Effect of Service Temperature on the Mechanical and Fatigue Behaviour of Metal–Polymer Friction Stir Composite Joints

Abstract

1. Introduction

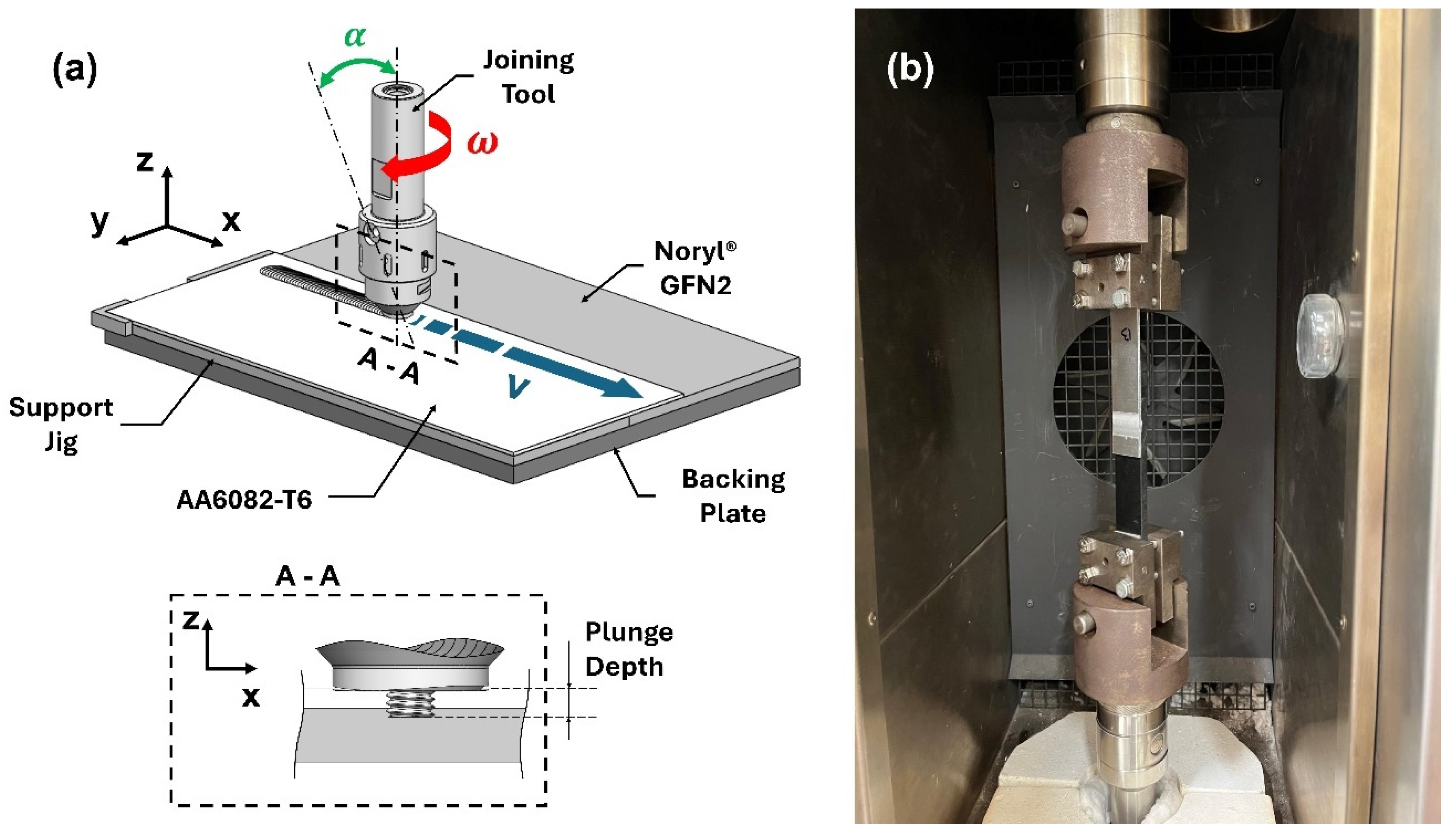

2. Materials and Methods

| Base Material | (g/cm3) | E (GPa) | (MPa) | Tmelt (°C) | Tg (°C) | K (W/(m°C)) |

|---|---|---|---|---|---|---|

| AA6082-T6 | 2.70 | 70 | >290 | 582 | - | 180 |

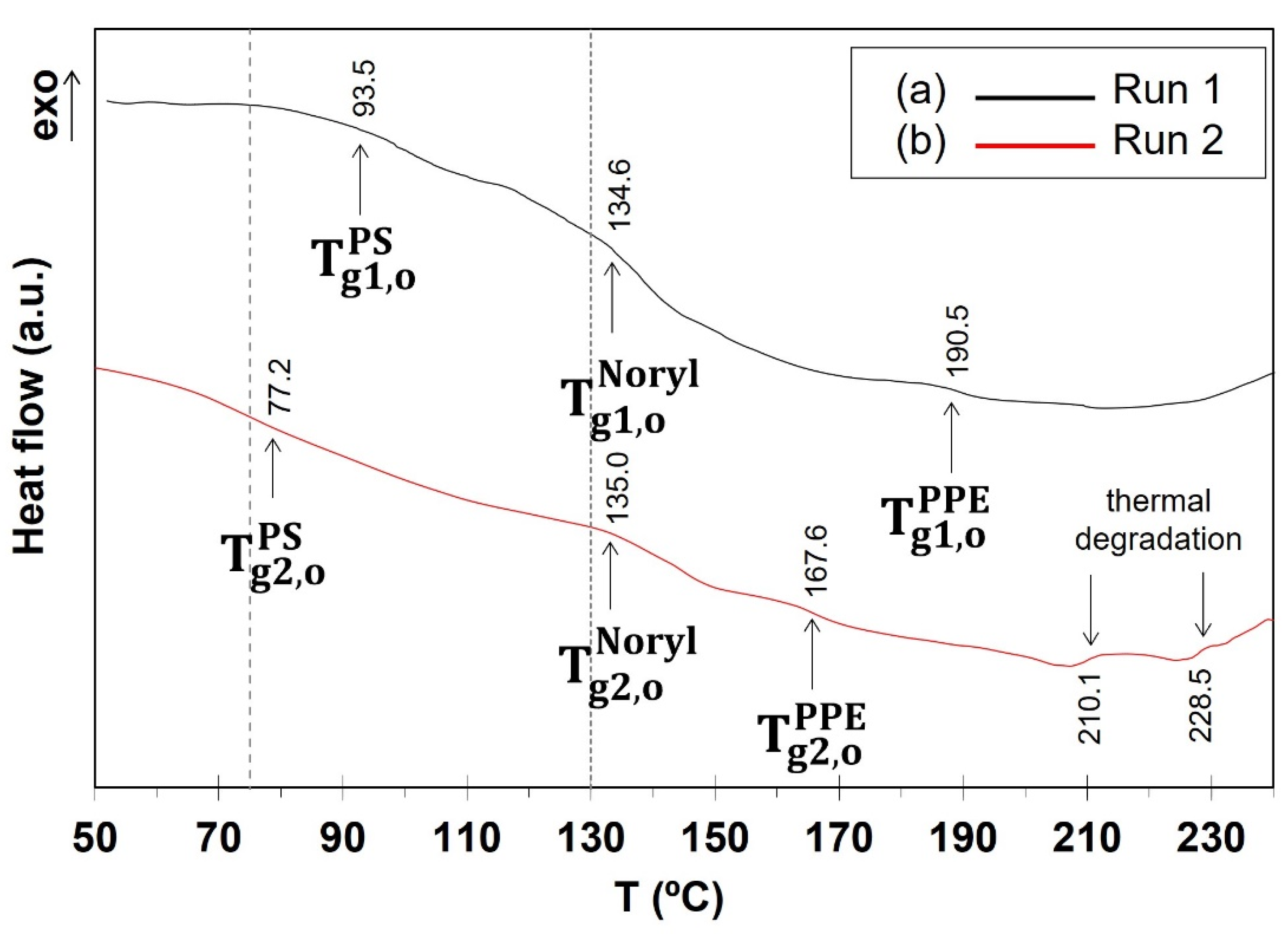

| Noryl® GFN2 | 1.25 | 6 | 80 | 280 | 135–145 | 0.26 |

3. Results and Discussion

3.1. Quasi-Static Strength Under Different Service Temperatures

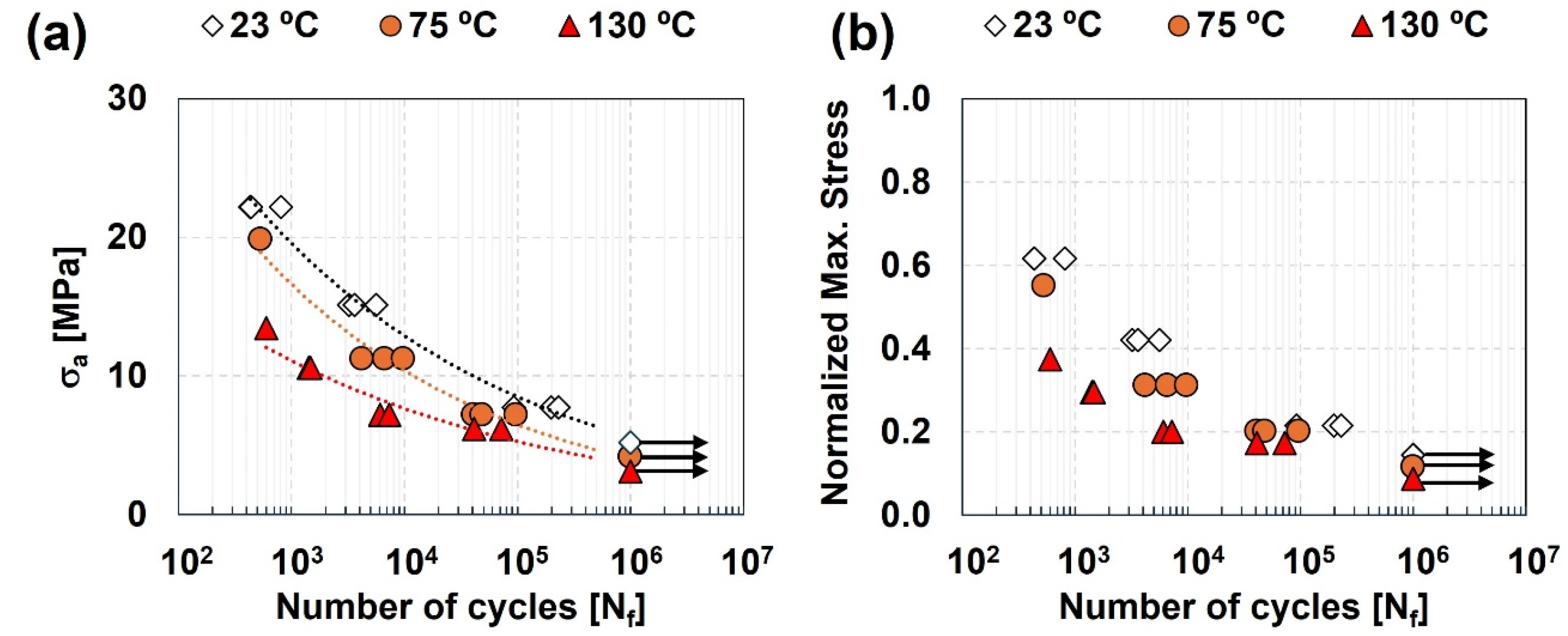

3.2. Fatigue Strength Under Different Service Temperatures

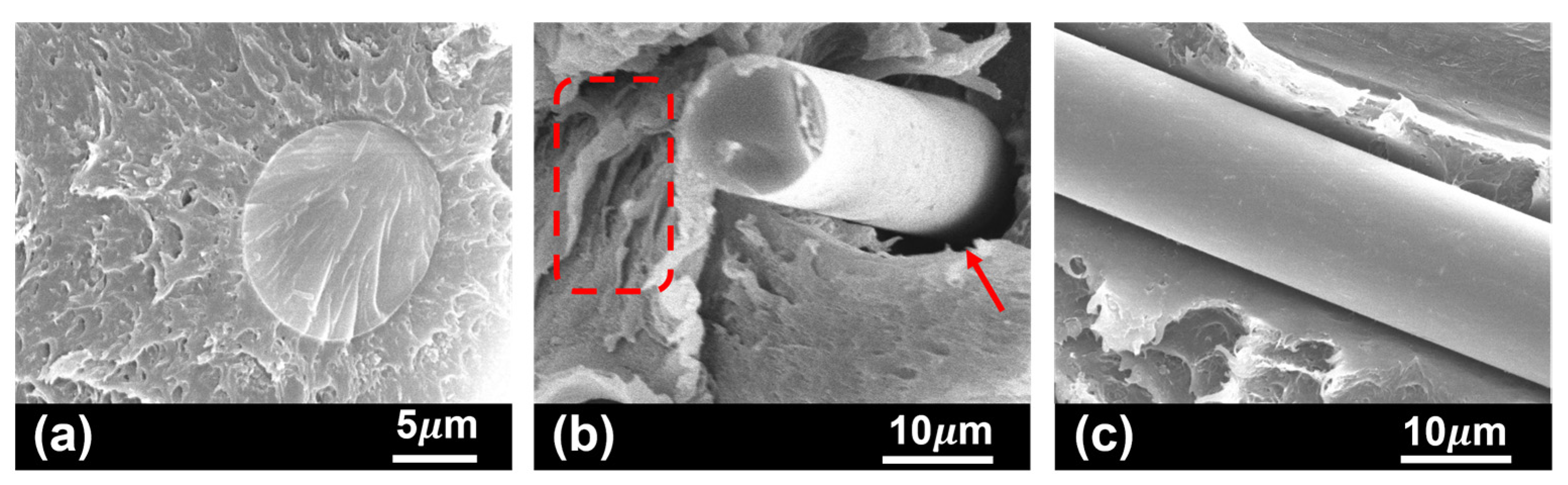

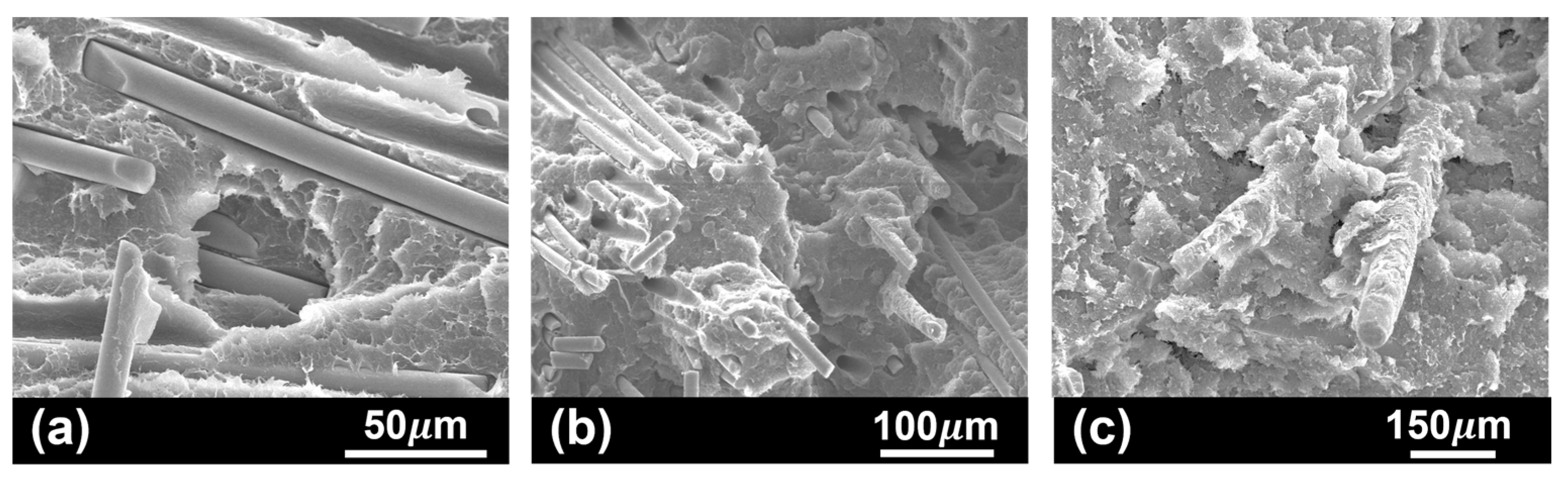

3.3. Fracture Surface

4. Conclusions

- In all tested scenarios, the failure of joints occurred at the polymeric base material close to the interface region, confirming the quality and strength of the binding mechanisms within this region.

- The joints mimic and are limited by the mechanical behaviour of the polymeric base material, regardless the testing conditions.

- Joints sensitivity to service temperature increases as it gets close to the softening temperature of Noryl® GFN2, both under quasi-static and cyclic loading conditions.

- The quasi-static strength decreased by 10% and 56% when the testing temperature is increased to 75 and 130 °C, respectively.

- Fatigue lifespans over 104 cycles were obtained with stress levels below 20 MPa (25% of the polymeric base material’s UTS at 23 °C), regardless of the testing temperature.

- At high temperatures, the polymeric base material undergoes softening and glass fibres debonding from the polymeric matrix, decreasing its load bearing capacity.

- At testing temperatures close to the softening temperature of Noryl® GFN2, the joints show more ductility, and the failure occurs progressively, whereas at temperatures between 23 and 75 °C, the joints evidence a brittle nature with crack nucleation and instantaneous propagation.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Weman, K. 11—Pressure welding methods. In Welding Processes Handbook, 2nd ed.; Woodhead Publishing: Sawston, UK, 2012; pp. 119–132. [Google Scholar] [CrossRef]

- Mishra, R.S.; Ma, Z.Y. Friction stir welding and processing. Mater. Sci. Eng. R Rep. 2005, 50, 1–78. [Google Scholar] [CrossRef]

- Dias, F.; Cipriano, G.; Correia, A.N.; Braga, D.F.O.; Moreira, P.; Infante, V. Joining of Aluminum Alloy AA7075 and Titanium Alloy Ti-6Al-4V through a Friction Stir Welding-Based Process. Metals 2023, 13, 249. [Google Scholar] [CrossRef]

- Kumar, N.; Yuan, W.; Mishra, R.S. Friction Stir Welding of Dissimilar Alloys and Materials. Elsevier, Ed.; Butterworth-Heinemann: Oxford, UK, 2015. [Google Scholar] [CrossRef]

- Correia, A.N.; Braga, D.F.O.; Moreira, P.M.G.P.; Infante, V. Review on dissimilar structures joints failure. Eng. Fail. Anal. 2021, 129, 105652. [Google Scholar] [CrossRef]

- Ahmed, M.M.Z.; El-Sayed Seleman, M.M.; Fydrych, D.; Cam, G. Friction Stir Welding of Aluminum in the Aerospace Industry: The Current Progress and State-of-the-Art Review. Materials 2023, 16, 2971. [Google Scholar] [CrossRef] [PubMed]

- Barakat, A.A.; Darras, B.M.; Nazzal, M.A.; Ahmed, A.A. A Comprehensive Technical Review of the Friction Stir Welding of Metal-to-Polymer Hybrid Structures. Polymers 2022, 15, 220. [Google Scholar] [CrossRef]

- Simões, F.; Rodrigues, D.M. Material flow and thermo-mechanical conditions during Friction Stir Welding of polymers: Literature review, experimental results and empirical analysis. Mater. Des. 2014, 59, 344–351. [Google Scholar] [CrossRef]

- Pereira, M.A.R.; Amaro, A.M.; Reis, P.N.B.; Loureiro, A. Effect of Friction Stir Welding Techniques and Parameters on Polymers Joint Efficiency—A Critical Review. Polymers 2021, 13, 2056. [Google Scholar] [CrossRef]

- Xu, M.; Liu, B.; Zhao, Y.; Wang, Z.; Dong, Z. Direct joining of thermoplastic ABS to aluminium alloy 6061-T6 using friction lap welding. Sci. Technol. Weld. Join. 2020, 25, 391–397. [Google Scholar] [CrossRef]

- Guo, Y.; Zhao, H.; Ai, C.; Zhao, J.; Su, H.; Chen, J.; Zhao, G. Parameter optimization of friction stir spot welded Al 6061 and CFRTP PA6 with surface treatment and interfacial adhesion. Thin-Walled Struct. 2024, 197, 111585. [Google Scholar] [CrossRef]

- Correia, A.N.; Santos, P.A.M.; Braga, D.F.O.; Cipriano, G.P.; Moreira, P.M.G.P.; Infante, V. Effects of processing temperature on failure mechanisms of dissimilar aluminum-to-polymer joints produced by friction stir welding. Eng. Fail. Anal. 2023, 146, 107155. [Google Scholar] [CrossRef]

- Khodabakhshi, F.; Haghshenas, M.; Sahraeinejad, S.; Chen, J.; Shalchi, B.; Li, J.; Gerlich, A.P. Microstructure-property characterization of a friction-stir welded joint between AA5059 aluminum alloy and high density polyethylene. Mater. Charact. 2014, 98, 73–82. [Google Scholar] [CrossRef]

- Khodabakhshi, F.; Haghshenas, M.; Chen, J.; Shalchi Amirkhiz, B.; Li, J.; Gerlich, A.P. Bonding mechanism and interface characterisation during dissimilar friction stir welding of an aluminium/polymer bi-material joint. Sci. Technol. Weld. Join. 2016, 22, 182–190. [Google Scholar] [CrossRef]

- Choi, J.-W.; Morisada, Y.; Liu, H.; Ushioda, K.; Fujii, H.; Nagatsuka, K.; Nakata, K. Dissimilar friction stir welding of pure Ti and carbon fibre reinforced plastic. Sci. Technol. Weld. Join. 2020, 25, 600–608. [Google Scholar] [CrossRef]

- Li, M.; Xiong, X.; Ji, S.; Hu, W.; Yue, Y. Achieving high-quality metal to polymer-matrix composites joint via top-thermic solid-state lap joining. Compos. Part B Eng. 2021, 219, 108941. [Google Scholar] [CrossRef]

- Amancio-Filho, S.T.; Bueno, C.; dos Santos, J.F.; Huber, N.; Hage, E. On the feasibility of friction spot joining in magnesium/fiber-reinforced polymer composite hybrid structures. Mater. Sci. Eng. A 2011, 528, 3841–3848. [Google Scholar] [CrossRef]

- Patel, A.R.; Kotadiya, D.J.; Kapopara, J.M.; Dalwadi, C.G.; Patel, N.P.; Rana, H.G. Investigation of Mechanical Properties for Hybrid Joint of Aluminium to Polymer using Friction Stir Welding (FSW). Mater. Today Proc. 2018, 5, 4242–4249. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, X.; Zhou, L.; Zhao, H.; Han, X.; Tan, C.; Song, X. Achievement of high-strength Al/CFRP hybrid joint via high-speed friction stir lap joining and laser texturing pretreatment parameters variation. Thin-Walled Struct. 2024, 199, 111762. [Google Scholar] [CrossRef]

- Derazkola, H.A.; Kashiry Fard, R.; Khodabakhshi, F. Effects of processing parameters on the characteristics of dissimilar friction-stir-welded joints between AA5058 aluminum alloy and PMMA polymer. Weld. World 2017, 62, 117–130. [Google Scholar] [CrossRef]

- Huang, Y.; Meng, X.; Wang, Y.; Xie, Y.; Zhou, L. Joining of aluminum alloy and polymer via friction stir lap welding. J. Mater. Process. Technol. 2018, 257, 148–154. [Google Scholar] [CrossRef]

- Derazkola, H.A.; Simchi, A. An investigation on the dissimilar friction stir welding of T-joints between AA5754 aluminum alloy and poly (methyl methacrylate). Thin-Walled Struct. 2019, 135, 376–384. [Google Scholar] [CrossRef]

- Nagatsuka, K.; Yoshida, S.; Tsuchiya, A.; Nakata, K. Direct joining of carbon-fiber–reinforced plastic to an aluminum alloy using friction lap joining. Compos. Part B Eng. 2015, 73, 82–88. [Google Scholar] [CrossRef]

- Ogawa, Y.; Akebono, H.; Tanaka, K.; Sugeta, A. Effect of welding time on fatigue properties of friction stir spot welds of Al to carbon fibre-reinforced plastic. Sci. Technol. Weld. Join. 2019, 24, 235–242. [Google Scholar] [CrossRef]

- Correia, A.N.; Braga, D.F.O.; Baptista, R.; Infante, V. Experimental and numerical investigation on failure behaviour of aluminum-polymer friction stir composite joints. Eng. Fail. Anal. 2024, 165, 108805. [Google Scholar] [CrossRef]

- Pinto, L.; Cipriano, G.; Braga, D.F.O.; Vidal, C.; Machado, M.A.; Correia, A.; Infante, V. Mechanical behavior of friction stir butt welded joints under different loading and temperature conditions. Mech. Adv. Mater. Struct. 2022, 31, 1413–1422. [Google Scholar] [CrossRef]

- Guster, C.; Pinter, G.; Mösenbacher, A.; Eichlseder, W. Evaluation of a Simulation Process for Fatigue Life Calculation of Short Fibre Reinforced Plastic Components. Procedia Eng. 2011, 10, 2104–2109. [Google Scholar] [CrossRef]

- Mortazavian, S.; Fatemi, A. Fatigue behavior and modeling of short fiber reinforced polymer composites including anisotropy and temperature effects. Int. J. Fatigue 2015, 77, 12–27. [Google Scholar] [CrossRef]

- Ogawa, Y.; Nakahara, F.; Akebono, H.; Tanaka, K.; Sugeta, A. Effect of jig constraint state during welding process on fatigue properties of Al/CFRP dissimilar welds and fatigue life evaluation based on singular stress. Fatigue Fract. Eng. Mater. Struct. 2020, 43, 2259–2269. [Google Scholar] [CrossRef]

- Maciel, R.; Bento, T.; Braga, D.F.O.; da Silva, L.F.M.; Moreira, P.M.G.P.; Infante, V. Fatigue properties of combined friction stir and adhesively bonded AA6082-T6 overlap joints. Fatigue Fract. Eng. Mater. Struct. 2020, 43, 2169–2180. [Google Scholar] [CrossRef]

- Moreira, P.M.G.P.; Santos, T.; Tavares, S.M.O.; Richter-Trummer, V.; Vilaça, P.; de Castro, P.M.S.T. Mechanical and metallurgical characterization of friction stir welding joints of AA6061-T6 with AA6082-T6. Mater. Des. 2009, 30, 180–187. [Google Scholar] [CrossRef]

- Ahmed, M.M.Z.; El-Sayed Seleman, M.M.; Ahmed, E.; Reyad, H.A.; Touileb, K.; Albaijan, I. Friction Stir Spot Welding of Different Thickness Sheets of Aluminum Alloy AA6082-T6. Matereirals 2022, 15, 2971. [Google Scholar] [CrossRef]

- Ahmed, M.M.Z.; Elnaml, A.; Shazly, M.; El-Sayed Seleman, M.M. The Effect of Top Surface Lubrication on the Friction Stir Welding of Polycarbonate Sheets. Int. Polym. Process. 2021, 36, 94–102. [Google Scholar] [CrossRef]

- Leoni, F.; Sandness, L.; Grong, Ø.; Berto, F. Mechanical behavior of gas metal arc AA6082-T6 weldments. Procedia Struct. Integr. 2019, 18, 449–456. [Google Scholar] [CrossRef]

- Peters, E.N. Poly (phenylene ether) Based Amphiphilic Block Copolymers. Polymers 2017, 9, 433. [Google Scholar] [CrossRef] [PubMed]

- Warren, R.I. Polyphenylene ethers and their alloys. Polym. Eng. Sci. 1985, 25, 477–482. [Google Scholar] [CrossRef]

- Rodriguez-Millan, M.; Garcia-Gonzalez, D.; Rusinek, A.; Arias, A. Influence of Stress State on the Mechanical Impact and Deformation Behaviors of Aluminum Alloys. Metals 2018, 8, 520. [Google Scholar] [CrossRef]

- SABIC Innovative Plastics IP, B.V. Noryl Resin—Modified PPE-PS Americas; SABIC Innovative Plastics IP B.V.: Riyadh, Saudi Arabia, 2007. [Google Scholar]

- Torić, N.; Brnić, J.; Boko, I.; Brčić, M.; Burgess, I.W.; Uzelac, I. Experimental Analysis of the Behaviour of Aluminium Alloy EN 6082AW T6 at High Temperature. Metals 2017, 7, 126. [Google Scholar] [CrossRef]

- Correia, A.N.; Gaspar, B.M.; Cipriano, G.; Braga, D.F.O.; Baptista, R.; Infante, V. Thermo-Mechanical Characterization of Metal-Polymer Friction Stir Composite Joints—A Full Factorial Design of Experiments. Polymers 2024, 16, 602. [Google Scholar] [CrossRef]

- Viana, G.; Costa, M.; Banea, M.D.; da Silva, L.F.M. Moisture and temperature degradation of double cantilever beam adhesive joints. J. Adhes. Sci. Technol. 2017, 31, 1824–1838. [Google Scholar] [CrossRef]

- Vargas-Arista, B.; Cruz-González, C.E.; León-Méndez, I.A.; Guzmán-Flores, I.; Del Llano-Vizcaya, L. Mechanical and Fracture Behavior of Dissimilar Adhesive Joints, Dual Phase Steel/AA6061-T6, at Extreme Temperature. J. Mater. Eng. Perform. 2023, 32, 11275–11284. [Google Scholar] [CrossRef]

- Mura, A.; Ricci, A.; Canavese, G. Investigation of Fatigue Behavior of ABS and PC-ABS Polymers at Different Temperatures. Materials 2018, 11, 1818. [Google Scholar] [CrossRef]

- Eslami, S.; Farahani, B.V.; Tavares, P.J.; Moreira, P.M.G.P. Fatigue behaviour evaluation of dissimilar polymer joints: Friction stir welded, single and double-rivets. Int. J. Fatigue 2018, 113, 351–358. [Google Scholar] [CrossRef]

- Plaine, A.H.; Suhuddin, U.F.H.; Alcântara, N.G.; dos Santos, J.F. Fatigue behavior of friction spot welds in lap shear specimens of AA5754 and Ti6Al4V alloys. Int. J. Fatigue 2016, 91, 149–157. [Google Scholar] [CrossRef]

- Freire Júnior, R.C.S.; Belísio, A.S. Probabilistic S–N curves using exponential and power laws equations. Compos. Part B Eng. 2014, 56, 582–590. [Google Scholar] [CrossRef]

- Barbosa, J.F.; Correia, J.A.F.O.; Júnior, R.C.S.F.; Jesus, A.M.P.D. Fatigue life prediction of metallic materials considering mean stress effects by means of an artificial neural network. Int. J. Fatigue 2020, 135, 105527. [Google Scholar] [CrossRef]

- Braga, D.F.O.; Maciel, R.; Bergmann, L.; da Silva, L.F.M.; Infante, V.; dos Santos, J.F.; Moreira, P.M.G.P. Fatigue performance of hybrid overlap friction stir welding and adhesive bonding of an Al-Mg-Cu alloy. Fatigue Fract. Eng. Mater. Struct. 2018, 42, 1262–1270. [Google Scholar] [CrossRef]

- Enrique Castillo, A.F.-C. A Unified Statistical Methodology for Modeling Fatigue Damage; Springer: Dordrecht, The Netherlands, 2009. [Google Scholar] [CrossRef]

- Fernández-Canteli, A.; Przybilla, C.; Nogal, M.; Aenlle, M.L.; Castillo, E. ProFatigue: A Software Program for Probabilistic Assessment of Experimental Fatigue Data Sets. Procedia Eng. 2014, 74, 236–241. [Google Scholar] [CrossRef]

- Wei, G.X.; Sue, H.J.; Chu, J.; Huang, C.; Gong, K. Toughening and strengthening of polypropylene using the rigid–rigid polymer toughening concept Part I. Morphology and mechanical property investigations. Polymer 2000, 41, 2947–2960. [Google Scholar] [CrossRef]

- Chawla, K.K. Composite Materials—Science and Engineering, 4th ed.; Springer: Cham, The Netherlands, 2019. [Google Scholar] [CrossRef]

- Crawford, R.J.; Martin, P.J. Plastics Engineering, 4th ed.; Elsevier: Kidlington, UK, 2020. [Google Scholar] [CrossRef]

- Stack, S.; O’Donoghue, O.; Birkinshaw, C. The thermal stability and thermal degradation of blends of syndiotactic polystyrene and polyphenylene ether. Polym. Degrad. Stab. 2003, 79, 29–36. [Google Scholar] [CrossRef]

| Base Materials | Joint Configuration | Joint Strength (MPa) | Reference |

|---|---|---|---|

| AA7075, GFR * PEEK | Lap Joint | ~60 | [16] |

| AZ31, GFR */CFR ** PPS | Lap Joint | ~28 | [17] |

| AA6061, PC | Butt Joint | ~15 | [18] |

| AA6061, CFR ** PA66 | Lap Joint | ~25 | [19] |

| AA5058, PMMA | Lap Joint | ~46 | [20] |

| AA6061, PEEK | Lap Joint | ~20 | [21] |

| AA5059, HDPE | Butt Joint | ~10 | [13] |

| AA5754, PMMA | T Joint | ~50 | [22] |

| AA5052, CFR ** PA6 | Lap Joint | ~64 *** | [23] |

| AA5182, CFR ** PP | Lap Joint | ~47 *** | [24] |

| AA6082, Noryl® GFN2 | Lap Joint | ~70 | [25] |

| Cr (%) | Fe (%) | Mg (%) | Mn (%) | Si (%) | Ti (%) | Zn (%) | Cu (%) | Al (%) |

|---|---|---|---|---|---|---|---|---|

| ≤0.10 | 0.20–0.21 | 0.63–0.64 | 0.47–0.48 | 0.97–1.00 | ≤0.10 | ≤0.10 | ≤0.10 | Balance |

| Dwell Time (s) | (RPM) | v (mm/s) | (°) | Pin Length (mm) | Plunge Depth (mm) |

|---|---|---|---|---|---|

| 15 | 1000 | 2.33 | 2 | 2 | 2.2 |

| Temperature (°C) | A | b | R2 |

|---|---|---|---|

| 23 | 68.383 | −0.181 | 0.980 |

| 75 | 68.096 | −0.204 | 0.971 |

| 130 | 34.042 | −0.162 | 0.916 |

| Temperature (°C) | B | C | |||

|---|---|---|---|---|---|

| 23 | 5.19 | 4.12 | 11.72 | 0 (1 cycle) | 0.76 (2.13 MPa) |

| 75 | 3.18 | 2.78 | 16.03 | 0 (1 cycle) | 0.27 (1.31 MPa) |

| 130 | 2.46 | 5.62 | 0.30 | 2.46 (11 cycles) | 1.11 (3.05 MPa) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Correia, A.N.; Coelho, R.J.; Braga, D.F.O.; Guedes, M.; Baptista, R.; Infante, V. Effect of Service Temperature on the Mechanical and Fatigue Behaviour of Metal–Polymer Friction Stir Composite Joints. Polymers 2025, 17, 1366. https://doi.org/10.3390/polym17101366

Correia AN, Coelho RJ, Braga DFO, Guedes M, Baptista R, Infante V. Effect of Service Temperature on the Mechanical and Fatigue Behaviour of Metal–Polymer Friction Stir Composite Joints. Polymers. 2025; 17(10):1366. https://doi.org/10.3390/polym17101366

Chicago/Turabian StyleCorreia, Arménio N., Rodrigo J. Coelho, Daniel F. O. Braga, Mafalda Guedes, Ricardo Baptista, and Virgínia Infante. 2025. "Effect of Service Temperature on the Mechanical and Fatigue Behaviour of Metal–Polymer Friction Stir Composite Joints" Polymers 17, no. 10: 1366. https://doi.org/10.3390/polym17101366

APA StyleCorreia, A. N., Coelho, R. J., Braga, D. F. O., Guedes, M., Baptista, R., & Infante, V. (2025). Effect of Service Temperature on the Mechanical and Fatigue Behaviour of Metal–Polymer Friction Stir Composite Joints. Polymers, 17(10), 1366. https://doi.org/10.3390/polym17101366