Polymer-Based Thermal Protective Composites: The Role of Reinforcement and Matrix in Providing Strength and Fire Resistance

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Materials Processing

2.3. Testing Methods

2.3.1. Tensile and Compressive Testing

2.3.2. Hardness Testing

2.3.3. Flame Resistance Testing

2.3.4. Thermal Conductivity Measurement

2.3.5. Scanning Electron Microscopy (SEM)

3. Results and Discussion

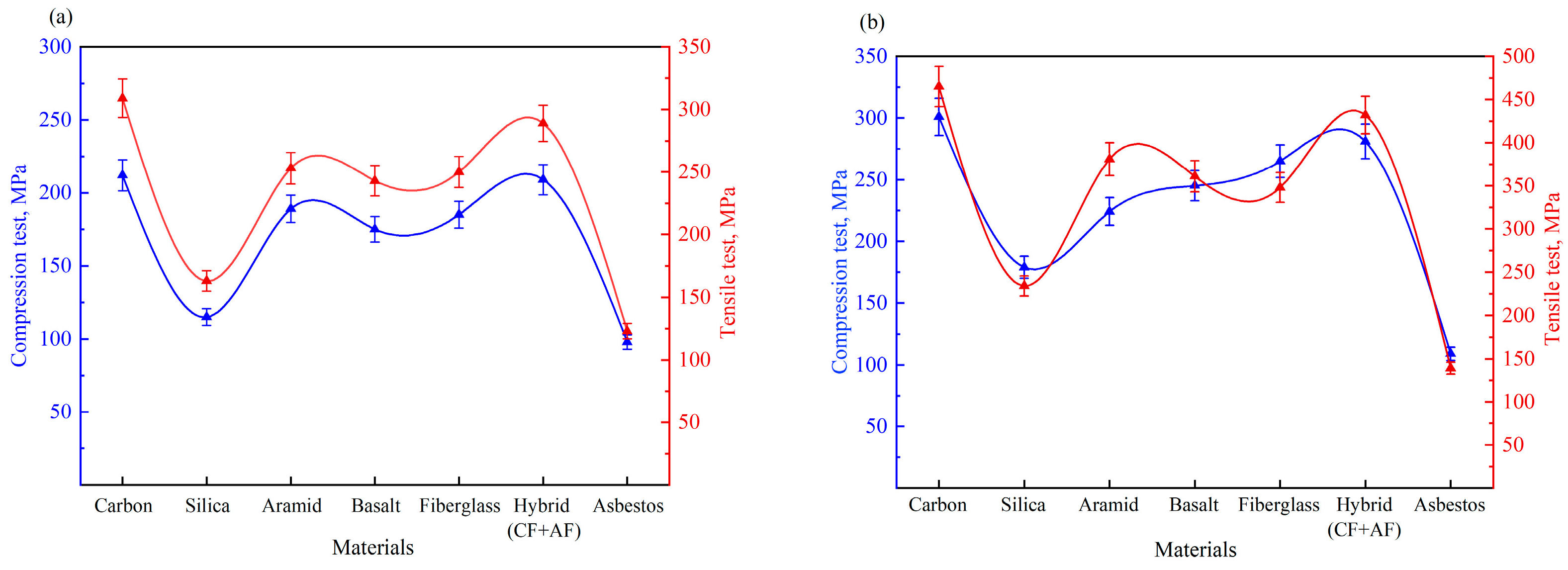

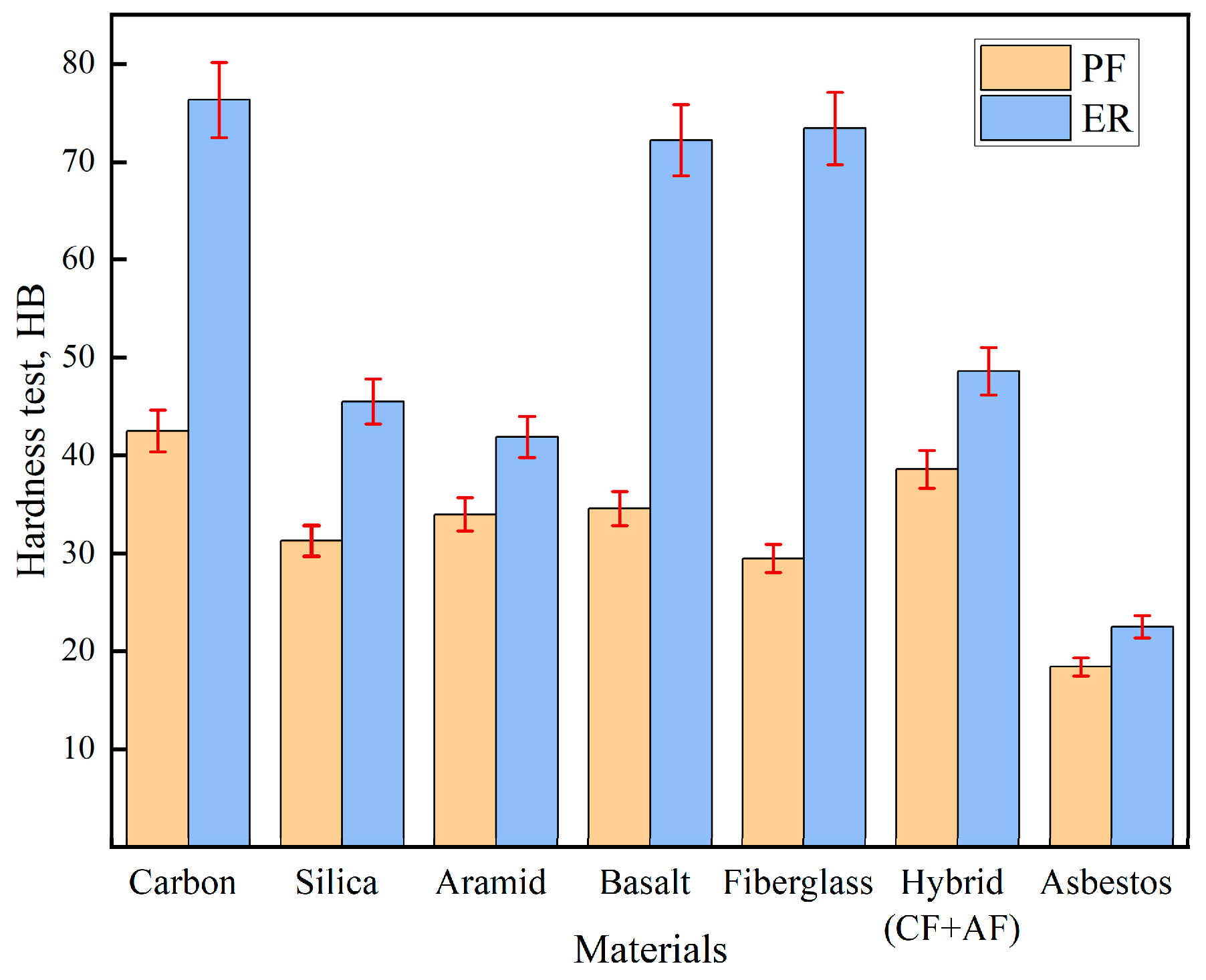

3.1. Mechanical Properties

3.2. Fire Resistance Testing

3.3. Morphological Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| TPSs | Thermal protection systems |

| PF | Phenol-formaldehyde resin |

| ER | Epoxy resin |

| SRM | Solid rocket motors |

| SEM | Scanning Electron Microscopy |

| CF | Carbon fiber |

| AF | Aramid fiber |

References

- Mahjub, A.; Mazlan, N.M.; Abdullah, M.Z.; Azam, Q. Design Optimization of Solid Rocket Propulsion: A Survey of Recent Advancements. J. Spacecr. Rocket. 2020, 57, 3–11. [Google Scholar] [CrossRef]

- Uyanna, O.; Najafi, H. Thermal Protection Systems for Space Vehicles: A Review on Technology Development, Current Challenges and Future Prospects. Acta Astronaut. 2020, 176, 341–356. [Google Scholar] [CrossRef]

- Sanoj, P.; Kandasubramanian, B. Hybrid Carbon-Carbon Ablative Composites for Thermal Protection in Aerospace. J. Compos. 2014, 2014, 825607. [Google Scholar] [CrossRef]

- Saba, N.; Jawaid, M. A Review on Thermomechanical Properties of Polymers and Fibers Reinforced Polymer Composites. J. Ind. Eng. Chem. 2018, 67, 1–11. [Google Scholar] [CrossRef]

- Mungiguerra, S.; Silvestroni, L.; Savino, R.; Zoli, L.; Esser, B.; Lagos, M.; Sciti, D. Qualification and Reusability of Long and Short Fibre-Reinforced Ultra-Refractory Composites for Aerospace Thermal Protection Systems. Corros. Sci. 2022, 195, 109955. [Google Scholar] [CrossRef]

- Meiirbekov, M.; Yermekov, A.; Nurguzhin, M.; Kulbekov, A. Identifying the Influence of Winding Angles on the Strength Properties of Carbon Fiber-Reinforced Plastic Tubes. East.-Eur. J. Enterp. Technol. 2025, 1, 26–32. [Google Scholar] [CrossRef]

- Meiirbekov, M.N.; Ismailov, M.B. The Effect of Rubber on the Mechanical Properties of Epoxy and Carbon Fiber (Review). Complex Use Miner. Resour. 2020, 312, 11–21. [Google Scholar] [CrossRef]

- Pareek, K.; Saha, P. Basalt Fiber and Its Composites: An Overview; Department of Civil Engineering National Institute of Technology Silchar: Silchar, India, 2019. [Google Scholar]

- Sun, G.; Tong, S.; Chen, D.; Gong, Z.; Li, Q. Mechanical Properties of Hybrid Composites Reinforced by Carbon and Basalt Fibers. Int. J. Mech. Sci. 2018, 148, 636–651. [Google Scholar] [CrossRef]

- Mazraeh-shahi, Z.T.; Shoushtari, A.M.; Bahramian, A.R. A New Method for Measuring the Thermal Insulation Properties of Fibrous Silica Aerogel Composite. Procedia Mater. Sci. 2015, 11, 583–587. [Google Scholar] [CrossRef]

- Gore, P.M.; Kandasubramanian, B. Functionalized Aramid Fibers and Composites for Protective Applications: A Review. Ind. Eng. Chem. Res. 2018, 57, 16537–16563. [Google Scholar] [CrossRef]

- Hirai, Y.; Hamada, H.; Kim, J.-K. Impact Response of Woven Glass-Fabric Composites-I. Compos. Sci. Technol. 1998, 58, 91–104. [Google Scholar] [CrossRef]

- Wang, J.; Schlagenhauf, L.; Setyan, A. Transformation of the Released Asbestos, Carbon Fibers and Carbon Nanotubes from Composite Materials and the Changes of Their Potential Health Impacts. J. Nanobiotechnol. 2017, 15, 15. [Google Scholar] [CrossRef] [PubMed]

- Barato, F.; Paccagnella, E.; Franco, M.; Pavarin, D. Numerical Analyses of Thermal Protection Design in Hybrid Rocket Motors. In Proceedings of the AIAA Propulsion and Energy 2020 Forum, Virtual, 24–28 August 2020; American Institute of Aeronautics and Astronautics Inc., AIAA: Reston, VA, USA, 2020; pp. 1–24. [Google Scholar]

- Gale, M.P.; Alam, M.F.; Mehta, R.S.; Luke, E.A. Multiphase Modeling of Solid Rocket Motor Internal Environment. In Proceedings of the AIAA Propulsion and Energy 2020 Forum, Virtual, 24–28 August 2020; American Institute of Aeronautics and Astronautics Inc., AIAA: Reston, VA, USA, 2020; pp. 1–12. [Google Scholar]

- Cegła, M.; Ruliński, P.; Zmywaczyk, J.; Koniorczyk, P. Complex Thermal Analysis of Solid Rocket Propellants. AIP Conf. Proc. 2019, 2133, 020007. [Google Scholar]

- Ho, D.W.K.; Koo, J.H.; Ezekoye, O.A. Kinetics and Thermophysical Properties of Polymer Nanocomposites for Solid Rocket Motor Insulation. J. Spacecr. Rocket. 2009, 46, 526–544. [Google Scholar] [CrossRef]

- Xu, Y.H.; Hu, X.; Yang, Y.X.; Zeng, Z.X.; Hu, C.B. Dynamic Simulation of Insulation Material Ablation Process in Solid Propellant Rocket Motor. J. Aerosp. Eng. 2014, 28, 04014118. [Google Scholar] [CrossRef]

- Park, J.K.; Kang, T.J. Thermal and Ablative Properties of Low Temperature Carbon Fiber–Phenol Formaldehyde Resin Composites. Carbon 2002, 40, 2125–2134. [Google Scholar] [CrossRef]

- Haupt, R.A.; Sellers, T., Jr. Characterizations of Phenol-Formaldehyde Resol Resins. Ind. Eng. Chem. Res. 1994, 33, 693–697. [Google Scholar] [CrossRef]

- Berdnikova, P.V.; Zhizhina, E.G.; Pai, Z.P. Phenol-Formaldehyde Resins: Properties, Fields of Application, and Methods of Synthesis. Catal. Ind. 2021, 13, 119–124. [Google Scholar] [CrossRef]

- Pizzi, A.; Ibeh, C.C. Phenol–Formaldehydes. In Handbook of Thermoset Plastics; Elsevier: Amsterdam, The Netherlands, 2014; pp. 13–44. [Google Scholar]

- Wang, X.; Xu, Q.; Zheng, Q.; Shao, Y.; Shen, J. Reviews of Fiber-Reinforced Phenolic Resin-Based Thermal Protection Materials for Aircraft. Energies 2025, 18, 819. [Google Scholar] [CrossRef]

- Li, Y.; Shi, C.; Pan, X.; Wang, Z.; Yang, L. Construction of an Interfacial Layer of Aramid Fibers Grafted with Glycidyl POSS Assisted by Heat Treatment and Evaluation of Interfacial Adhesion Properties with Epoxy Resin. ACS Omega 2024, 9, 24489–24499. [Google Scholar] [CrossRef] [PubMed]

- Koyunbakan, M.; Uslugil, Y.; Ekrem, M.; Eser, Ü. Investigation of the Mechanical Properties of Aramid Fiber-Reinforced Hybrid Nanocomposites with BNNP-Enhanced Epoxy Matrix. Compos. Interfaces 2025, 1–17. [Google Scholar] [CrossRef]

- Jin, F.-L.; Li, X.; Park, S.-J. Synthesis and Application of Epoxy Resins: A Review. J. Ind. Eng. Chem. 2015, 29, 1–11. [Google Scholar] [CrossRef]

- Mohan, P. A Critical Review: The Modification, Properties, and Applications of Epoxy Resins. Polym. Plast. Technol. Eng. 2013, 52, 107–125. [Google Scholar] [CrossRef]

- Ekşı, S.; Genel, K. Comparison of Mechanical Properties of Unidirectional and Woven Carbon, Glass and Aramid Fiber Reinforced Epoxy Composites. Acta Phys. Pol. A 2017, 132, 879–882. [Google Scholar] [CrossRef]

- Pham, H.Q.; Marks, M.J. Epoxy Resins. In Ullmann’s Encyclopedia of Industrial Chemistry; Wiley: Hoboken, NJ, USA, 2005. [Google Scholar]

- Meiirbekov, M.N.; Ismailov, M.B.; Kenzhegulov, A.K.; Mustafa, L.M.; Tashmukhanbetova, I.B. Study of the Effect of Combined Reinforcement and Modification of Epoxy Resin with Rubbers on the Impact Strength of Carbon Fiber-Reinforced Plastic. Eurasian J. Phys. Funct. Mater. 2024, 8, 23–32. [Google Scholar] [CrossRef]

- Dombrovsky, L.A.; Baillis, D. Thermal Radiation in Disperse Systems: An Engineering Approach; Begell House Inc.: Danbury, CT, USA, 2010; ISBN 978-1-56700-268-3. [Google Scholar]

- Natali, M.; Kenny, J.M.; Torre, L. Science and Technology of Polymeric Ablative Materials for Thermal Protection Systems and Propulsion Devices: A Review. Prog. Mater. Sci. 2016, 84, 192–275. [Google Scholar] [CrossRef]

- German, R.M.; Messing, G.L.; Cornwall, R.G. Sintering Technology; CRC Press: Boca Raton, FL, USA, 2020; ISBN 9781000105391. [Google Scholar]

- Michaud, V.; Mortensen, A. Infiltration Processing of Fibre Reinforced Composites: Governing Phenomena. Compos. Part A Appl. Sci. Manuf. 2001, 32, 981–996. [Google Scholar] [CrossRef]

- Najmon, J.C.; Raeisi, S.; Tovar, A. Review of Additive Manufacturing Technologies and Applications in the Aerospace Industry. In Additive Manufacturing for the Aerospace Industry; Elsevier: Amsterdam, The Netherlands, 2019; pp. 7–31. [Google Scholar]

- Wu, H.; Koo, J.H. High-Temperature Polymers and Their Composites for Extreme Environments: A Review. In Proceedings of the AIAA SCITECH 2022 Forum, San Diego, CA, USA, 3–7 January 2022; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2022. [Google Scholar]

- Ma, Y.; Wang, J.; Zhao, Y.; Wei, X.; Ju, L.; Chen, Y. A New Vacuum Pressure Infiltration CFRP Method and Preparation Experimental Study of Composite. Polymers 2020, 12, 419. [Google Scholar] [CrossRef]

- Servadei, F.; Zoli, L.; Galizia, P.; Melandri, C.; Sciti, D. Preparation of UHTCMCs by Hybrid Processes Coupling Polymer Infiltration and Pyrolysis with Hot Pressing and Vice Versa. J. Eur. Ceram. Soc. 2022, 42, 2118–2126. [Google Scholar] [CrossRef]

- Martín, J.; Mijangos, C. Tailored Polymer-Based Nanofibers and Nanotubes by Means of Different Infiltration Methods into Alumina Nanopores. Langmuir 2009, 25, 1181–1187. [Google Scholar] [CrossRef]

- GOST 9012–2016; Metals. Brinell Hardness Test Method. Standartinform: Moscow, Russia, 2017.

- ISO 2685:1998; Aircraft—Environmental Test Procedures for Airborne Equipment—Resistance to Fire in Designated Fire Zones. International Organization for Standardization: Geneva, Switzerland, 1998.

- GOST R 52781-2007; Fire-Protective Materials and Products. Test Methods for Ignitability. Standartinform: Moscow, Russia, 2008.

- ISO 22007-2:2015; Plastics—Determination of Thermal Conductivity and Thermal Diffusivity—Part 2: Transient Plane Heat Source (Hot Disc) Method. International Organization for Standardization: Geneva, Switzerland, 2015.

- ISO 16700:2020; Space Systems—Structural Materials and Elements—Test Methods. International Organization for Standardization: Geneva, Switzerland, 2020.

| Fabric Type | Grade | Tensile Strength (MPa) | Young’s Modulus (GPa) | Areal Density, g/m2 | Temperature Resistance, °C |

|---|---|---|---|---|---|

| Carbon fabric | CW180 | 4000–4900 | 260 | 180 | up to 2000 (in inert atmosphere) |

| Silica fabric | KT-11-30K | 800–1000 | 70–80 | 300 | up to 1000 |

| Aramid fabric | Togilen 160 | 2700–3600 | 60–145 | 160 | up to 500 |

| Basalt fabric | TBK-100 | 800–1000 | 89–100 | 210 | up to 800 |

| Fiberglass fabric | TR-0.7 (100) | 1000–1500 | 70–80 | 290 | up to 600 |

| Hybrid carbon/aramid fabric | C03K15P-195 | 4000–4500 | 200–220 | 195 | up to 500–800 |

| Asbestos fabric | AT-16 | 700–900 | 50–60 | 3200 | up to 400 |

| Characteristic | Phenol-Formaldehyde Resin | Epoxy Resin |

|---|---|---|

| Manufacturer | Shandong Shengquan Group Co., Ltd., Jinan, China | JSC “Epital”, Russia |

| Grade | R-75 | Etal-Inject T |

| Type of Binder | Phenol-formaldehyde, resol-type | Epoxy, thermosetting |

| Maximum Operating Temperature, °C | up to 250 °C | up to 180–200 °C |

| Viscosity at 25 °C | 2500–3500 mPa·s | 400–500 mPa·s |

| Behavior on Heating | Forms a carbonaceous residue, suitable for carbonization | Forms a heat-resistant residue, not prone to carbonization |

| Type of Hardener | Does not require hardener (self-curing when heated) | Amino-type, external component |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Meiirbekov, M.; Kuandyk, A.; Sadykov, M.; Nurzhanov, M.; Yesbolov, N.; Baiserikov, B.; Ablakatov, I.; Mustafa, L.; Medyanova, B.; Kulbekov, A.; et al. Polymer-Based Thermal Protective Composites: The Role of Reinforcement and Matrix in Providing Strength and Fire Resistance. Polymers 2025, 17, 1419. https://doi.org/10.3390/polym17101419

Meiirbekov M, Kuandyk A, Sadykov M, Nurzhanov M, Yesbolov N, Baiserikov B, Ablakatov I, Mustafa L, Medyanova B, Kulbekov A, et al. Polymer-Based Thermal Protective Composites: The Role of Reinforcement and Matrix in Providing Strength and Fire Resistance. Polymers. 2025; 17(10):1419. https://doi.org/10.3390/polym17101419

Chicago/Turabian StyleMeiirbekov, Mohammed, Assem Kuandyk, Mukhammed Sadykov, Meiir Nurzhanov, Nurmakhan Yesbolov, Berdiyar Baiserikov, Ilyas Ablakatov, Laura Mustafa, Botagoz Medyanova, Arman Kulbekov, and et al. 2025. "Polymer-Based Thermal Protective Composites: The Role of Reinforcement and Matrix in Providing Strength and Fire Resistance" Polymers 17, no. 10: 1419. https://doi.org/10.3390/polym17101419

APA StyleMeiirbekov, M., Kuandyk, A., Sadykov, M., Nurzhanov, M., Yesbolov, N., Baiserikov, B., Ablakatov, I., Mustafa, L., Medyanova, B., Kulbekov, A., Orazbek, S., & Yermekov, A. (2025). Polymer-Based Thermal Protective Composites: The Role of Reinforcement and Matrix in Providing Strength and Fire Resistance. Polymers, 17(10), 1419. https://doi.org/10.3390/polym17101419