Empirical Modeling of Seasonal Cooling Performance Based on Test Devices Using Zinc Oxide/Low-Density Polyethylene Passive Cooling Membranes

Abstract

1. Introduction

2. Fabrications and Experimentation

2.1. Materials

2.2. Preparation of ZnO/LDPE Membranes

2.3. Characterization and Evaluation

2.4. Cooling Performance Test

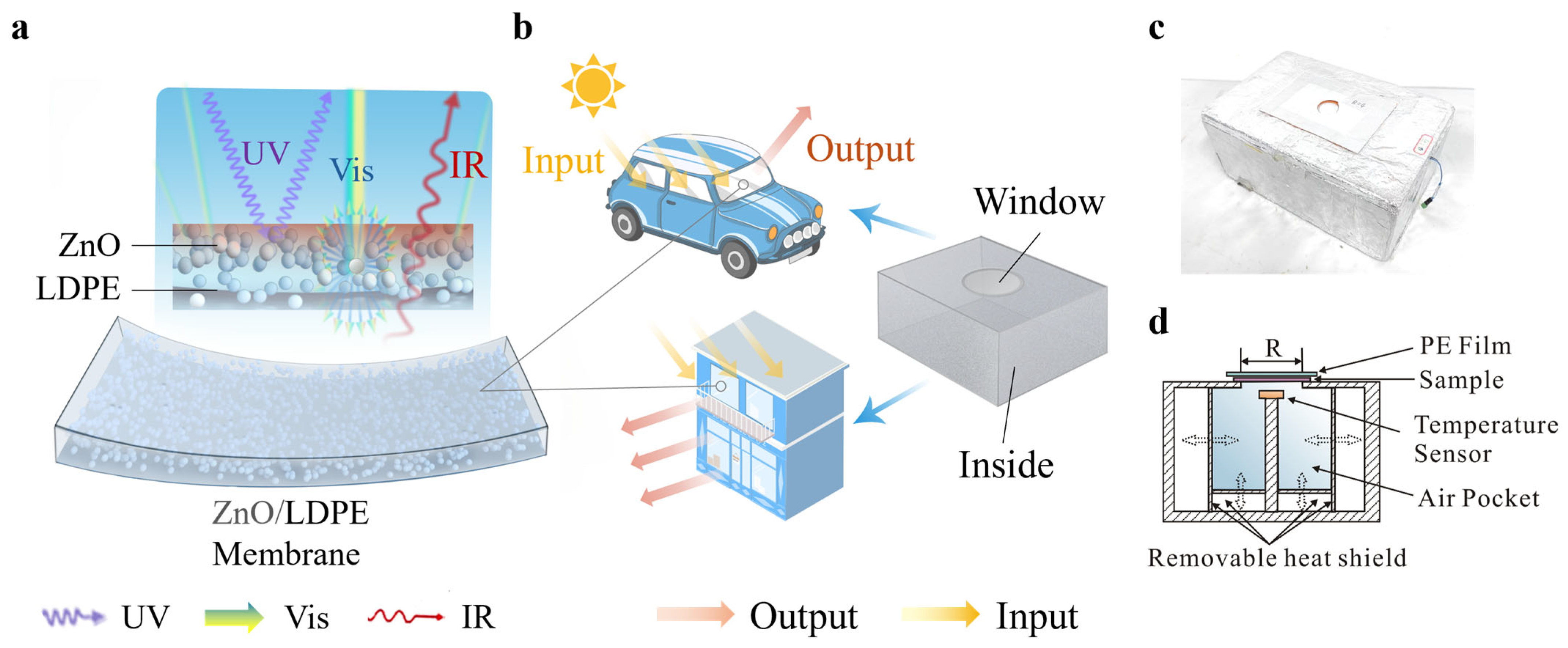

2.5. Principles and Applications

3. Results and Discussion

3.1. Characterization of the ZnO/LDPE Membrane

3.2. Optical Properties and Passive Cooling Performances

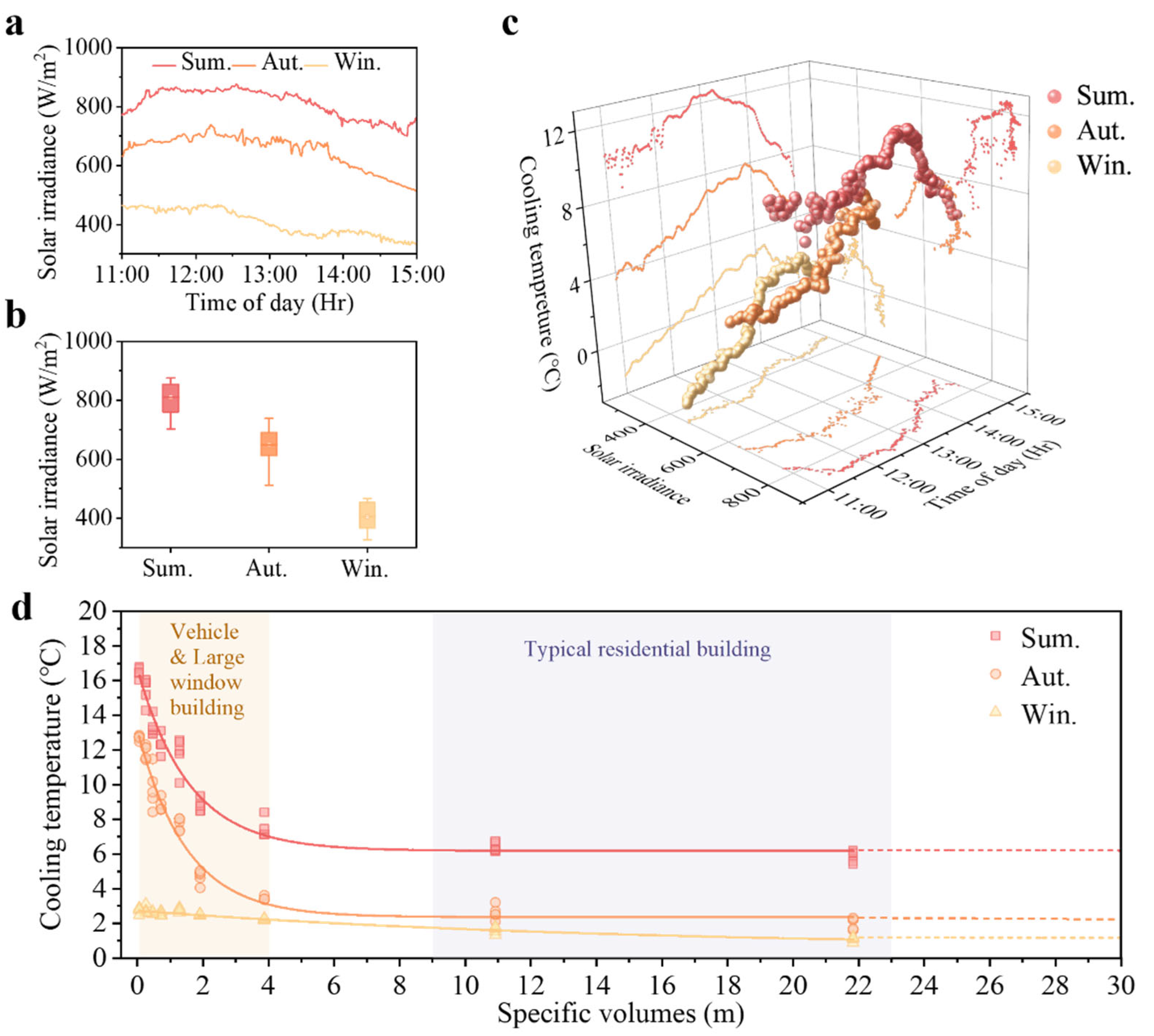

3.3. Mechanism of Seasonal Cooling Performance

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Walther, G.R.; Post, E.; Convey, P.; Menzel, A.; Parmesan, C.; Beebee, T.J.C.; Fromentin, J.-M.; Hoegh-Guldberg, O.; Bairlein, F. Ecological Responses to Recent Climate Change. Nature 2002, 416, 389–395. [Google Scholar] [CrossRef] [PubMed]

- IPCC. Climate Change 2023: Synthesis Report (Full Volume) Contribution of Working Groups I, II and III to the Sixth Assessment Report of the Intergovernmental Panel on Climate Change; IPCC: Geneva, Switzerland, 2023. [Google Scholar]

- Grover, V.I. Global Warming and Climate Change (2 Vols.): Ten Years After Kyoto and Still Counting; CRC Press: Boca Raton, FL, USA, 2016. [Google Scholar]

- Weart, S.R. The Discovery of Global Warming; Harvard University Press: Cambridge, MA, USA, 2003. [Google Scholar]

- Chen, M.; Li, W.; Tao, S.; Fang, Z.; Lu, C.; Xu, Z. A Pragmatic and High-Performance Radiative Cooling Coating with Near-Ideal Selective Emissive Spectrum for Passive Cooling. Coatings 2020, 10, 144. [Google Scholar] [CrossRef]

- Pereira, J.; Glória Gomes, M.; Moret Rodrigues, A.; Almeida, M. Thermal, luminous and energy performance of solar control films in single-glazed windows: Use of energy performance criteria to support decision making. Energy Build. 2019, 198, 431–443. [Google Scholar] [CrossRef]

- Prugh, T.; Costanza, R.; Daly, H.E.; Goodland, R.J.A.; Cumberland, J.H.; Norgaard, R.B. Natural Capital and Human Economic Survival; CRC Press: Boca Raton, FL, USA, 2020. [Google Scholar]

- Kang, X.Y.; Wang, M.X.; Lin, J.; Li, X. Trends and status in resources security, ecological stability, and sustainable development research: A systematic analysis. Environ. Sci. Pollut. Res. 2022, 29, 50192–50207. [Google Scholar] [CrossRef]

- Philander, S.G. Encyclopedia of Global Warming and Climate Change, 2nd ed.; SAGE Publications: Thousand Oaks, CA, USA, 2012. [Google Scholar]

- Revelle, R.; Khosla, A.; Vinovskis, M.; Vinovskis, M.A. The Survival Equation: Man, Resources, and His Environment; Houghton Mifflin: Boston, MA, USA, 1971. [Google Scholar]

- Emdadi, Z.; Asim, N.; Ambar Yarmo, M.; Shamsudin, R.; Mohammad, M.; Sopian, K. Green Material Prospects for Passive Evaporative Cooling Systems: Geopolymers. Energies 2016, 9, 586. [Google Scholar] [CrossRef]

- Raj, V.A.A.; Velraj, R. Review on free cooling of buildings using phase change materials. Renew. Sustain. Energy Rev. 2010, 14, 2819–2829. [Google Scholar] [CrossRef]

- Wu, S.L.; Cao, Y.J.; Li, Y.Q.; Sun, W. Recent Advances in Material Engineering and Applications for Passive Daytime Radiative Cooling. Adv. Opt. Mater. 2023, 11, 2202163. [Google Scholar] [CrossRef]

- Miranda, N.D.; Renaldi, R.; Khosla, R.; McCulloch, M.D. Bibliometric analysis and landscape of actors in passive cooling research. Renew. Sustain. Energy Rev. 2021, 149, 111406. [Google Scholar] [CrossRef]

- Zhang, Y.R.; Liu, X.H.; Li, Z.Y.; Xie, W.; Lou, X.; Fan, Y.L.; Cao, K.L.; Liu, G.; Kondo, H.; Zhou, H. Colourful phase change material-incorporated flexible film for efficient passive radiative cooling. Nanotechnology 2023, 34, 415702. [Google Scholar] [CrossRef]

- Tong, J.K.; Huang, X.; Boriskina, S.V.; Loomis, J.; Xu, Y.; Chen, G. Infrared-Transparent Visible-Opaque Fabrics for Wearable Personal Thermal Management. ACS Photonics 2015, 2, 769–778. [Google Scholar] [CrossRef]

- Lee, T.-W. Thermal and flow Measurements; CRC Press: Boca Raton, FL, USA, 2008. [Google Scholar]

- Alberghini, M.; Hong, S.; Lozano, L.M.; Korolovych, V.; Huang, Y.; Signorato, F.; Zandavi, S.H.; Fucetola, C.; Uluturk, I.; Tolstorukov, M.Y.; et al. Sustainable polyethylene fabrics with engineered moisture transport for passive cooling. Nat. Sustain. 2021, 4, 715–724. [Google Scholar] [CrossRef]

- Steketee, J. Spectral emissivity of skin and pericardium. Phys. Med. Biol. 1973, 18, 686. [Google Scholar] [CrossRef]

- Hardy, J.D.; Muschenheim, C. Radiation of heat from the human body. V. The transmission of infra-red radiation through skin. J. Clin. Investig. 1936, 15, 1–9. [Google Scholar] [CrossRef]

- Hardy, J.D.; Muschenheim, C. The radiation of heat from the human body. IV. The emission, reflection, and transmission of infra-red radiation by the human skin. J. Clin. Investig. 1934, 13, 817–831. [Google Scholar] [CrossRef] [PubMed]

- Togawa, T. Non-contact skin emissivity: Measurement from reflectance using step change in ambient radiation temperature. Clin. Phys. Physiol. Meas. 1989, 10, 39. [Google Scholar] [CrossRef]

- Sanchez-Marin, F.; Calixto-Carrera, S.; Villaseñor-Mora, C. Novel approach to assess the emissivity of the human skin. J. Biomed. Opt. 2009, 14, 024006. [Google Scholar] [CrossRef]

- Lee, M.; Kim, G.; Jung, Y.; Pyun, K.R.; Lee, J.; Kim, B.-W.; Ko, S.H. Photonic structures in radiative cooling. Light Sci. Appl. 2023, 12, 134. [Google Scholar] [CrossRef] [PubMed]

- Song, Y.; Li, Y.; Ge, B.; Wang, J.; Li, J. Self-Cleaning and Spectral Selective Membrane for Sustainable Radiative Cooling. ACS Appl. Mater. Interfaces 2023, 15, 57679–57686. [Google Scholar] [CrossRef]

- Aili, A.; Jiang, T.; Chen, J.; Wen, Y.; Yang, R.; Yin, X.; Tan, G. Passive daytime radiative cooling: Moving beyond materials towards real-world applications. Next Energy 2024, 3, 100121. [Google Scholar] [CrossRef]

- Mabchour, G.; Benlattar, M.; Saadouni, K.; Mazroui, M. Optically selective PDMS/AIN coatings as a passive daytime radiative cooling design. Mater. Today Proc. 2022, 66, 390–395. [Google Scholar] [CrossRef]

- Family, R.; Mengüç, M.P. Materials for Radiative Cooling: A Review. Procedia Environ. Sci. 2017, 38, 752–759. [Google Scholar] [CrossRef]

- Bhatia, B.; Leroy, A.; Shen, Y.; Zhao, L.; Gianello, M.; Li, D.; Gu, T.; Hu, J.; Soljačić, M.; Wang, E.N. Passive directional sub-ambient daytime radiative cooling. Nat. Commun. 2018, 9, 5001. [Google Scholar] [CrossRef] [PubMed]

- Huang, X.; Li, N.; Wang, J.; Liu, D.; Xu, J.; Zhang, Z.; Zhong, M. Single nanoporous MgHPO4·1.2 H2O for daytime radiative cooling. ACS Appl. Mater. Interfaces 2019, 12, 2252–2258. [Google Scholar] [CrossRef] [PubMed]

- Jiang, K.; Zhang, K.; Shi, Z.; Li, H.; Wu, B.; Mahian, O.; Zhu, Y. Experimental and numerical study on the potential of a new radiative cooling paint boosted by SiO2 microparticles for energy saving. Energy 2023, 283, 128473. [Google Scholar] [CrossRef]

- Yoon, T.Y.; Son, S.; Min, S.; Chae, D.; Woo, H.Y.; Chae, J.-Y.; Lim, H.; Shin, J.; Paik, T.; Lee, H. Colloidal deposition of colored daytime radiative cooling films using nanoparticle-based inks. Mater. Today Phys. 2021, 21, 100510. [Google Scholar] [CrossRef]

- Tang, K.; Dong, K.; Li, J.; Gordon, M.P.; Reichertz, F.G.; Kim, H.; Rho, Y.; Wang, Q.; Lin, C.-Y.; Grigoropoulos, C.P.; et al. Temperature-adaptive radiative coating for all-season household thermal regulation. Science 2021, 374, 1504–1509. [Google Scholar] [CrossRef]

- Zeng, S.; Pian, S.; Su, M.; Wang, Z.; Wu, M.; Liu, X.; Chen, M.; Xiang, Y.; Wu, J.; Zhang, M. Hierarchical-morphology metafabric for scalable passive daytime radiative cooling. Science 2021, 373, 692–696. [Google Scholar] [CrossRef]

- Li, T.; Zhai, Y.; He, S.; Gan, W.; Wei, Z.; Heidarinejad, M.; Dalgo, D.; Mi, R.; Zhao, X.; Song, J. A radiative cooling structural material. Science 2019, 364, 760–763. [Google Scholar] [CrossRef] [PubMed]

- Hsu, P.-C.; Liu, C.; Song, A.Y.; Zhang, Z.; Peng, Y.; Xie, J.; Liu, K.; Wu, C.-L.; Catrysse, P.B.; Cai, L. A dual-mode textile for human body radiative heating and cooling. Sci. Adv. 2017, 3, e1700895. [Google Scholar] [CrossRef]

- Jeon, S.; Son, S.; Lee, S.Y.; Chae, D.; Bae, J.H.; Lee, H.; Oh, S.J. Multifunctional daytime radiative cooling devices with simultaneous light-emitting and radiative cooling functional layers. ACS Appl. Mater. Interfaces 2020, 12, 54763–54772. [Google Scholar] [CrossRef]

- Wang, T.; Wu, Y.; Shi, L.; Hu, X.; Chen, M.; Wu, L. A structural polymer for highly efficient all-day passive radiative cooling. Nat. Commun. 2021, 12, 365. [Google Scholar] [CrossRef]

- Raman, A.P.; Anoma, M.A.; Zhu, L.; Rephaeli, E.; Fan, S. Passive radiative cooling below ambient air temperature under direct sunlight. Nature 2014, 515, 540–544. [Google Scholar] [CrossRef] [PubMed]

- Lee, D.; Go, M.; Son, S.; Kim, M.; Badloe, T.; Lee, H.; Kim, J.K.; Rho, J. Sub-ambient daytime radiative cooling by silica-coated porous anodic aluminum oxide. Nano Energy 2021, 79, 105426. [Google Scholar] [CrossRef]

- Panwar, K.; Jassal, M.; Agrawal, A.K. TiO2–SiO2 Janus particles treated cotton fabric for thermal regulation. Surf. Coat. Technol. 2017, 309, 897–903. [Google Scholar] [CrossRef]

- Zhang, H.; Huang, J.; Fan, D. Switchable radiative cooling from temperature-responsive thermal resistance modulation. ACS Appl. Energy Mater. 2022, 5, 6003–6010. [Google Scholar] [CrossRef]

- Cui, L.; Huang, C.; Xia, H.; Qiu, Y.; Ni, Q.-Q. Transparent passive-cooling composite films for indoor and outdoor spaces. Compos. Commun. 2021, 24, 100611. [Google Scholar] [CrossRef]

- Chýlek, P.; Zhan, J. Interference structure of the Mie extinction cross section. J. Opt. Soc. Am. A 1989, 6, 1846–1851. [Google Scholar] [CrossRef]

- Danca, P.; Vartires, A.; Dogeanu, A. An Overview of Current Methods for Thermal Comfort Assessment in Vehicle Cabin. Energy Procedia 2016, 85, 162–169. [Google Scholar] [CrossRef]

- Ruzic, D. Design of vehicle cabin air distribution system based on human thermal sensation. In Proceedings of the Seventh International Symposium KOD 2012 Machine and Industrial Design in Mechanical Engineering, Balatonfüred, Hungary, 24–26 May 2012. [Google Scholar]

- Serrano, M.-A.; Moreno, J.C. Spectral transmission of solar radiation by plastic and glass materials. J. Photochem. Photobiol. B Biol. 2020, 208, 111894. [Google Scholar] [CrossRef]

- Cai, L.; Song, A.Y.; Li, W.; Hsu, P.-C.; Lin, D.; Catrysse, P.B.; Liu, Y.; Peng, Y.; Chen, J.; Wang, H.; et al. Spectrally Selective Nanocomposite Textile for Outdoor Personal Cooling. Adv. Mater. 2018, 30, 1802152. [Google Scholar] [CrossRef]

- Zhang, Y.; Natsuki, J.; Liu, W.; Zhao, W.; Cui, L.; Natsuki, T. Hybrid passive cooling composites based on silane-bridged titanium dioxide and low-density polyethylene. Polym. Compos. 2025. [Google Scholar] [CrossRef]

- Adams, M. Optical waves in crystals. IEEE J. Quantum Electron. 1984, 20, 1294. [Google Scholar] [CrossRef]

- Fourier, J.B.J. The Analytical Theory of Heat; Cambridge University Press: Cambridge, UK, 2009. [Google Scholar]

- Newton, I. Scala Graduum Caloris. Calorum Descriptiones & Figna. Philos. Trans. (1683–1775) 1700, 22, 824–829. [Google Scholar]

- Bergman, T.L. Fundamentals of Heat and Mass Transfer; Wiley: Hoboken, NJ, USA, 2011. [Google Scholar]

- Han, T.; Chen, K.-H.; Khalighi, B.; Curran, A.; Pryor, J.; Hepokoski, M. Assessment of Various Environmental Thermal Loads on Passenger Thermal Comfort. SAE Int. J. Passeng. Cars-Mech. Syst. 2010, 3, 830–841. [Google Scholar] [CrossRef]

- Suhaimi, M.F.B.; Kim, W.G.; Cho, C.-W.; Lee, H. Impact of solar radiation on human comfort in a vehicle cabin: An analysis of body segment mean radiant temperature. Build. Environ. 2023, 245, 110849. [Google Scholar] [CrossRef]

- Chen, B.; Lian, Y.; Xu, L.; Deng, Z.; Zhao, F.; Zhang, H.; Liu, S. State-of-the-art thermal comfort models for car cabin Environment. Build. Environ. 2024, 262, 111825. [Google Scholar] [CrossRef]

- Joule, J.P. XXXII. On the calorific effects of magneto-electricity, and on the mechanical value of heat. Lond. Edinb. Dublin Philos. Mag. J. Sci. 1843, 23, 263–276. [Google Scholar] [CrossRef][Green Version]

- Boltzmann, L. Ueber eine von Hrn. Bartoli entdeckte Beziehung der Wärmestrahlung zum zweiten Hauptsatze. Ann. Der Phys. 1884, 258, 31–39. [Google Scholar] [CrossRef]

- Lockwood, M. Solar Influence on Global and Regional Climates. Surv. Geophys. 2012, 33, 503–534. [Google Scholar] [CrossRef]

- Cubasch, U.; Voss, R.; Hegerl, G.C.; Waszkewitz, J.; Crowley, T.J. Simulation of the influence of solar radiation variations on the global climate with an ocean-atmosphere general circulation model. Clim. Dyn. 1997, 13, 757–767. [Google Scholar] [CrossRef]

- Chen, Y.; Mandal, J.; Li, W.; Smith-Washington, A.; Tsai, C.-C.; Huang, W.; Shrestha, S.; Yu, N.; Han, R.P.S.; Cao, A.; et al. Colored and paintable bilayer coatings with high solar-infrared reflectance for efficient cooling. Sci. Adv. 2020, 6, eaaz5413. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Natsuki, J.; Weng, C.; Trung, V.D.; Wang, Y.; Cui, L.; Natsuki, T. Empirical Modeling of Seasonal Cooling Performance Based on Test Devices Using Zinc Oxide/Low-Density Polyethylene Passive Cooling Membranes. Polymers 2025, 17, 1420. https://doi.org/10.3390/polym17101420

Zhang Y, Natsuki J, Weng C, Trung VD, Wang Y, Cui L, Natsuki T. Empirical Modeling of Seasonal Cooling Performance Based on Test Devices Using Zinc Oxide/Low-Density Polyethylene Passive Cooling Membranes. Polymers. 2025; 17(10):1420. https://doi.org/10.3390/polym17101420

Chicago/Turabian StyleZhang, Yinjia, Jun Natsuki, Chengwu Weng, Vuong Dinh Trung, Yiwen Wang, Lina Cui, and Toshiaki Natsuki. 2025. "Empirical Modeling of Seasonal Cooling Performance Based on Test Devices Using Zinc Oxide/Low-Density Polyethylene Passive Cooling Membranes" Polymers 17, no. 10: 1420. https://doi.org/10.3390/polym17101420

APA StyleZhang, Y., Natsuki, J., Weng, C., Trung, V. D., Wang, Y., Cui, L., & Natsuki, T. (2025). Empirical Modeling of Seasonal Cooling Performance Based on Test Devices Using Zinc Oxide/Low-Density Polyethylene Passive Cooling Membranes. Polymers, 17(10), 1420. https://doi.org/10.3390/polym17101420