Investigation of the Thermal, Physical, and Microstructural Properties of Polymeric Composites Bio-Reinforced with Charcoal Fines

Abstract

1. Introduction

2. Materials and Methods

2.1. Production of the Composites

2.2. Determination of the Thermal, Physical, and Microstructural Properties of the Composites

Thermogravimetric Analysis (TGA)

3. Results and Discussion

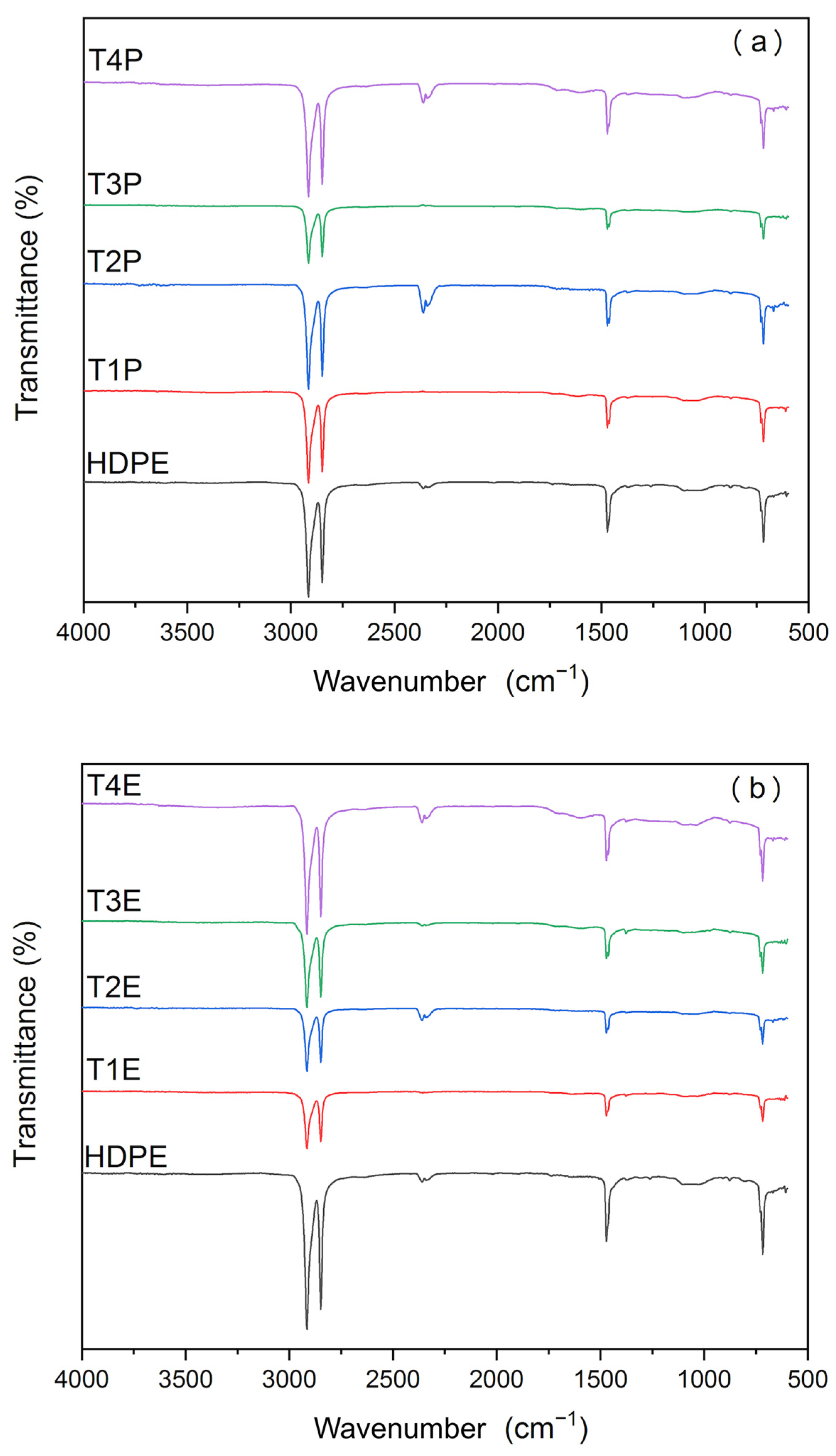

3.1. Fourier Transform Infrared Spectroscopy (FTIR)

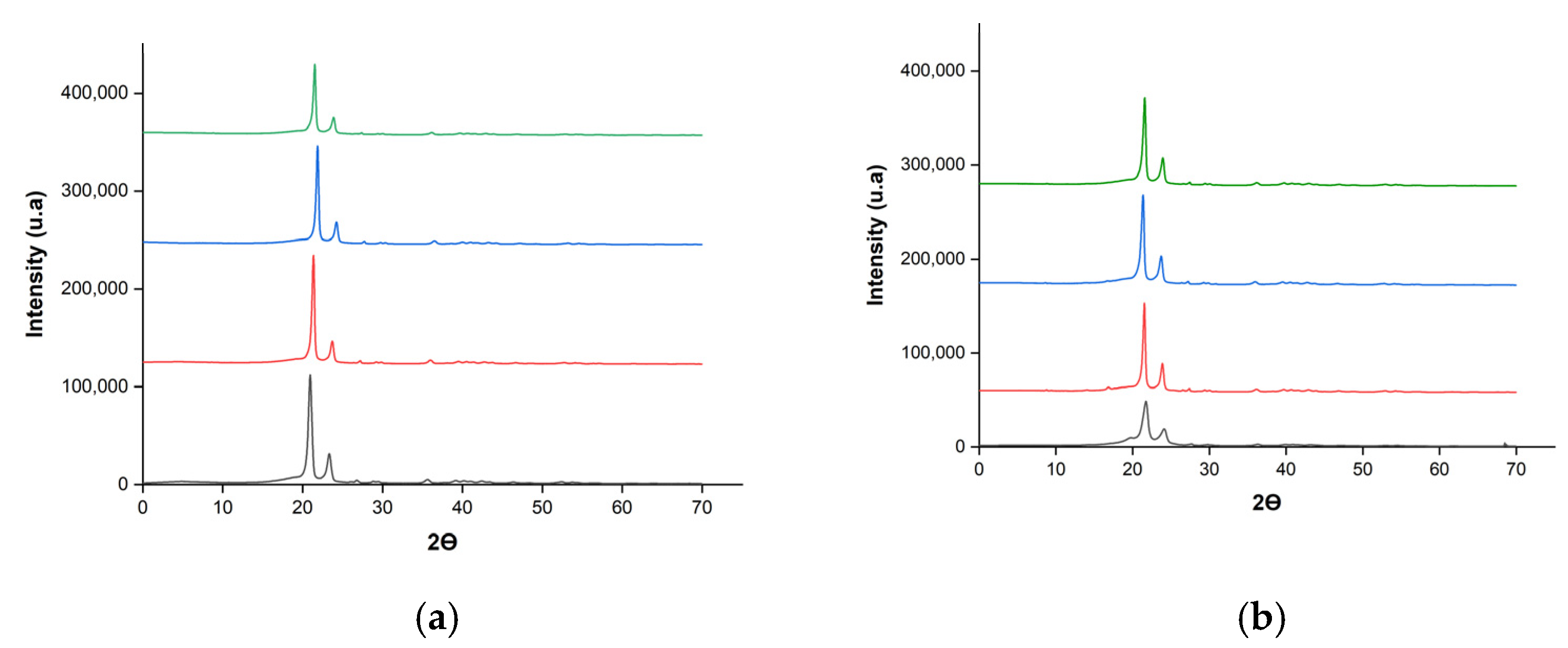

3.2. X-Ray Diffraction

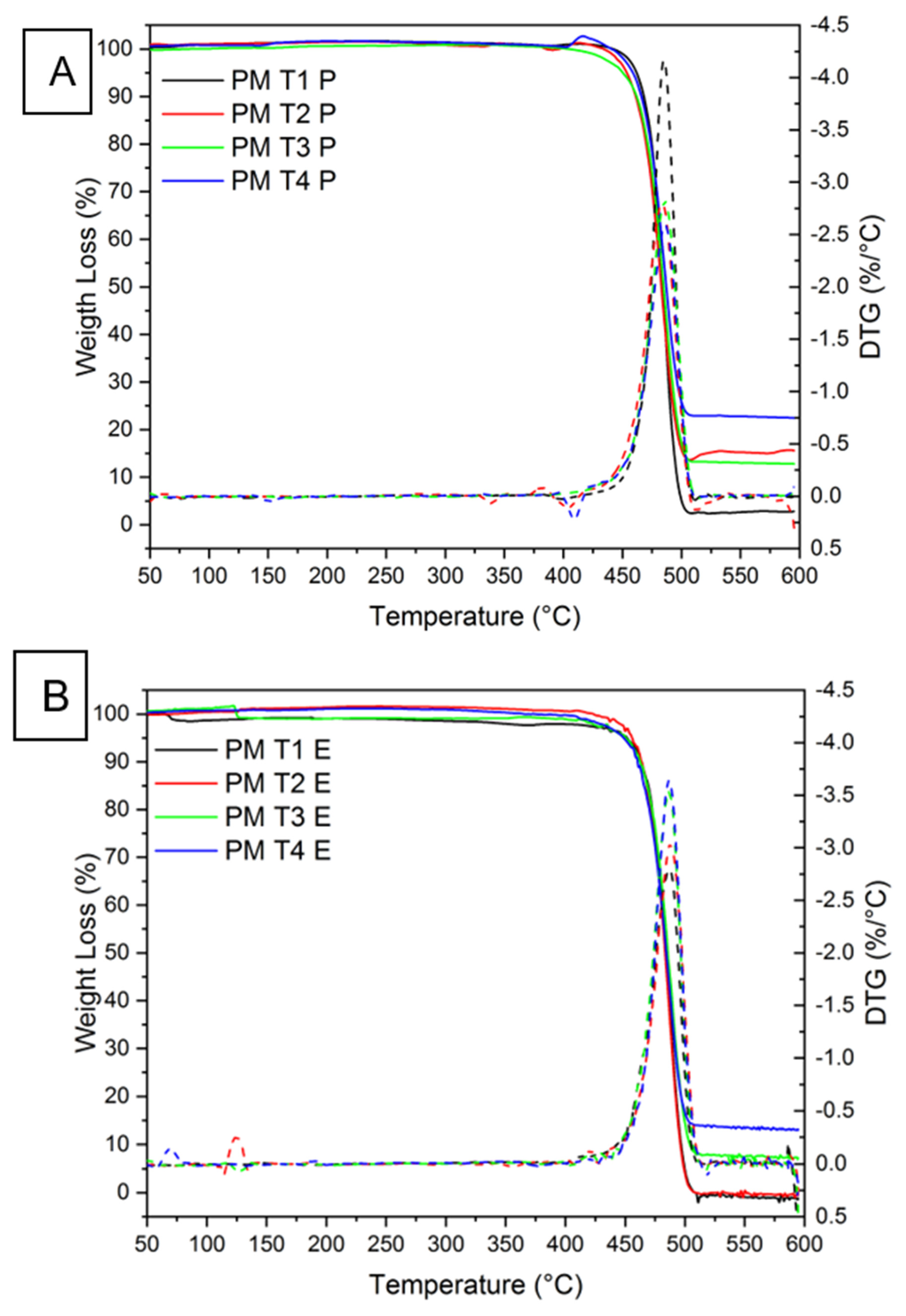

3.3. Thermogravimetric Analysis (TGA)

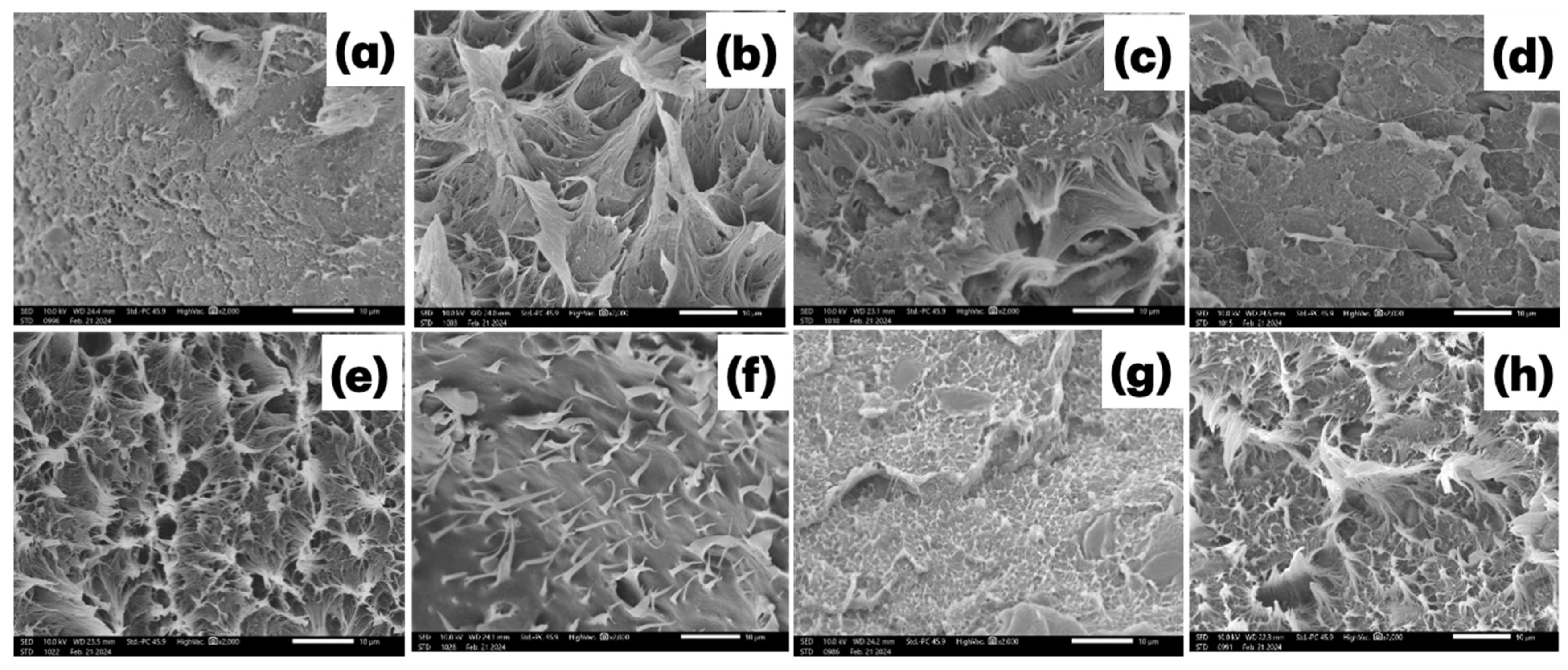

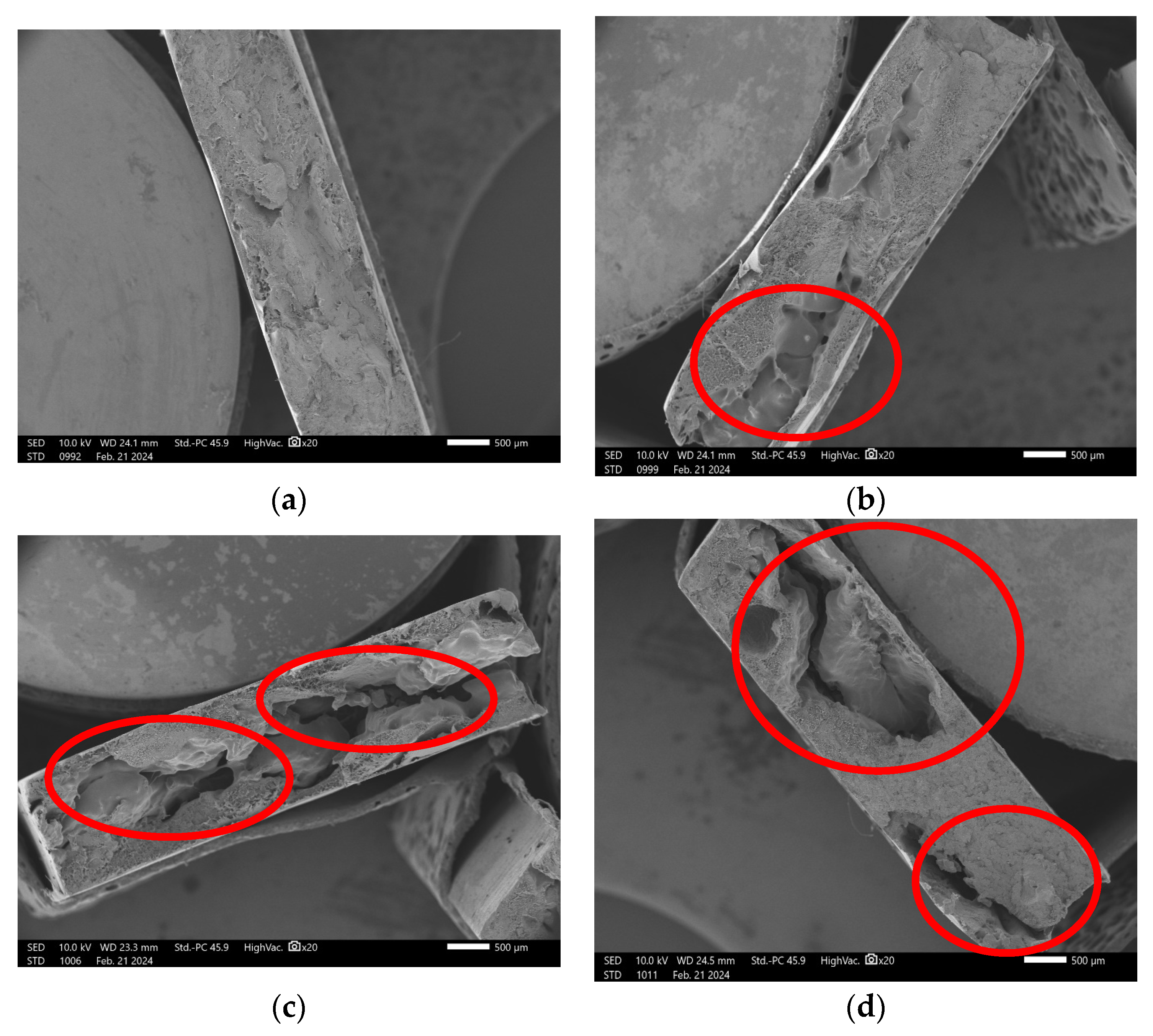

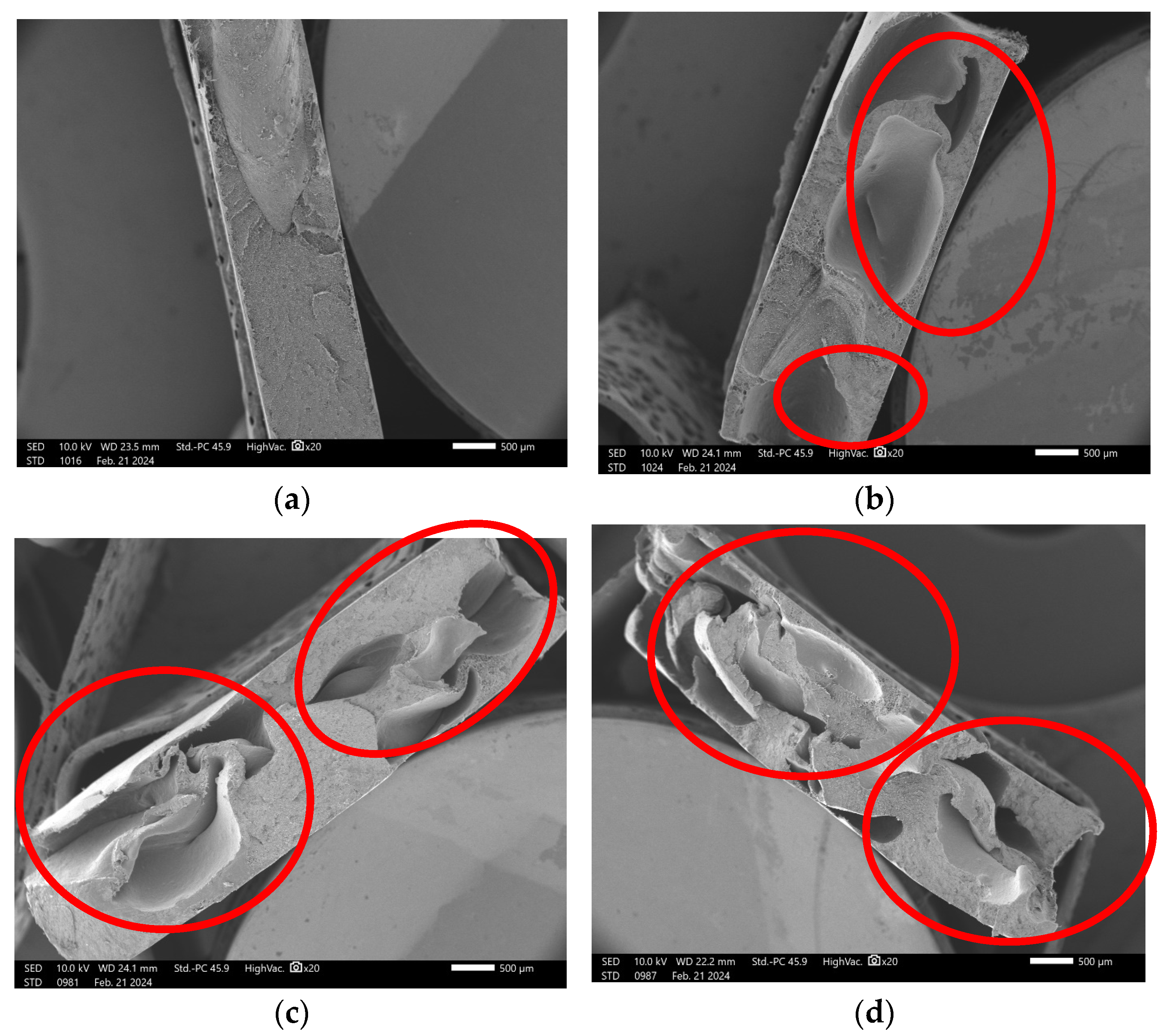

3.4. Scanning Electron Microscopy (SEM)

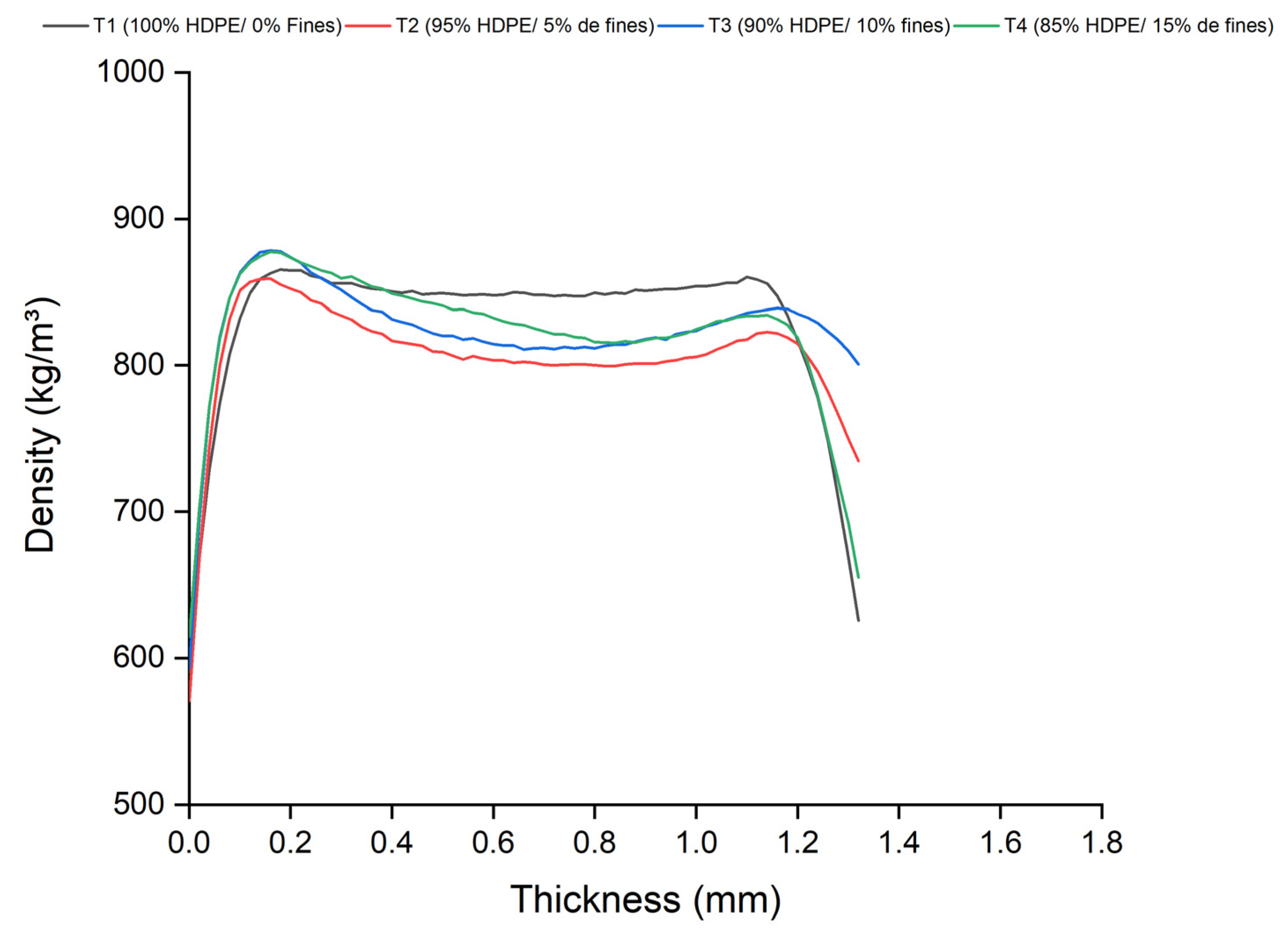

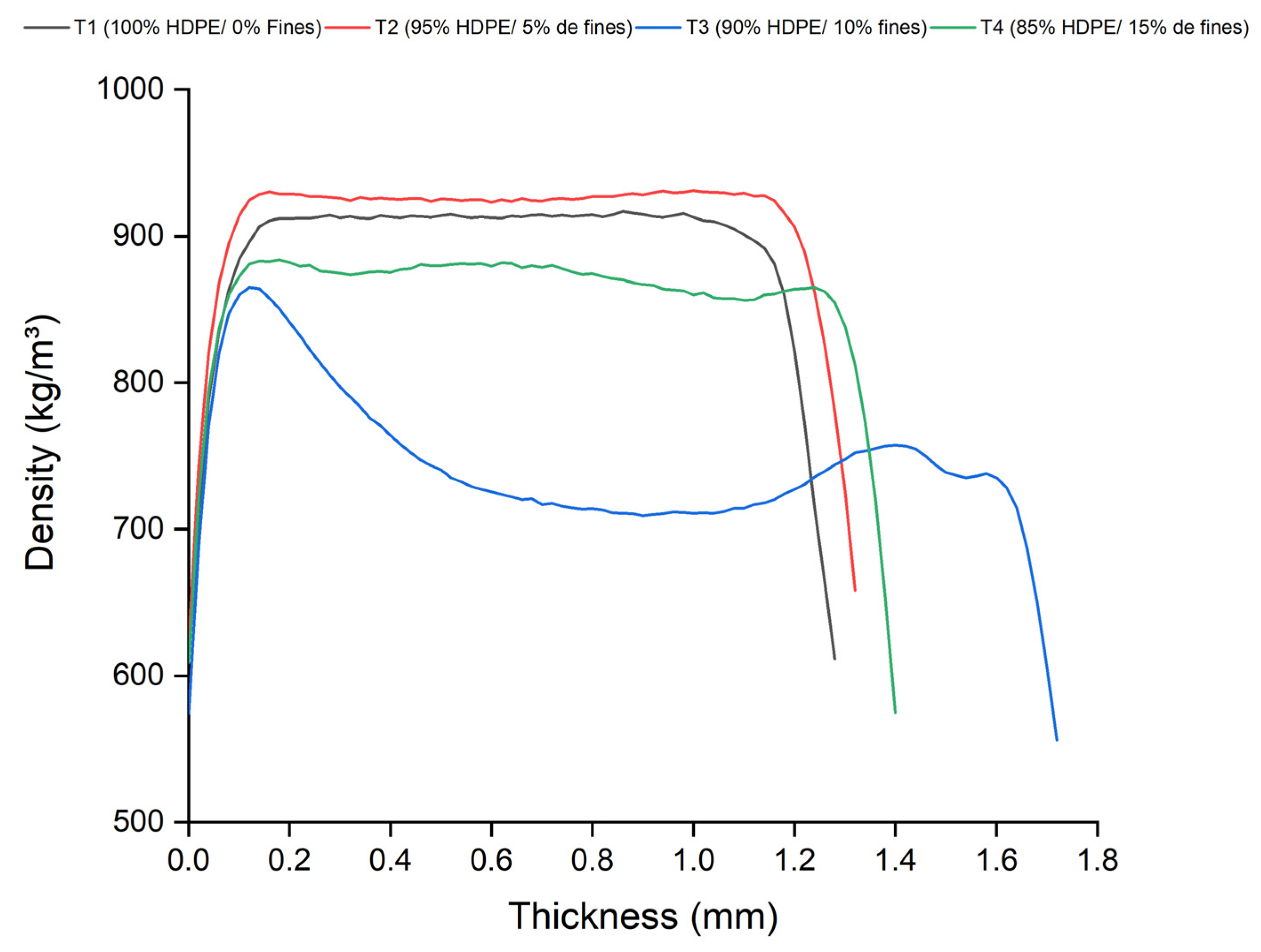

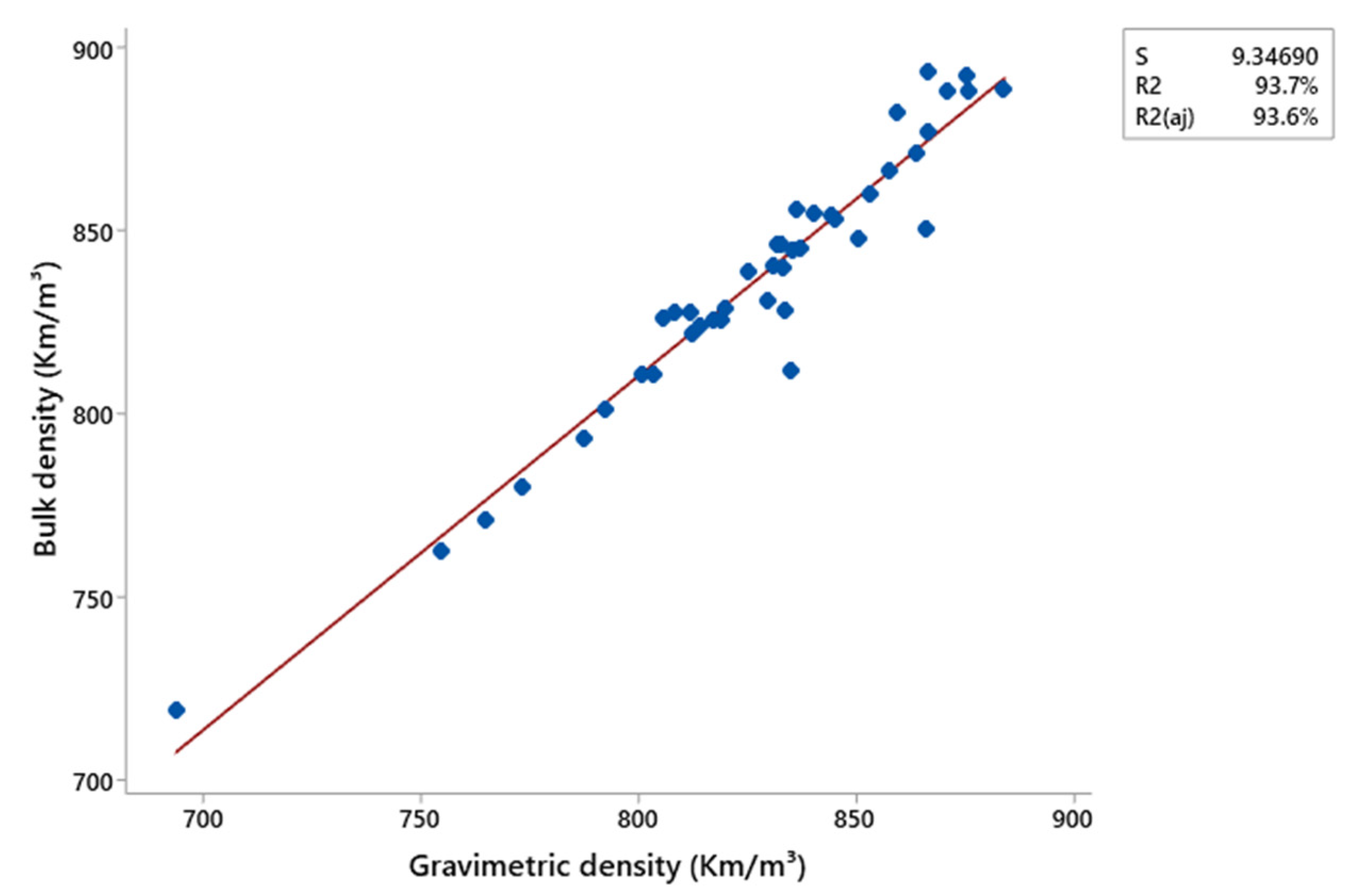

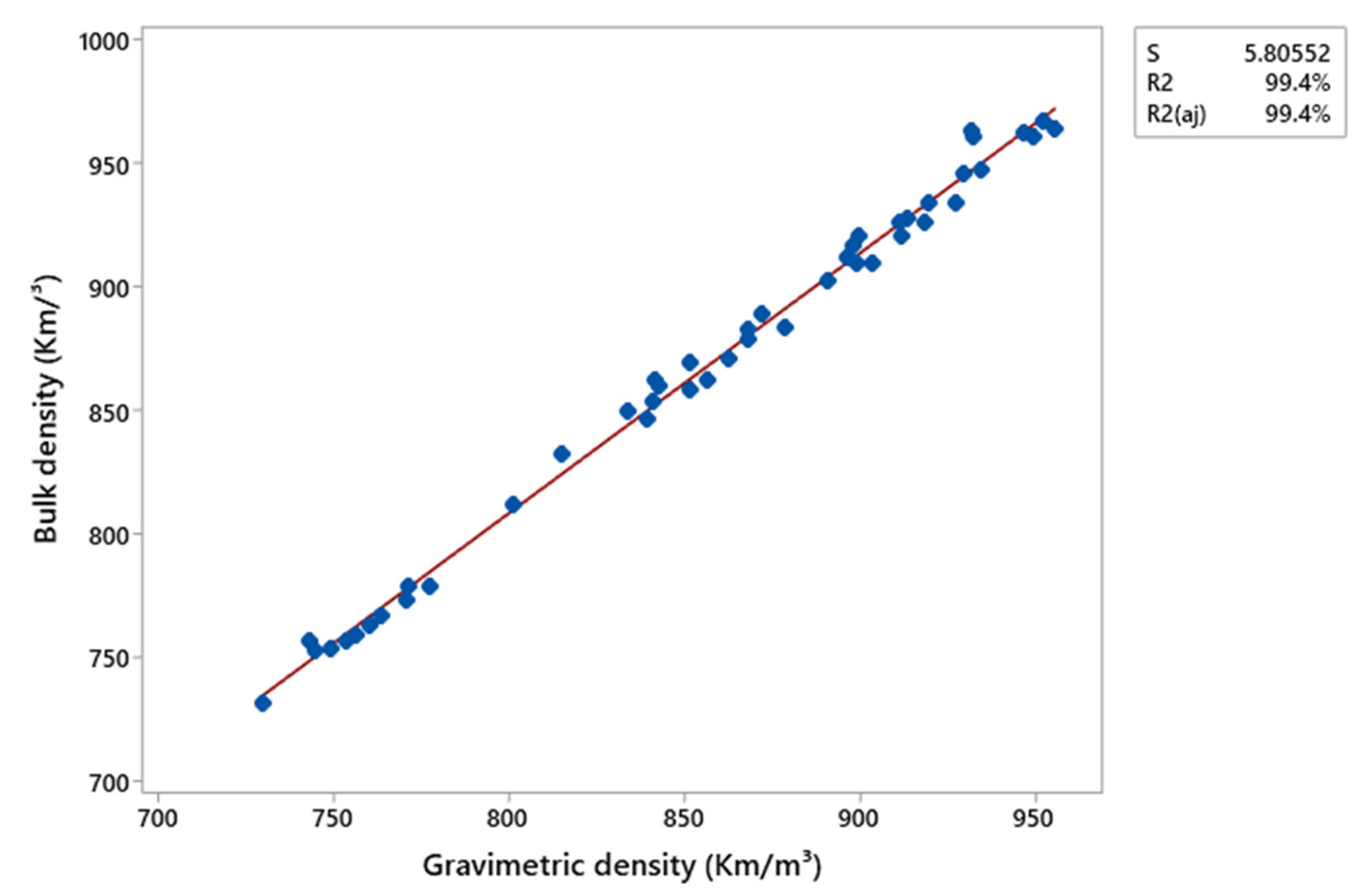

3.5. X-Ray Densitometry

4. Conclusions

- The production methods by pressing and extrusion, as well as the addition of charcoal fines, did not exhibit a significant influence on the thermal properties and crystallinity of the investigated composites.

- The microstructural analysis, conducted through scanning electron microscopy (SEM), confirmed an increase in the porosity of the composites, which may explain the reduction in mechanical properties observed during the tensile testing and non-destructive methods.

- The analysis by Fourier transform infrared (FTIR) spectroscopy did not reveal significant differences with the addition of charcoal fines, as no additional peaks were observed in the spectrum. These results suggest that the charcoal fines acted as a bio-reinforcement, exerting a stabilizing or conservating effect on the material’s structure.

- The thermogravimetric analysis (TGA) and X-ray diffraction (XRD) demonstrated that the addition of fine charcoal particles to high-density polyethylene (HDPE), regardless of the processing method, did not significantly affect the thermal stability or crystallinity of the composites. These characteristics indicate a high potential for industrial applications requiring thermal resistance and dimensional stability.

- The composites exhibited potential for applications that demand low weight, thermal stability, and high porosity. Additionally, these materials contribute to sustainability by valorizing plastic waste and promoting the circular economy.

- The use of fine charcoal particles as a filler for high-density polyethylene (HDPE) presents significant potential, offering advantages such as waste mitigation, the valorization of byproducts, and the possibility of developing materials with enhanced properties.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AE | Statistical Clustering |

| CEFET | Federal Center for Technological Education |

| XRD | X-ray Diffraction |

| FTIR | Fourier Transform Infrared Spectroscopy |

| SEM | Scanning Electron Microscopy |

| PE | Polyethylene |

| HDPE | High-Density Polyethylene |

| TGA | Thermogravimetric Analysis |

References

- Li, C.; Liao, H.; Gao, H.; Zhang, H.; Cheng, F. A facile green and cost-effective manufacturing process from coal gangue-reinforced composites. Compos. Sci. Technol. 2023, 233, 109908. [Google Scholar] [CrossRef]

- Ren, Y.; Zhang, D.; Yin, Y.; Ye, Z.; Yin, Z.; Tu, S.; Ye, L.; Righetti, M.C.; Cinelli, P.; Mallegni, M.; et al. Mechanically strong, thermostable, and flame-retardant composites enabled by Brown paper made from bamboo. Compos. Sci. Technol. 2022, 226, 109544. [Google Scholar] [CrossRef]

- Mishra, T.; Mandal, P.; Rout, A.K.; Sahoo, D. A state-of-the-art review on potential applications of natural fiber-reinforced polymer composite filled with inorganic nanoparticle. Compos. Part C Open Access 2022, 9, 100298. [Google Scholar] [CrossRef]

- Lotfi, A.; Li, H.; Dao, D.V.; Prusty, G. Natural fiber–reinforced composites: A review on material, manufacturing, and machinability. J. Thermoplast. Compos. Mater. 2021, 34, 238–284. [Google Scholar] [CrossRef]

- Lu, X.B.; Liu, Y.; Zhou, H. Learning nature: Recyclable monomers and polymers. Chem.–A Eur. J. 2018, 24, 11255–11266. [Google Scholar] [CrossRef]

- Hsissou, R.; Seghiri, R.; Benzekri, Z.; Hilali, M.; Rafik, M.; Elharfi, A. Polymer composite materials: A comprehensive review. Compos. Struct. 2021, 262, 113640. [Google Scholar] [CrossRef]

- Park, S.; Shou, W.; Makatura, L.; Matusik, W.; Fu, K.K. 3D printing of polymer composites: Materials, processes, and applications. Matter 2022, 5, 43–76. [Google Scholar] [CrossRef]

- Crawford, E.; Lesser, A.J. Mechanics of rubber particle cavitation in toughened polyvinylchloride (PVC). Polymers 2000, 41, 5865–5870. [Google Scholar] [CrossRef]

- Das, P.; Tiwari, P. Thermal degradation study of waste polyethylene terephthalate (PET) under inert and oxidative environments. Thermochim. Acta 2019, 679, 178340. [Google Scholar] [CrossRef]

- Datsyuk, V.; Trotsenko, S.; Trakakis, G.; Boden, A.; Vyzas-Asimakopoulos, K.; Parthenios, J.; Papagelis, K. Thermal properties enhancement of epoxy resins by incorporating polybenzimidazole nanofibers filled with graphene and carbon nanotubes as reinforcing material. Polym. Test. 2020, 82, 106317. [Google Scholar] [CrossRef]

- Deka, B.K.; Maji, T.K. Effect of coupling agent and nanoclay on properties of HDPE, LDPE, PP, PVC blend and Phargamites karka nanocomposite. Compos. Sci. Technol. 2010, 70, 1755–1761. [Google Scholar] [CrossRef]

- Li, J.; Wang, J. Comprehensive utilization and environmental risks of coal gangue: A review. J. Clean. Prod. 2019, 239, 117946. [Google Scholar] [CrossRef]

- Delatorre, F.M.; Cupertino, G.F.M.; Silva, Á.M.; Santos Junior, A.J.; Mesquita, J.G.; Júnior, A.F.D. Potencial energético dos finos de carvão vegetal. In Engenharia Florestal: Desafios, Limites e Potencialidade; Editora Científica Digital: Guarujá, Brazil, 2020; pp. 639–653. [Google Scholar]

- Bueno, W.A. Manual de Espectroscopia Vibracional; McGraw-Hill: Rio de Janeiro, Brazil, 1990; p. 584. [Google Scholar]

- Poulose, A.M.; Elnour, A.Y.; Anis, A.; Shaikh, H.; Al-Zahrani, S.M.; George, J.; Al-Wabel, M.I.; Usman, A.R.; Ok, Y.S.; Tsang, D.C.; et al. Date palm biochar-polymer composites: An investigation of electrical, mechanical, thermal and rheological characteristics. Sci. Total Environ. 2018, 619, 311–318. [Google Scholar] [CrossRef] [PubMed]

- Ahmed, K.; Hasan, M.; Haider, J. Electrical and mechanical properties of sugarcane bagasse pyrolyzed biochar reinforced polyvinyl alcohol biocomposite films. J. Compos. Sci. 2021, 5, 249. [Google Scholar] [CrossRef]

- Delatorre, F.M.; Pereira, A.K.S.; da Silva, Á.M.; de Souza, E.C.; Oliveira, M.P.; Profeti, D.; Profeti, L.P.R.; Dias Júnior, A.F. The addition of charcoal fines can increase the photodegradation resistance of polymeric biocomposites. Environ. Sci. Proc. 2021, 13, 8. [Google Scholar]

- Delatorre, F.M.; Cupertino, G.F.M.; Oliveira, M.P.; Silva, G.F.; Profeti, L.P.R.; Profeti, D.; Júnior, M.G.; Azevedo, M.G.; Saloni, D.; Júnior, A.F.D. A novel approach to charcoal fine waste: Sustainable use as filling of polymeric matrices. Polymers 2022, 14, 5525. [Google Scholar] [CrossRef]

- Li, D.; Garmestani, H.; Kalidindi, S.R.; Alamo, R. Crystallographic texture evolution in high-density polyethylene during uniaxial tension. Polymer 2001, 42, 4903–4913. [Google Scholar] [CrossRef]

- Furtado, J.B.D.M.; Oliveira, T.P.; Caetano, M.R.D.S.; Santos Júnior, J.R.D.; Furtado Filho, P.A.; Figueiredo, F.C. Polyethylene/fiber composite: Characterization and degradation. Rev. Virtual Quim. 2020, 12, 272–285. [Google Scholar]

- Salem, E.F.; Khozemy, E.E.; Ali, A.E. Potential flame retardancy of high-density polyethylene (HDPE) composite for possible use as a radiation shield. Prog. Nucl. Energy 2023, 165, 104900. [Google Scholar] [CrossRef]

- Jia, Y.; Mao, Z.; Huang, W.; Zhang, J. Effect of temperature and crystallinity on the thermal conductivity of semi-crystalline polymers: A case study of polyethylene. Mater. Chem. Phys. 2022, 287, 126325. [Google Scholar] [CrossRef]

- Chaudhary, A.K.; Vijayakumar, R.P. Effect of chemical treatment on biological degradation of high-density polyethylene (HDPE). Environ. Dev. Sustain. 2020, 22, 1093–1104. [Google Scholar] [CrossRef]

- Ho, M.P.; Lau, K.T.; Wang, H.; Hui, D. Improvement on the properties of polylactic acid (PLA) using bamboo charcoal particles. Compos. Part B Eng. 2015, 81, 14–25. [Google Scholar] [CrossRef]

- Tarani, E.; Arvanitidis, I.; Christofilos, D.; Bikiaris, D.N.; Chrissafis, K.; Vourlias, G. Calculation of the degree of crystallinity of HDPE/GNPs nanocomposites by using various experimental techniques: A comparative study. J. Mater. Sci. 2023, 58, 1621–1639. [Google Scholar] [CrossRef]

- Koffi, A.; Mijiyawa, F.; Koffi, D.; Erchiqui, F.; Toubal, L. Mechanical properties, wettability and thermal degradation of HDPE/birch fiber composite. Polymers 2021, 13, 1459. [Google Scholar] [CrossRef]

- Fensterseifer, C.R.; Brambilla, R. Compósitos de PEAD/diatomita modificada com grupos metilsilano: Análise das propriedades térmicas e mecânicas. Periódico Tchê Química 2019, 16, 31. [Google Scholar]

- Sathish, T.; Jagadeesh, P.; Rangappa, S.M.; Siengchin, S. Mechanical and thermal analysis of coir fiber reinforced jute/bamboo hybrid epoxy composites. Polym. Compos. 2022, 43, 4700–4710. [Google Scholar] [CrossRef]

- Norizan, M.N.; Abdan, K.; Salit, M.S.; Mohamed, R. Physical, mechanical and thermal properties of sugar palm yarn fibre loading on reinforced unsaturated polyester composites. J. Phys. Sci. 2017, 28, 115–136. [Google Scholar] [CrossRef]

- Nurazzi, N.; Asyraf, M.R.M.; Rayung, M.; Norrrahim, M.N.F.; Shazleen, S.S.; Rani, M.S.A.; Abdan, K. Thermogravimetric analysis properties of cellulosic natural fiber polymer composites: A review on influence of chemical treatments. Polymers 2021, 13, 2710. [Google Scholar] [CrossRef]

- Sarkhel, G.; Choudhury, A. Dynamic mechanical and thermal properties of PE-EPDM based jute fiber composites. J. Appl. Polym. Sci. 2008, 108, 3442–3453. [Google Scholar] [CrossRef]

- Xie, Y.; Hill, C.A.; Xiao, Z.; Militz, H.; Mai, C. Silane coupling agents used for natural fiber/polymer composites: A review. Compos. Part A Appl. Sci. Manuf. 2010, 41, 806–819. [Google Scholar] [CrossRef]

- Marinelli, A.L.; Monteiro, M.R.; Ambrósio, J.D.; Branciforti, M.C.; Kobayashi, M.; Nobre, A.D. Desenvolvimento de compósitos poliméricos com fibras vegetais naturais da biodiversidade: Uma contribuição para a sustentabilidade amazônica. Polímeros 2008, 18, 92–99. [Google Scholar] [CrossRef]

- Gonçalves, F.G.; Lelis, R.C.C.; Carvalho, A.M.D.; Tomazello Filho, M. Densitometria de raios x na avaliação da densidade em painéis de partículas. Ciências Florest. 2018, 28, 1151–1162. [Google Scholar] [CrossRef]

- Xu, W. Influence of vertical density distribution on bending modulus of elasticity of wood composite panels: A theoretical consideration. Wood Fiber Sci. 1999, 31, 277–282. [Google Scholar]

- Wong, E.D.; Zhang, M.; Han, G.; Kawai, S.; Wang, Q. Formation of the density profile and its effects on the properties of fiberboard. J. Wood Sci. 2000, 46, 202–209. [Google Scholar] [CrossRef]

- Medina, L.A.; Dzalto, J. Natural Fibers. In Comprehensive Composite Materials II; Elsevier: Amsterdam, The Netherlands, 2018; pp. 269–294. [Google Scholar]

| Production Process | Treatments | HDPE (%) | Fines (%) |

|---|---|---|---|

| Pressing | T1 | 100 | 0 |

| T2 | 95 | 5 | |

| T3 | 90 | 10 | |

| T4 | 85 | 15 | |

| Extrusion | T1 | 100 | 0 |

| T2 | 95 | 5 | |

| T3 | 90 | 10 | |

| T4 | 85 | 15 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dias, J.O.; Conceição, A.O.; Siqueira, R.; Coelho, B.F.; Oliveira, P.S. Investigation of the Thermal, Physical, and Microstructural Properties of Polymeric Composites Bio-Reinforced with Charcoal Fines. Polymers 2025, 17, 1370. https://doi.org/10.3390/polym17101370

Dias JO, Conceição AO, Siqueira R, Coelho BF, Oliveira PS. Investigation of the Thermal, Physical, and Microstructural Properties of Polymeric Composites Bio-Reinforced with Charcoal Fines. Polymers. 2025; 17(10):1370. https://doi.org/10.3390/polym17101370

Chicago/Turabian StyleDias, Josinaldo O., Amanda O. Conceição, Rayara Siqueira, Bruno Fonseca Coelho, and Patrícia S. Oliveira. 2025. "Investigation of the Thermal, Physical, and Microstructural Properties of Polymeric Composites Bio-Reinforced with Charcoal Fines" Polymers 17, no. 10: 1370. https://doi.org/10.3390/polym17101370

APA StyleDias, J. O., Conceição, A. O., Siqueira, R., Coelho, B. F., & Oliveira, P. S. (2025). Investigation of the Thermal, Physical, and Microstructural Properties of Polymeric Composites Bio-Reinforced with Charcoal Fines. Polymers, 17(10), 1370. https://doi.org/10.3390/polym17101370