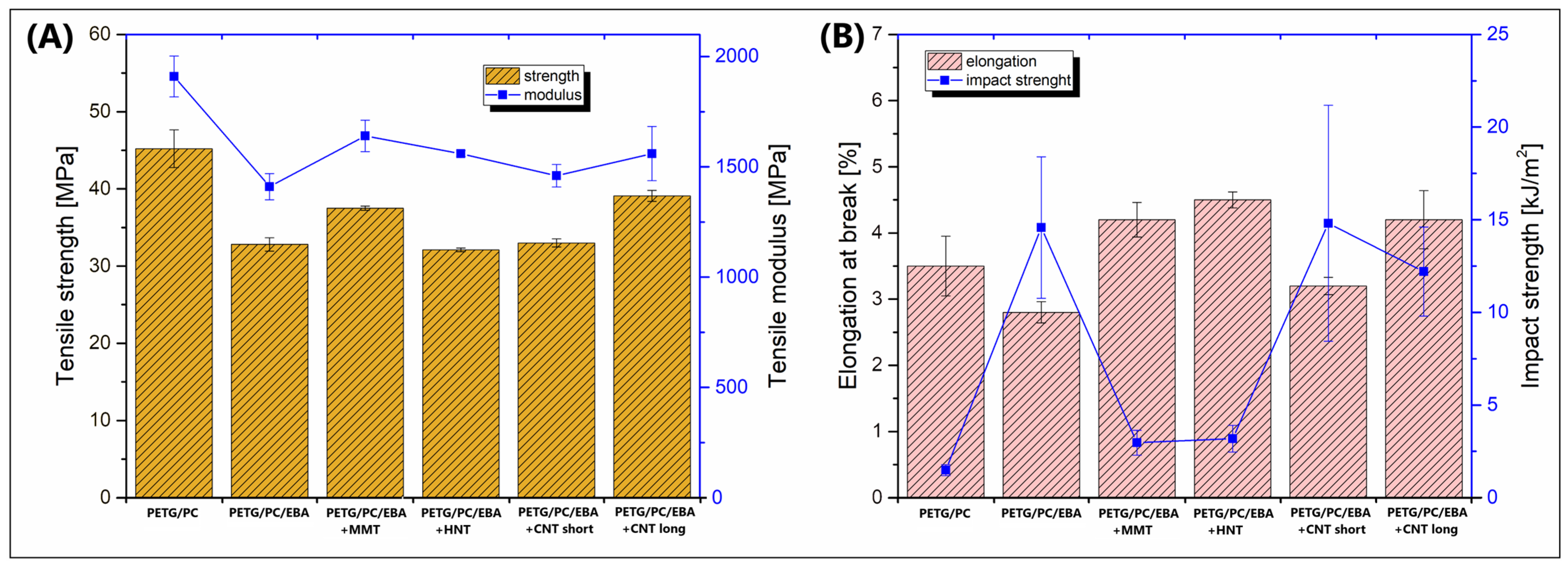

3.2. Mechanical Performance—Static Tensile Test/Charpy Impact Measurements

3.3. Thermomechanical Performance—Dynamic Mechanical Thermal Analysis/Heat Deflection Temperature (DMTA/HDT)

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Pötschke, P.; Paul, D.R. Formation of Co-Continuous Structures in Melt-Mixed Immiscible Polymer Blends. J. Macromol. Sci. Polym. Rev. 2003, 43, 87–141. [Google Scholar] [CrossRef]

- Nassar, T.R.; Paul, D.R.; Barlow, J.W. Polyester–Polycarbonate Blends. II. Poly(Ethylene Terephthalate). J. Appl. Polym. Sci. 1979, 23, 85–99. [Google Scholar] [CrossRef]

- Santos, J.M.R.C.A.; Guthrie, J.T. Polymer Blends: The PC-PBT Case. J. Mater. Chem. 2006, 16, 237–245. [Google Scholar] [CrossRef]

- Fortelny, I.; Ujcic, A.; Fambri, L.; Slouf, M. Phase Structure, Compatibility, and Toughness of PLA/PCL Blends: A Review. Front. Mater. 2019, 6, 206. [Google Scholar] [CrossRef]

- Yuryev, Y.; Mohanty, A.K.; Misra, M. Novel Biocomposites from Biobased PC/PLA Blend Matrix System for Durable Applications. Compos. B Eng. 2017, 130, 158–166. [Google Scholar] [CrossRef]

- Yuryev, Y.; Mohanty, A.K.; Misra, M. Novel Super-Toughened Bio-Based Blend from Polycarbonate and Poly(Lactic Acid) for Durable Applications. RSC Adv. 2016, 6, 105094–105104. [Google Scholar] [CrossRef]

- Lombardo, B.S.; Keskkula, H.; Paul, D.R. Influence of ABS Type on Morphology and Mechanical Properties of PC/ABS Blends. J. Appl. Polym. Sci. 1994, 54, 1697–1720. [Google Scholar] [CrossRef]

- Seelig, T.; Giessen, E. Effects of Microstructure on Crack Tip Fields and Fracture Toughness in PC/ABS Polymer Blends. Int. J. Fract. 2007, 145, 205–222. [Google Scholar] [CrossRef]

- Vadori, R.; Misra, M.; Mohanty, A.K. Statistical Optimization of Compatibilized Blends of Poly(Lactic Acid) and Acrylonitrile Butadiene Styrene. J. Appl. Polym. Sci. 2017, 134, 44516. [Google Scholar] [CrossRef]

- Vadori, R.; Misra, M.; Mohanty, A.K. Sustainable Biobased Blends from the Reactive Extrusion of Polylactide and Acrylonitrile Butadiene Styrene. J. Appl. Polym. Sci. 2016, 133, 43771. [Google Scholar] [CrossRef]

- Codou, A.; Anstey, A.; Misra, M.; Mohanty, A.K. Novel Compatibilized Nylon-Based Ternary Blends with Polypropylene and Poly(Lactic Acid): Morphology Evolution and Rheological Behaviour. RSC Adv. 2018, 8, 15709–15724. [Google Scholar] [CrossRef] [PubMed]

- Anstey, A.; Codou, A.; Misra, M.; Mohanty, A.K. Novel Compatibilized Nylon-Based Ternary Blends with Polypropylene and Poly(Lactic Acid): Fractionated Crystallization Phenomena and Mechanical Performance. ACS Omega 2018, 3, 2845–2854. [Google Scholar] [CrossRef]

- Zhou, Y.; Luo, L.; Liu, W.; Zeng, G.; Chen, Y. Preparation and Characteristic of PC/PLA/TPU Blends by Reactive Extrusion. Adv. Mater. Sci. Eng. 2015, 2015, 1–9. [Google Scholar] [CrossRef]

- Lin, L.; Deng, C.; Lin, G.; Wang, Y. Mechanical Properties, Heat Resistance and Flame Retardancy of Glass Fiber-Reinforced PLA-PC Alloys Based on Aluminum Hypophosphite. Polym. Plast. Technol. Eng. 2014, 53, 613–625. [Google Scholar] [CrossRef]

- Techawinyutham, L.; Tengsuthiwat, J.; Srisuk, R.; Techawinyutham, W.; Mavinkere Rangappa, S.; Siengchin, S. Recycled LDPE/PETG Blends and HDPE/PETG Blends: Mechanical, Thermal, and Rheological Properties. J. Mater. Res. Technol. 2021, 15, 2445–2458. [Google Scholar] [CrossRef]

- Paszkiewicz, S.; Irska, I.; Piesowicz, E. Environmentally Friendly Polymer Blends Based on Post-Consumer Glycol-Modified Poly(Ethylene Terephthalate) (PET-G) Foils and Poly(Ethylene 2,5-Furanoate) (PEF): Preparation and Characterization. Materials 2020, 13, 2673. [Google Scholar] [CrossRef]

- Bouguermouh, K.; Habibi, M.; Laperrière, L.; Li, Z.; Abdin, Y. 4D-Printed PLA-PETG Polymer Blends: Comprehensive Analysis of Thermal, Mechanical, and Shape Memory Performances. J. Mater. Sci. 2024, 59, 11596–11613. [Google Scholar] [CrossRef]

- Garwacki, M.; Cudnik, I.; Dziadowiec, D.; Szymczak, P.; Andrzejewski, J. The Development of Sustainable Polyethylene Terephthalate Glycol-Based (PETG) Blends for Additive Manufacturing Processing—The Use of Multilayered Foil Waste as the Blend Component. Materials 2024, 17, 1083. [Google Scholar] [CrossRef]

- Andrzejewski, J.; Chmielewski, P.; Osiński, F.; Markowski, M.; Marciniak-Podsadna, L.; Piasecki, A. Use of Recycled Poly(Ethylene Terephthalate)-Based (RPET) Blends in Additive Manufacturing Techniques to Prepare Sustainable, Tough, and Heat-Resistant Parts. ACS Sustain. Chem. Eng. 2024, 12, 17383–17405. [Google Scholar] [CrossRef]

- Andrzejewski, J.; Marciniak-Podsadna, L. Development of Thermal Resistant FDM Printed Blends. The Preparation of GPET/PC Blends and Evaluation of Material Performance. Materials 2020, 13, 2057. [Google Scholar] [CrossRef]

- Andrzejewski, J. The Use of Recycled Polymers for the Preparation of Self-Reinforced Composites by the Overmolding Technique: Materials Performance Evaluation. Sustainability 2023, 15, 11318. [Google Scholar] [CrossRef]

- Chang, B.P.; Mohanty, A.K.; Misra, M. Tuning the Compatibility to Achieve Toughened Biobased Poly(Lactic Acid)/Poly(Butylene Terephthalate) Blends. RSC Adv. 2018, 8, 27709–27724. [Google Scholar] [CrossRef] [PubMed]

- You, X.; Snowdon, M.R.; Misra, M.; Mohanty, A.K. Biobased Poly(Ethylene Terephthalate)/Poly(Lactic Acid) Blends Tailored with Epoxide Compatibilizers. ACS Omega 2018, 3, 11759–11769. [Google Scholar] [CrossRef] [PubMed]

- Diederichs, E.V.; Picard, M.C.; Chang, B.P.; Misra, M.; Mielewski, D.F.; Mohanty, A.K. Strategy to Improve Printability of Renewable Resource-Based Engineering Plastic Tailored for Fdm Applications. ACS Omega 2019, 4, 20297–20307. [Google Scholar] [CrossRef]

- Toth, L.; Slezák, E.; Bocz, K.; Ronkay, F. Progress in 3D Printing of Recycled PET. Mater. Today Sustain. 2024, 26, 100757. [Google Scholar] [CrossRef]

- Diederichs, E.; Picard, M.; Chang, B.P.; Misra, M.; Mohanty, A. Extrusion Based 3d Printing of Sustainable Biocomposites from Biocarbon and Poly(Trimethylene Terephthalate). Molecules 2021, 26, 4164. [Google Scholar] [CrossRef]

- Zubkiewicz, A.; Szymczyk, A.; Franciszczak, P.; Kochmanska, A.; Janowska, I.; Paszkiewicz, S. Comparing Multi-Walled Carbon Nanotubes and Halloysite Nanotubes as Reinforcements in EVA Nanocomposites. Materials 2020, 13, 3809. [Google Scholar] [CrossRef]

- Kumar, A.; Sharma, K.; Dixit, A.R. A Review on the Mechanical Properties of Polymer Composites Reinforced by Carbon Nanotubes and Graphene. Carbon. Lett. 2021, 31, 149–165. [Google Scholar] [CrossRef]

- Paszkiewicz, S. Adding Carbon Nanoparticles with Different Geometries to Poly(Ethylene Terephthalate). Plast. Res. Online 2015, 1, 1–3. [Google Scholar] [CrossRef]

- Nabels-Sneiders, M.; Barkane, A.; Platnieks, O.; Orlova, L.; Gaidukovs, S. Biodegradable Poly(Butylene Succinate) Laminate with Nanocellulose Interphase Layer for High-Barrier Packaging Film Application. Foods 2023, 12, 4136. [Google Scholar] [CrossRef]

- Raja Beryl, J.; Xavier, J.R. Influence of Silane Functionalized Nanoclay on the Barrier, Mechanical and Hydrophobic Properties by Clay Nanocomposite Films in an Aggressive Chloride Medium. Colloids Surf. A Physicochem. Eng. Asp. 2021, 630, 127625. [Google Scholar] [CrossRef]

- Perera, K.Y.; Hopkins, M.; Jaiswal, A.K.; Jaiswal, S. Nanoclays-Containing Bio-Based Packaging Materials: Properties, Applications, Safety, and Regulatory Issues. J. Nanostructure Chem. 2024, 14, 71–93. [Google Scholar] [CrossRef] [PubMed]

- Paszkiewicz, S.; Taraghi, I.; Szymczyk, A.; Huczko, A.; Kurcz, M.; Przybyszewski, B.; Stanik, R.; Linares, A.; Ezquerra, T.A.; Rosłaniec, Z. Electrically and Thermally Conductive Thin Elastic Polymer Foils Containing SiC Nanofibers. Compos. Sci. Technol. 2017, 146, 20–25. [Google Scholar] [CrossRef]

- Bilisik, K.; Akter, M. Polymer Nanocomposites Based on Graphite Nanoplatelets (GNPs): A Review on Thermal-Electrical Conductivity, Mechanical and Barrier Properties. J. Mater. Sci. 2022, 57, 7425–7480. [Google Scholar] [CrossRef]

- Taraghi, I.; Paszkiewicz, S.; Fereidoon, A.; Szymczyk, A.; Stanik, R.; Gude, M.; Linares, A.; Ezquerra, T.A.; Piesowicz, E.; Wilpiszewska, K.; et al. Thermally and Electrically Conducting Polycarbonate/Elastomer Blends Combined with Multiwalled Carbon Nanotubes. J. Thermoplast. Compos. Mater. 2021, 34, 1488–1503. [Google Scholar] [CrossRef]

- Kitjanon, J.; Khuntawee, W.; Phongphanphanee, S.; Sutthibutpong, T.; Chattham, N.; Karttunen, M.; Wong-Ekkabut, J. Nanocomposite of Fullerenes and Natural Rubbers: Martini Force Field Molecular Dynamics Simulations. Polymers 2021, 13, 4044. [Google Scholar] [CrossRef]

- Olkhov, Y.A.; Jurkowski, B. Effect of Fullerenes on the Structure and Properties of Linear and Crosslinked Polyesterurethane Ureas. J. Appl. Polym. Sci. 2007, 104, 1431–1442. [Google Scholar] [CrossRef]

- Skórczewska, K.; Lewandowski, K.; Wilczewski, S. Novel Composites of Poly(Vinyl Chloride) with Carbon Fibre/Carbon Nanotube Hybrid Filler. Materials 2022, 15, 5625. [Google Scholar] [CrossRef]

- Wilczewski, S.; Skórczewska, K.; Tomaszewska, J.; Lewandowski, K.; Szulc, J.; Runka, T. Manufacturing Homogenous PVC/Graphene Nanocomposites Using a Novel Dispersion Agent. Polym. Test. 2020, 91, 106868. [Google Scholar] [CrossRef]

- Li, Y.; Feng, Z.; Huang, L.; Essa, K.; Bilotti, E.; Zhang, H.; Peijs, T.; Hao, L. Additive Manufacturing High Performance Graphene-Based Composites: A Review. Compos. Part A Appl. Sci. Manuf. 2019, 124, 105483. [Google Scholar] [CrossRef]

- Bouakaz, B.S.; Habi, A.; Grohens, Y.; Pillin, I. Organomontmorillonite/Graphene-PLA/PCL Nanofilled Blends: New Strategy to Enhance the Functional Properties of PLA/PCL Blend. Appl. Clay Sci. 2017, 139, 81–91. [Google Scholar] [CrossRef]

- Coiai, S.; Cicogna, F.; de Santi, A.; Pérez Amaro, L.; Spiniello, R.; Signori, F.; Fiori, S.; Oberhauser, W.; Passaglia, E. MMT and LDH Organo-Modification with Surfactants Tailored for PLA Nanocomposites. Express Polym. Lett. 2017, 11, 163–175. [Google Scholar] [CrossRef]

- Shibata, M.; Someya, Y.; Orihara, M.; Miyoshi, M. Thermal and Mechanical Properties of Plasticized Poly(L-Lactide) Nanocomposites with Organo-Modified Montmorillonites. J. Appl. Polym. Sci. 2006, 99, 2594–2602. [Google Scholar] [CrossRef]

- Banerjee, R.; Li, Y.; Ray, S.S. Nanoparticle-Induced Morphology Evolution and Property Expression in Immiscible Polymer Blend Composites−A Review of Fundamental Understanding on Nanoparticle Migration and Interface Crossing. Polymer 2025, 316, 127844. [Google Scholar] [CrossRef]

- Zhang, K.; Yu, H.O.; Shi, Y.D.; Chen, Y.F.; Zeng, J.B.; Guo, J.; Wang, B.; Guo, Z.; Wang, M. Morphological Regulation Improved Electrical Conductivity and Electromagnetic Interference Shielding in Poly(l-Lactide)/Poly(ε-Caprolactone)/Carbon Nanotube Nanocomposites via Constructing Stereocomplex Crystallites. J. Mater. Chem. C Mater. 2017, 5, 2807–2817. [Google Scholar] [CrossRef]

- Zhang, J.; Wu, G.; Huang, S.; Sang, M.; Wang, H.; Ye, L.; Ray, S.S.; Li, Y. Wetting Kinetics-Controlled Interplay between Nanoparticles and Polymer Domains in Multiphase Polymer Blends. ACS Appl. Polym. Mater. 2024, 6, 10779–10787. [Google Scholar] [CrossRef]

- ISO 527-2; ISO-Committee Plastics—Determination of Tensile Properties. ISO: Geneve, Switzerland, 2012.

- ISO 179-1; ISO-Committee Plastics—Determination of Charpy Impact Properties. ISO: Geneve, Switzerland, 2010.

- ISO 75; ISO-Committee Plastics—Determination of Temperature of Deflection under Load. ISO: Geneve, Switzerland, 2013.

- Wu, H.; Hou, A.; Qu, J.P. Phase Morphology and Performance of Supertough PLA/EMA-GMA/ZrP Nanocomposites Prepared through Reactive Melt-Blending. ACS Omega 2019, 4, 19046–19053. [Google Scholar] [CrossRef]

- Zolali, A.M.; Favis, B.D. Toughening of Cocontinuous Polylactide/Polyethylene Blends via an Interfacially Percolated Intermediate Phase. Macromolecules 2018, 51, 3572–3581. [Google Scholar] [CrossRef]

- Chen, Q.; Shan, P.; Tong, C.; Yan, D.; Zhang, Y.; Liu, H.; Hao, C. Influence of Reactive Blending Temperature on Impact Toughness and Phase Morphologies of PLA Ternary Blend System Containing Magnesium Ionomer. J. Appl. Polym. Sci. 2019, 136, 47682. [Google Scholar] [CrossRef]

- Ma, P.C.; Siddiqui, N.A.; Marom, G.; Kim, J.K. Dispersion and Functionalization of Carbon Nanotubes for Polymer-Based Nanocomposites: A Review. Compos. Part A Appl. Sci. Manuf. 2010, 41, 1345–1367. [Google Scholar] [CrossRef]

- Kasaliwal, G.R.; Pegel, S.; Göldel, A.; Pötschke Petra, P.; Heinrich, G. Analysis of Agglomerate Dispersion Mechanisms of Multiwalled Carbon Nanotubes during Melt Mixing in Polycarbonate. Polymer 2010, 51, 2708–2720. [Google Scholar] [CrossRef]

- Andrzejewski, J.; Markowski, M.; Barczewski, M. The Use of Nanoscale Montmorillonite (MMT) as Reinforcement for Polylactide Acid (PLA) Prepared by Fused Deposition Modeling (FDM)—Comparative Study with Biocarbon and Talc Fillers. Materials 2022, 15, 5205. [Google Scholar] [CrossRef] [PubMed]

- He, H.; Liu, B.; Xue, B.; Zhang, H. Study on Structure and Properties of Biodegradable PLA/PBAT/Organic-Modified MMT Nanocomposites. J. Thermoplast. Compos. Mater. 2022, 35, 503–520. [Google Scholar] [CrossRef]

- Murariu, M.; Dechief, A.L.; Paint, Y.; Peeterbroeck, S.; Bonnaud, L.; Dubois, P. Polylactide (PLA)-Halloysite Nanocomposites: Production, Morphology and Key-Properties. J. Polym. Environ. 2012, 20, 932–943. [Google Scholar] [CrossRef]

- Rashmi, B.J.; Prashantha, K.; Lacrampe, M.F.; Krawczak, P. Toughening of Poly(Lactic Acid) without Sacrificing Stiffness and Strength by Melt-Blending with Polyamide 11 and Selective Localization of Halloysite Nanotubes. Express Polym. Lett. 2015, 9, 721–735. [Google Scholar] [CrossRef]

- Salzano De Luna, M.; Filippone, G. Effects of Nanoparticles on the Morphology of Immiscible Polymer Blends—Challenges and Opportunities. Eur. Polym. J. 2016, 79, 198–218. [Google Scholar] [CrossRef]

- Cai, X.; Li, B.; Pan, Y.; Wu, G. Morphology Evolution of Immiscible Polymer Blends as Directed by Nanoparticle Self-Agglomeration. Polymer 2012, 53, 259–266. [Google Scholar] [CrossRef]

- Kajornprai, T.; Jarapanyacheep, R.; Saikaeo, J.; Pojprapai, S.; Jarukumjorn, K.; Trongsatitkul, T. Double Percolation of Poly(Lactic Acid)/Low-Density Polyethylene/Carbon Nanotube (PLA/LDPE/CNT) Composites for Force-Sensor Application: Impact of Preferential Localization and Mixing Sequence. Polymers 2024, 16, 1906. [Google Scholar] [CrossRef]

- Kong, M.; Huang, Y.; Lv, Y.; Wang, S.; Yang, Q.; Li, G. Flow-Induced Morphological Instability in Nanosilica-Filled Polyamide 6/Polystyrene Blends. Polymer 2014, 55, 4348–4357. [Google Scholar] [CrossRef]

- de Luna, M.S.; Causa, A.; Filippone, G. Interfacially-Located Nanoparticles Anticipate the Onset of Co-Continuity in Immiscible Polymer Blends. Polymers 2017, 9, 393. [Google Scholar] [CrossRef]

- Nuzzo, A.; Bilotti, E.; Peijs, T.; Acierno, D.; Filippone, G. Nanoparticle-Induced Co-Continuity in Immiscible Polymer Blends—A Comparative Study on Bio-Based PLA-PA11 Blends Filled with Organoclay, Sepiolite, and Carbon Nanotubes. Polymer 2014, 55, 4908–4919. [Google Scholar] [CrossRef]

- Frielinghaus, H.; Koch, K.; Antonio, V.P.; Noda, Y.; Koizumi, S. The Locally Columnar Model for Clay/Polymer Systems: Connections to Scattering Experiments. J. Colloid. Interface Sci. 2019, 544, 172–177. [Google Scholar] [CrossRef]

| PETG [wt%] | PC [wt%] | EBA-g-GMA [wt%] | Chain Extender [pph *] | Nanofiller [pph] | |

|---|---|---|---|---|---|

| PETG/PC | 50 | 50 | - | 0.5 | - |

| PETG/PC/EBA | 40 | 40 | 20 | 0.5 | - |

| PETG/PC/EBA+MMT | 40 | 40 | 20 | 0.5 | 1 |

| PETG/PC/EBA+HNT | 40 | 40 | 20 | 0.5 | 1 |

| PETG/PC/EBA+(CNT short) | 40 | 40 | 20 | 0.5 | 1 |

| PETG/PC/EBA+(CNT long) | 40 | 40 | 20 | 0.5 | 1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Markowski, M.; Piasecki, A.; Andrzejewski, J. The Application of Montmorillonite (MMT), Halloysite (HNT), and Carbon Nanotubes (CNT) in Toughened Polyethylene Terephthalate Glycol/Polycarbonate (PETG/PC) Blends: The Critical View on the Use of Nanosized Fillers as Phase Structure Modifiers. Polymers 2025, 17, 1463. https://doi.org/10.3390/polym17111463

Markowski M, Piasecki A, Andrzejewski J. The Application of Montmorillonite (MMT), Halloysite (HNT), and Carbon Nanotubes (CNT) in Toughened Polyethylene Terephthalate Glycol/Polycarbonate (PETG/PC) Blends: The Critical View on the Use of Nanosized Fillers as Phase Structure Modifiers. Polymers. 2025; 17(11):1463. https://doi.org/10.3390/polym17111463

Chicago/Turabian StyleMarkowski, Mateusz, Adam Piasecki, and Jacek Andrzejewski. 2025. "The Application of Montmorillonite (MMT), Halloysite (HNT), and Carbon Nanotubes (CNT) in Toughened Polyethylene Terephthalate Glycol/Polycarbonate (PETG/PC) Blends: The Critical View on the Use of Nanosized Fillers as Phase Structure Modifiers" Polymers 17, no. 11: 1463. https://doi.org/10.3390/polym17111463

APA StyleMarkowski, M., Piasecki, A., & Andrzejewski, J. (2025). The Application of Montmorillonite (MMT), Halloysite (HNT), and Carbon Nanotubes (CNT) in Toughened Polyethylene Terephthalate Glycol/Polycarbonate (PETG/PC) Blends: The Critical View on the Use of Nanosized Fillers as Phase Structure Modifiers. Polymers, 17(11), 1463. https://doi.org/10.3390/polym17111463