The Preparation and Performance of Epoxy/Acetylene Carbon Black Wave-Absorbing Foam

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation

2.3. Characterization and Measurements

3. Results and Discussion

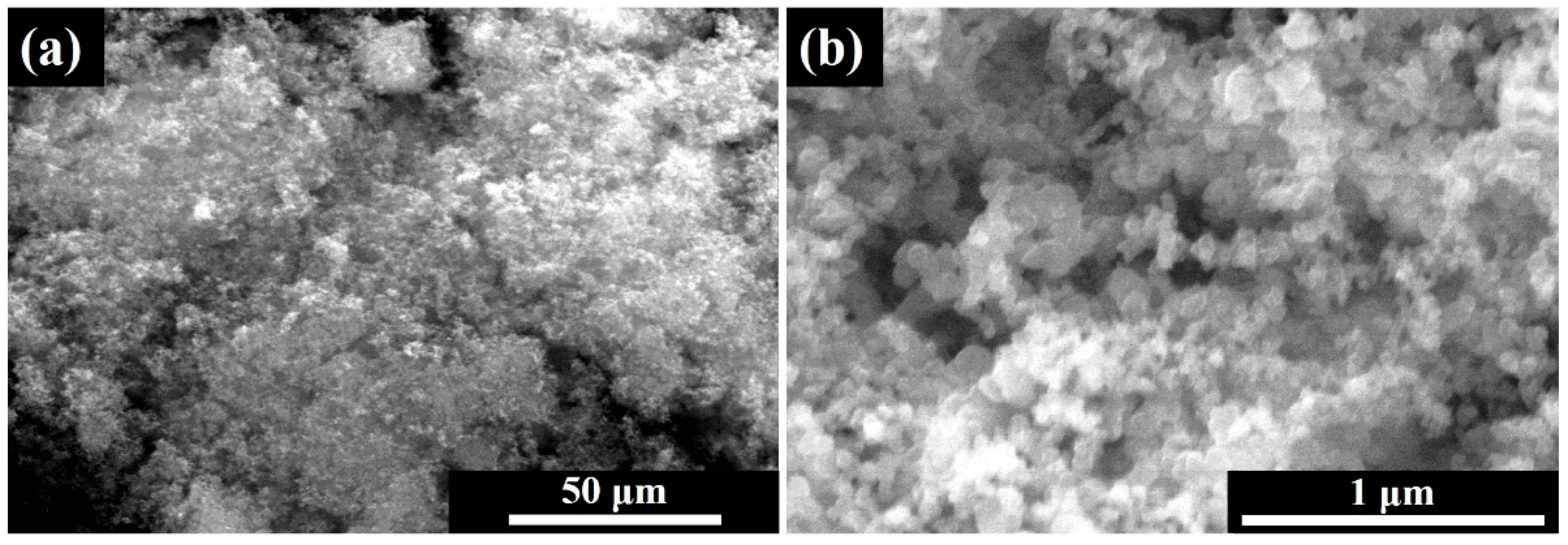

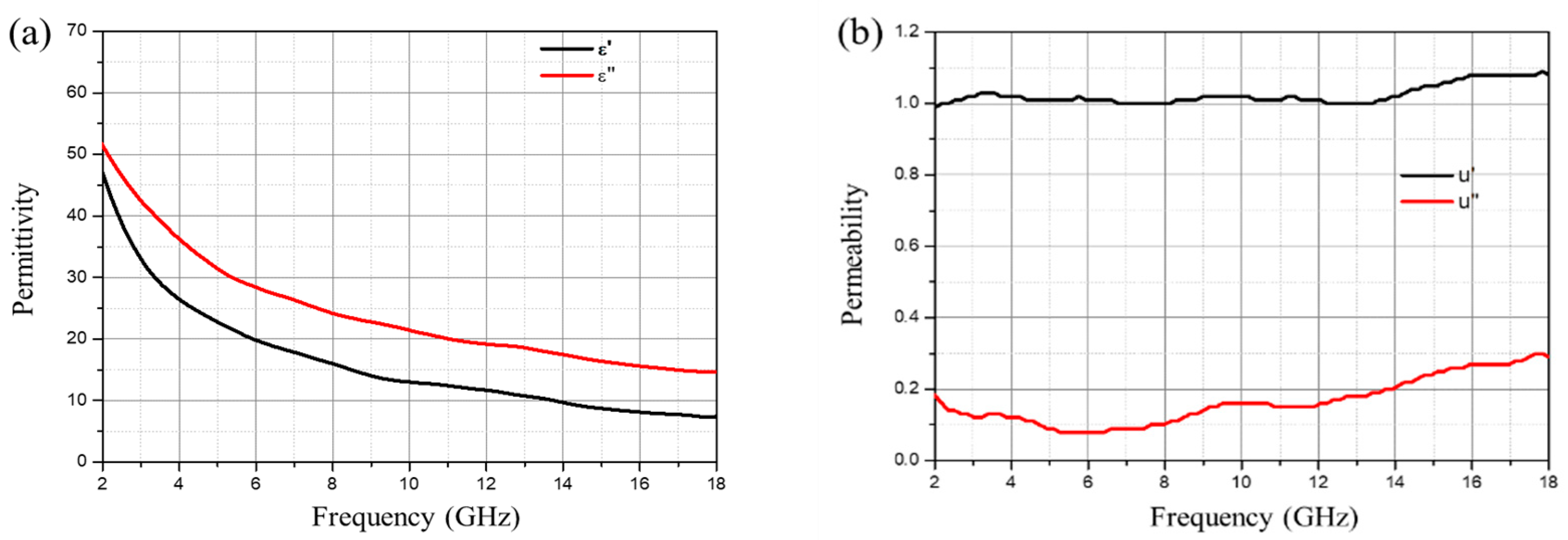

3.1. Absorbent Characteristics

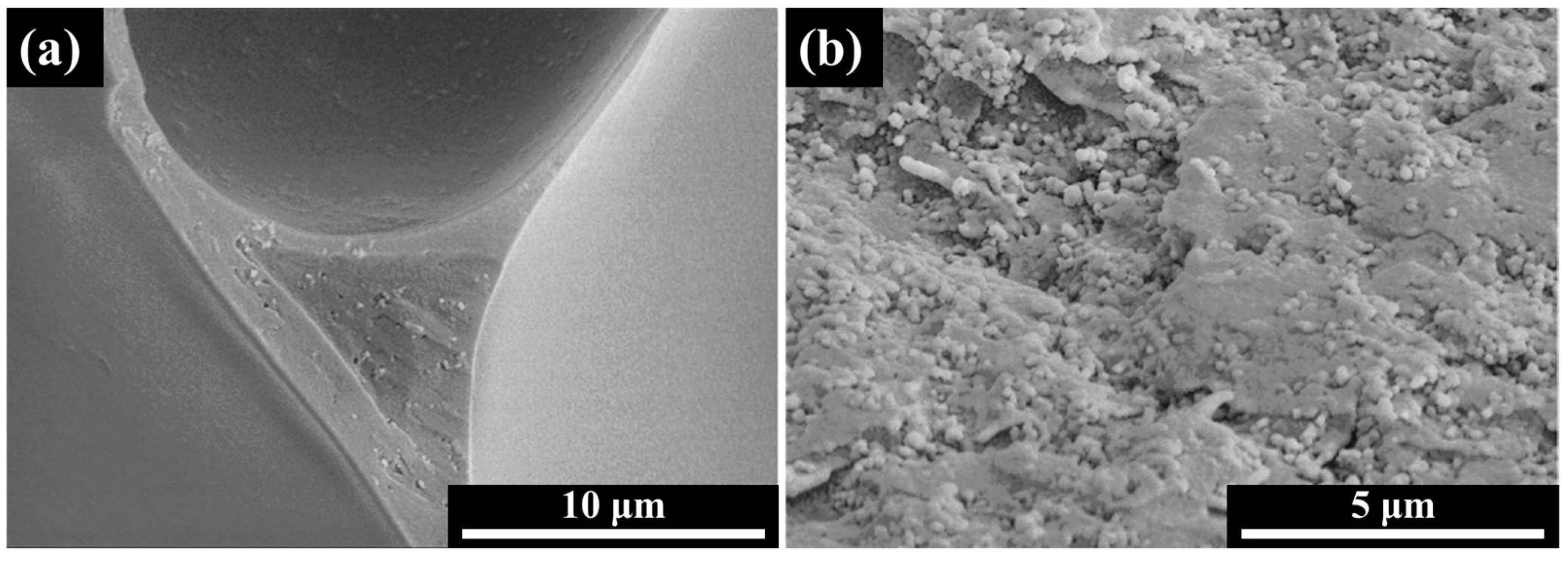

3.2. Distribution State of CB in Epoxy Foam

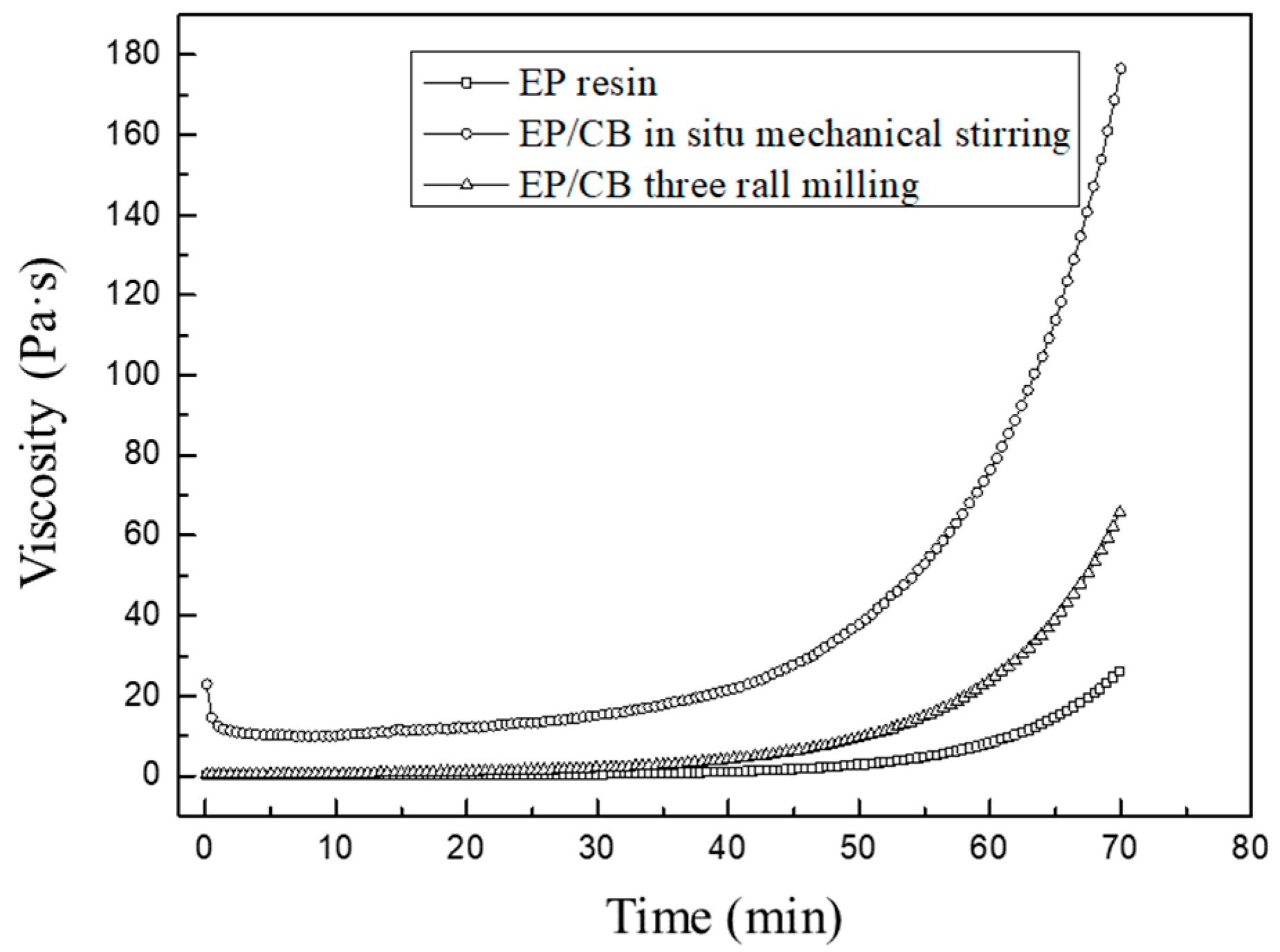

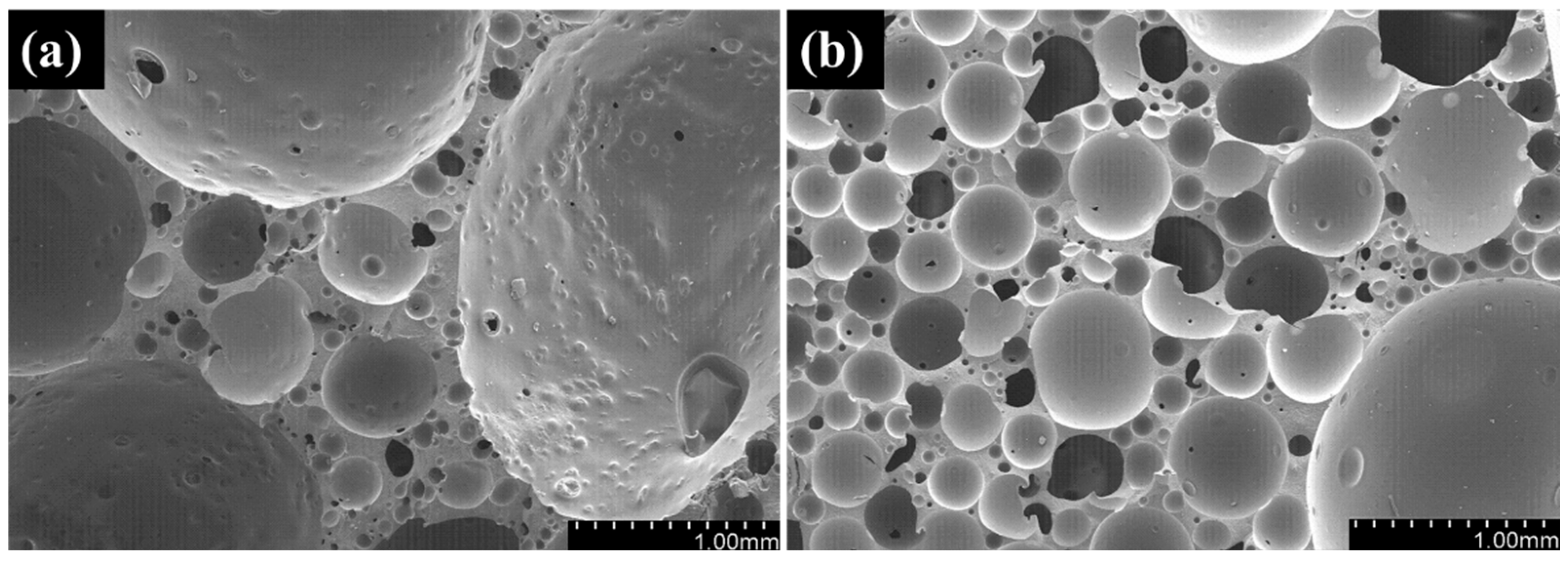

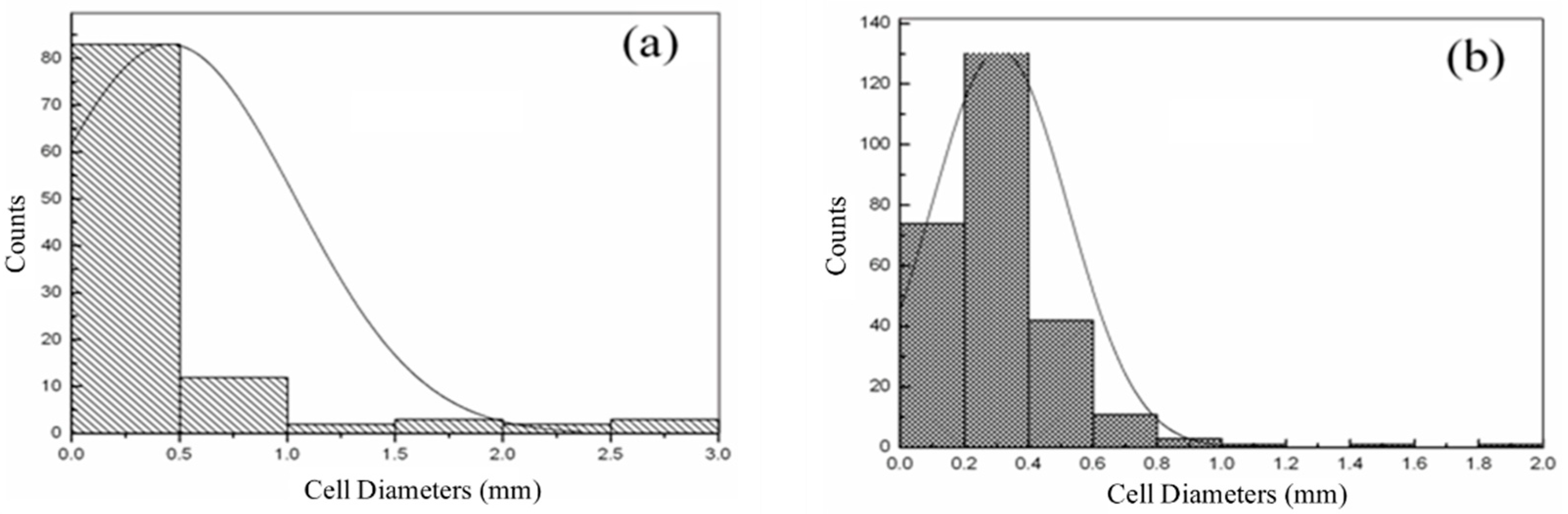

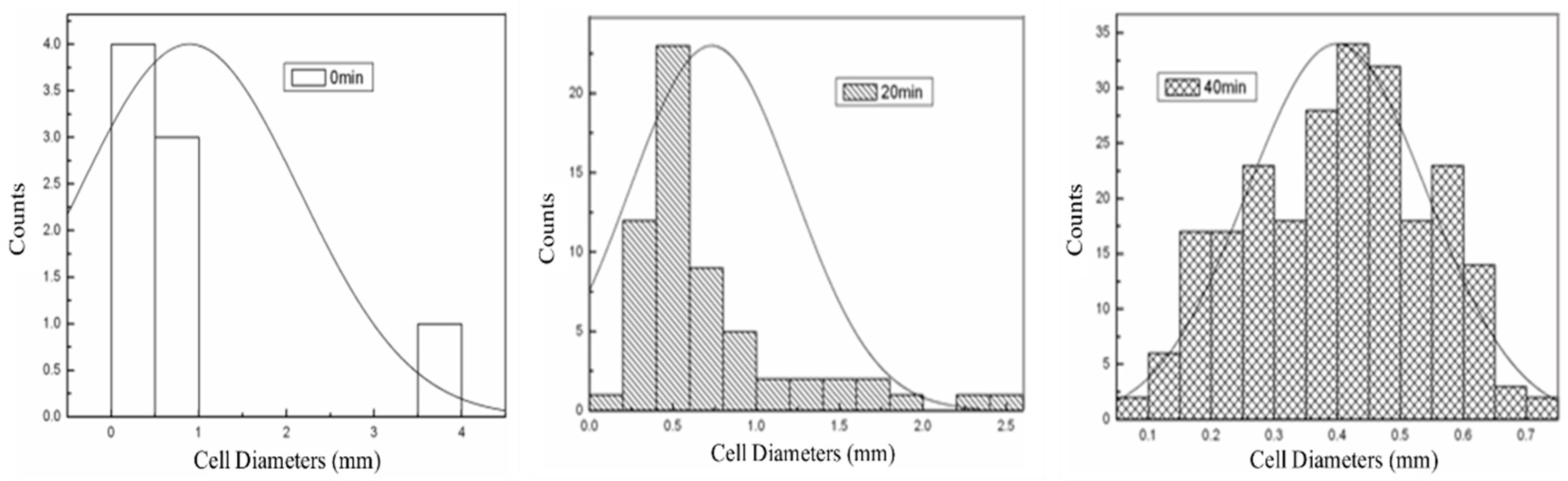

3.3. Influence of Pre-Polymerization Time on Pore Structure and Properties

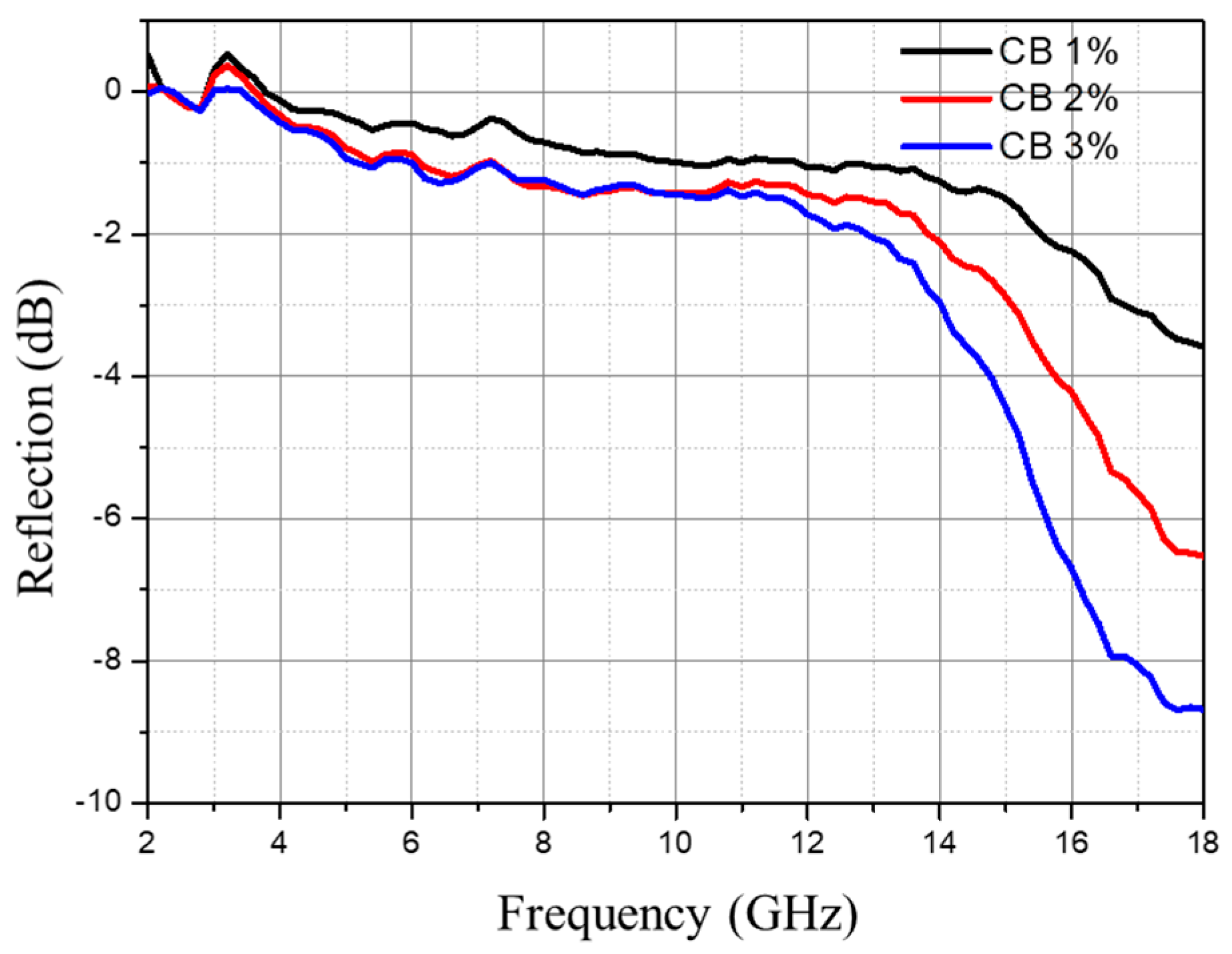

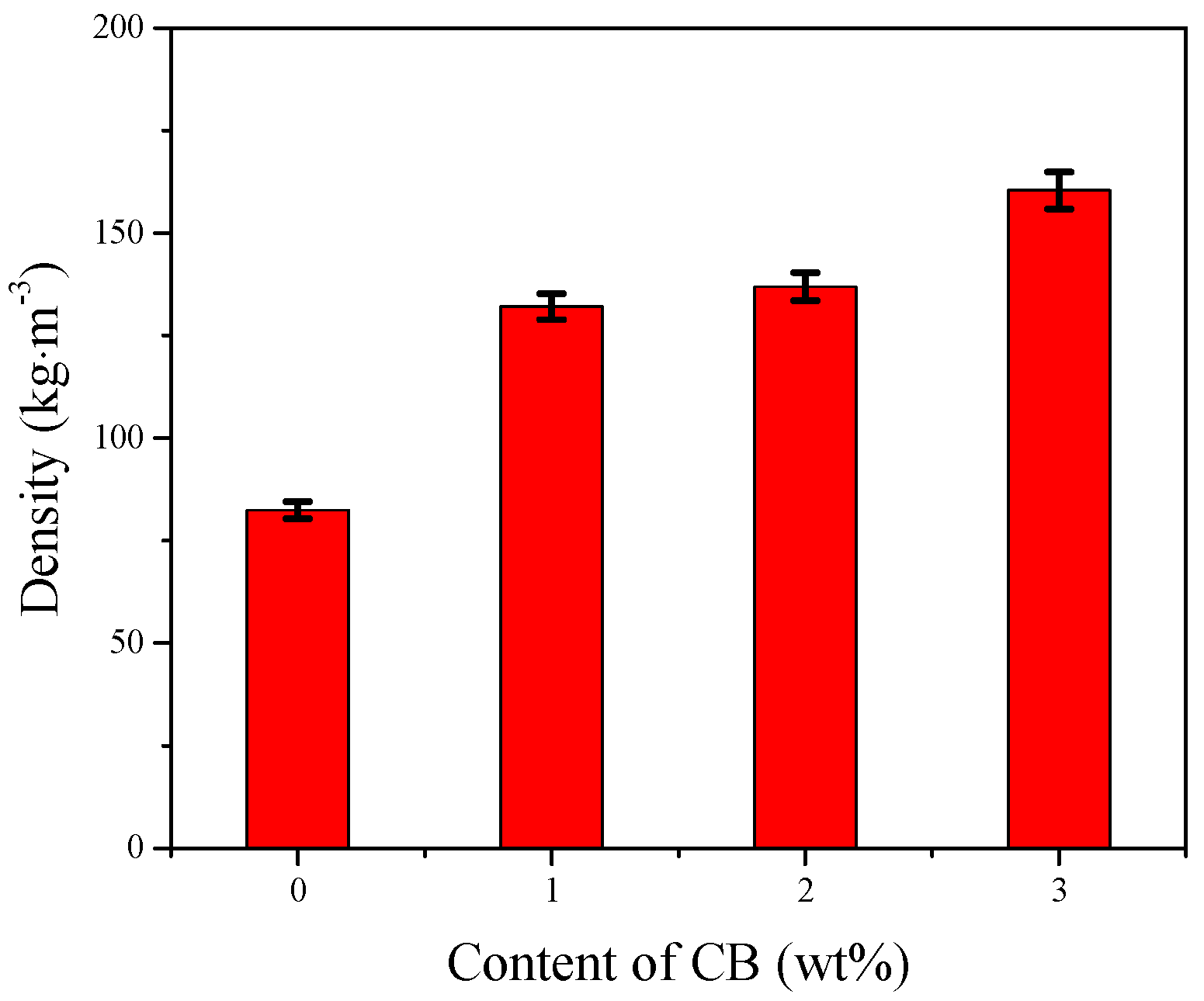

3.4. Impact of CB Content on Pore Structure and Performance of Foam

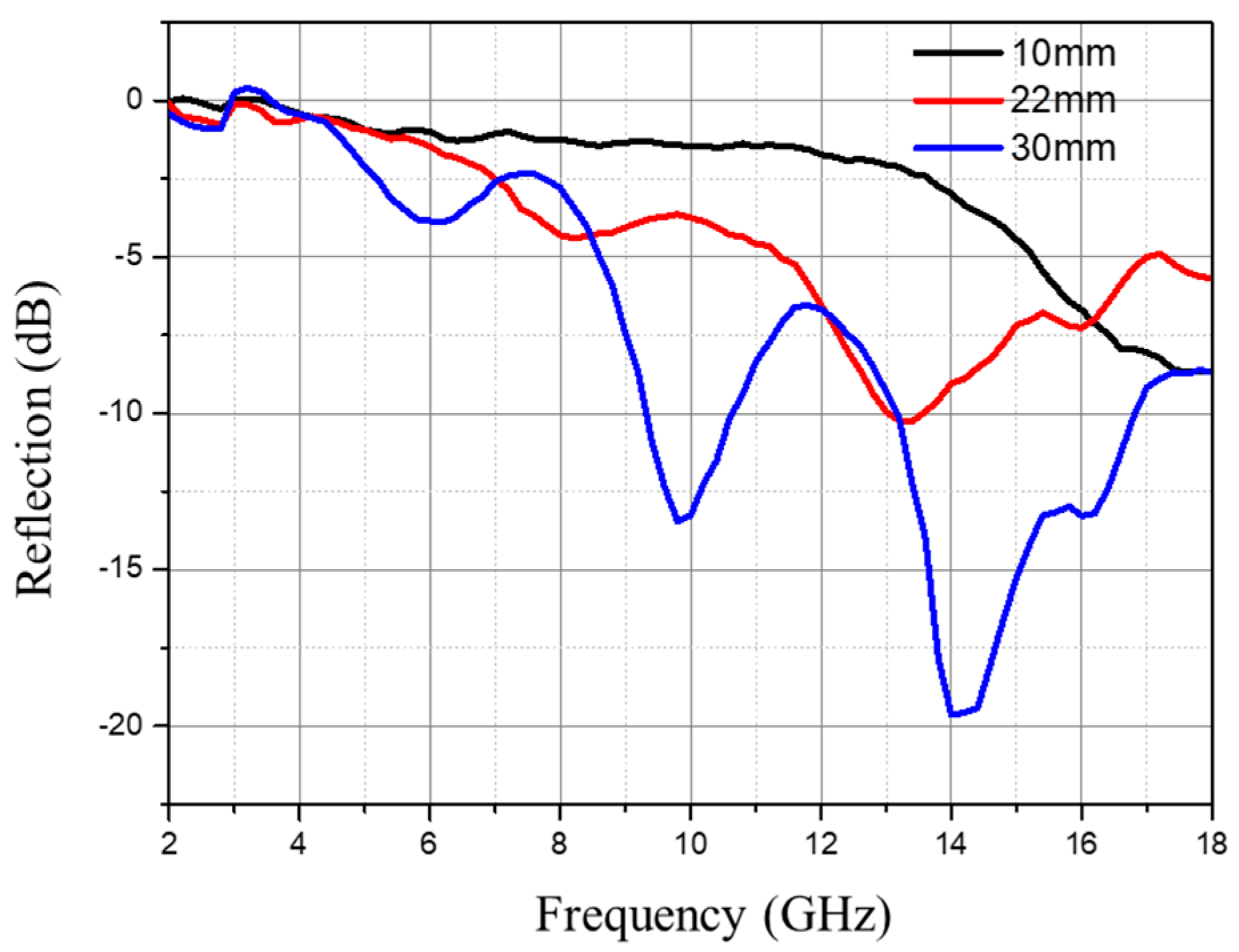

3.5. Effect of Foam Thickness on Electrical Performance

4. Conclusions

- (1)

- CB has good absorption performance in the high-frequency range, and a lower CB content is advantageous in reducing electromagnetic wave loss. Moreover, when the CB content exceeds 3 wt%, pre-polymerization becomes difficult, making it challenging to achieve the desired degree of pre-polymerization.

- (2)

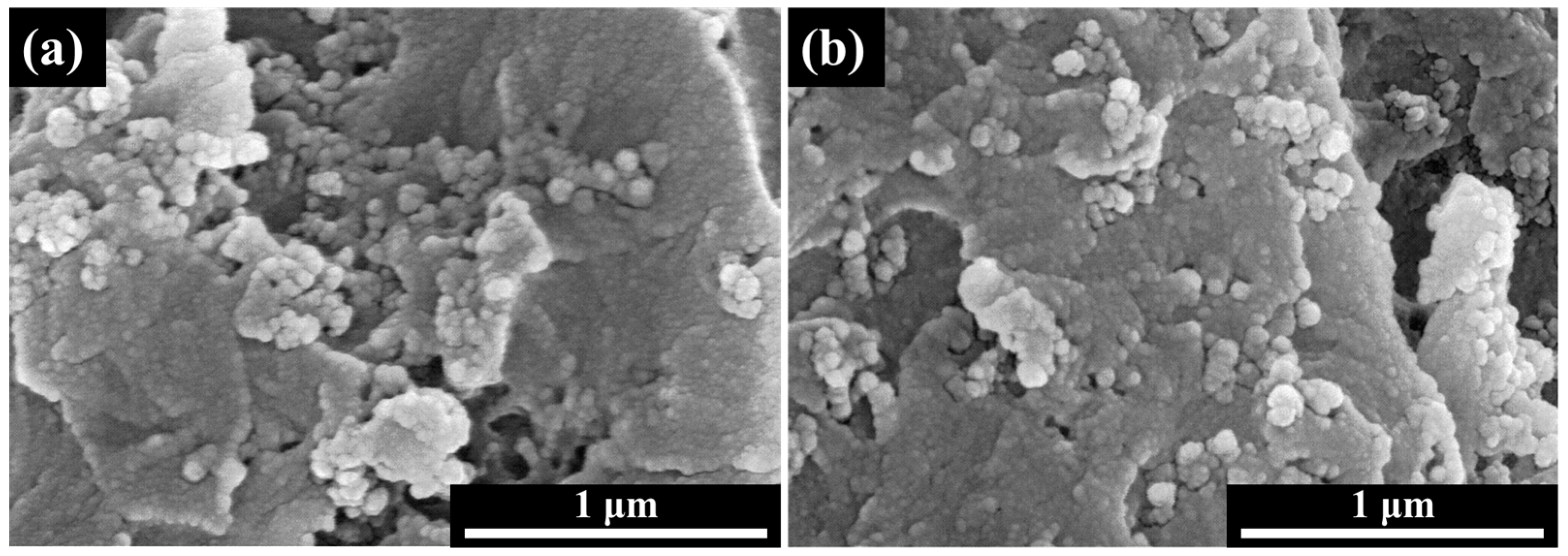

- Mechanical stirring results in the severe aggregation of CB, with aggregate sizes of about 300–400 nm, leading to poor dispersion. However, after three-roll grinding, the large aggregates are broken down, resulting in aggregate sizes of approximately 70–80 nm, thereby improving the dispersion of CB.

- (3)

- Although three-roll grinding dispersion results in good dispersion of CB, lower viscosity, and a fine and uniform pore structure, it may be advantageous for mechanical properties. However, the absorption performance is not ideal, as the foam prepared using three-roll grinding has nearly 0 reflectivity in the 2–16 GHz range and a reflectivity rate of around −1 dB in the 16–18 GHz range.

- (4)

- With the prolongation of pre-polymerization time, the pore diameter decreases from 1.02 mm to 0.4 mm, exhibiting a typical normal distribution.

- (5)

- The addition of CB increases the foam wall thickness, enhances its resistance to deformation, and thereby increases its strength and modulus.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sun, T.; Liu, Z.; Li, S.; Liu, H.; Chen, F.; Wang, K.; Zhao, Y. Effective improvement on microwave absorbing performance of epoxy resin-based composites with 3D MXene foam prepared by one-step impregnation method. Compos. Part A Appl. Sci. Manuf. 2021, 150, 106594. [Google Scholar] [CrossRef]

- Qian, Y.; Tao, Y.; Li, Y.; Hao, J.; Xu, C.; Yan, W.; Jiang, Q.; Luo, Y.; Yang, J. High performance epoxy resin with efficient electromagnetic wave absorption and heat dissipation properties for electron packaging by modification of 3D MDCF@hBN. Chem. Eng. J. 2022, 441, 136033. [Google Scholar] [CrossRef]

- Luo, C.M.; Wang, W.C.; Yang, W.; Liu, X.Y.; Lin, J.; Zhang, L.Q.; He, S.J. High strength and multi-recyclable epoxy vitrimer containing dual-dynamic covalent bonds based on the disulfide and imine bond metathesis. ACS Sustain. Chem. Eng. 2023, 11, 14591–14600. [Google Scholar] [CrossRef]

- Qian, Y.; Tao, Y.; Li, W.; Li, Y.; Xu, T.; Hao, J.; Jiang, Q.; Luo, Y.; Yang, J. High electromagnetic wave absorption and thermal management performance in 3D CNF@C-Ni/epoxy resin composites. Chem. Eng. J. 2021, 425, 131608. [Google Scholar] [CrossRef]

- Luo, C.M.; Yang, W.; Qi, W.; Chen, Z.L.; Lin, J.; Bian, X.M.; He, S.J. Cost-efficient and recyclable epoxy vitrimer composite with low initial viscosity based on exchangeable disulfide crosslinks. Polym. Test. 2022, 113, 107670. [Google Scholar] [CrossRef]

- Yang, W.; Zhang, E.; Zhao, J.; Zhao, Y.; Tang, K.; Cui, Y.; Luo, X.; Zhang, Z.; Li, C.; Zhang, F.; et al. Dawn of clean energy: Enhanced heat transfer, radiative cooling, and firecracker-style controlled nuclear fusion power generation system. Clean Energy Sci. Technol. 2023, 1, 61. [Google Scholar] [CrossRef]

- Luo, C.M.; Li, J.; Chen, Z.L.; Lin, J.; Chen, L.; He, S.J. Improving the charge dissipating performance and breakdown strength of epoxy resin by incorporating polydopamine-coated barium titanate. Mater. Today Comm. 2022, 31, 103619. [Google Scholar] [CrossRef]

- He, S.J.; Luo, C.M.; Zheng, Y.Z.; Xue, Y.; Song, X.P.; Lin, J. Improvement in the charge dissipation performance of epoxy resin composites by incorporating amino-modified boron nitride nanosheets. Mater. Lett. 2021, 298, 130009. [Google Scholar] [CrossRef]

- Stefani, P.M.; Barchi, A.T.; Sabugal, J.; Vazquez, A. Characterization of epoxy foams. J. Appl. Polym. Sci. 2003, 90, 2992–2996. [Google Scholar] [CrossRef]

- Wan Hamad, W.N.F.; Teh, P.L.; Yeoh, C.K. Effect of Acetic Acid as Catalyst on the Properties of Epoxy Foam. Polym.-Plast. Technol. 2013, 52, 754–760. [Google Scholar] [CrossRef]

- Ren, Q.; Zhu, S. One-Pack Epoxy Foaming with CO2 as Latent Blowing Agent. ACS Macro Lett. 2015, 4, 693–697. [Google Scholar] [CrossRef] [PubMed]

- Mostovoi, A.S.; Bunenkov, P.N.; Panova, L.G. Fireproof foamed epoxy polymers. Inorg. Mater. Appl. Res. 2016, 7, 768–772. [Google Scholar] [CrossRef]

- Ito, A.; Semba, T.; Taki, K.; Ohshima, M. Effect of the molecular weight between crosslinks of thermally cured epoxy resins on the CO2-bubble nucleation in a batch physical foaming process. J. Appl. Polym. Sci. 2014, 131, 40407. [Google Scholar] [CrossRef]

- Lyu, J.; Liu, T.; Xi, Z.; Zhao, L. Effect of pre-curing process on epoxy resin foaming using carbon dioxide as blowing agent. J. Cell. Plast. 2016, 53, 181–197. [Google Scholar] [CrossRef]

- Hu, G.; Yu, D. Tensile, thermal and dynamic mechanical properties of hollow polymer particle-filled epoxy syntactic foam. Mater. Sci. Eng. A-Struct. 2011, 528, 5177–5183. [Google Scholar] [CrossRef]

- Wang, L.; Yang, X.; Zhang, J.; Zhang, C.; He, L. The compressive properties of expandable microspheres/epoxy foams. Compos. Part B-Eng. 2014, 56, 724–732. [Google Scholar] [CrossRef]

- Anbuchezhiyan, G.; Mohan, B.; Sathianarayanan, D.; Muthuramalingam, T. Synthesis and characterization of hollow glass microspheres reinforced magnesium alloy matrix syntactic foam. J. Alloys Compd. 2017, 719, 125–132. [Google Scholar] [CrossRef]

- Takiguchi, O.; Ishikawa, D.; Sugimoto, M.; Taniguchi, T.; Koyama, K. Effect of rheological behavior of epoxy during precuring on foaming. J. Appl. Polym. Sci. 2008, 110, 657–662. [Google Scholar] [CrossRef]

- Chen, K.; Tian, C.; Lu, A.; Zhou, Q.; Jia, X.; Wang, J. Effect of SiO2 on rheology, morphology, thermal, and mechanical properties of high thermal stable epoxy foam. J. Appl. Polym. Sci. 2014, 131, 40068. [Google Scholar] [CrossRef]

- Wang, L.; Yang, X.; Jiang, T.; Zhang, C.; He, L. Cell morphology, bubbles migration, and flexural properties of non-uniform epoxy foams using chemical foaming agent. J. Appl. Polym. Sci. 2014, 131, 41175. [Google Scholar] [CrossRef]

- Park, K.Y.; Lee, S.E.; Kim, C.G.; Han, J.H. Fabrication and electromagnetic characteristics of electromagnetic wave absorbing sandwich structures. Compos. Sci. Technol. 2006, 66, 576–584. [Google Scholar] [CrossRef]

- Gao, Q.; Zhang, G.; Zhang, Y.; Fan, X.; Wang, Z.; Zhang, S.; Xiao, R.; Huang, F.; Shi, X.; Qin, J. Absorption dominated high-performance electromagnetic interference shielding epoxy/functionalized reduced graphene oxide/Ni-chains microcellular foam with asymmetric conductive structure. Compos. Sci. Technol. 2022, 223, 109419. [Google Scholar] [CrossRef]

- Yue, L.; Yang, Y.; Zhou, Q.; Lei, Y.; Deng, G.; Yang, T. Broadband electromagnetic wave absorbing performance by designing the foam structure and double-layer for cement-based composites containing MWCNTs. Cem. Concr. Comp. 2022, 131, 104595. [Google Scholar] [CrossRef]

- Xu, X.; Tian, X.; Bo, G.; Su, X.; Yan, J.; Yan, Y. Synthesis of Lightweight Renewable Microwave-Absorbing Bio-Polyurethane/Fe3O4 Composite Foam: Structure Analysis and Absorption Mechanism. Int. J. Mol. Sci. 2022, 23, 12301. [Google Scholar] [CrossRef]

- He, S.J.; He, T.F.; Wang, J.Q.; Wu, X.H.; Xue, Y.; Zhang, L.Q.; Lin, J. A novel method to prepare acrylonitrile-butadiene rubber/clay nanocomposites by compounding with clay gel. Compos. Part B-Eng. 2019, 167, 356–361. [Google Scholar] [CrossRef]

- Chen, Z.L.; Wang, W.C.; Li, J.; Lin, J.; Li, F.Z.; Zhang, L.Q.; He, S.J. Bioinspired design of nitrile-butadiene rubber/montmorillonite nanocomposites with hydrogen bond interactions leading to highly effective reinforcement. Polymer 2023, 277, 125968. [Google Scholar] [CrossRef]

- He, S.J.; Li, J.; Zhang, X.M.; Chen, Z.L.; Zhou, H.F.; Pang, C.; Weng, Y.X.; Lin, J. Nitrile butadiene rubber/clay nanocomposites cured and reinforced by copper sulfate pentahydrate. J. Mater. Res. Technol. 2023, 22, 2338–2342. [Google Scholar] [CrossRef]

- Zhang, X.M.; Chen, Z.L.; Li, J.; Wu, X.H.; Lin, J.; He, S.J. Mechanical performance design via regulating the interactions in acrylonitrile-butadiene rubber/clay nanocomposites by small molecule compounds. Polym. Test. 2022, 110, 107565. [Google Scholar] [CrossRef]

- Li, J.; Chen, S.L.; Zhang, X.M.; Liu, X.; Chen, Z.L.; Lin, J.; He, S.J. Effect of triethylene glycol bis(3-tert-butyl-4-hydroxy-5-methylphenyl)propionate on structure and mechanical properties of nitrile butadiene rubber/clay nanocomposites. J. Appl. Polym. Sci. 2023, 140, e53984. [Google Scholar] [CrossRef]

- He, S.J.; Bai, F.J.; Liu, S.X.; Ma, H.F.; Hu, J.B.; Chen, L.; Lin, J.; Wei, G.S.; Du, X.Z. Aging properties of styrene-butadiene rubber nanocomposites filled with carbon black and rectorite. Polym. Test. 2017, 64, 92–100. [Google Scholar] [CrossRef]

- Jang, D.; Park, J.E.; Kim, Y.K. Evaluation of (CNT@CIP)-Embedded Magneto-Resistive Sensor Based on Carbon Nanotube and Carbonyl Iron Powder Polymer Composites. Polymers 2022, 14, 542. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.; Zhou, X.; Gao, Y.; Wang, Y.; Liao, Y.; Wu, L.; Lyu, L. Electromagnetic Wave-Absorbing and Bending Properties of Three-Dimensional Gradient Woven Composites with Triangular Sections. Polymers 2022, 14, 1745. [Google Scholar] [CrossRef]

- Gu, W.; Shi, J.; Pang, T.; Sun, Q.; Jia, Q.; Hu, J.; Zhang, J. Mechanical and Electromagnetic Wave Absorption Performance of Carbonyl Iron Powder-Modified Nonwoven Materials. Materials 2023, 16, 7403. [Google Scholar] [CrossRef]

- Huang, Y.Y.; Wu, J. Preparation and Characterization of Graphene Oxide/Polyaniline/Carbonyl Iron Nanocomposites. Materials 2022, 15, 484. [Google Scholar] [CrossRef]

- ASTM D 1621; Standard Test Method for Compressive Properties of Rigid Cellular Plastics. ASTM: West Conshohocken, PA, USA, 2023.

- Dai, Y.; Sun, M.; Liu, C.; Li, Z. Electromagnetic wave absorbing characteristics of carbon black cement-based composites. Cem. Concr. Comp. 2010, 32, 508–513. [Google Scholar] [CrossRef]

- Wu, Y.; Liu, X.; Wang, Z.; Ma, G.; Hao, Y. Optimization of multicomponent microwave absorbents for improved electromagnetic wave absorption of layered foamed cementitious materials. Constr. Build. Mater. 2023, 396, 132385. [Google Scholar] [CrossRef]

- Hu, S.-H.; Yuan, J.-J.; Dai, H.; Liu, Y.-Y.; He, J.; Tu, J.-L. Preparation of a Flexible X-Band Radar-Wave-Absorbing Composite Material by Using Beta-Silicon Carbide and Polyurethane as Substrates and Multiwalled Carbon Nanotubes as Additives. Symmetry 2022, 14, 2144. [Google Scholar] [CrossRef]

| CB Content (wt%) | Density (kg·m−3) | Foam Wall Thickness (mm) | Compression Strength (MPa) | Compression Modulus (MPa) |

|---|---|---|---|---|

| 0 | 82.4 ± 2.1 | 0.014 ± 0.001 | 0.58 ± 0.02 | 16.0 ± 0.8 |

| 1 | 132.1 ± 3.2 | 0.021 ± 0.001 | 0.83 ± 0.05 | 26.1 ± 1.2 |

| 2 | 137.0 ± 3.4 | 0.023 ± 0.002 | 0.84 ± 0.06 | 31.7 ± 1.3 |

| 3 | 160.4 ± 4.5 | 0.032 ± 0.002 | 0.82 ± 0.04 | 28.5 ± 0.9 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, X.; Huang, H.; Lu, H. The Preparation and Performance of Epoxy/Acetylene Carbon Black Wave-Absorbing Foam. Polymers 2024, 16, 1074. https://doi.org/10.3390/polym16081074

Liu X, Huang H, Lu H. The Preparation and Performance of Epoxy/Acetylene Carbon Black Wave-Absorbing Foam. Polymers. 2024; 16(8):1074. https://doi.org/10.3390/polym16081074

Chicago/Turabian StyleLiu, Xiaoli, Hao Huang, and Haijun Lu. 2024. "The Preparation and Performance of Epoxy/Acetylene Carbon Black Wave-Absorbing Foam" Polymers 16, no. 8: 1074. https://doi.org/10.3390/polym16081074

APA StyleLiu, X., Huang, H., & Lu, H. (2024). The Preparation and Performance of Epoxy/Acetylene Carbon Black Wave-Absorbing Foam. Polymers, 16(8), 1074. https://doi.org/10.3390/polym16081074