Permeable Properties of Hygienic Nonwovens Bonded Using Mechanical, Chemical, and Thermal Techniques

Abstract

1. Introduction

1.1. Hygiene Nonwovens

1.2. Technology Process of Web Bonding of Hygiene Nonwovens

- mechanical process (needling, felting, water jet, and quilting),

- chemical process (impregnation, printing, or spraying with binder-glue),

- thermal process (melting of the binder fibre coating),

- combined processes.

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Breaking Stress and Elongation

2.2.2. Air Permeability

2.2.3. Thermal Conductivity

2.2.4. Porosity

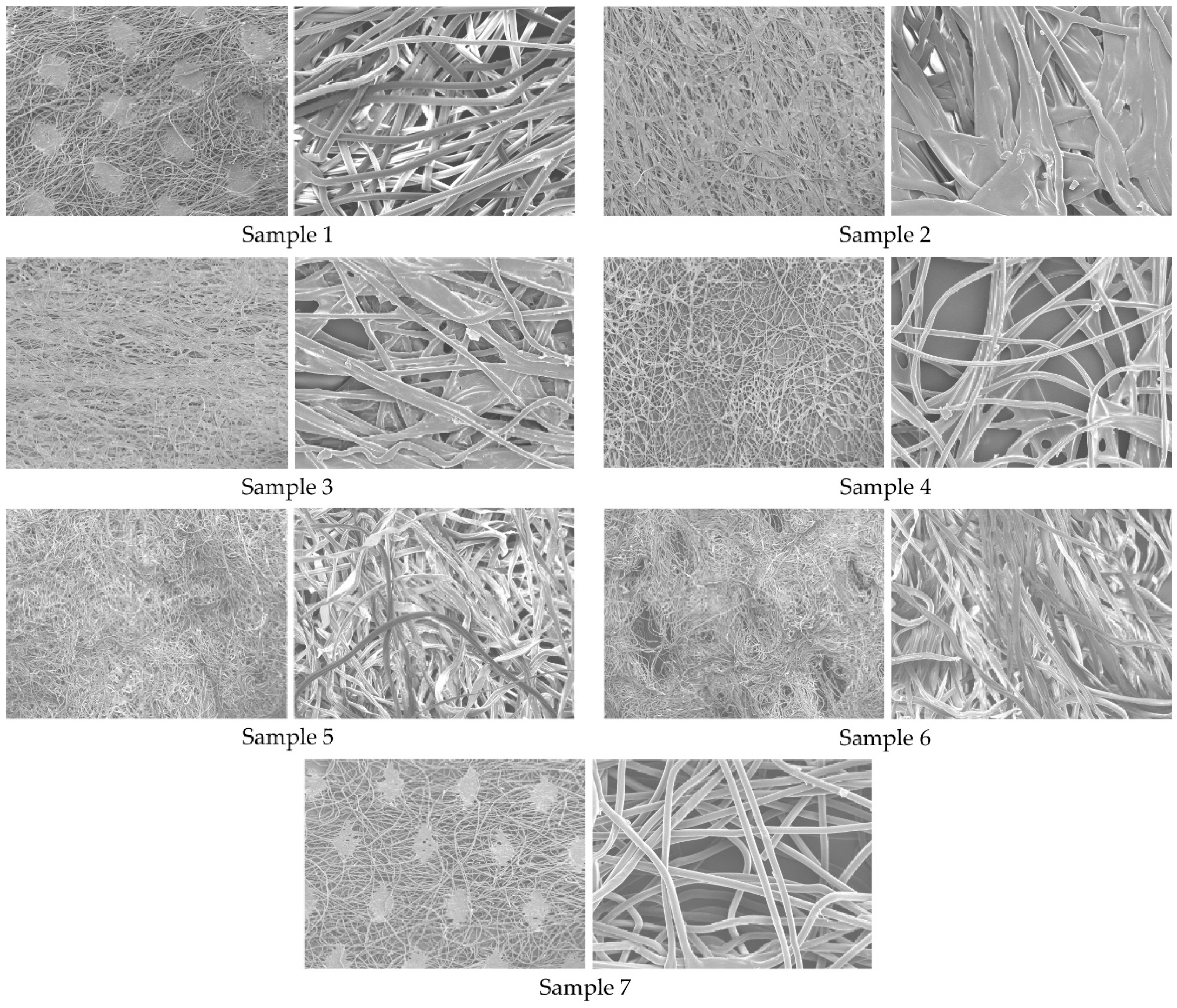

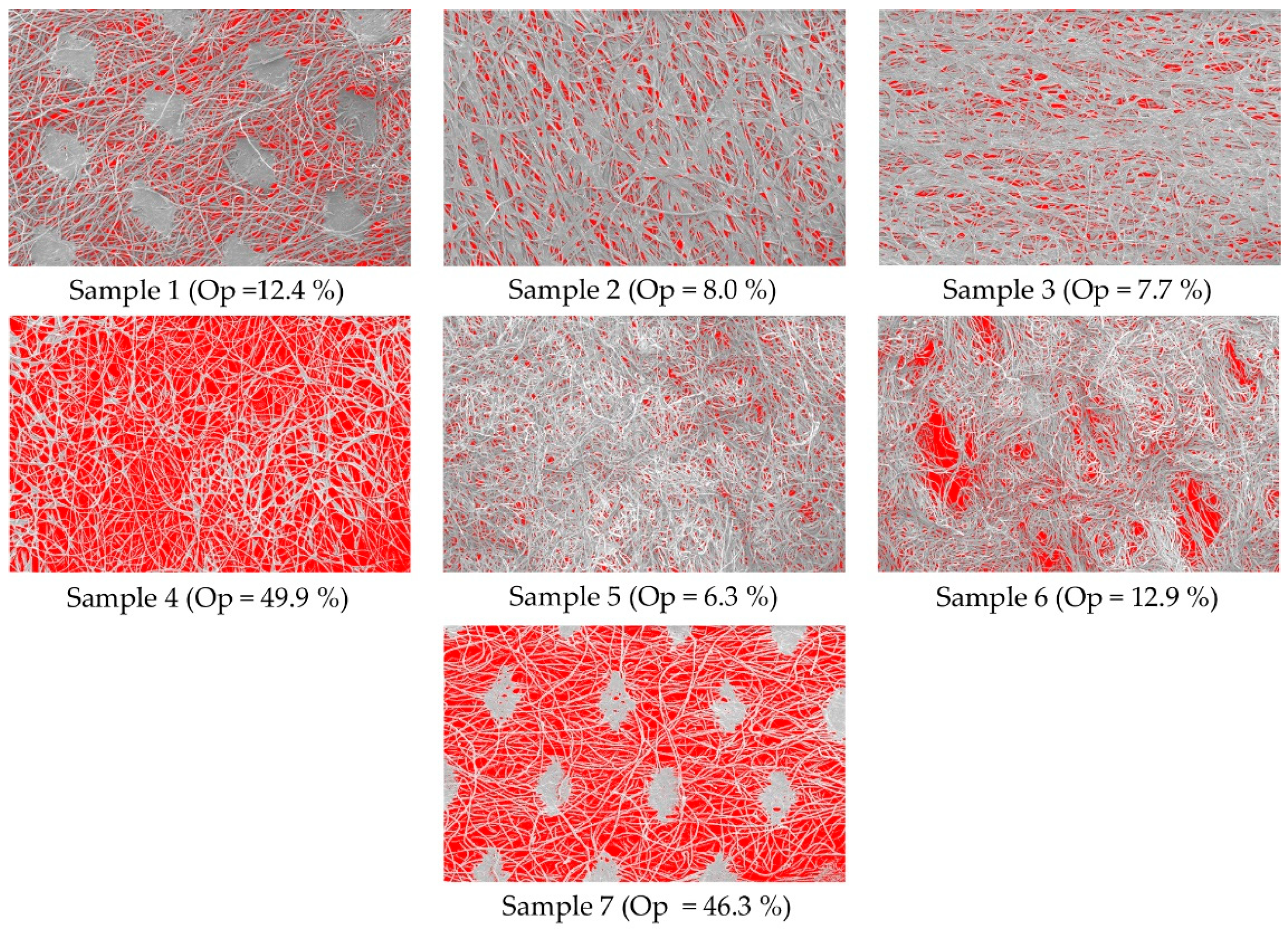

2.2.5. Surface Openness Using Image Analysis

2.2.6. Statistical Analysis

3. Results and Discussion

3.1. Results and Discussion of Breaking Stress and Elongation

3.2. Results and Discussion of Air Permeability

3.3. Results and Discussion of Thermal Conductivity

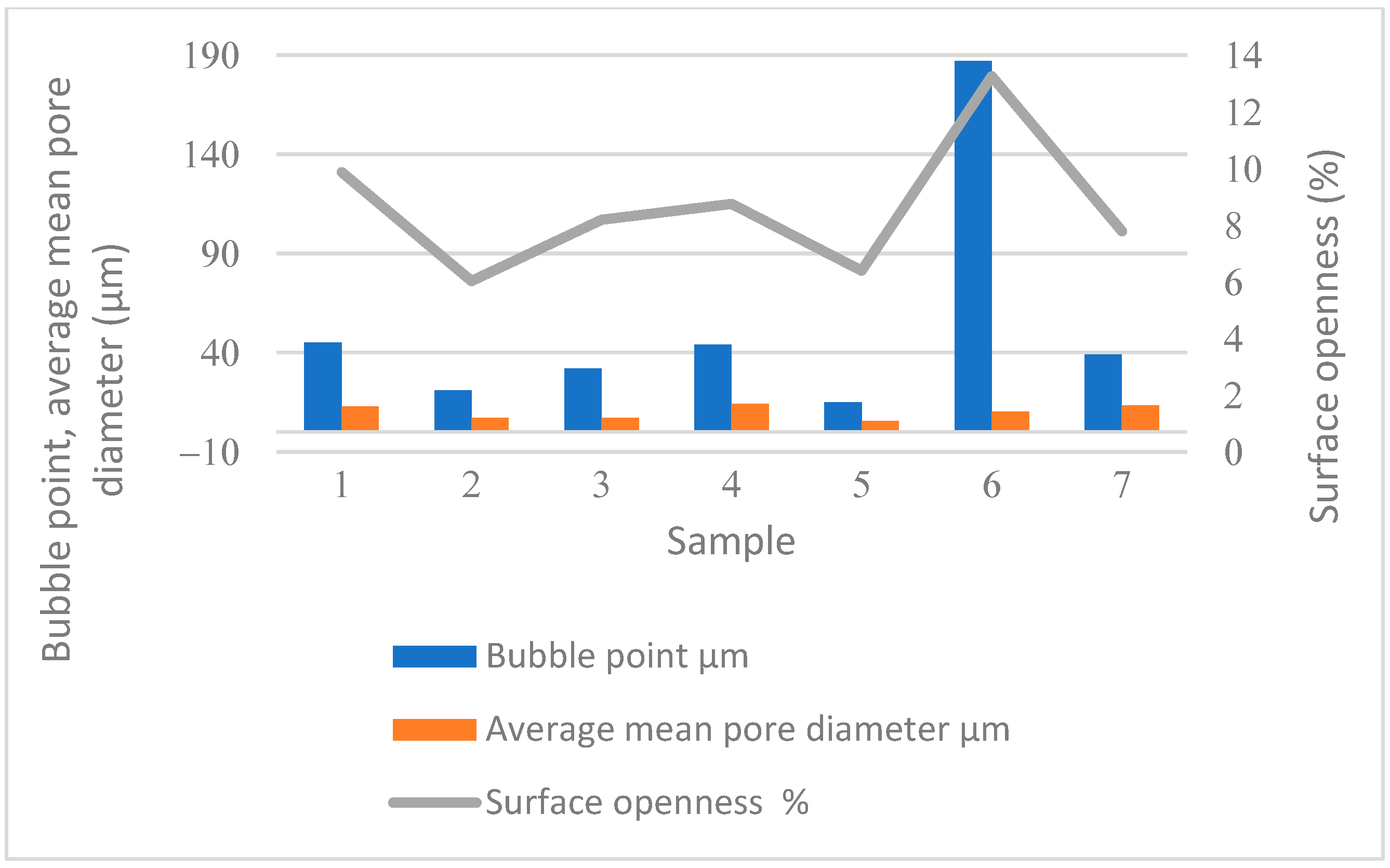

3.4. Results and Discussion of Surface Openness

3.5. Results and Discussion of Porosity

3.6. Results and Discussion of Statistical Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Albrecht, W.; Fuchs, H.; Kittelmann, W. Nonwoven Fabrics: Raw Materials, Manufacture, Applications, Characteristics, Testing Processes; John Wiley & Sons: Weinheim, Germany, 2006; pp. 1–11. [Google Scholar]

- Kumar Singh, M. Engineered Fabrics; IntechOpen: London, UK, 2019; p. 8. [Google Scholar]

- Lu, H.; Lin, M.; Li, T.; Zhang, H.; Feng, L.; Zhang, C. Polyimide (PI) Composite Spunlace Nonwovens for Hygiene Material with Excellent Comfort and Antimicrobial Properties. Processes 2024, 12, 354. [Google Scholar] [CrossRef]

- Venkataraman, D.; Shabani, E.; Park, J.H. Advancement of Nonwoven Fabrics in Personal Protective Equipment. Materials 2023, 16, 3964. [Google Scholar] [CrossRef]

- Korkmaz, G.; Kılınç, M.; Razak, S.A.; Ocak, M.; Korkmaz, S.; Kut, Y.D.T. Comparison of the performance properties of spunlaid non-woven fabrics used as face mask. J. Text. Inst. 2023, 114, 250–256. [Google Scholar] [CrossRef]

- Somogyi Škoc, M.; Stevelić, N.; Rezić, I. Development and Characterization of Sustainable Coatings on Cellulose Fabric and Nonwoven for Medical Applications. Sustainability 2024, 16, 857. [Google Scholar] [CrossRef]

- Srisuk, T.; Charoenlarp, K.; Kampeerapappun, P. Utilization of Waste Natural Fibers Mixed with Polylactic Acid (PLA) Bicomponent Fiber: Incorporating Kapok and Cattail Fibers for Nonwoven Medical Textile Applications. Polymers 2024, 16, 76. [Google Scholar] [CrossRef]

- Torsten Bartels, V. Handbook of Medical Textiles; Elsevier Science: Manchester, UK, 2011; pp. 1–124. [Google Scholar]

- Sau-Fun, N.; Chi-Leung, H.; Lai-Fan, W. Development of Medical Garments and Apparel for the Elderly and the Disabled; CRC Press: Boca Raton, FL, USA, 2020; pp. 1–58. [Google Scholar]

- Dhiman, R.; Chattopadhyay, R. Absorbency of synthetic urine by cotton nonwoven fabric. J. Text. Inst. 2021, 112, 996–1003. [Google Scholar] [CrossRef]

- Liu, H.; Feng, Y.; Qian, X. Preparation and properties of eccentric hollow fiber nonwovens for acquisition distribution layer. J. Eng. Fibers Fabr. 2019, 14, 1–8. [Google Scholar] [CrossRef]

- Santos, A.S.; Ferreira, P.J.T.; Maloney, T. Bio-based materials for nonwovens. Cellulose 2021, 28, 8939–8969. [Google Scholar] [CrossRef]

- Mohammed, H.; Sukumar, N. Water Penetration and Abrasion Resistance of Functional Nonwoven Fabrics Produced Using Recycled Cotton and Acrylic Fibers. J. Nat. Fibers 2022, 19, 10001–10014. [Google Scholar] [CrossRef]

- Uzun, M.; Anand, S.C.; Shah, T. A novel approach for designing nonwoven hybrid wound dressings: Processing and characterisation. J. Ind. Text. 2016, 45, 1383–1398. [Google Scholar] [CrossRef]

- Hinchliffe, D.J.; Lucca, A.D.; Condon, B.; O’Regan, J.; Clemmons, J.; Zeng, L.; Byler, R.K.; Reynolds, M.; Allen, H.; Cintron, M.S.; et al. A pilot-scale nonwoven roll goods manufacturing process reduces microbial burden to pharmacopeia acceptance levels for non-sterile hygiene applications. Text. Res. J. 2014, 84, 546–558. [Google Scholar] [CrossRef]

- Zhao, Y.; Chen, R.; Ni, R.; Liu, H.; Li, J.; Huang, C. Fabrication and characterization of a novel facial mask substrates based on thermoplastic polyester elastomer fibers. J. Text. Inst. 2020, 111, 1231–1237. [Google Scholar] [CrossRef]

- Kellie, G. Advances in Technical Nonwovens; Elsevier Science: Manchester, UK, 2011; pp. 477–481. [Google Scholar]

- Peng, F.; Ma, W.; Zhang, Y.; Chen, Y.; Qi, H.; Zhang, C. Fabrication of laminated composite filter with nonwoven fabrics for oil/water separation. J. Text. Inst. 2023, 114, 834–842. [Google Scholar] [CrossRef]

- Zhang, X.; Li, T.T.; Sun, F.; Peng, H.K.; Wang, Z.; Lin, J.H.; Lou, C.W. Stab/Puncture Resistance Performance of Needle Punched Nonwoven Fabrics: Effects of Filament Reinforcement and Thermal Bonding. Fibers Polym. 2022, 23, 2330–2339. [Google Scholar] [CrossRef]

- Kwon, S.; Zambrano, M.C.; Venditti, R.A.; Frazier, R.; Zambrano, F.; Gonzalez, R.W.; Pawlak, J.J. Microfiber shedding from nonwoven materials including wipes and meltblown nonwovens in air and water environments. Environ. Sci. Pollut. Res. 2022, 29, 60584–60599. [Google Scholar] [CrossRef]

- Chao, D.; Wanjun, L.; Yinjiang, Z.; Chen, H.; Zhao, Y.; Xiangyu, J. Environmentally friendly and breathable wet-laid hydroentangled nonwovens for personal hygiene care with excellent water absorbency and flushability. R. Soc. Open Sci. 2018, 5, 171486. [Google Scholar]

- ISO 9073; Textiles—Test Methods for Nonwovens (Part 1 and Part 2). ISO: Geneva, Switzerland, 1995.

- ISO 13934-1; Textiles—Tensile Properties of Fabrics—Part 1: Determination of Maximum Force and Elongation at Maximum Force Using the Strip Method. ISO: Geneva, Switzerland, 2013.

- Gültekin, E.; Çelik, H.I.; Nohut, S.; Elma, S.K. Predicting air permeability and porosity of nonwovens with image processing and artificial intelligence methods. J. Text. Inst. 2020, 111, 1641–1651. [Google Scholar] [CrossRef]

- Yesil, Y.; Bhat, G.S. Porosity and barrier properties of polyethylene meltblown nonwovens. J. Text. Inst. 2017, 108, 1035–1040. [Google Scholar] [CrossRef]

- Pradhan, A.K.; Das, D.; Chattopadhyay, R.; Singh, S.N. Studies on air permeability of multi-constituent nonwovens. J. Text. Inst. 2017, 108, 788–793. [Google Scholar] [CrossRef]

- Habibi, M.; Ruiz, É.; Lebrun, G.; Laperrière, L. Effect of surface density and fiber length on the porosity and permeability of nonwoven flax reinforcement. Text. Res. J. 2018, 88, 1776–1787. [Google Scholar] [CrossRef]

- ISO 9237; Textiles—Determination of the Permeability of Fabrics to Air. ISO: Geneva, Switzerland, 1995.

- DIN 52 612; Testing of Thermal Insulating Materials; Determination of Thermal Conductivity by the Guarded Hot Plate Apparatus; Test Procedure and Evaluation. DIN: Berlin, Germany, 1979.

- Mohammed, H.; Sukumar, N.; Seyoum, B. Thermal Conductivity & Tensile Properties of Stitch Bonded Nonwoven Fabric Developed Using Reclaimed Cotton and Virgin Acrylic Blend. J. Nat. Fibers 2022, 19, 4188–4197. [Google Scholar]

- Dupade, V.; Kumari, R.; Premachandran, B.; Rengasamy, R.S.; Talukdar, P. Effect of layering sequence and ambient temperature on thermal insulation of multilayer high bulk nonwoven under extreme cold temperatures. J. Ind. Text. 2022, 51, 2709S–2730S. [Google Scholar] [CrossRef]

- Wazna, M.E.; Gounni, A.; Bouari, A.E.; Alami, M.E.; Cherkaoui, O. Development, characterization and thermal performance of insulating nonwoven fabrics made from textile waste. J. Ind. Text. 2019, 48, 1167–1183. [Google Scholar] [CrossRef]

- Gnanauthayan, G.; Rengasamy, R.S.; Kothari, V.K. Heat insulation characteristics of high bulk nonwovens. J. Text. Inst. 2017, 108, 2173–2179. [Google Scholar] [CrossRef]

- Jahanzeb, S.; Siddique, S.H.; Hussain, D. Porosity and Fiber Orientation of Banana Fiber Nonwoven Webs Using Image Analysis Technique. J. Nat. Fibers 2022, 19, 6056–6073. [Google Scholar] [CrossRef]

- Liu, X.; Yan, X.; Zhang, H. Effects of pore structure on sound absorption of kapok-based fiber nonwoven fabrics at low frequency. Text. Res. J. 2016, 86, 755–764. [Google Scholar] [CrossRef]

- Jaksic, D.; Jaksic, N. Assessment of Porosity of Flat Textile Fabrics. Text. Res. J. 2007, 77, 105–111. [Google Scholar] [CrossRef]

- Bhuiyan, M.R.; Wang, L.; Shaid, A.; Jahan, I.; Shanks, R.A. Silica aerogel-integrated nonwoven protective fabrics for chemical and thermal protection and thermophysiological wear comfort. J. Mater. Sci. 2020, 55, 2405–2418. [Google Scholar] [CrossRef]

- Karthik, T.; Prabha Karan, C.R. Rathinamoorthy. In Nonwovens: Process, Structure, Properties and Applications; Woodhead Publishing Limited: New Delhi, India, 2016; pp. 34–156. [Google Scholar]

- Horrocks, A.R.; Subhash, C.A. Handbook of Technical Textiles: Technical Textile Applications; Woodhead Publishing Limited: Cambridge, UK, 2016; pp. 27–281. [Google Scholar]

- Gopalakrishnan, D. Technical Textiles; DAYA Publishing House: New Delhi, India, 2019; pp. 110–111. [Google Scholar]

- Nagla, J.R. Statistics for Textile Engineers, 1st ed.; Woodhead Publishing Limited: New Delhi, India, 2014; pp. 5–90. [Google Scholar]

| Sample | Web Bonding | Raw Material Composition | Nominal Mass (g/m2) |

|---|---|---|---|

| 1. | Thermal process | 70% polypropylene, 15% viscose, 15% cotton | 30 |

| 2. | Chemical process | 100% polypropylene | 70 |

| 3. | Chemical process | 100% polypropylene | 50 |

| 4. | Chemical process | 100% viscose | 25 |

| 5. | Mechanical process | 100% cotton | 120 |

| 6. | Mechanical process | 100% cotton | 35 |

| 7. | Thermal process | 100% polypropylene | 40 |

| Sample | Diameter of Fibres (µm) | Thickness (mm) | Mass (g/m2) |

|---|---|---|---|

| 1. | 17.2 | 0.27 | 30.9 |

| 2. | 13.3 | 0.20 | 74.2 |

| 3. | 12.8 | 0.09 | 49.8 |

| 4. | 13.7 | 0.17 | 26.8 |

| 5. | 14.5 | 0.98 | 110.2 |

| 6. | 15.7 | 0.27 | 41.3 |

| 7. | 17.9 | 0.34 | 39.2 |

| Sample | Breaking Elongation, ε (%) | Breaking Stress, σ (N/mm2) | ||

|---|---|---|---|---|

| Longitudinal | CV [%] | Longitudinal | CV [%] | |

| 1. | 21.54 | 9.871 | 3.098 | 12.951 |

| 2. | 15.85 | 8.137 | 37.922 | 9.631 |

| 3. | 11.56 | 9.068 | 50.817 | 8.069 |

| 4. | 9.86 | 7.350 | 4.618 | 9.046 |

| 5. | 33.23 | 7.723 | 0.519 | 10.529 |

| 6. | 27.44 | 8.950 | 1.448 | 13.250 |

| 7. | 65.71 | 3.355 | 4.818 | 6.605 |

| Sample | Air Permeability Q [m3m−2min−1] | ||

|---|---|---|---|

| Q [m3m−2min−1] | Sx [m3m−2min−1] | CV [%] | |

| 1. | 56.75 | 2.34 | 4.12 |

| 2. | 15.45 | 0.62 | 3.98 |

| 3. | 15.10 | 1.63 | 10.76 |

| 4. | 112.9 | 16.61 | 14.71 |

| 5. | 12.11 | 1.18 | 9.74 |

| 6. | 30.75 | 2.03 | 6.60 |

| 7. | 47.45 | 1.63 | 3.45 |

| Sample | Thermal Conductivity λ [Wm−1K−1] | ||

|---|---|---|---|

| λ [Wm−1K−1] | Sx [Wm−1K−1] | CV [%] | |

| 1. | 0.0634 | 0.00032 | 0.507 |

| 2. | 0.0643 | 0.0028 | 4.367 |

| 3. | 0.0573 | 0.00023 | 0.410 |

| 4. | 0.0635 | 0.0010 | 1.576 |

| 5. | 0.0804 | 0.0010 | 1.244 |

| 6. | 0.0749 | 0.0018 | 2.400 |

| 7. | 0.0607 | 0.0021 | 3.502 |

| Sample | Maximum Mean Pore Diameter Dsmax (μm) | Minimal Mean Pore Diameter Dsmin (μm) | Average Mean Pore Diameter DSavg (μm) | Maximum Pore Diameter —Bubble Point Dmax (μm) |

|---|---|---|---|---|

| 1. | 15.15 | 10.78 | 12.55 | 45 |

| 2. | 7.44 | 6.68 | 7.00 | 21 |

| 3. | 7.69 | 6.47 | 7.22 | 32 |

| 4. | 15.84 | 12.41 | 14.41 | 44 |

| 5. | 6.00 | 5.32 | 5.61 | 15 |

| 6. | 12.23 | 8.27 | 9.18 | 187 |

| 7. | 14.93 | 11.95 | 13.56 | 39 |

| Variables | ** | Observ. | Min. | Max. | Mean | Std. |

|---|---|---|---|---|---|---|

| Average mean pore diameter (µm) | APd | 14 | 5.660 | 14.120 | 10.083 | 3.366 |

| Bubble point (μm) | BP | 14 | 15.000 | 187.000 | 54.714 | 57.090 |

| Breaking stress (N/mm2) | BS | 14 | 0.519 | 50.817 | 14.749 | 19.823 |

| Breaking elongation (%) | BE | 14 | 9.860 | 65.710 | 26.456 | 18.488 |

| Air permeability (m3m−2min−1) | AP | 14 | 12.110 | 112.900 | 41.500 | 35.870 |

| Thermal conductivity (Wm−1K−1) | TC | 14 | 0.057 | 0.080 | 0.066 | 0.008 |

| Diameter of fibres (µm) | Df | 14 | 12.800 | 17.900 | 15.014 | 1.898 |

| Thickness (mm) | T | 14 | 0.090 | 0.980 | 0.331 | 0.286 |

| Mass (g/m2) | M | 14 | 26.800 | 110.200 | 53.200 | 28.375 |

| Surface openness (%) | Op | 14 | 6.270 | 49.870 | 20.497 | 18.278 |

| ANOVA for Breaking Stress Results | ||||||

| Source of Variation | SS | df | MS | F | p-Value | F-Crit |

| Between Groups (technology of bonding technique) | 3309.4 | 2 | 1654.7 | 10.8 | 0.0012 | 3.68 |

| Within groups | 2278.9 | 15 | 151.9 | |||

| ANOVA for Breaking Elongation Results | ||||||

| Source of Variation | SS | df | MS | F | p-Value | F-Crit |

| Between Groups (technology of bonding technique) | 2941.9 | 2 | 471.0 | 7.3 | 0.01 | 3.68 |

| Within groups | 3014.8 | 15 | 200.9 | |||

| ANOVA for Air Permeability Results | ||||||

| Source of Variation | SS | df | MS | F | p-Value | F-Crit |

| Between Groups (technology of bonding technique) | 1544.1 | 2 | 1544.1 | 1.86 | 0.19 | 4.75 |

| Within groups | 9892.4 | 15 | 824.4 | |||

| ANOVA for Thermal Conductivity Results | ||||||

| Source of Variation | SS | df | MS | F | p-Value | F-Crit |

| Between Groups (technology of bonding technique) | 0.00099 | 2 | 0.00049 | 64.92458 | 4.11 × 10−8 | 3.68 |

| Within groups | 0.00015 | 15 | 7.67 × 10−6 | |||

| ANOVA for Porosity (Average Mean Pore Diameter) Results | ||||||

| Source of Variation | SS | df | MS | F | p-Value | F-Crit |

| Between Groups (technology of bonding technique) | 88.07 | 2.00 | 44.03 | 6.73 | 0.01 | 3.68 |

| Within groups | 98.20 | 15.00 | 6.55 | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Šajn Gorjanc, D.; Kostajnšek, K. Permeable Properties of Hygienic Nonwovens Bonded Using Mechanical, Chemical, and Thermal Techniques. Polymers 2024, 16, 1132. https://doi.org/10.3390/polym16081132

Šajn Gorjanc D, Kostajnšek K. Permeable Properties of Hygienic Nonwovens Bonded Using Mechanical, Chemical, and Thermal Techniques. Polymers. 2024; 16(8):1132. https://doi.org/10.3390/polym16081132

Chicago/Turabian StyleŠajn Gorjanc, Dunja, and Klara Kostajnšek. 2024. "Permeable Properties of Hygienic Nonwovens Bonded Using Mechanical, Chemical, and Thermal Techniques" Polymers 16, no. 8: 1132. https://doi.org/10.3390/polym16081132

APA StyleŠajn Gorjanc, D., & Kostajnšek, K. (2024). Permeable Properties of Hygienic Nonwovens Bonded Using Mechanical, Chemical, and Thermal Techniques. Polymers, 16(8), 1132. https://doi.org/10.3390/polym16081132