Evaluation of the Viability of 3D Printing in Recycling Polymers

Abstract

1. Introduction

- To find, in detail, the methods and parameters and other aspects (types of polymer materials) used for recycling through 3D printing.

- To investigate the benefits and limitations of using 3D printing for recycling/re-production.

- To identify future directions regarding using 3D printing for recycling/re-production.

- To investigate beneficial applications, especially in low recycling categories like agricultural plastics.

2. Risks of Recycling Polymers Using 3D Printing

3. Systematic Review and Analysis

3.1. Literature Search Process

3.2. An Overview of the Research Methods Used in the 39 Studies

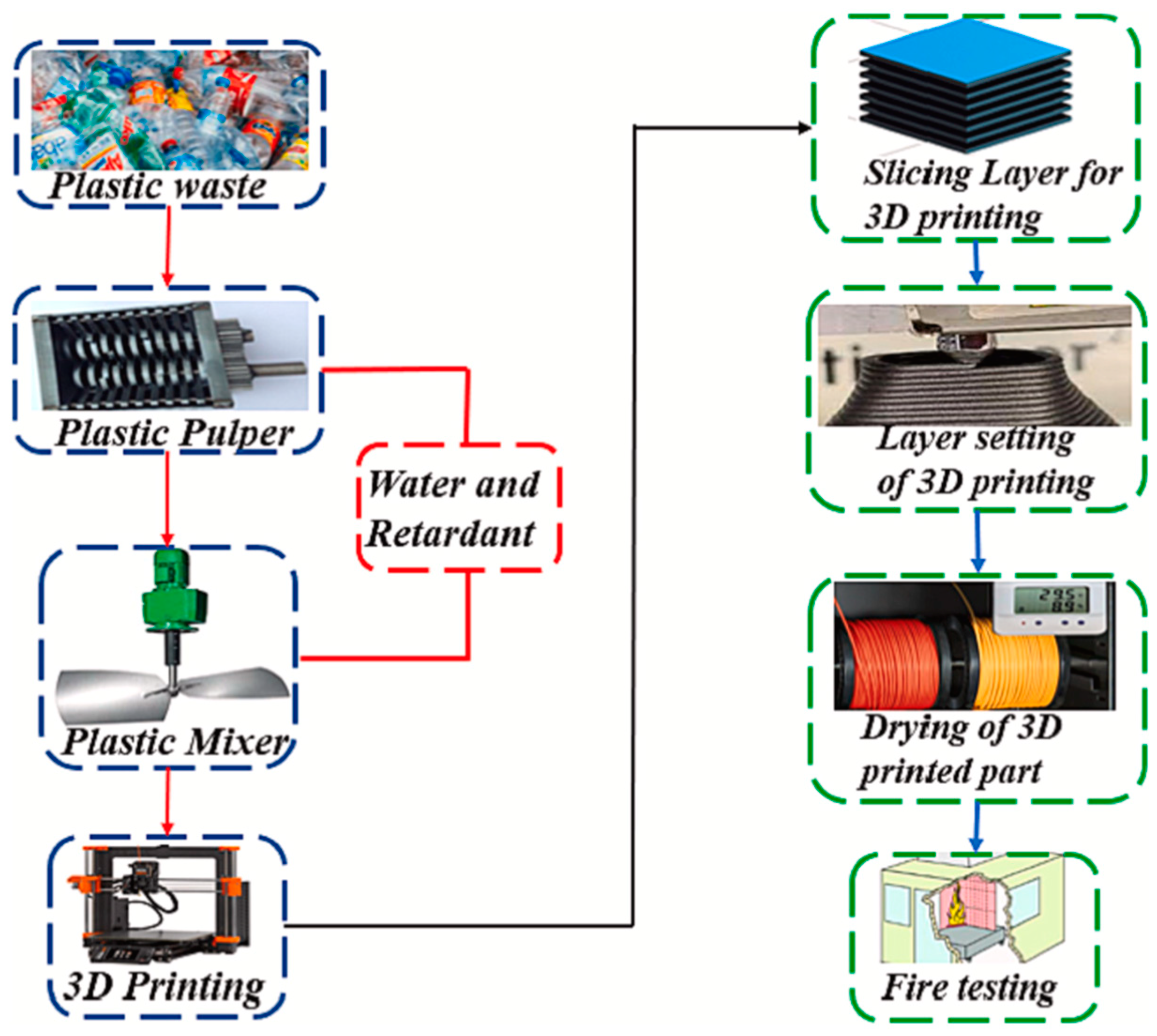

3.3. Methods of Recycling Polymers to Make 3D Printing Materials

3.4. Recycling Plastics for 3D Printing

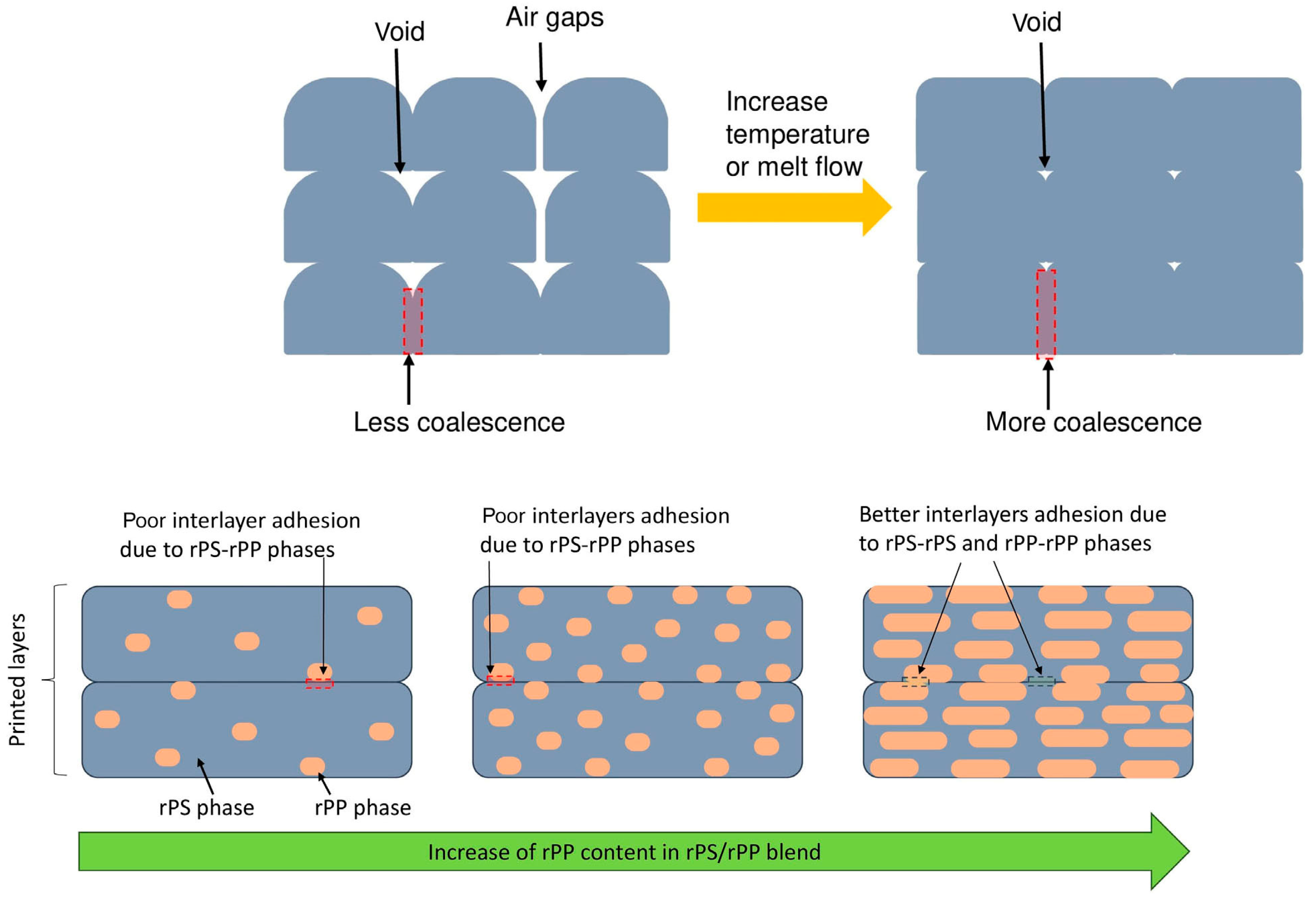

3.5. Recycled 3D Printing Materials and Their Properties

3.6. Challenges of Recycling 3D Printed Plastic Wastes

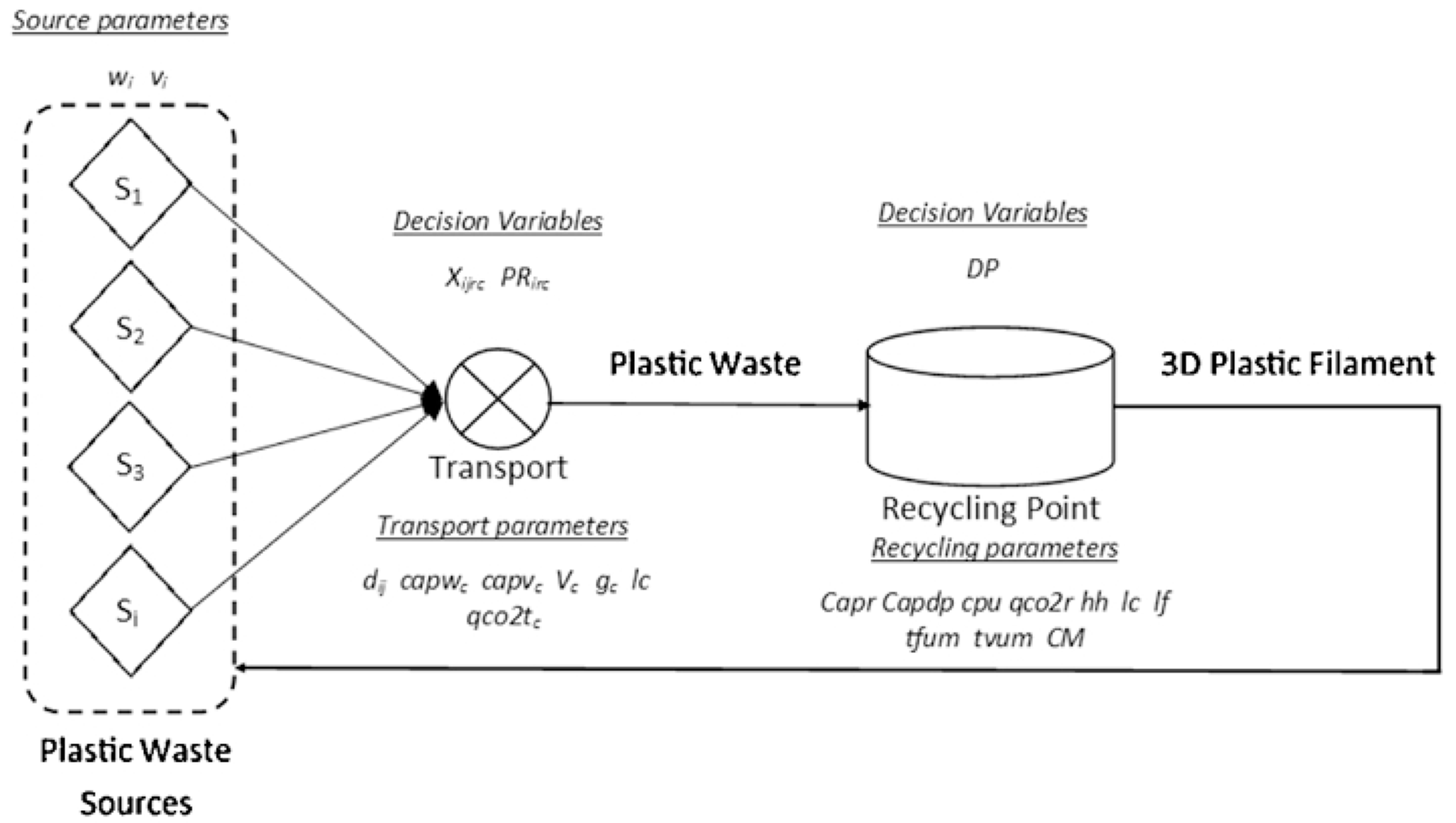

3.7. Local and Distributed Recycling and their Environmental and Economic Sustainability

3.8. Application of 3D Printing in Agriculture

3.9. Future Directions and Further Research in the Use of 3D Printing for Recycling Plastics

4. Discussion

4.1. 3D Printing as a Plastic Recycling Method and Its Advantages and Limitations

4.2. 3D Printing in Agriculture

4.3. Future Directions in the Use of 3D Printing for Recycling Plastics Concerning Lifecycle

4.4. Limitations

4.5. Recommendations

5. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A. Literature Matrix

| Source | Nature of the Study/Methodology | Materials | Results | Relevance |

|---|---|---|---|---|

| [72] | A quantitative study with an experimental design. | PLA, ABS, PET, and PP | 3D printed polymers are vulnerable to defects, including fiber misalignment and breakage. A weak fiber and matrix interface with uneven pressure during extrusion results in misalignment that has been found to lead to porosity. Angles of curvature exceeding 120 degrees and a turn radius of less than 5 mm account for ease of breakage of 3D printed polymer filaments. The inner periphery also develops lines of weakness with a decline in the radius of curvature and an increase in angle of curvature. | The study demonstrates the defects likely to occur in recycled 3D printing polymers. |

| [73] | A quantitative study with an experimental design. | PLA | The radius of curvature decreases as the material is heated at gradually increasing temperatures. ABS and PLA exhibit the properties at temperatures of about 125 degrees centigrade. Therefore, the 3D printed recycled polymers cannot be curved at bigger radius because they are likely to fail or break. | The findings of the study contribute to an understanding of the nature of defects and limitations likely to occur in the use of 3D printing materials. Also, Mendenhall and Eslami (2023) provided in-depth insights into the expected mechanical properties of ABS and PLA filaments made from respective polymer wastes. |

| [83] | A quantitative study with an experimental design. | ABS, PLA, PET, and PP | Horizontally printed polymers have higher compressive strength and compressive modulus. A high compressive modulus of about 1.8 GPa is achieved for 3D printed material with equidistant fiber reinforcement. For horizontal 3D printed polymers, the compressive modulus increases by 11.64%, while the compressive strength increases by 12.80%. A higher polymer volume in the 3D printed material predicts higher compressive modulus and compressive strength, which are desirable mechanical properties for materials for tough applications. | The study provides a strategic approach to strengthening recycled 3D printing materials. The study therefor fosters an understanding of the different approaches by which polymer wastes can be used despite being linked to particular defects. |

| [77] | A quantitative study with an experimental design. | ABS | Electronic waste plastics mainly polycarbonates were transformed into 3D printing filaments. The materials had 76% and 83% breaking strength and tensile strength of their virgin materials such as ABS. 3D printed filaments from e-waste also exhibited high flexibility compared to virgin filaments. Using the 3D filaments from e-waste as feedstocks instead of virgin polymers accounted for a 28% decline in carbon emissions. However, periodic recycling could lead to a weak internal structure and render them susceptible to breakage upon loading. | The study confirmed that 3D printing can be used in addressing the electronic plastic waste menace, demonstrating its reliability in recycling polymers and reducing the carbon footprint. |

| [36] | A mixed-methods study with an experimental research design and mechanical property analysis of recycled 3D printing polymers. | ABS, PET, and PLA | Consumer-grade plastics and polymers are considered a sustainable feedstock for 3D printing. Given that separation of e-waste is often challenging, blended 3D polymer filaments are produced by PET, PLA, and ABS together. Resulting filaments exhibit exemplary mechanical properties, including higher tensile strength of up to 35 Mpa. Glass transition for the materials also rose, suggesting that the materials could not easily melt at elevated temperatures. The aspect renders 3D printed filaments from blended polymers thermal resistant. | The study demonstrated the feasibility of recycling consumer plastics by 3D printing. The production of usable components through 3D printing using waste plastics as feedstock demonstrates the sustainability of the process. |

| [27] | A mixed-methods experimental study with thematic and descriptive analysis. | Plastic wastes | 3D printing of plastic waste has helped in creating a circular economy. The 3D printing technique for plastic wastes has proven economically and environmentally viable because it reduces over-reliance on virgin material that are expensive in comparison to plastic wastes and minimizes accumulation and incineration of plastics in the surrounding. Overall, it reduces the over-dependence on virgin plastics for production of functional products, an aspect that is acknowledged for reducing carbon emissions and emptying landfills that pose danger to soil micro-organisms. | The study affirmed the sustainability of 3D printing. From the study, plastic wastes can be turned into 3D printing filaments, thus preventing their accumulation in the surrounding. Therefore the study confirms that 3D printing is a reliable method of recycling polymers. |

| [91] | A quantitative study with an experimental design. | Anti-hail, windbreak, and anti-insect plastics are produced from 3D printed filaments from plastic wastes. 3D printed wastes for HDPE, PVC, and PE are the material of choice for agricultural applications due to their high tensile strength in comparison to bioplastics that are weak and often interfere with the lifecycle of natural predators like spiders. | The study demonstrates how 3D printing can be used to make agricultural plastics with outstanding properties for durability and reduced plastic wastes as a result of rapid deterioration. | |

| [76] | A quantitative study with an experimental design. | PET and PP | Fused Particle Fabrication (FPF) is a polymer recycling method that has increased the use of 3D printing to make polymer filaments. Recycling of Polyethylene Terephthalate (PET) and Polypropylene (PP), the most common plastic wastes, was successful with no identifiable defects and negative effects on the mechanical properties of the reprocessed filaments. | The study affirms the reliability of FPF in recycling plastics and making 3D printing feedstock. It therefore contributes to prior evidence that 3D printing can be relied upon in recycling plastics. |

| [21] | A case study with an experimental research design. | PET | The mechanical properties of recycled Polyethylene Terephthalate (PET) change following Fused Deposition Modelling (FDM). The hardness of recycled PET decreased by 6% while the shear and tensile strengths increased by 2.8% and 14.7%, respectively, in comparison to the virgin PET. The tensile strength of recycled PET also reached a high of 43.15 MPa at a 3% elongation, suggesting that it is an ideal 3D printing material. | The study demonstrated the viability of FDM as a method of recycling PET wastes for 3D printing filaments. The findings also affirm the mechanical reliability of 3D printed filaments from recycled PET. |

| [79] | A quantitative study with an experimental design. | PLA, ABS, Nylon, PET, and PP | 3D printing supports rapid prototyping, which has led to increase in production of 3D printed plastics. There has been an alarming rise in 3D printed plastic wastes due to the rapid growth in the 3D printing technology. Thermosets used in 3D printing are considered perilous to the environment and thus, alternative biodegradable 3D printable resins are being sought. | The study reveals that 3D printing can be used to support rapid prototyping and therefore increase the use of filaments from recycled plastics. In essence, the study provides evidence about the ways by which 3D printing promotes sustainable plastic waste management. |

| [74] | A quantitative study with an experimental design. | PLA | Recycling of PLA using FDM 3D printing technique results in production of biodegradable products with improved tensile and impact strength to up to 25.66% and 32.16%, respectively. The technique also reduces the water absorption rate of the recycled PLA material by up to 89.96%, rendering it a reliable method for making sustainable polymer products. | The study revealed that PLA can be recycled by the FDM method to make filaments with improved mechanical properties in comparison to the virgin PLA feedstock. |

| [94] | A quantitative research with an experimental design. | PVC | PVC undergo degradation by photolysis when exposed to ultraviolet light. The long chain hydrocarbons break, rendering a material brittle. However, the use of UV stabilizers such as Schiff bases reduces the vulnerability of PVC materials to photolysis. | The study demonstrates the likely solution to the limitations to use of polymers. The evidence is reliable in demonstrating how 3D printed filaments from recycled PVC can be made resistant to UV light to increase their durability and reduce their wastes in the surrounding. |

| [44] | A quantitative study with an experimental design. | PLA | Recycled PLA is turned into 3D printed filaments through melt extrusion with compression molding to industrial standards. However the heating process reduces polymer chains and increases the rate of degradation of the recycled polymers. However, polymerization at about 130 degrees Celsius improves the strength of the materials, rendering them durable and less likely to generate lots of wastes as it is with conventional virgin PLA material. | The findings demonstrate that PLA wastes can be turned into 3D printing filaments. The findings also show the likely defects of using hot melt extrusion in recycling PLA to make 3D printing filaments. |

| [78] | A quantitative study with an experimental design. | PET | Polyethylene terephthalate (PET) is the primary material for making packing products. Recycled PET is used in making filaments for 3D printing. It is also used in making 3D printed product prototypes. The materials exhibit thermally driven shape memory behavior evidenced by their recovery of their straight shape following heating and after being bent. The resulting material also has a high glass transition point and low recrystallization temperature. 3D printed PET can be recycled up to three times, an indication that 3D printed PET wastes are less likely to accumulate in the surrounding or case significant alarm because they can have a longer lifespan given the likelihood of recycling them multiple times. | The study suggests that commonly used plastics can be effectively recycled to make 3D printing filaments. The findings affirm that PET plastic wastes can be managed through their use in production of 3D printing filaments. |

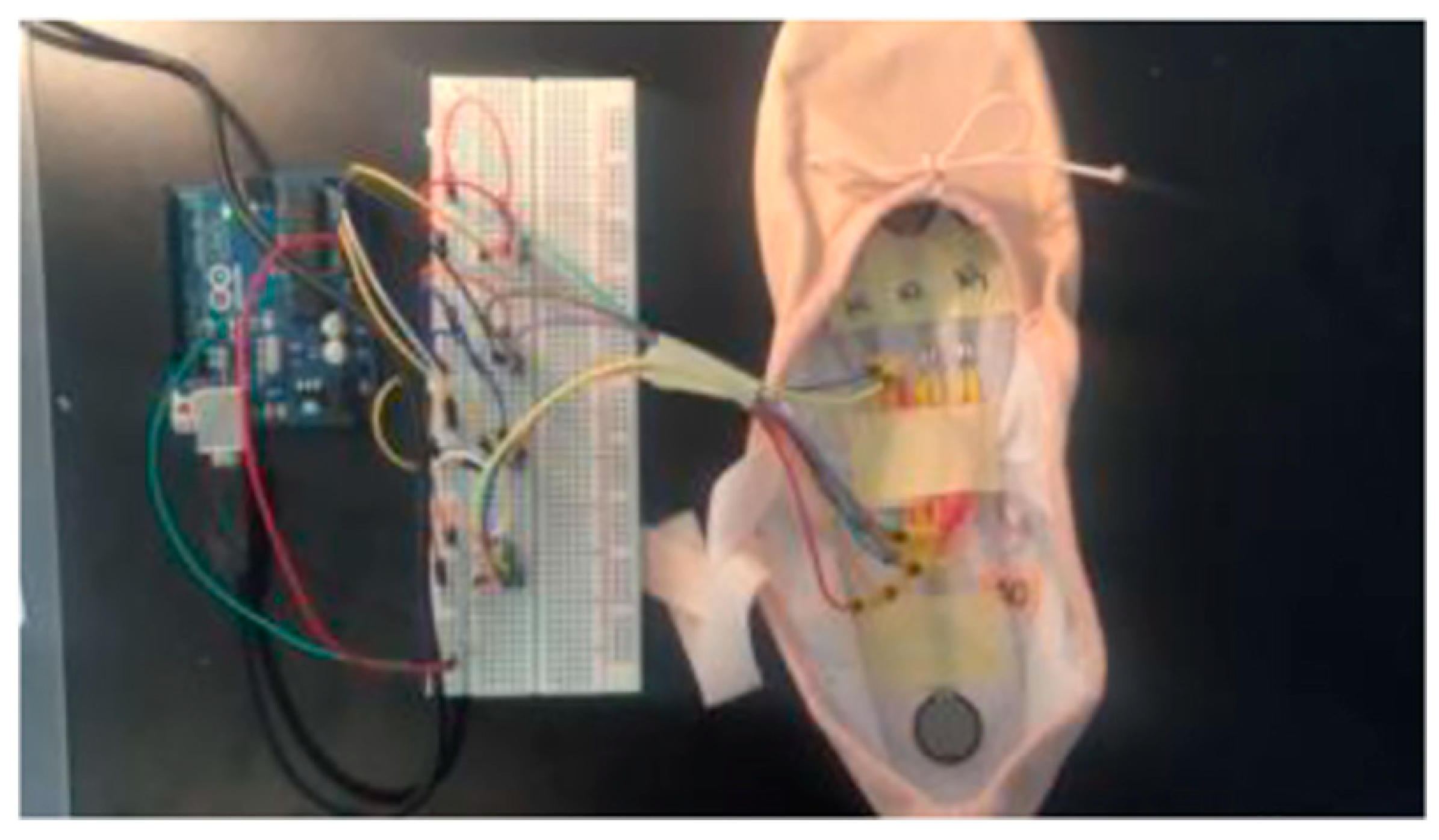

| [102] | A mixed methods study with an experimental research design. | PLA | Plastic wastes from production of personal protective equipment are molded into filaments that are used for making 3D printed parts. 3D wastes from Fused Filament Fabrication (FFF) are also recycled and used as feedstock for 3D printers. | The evidence demonstrates recycling of plastic wastes from production of protective equipment by 3D printing. The study therefore provides reliable evidence regarding the use of 3D printing as a plastic recycling method. |

| [71] | A quantitative study with an experimental research design. | PLA | PLA is recycled by melt blending and transformed into strands that are used in 3D printing. However, the recycled PLA had high melt flow due to reduced molecular weight. The challenge particularly limited FDM 3D printing because of high extrusion flow. Nonetheless, the use of a chain extender for the materials improved its strength by up to 88%. | The study confirms the use of 3D printing in recycling plastics. Cisneros-López et al. (2020) affirmed FDM and HME are reliable methods for recycling polymers for production of 3D printing feedstock. However, the heating or melting process involved reduces the molecular weight of the material, suggesting a high likelihood of defects in 3D printing filaments produced from plastics recycled by HME and FDM. |

| [88] | Experimental study with quantitative and qualitative analysis of properties of 3D printed polymers suitable for greenhouse. | HDPE and Nylon | 3D printing is used in the production of smart solar and greenhouse covers. The solar greenhouse covers made by 3D printing converted solar energy to electric energy and also provided optimum conditions under which plants grew. | The study demonstrates the viability of 3D printing in making reliable materials for agricultural applications. In ascertains the usefulness of 3D printing in production of advanced agricultural materials. |

| [89] | A quantitative method with an experimental design. | PET and PP | Synthetic plastics such as PET and PP from agricultural waste are recycled by co-polymer blending and alkali or acid treatment for production of functional components. Bio-based polymers are also synthesized from agricultural waste including fruits and vegetables. The availability of adequate agricultural waste has rendered the method scalable because it is cost-effective and has proven reliable in production of biodegradable polymers as a replacement for synthetic polymers for agricultural applications. | The study illustrates the recycling of plastic wastes from agricultural activities. The process’s efficacy is demonstrated by the fact that the wastes can be turned into 3D printing filaments and used as feedstock. |

| [90] | A mixed-methods study with an experimental research design. | Nylon | 3D printed Nano-composite polymers, for example, Nylon 12 (PA12/TiO2) have lower mechanical strength but good antibacterial characteristics. | The study demonstrates how 3D printing is used to recycle plastic wastes. It also demonstrates the expected material properties for recycled plastic, in this case, Nylon. |

| [85] | A quantitative study with an experimental research design and quantitative analysis of recycled PLA material properties. | PLA | Repeated 3D printing of PLA leads to deterioration of its mechanical properties. Thus, repeated recycling of 3D printed products is nearly impossible, suggesting a likelihood of accumulation of 3D printed polymer wastes in the surrounding. | The findings suggest a likelihood of limited recycling cycles for PLA. The results contribute to an understanding of the limitations of 3D printing as a method of recycling plastics. |

| [70] | A mixed-methods study with thematic and statistical analysis. | Ocean plastic wastes | Plastics retrieved from oceans were converted into filaments by twisted screw extrusion to make feedstock for 3D printing. | The findings provided in-depth insights into the process of recycling ocean plastics and turning them into 3D printing filaments. |

| [69] | A quantitative method with an experimental design. | Plastics from landfills. | Plastics from landfills are collected and turned into filaments through extrusion for use in 3D printing. The process begins with shredding plastics into flakes that are hot extruded to create filaments. However, there is a likelihood of variability in strength due to the heat treatment of the materials. | The study provides evidence on the viability of hot melt extrusion in recycling used polymers and production of 3D printing filaments. |

| [75] | A quantitative analysis of the properties of virgin and recycled materials for 3D printing. | Virgin and recycled polymers | Virgin materials have superior mechanical properties. On the other hand, 3D printed filaments deteriorate on exposure to ultraviolet light, rendering them mechanically weaker. However they are preferred for production of cheaper 3D printed products. | The findings show that 3D printing is used in recycling plastics. It also adds to evidence that recycled plastic can deteriorate faster, demonstrating a limitation to use of 3D printing in recycling polymers. |

| [95] | Quantitative analysis of the properties of greenhouse covering material. | PVC and LLDPE | 3D printing as an additive manufacturing technique is used in improving the UV transmittance of greenhouse covers with slow insecticide release and improved anti-microbial properties. PVC and LLDPE are also reinforced and stabilized with fillers to make them weather resistant and more durable. | The study shows how 3D printing can be used to enhance the properties of recycled polymers for agricultural applications. The findings therefore demonstrate how 3D printing can be leveraged in recycling plastic wastes. |

| [91] | A mixed methods study with analysis of the properties of 3D printed agricultural plastics. | Agricultural plastics | 3D printing is employed in the production of polymer-based shed nets due to their heat resistance and anti-oxidation. Recycled polymers from agricultural plastics are usually collected, cleaned, and turned into flakes for hot extrusion into filaments for 3D printing. | The results from the study show how 3D printing is used as a recycling method. |

| [68] | An experimental study with Taguchi and ANOVA | Virgin and recycled Polypropylene | Polypropylene is extruded to make filaments that are used in 3D printing. However, the filaments from recycled propylene have a rough surface and easily bend. | The evidence demonstrated the feasibility of hot melt extrusion in recycling polypropylene polymers for 3D printing. |

| [80] | A quantitative study with an experimental research design. | PET | Recycled PET has properties similar to virgin PET. Thus, it is a reliable substitute material in making filaments for 3D printing. The materials have similar tensile strength, an aspect that suggests that they can be used as a replacement for virgin PET. | The study shows how hot melt extrusion can be utilized in production of 3D printing filaments and likely defects that might result from producing 3D filaments from polypropylene wastes. |

| [81] | A quantitative study with mechanical strength assessment experiments. | PLA | 3D printing with recycled PLA is a viable option because it has properties similar to virgin PLA. For instance, the short beam strength of recycled PLA was 106 MPa with an allowance for 9 Mpa. On the other hand, virgin PLA had a short bean strength of 119 MPa plus or minus an allowable strength of 6.6 Mpa. Upon second recycling, PLA had a short beam strength of 108 MPa and 75 MPa following the third recycling. Arguably, the strength might deteriorate with the frequency of recycling. | The results from the study show the viability of 3D printing in recycling plastics to make feedstock with properties similar to the virgin material. |

| [93] | A quantitative study based on cycle analysis of HDPE. | Polystyrene | The weight and surface morphology of polystyrene changes following irradiation with UV light. However, upon addition of Schiff bases, polystyrene stabilized against UV radiation. | The study outcomes demonstrates how polymers can be protected against photo degradation to increase their longevity and limit their disposal as wastes in the surrounding. |

| [65] | A quantitative method with an experimental design. | ABS and HDPE | ABS and HDPE are granulated and hot extruded at 230 degrees Celsius to make 3D printing filaments. An assessment of the filaments demonstrated that a combination of 90% of ABS and 10% of HDPE produces filaments with consistent 3D prints. | The results from the study show how 3D printing is used as a recycling method. The study also shows how the properties of recycled polymers can be enhanced for durability and low plastic waste generation. |

| [45] | A quantitative method with an experimental design. | PLA | 3D printing filaments from recycled PLA have a 10.9% less tensile strength, a 6.8% higher shear strength, and a 2.4% lesser hardness in comparison to virgin PLA. The modulus of elasticity remained unchanged for both the virgin and recycled PLA, an indication that recycled PLA filaments can retain their initial strength. | The results from the study show the viability of 3D printing in recycling plastics to make feedstock with properties similar to the virgin material. |

| [67] | A quantitative research with mechanical and structural experiments for PP. | PP | Polypropylene polymer cannot be recycled multiple times because their mechanical properties deteriorate with every subsequent hot extrusion at temperatures of 200 Celsius. | The results demonstrated the feasibility of hot melt extrusion in recycling polypropylene polymers for 3D printing. Therefore, it adds to available evidence about 3D printing as a plastic recycling method. |

| [86] | A quantitative study with an experimental research design. | PP | The mechanical properties of Polypropylene (PP) decline following recycling and extruding them into filaments. The elastic modulus decrease by 20%, while the elastic modulus decreases by 12.9%. | The findings suggest the limitation of 3D printing of recycled polymer filaments. It contributes to the rigor and diversity of evidence in assessment of 3D printing as a technique for recycling plastics. |

| [64] | A quantitative study based on the analysis of the mechanical properties of PLA composite from recycled PLA plastics. | PLA | PLA loses 50 to 60% of its strength following third time recycling. PLA recycled from virgin materials yields a 22% decline in mechanical strength in comparison to the original virgin PLA polymer. Only 85% of the strength is retained following first-time recycling. | The findings demonstrate a likely limitation to recycling polymers by 3D printing. The research outcomes contribute to an understanding of some of the challenges that one expects in using 3D printing as a recycling method. |

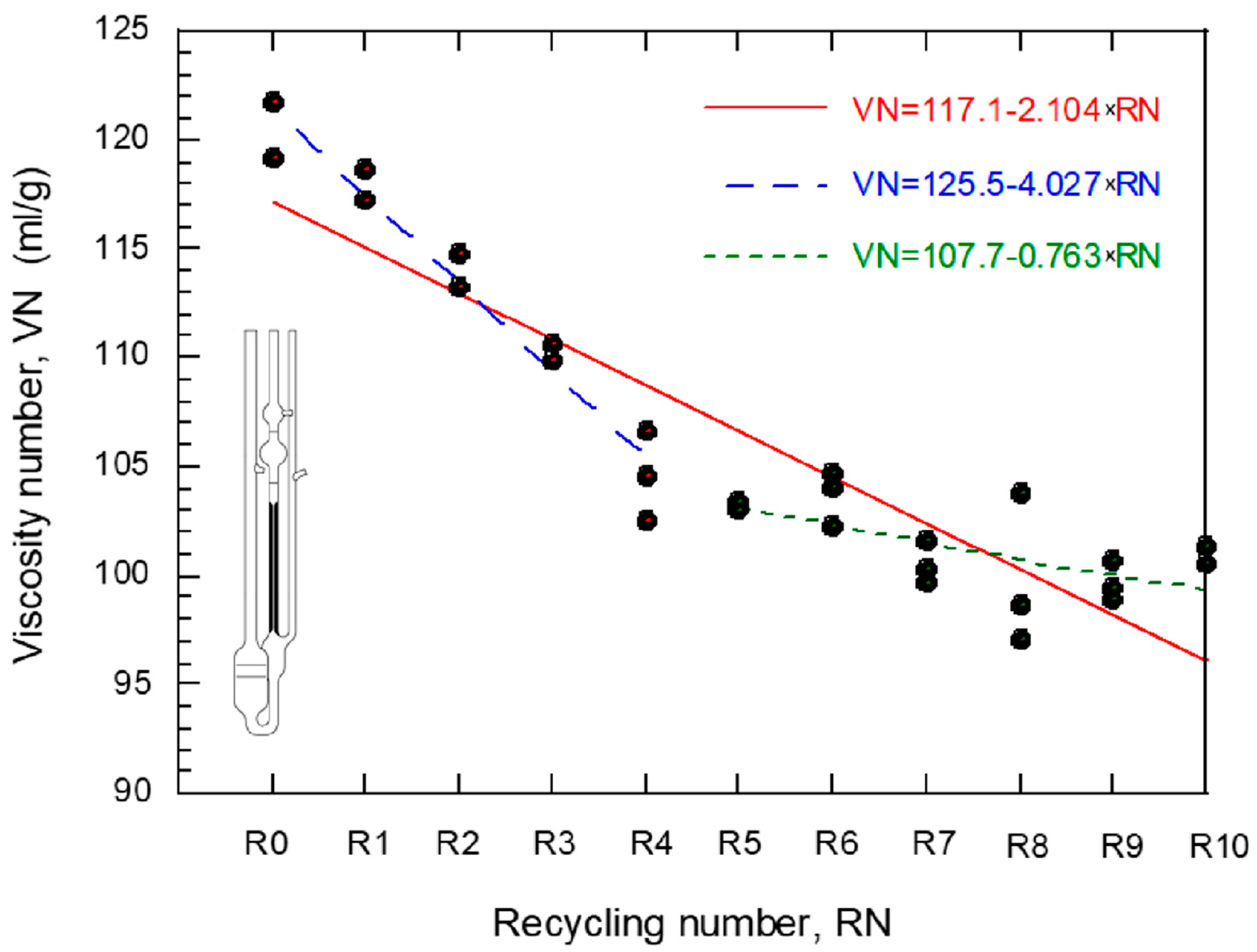

| [82] | A quantitative study involving testing and analyzing the mechanical behavior of recycled PLA. | PLA | Polyamide (PLA) losses viscosity by 15% for every recycling cycle. The change in viscosity after 10 recycling cycles results in a 70% decline in ultimate strength, 41% decrease in yield stress, a 38% decrease in young’s modulus, and 69% drop in fatigue resistance. However, changes after the first to the third recycling cycle are negligible, an indication that recycled PA can retain its properties at initial stages. | The findings demonstrate a likely limitation to recycling polymers by 3D printing. The research outcomes contribute to an understanding of some of the challenges that one expects in using 3D printing as a recycling method. |

| [84] | A quantitative study with an experimental research design. | PP and PLA | 3D printed PLA losses its mechanical strength following thermomechanical treatment. Degradation was also noticed in its rheological and dimensional properties. | The findings demonstrate a likely limitation to recycling polymers by 3D printing. The research outcomes contribute to an understanding of some of the challenges that one expects in using 3D printing as a recycling method. |

| [63] | A quantitative method with an experimental design. | PLA | The strength of PLA significantly reduced following recycling. However, adding more PLA material during recycling yielded strengths of 52.61 MPa, representing an increase from 44.20 MPa for the virgin material. Thus, additive manufacturing can help enhance the mechanical properties of recycled PLA. | The findings demonstrate a likely limitation to recycling polymers by 3D printing. The research outcomes contribute to an understanding of some of the challenges that one expects in using 3D printing as a recycling method. |

| [66] | Mechanical fabrication with quantitative analysis. | Polystyrene and polypropylene | Mixing polypropylene and polystyrene wastes by Fuse Filament Fabrication yields 3D printing filaments with more than 32 MPa mechanical strength at extrusion temperatures of about 230 Celsius. | The study provides evidence on the viability of hot melt extrusion in recycling used polymers and production of 3D printing filaments. |

| [101] | A quantitative survey with structured questionnaires | Maritime plastic wastes. | Companies undertaking maritime operations acknowledge collecting, grading, and melting plastic wastes from oceans and seas for use in making 3D printing filaments. The move has particularly promoted recycling of oceanic plastic wastes and reduced their overall impact on aquatic life. | The study findings affirms that 3D printing can be used in recycling maritime plastic wastes. |

References

- Hunt, E.J.; Zhang, C.; Anzalone, N.; Pearce, J.M. Polymer recycling codes for distributed manufacturing with 3-D printers. Resour. Conserv. Recycl. 2015, 97, 24–30. [Google Scholar] [CrossRef]

- Pinho, A.C.; Amaro, A.M.; Piedade, A.P. 3D printing goes greener: Study of the properties of post-consumer recycled polymers for the manufacturing of engineering components. Waste Manag. 2020, 118, 426–434. [Google Scholar] [CrossRef] [PubMed]

- Karimi, A.; Rahmatabadi, D.; Baghani, M. Direct Pellet Three-Dimensional Printing of Polybutylene Adipate-co-Terephthalate for a Greener Future. Polymers 2024, 16, 267. [Google Scholar] [CrossRef] [PubMed]

- Devasahayam, S. Opportunities for simultaneous energy/materials conversion of carbon dioxide and plastics in metal-lurgical processes. Sustain. Mater. Technol. 2019, 22, 119. [Google Scholar]

- Hussin, F.; Aroua, M.K.; Kassim, M.A.; Ali, U.F.M. Transforming Plastic Waste into Porous Carbon for Capturing Carbon Dioxide: A Review. Energies 2021, 14, 8421. [Google Scholar] [CrossRef]

- Oberoi, I.S.; Rajkumar, P.; Das, S. Disposal and recycling of plastics. Mater. Today Proc. 2021, 46, 7875–7880. [Google Scholar] [CrossRef]

- Choudhury, A.; Simnani, F.Z.; Singh, D.; Patel, P.; Sinha, A.; Nandi, A.; Ghosh, A.; Saha, U.; Kumari, K.; Jaganathan, S.K.; et al. Atmospheric microplastic and nanoplastic: The toxicological paradigm on the cellular system. Ecotoxicol. Environ. Saf. 2023, 259, 115018. [Google Scholar] [CrossRef]

- Allen, S.; Allen, D.; Moss, K.; Le Roux, G.; Phoenix, V.R.; Sonke, J.E. Examination of the ocean as a source for atmospheric microplastics. PLoS ONE 2020, 15, e0232746. [Google Scholar] [CrossRef]

- Tong, H.; Zhong, X.; Duan, Z.; Yi, X.; Cheng, F.; Xu, W.; Yang, X. Micro- and nanoplastics released from biodegradable and conventional plastics during degradation: Formation, aging factors, and toxicity. Sci. Total. Environ. 2022, 833, 155275. [Google Scholar] [CrossRef] [PubMed]

- Panda, P.K.; Chavda, V.P.; Neve, K.; Mishra, S.; Verma, S.K.; Ahuja, R. COVID-19: Lesson Learnt from Diagnostics to Therapeutics. In Microbial Engineering for Therapeutics; Springer Nature: Singapore, 2022; pp. 345–374. [Google Scholar] [CrossRef]

- Madhu, N.R.; Erfani, H.; Jadoun, S.; Amir, M.; Thiagarajan, Y.; Chauhan, N.P.S. Fused deposition modelling ap-proach using 3D printing and recycled industrial materials for a sustainable environment: A review. Int. J. Adv. Manuf. Technol. 2022, 122, 2125–2138. [Google Scholar] [CrossRef]

- Voet, V.S.D.; Guit, J.; Loos, K. Sustainable Photopolymers in 3D Printing: A Review on Biobased, Biodegradable, and Recyclable Alternatives. Macromol. Rapid Commun. 2021, 42, e2000475. [Google Scholar] [CrossRef] [PubMed]

- Tsuchimoto, I.; Kajikawa, Y. Recycling of Plastic Waste: A Systematic Review Using Bibliometric Analysis. Sustainability 2022, 14, 16340. [Google Scholar] [CrossRef]

- Biron, M. Genesis of Renewable Plastics and Integration in the Plastics Stream; Elsevier: Amsterdam, The Netherlands, 2017; pp. 35–66. [Google Scholar] [CrossRef]

- Klotz, M.; Haupt, M.; Hellweg, S. Potentials and limits of mechanical plastic recycling. J. Ind. Ecol. 2023, 27, 1043–1059. [Google Scholar] [CrossRef]

- Jiang, J.; Shi, K.; Zhang, X.; Yu, K.; Zhang, H.; He, J.; Ju, Y.; Liu, J. From plastic waste to wealth using chemical recycling: A review. J. Environ. Chem. Eng. 2022, 10, 106867. [Google Scholar] [CrossRef]

- Mikula, K.; Skrzypczak, D.; Izydorczyk, G.; Warchoł, J.; Moustakas, K.; Chojnacka, K.; Witek-Krowiak, A. 3D print-ing filament as a second life of waste plastics—A review. Environ. Sci. Pollut. Res. 2021, 28, 12321–12333. [Google Scholar] [CrossRef] [PubMed]

- Chong, S.; Pan, G.-T.; Khalid, M.; Yang, T.C.-K.; Hung, S.-T.; Huang, C.-M. Physical Characterization and Pre-assessment of Recycled High-Density Polyethylene as 3D Printing Material. J. Polym. Environ. 2017, 25, 136–145. [Google Scholar] [CrossRef]

- Kazmer, D. Three-dimensional printing of plastics. In Applied Plastics Engineering Handbook; Kutz, M., Ed.; William Andrew Publishing: Norwich, UK, 2017; pp. 617–634. [Google Scholar]

- Lee, J.-Y.; An, J.; Chua, C.K. Fundamentals and applications of 3D printing for novel materials. Appl. Mater. Today 2017, 7, 120–133. [Google Scholar] [CrossRef]

- Oussai, A.; Bártfai, Z.; Kátai, L. Development of 3D printing raw materials from plastic waste. A case study on recycled polyethylene terephthalate. Appl. Sci. 2021, 11, 7338. [Google Scholar] [CrossRef]

- Rodríguez-Hernández, A.G.; Chiodoni, A.; Bocchini, S.; Vazquez-Duhalt, R. 3D printer waste, a new source of neo-plastic pollutants. Environ. Pollut. 2020, 267, 115609. [Google Scholar] [CrossRef] [PubMed]

- Karimi, A.; Rahmatabadi, D.; Baghani, M. Various FDM Mechanisms Used in the Fabrication of Continuous-Fiber Reinforced Composites: A Review. Polymers 2024, 16, 831. [Google Scholar] [CrossRef]

- Despeisse, M.; Baumers, M.; Brown, P.; Charnley, F.; Ford, S.; Garmulewicz, A.; Knowles, S.; Minshall, T.; Mortara, L.; Reed-Tsochas, F.; et al. Unlocking value for a circular economy through 3D printing: A research agenda. Technol. Forecast. Soc. Chang. 2017, 115, 75–84. [Google Scholar] [CrossRef]

- Chin, H.H. Extending Process Integration to Asset Maintenance and Resource Conservation in Circular Economies; Elsevier: Amsterdam, The Netherlands, 2023; pp. 743–764. [Google Scholar] [CrossRef]

- Al Rashid, A.; Koç, M. Additive manufacturing for sustainability and circular economy: Needs, challenges, and opportunities for 3D printing of recycled polymeric waste. Mater. Today Sustain. 2023, 24, 100529. [Google Scholar] [CrossRef]

- Santander, P.; Sanchez, F.A.C.; Boudaoud, H.; Camargo, M. Closed loop supply chain network for local and distrib-uted plastic recycling for 3D printing: A MILP-based optimization approach. Resour. Conserv. Recycl. 2020, 154, 104531. [Google Scholar] [CrossRef]

- Valera, E.H.; Cremades, R.; van Leeuwen, E.; van Timmeren, A. Additive manufacturing in cities: Closing circular resource loops. Circ. Econ. 2023, 2, 100049. [Google Scholar] [CrossRef]

- Olawumi, M.A.; Oladapo, B.I.; Ikumapayi, O.M.; Akinyoola, J.O. Waste to wonder to explore possibilities with recycled materials in 3D printing. Sci. Total. Environ. 2023, 905, 167109. [Google Scholar] [CrossRef] [PubMed]

- Khan, S.A.; Jassim, M.; Ilcan, H.; Sahin, O.; Bayer, I.R.; Sahmaran, M.; Koc, M. 3D printing of circular materials: Comparative environmental analysis of materials and construction techniques. Case Stud. Constr. Mater. 2023, 18, e02059. [Google Scholar] [CrossRef]

- Peeters, B.; Kiratli, N.; Semeijn, J. A barrier analysis for distributed recycling of 3D printing waste: Taking the maker movement perspective. J. Clean. Prod. 2019, 241, 118313. [Google Scholar] [CrossRef]

- Oyinlola, M.; Okoya, S.A.; Whitehead, T.; Evans, M.; Lowe, A.S. The potential of converting plastic waste to 3D printed products in Sub-Saharan Africa. Resour. Conserv. Recycl. Adv. 2023, 17, 200129. [Google Scholar] [CrossRef]

- Hassan, M.; Mohanty, A.K.; Misra, M. 3D printing in upcycling plastic and biomass waste to sustainable polymer blends and composites: A review. Mater. Des. 2023, 237, 112558. [Google Scholar] [CrossRef]

- Patel, K.S.; Shah, D.B.; Joshi, S.J.; Patel, K.M. Developments in 3D printing of carbon fiber reinforced polymer containing recycled plastic waste: A review. Clean. Mater. 2023, 9, 100207. [Google Scholar] [CrossRef]

- Bayati, A.; Rahmatabadi, D.; Ghasemi, I.; Khodaie, M.; Baniassadi, M.; Abrinia, K.; Baghani, M. 3D printing super stretchable propylene-based elastomer. Mater. Lett. 2024, 361, 136075. [Google Scholar] [CrossRef]

- Zander, N.E.; Gillan, M.; Burckhard, Z.; Gardea, F. Recycled polypropylene blends as novel 3D printing materials. Addit. Manuf. 2019, 25, 122–130. [Google Scholar] [CrossRef]

- Cafiero, L.; De Angelis, D.; Di Dio, M.; Di Lorenzo, P.; Pietrantonio, M.; Pucciarmati, S.; Terzi, R.; Tuccinardi, L.; Tuffi, R.; Ubertini, A. Characterization of WEEE plastics and their potential valorisation through the production of 3D printing filaments. J. Environ. Chem. Eng. 2021, 9, 105532. [Google Scholar] [CrossRef]

- Xu, W.; Jambhulkar, S.; Zhu, Y.; Ravichandran, D.; Kakarla, M.; Vernon, B.; Lott, D.G.; Cornella, J.L.; Shefi, O.; Miquelard-Garnier, G.; et al. 3D printing for polymer/particle-based processing: A review. Compos. Part B: Eng. 2021, 223, 109102. [Google Scholar] [CrossRef]

- Zhu, C.; Li, T.; Mohideen, M.M.; Hu, P.; Gupta, R.; Ramakrishna, S.; Liu, Y. Realization of Circular Economy of 3D Printed Plastics: A Review. Polymers 2021, 13, 744. [Google Scholar] [CrossRef] [PubMed]

- Gomes, T.E.; Cadete, M.S.; Dias-De-Oliveira, J.; Neto, V. Controlling the properties of parts 3D printed from recycled thermoplastics: A review of current practices. Polym. Degrad. Stab. 2022, 196, 109850. [Google Scholar] [CrossRef]

- Atakok, G.; Kam, M.; Koc, H.B. A review of mechanical and thermal properties of products printed with recycled filaments for use in 3D printers. Surf. Rev. Lett. 2022, 29, 222. [Google Scholar] [CrossRef]

- Hidalgo-Carvajal, D.; Muñoz, H.; Garrido-González, J.J.; Carrasco-Gallego, R.; Montero, V.A. Recycled PLA for 3D Printing: A Comparison of Recycled PLA Filaments from Waste of Different Origins after Repeated Cycles of Extrusion. Polymers 2023, 15, 3651. [Google Scholar] [CrossRef] [PubMed]

- Di, L.; Yang, Y. Towards closed-loop material flow in additive manufacturing: Recyclability analysis of thermo-plastic waste. J. Clean. Prod. 2022, 362, 132427. [Google Scholar] [CrossRef]

- Beltrán, F.R.; Arrieta, M.P.; Moreno, E.; Gaspar, G.; Muneta, L.M.; Carrasco-Gallego, R.; Yáñez, S.; Hidalgo-Carvajal, D.; de la Orden, M.U.; Urreaga, J.M. Evaluation of the Technical Viability of Distributed Mechanical Recycling of PLA 3D Printing Wastes. Polymers 2021, 13, 1247. [Google Scholar] [CrossRef]

- Anderson, I. Mechanical Properties of Specimens 3D Printed with Virgin and Recycled Polylactic Acid. 3D Print. Addit. Manuf. 2017, 4, 110–115. [Google Scholar] [CrossRef]

- Cress, A.K.; Huynh, J.; Anderson, E.H.; O’neill, R.; Schneider, Y.; Keleş, Ö. Effect of recycling on the mechanical be-havior and structure of additively manufactured Acrylonitrile Butadiene Styrene (ABS). J. Clean. Prod. 2021, 279, 689. [Google Scholar] [CrossRef]

- Mishra, V.; Negi, S.; Kar, S. FDM-based additive manufacturing of recycled thermoplastics and associated compo-sites. J. Mater. Cycles Waste Manag. 2023, 25, 758–784. [Google Scholar] [CrossRef] [PubMed]

- Rigon, D.; Ricotta, M.; Meneghetti, G. A literature survey on the structural integrity of 3D printed virgin and recy-cled ABS and PP compounds. Procedia Struct. Integr. 2020, 28, 1655–1663. [Google Scholar] [CrossRef]

- Dertinger, S.C.; Gallup, N.; Tanikella, N.G.; Grasso, M.; Vahid, S.; Foot, P.J.; Pearce, J.M. Technical pathways for dis-tributed recycling of polymer composites for distributed manufacturing: Windshield wiper blades. Resour. Conserv. Recycl. 2020, 157, 104–810. [Google Scholar] [CrossRef]

- Cunico, M.W.M.; Kai, D.A.; Cavalheiro, P.M.; de Carvalho, J. Development and characterization of 3D printing fin-ishing process applying recycled plastic waste. Virtual Phys. Prototyp. 2019, 14, 37–52. [Google Scholar] [CrossRef]

- Thomas, G. How to Do Your Case Study; Sage: London, UK, 2021. [Google Scholar]

- Heale, R.; Twycross, A. What is a case study? Evid. Based Nurs. 2018, 21, 7–8. [Google Scholar] [CrossRef] [PubMed]

- Sjoberg, G.; Orum, A.M.; Feagin, J.R. A Case for the Case Study; The University of North Carolina Press: Raleigh, NC, USA, 2020. [Google Scholar]

- Ross, S.M.; Morrison, G.R. Experimental research methods. In Handbook of Re-Search on Educational Communications and Technology; Jonassen, D., Driscoll, M., Eds.; Routledge: London, UK, 2013; pp. 1007–1029. [Google Scholar]

- Ledyard, J.O. Public goods: A survey of experimental research. In The Handbook of Ex-Perimental Economics; Kagel, J.H., Roth, A.E., Eds.; Princeton University Press: Princeton, NJ, USA, 2020; pp. 111–195. [Google Scholar]

- Rogers, J.; Revesz, A. Experimental and quasi-experimental designs. In The Routledge Handbook of Research Methods in Applied Linguistics; McKinley, J., Rose, H., Eds.; Routledge: London, UK, 2019; pp. 133–143. [Google Scholar]

- Bloomfield, J.; Fisher, M.J. Quantitative research design. J. Australas. Rehabil. Nurses Assoc. 2019, 22, 27–30. [Google Scholar] [CrossRef]

- McKim, C.A. The value of mixed methods research: A mixed methods study. J. Mix. Methods Res. 2017, 11, 202–222. [Google Scholar] [CrossRef]

- Goertzen, M.J. Introduction to quantitative research and data. Libr. Technol. Rep. 2017, 53, 12–18. [Google Scholar]

- Åkerblad, L.; Seppänen-Järvelä, R.; Haapakoski, K. Integrative Strategies in Mixed Methods Research. J. Mix. Methods Res. 2021, 15, 152–170. [Google Scholar] [CrossRef]

- Dawadi, S.; Shrestha, S.; Giri, R.A. Mixed-Methods Research: A Discussion on its Types, Challenges, and Criticisms. J. Pr. Stud. Educ. 2021, 2, 25–36. [Google Scholar] [CrossRef]

- Esser, F.; Vliegenthart, R. Comparative research methods. In The International Encyclopedia of Communication Research Methods; Matthes, J., Davis, C., Potter, R., Eds.; Wiley: Hoboken, NJ, USA, 2017; pp. 1–22. [Google Scholar]

- Bergaliyeva, S.; Sales, D.L.; Delgado, F.J.; Bolegenova, S.; Molina, S.I. Manufacture and Characterization of Polylactic Acid Filaments Recycled from Real Waste for 3D Printing. Polymers 2023, 15, 2165. [Google Scholar] [CrossRef] [PubMed]

- Kumar, S.; Singh, R.; Singh, T.P.; Batish, A.; Singh, M. Multi-stage Primary and Secondary Recycled PLA Composite Matrix for 3D Printing Applications. Proc. Natl. Acad. Sci. India Sect. A Phys. Sci. 2022, 92, 677–698. [Google Scholar] [CrossRef]

- Mohammed, M.I.; Mohan, M.; Das, A.; Johnson, M.D.; Badwal, P.S.; McLean, D.; Gibson, I. A low carbon footprint approach to the reconstitution of plastics into 3D-printer filament for enhanced waste reduction. KnE Eng. 2017, 2, 234–241. [Google Scholar] [CrossRef]

- Chu, J.S.; Koay, S.C.; Chan, M.Y.; Choo, H.L.; Ong, T.K. Recycled plastic filament made from post-consumer expanded polystyrene and polypropylene for fused filamant fabrication. Polym. Eng. Sci. 2022, 62, 3786–3795. [Google Scholar] [CrossRef]

- Ji, H.S.; Jung, H.W. Effect of the multiple injection process on the structural and mechanical properties of PP impact copolymers focusing on the deformation of ethylene-propylene copolymer. Polym. Test. 2023, 124, 108051. [Google Scholar] [CrossRef]

- Atsani, S.I.; Mastrisiswadi, H. Recycled polypropylene filament for 3D printer: Extrusion process parameter optimization. IOP Conf. Ser. Mater. Sci. Eng. 2020, 722, 12022. [Google Scholar]

- Zhong, S.; Pearce, J.M. Tightening the loop on the circular economy: Coupled distributed recycling and manufacturing with recyclebot and RepRap 3-D printing. Resour. Conserv. Recycl. 2018, 128, 48–58. [Google Scholar] [CrossRef]

- Vones, K.; Allan, D.; Lambert, I.; Vettese, S. 3D-printing ‘ocean plastic’–fostering children’s engagement with sustainability. Mater. Today Commun. 2018, 16, 56–59. [Google Scholar] [CrossRef]

- Cisneros-López, E.O.; Pal, A.K.; Rodriguez, A.U.; Wu, F.; Misra, M.; Mielewski, D.F.; Kiziltas, A.; Mohanty, A.K. Re-cycled poly (lactic acid)–based 3D printed sustainable biocomposites: A comparative study with injection molding. Mater. Today Sustain. 2020, 7, 1–12. [Google Scholar]

- Zhang, H.; Chen, J.; Yang, D. Fiber misalignment and breakage in 3D printing of continuous carbon fiber reinforced thermoplastic composites. Addit. Manuf. 2021, 38, 101775. [Google Scholar]

- Mendenhall, R.; Eslami, B. Experimental Investigation on Effect of Temperature on FDM 3D Printing Polymers: ABS, PETG, and PLA. Appl. Sci. 2023, 13, 11503. [Google Scholar] [CrossRef]

- Elumalai, B.; Gurijala, C.; Giridharan, K.; Padmanabhan, S.; Boopathi, B. Property enhancement of 3D printed of timber waste/PLA composite by surface coating. Multidiscip. Sci. J. 2023, 6, 2024014. [Google Scholar] [CrossRef]

- Sun, L.; Wang, Y.; Hua, G.; Cheng, T.; Dong, J. Virgin or recycled? Optimal pricing of 3D printing platform and material suppliers in a closed-loop competitive circular supply chain. Resour. Conserv. Recycl. 2020, 162, 105035. [Google Scholar] [CrossRef]

- Woern, A.L.; Byard, D.J.; Oakley, R.B.; Fiedler, M.J.; Snabes, S.L.; Pearce, J.M. Fused Particle Fabrication 3-D Printing: Recycled Materials’ Optimization and Mechanical Properties. Materials 2018, 11, 1413. [Google Scholar] [CrossRef]

- Gaikwad, V.; Ghose, A.; Cholake, S.; Rawal, A.; Iwato, M.; Sahajwalla, V. Transformation of E-Waste Plastics into Sustainable Filaments for 3D Printing. ACS Sustain. Chem. Eng. 2018, 6, 14432–14440. [Google Scholar] [CrossRef]

- Pricop, B.; Sava, D.; Lohan, N.-M.; Bujoreanu, L.-G. DMA Investigation of the Factors Influencing the Glass Transition in 3D Printed Specimens of Shape Memory Recycled PET. Polymers 2022, 14, 2248. [Google Scholar] [CrossRef] [PubMed]

- Maines, E.M.; Porwal, M.K.; Ellison, C.J.; Reineke, T.M. Sustainable advances in SLA/DLP 3D printing materials and processes. Green Chem. 2021, 23, 6863–6897. [Google Scholar] [CrossRef]

- Exconde, M.K.J.E.; Co, J.A.A.; Manapat, J.Z.; Magdaluyo, E.R., Jr. Materials selection of 3D printing filament and uti-lization of recycled Polyethylene Terephthalate (PET) in a redesigned breadboard. Procedia CIRP 2019, 84, 28–32. [Google Scholar] [CrossRef]

- Lanzotti, A.; Martorelli, M.; Maietta, S.; Gerbino, S.; Penta, F.; Gloria, A. A comparison between mechanical proper-ties of specimens 3D printed with virgin and recycled PLA. Procedia Cirp 2019, 79, 143–146. [Google Scholar] [CrossRef]

- Diego, S.; Casado, J.; Carrascal, I.; Sainz-Aja, J.; Ferreño, D. Mechanical performance of recycled reinforced polyam-ide from rejected railway fastenings flanged plates. Polymers 2022, 14, 4940. [Google Scholar] [CrossRef] [PubMed]

- Eren, Z.; Burnett, C.A.; Wright, D.; Kazancı, Z. Compressive characterization of 3D printed composite materials us-ing continuous fiber fabrication. Int. J. Lightweight Mater. Manuf. 2023, 6, 494–507. [Google Scholar]

- Nagengast, N.; Bay, C.; Döpper, F.; Schmidt, H.W.; Neuber, C. Thermo-mechanical recyclability of additively man-ufactured polypropylene and polylactic acid parts and polypropylene support structures. Polymers 2023, 15, 2291. [Google Scholar] [CrossRef] [PubMed]

- Zhao, P.; Rao, C.; Gu, F.; Sharmin, N.; Fu, J. Close-looped recycling of polylactic acid used in 3D printing: An ex-perimental investigation and life cycle assessment. J. Clean. Prod. 2018, 197, 1046–1055. [Google Scholar] [CrossRef]

- Rigon, D.; Ricotta, M.; Ardengo, G.; Meneghetti, G. Static mechanical properties of virgin and recycled short glass fiber-reinforced polypropylene produced by pellet additive manufacturing. Fatigue Fract. Eng. Mater. Struct. 2021, 44, 2554–2569. [Google Scholar] [CrossRef]

- Kreiger, M.A.; Mulder, M.L.; Glover, A.G.; Pearce, J.M. Life cycle analysis of distributed recycling of post-consumer high density polyethylene for 3-D printing filament. J. Clean. Prod. 2014, 70, 90–96. [Google Scholar] [CrossRef]

- Maraveas, C.; Loukatos, D.; Bartzanas, T.; Arvanitis, K.G.; Uijterwaal, J.F. Smart and Solar Greenhouse Covers: Recent Developments and Future Perspectives. Front. Energy Res. 2021, 9, 783587. [Google Scholar] [CrossRef]

- Maraveas, C. Production of Sustainable and Biodegradable Polymers from Agricultural Waste. Polymers 2020, 12, 1127. [Google Scholar] [CrossRef]

- Vidakis, N.; Petousis, M.; Mountakis, N.; Maravelakis, E.; Zaoutsos, S.; Kechagias, J.D. Mechanical response assess-ment of antibacterial PA12/TiO2 3D printed parts: Parameters optimization through artificial neural networks modeling. Int. J. Adv. Manuf. Technol. 2022, 121, 785–803. [Google Scholar] [CrossRef]

- Maraveas, C. Environmental Sustainability of Plastic in Agriculture. Agriculture 2020, 10, 310. [Google Scholar] [CrossRef]

- Maraveas, C. The Sustainability of Plastic Nets in Agriculture. Sustainability 2020, 12, 3625. [Google Scholar] [CrossRef]

- Yousif, E.; Ahmed, D.S.; El-Hiti, G.A.; Alotaibi, M.H.; Hashim, H.; Hameed, A.S.; Ahmed, A. Fabrication of novel ball-like polystyrene films containing Schiff base microspheres as photo stabilizers. Polymers 2018, 10, 1185. [Google Scholar] [CrossRef] [PubMed]

- El-Hiti, G.A.; Ahmed, D.S.; Yousif, E.; Al-Khazrajy, O.S.A.; Abdallh, M.; Alanazi, S.A. Modifications of Polymers through the Addition of Ultraviolet Absorbers to Reduce the Aging Effect of Accelerated and Natural Irradiation. Polymers 2021, 14, 20. [Google Scholar] [CrossRef]

- Maraveas, C. Environmental Sustainability of Greenhouse Covering Materials. Sustainability 2019, 11, 6129. [Google Scholar] [CrossRef]

- Stefaniak, A.B.; Bowers, L.N.; Cottrell, G.; Erdem, E.; Knepp, A.K.; Martin, S.B., Jr.; Pretty, J.; Duling, M.G.; Arnold, E.D.; Wilson, Z.; et al. Towards sustainable additive manufacturing: The need for awareness of particle and vapor releases dur-ing polymer recycling, making filament, and fused filament fabrication 3-D printing. Resour. Conserv. Recycl. 2022, 176, 105911. [Google Scholar] [CrossRef] [PubMed]

- Shiferaw, M.Z.; Gebremedhen, H.S. Recycled polymer for FDM 3D printing filament material: Circular economy for sustainability of additive manufacturing. In Advances of Science and Technology, Proceedings of the 9th EAI International Conference, ICAST 2021, Hybrid Event, Bahir Dar, Ethiopia, 27–29 August 2021; Proceedings, Part II; Springer International Publishing: London, UK, 2022; pp. 243–261. [Google Scholar]

- Lee, D.; Lee, Y.; Lee, K.; Ko, Y.; Kim, N. Development and Evaluation of a Distributed Recycling System for Making Filaments Reused in Three-Dimensional Printers. J. Manuf. Sci. Eng. 2019, 141, 021007. [Google Scholar] [CrossRef]

- Morales, M.A.; Atencio Martinez, C.L.; Maranon, A.; Hernandez, C.; Michaud, V.; Porras, A. Development and char-acterization of rice husk and recycled polypropylene composite filaments for 3D printing. Polymers 2021, 13, 1–17. [Google Scholar] [CrossRef]

- Polline, M.; Mutua, J.M.; Mbuya, T.O.; Ernest, K. Recipe development and mechanical characterization of carbon fiber-reinforced recycled polypropylene 3D printing filament. Open J. Compos. Mater. 2021, 11, 47–61. [Google Scholar]

- Silva, D.; Garrido, J.; Lekube, B.; Arrillaga, A. On-board and port 3D printing to promote a maritime plastic circular economy. J. Clean. Prod. 2023, 407, 137151. [Google Scholar] [CrossRef]

- Gil Muñoz, V.; Muneta, L.M.; Carrasco-Gallego, R.; Marquez, J.d.J.; Hidalgo-Carvajal, D. Evaluation of the Circularity of Recycled PLA Filaments for 3D Printers. Appl. Sci. 2020, 10, 8967. [Google Scholar] [CrossRef]

- Garmulewicz, A.; Holweg, M.; Veldhuis, H.; Yang, A. Disruptive technology as an enabler of the circular economy: What potential does 3D printing hold? Calif. Manag. Rev. 2018, 60, 112–132. [Google Scholar] [CrossRef]

- Pavlo, S.; Fabio, C.; Hakim, B.; Mauricio, C. 3D-printing based distributed plastic recycling: A conceptual model for closed-loop supply chain design. In Proceedings of the 2018, The IEEE International Conference on Engineering, Technology, and Innovation (ICE/ITMC), Stuttgart, Germany, 17–20 June 2018; IEEE: Piscataway, NJ, USA, 2018; pp. 1–8. [Google Scholar]

- Nadagouda, M.N.; Ginn, M.; Rastogi, V. A review of 3D printing techniques for environmental applications. Curr. Opin. Chem. Eng. 2020, 28, 173–178. [Google Scholar] [CrossRef] [PubMed]

- Sanchez, F.A.C.; Boudaoud, H.; Camargo, M.; Pearce, J.M. Plastic recycling in additive manufacturing: A systematic literature review and opportunities for the circular economy. J. Clean. Prod. 2020, 264, 121602. [Google Scholar] [CrossRef]

- Mishra, V.; Ror, C.K.; Negi, S.; Kar, S.; Borah, L.N. 3D printing with recycled ABS resin: Effect of blending and printing temperature. Mater. Chem. Phys. 2023, 309, 128317. [Google Scholar] [CrossRef]

- Hong, J.-H.; Yu, T.; Park, S.-J.; Kim, Y.-H. Repetitive recycling of 3D printing PLA filament as renewable resources on mechanical and thermal loads. Int. J. Mod. Phys. B 2020, 34, 20–147. [Google Scholar] [CrossRef]

- Patti, A.; Acierno, S.; Cicala, G.; Zarrelli, M.; Acierno, D. Assessment of recycled PLA-based filament for 3D printing. Mater. Proc. 2021, 7, 16. [Google Scholar] [CrossRef]

- Allen, N.S.; Edge, M. Perspectives on additives for polymers. Part 2. Aspects of photo stabilization and role of fill-ers and pigments. J. Vinyl Addit. Technol. 2021, 27, 211–239. [Google Scholar] [CrossRef]

- Ambrogi, V.; Carfagna, C.; Cerruti, P.; Marturano, V. Additives in polymers. In Modification of Polymer Properties; Jasso-Gastinel, C.F., Kenny, J.M., Eds.; William Andrew Publishing: Norwich, UK, 2017; pp. 87–108. [Google Scholar]

- Maraveas, C.; Bayer, I.S.; Bartzanas, T. 4D printing: Perspectives for the production of sustainable plastics for agriculture. Biotechnol. Adv. 2022, 54, 1–23. [Google Scholar] [CrossRef]

- Ehrmann, G.; Ehrmann, A. 3D printing of shape memory polymers. J. Appl. Polym. Sci. 2021, 138, 50847. [Google Scholar] [CrossRef]

- Zhang, H.; Huang, T.; Jiang, Q.; He, L.; Bismarck, A.; Hu, Q. Recent progress of 3D printed continuous fiber rein-forced polymer composites based on fused deposition modeling: A review. J. Mater. Sci. 2021, 56, 12999–13022. [Google Scholar] [CrossRef]

- Jia, C.; Das, P.; Kim, I.; Yoon, Y.-J.; Tay, C.Y.; Lee, J.-M. Applications, treatments, and reuse of plastics from electrical and electronic equipment. J. Ind. Eng. Chem. 2022, 110, 84–99. [Google Scholar] [CrossRef]

- Ahmed, D.S.; Mohammed, A.; Husain, A.A.; El-Hiti, G.A.; Kadhom, M.; Kariuki, B.M.; Yousif, E. Fabrication of highly photos table polystyrene films embedded with organometallic complexes. Polymers 2022, 14, 1024. [Google Scholar] [CrossRef] [PubMed]

- Li, J. Synthesis, characterization, and thermoelectric properties of conducting metallopolymers. Int. J. Adv. Manuf. Technol. 2021, 1, 21–38. [Google Scholar]

- Amza, C.G.; Zapciu, A.; Baciu, F.; Vasile, M.I.; Popescu, D. Aging of 3D Printed Polymers under Sterilizing UV-C Radiation. Polymers 2021, 13, 4467. [Google Scholar] [CrossRef]

| Method | Number of Studies |

|---|---|

| Case study | 1 |

| Experimental quantitative | 33 |

| Experimental mixed methods | 6 |

| Sample Code | Weight Ratio (%) | |

|---|---|---|

| Virgin PLA | Recycled PLA | |

| V100R0 | 100 | 0 |

| V75R25 | 75 | 25 |

| V50R50 | 50 | 50 |

| V25R75 | 25 | 75 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Maraveas, C.; Kyrtopoulos, I.V.; Arvanitis, K.G. Evaluation of the Viability of 3D Printing in Recycling Polymers. Polymers 2024, 16, 1104. https://doi.org/10.3390/polym16081104

Maraveas C, Kyrtopoulos IV, Arvanitis KG. Evaluation of the Viability of 3D Printing in Recycling Polymers. Polymers. 2024; 16(8):1104. https://doi.org/10.3390/polym16081104

Chicago/Turabian StyleMaraveas, Chrysanthos, Ioannis Vasileios Kyrtopoulos, and Konstantinos G. Arvanitis. 2024. "Evaluation of the Viability of 3D Printing in Recycling Polymers" Polymers 16, no. 8: 1104. https://doi.org/10.3390/polym16081104

APA StyleMaraveas, C., Kyrtopoulos, I. V., & Arvanitis, K. G. (2024). Evaluation of the Viability of 3D Printing in Recycling Polymers. Polymers, 16(8), 1104. https://doi.org/10.3390/polym16081104