Sustainable Netting Materials for Marine and Agricultural Applications: A Perspective on Polymeric and Composite Developments

Abstract

1. Introduction

Methodological Framing

2. Types, Applications, and Materials for Technical Nets

2.1. Classification by Structural Configuration

- Monofilaments: continuous single fibers that provide strength but low elasticity.

- Multifilaments: aggregated or textured fibers, more flexible and deformable.

- Twisted or braided cords: used where higher robustness or cut resistance is required.

- Woven or knitted nets: commonly used in agriculture and covering systems.

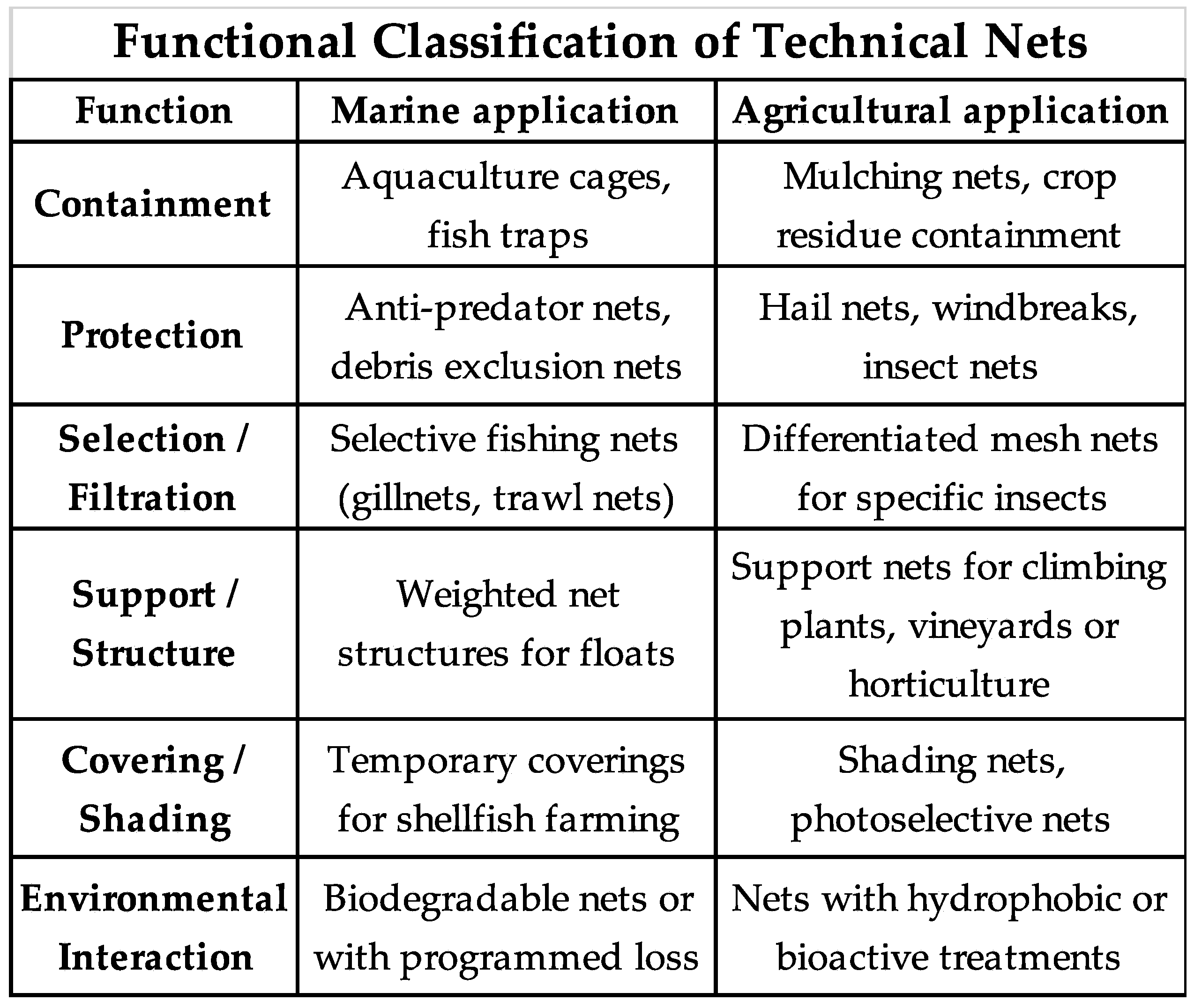

2.2. Classification by Intended Use

2.2.1. Nets for Marine Applications

2.2.2. Nets for Agricultural Applications

2.3. Classification by Material

2.3.1. Conventional Materials

- Polyamides (PA-6, PA-6.6): High strength, elasticity, good chemical stability; widely used in fishing and some agricultural nets. Studies by Moe et al. (2007) [12] showed that the tensile stiffness of PA nets increased significantly after antifouling treatments, with an average stiffness of about 81 MPa for untreated nets and approximately 131 MPa for treated ones.

- Polyethylene (HDPE, LDPE): good chemical resistance, low cost, low density, but relatively low tensile strength.

- Polypropylene (PP): lighter than PE but less resistant to UV radiation.

- Polyethylene terephthalate (PET): excellent mechanical and thermal resistance, also used in next-generation nets [5].

2.3.2. Innovative and Sustainable Materials

- PLA (Polylactic Acid): biodegradable under industrial composting, with limited mechanical performance in marine environments [6].

- PHA and PHB: biodegradable in seawater but still limited in large-scale use due to cost.

- PBAT (Polybutylene Adipate-co-Terephthalate): flexible, biodegradable, also used in nanostructured composite fibers [7].

- PBS (Polybutylene Succinate): good initial strength and controlled degradability; used in biodegradable fishing nets [1].

- PBAT/PBS Core–Shell Fibers: inspired by mussel byssus, designed to ensure strength and drapability [11].

- PBAT/CNC Nanocomposites: reinforced with cellulose nanocrystals, achieving performance comparable to nylon [11].

- Recycled Composites: regenerated nylon from discarded nets, reused in construction materials or low-impact nets [8].

2.3.3. Metallic Materials and Hybrid Structures

3. Properties and In-Service Performance

3.1. Mechanical Properties

3.2. Environmental Behavior

3.3. End-of-Life Behavior and Biodegradability

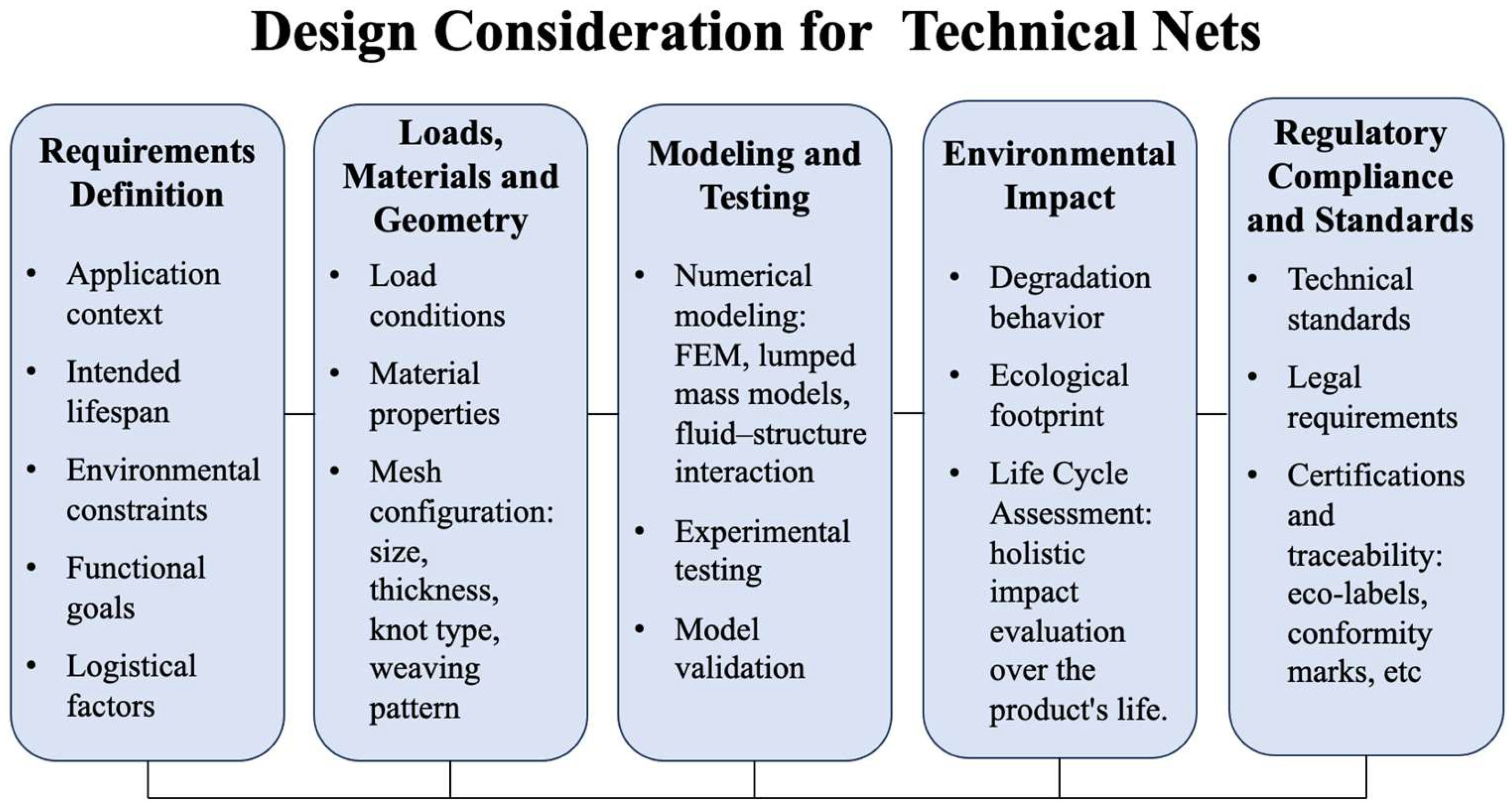

4. Design Criteria and Regulatory Framework

4.1. Design Approach: Performance, Environment, and Life Cycle

4.1.1. Fishing Nets: Simulation, Materials, and Controlled Degradation

- Catch selectivity;

- The hydrodynamic behavior of the panel (drag, vibration, resistance);

- Specific weight and net deformability;

- Material consumption and ease of retrieval.

- Morison’s equation [45], originally formulated for estimating forces on rigid cylinders, was adapted to net structures, providing a theoretical foundation for many FEM approaches.

- Tsukrov et al. [44] developed an FEM model extending Morison’s framework to flexible nets, considering drag, added mass, buoyancy, elasticity, and self-weight. Their simulations accurately predicted deformations, inclination changes, and stress distribution under marine environmental loads, offering valuable guidance for choosing initial tensioning and mesh configurations.

- Cifuentes and Kim [46] introduced an equivalent-net Morison-force model, analyzing the effects of the solidity ratio (Sn) and flow velocity. Their refined drag coefficient (Cd) formulation, validated against Raschel net experiments, highlighted the importance of shielding effects, especially at high solidity.

- Casanova et al. [47] developed an FEM model in ABAQUS using Timoshenko beam elements to simulate the static behavior of PET nets under distributed loads. Experimental validation confirmed the model’s reliability even for rigid configurations, promoting its use for low-impact technical nets.

- Moe-Føre [48] applied a lumped mass model to simulate aquaculture net deformations under hydrodynamic loading, using discrete mass–spring networks and empirical hydrodynamic coefficients. Although effective for capturing global behavior, this approach lacked full fluid–structure interaction coupling.

- Chen [49] advanced lumped mass modeling by integrating porous media theory, updating hydrodynamic loads dynamically based on net deformation. His model significantly improved the prediction of drag forces and structural responses in flexible nets subjected to currents and waves.

- Building upon Chen’s work, Zhang [50] introduced dynamic permeability updating and validated the model against both experimental flume tank tests and field measurements. His results demonstrated enhanced accuracy in predicting net deformation, drag reduction phenomena, and flow-induced effects, paving the way for more realistic simulations of net structures under operational conditions.

- Tang et al. [52] demonstrated, through flume tank experiments, that knot presence, yarn twist, and mesh orientation could influence hydrodynamic drag coefficients by up to 25%, confirming that detailed construction features significantly affect operational performance.

4.1.2. Agricultural Nets: Environmental Requirements, Seasonal Functionality, and Emerging Materials

- Resistance to environmental agents (UV radiation, humidity, thermal fluctuations);

- Dimensional stability during service;

- Functional lifespan limited to the crop cycle or specific seasons;

- Importantly, end-of-life behavior in open soil or composting conditions.

- The specific weight of the net and material consumption;

- Breathability and moisture evaporation;

- Wind resistance and panel deformability;

- Biodegradability and composting compatibility.

Case Study 1—Biodegradable Mulching Nets in PBAT/PLA Blends for Seasonal Horticulture

Case Study 2—Commercial Biodegradable Climbing Plant Nets

Additional Observations on Insect- and Bird-Protection Nets

Concluding Remarks: Standards and Outlook

- Greater standardization of durability and soil degradation tests;

- The introduction of assisted design tools for lightweight mesh structures;

- Comparative LCA (life cycle assessment) and agronomic performance evaluations, initiatives that have already begun to emerge in recent research efforts.

4.2. Technical Standards for Marine and Agricultural Nets

4.2.1. Performance and Biodegradability Standards for Marine Nets

- ISO 1107: defines terminology and geometric specifications for nets, including mesh, yarn, knots, and finishes.

- ISO 1806: establishes test methods for determining knot breaking strength.

- NS 9415 (Norway): national standard specifying structural and performance requirements for marine aquaculture systems, including nets, in relation to environmental loads such as currents, waves, and wind.

- ASTM D6691/ISO 19679: international standards used to evaluate aerobic biodegradability of plastic materials in marine environments, also applied to nets made from compostable polymers.

4.2.2. Performance and Biodegradability Standards for Agricultural Nets

- ASTM D1709: measures impact resistance of plastic films and can be extended to certain lightweight nets.

- ISO 10319: defines tensile strength test methods for geotextiles, useful for analyzing mulching or containment nets.

- UNI 11325-4: Italian standard that sets minimum performance requirements for anti-hail and windbreak nets, including specifications on mechanical strength and dimensional stability.

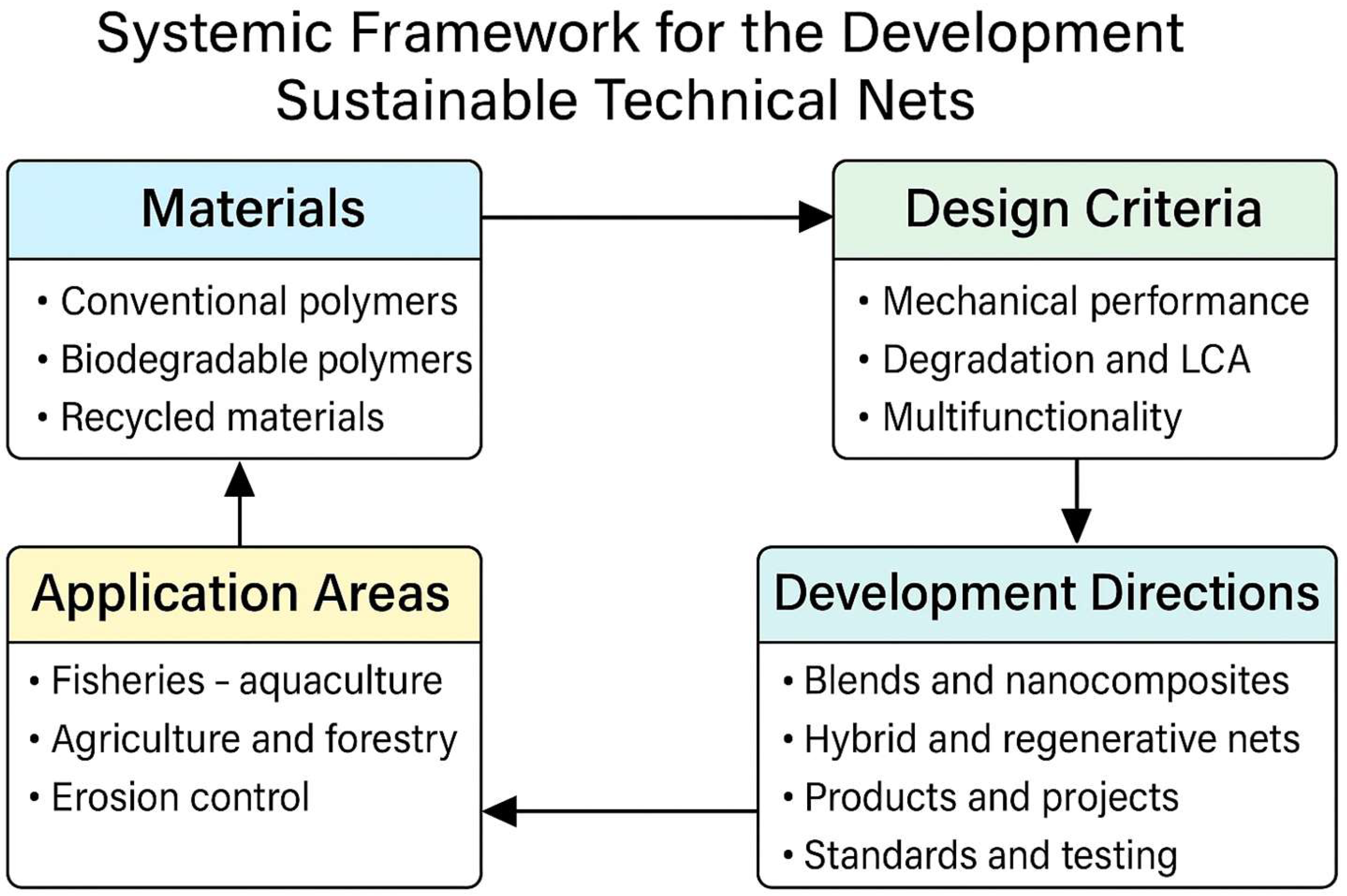

4.3. Toward Integrated and Sustainable Design

- Material and geometry, the foundational aspects of mesh design, including yarn selection, mesh size, and fabrication method;

- Mechanical performance, related to strength, elasticity, durability, and load resistance;

- Environmental degradability, the ability of materials to decompose under specific conditions without harmful residues;

- The application-specific customization of lifetime, recovery strategies, and end-of-life solutions (e.g., reuse, composting, marine degradation);

- Numerical simulations validated by experimental data, enabling the prediction and optimization of structural response under real operating conditions;

- Environmental assessment tools, such as life cycle analysis (LCA) and eco-indicators, to compare material options and assess their impact across the entire life cycle.

5. Sustainable Netting Materials: Current Trends and Future Directions

5.1. Biopolymers and Biodegradable Polymer Blends

- The need to improve mechanical strength, generally lower than in traditional synthetic polymers;

- The need to fine-tune degradation timing and conditions according to the application context;

- High production costs compared to conventional materials.

5.2. Recycled Polymers, Hybrid Composites, and Circular Strategies

- Significantly extending material service life;

- Reducing reliance on virgin raw materials;

- Supporting the development of recycling-based spinning processes for technically viable new nets.

5.3. Natural Fibers, Advanced Processing, and Functional Design

- Withstand mechanical stresses typical of marine and open-field applications;

- Degrade selectively;

- Interact with the environment (e.g., via visual degradation indicators or antibacterial properties).

- Expand and update technical standards, which are still inadequate for new generations of materials;

- Consolidate environmental assessment tools such as LCA and ecological risk analysis;

- Build production chains capable of supporting new high-performance, low-impact mesh materials.

5.4. International Programs and Pilot Initiatives for Biodegradable Nets

5.4.1. Projects on Marine-Biodegradable Nets

- LIFE MUSCLES (Marine Use of Sustainable Compostable Light-Weight Eco-friendly Socks)—Replacement of conventional polypropylene socks in mussel farming with compostable biopolymers and implementation of an on-site recycling model (EU LIFE Programme; 2021–2025; Italy/European Union). Status: ongoing [65].

- TEFIBIO (Test d’Engins de Pêche Biodégradables)—Development and field testing of biodegradable, bio-sourced, and recyclable trammel-type fishing nets with recycling feasibility into compost (European Maritime and Fisheries Fund—FEAMP; 2019–2023; France). Status: concluded. Result: biodegradable nets validated for compostability and functional use [68,69].

- SFI Dsolve (Sustainable Fishing Gear for Reduction of Marine Plastic Pollution)—Research on biodegradable fishing gear (nets, ropes, lines) capable of degrading naturally without releasing microplastics (Research Council of Norway—RCN; 2020–2028; Norway). Status: ongoing [70].

- Glaukos (Triggerable Bio-based Textile Polymers with Tailored Degradation and Recycling Properties)—Design of new bio-based, biodegradable, and recyclable fibers and coatings for fishing nets and textiles, integrated into a circular life cycle approach (Horizon 2020 Programme—EU; 2020–2024; European Union). Status: concluded. Results: development of bio-based and biodegradable fishing nets with marine-safe coatings, designed for controlled degradation and integration into a circular life cycle [71].

- Biodegradable Gillnets—China—National campaign for replacing conventional gillnets with PBS-based biodegradable alternatives to prevent marine plastic pollution (Ministry of Agriculture and Rural Affairs—MARA; 2021–ongoing; China). Status: ongoing [74].

- ICAR-CIFT Biodegradable Nets (Indian Council of Agricultural Research—Central Institute of Fisheries Technology)—Development and field testing of biodegradable PBS and PBAT nets for marine and inland fisheries, aligned with SDGs (Indian Council of Agricultural Research—ICAR; 2018–ongoing; India). Status: ongoing [75].

- GREENET (Green Fishing Net Project)—Research-driven development of prototype fishing nets from naturally degradable materials to minimize environmental impact (Queensland University of Technology—QUT; 2023 (prototype stage); Australia). Status: ongoing [76].

5.4.2. Projects on Agricultural Biodegradable Nets

- BBioNets (Boosting Bio-Based Technologies Adoption through Forest and Agriculture Networks)—Promotion of bio-based technologies and creation of regional networks to accelerate the use of biodegradable agricultural nets (Horizon Europe Programme; 2023–2026; European Union). Status: ongoing [80].

- CompostNet (Compostable Nets for Sustainable Agriculture)—Design of biodegradable insect exclusion nets suitable for household composting, combining durability and environmental friendliness (Auvergne-Rhône-Alpes Region; 2023–2026; France). Status: ongoing [81].

- BioNetAgro (Eco-Friendly Netting Initiative for Sustainable Agriculture)—Provision of eco-friendly nets to small-scale farmers for sustainable crop protection in Kenya (ICIPE—Kenya; 2017–2021; Kenya). Result: Nets successfully validated in field applications with positive outcomes in tomato farming. The BioNetAgro initiative (2017–2021), promoted by ICIPE, built upon earlier research on eco-friendly netting for tomato protection. Field validation confirmed the effectiveness of these solutions, already explored in preliminary studies (Gogo et al., 2014) [82].

- University of Queensland Bio-Packaging Project—Research on biodegradable packaging and agricultural netting solutions derived from agricultural waste (e.g., sugarcane fibers), aimed at replacing conventional plastics in farming applications (University of Queensland research funding; 2020–ongoing; Australia). Status: ongoing [83].

- MEDLIFE Greenhouse Project—Construction of family greenhouses to improve the agricultural capacity of the Chahauitiri community near Cusco, Peru, enabling vegetable cultivation despite the high-altitude climate (MEDLIFE; 2020–ongoing; Peru). Status: ongoing [84].

5.4.3. Comparative Insights and Commercial Developments

- The NetPlus® Program (Bureo; 2013–ongoing), which recovers and recycles discarded fishing nets into consumer goods within a circular materials model [85];

- The Nets for Change initiative (NBA and World Surf League; 2024–ongoing), which upcycles ghost nets into basketball nets for use in community courts [86];

- The BioPBS Turf Net Project (PTT MCC Biochem; 2020–2023), which demonstrated the technical viability of biodegradable turfgrass netting [87];

6. Discussion

7. Conclusions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| PLA | Polylactic Acid |

| PHA | Polyhydroxyalkanoates |

| PBAT | Polybutylene Adipate-co-Terephthalate |

| PBS | Polybutylene Succinate |

| CNCs | Cellulose Nanocrystals |

| FEM | Finite Element Modeling |

| LCA | Life Cycle Assessment |

| SUP | Single-Use Plastics |

| EMFAF | European Maritime, Fisheries and Aquaculture Fund |

References

- Kim, J.; Park, S.; Jung, S.; Yun, H.; Choi, K.; Heo, G.; Jin, H.-J.; Park, S.; Kwak, H.W. Biodegradation behavior of polybutylene succinate (PBS) fishing gear in marine sedimentary environments for ghost fishing prevention. Polym. Degrad. Stab. 2023, 216, 110490. [Google Scholar] [CrossRef]

- Briassoulis, D.; Mistriotis, A.; Eleftherakis, D. Mechanical behaviour and properties of agricultural nets—Part I: Testing methods for agricultural nets. Polym. Test. 2007, 26, 822–832. [Google Scholar] [CrossRef]

- Briassoulis, D.; Mistriotis, A.; Eleftherakis, D. Mechanical behaviour and properties of agricultural nets. Part II: Analysis of the performance of the main categories of agricultural nets. Polym. Test. 2007, 26, 970–984. [Google Scholar] [CrossRef]

- Bekker-Nielsen, T.; Casasola, D.B. Ancient Nets and Fishing Gear. In Proceedings of the International Workshop on Nets and Fishing Gear in Classical Antiquity: A First Approach, Aarhus, Denmark, 15–17 November 2007; Universidad De Cádiz, Servicio De Publicaciones Aarhus University Press: Aarhus, Denmark, 2007. [Google Scholar]

- Thomas, S.N. Netting Materials for Fishing Gear with Special Reference to Resource Conservation and Energy Saving. In Proceedings of the ICAR Winter School. Responsible Fishing: Recent Advances in Resource and Energy Conservation, Kochi, Indian, 21 November–11 December 2019; Aarhus Universitu Press: Aarhus, Denmark, 2019; pp. 55–70. [Google Scholar]

- Greene, J. Marine Biodegradation of PLA, PHA, and Bio-additive Polyethylene Based on ASTM D708; Academia: San Francisco, CA, USA, 2012. [Google Scholar]

- Lee, Y.; Kim, M.W.; Kim, H.J.; Kim, J.K.; Won, T.K.; Miyawaki, J.; Chae, H.G.; Eom, Y. Ultra-strong and biodegradable nanocomposite fibers of poly(butylene adipate-co-terephthalate)/cellulose nanocrystal prepared by dry-jet wet spinning. Polym. Compos. 2024, 45, 8825–8839. [Google Scholar] [CrossRef]

- Romero-Gómez, M.I.; Silva, R.V.; Flores-Colen, I.; Rubio-de-Hita, P. Mechanical performance of waste fishing net fibre-reinforced gypsum composites. Constr. Build. Mater. 2023, 387, 131675. [Google Scholar] [CrossRef]

- Fan, Z.-Q.; Liang, Y.-H.; Yun-Peng, Z. Review of the research on the hydrodynamics of fishing cage nets. Ocean Eng. 2023, 276, 114192. [Google Scholar] [CrossRef]

- Castellano, S.; Mugnozza, G.S.; Russo, G.; Briassoulis, D.; Mistriotis, A.; Hemming, S.; Waaijenberg, D. Plastic Nets in Agriculture: A General Review of Types and Applications. Appl. Eng. Agric. 2008, 24, 799–808. [Google Scholar] [CrossRef]

- Hong, Y.; Yang, H.-S.; Lee, M.H.; Kim, S.; Park, S.B.; Hwang, S.Y.; Park, J.; Koo, J.M.; Oh, D.; Hwang, D.S. Fishing gear with enhanced drapability and biodegradability: Artificial, eco-friendly fibers inspired by the mussel byssus. Chem. Eng. J. 2024, 489, 151388. [Google Scholar] [CrossRef]

- Moe, H.; Olsen, A.; Hopperstad, O.S.; Jensen, Ø.; Fredheim, A. Tensile properties for netting materials used in aquaculture net cages. Aquac. Eng. 2007, 37, 252–265. [Google Scholar] [CrossRef]

- Castellano, S.; Starace, G.; De Pascalis, L.; Lippolis, M.; Scarascia Mugnozza, G. Test results and empirical correlations to account for air permeability of agricultural nets. Biosyst. Eng. 2016, 150, 131–141. [Google Scholar] [CrossRef]

- Rudlof, G.A.V.; Montecinos, H.P. Aquaculture Net with Different Densities of Weight. U.S. Patent No. 8,210,125, 3 July 2012. [Google Scholar]

- Enviro-Friendly Bio-Line: Biodegradable Fishing Line Launched in Australia. Fishing World Magazine. Available online: https://fishingworld.com.au/news/enviro-friendly-bio-line/ (accessed on 25 April 2025).

- Biodegradable Monofilament Line. Mustad TUF-LINE. Available online: https://mustad-fishing.com/tuf-line/us/product/bo/ (accessed on 17 April 2025).

- GAIA Biomaterials AB: Biodolomer® Ocean for Fishing Nets. SMEP Programme. Available online: https://smepprogramme.org/project/gaia-biomaterials-ab/ (accessed on 27 April 2025).

- Maraveas, C. The Sustainability of Plastic Nets in Agriculture. Sustainability 2020, 12, 3625. [Google Scholar] [CrossRef]

- Knoch, S.; Pelletier, F.; Larose, M.; Chouinard, G.; Dumont, M.-J.; Tavares, J.R. Surface modification of PLA nets intended for agricultural applications. Colloids Surf. Physicochem. Eng. Asp. 2020, 598, 124787. [Google Scholar] [CrossRef]

- Liu, H.-Y.; Pang, G.-L.; Xiong, Y.-L.; Yang, S.; Yuan, T.-P.; Chen, X.-T.; Huang, X.-H.; Yuan, S. Material mechanics properties and critical analyses of fish farm netting and trusses. Ocean Eng. 2024, 292, 116512. [Google Scholar] [CrossRef]

- Dos Santos Filho, E.A.; Luna, C.B.B.; Da Silva Barbosa Ferreira, E.; Pinto, G.M.; Andrade, R.J.E.; Fechine, G.J.M.; Araújo, E.M. Enhancing PLA/ABS Blends Compatibility: A Comparative Study with SAN—Epoxy and SAN—MA. Polym. Adv. Technol. 2025, 36, e70078. [Google Scholar] [CrossRef]

- Chen, R.; Zhang, F.; Jin, B.; Han, L.; Zhang, Z.; Lin, B.; Pan, F.; Fang, S. Preparation and Properties of Toughened PLA/PBAT Blends Based on EVA and Multi-Functional Epoxy Chain Extender. J. Appl. Polym. Sci. 2025, 142, e56857. [Google Scholar] [CrossRef]

- Andrea Fusari Relazione Finale; Progetto: PEsca Senza PLAstica (PE.S.PLA.). Fondo Europeo per gli Affari Marittimi e la Pesca (FEAMP)—Regolamento (UE) 508 del 15/05/2014 Priorità 1—Misura 1.26; Ente Esecutore: ATS AGCI Agrital (capofila), Legacoop Puglia, Federcoopesca, I.C.R. Consorzio Mediterraneo e C.I.R.S.PE. 2022. Available online: https://www.agciagrital.it/wp-content/uploads/2023/05/00-011-INP-17-Relazione-finale.pdf (accessed on 25 April 2025).

- Banthia, N.; Bindiganavile, V.; Jones, J.; Novak, J. Fiber-reinforced concrete in precast concrete applications: Research leads to innovative products. PCI J. 2012, 57, 33–46. [Google Scholar] [CrossRef]

- Bertelsen, I.M.G.; Ottosen, L.M. Engineering Properties of Fibres from Waste Fishing Nets. In Proceedings of the International RILEM Conference on Materials, Systems and Structures in Civil Engineering, Copenhagen, Denmark, 15–29 August 2016. [Google Scholar]

- Rossi, D.; Cappello, M.; Filippi, S.; Bartoli, M.; Malucelli, G.; Cinelli, P.; Seggiani, M. Polyamide 6 recycled fishing nets modified with biochar fillers: An effort toward sustainability and circularity. Mater. Today Commun. 2024, 41, 110650. [Google Scholar] [CrossRef]

- Ko, H.-S.; Lee, S.; Lee, D.; Jho, J.Y. Mechanical Properties and Bioactivity of Poly(Lactic Acid) Composites Containing Poly(Glycolic Acid) Fiber and Hydroxyapatite Particles. Nanomaterials 2021, 11, 249. [Google Scholar] [CrossRef]

- Hernández-López, M.; Correa-Pacheco, Z.N.; Bautista-Baños, S.; Zavaleta-Avejar, L.; Benítez-Jiménez, J.J.; Sabino-Gutiérrez, M.A.; Ortega-Gudiño, P. Bio-based composite fibers from pine essential oil and PLA/PBAT polymer blend. Morphological, physicochemical, thermal and mechanical characterization. Mater. Chem. Phys. 2019, 234, 345–353. [Google Scholar] [CrossRef]

- Soatthiyanon, N.; Aumnate, C.; Srikulkit, K. Rheological, tensile, and thermal properties of poly(butylene succinate) composites filled with two types of cellulose (kenaf cellulose fiber and commercial cellulose). Polym. Compos. 2020, 41, 2777–2791. [Google Scholar] [CrossRef]

- Czarnecka-Komorowska, D.; Wachowiak, D.; Gizelski, K.; Kanciak, W.; Ondrušová, D.; Pajtášová, M. Sustainable Composites Containing Post-Production Wood Waste as a Key Element of the Circular Economy: Processing and Physicochemical Properties. Sustainability 2024, 16, 1370. [Google Scholar] [CrossRef]

- Aliotta, L.; Gigante, V.; Coltelli, M.-B.; Cinelli, P.; Lazzeri, A.; Seggiani, M. Thermo-Mechanical Properties of PLA/Short Flax Fiber Biocomposites. Appl. Sci. 2019, 9, 3797. [Google Scholar] [CrossRef]

- Singh, J.I.P.; Singh, S.; Dhawan, V.; Gulati, P. Flax fiber reinforced polylactic acid composites for non-structural engineering applications: Effect of molding temperature and fiber volume fraction on its mechanical properties. Polym. Polym. Compos. 2021, 29, S780–S789. [Google Scholar] [CrossRef]

- Garkhail, S.K.; Heijenrath, R.W.H.; Peijs, T. Mechanical Properties of Natural-Fibre-Mat- Reinforced Thermoplastics based on Flax Fibres and Polypropylene. Appl. Compos. Mater. 2000, 7, 351–372. [Google Scholar] [CrossRef]

- Van den Oever, M.J.A.; Bos, H.L.; Van Kemenade, M.J.J.M. Influence of the physical structure of flax fibres on the mechanical properties of flax fibre reinforced polypropylene composites. Appl. Compos. Mater. 2000, 7, 387–402. [Google Scholar] [CrossRef]

- Sharif, N.F.H.; Mon, S.Z.K. A Review on the Strength of Fishing Net; The Effect of Material, Yarn Diameter and Mesh Size. Prog. Eng. Appl. Technol. 2021, 2, 1030–1036. [Google Scholar]

- Castellano, S.; Russo, G.; Mugnozza, G.S. The Influence of Construction Parameters on Radiometric Performances of Agricultural Nets. In III International Symposium on Models for Plant Growth, Environmental Control and Farm Management in Protected Cultivation (HortiModel 2006); ISHS: Wageningen, The Netherlands, 2006; pp. 283–290. [Google Scholar] [CrossRef]

- Halim, N.A.; Mon, S.Z.K. A Review on Impact of Environmental Conditions on Fishing Net Mechanical Properties. Prog. Eng. Appl. Technol. 2021, 2, 957–964. [Google Scholar]

- Amala Mithin Minther Singh, A.; Michael Raj, F.; Arul Franco, P.; Binoj, J.S. Evaluation of mechanical behavior of multifilament discarded fishnet/glass fiber and polyester composites for marine applications. Mar. Struct. 2018, 58, 361–366. [Google Scholar] [CrossRef]

- Spadea, S.; Farina, I.; Carrafiello, A.; Fraternali, F. Recycled nylon fibers as cement mortar reinforcement. Constr. Build. Mater. 2015, 80, 200–209. [Google Scholar] [CrossRef]

- Thomas, S.N.; Hridayanathan, C. The effect of natural sunlight on the strength of polyamide 6 multifilament and monofilament fishing net materials. Fish. Res. 2006, 81, 326–330. [Google Scholar] [CrossRef]

- Castellano, S.; Scarascia Mugnozza, G.; Russo, G.; Briassoulis, D.; Mistrotis, A.; Hemming, S.; Waaijenberg, D. Design And Use Criteria Of Netting Systems For Agricultural Production In Italy. J. Agric. Eng. 2008, 39, 31. [Google Scholar] [CrossRef]

- Baranov, F.I. Theory and Estimation of Fishing Gear; A.M. McCombie Ontario Ministry of Natural Resources Research Section, Fisheries Branch; Fish Industry Press: Ottawa, ON, Canada, 1948. [Google Scholar]

- Prado, J.; Dremiere, P.Y.; Leite, A.M. Guia Pratico Do Pescador; EDITAMAR Edigões Maritimas, Lda.: Lisbon, Portugal, 1988; ISBN 972-95458-0-4. [Google Scholar]

- Tsukrov, I.; Eroshkin, O.; Fredriksson, D.; Swift, M.R.; Celikkol, B. Finite element modeling of net panels using a consistent net element. Ocean Eng. 2003, 30, 251–270. [Google Scholar] [CrossRef]

- Morison, J.R.; Johnson, J.W.; Schaaf, S.A. The Force Exerted by Surface Waves on Piles. J. Pet. Technol. 1950, 2, 149–154. [Google Scholar] [CrossRef]

- Cifuentes, C.; Kim, M.H. Numerical simulation of fish nets in currents using a Morison force model. Ocean Syst. Eng. 2017, 7, 143–155. [Google Scholar] [CrossRef]

- Casanova, C.; Dwikartika, W. Modeling of Aquaculture PET Net with the Use of Finite Element Method. Master’s Thesis, Marine Systems, Norwegian University of Science and Technology Department of Marine Technology, Trondheim, Norway, 2013. [Google Scholar]

- Moe-Føre, H.; Lader, P.F.; Lien, E.; Hopperstad, O.S. Structural response of high solidity net cage models in uniform flow. J. Fluids Struct. 2016, 65, 180–195. [Google Scholar] [CrossRef]

- Chen, H.; Christensen, E.D. Development of a numerical model for fluid-structure interaction analysis of flow through and around an aquaculture net cage. Ocean Eng. 2017, 142, 597–615. [Google Scholar] [CrossRef]

- Zhang, K.; Liu, B.; Chen, H.; Chen, J.; Yao, H.-D. Solving fluid-structure interaction of flexible net structures in current and waves based on a coupled truss–porous medium model. Ocean Eng. 2025, 329, 121115. [Google Scholar] [CrossRef]

- Myrli, O.; Khawaja, H. Fluid-Structure Interaction (FSI) Modelling of Aquaculture Net Cage. Int. J. Multiphysics 2019, 13, 97–111. [Google Scholar] [CrossRef]

- Tang, H.; Hu, F.; Xu, L.; Dong, S.; Zhou, C.; Wang, X. Variations in hydrodynamic characteristics of netting panels with various twine materials, knot types, and weave patterns at small attack angles. Sci. Rep. 2019, 9, 1923. [Google Scholar] [CrossRef]

- Kim, S.; Kim, P.; Lim, J.; An, H.; Suuronen, P. Use of biodegradable driftnets to prevent ghost fishing: Physical properties and fishing performance for yellow croaker. Anim. Conserv. 2016, 19, 309–319. [Google Scholar] [CrossRef]

- Gilman, E. Biodegradable fishing gear: Part of the solution to ghost fishing and marine pollution. Anim. Conserv. 2016, 19, 320–321. [Google Scholar] [CrossRef]

- Yu, M.; Tang, Y.; Min, M.; Herrmann, B.; Cerbule, K.; Liu, C.; Dou, Y.; Zhang, L. Comparison of physical properties and fishing performance between biodegradable PLA and conventional PA trammel nets in grey mullet (Mugil cephalus) and red-lip mullet (Liza haematocheila) fishery. Mar. Pollut. Bull. 2023, 195, 115545. [Google Scholar] [CrossRef] [PubMed]

- Kopitar, D.; Marasovic, P.; Jugov, N.; Schwarz, I. Biodegradable Nonwoven Agrotextile and Films—A Review. Polymers 2022, 14, 2272. [Google Scholar] [CrossRef] [PubMed]

- Intermas TrellisNet Bio. Available online: https://intermas.com/en/products/trellisnet-bio (accessed on 28 April 2025).

- The Farm Dream Jute Net. Available online: https://thefarmdream.com/products/natural-jute-climbing-netting-1-8m-x-5-0m-plant-support (accessed on 28 April 2025).

- Ladybird Plant Care InsectONet. Available online: https://ladybirdplantcare.co.uk/products/new-insectonet-plastic-free-netting (accessed on 25 April 2025).

- Zudaire, I.; Moreno, G.; Murua, J.; Murua, H.; Tolotti, M.; Roman, M.; Hall, M.; Lopez, J.; Grande, M.; Escalle, L.; et al. Biodegradable Dfads: Current Status and Prospects. In Proceedings of the 2nd IOTC Ad Hoc Working Group on FADs (WGFAD02), Online/Virtual, 4–6 October 2021. [Google Scholar]

- Juan, R.; Domínguez, C.; Robledo, N.; Paredes, B.; Galera, S.; García-Muñoz, R.A. Challenges and Opportunities for Recycled Polyethylene Fishing Nets: Towards a Circular Economy. Polymers 2021, 13, 3155. [Google Scholar] [CrossRef]

- Pinto, Â.; Esteves, D.; Nobre, L.; Bessa, J.; Cunha, F.; Fangueiro, R. Mechanical Performance Enhancement in Natural Fibre-Reinforced Thermoplastic Composites Through Surface Treatment and Matrix Functionalisation. Polymers 2025, 17, 532. [Google Scholar] [CrossRef]

- Banasaz, S.; Ferraro, V. Keratin from Animal By-Products: Structure, Characterization, Extraction and Application—A Review. Polymers 2024, 16, 1999. [Google Scholar] [CrossRef]

- Siwal, S.S.; Mishra, K.; Saini, A.K.; Alsanie, W.F.; Kovalcik, A.; Thakur, V.K. Additive manufacturing of bio-based hydrogel composites: Recent advances. J. Polym. Environ. 2022, 30, 4501–4516. [Google Scholar] [CrossRef]

- Life Muscles (EU LIFE Programme) Circular Innovation to Protect the Sea. Available online: https://lifemuscles.eu/il-progetto/ (accessed on 29 April 2025).

- Toscana Chianti Ambiente. Da Livorno Reti Biodegradabili per Riforestare le Praterie di Posidonia dell’Isola d’Elba. Available online: https://www.toscanachiantiambiente.it/da-livorno-reti-biodegradabili-per-riforestare-le-praterie-di-posidonia-dellisola-delba/ (accessed on 29 April 2025).

- ISPRA. Le Radici del Mare—Innovazione e Buone Pratiche per Proteggere L’ecosistema Marino. Available online: https://www.isprambiente.gov.it/it/archivio/notizie-e-novita-normative/notizie-ispra/2023/03/documentario-the-roots-of-the-sea-innovazione-e-buone-pratiche-a-tutela-dellecosistema-marino (accessed on 25 April 2025).

- TEFIBIO Test d’Engins de Pêche Biodégradables. Pôle Aquimer. Available online: https://www.poleaquimer.com (accessed on 29 April 2025).

- TEFIBIO Project. CORDIS Community Research and Development Information Service. Available online: https://www.poleaquimer.com/en/projects/tefibio/ (accessed on 25 April 2025).

- SFI Dsolve (Sustainable Fishing Gear for Reduction of Marine Plastic Pollution). Available online: https://dsolve-sfi.no/ (accessed on 29 April 2025).

- Glaukos (Triggerable Bio-Based Textile Polymers with Tailored Degradation and Recycling Properties). Available online: https://glaukos-project.eu/ (accessed on 29 April 2025).

- National Institute of Fisheries Science. Biodegradable Nets to Reduce Ghost Fishing. Available online: https://www.korea.net/Government/Briefing-Room/Press-Releases/view?articleId=6375&type=O (accessed on 29 April 2025).

- Jeju to Supply Biodegradable Fishing Nets to Local Fishers. Available online: https://www.mk.co.kr/en/society/10998529 (accessed on 29 April 2025).

- Ministry of Agriculture and Rural Affairs of the People’s Republic of China. Development and Field Evaluation of Biodegradable Fishing Nets. Available online: https://english.moa.gov.cn/ (accessed on 29 April 2025).

- ICAR-CIFT Biodegradable Nets (Indian Council of Agricultural Research—Central Institute of Fisheries Technology). Available online: https://cift.res.in/consultancies-2020-2023 (accessed on 29 April 2025).

- GREENET—Biodegradable Fishing Nets. Queensland University of Technology Design Festival 2020. Available online: https://industrial.2020.qutdesignfestival.com.au/projects/biodegradable-fishing-nets/ (accessed on 29 April 2025).

- Catchgreen Project Biodegradable Fishing Nets. Available online: https://www.catchgreen.net/ (accessed on 29 April 2025).

- SMEP Programme Biodolomer® Ocean for Fishing Nets. Available online: https://smepprogramme.org/project (accessed on 29 April 2025).

- UNCTAD Biodegradable Fishing Nets—Catchgreen Project. Available online: https://unctad.org/system/files/non-official-document/ditc-ted-29052323-problue-catchgreen-1.pdf (accessed on 29 April 2025).

- BBioNets Consortium BBioNets—Boosting the Adoption of Bio-Based Technologies in Agriculture & Forestry. Available online: https://bbionets.eu/ (accessed on 2 April 2025).

- CompostNet Compostable Nets for Sustainable Agriculture. Available online: https://www.techtera.org/en/news/the-compostnet-project-aims-for-sustainable-agriculture-thanks-to-innovative-biodegradable-nets-with-promising-results/ (accessed on 29 April 2025).

- Gogo, E.O.; Saidi, M.; Itulya, F.M.; Martin, T.; Ngouajio, M. Eco-Friendly Nets and Floating Row Covers Reduce Pest Infestetion and Improve Tomato (Solarium lycopersicum L.) Yields for Smallholder Farmers in Kenia. Agronomy 2014, 4, 1–12. [Google Scholar] [CrossRef]

- Australian Institute for Bioengineering and Nanotechnology (AIBN), University of Queensland. AIBN Nanotechnologist Turning Sugarcane Waste into Sustainable Packaging. Available online: https://aibn.uq.edu.au/article/2020/10/aibn-nanotechnologist-turning-sugarcane-waste-sustainable-packaging (accessed on 29 April 2025).

- MEDLIFE. Sustainable Agriculture Initiatives in South America. MEDLIFE Greenhouse Project. Available online: https://www.safehomesmovement.org/2024/02/09/sustainable-agriculture-initiatives-in-south-america/ (accessed on 29 April 2025).

- Turning Discarded Fishing Nets into Premium Recycled Materials. Available online: https://bureo.co/ (accessed on 29 April 2025).

- Nets for Change. Available online: https://www.worldsurfleague.com/posts/537605/nba-and-world-surf-league-partner-to-repurpose-discarded-fishing-nets-into-basketball-courts-in-brazil (accessed on 29 April 2025).

- BioPBS Turf Net Project. Available online: https://pttmcc.com/biopbs-story (accessed on 29 April 2025).

- Intermas Biodegradable Nets. Available online: https://www.intermas.com (accessed on 29 April 2025).

- InCord. InCord Biodegradable Agricultural Nets. Available online: https://incord.com/home-garden/homesteading/ (accessed on 29 April 2025).

- Dylaa Biodegradable Jute Netting. Available online: https://www.dylaa.com/product/biodegradable-jute-netting/ (accessed on 29 April 2025).

| Configuration | Application Field | Materials | Notes | References |

|---|---|---|---|---|

| (A) | ||||

| Knotted net | Marine | PA, PE | High stability, visible knots, abrasion resistance | [10,12] |

| Knotless net | Marine, Agricultural | PA, PE, PLA | Flexible mesh, low fish damage, knot-free | [2,10] |

| Raschel net | Marine (limited), Agricultural | HDPE, PP, PLA | Chain-like mesh, flexible, suitable for seasonal use | [2,13] |

| Leno weave | Agricultural | HDPE, PP | Rigid interlacing, good dimensional stability | [10,13] |

| Flat woven net | Marine (limited), Agricultural | HDPE, PA | Regular mesh, moderate structural resistance | [10] |

| Braided rope | Marine, Agricultural (structural) | PE, PA, twisted synthetic fibers | High tenacity, used for edges and structural support | [5] |

| (B) | ||||

| Hexagonal mesh | Marine (limited) | PA, HDPE | Flexible hexagonal openings, used for mollusk containment | [5,9] |

| Spiral netting | Aquaculture (modular nets) | Metal wires | Helical structure with lateral walls interconnected through spirals, enhancing flexibility and mechanical strength | [14] |

| Strap net | Agricultural (mulching) | Biodegradable PE | Perforated band-like mesh, ground stability | [2,3] |

| Thermofused net | Marine (evolved knotless) | PA | Heat-welded mesh, regular shape and knotless | [9] |

| 3D multilayer net | Experimental | Bio-based composites | Multilayer net structures for advanced aquaculture cages | [7,8] |

| Material | Fiber Diameter (μm) | Tensile Strength (MPa) | Elastic Modulus (GPa) | Elongation at Break (%) | Reference(s) |

|---|---|---|---|---|---|

| PA6 (nylon) | 10–50 | 700–1000 | 3.9–6.0 | 10–15 | [24] |

| HDPE | 300 | 403–441 | 1 | 27–31 | [25] |

| PP | 10–150 | 200–700 | 0.5–9.8 | 10–15 | [24] |

| PE | 40 | 400 | 2–4 | 100–400 | [24] |

| Recycled PA6 | bulk | 47 | 2.6 | 12 | [26] |

| PA6/15% biochar composite | bulk | 47 | 4.5 | 6.3 | [26] |

| PLA | 10–50 | 74 | 3.1 | 3.3 | [27] |

| PBAT | film | 17.7 | 0.0016 | 1207.6 | [28] |

| PBS | bulk | 34 | 0.254 | 23.1 | [29] |

| Mater-Bi® | “ | 11.7 | 0.18 | 95 | [30] |

| PLA/flax composite | “ | 35–66 | 3–5 | - | [31,32] |

| PP/flax composite | “ | 45–57 | 6.5 | - | [33,34] |

| Agronomic Function | Mesh Design Criteria |

|---|---|

| Insect protection | Mesh size < 2 mm (physical barrier against small insects) |

| Bird protection | Mesh size 15–20 mm (corresponding to target bird body size) |

| Support for climbing plants | Mesh size 30–50 mm (compatibility with stems and tendrils) |

| Shading | Dense weaving, coverage ≥ 50%, oriented for solar shading |

| Mulching | Dense mesh or microperforated film, thickness < 100 μm |

| Project/Initiative | Application Area | Materials/Technologies | Country/Coordination | Period |

|---|---|---|---|---|

| LIFE MUSCLES | Mussel farming (tubular nets) | Compostable biopolymers, mechanical recycling | Italy/EU | 2021–2025 |

| Elba Island Posidonia | Seagrass restoration | Marine-biodegradable bioplastic yarns | Italy | 2023–2026 |

| TEFIBIO Project | Fishing nets (trammel type) | Biodegradable, bio-sourced materials | France | 2019–2023 |

| Dsolve Project | Fishing gear | Biodegradable synthetic replacements | Norway | 2020–2028 |

| Glaukos Project | Fishing nets and textiles | Bio-based, biodegradable fibers and coatings | European Union | 2020–2024 |

| Biodegradable Nets | Fishing nets | Biodegradable materials (ANKOR Bioplastics) | South Korea | 2020–ongoing |

| Biodegradable Gillnets | Gillnets | PBS biodegradable polymers | China | 2021–ongoing |

| ICAR-CIFT Biodegradable Nets | Marine and inland fishing nets | PBS and PBAT polymers | India | 2018–ongoing |

| GREENET Project | Biodegradable nets | Naturally degradable materials | Australia | 2023 (prototype) |

| Catchgreen Project | Marine and freshwater fishing nets | Marine-degradable Biodolomer®Ocean (PBS/PBAT) | Kenya/South Africa | 2022–ongoing |

| Project/Initiative | Application Area | Materials/Technologies | Country/Coordination | Period |

|---|---|---|---|---|

| BBioNets | Agriculture/Forestry | Bio-based materials from plant biomass | European Union | 2023–2026 |

| CompostNet | Insect exclusion nets | Compostable biomaterials | France (Auvergne-Rhône-Alpes) | 2023–2026 |

| BioNetAgro | Crop protection (tomato farming) | Eco-friendly agricultural netting | Kenya (ICIPE) | 2017–2021 |

| University of Queensland Bio-Packaging Project | Agricultural packaging and netting | Biodegradable composites from agricultural waste | Australia (University of Queensland) | 2023–ongoing |

| MEDLIFE Greenhouse Project | High-altitude community agriculture | Greenhouse nets and structures | Peru (MEDLIFE) | 2020–ongoing |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pagnotta, L. Sustainable Netting Materials for Marine and Agricultural Applications: A Perspective on Polymeric and Composite Developments. Polymers 2025, 17, 1454. https://doi.org/10.3390/polym17111454

Pagnotta L. Sustainable Netting Materials for Marine and Agricultural Applications: A Perspective on Polymeric and Composite Developments. Polymers. 2025; 17(11):1454. https://doi.org/10.3390/polym17111454

Chicago/Turabian StylePagnotta, Leonardo. 2025. "Sustainable Netting Materials for Marine and Agricultural Applications: A Perspective on Polymeric and Composite Developments" Polymers 17, no. 11: 1454. https://doi.org/10.3390/polym17111454

APA StylePagnotta, L. (2025). Sustainable Netting Materials for Marine and Agricultural Applications: A Perspective on Polymeric and Composite Developments. Polymers, 17(11), 1454. https://doi.org/10.3390/polym17111454