The Use of Bio-Polyurethane Binder for the Development of Engineered Wood Composites

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Materials

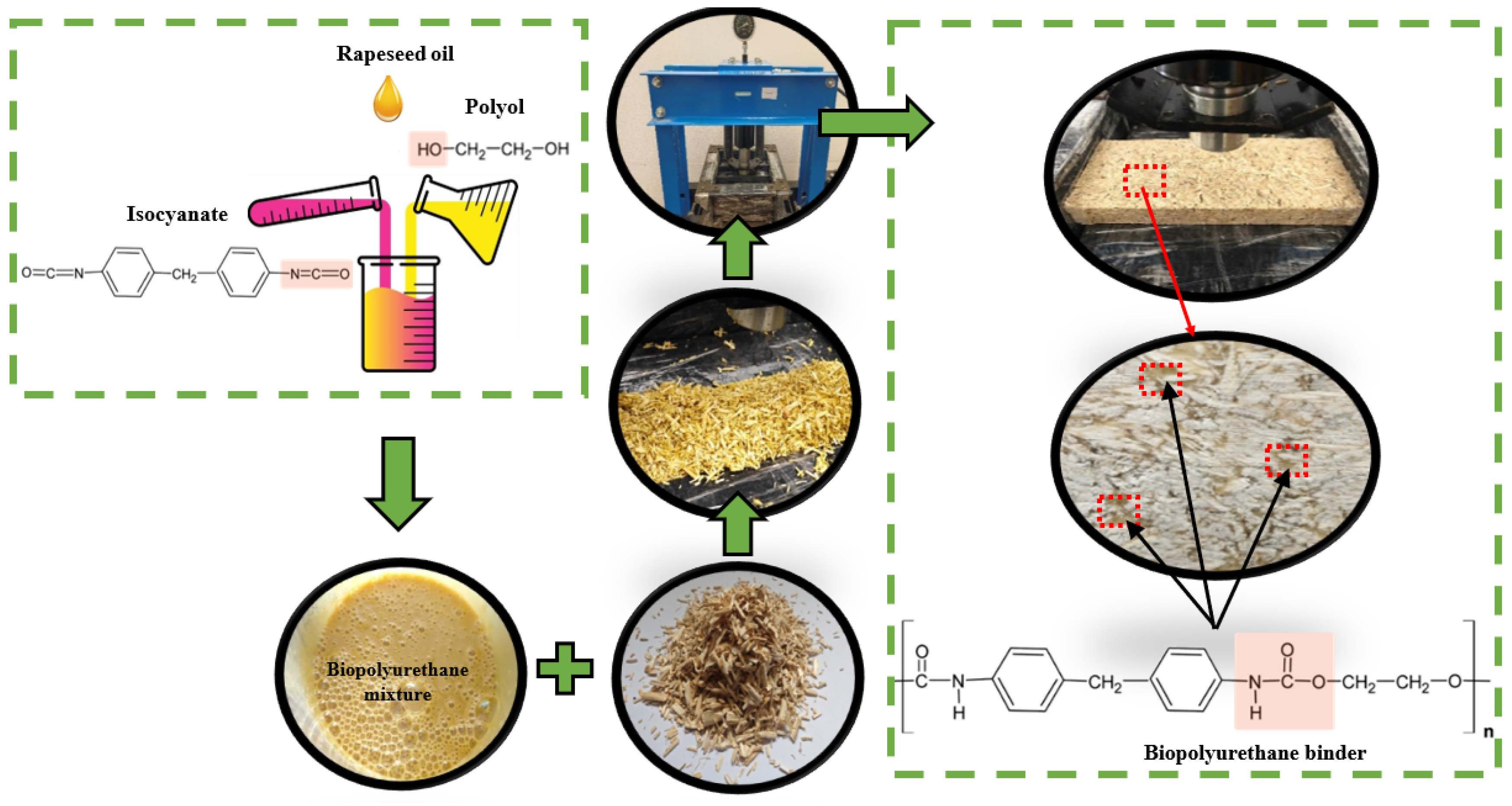

2.2. Preparation of Binding Material, Mixture, and Specimens

2.3. Characterization Methods

3. Results and Discussion

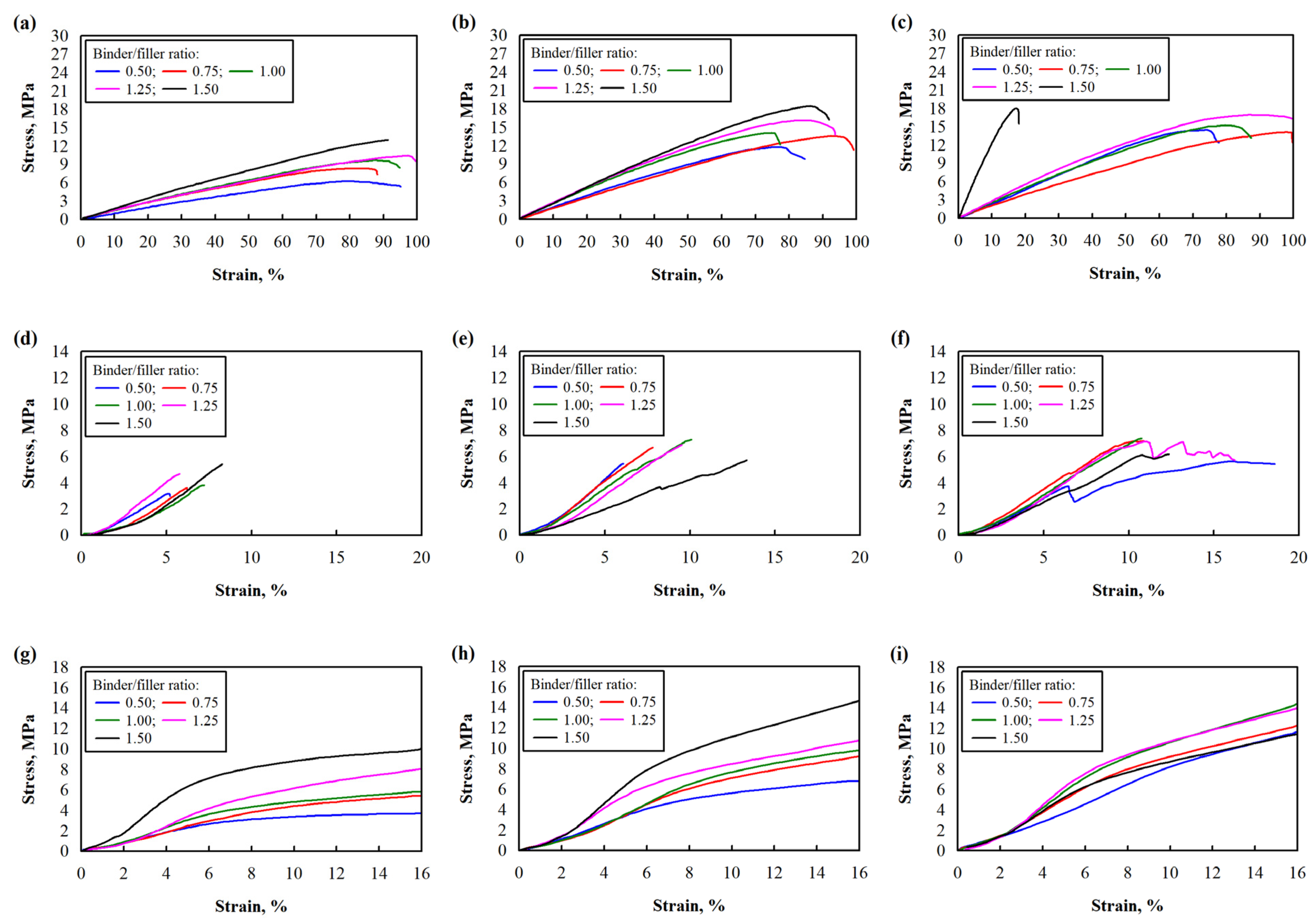

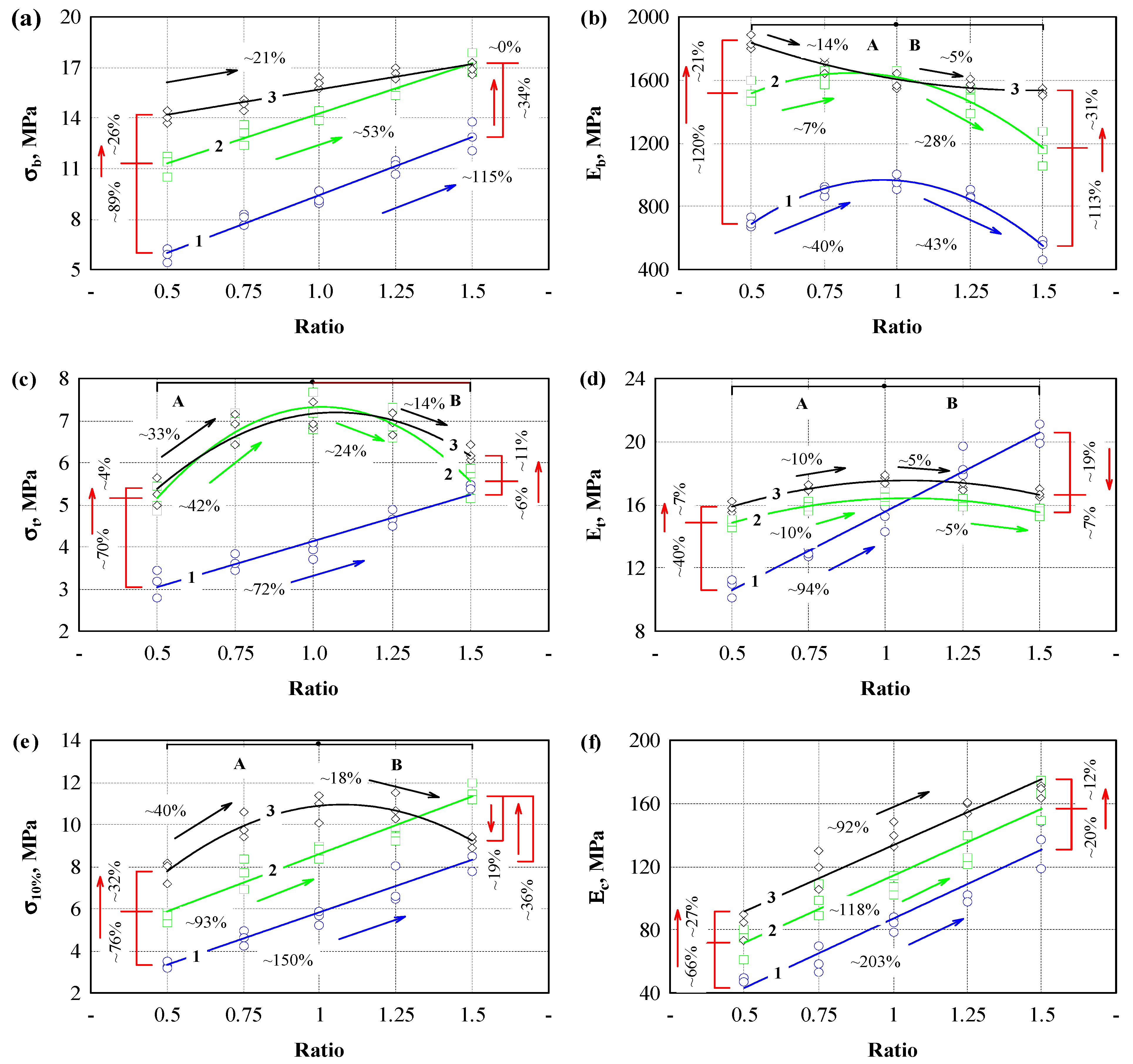

3.1. Evaluation of Mechanical Properties

3.2. Evaluation of Water Impact

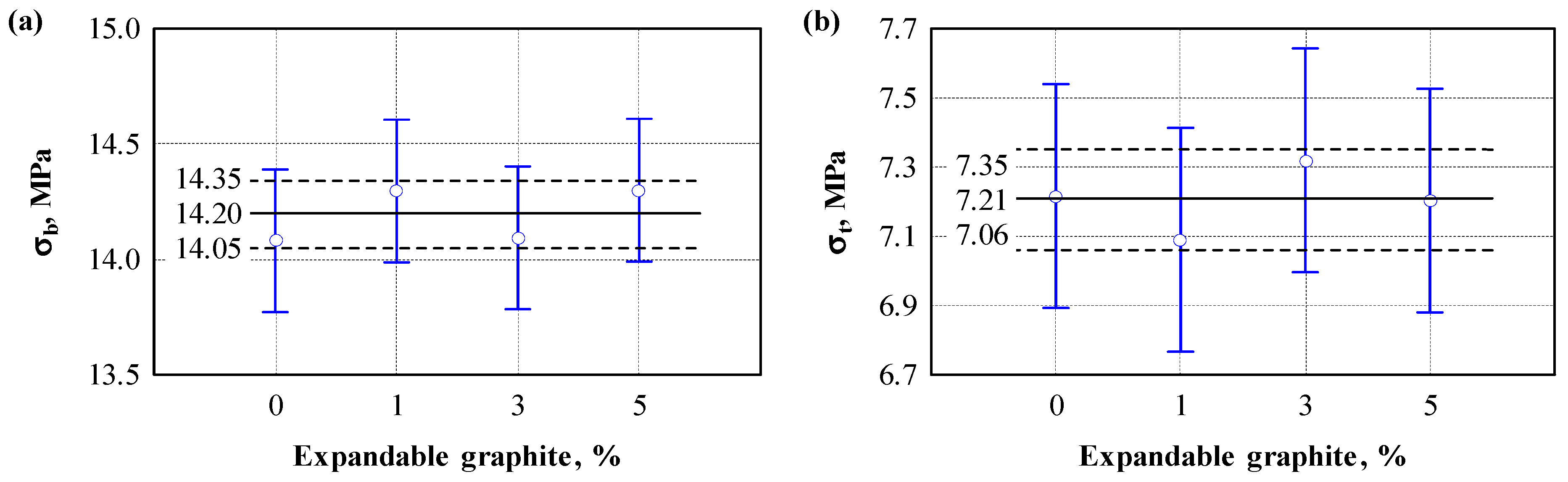

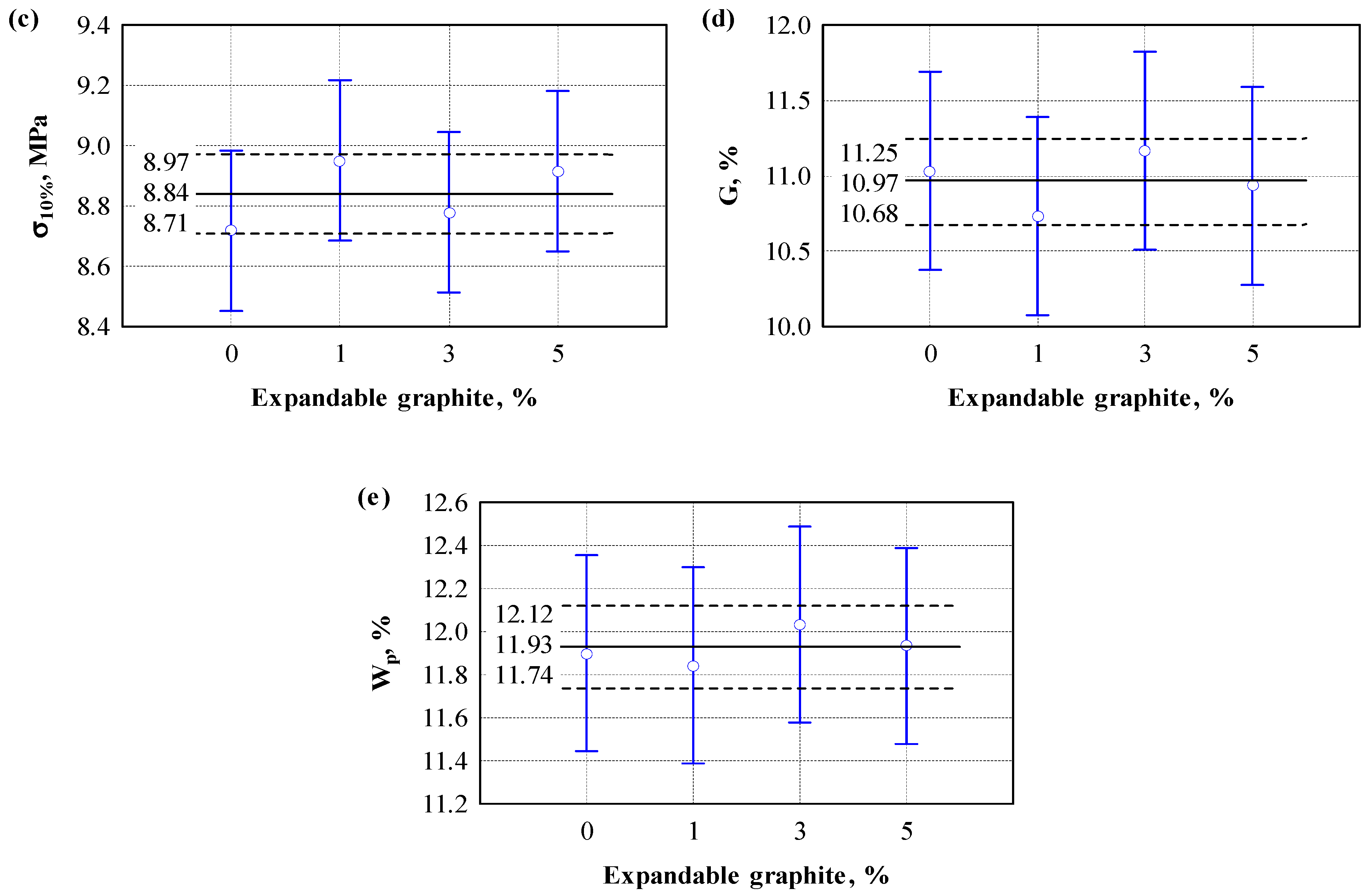

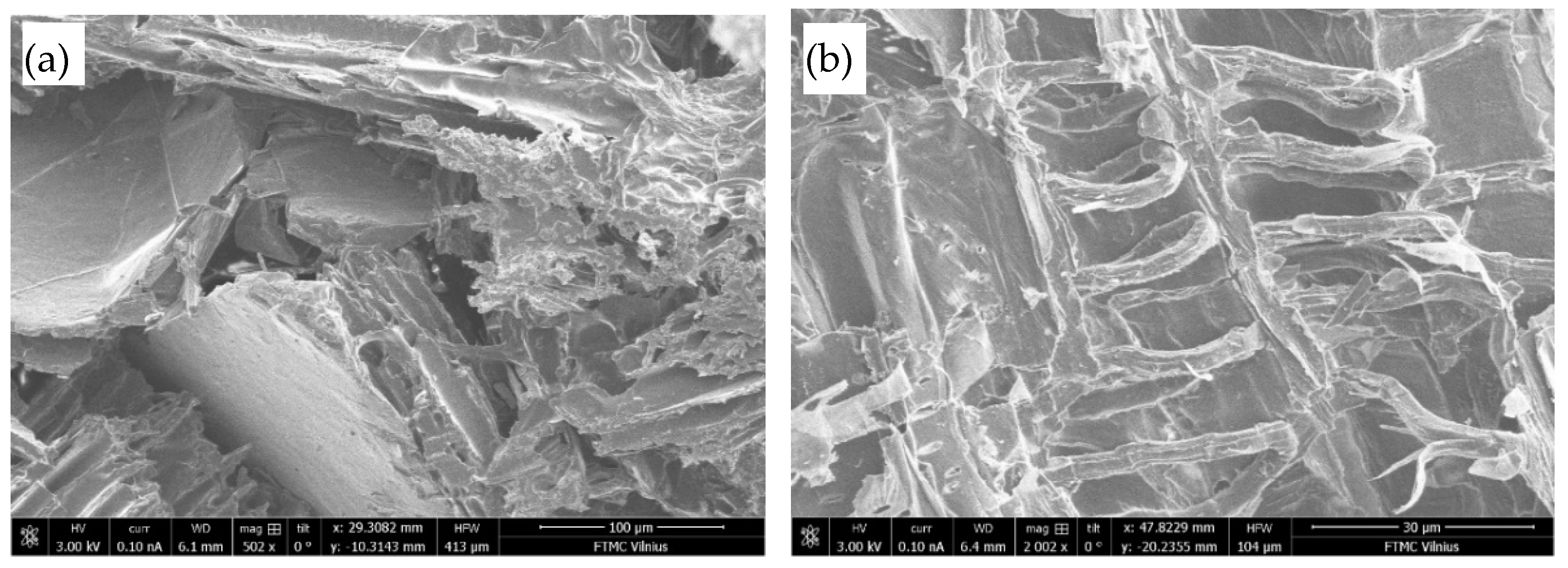

3.3. Evaluation of the Influence of Expandable Graphite on Strength and Water-Absorption Characteristics

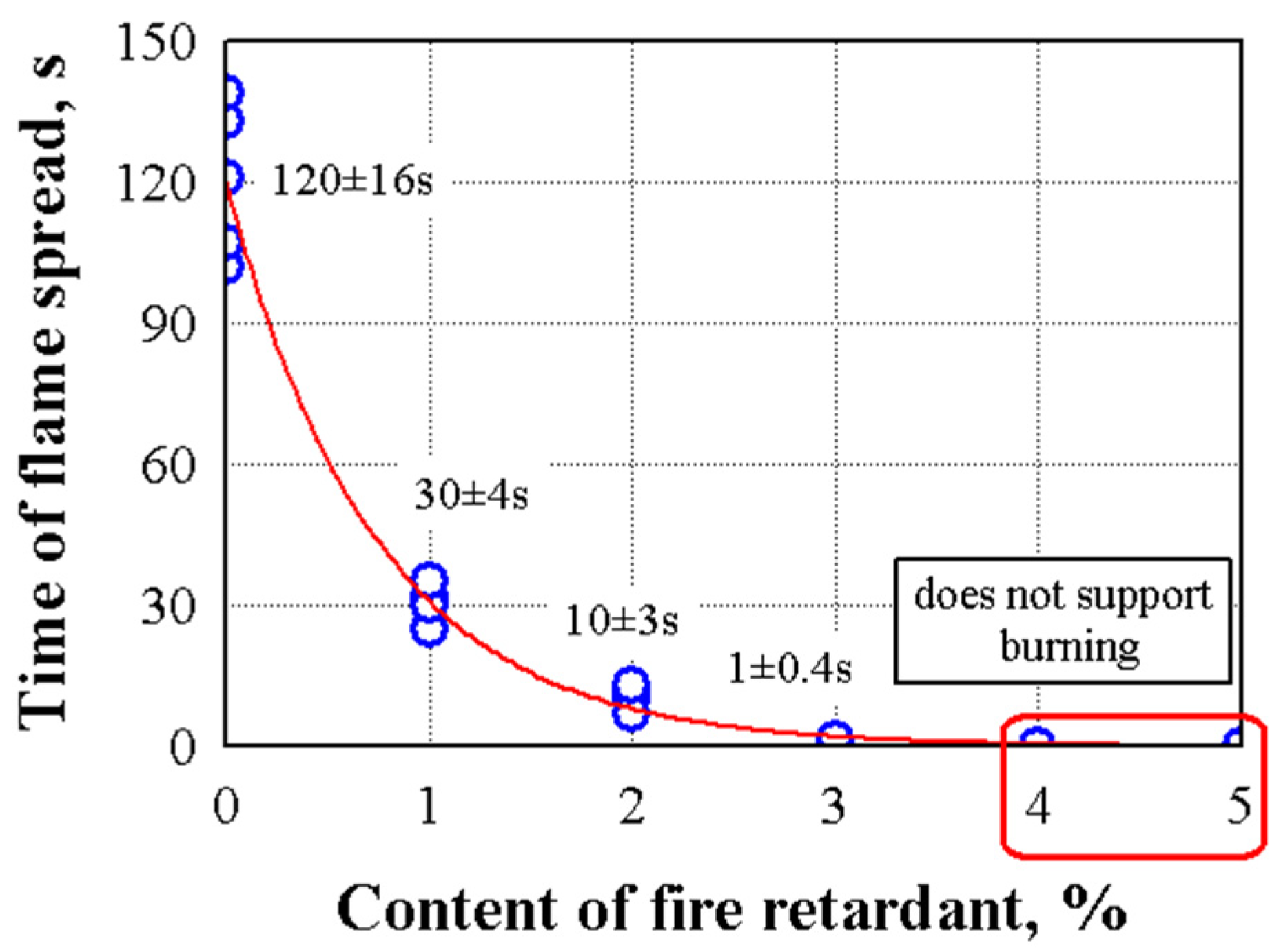

3.4. Assessment of Ignitability

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Jiang, Y.; May, H.D.; Lu, L.; Liang, P.; Huang, X.; Ren, Z.J. Carbon dioxide and organic waste valorization by microbial electrosynthesis and electro-fermentation. Water Res. 2019, 149, 42–55. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Fu, J.; Zhao, Z.; Bing, L.; Xi, F.; Wang, F.; Dong, J.; Wang, S.; Lin, G.; Yin, Y.; et al. Benefit analysis of multi-approach biomass energy utilization toward carbon neutrality. Innovation 2023, 4, 100423. [Google Scholar] [CrossRef]

- Unegg, M.C.; Steininger, K.W.; Ramsauer, C.; Rivera-Aguilar, M. Assessing the environmental impact of waste management: A comparative study of CO2 emissions with a focus on recycling and incineration. J. Clean. Prod. 2023, 415, 137745. [Google Scholar] [CrossRef]

- Thomson, A.; Price, G.W.; Arnold, P.; Dixon, M.; Graham, T. Review of the potential for recycling CO2 from organic waste composting into plant production under controlled environment agriculture. J. Clean. Prod. 2022, 333, 130051. [Google Scholar] [CrossRef]

- Kharola, S.; Ram, M.; Goyal, N.; Mangla, S.K.; Nautiyal, O.P.; Rawat, A.; Kazancoglu, Y.; Pant, D. Barriers to organic waste management in a circular economy. J. Clean. Prod. 2022, 362, 132282. [Google Scholar] [CrossRef]

- Zhu, J.; Liu, Y.; Luo, Z.; Ling, C.; Yin, K.; Tong, H. Methane mitigation strategy for food waste management: Balancing socio-economic acceptance and environmental impacts. Sustain. Prod. Consum. 2023, 37, 389–397. [Google Scholar] [CrossRef]

- Mishra, M.; Shukla, S.; Mishra, A.; Zohra, F.; Singh, S.; Kushwaha, A.; Goswami, L.; Upadhyay, N. Biotechnological interventions in the valorization of the organic waste. In Advanced Zero Waste Tools, Bio-Based Materials and Waste for Energy Generation and Resource Management; Elsevier: Amsterdam, The Netherlands, 2023; pp. 357–385. [Google Scholar]

- Jiang, K.; Xing, R.; Luo, Z.; Huang, W.; Yi, F.; Men, Y.; Zhao, N.; Chang, Z.; Zhao, J.; Pan, B.; et al. Pollutant emissions from biomass burning: A review on emission characteristics, environmental impacts, and research perspectives. Particuology 2024, 85, 296–309. [Google Scholar] [CrossRef]

- Su, M.; Shi, Y.; Yang, Y.; Guo, W. Impacts of different biomass burning emission inventories: Simulations of atmospheric CO2 concentrations based on GEOS-Chem. Sci. Total Environ. 2023, 876, 162825. [Google Scholar] [CrossRef]

- Imran, M.; Zahid, A.; Mouneer, S.; Özçatalbaş, O.; Ul Haq, S.; Shahbaz, P.; Muzammil, M.; Murtaza, M.R. Relationship between Household Dynamics, Biomass Consumption, and Carbon Emissions in Pakistan. Sustainability 2022, 14, 6762. [Google Scholar] [CrossRef]

- Hanaki, K.; Portugal-Pereira, J. The Effect of Biofuel Production on Greenhouse Gas Emission Reductions. In Biofuels and Sustainability; Springer: Tokyo, Japan, 2018; pp. 53–71. [Google Scholar]

- Jeswani, H.K.; Chilvers, A.; Azapagic, A. Environmental sustainability of biofuels: A review. In Proceedings of the Royal Society A: Mathematical, Physical and Engineering Sciences, 25 November 2020; The Royal Society Publishing: London, UK, 2020; pp. 1–37. [Google Scholar]

- Paletto, A.; Bernardi, S.; Pieratti, E.; Teston, F.; Romagnoli, M. Assessment of environmental impact of biomass power plants to increase the social acceptance of renewable energy technologies. Heliyon 2019, 5, e02070. [Google Scholar] [CrossRef]

- de Carvalho Araújo, C.K.; Salvador, R.; Moro Piekarski, C.; Sokulski, C.C.; de Francisco, A.C.; de Carvalho Araújo Camargo, S.K. Circular Economy Practices on Wood Panels: A Bibliographic Analysis. Sustainability 2019, 11, 1057. [Google Scholar] [CrossRef]

- Antov, P.; Krišták, L.; Réh, R.; Savov, V.; Papadopoulos, A.N. Eco-Friendly Fiberboard Panels from Recycled Fibers Bonded with Calcium Lignosulfonate. Polymers 2021, 13, 639. [Google Scholar] [CrossRef]

- Lee, S.H.; Lum, W.C.; Boon, J.G.; Kristak, L.; Antov, P.; Pędzik, M.; Rogoziński, T.; Taghiyari, H.R.; Lubis, M.A.R.; Fatriasari, W.; et al. Particleboard from agricultural biomass and recycled wood waste: A review. J. Mater. Res. Technol. 2022, 20, 4630–4658. [Google Scholar] [CrossRef]

- Azambuja, R.R.; Castro, V.G.; Trianoski, R.; Iwakiri, S. Recycling wood waste from construction and demolition to produce particleboards. Maderas Cienc. Tecnol. 2018, 20, 681–690. [Google Scholar] [CrossRef]

- Campos Filho, L.E.; Steigenberger, A.C.; Martins, R.H.B.; Júnior, W.E.L.; Favarim, H.R.; Pallone, E.M.J.A.; Freire, M.T.A.; Tosi, M.M.; Fiorelli, J. Oriented Strand Board panels of residual reforestation wood with Al2O3 nanoparticles. Ind. Crops Prod. 2023, 200, 116777. [Google Scholar] [CrossRef]

- Rebollar, M.; Pérez, R.; Vidal, R. Comparison between oriented strand boards and other wood-based panels for the manufacture of furniture. Mater. Des. 2007, 28, 882–888. [Google Scholar] [CrossRef]

- Berger, F.; Gauvin, F.; Brouwers, H.J.H. The recycling potential of wood waste into wood-wool/cement composite. Constr. Build. Mater. 2020, 260, 119786. [Google Scholar] [CrossRef]

- Keskisaari, A.; Kärki, T. The use of waste materials in wood-plastic composites and their impact on the profitability of the product. Resour. Conserv. Recycl. 2018, 134, 257–261. [Google Scholar] [CrossRef]

- Ramli, R.A. A comprehensive review on utilization of waste materials in wood plastic composite. Mater. Today Sustain. 2024, 27, 100889. [Google Scholar] [CrossRef]

- Ibrahim, R.A.; Fahim, I.S.; Shaban, M.; Gomaa, O.M. Sustainable wood composite production using cotton waste and exopolysaccharides as green binders. Int. J. Biol. Macromol. 2024, 281, 135710. [Google Scholar] [CrossRef]

- Deng, N.; Wang, J.; Li, J.; Sun, J. Straw density board vs. conventional density board: Is straw density board more sustainable? Sci. Total Environ. 2023, 888, 164020. [Google Scholar] [CrossRef] [PubMed]

- Zheng, C.; Sun, K.; Chen, Y.; Zhang, W.; Wu, Y. Mechanical and thermal properties of environmentally friendly straw boards. Constr. Build. Mater. 2023, 407, 133493. [Google Scholar] [CrossRef]

- Kammoun, Z.; Trabelsi, A. A high-strength lightweight concrete made using straw. Mag. Concr. Res. 2020, 72, 460–470. [Google Scholar] [CrossRef]

- Mokhtar, N.; Razali, S.M.; Sulaiman, M.S.; Edin, T.; Wahab, R. Converting wood-related waste materials into other value-added products: A short review. Earth Environ. Sci. 2022, 1053, 012030. [Google Scholar] [CrossRef]

- Grebner, D.L.; Bettinger, P.; Siry, J.P.; Boston, K. Forest products. In Introduction to Forestry and Natural Resources; Academic Press: New York, NY, USA, 2022; pp. 97–124. [Google Scholar]

- Yang, H.S.; Kim, D.J.; Kim, H.J. Rice straw–wood particle composite for sound absorbing wooden construction materials. Bioresour. Technol. 2003, 86, 117–121. [Google Scholar] [CrossRef]

- Li, X.; Cai, Z.; Winandy, J.E.; Basta, A.H. Selected properties of particleboard panels manufactured from rice straws of different geometries. Bioresour. Technol. 2010, 101, 4662–4666. [Google Scholar] [CrossRef] [PubMed]

- Tabarsa, T.; Jahanshahi, S.; Ashori, A. Mechanical and physical properties of wheat straw boards bonded with a tannin modified phenol–formaldehyde adhesive. Compos. Part B Eng. 2011, 42, 176–180. [Google Scholar] [CrossRef]

- Neudecker, F.; Veigel, S.; Bodner, S.C.; Keckes, J.; Duchoslav, J.; Stifter, D.; Gindl-Altmutter, W. Strong high-density composites from wheat straw. Compos. Appl. Sci. Manuf. 2025, 188, 108533. [Google Scholar] [CrossRef]

- Nkeuwa, W.N.; Zhang, J.; Semple, K.E.; Chen, M.; Xia, Y.; Dai, C. Bamboo-based composites: A review on fundamentals and processes of bamboo bonding. Compos. Part B Eng. 2022, 235, 109776. [Google Scholar] [CrossRef]

- Rimkienė, A.; Vėjelis, S.; Kremensas, A.; Vaitkus, S.; Kairytė, A. Development of High Strength Particleboards from Hemp Shives and Corn Starch. Materials 2023, 16, 5003. [Google Scholar] [CrossRef]

- Kremensas, A.; Vaitkus, S.; Vėjelis, S.; Członka, S.; Kairytė, A. Hemp shivs and corn-starch-based biocomposite boards for furniture industry: Improvement of water resistance and reaction to fire. Ind. Crops Prod. 2021, 166, 113477. [Google Scholar] [CrossRef]

- Indrayani, Y.; Setyawati, D.; Munawar, S.S.; Umemura, K.; Yoshimura, T. Evaluation of Termite Resistance of Medium Density Fiberboard (MDF) Manufacture from Agricultural Fiber Bonded with Citric Acid. Procedia Environ. Sci. 2015, 28, 778–782. [Google Scholar] [CrossRef][Green Version]

- Grigoriou, A.H.; Ntalos, G.A. The potential use of Ricinus communis L. (Castor) stalks as a lignocellulosic resource for particleboards. Ind. Crops Prod. 2001, 13, 209–218. [Google Scholar] [CrossRef]

- van Dam, J.E.G.; den Oever, M.J.A.; Teunissen, W.; Keijsers, E.R.P.; Peralta, A.G. Process for production of high density/high performance binderless boards from whole coconut husk: Part 1: Lignin as intrinsic thermosetting binder resin. Ind. Crops Prod. 2004, 19, 207–216. [Google Scholar] [CrossRef]

- Yin, D.; Zhai, M.; Wang, X.; Hu, S.; Zhao, X. Fully bio-based thermoplastic polyurethane composites with enhanced flame retardancy via phytic acid integration. Mater. Today Commun. 2025, 45, 112348. [Google Scholar] [CrossRef]

- Acharya, S.R.; Mohanty, S.; Palai, A.K. Flame retardant rigid polyurethane foam derived from biobased polyols and water as Co-blowing agent: Synergistic effect of expanded graphite and boron nitride. Mater. Today Commun. 2024, 41, 110278. [Google Scholar] [CrossRef]

- Ogabi, R.; Manescau, B.; Chetehouna, K.; Lamoot, L.; Muhammed Raji, A. Evaluation of fire-retardant biocomposites exposed to various heat fluxes at medium and large scales. J. Fire Sci. 2024, 43, 125–148. [Google Scholar] [CrossRef]

- Oktem, M.F.; Aydaş, B. Flame retardant characteristics of polymerized dopamine hydrochloride coated jute fabric and jute fabric composites: Scientific paper. J. Serbian Chem. Soc. 2022, 87, 363–375. [Google Scholar] [CrossRef]

- Nazmul, R.T.; Sainsbury, B.-A.; Al-Deen, S.; Garcez, E.O.; Ashraf, M. An Experimental Evaluation of Hemp as an Internal Curing Agent in Concrete Materials. Materials 2023, 16, 3993. [Google Scholar] [CrossRef]

- Yang, Y.; Zhang, Y.; Yu, W.; Kim, N.; Qi, Y. A novel bio-based waterproofing agent with lignosulfonate-encapsulated paraffin (LEP) against water absorption in wood-based composite. Case Stud. Constr. Mater. 2025, 22, e04523. [Google Scholar] [CrossRef]

- Mokhothu, T.H.; John, M.J. Bio-based coatings for reducing water sorption in natural fibre reinforced composites. Sci. Rep. 2017, 7, 13335. [Google Scholar] [CrossRef] [PubMed]

- Church, J.S.; Voda, A.S.; Sutti, A.; George, J.; Fox, B.L.; Magniez, K. A simple and effective method to ameliorate the interfacial properties of cellulosic fibre based bio-composites using poly (ethylene glycol) based amphiphiles. Eur. Polym. J. 2015, 64, 70–78. [Google Scholar] [CrossRef]

- Vitrone, F.; Ramos, D.; Ferrando, F.; Salvadó, J. The influence of thickness and final heat treatment on mechanical properties and dimensional stability of binderless fiberboards from steam exploded Arundo donax L. Mater. Today Proc. 2022, 58, 999–1004. [Google Scholar] [CrossRef]

- Nasir, M.; Khali, D.P.; Jawaid, M.; Tahir, P.M.; Siakeng, R.; Asim, M.; Khan, T.A. Recent development in binderless fiber-board fabrication from agricultural residues: A review. Constr. Build. Mater. 2019, 211, 502–516. [Google Scholar] [CrossRef]

- Mendes, R.F.; Júnior, G.B.; de Almeida, N.F.; Surdi, P.G.; Barbeiro, I.N. Effect of thermal treatment on properties of OSB panels. Wood Sci. Technol. 2013, 47, 243–256. [Google Scholar] [CrossRef]

- Rimkienė, A.; Kairytė, A.; Vėjelis, S.; Kremensas, A.; Vaitkus, S.; Šeputytė-Jucikė, J. Structure Formation in Engineered Wood Using Wood Waste and Biopolyurethane. Materials 2024, 17, 4087. [Google Scholar] [CrossRef]

- Serrano-Martínez, V.M.; Hernández-Fernández, C.; Pérez-Aguilar, H.; Carbonell-Blasco, M.P.; García-García, A.; Orgilés-Calpena, E. Development and Application of a Lignin-Based Polyol for Sustainable Reactive Polyurethane Adhesives Synthesis. Polymers 2024, 16, 1928. [Google Scholar] [CrossRef]

- Pan, Z.; Feng, G.; Xue, Y.; Song, F.; Zhang, M.; Zhou, Y. A novel green polyurethane adhesive based on castor oil and tannic acid with excellent water, salt, acid, alkali and antibacterial properties. Ind. Crops Prod. 2023, 204, 117325. [Google Scholar] [CrossRef]

- Liu, Z.; Kou, F.J.; Duan, Y.C.; Wang, W.J.; Peng, L.; Li, J.Z.; Gao, Q. Preparation and Investigation of Distillers-dried Grains with Solubles-based Wood Adhesive. J. For. Eng. 2021, 6, 105–111. [Google Scholar] [CrossRef]

- Kumar, C.; Leggate, W. An overview of bio-adhesives for engineered wood products. Int. J. Adhes. Adhes. 2022, 118, 103187. [Google Scholar] [CrossRef]

- Jeffri, N.I.; Mohammad Rawi, N.F.; Mohamad Kassim, M.H.; Abdullah, C.K. Unlocking the potential: Evolving role of technical lignin in diverse applications and overcoming challenges. Int. J. Biol. Macromol. 2024, 274, 133506. [Google Scholar] [CrossRef] [PubMed]

- Huang, C.; Peng, Z.; Li, J.; Li, X.; Jiang, X.; Dong, Y. Unlocking the role of lignin for preparing the lignin-based wood adhesive: A review. Ind. Crops Prod. 2022, 187, 115388. [Google Scholar] [CrossRef]

- Mušič, B.; Pečnik, J.G.; Pondelak, A. Stabilization of Fish Protein-Based Adhesive by Reduction of Its Hygroscopicity. Polymers 2024, 16, 2195. [Google Scholar] [CrossRef]

- Xu, Y.; Han, Y.; Li, J.; Luo, J.; Shi, S.Q.; Li, J.; Gao, Q.; Mao, A. Research Progress of Soybean Protein Adhesive: A Review. J. Renew. Mater. 2022, 10, 2519–2541. [Google Scholar] [CrossRef]

- Li, H.; Wang, R.; Zheng, M.; He, M.; Liu, X.; Wang, K.; Dong, Y.; Li, Y.; Li, J. Mantis shrimp-inspired functionalized plant fibers to fabricate a soy protein adhesive with high strength and mildew resistance. Int. J. Biol. Macromol. 2025, 306, 141532. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Yan, L.; Cai, L.; Xu, Y.; Li, J.; Li, J.; Shi, S.Q.; Gao, Q. Low-temperature curable and strong soy protein/allicin adhesive with excellent mildew resistance via a free-radical-polymerization curing system. Ind. Crops Prod. 2022, 189, 115768. [Google Scholar] [CrossRef]

- Jiang, S.; Niu, H.; Wang, S.; Qian, Z.; Du, G.; Zhou, X.; Shen, Y.; Yang, Z.; Li, T. Novel and high-performance tannin-polyamine adhesive: New insight into phenol-amine chemistry. Ind. Crops Prod. 2023, 192, 116129. [Google Scholar] [CrossRef]

- Wu, T.; Jia, Z.; Meng, Y.; Ye, J.; Li, W.; Sun, Y.; Li, J.; Li, L.; Liu, Z.; Wang, S.; et al. Biomass-based strong adhesive based on supramolecular deep eutectic solvents pretreatment. Chem. Eng. J. 2025, 505, 159055. [Google Scholar] [CrossRef]

- Sun, S.; Zhao, Z. Influence of acid on the curing process of tannin-sucrose adhesives. Bioresources 2018, 13, 7683–7697. [Google Scholar] [CrossRef]

- Ali, M.R.; Salit, M.S.; Jawaid, M.; Mansur, M.R.; Manap, M.F.A. Polyurethane-Based Biocomposites. In Polyurethane Polymers; Elsevier: Amsterdam, The Netherlands, 2017; pp. 525–546. [Google Scholar]

- Gomez-Lopez, A.; Panchireddy, S.; Grignard, B.; Calvo, I.; Jerome, C.; Detrembleur, C.; Sardon, H. Poly(hydroxyurethane) Adhesives and Coatings: State-of-the-Art and Future Directions. ACS Sustain. Chem. Eng. 2021, 9, 9541–9562. [Google Scholar] [CrossRef]

- Hernández-Ramos, F.; Esteves, B.; Carvalho, L.; Labidi, J.; Erdocia, X. Synthesis, characterisation, and thermal degradation kinetics of lignin-based polyurethane wood adhesives. Int. J. Adhes. Adhes. 2025, 136, 103889. [Google Scholar] [CrossRef]

- Parekh, S.; Chaudhary, M.L.; Patel, R.; Patel, P.; Gupta, R.K. Analyzing the influence of diols’ chain length on the properties of bio-based wood adhesive. Polym. Eng. Sci. 2024, 64, 4234–4245. [Google Scholar] [CrossRef]

- Wendels, S.; Balahura, R.; Dinescu, S.; Ignat, S.; Costache, M.; Avérous, L. Influence of the Macromolecular architecture on the properties of biobased polyurethane tissue adhesives. Eur. Polym. J. 2022, 164, 110968. [Google Scholar] [CrossRef]

- Delavarde, A.; Savin, G.; Derkenne, P.; Boursier, M.; Morales-Cerrada, R.; Nottelet, B.; Pinaud, J.; Caillol, S. Sustainable polyurethanes: Toward new cutting-edge opportunities. Prog. Polym. Sci. 2024, 151, 101805. [Google Scholar] [CrossRef]

- Huang, X.; De Hoop, C.F.; Xie, J.; Wu, Q.; Boldor, D.; Qi, J. High bio-content polyurethane (PU) foam made from bio-polyol and cellulose nanocrystals (CNCs) via microwave liquefaction. Mater. Des. 2018, 138, 11–20. [Google Scholar] [CrossRef]

- Kausar, A.; Zulfiqar, S.; Sarwar, M.I. High performance segmented polyurethanes derived from a new aromatic diisocyanate and polyol. Polym. Degrad. Stab. 2013, 98, 368–376. [Google Scholar] [CrossRef]

- Gama, N.V.; Ferreira, A.; Barros-Timmons, A. Polyurethane Foams: Past, Present, and Future. Materials 2018, 11, 1841. [Google Scholar] [CrossRef]

- Noreen, A.; Zia, K.M.; Zuber, M.; Tabasum, S.; Zahoor, A.F. Bio-based polyurethane: An efficient and environment friendly coating systems: A review. Prog. Org. Coat. 2016, 91, 25–32. [Google Scholar] [CrossRef]

- Aristri, M.A.; Lubis, M.A.R.; Yadav, S.M.; Antov, P.; Papadopoulos, A.N.; Pizzi, A.; Fatriasari, W.; Ismayati, M.; Iswanto, A.H. Recent Developments in Lignin- and Tannin-Based Non-Isocyanate Polyurethane Resins for Wood Adhesives—A Review. Appl. Sci. 2021, 11, 4242. [Google Scholar] [CrossRef]

- Cui, S.; Luo, X.; Li, Y. Synthesis and properties of polyurethane wood adhesives derived from crude glycerol-based polyols. Int. J. Adhes. Adhes. 2017, 79, 67–72. [Google Scholar] [CrossRef]

- EN 310:1993; Wood-Based Panels. Determination of Modulus of Elasticity in Bending and of Bending Strength. European Committee for Standardization: Brussels, Belgium, 1993.

- EN 319:1996; Particleboards and Fibreboards—Determination of Tensile Strength Perpendicular to the Plane of the Board. European Committee for Standardization: Brussels, Belgium, 1996.

- ISO 29469:2022; Thermal Insulating Products for Building Applications—Determination of Compression Behaviour (ISO 29469:2022). ISO: Geneva, Switzerland, 2022.

- EN 1609:1996; Thermal Insulating Products for Building Applications—Determination of Short Term Water Absorption by Partial Immersion. European Committee for Standardization: Brussels, Belgium, 1996.

- EN 317:1996; Particleboards and Fibreboards—Determination of Swelling in Thickness After Immersion in Water. European Committee for Standardization: Brussels, Belgium, 1996.

- ISO 11925-2:2020; Reaction to Fire Tests—Ignitability of Products Subjected to Direct Impingement of Flame. Part 2: Single-Flame Source Test. ISO: Geneva, Switzerland, 2020.

- Dukarska, D.; Rogoziński, T.; Antov, P.; Kristak, L.; Kmieciak, J. Characterisation of wood particles used in the particleboard production as a function of their moisture content. Materials 2022, 15, 48. [Google Scholar] [CrossRef] [PubMed]

- Flores, J.A.; Pastor, J.J.; Martinez-Gabarron, A.; Gimeno-Blanes, F.J.; Frutos, M.J. Pressure Impact on Common Reed Particleboards Manufacturing Procedure. Syst. Eng. Procedia 2011, 1, 499–507. [Google Scholar] [CrossRef][Green Version]

- Mitchual, S.J.; Mensah, P.; Mensah, K.F.; Appiah-Kubi, E. Characterization of particleboard produced from residues of plantain pseudostem, cocoa pod and stem and ceiba. Mater. Sci. Appl. 2020, 11, 817–836. [Google Scholar] [CrossRef]

- Owodunni, A.A.; Lamaming, J.; Hashim, R.; Taiwo, O.F.A.; Hussin, M.H.; Mohamad Kassim, M.H.; Bustami, Y.; Sulaiman, O.; Amini, M.H.M.; Hiziroglu, S. Adhesive application on particleboard from natural fibers: A review. Polym. Compos. 2020, 41, 4448–4460. [Google Scholar] [CrossRef]

- Faria, D.L.; Lopes, T.A.; Mendes, L.M.; Guimarães Júnior, J.B. Valorization of wood shavings waste for the production of wood particulate composites. Matéria 2020, 25, e-12780. [Google Scholar] [CrossRef]

- Savastano, H.; Santos, S.F.; Fiorelli, J.; Agopyan, V. Sustainable use of vegetable fibres and particles in civil construction. In Sustainability of Construction Materials; Woodhead Publishing: Cambridge, UK, 2016; pp. 477–520. [Google Scholar]

- Ahmad, M.R.; Chen, B.; Oderji, S.Y.; Mohsan, M. Development of a new bio-composite for building insulation and structural purpose using corn stalk and magnesium phosphate cement. Energy Build. 2018, 173, 719–733. [Google Scholar] [CrossRef]

- EN 312:2010; Particleboards—Specifications. European Committee for Standardization: Brussels, Belgium, 2010.

- Kallakas, H.; Närep, M.; Närep, A.; Poltimäe, T.; Kers, J. Mechanical and physical properties of industrial hemp-based insulation materials. Proc. Est. Acad. Sci. 2018, 67, 183–192. [Google Scholar] [CrossRef]

- Buzo, A.L.S.C.; Silva, S.A.M.; de Moura Aquino, V.B.; Chahud, E.; Branco, L.A.M.N.; de Almeida, D.H.; Christoforo, A.L.; Almeida, J.P.B.; Lahr, F.A.R. Addition of sugarcane bagasse for the production of particleboards bonded with urea-formaldehyde and polyurethane resins. Wood Res. 2020, 65, 727–736. [Google Scholar] [CrossRef]

- Pleiksnis, S.; Skujans, J.; Visockis, E.; Pulkis, K. Increasing fire proofness of sapropel and hemp shive insulation material. In Proceedings of the 15th International Scientific Conference Engineering for Rural Development, Jelgava, Latvia, 25–27 May 2016; Latvia University of Agriculture: Jelgava, Latvia, 2016; pp. 403–408. [Google Scholar]

- Gondaliya, A.M.; Foster, K.; Foster, E.J. Polylactic acid/wood-based in situ polymerized densified composite material. Mater. Adv. 2023, 4, 5633–5642. [Google Scholar] [CrossRef]

- Olszewski, A.; Kosmela, P.; Piszczyk, Ł. Towards sustainable catalyst-free biomass-based polyurethane-wood composites (PU-WC): From valorization and liquefaction to future generation of biocomposites. J. Clean. Prod. 2024, 468, 143046. [Google Scholar] [CrossRef]

- Shafigullin, L.; Romanova, N.; Shafigullina, G.; Sokolova, Y. Influence of the Expandable Graphite on the Thermal properties of a Rigid Polyurethane Foam for construction. E3S Web Conf. 2021, 263, 01009. [Google Scholar] [CrossRef]

| Mixture No. | Hemp Shives, % | Polyurethane Binder, % | Expandable Graphite, % |

|---|---|---|---|

| 1-1 | 100 | 50 | 0 |

| 1-2 | 75 | ||

| 1-3 | 100 | ||

| 1-4 | 125 | ||

| 1-5 | 150 | ||

| 2-1 | 100 | 1 | |

| 2-2 | 2 | ||

| 2-3 | 3 | ||

| 2-4 | 4 | ||

| 2-5 | 5 |

| Figure | Specimen | Statistical Characteristics | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| R | R2 | Adjusted R2 | F | p | ||||||

| Bending strength | ||||||||||

| 3a | 15 | (1) | ||||||||

| 2.54867 | 6.87867 | 0.983 | 0.967 | 0.964 | 0.483 | 380.4 | 0.0 | |||

| 15 | (2) | |||||||||

| 8.3360 | 5.94267 | 0.977 | 0.955 | 0.951 | 0.490 | 275.3 | 0.0 | |||

| 15 | (3) | |||||||||

| 12.68867 | 3.00800 | 0.942 | 0.887 | 0.879 | 0.407 | 102.3 | 0.0 | |||

| Bending modulus of elasticity | ||||||||||

| 3b | 15 | (4) | ||||||||

| −273.333 | 2615.410 | −1377.90 | 0.968 | 0.937 | 0.926 | 44.30 | 88.78 | 0.0 | ||

| 15 | (5) | |||||||||

| 867.4667 | 1847.981 | −1097.52 | 0.943 | 0.889 | 0.871 | 66.08 | 48.49 | 0.0 | ||

| 15 | (6) | |||||||||

| 2227.133 | −945.829 | 323.0476 | 0.949 | 0.901 | 0.884 | 41.25 | 54.52 | 0.0 | ||

| Tensile strength | ||||||||||

| 3c | 15 | (7) | ||||||||

| 1.94780 | 2.19347 | 0.962 | 0.925 | 0.91 | 0.238 | 159.5 | 0.0 | |||

| 15 | (8) | |||||||||

| −0.92500 | 16.08992 | −7.84343 | 0.935 | 0.873 | 0.852 | 0.354 | 41.43 | 0.0 | ||

| 15 | (9) | |||||||||

| 0.800133 | 11.94787 | −5.58133 | 0.919 | 0.844 | 0.818 | 0.311 | 32.49 | 0.0 | ||

| Tensile modulus of elasticity | ||||||||||

| 3d | 15 | (10) | ||||||||

| 5.60200 | 9.98400 | 0.983 | 0.967 | 0.965 | 0.698 | 383.8 | 0.0 | |||

| 15 | (11) | |||||||||

| 10.93333 | 10.26667 | −4.80000 | 0.923 | 0.851 | 0.826 | 0.259 | 34.31 | 0.00 | ||

| 15 | (12) | |||||||||

| 11.74000 | 10.80381 | −5.02857 | 0914 | 0.835 | 0.808 | 0.292 | 30.45 | 0.00 | ||

| Compressive stress at 10% deformation | ||||||||||

| 3e | 15 | (13) | ||||||||

| 0.850093 | 4.98632 | 0.968 | 0.938 | 0.933 | 0.487 | 196.3 | 0.0 | |||

| 15 | (14) | |||||||||

| 3.146200 | 5.46347 | 0.971 | 0.943 | 0.939 | 0.509 | 215.8 | 0.0 | |||

| 15 | (15) | |||||||||

| −0.129067 | 20.58166 | −9.56076 | 0.925 | 0.856 | 0.832 | 0.516 | 35.63 | 0.0 | ||

| Compressive modulus of elasticity | ||||||||||

| 3f | 15 | (16) | ||||||||

| −0.563333 | 87.60800 | 0.961 | 0.923 | 0.917 | 9.616 | 155.6 | 0.0 | |||

| 15 | (17) | |||||||||

| 29.52000 | 84.82667 | 0.949 | 0.901 | 0.894 | 10.651 | 118.9 | 0.0 | |||

| 15 | (18) | |||||||||

| 49.68533 | 83.82400 | 0.953 | 0.908 | 0.901 | 10.110 | 128.9 | 0.0 | |||

| Figure | Specimen | Statistical Characteristics | |||||||

|---|---|---|---|---|---|---|---|---|---|

| R | R2 | Adjusted R2 | F | p | |||||

| Density | |||||||||

| 4 | 45 | Level of pressure (1 *) (19) | |||||||

| 290.3556 | 277.6444 | 0.980 | 0.961 | 0.960 | 20.36 | 1046.5 | 0.0 | ||

| 45 | Level of pressure (2 *) (20) | ||||||||

| 502.4444 | 201.1556 | 0.941 | 0.886 | 0.883 | 26.09 | 334.6 | 0.0 | ||

| 45 | Level of pressure (3 *) (21) | ||||||||

| 650.3778 | 119.6444 | 0.873 | 0.762 | 0.757 | 24.16 | 137.9 | 0.0 | ||

| Figure | Specimen | Statistical Characteristics | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| R | R2 | Adjusted R2 | F | p | ||||||

| G—swelling | ||||||||||

| 5a | 15 | (22) | ||||||||

| 16.32000 | −9.17524 | 3.314286 | 0.942 | 0.887 | 0.868 | 0.386 | 46.88 | 0.0 | ||

| 15 | (23) | |||||||||

| 41.85333 | −52.0571 | 21.02857 | 0.987 | 0.974 | 0.969 | 0.763 | 223.3 | 0.0 | ||

| 15 | (24) | |||||||||

| 50.16667 | −62.1638 | 25.82857 | 0.963 | 0.928 | 0.916 | 1.431 | 77.28 | 0.0 | ||

| G—swelling | ||||||||||

| 5b | 18 | |||||||||

| 0.680 | 0.463 | 0.239 | 0.679 | 2.067 | 0.14 | |||||

| 9 | ||||||||||

| 0.469 | 0.220 | −0.0402 | 1.109 | 0.845 | 0.47 | |||||

| Figure | Specimen | Statistical Characteristics | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| R | R2 | Adjusted R2 | F | p | ||||||

| Water absorption | ||||||||||

| 6a | 15 | (25) | ||||||||

| 71.85961 | −94.5193 | 37.21578 | 0.979 | 0.959 | 0.952 | 1.876 | 139.8 | 0.0 | ||

| 15 | (26) | |||||||||

| 50.97333 | −65.3257 | 26.20952 | 0.980 | 0.960 | 0.954 | 1.212 | 144.6 | 0.0 | ||

| 15 | (27) | |||||||||

| 57.81333 | −71.5600 | 29.06667 | 0.985 | 0.970 | 0.965 | 1.101 | 196.6 | 0.0 | ||

| Water absorption | ||||||||||

| 6b | 9 | |||||||||

| 0.771 | 0.595 | 0.460 | 0.981 | 4.404 | 0.067 | |||||

| 9 | ||||||||||

| 0.427 | 0.183 | −0.0897 | 0.644 | 0.671 | 0.54 | |||||

| 9 | ||||||||||

| 0.571 | 0.326 | 0.101 | 0.546 | 1.448 | 0.31 | |||||

| Content of Expandable Graphite | Bending Strength, MPa | Tensile Strength, MPa | Compressive Stress, MPa | Swelling, % | Water Absorption, % | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| 0% | 14.1 | 0.293 | 7.2 | 0.439 | 8.7 | 0.294 | 11.0 | 0.833 | 11.9 | 0.557 |

| 1% | 14.3 | 0.259 | 7.1 | 0.141 | 8.9 | 0.105 | 10.7 | 0.321 | 11.8 | 0.280 |

| 3% | 14.1 | 0.110 | 7.3 | 0.147 | 8.8 | 0.182 | 11.2 | 0.231 | 12.0 | 0.0971 |

| 5% | 14.3 | 0.225 | 7.2 | 0.0378 | 8.9 | 0.170 | 10.9 | 0.351 | 11.9 | 0.263 |

| Mean | 14.20 | 0.227 | 7.21 | 0.224 | 8.84 | 0.197 | 10.97 | 0.452 | 11.93 | 0.300 |

| Anova | ||||||||||

| F(3,8) | 0.832 | 0.450 | 0.920 | 0.411 | 0.163 | |||||

| p(0.05) | 0.513 | 0.724 | 0.474 | 0.750 | 0.918 | |||||

| Fcr | 4.066 | |||||||||

| Amount of Expandable Graphite, wt.% | T, °C | Char Yield at 800 °C, wt.% | ||

|---|---|---|---|---|

| T5wt.% | T50wt.% | Tmax. | ||

| 0 | 219 | 356 | 346 | 20.4 |

| 1 | 247 | 356 | 344 | 22.5 |

| 3 | 231 | 356 | 341 | 23.7 |

| 5 | 217 | 356 | 341 | 25.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vėjelis, S.; Kairytė, A.; Vaitkus, S.; Kremensas, A. The Use of Bio-Polyurethane Binder for the Development of Engineered Wood Composites. Polymers 2025, 17, 1434. https://doi.org/10.3390/polym17111434

Vėjelis S, Kairytė A, Vaitkus S, Kremensas A. The Use of Bio-Polyurethane Binder for the Development of Engineered Wood Composites. Polymers. 2025; 17(11):1434. https://doi.org/10.3390/polym17111434

Chicago/Turabian StyleVėjelis, Sigitas, Agnė Kairytė, Saulius Vaitkus, and Arūnas Kremensas. 2025. "The Use of Bio-Polyurethane Binder for the Development of Engineered Wood Composites" Polymers 17, no. 11: 1434. https://doi.org/10.3390/polym17111434

APA StyleVėjelis, S., Kairytė, A., Vaitkus, S., & Kremensas, A. (2025). The Use of Bio-Polyurethane Binder for the Development of Engineered Wood Composites. Polymers, 17(11), 1434. https://doi.org/10.3390/polym17111434