Carbon Fiber Reinforced Recycled Polypropylene/Polyolefin Elastomer Composites with High Mechanical Properties

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

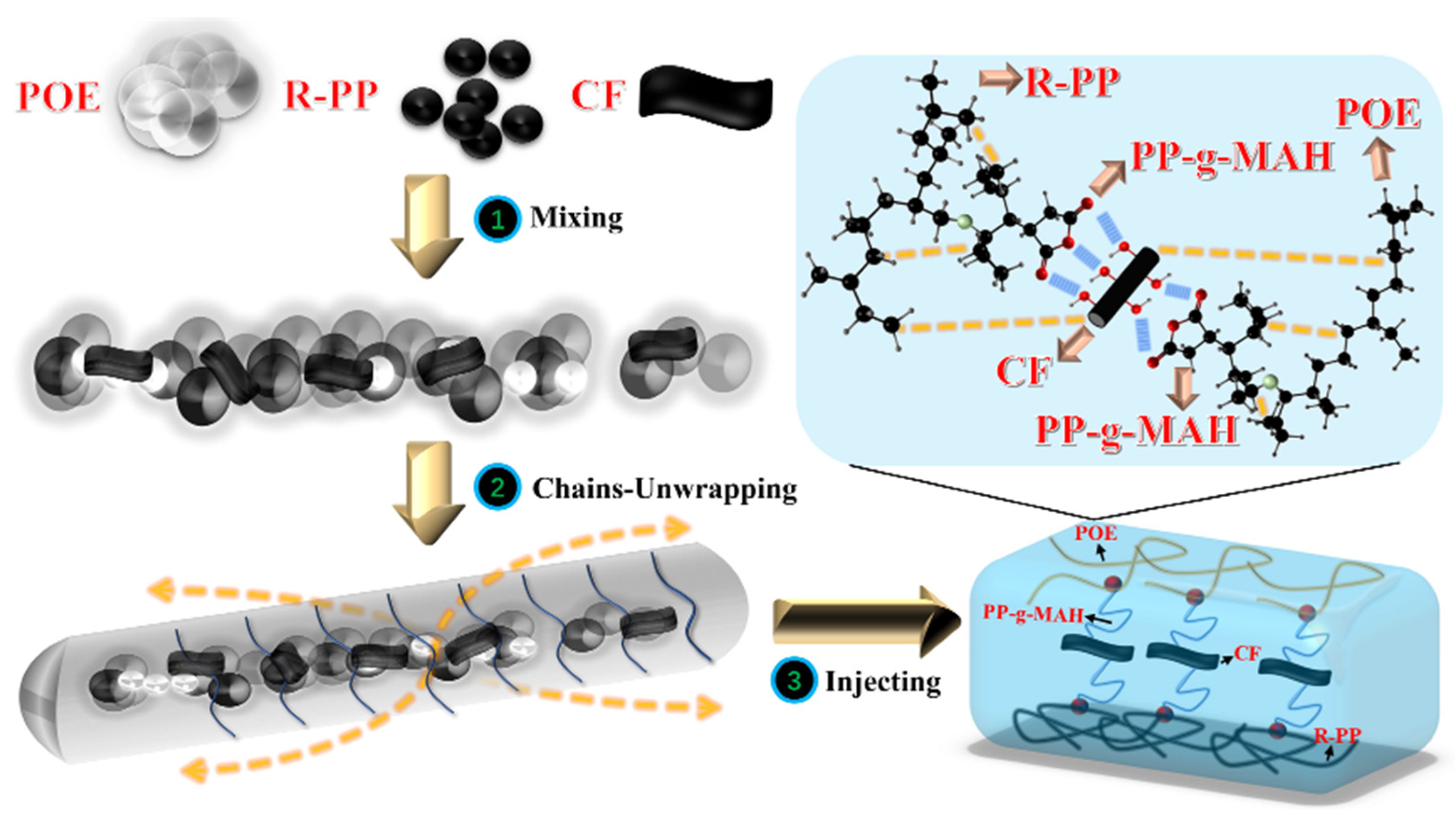

2.2. Sample Preparation

2.3. Methods

2.3.1. Density

2.3.2. The Mechanical Testing

2.3.3. Scanning Electron Microscopy (SEM)

2.3.4. Thermal Differential Scanning Calorimetry (DSC)

2.3.5. Thermogravimetry (TGA)

2.3.6. Fourier Transform Infrared (FT-IR) Spectroscopy

2.3.7. X-ray Diffraction (XRD) Testing

3. Results and Discussion

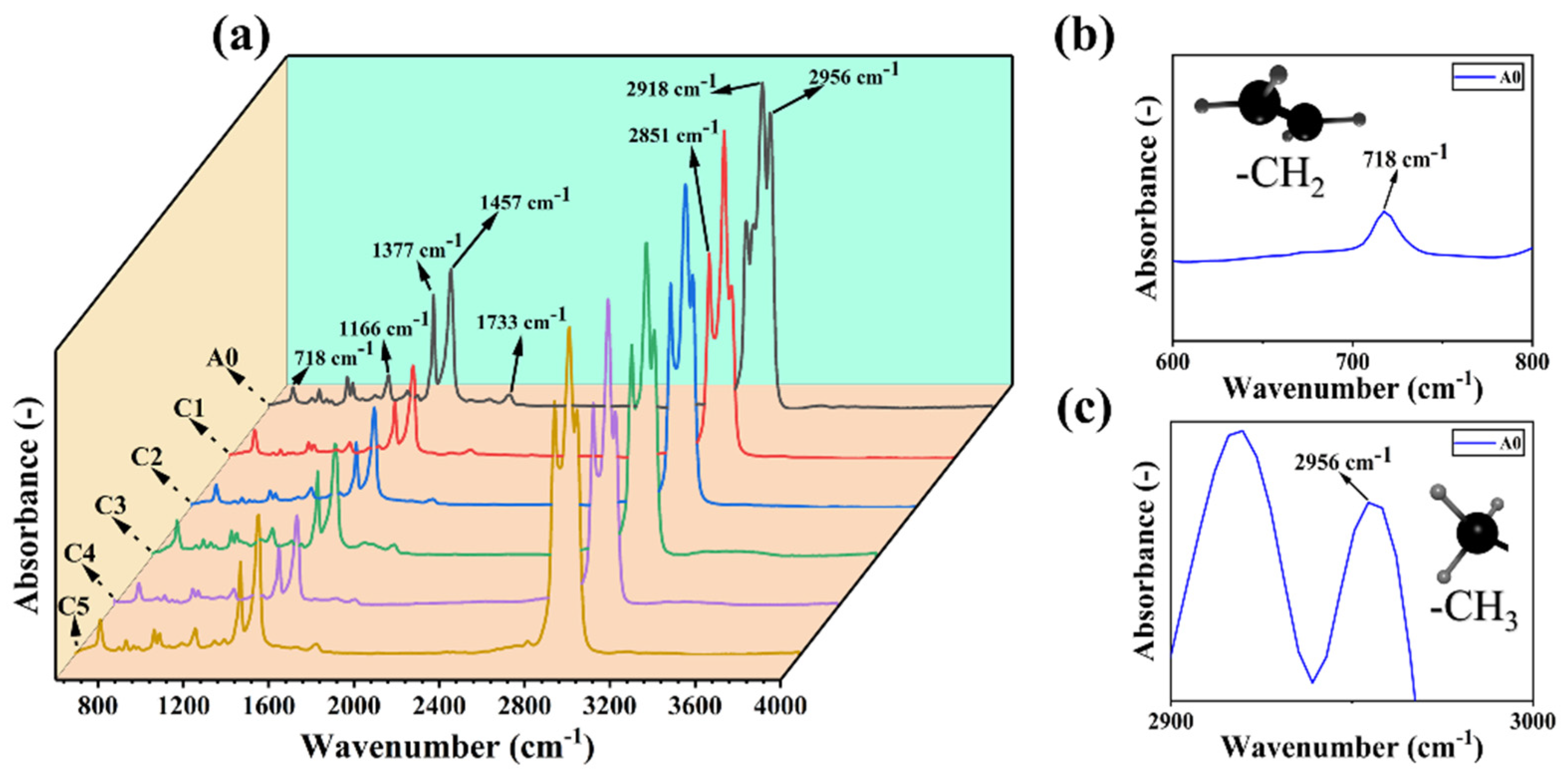

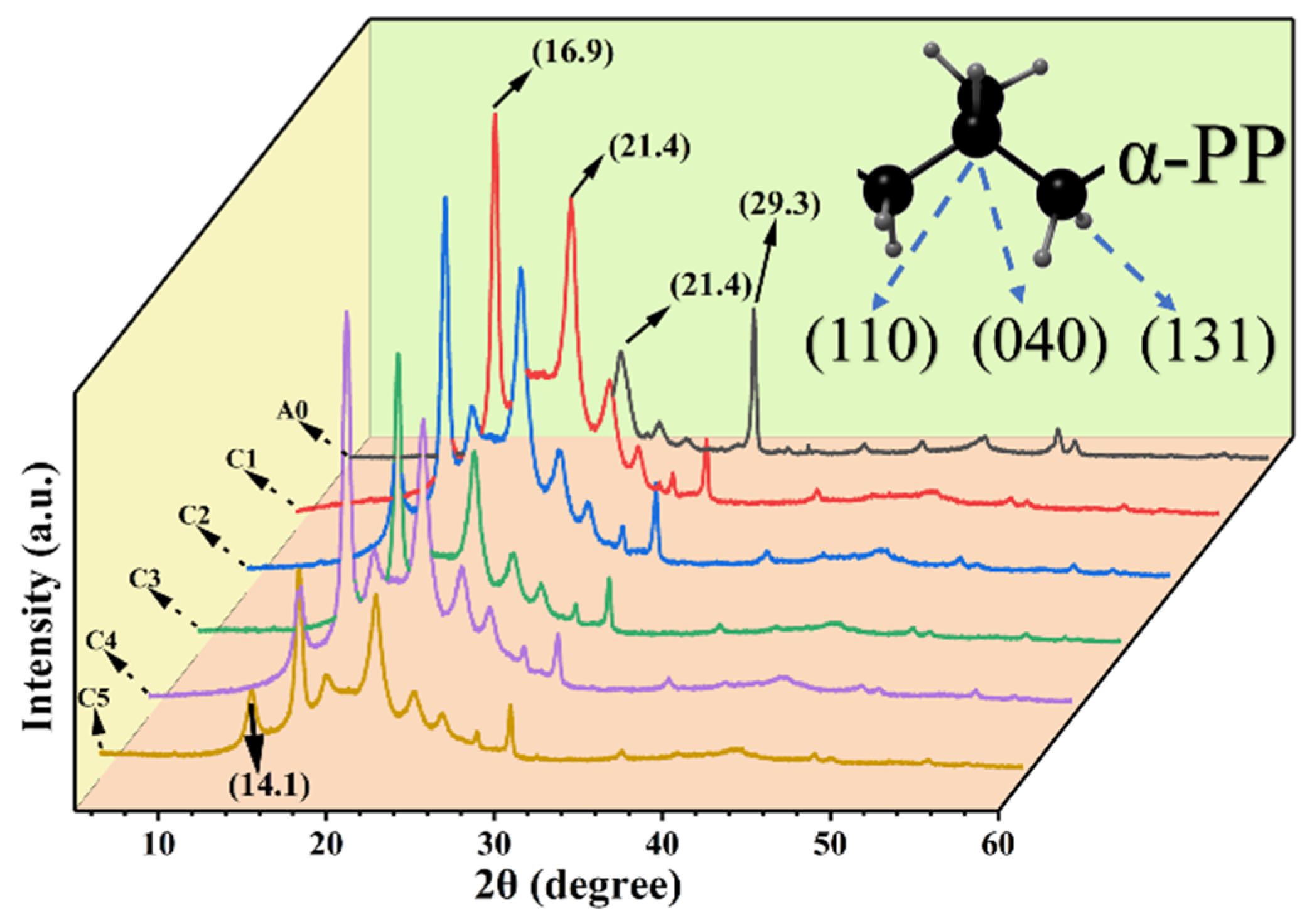

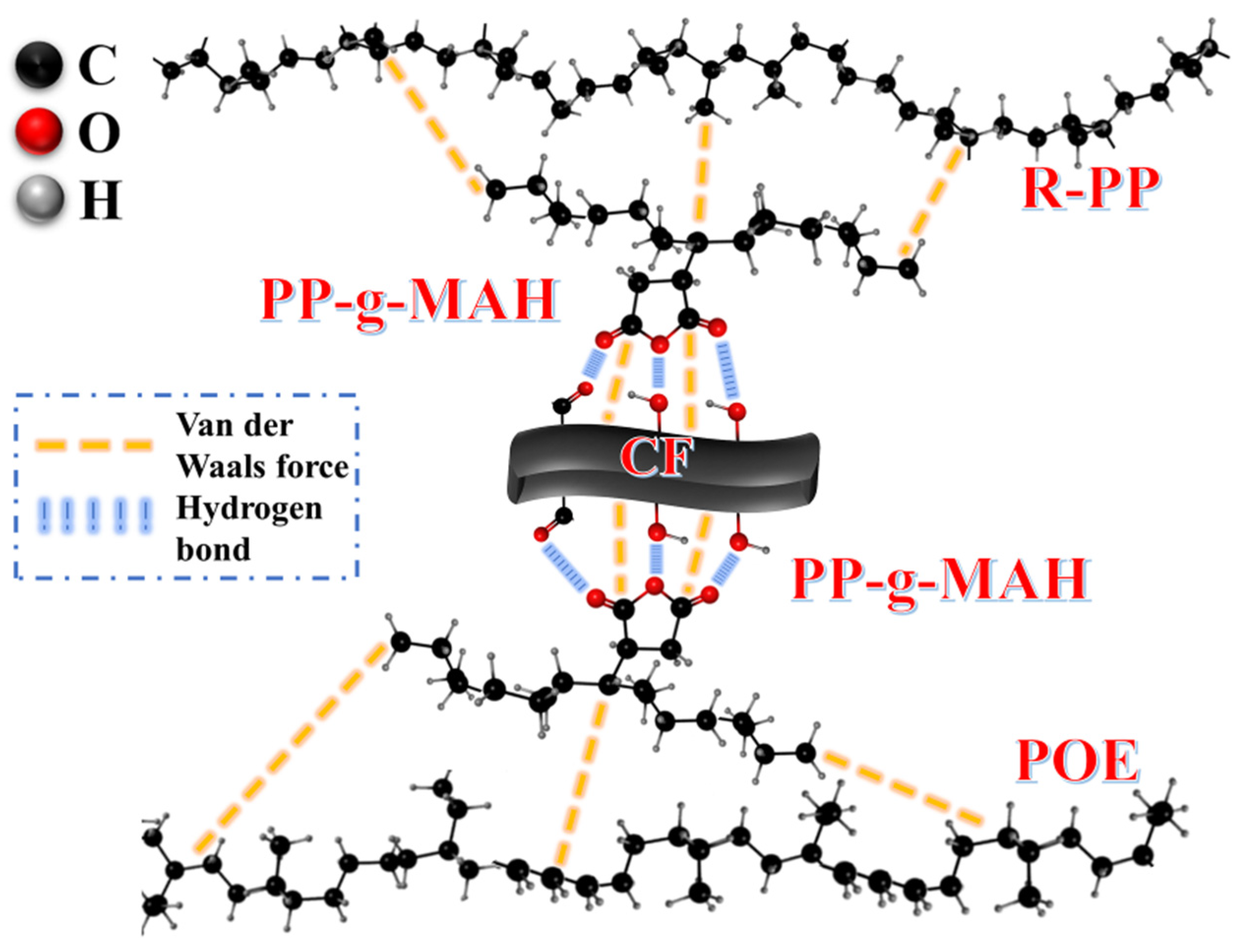

3.1. Chemical Structure Analysis

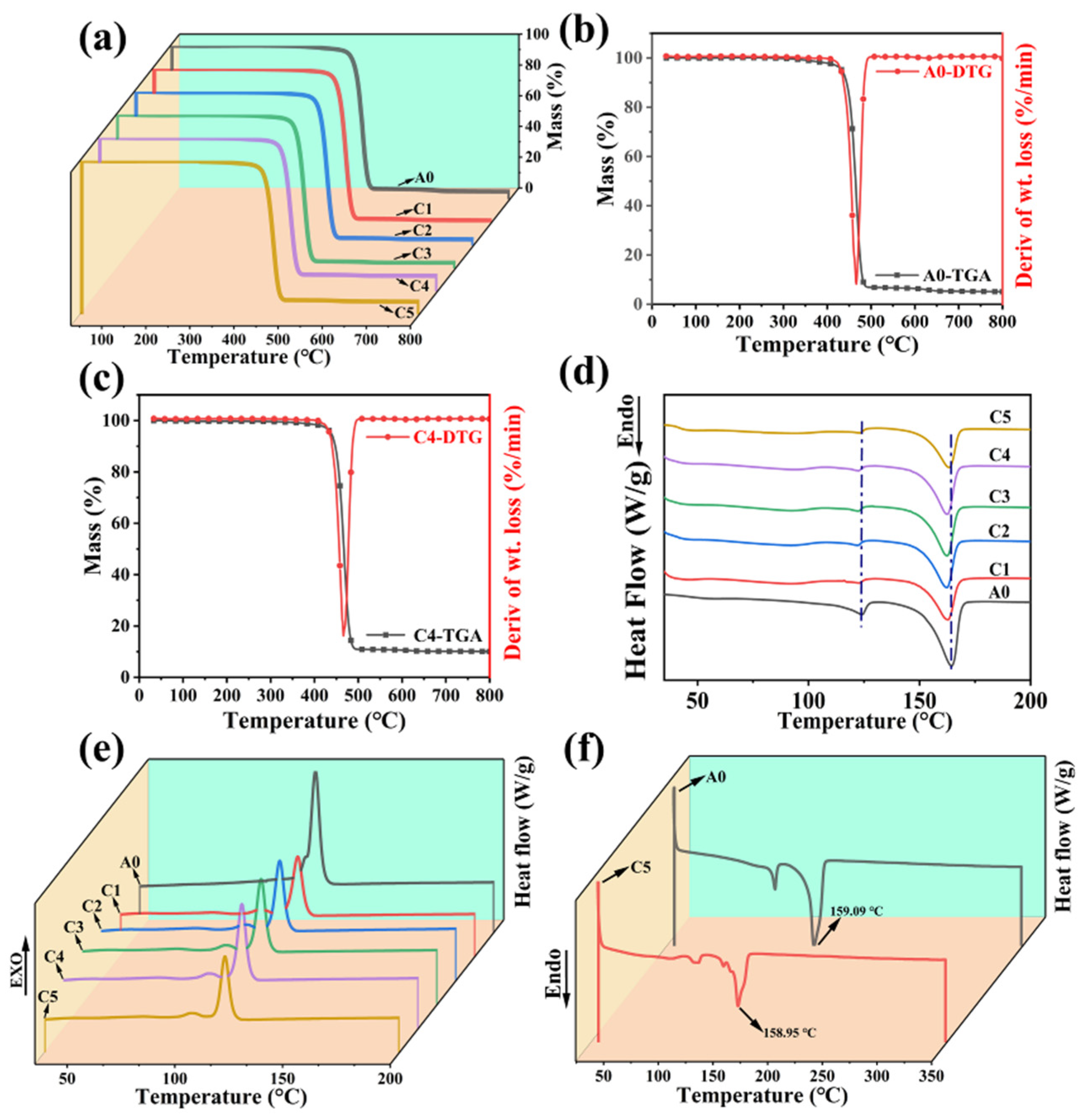

3.2. Thermal Profile

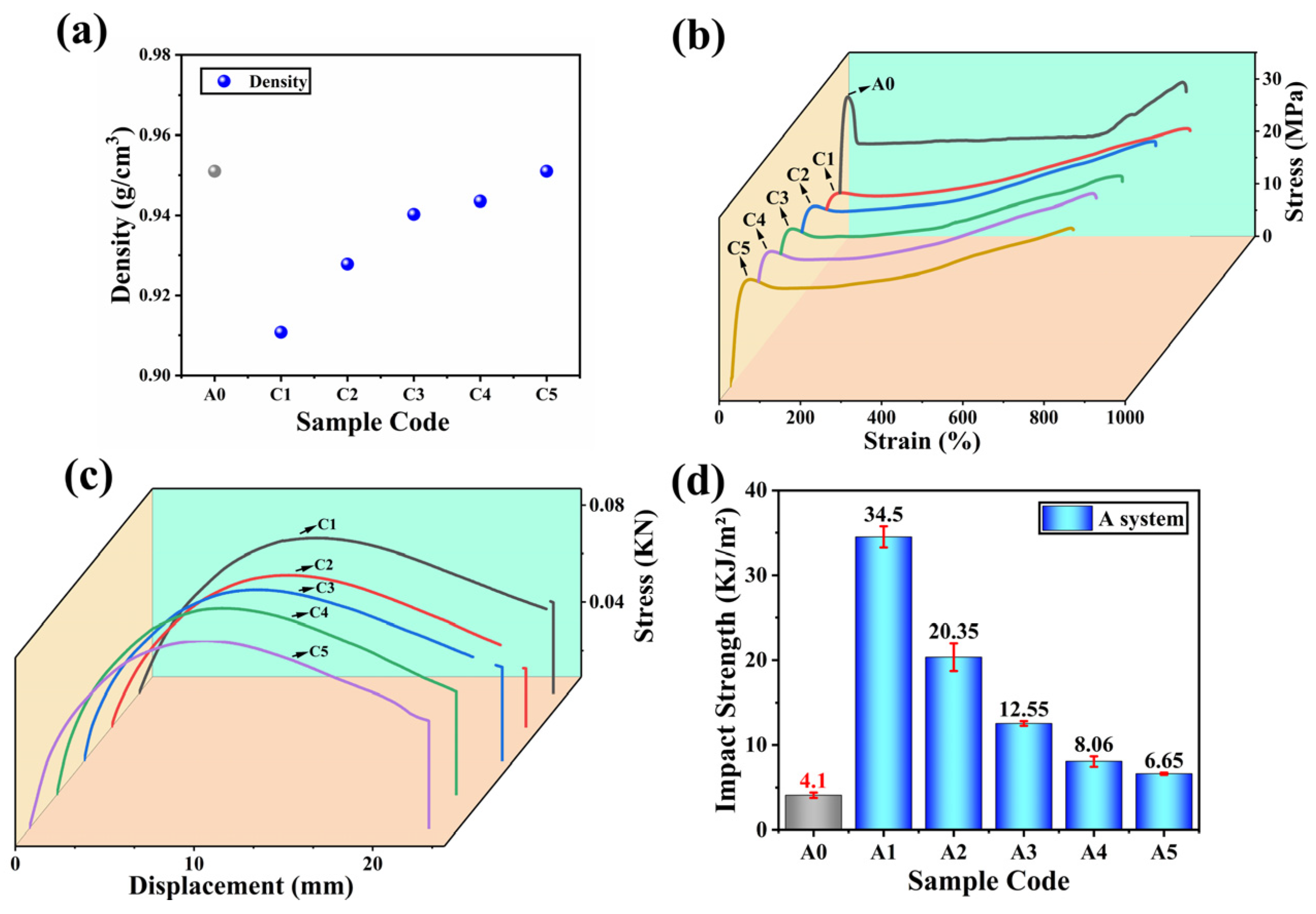

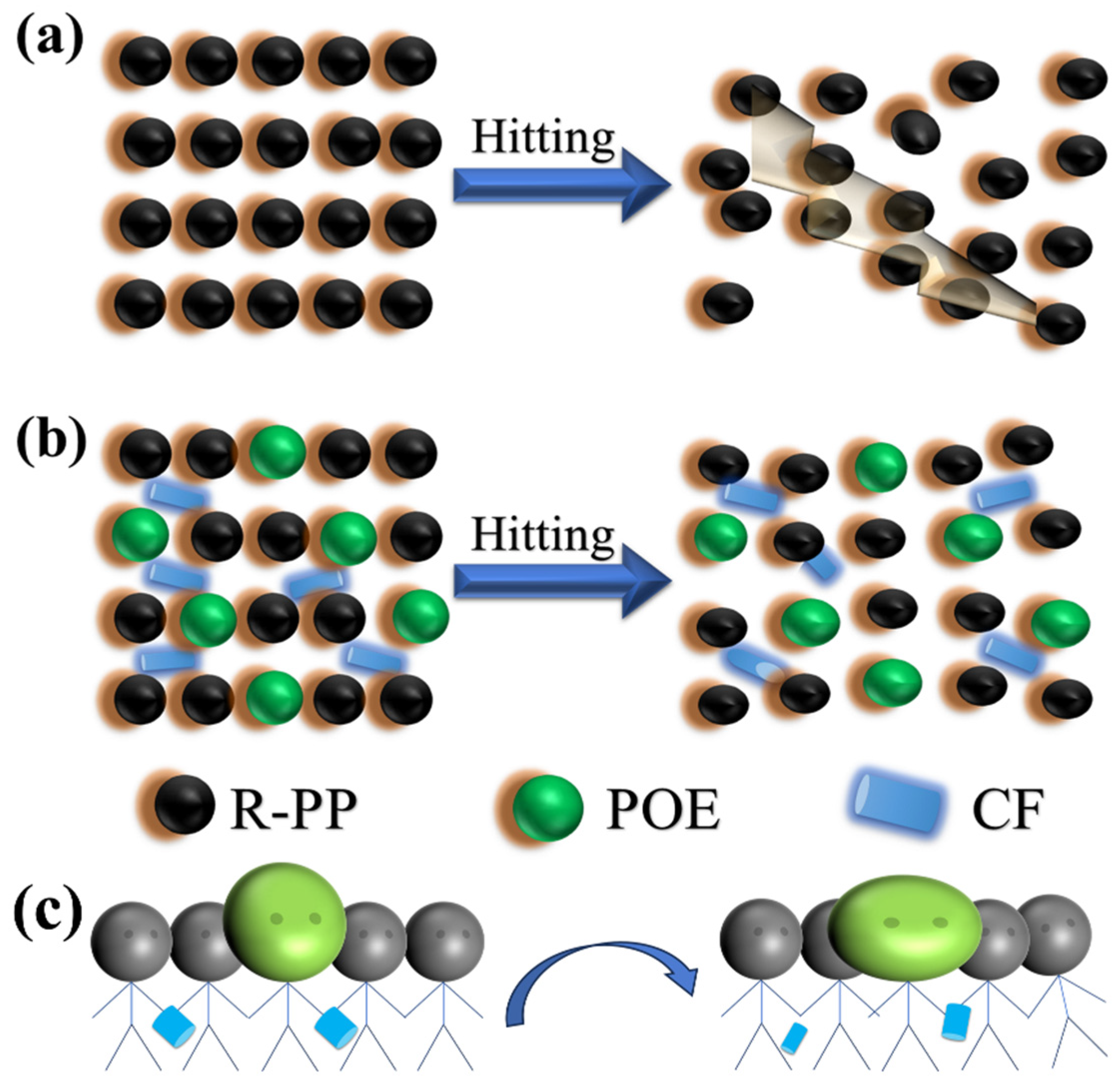

3.3. Mechanical and Surface Profile

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Priyadarsini, M.; Biswal, T.; Acharya, S.K. Study of mechanical properties of reinforced polypropylene (PP)/nettle fibers biocomposites and its application in automobile industry. Mater. Today Proc. 2023, 74, 980–984. [Google Scholar] [CrossRef]

- Velásquez, E.; Garrido, L.; Valenzuela, X.; Galotto, M.J.; Guarda, A.; López de Dicastillo, C. Valorization of post-consumer recycled polypropylene through their reinforcement with amine and amine/silane organically modified clays for potential use in food packaging. Food Packag. Shelf Life 2023, 38, 101121. [Google Scholar] [CrossRef]

- Nguyen, H.-L.; Tran, T.H.; Hao, L.T.; Jeon, H.; Koo, J.M.; Shin, G.; Hwang, D.S.; Hwang, S.Y.; Park, J.; Oh, D.X. Biorenewable, transparent, and oxygen/moisture barrier nanocellulose/nanochitin-based coating on polypropylene for food packaging applications. Carbohydr. Polym. 2021, 271, 118421. [Google Scholar] [CrossRef]

- Zhang, Z.; Liu, K.; Chong, D.; Niu, D.; Lin, P.; Liu, X.; Niu, Y.; Jing, R. Evaluation of photocatalytic micro-surfacing mixture: Road performance, vehicle exhaust gas degradation capacity and environmental impacts. Constr. Build. Mater. 2022, 345, 128367. [Google Scholar] [CrossRef]

- Akoueson, F.; Paul-Pont, I.; Tallec, K.; Huvet, A.; Doyen, P.; Dehaut, A.; Duflos, G. Additives in polypropylene and polylactic acid food packaging: Chemical analysis and bioassays provide complementary tools for risk assessment. Sci. Total Environ. 2023, 857, 159318. [Google Scholar] [CrossRef]

- Su, Y.; Shi, L.; Zhao, H.; Wang, J.; Li, W.; Jiang, Z.; Wang, X.; Yao, Y.; Sun, X. A green strategy to recycle the waste PP melt-blown materials: From 2D to 3D construction. Waste Manag. 2023, 157, 159–167. [Google Scholar] [CrossRef]

- Ng, E.L.; Lwanga, E.H.; Eldridge, S.M.; Johnston, P.; Hu, H.W.; Geissen, V.; Chen, D. An overview of microplastic and nanoplastic pollution in agroecosystems. Sci. Total Environ. 2018, 627, 1377–1388. [Google Scholar] [CrossRef]

- Inácio, A.L.N.; Nonato, R.C.; Bonse, B.C. Mechanical and thermal behavior of aged composites of recycled PP/EPDM/talc reinforced with bamboo fiber. Polym. Test. 2018, 72, 357–363. [Google Scholar] [CrossRef]

- Bhuiyan, M.A.R.; Darda, M.A.; Ali, A.; Talha, A.R.; Hossain, M.F.; Mohebbullah, M.; Islam, M.A. Heat insulating jute-reinforced recycled polyethylene and polypropylene bio-composites for energy conservation in buildings. Mater. Today Commun. 2023, 37, 106948. [Google Scholar] [CrossRef]

- Jan, P.; Matkovič, S.; Bek, M.; Perše, L.S.; Kalin, M. Tribological behaviour of green wood-based unrecycled and recycled polypropylene composites. Wear 2023, 524–525, 204826. [Google Scholar] [CrossRef]

- Jones, H.; McClements, J.; Ray, D.; Hindle, C.S.; Kalloudis, M.; Koutsos, V. Thermomechanical Properties of Virgin and Recycled Polypropylene—High-Density Polyethylene Blends. Polymers 2023, 15, 4200. [Google Scholar] [CrossRef]

- Kang, D.; Lee, J.M.; Moon, C.; Kim, H.I. Improvement in mechanical properties of recycled polypropylene composite by controlling the length distribution of glass fibers. Polym. Compos. 2021, 42, 2171–2179. [Google Scholar] [CrossRef]

- AlMaadeed, M.A.; Kahraman, R.; Noorunnisa Khanam, P.; Madi, N. Date palm wood flour/glass fibre reinforced hybrid composites of recycled polypropylene: Mechanical and thermal properties. Mater. Des. 2012, 42, 289–294. [Google Scholar] [CrossRef]

- Črešnar, K.P.; Bek, M.; Luxbacher, T.; Brunčko, M.; Zemljič, L.F. Insight into the Surface Properties of Wood Fiber-Polymer Composites. Polymers 2021, 13, 1535. [Google Scholar] [CrossRef]

- Stanic, S.; Koch, T.; Schmid, K.; Knaus, S.; Archodoulaki, V.-M. Improving Rheological and Mechanical Properties of Various Virgin and Recycled Polypropylenes by Blending with Long-Chain Branched Polypropylene. Polymers 2021, 13, 1137. [Google Scholar] [CrossRef]

- Yang, J.; Zhang, Y.; Zhang, Y. Brittle–ductile transition of PP/POE blends in both impact and high speed tensile tests. Polymer 2003, 44, 5047–5052. [Google Scholar] [CrossRef]

- Wang, Y.; Li, J.; Zhang, Z.; Wang, J.; Yang, Y.; Cao, Y.; Wang, W. Magnetic polypropylene composites with selectively localized reactive nano-Fe3O4 in toughener of POE-g-MAH: Towards super toughness, high flexibility and balanced strength. Mater. Des. 2022, 217, 110607. [Google Scholar] [CrossRef]

- Yue, X.-H.; Zhang, F.-S.; Wu, L.; Zhang, C.-C.; Qian, P. Upcycling of blending waste plastics as flexible growing substrate with superabsorbing property. Chem. Eng. J. 2022, 435, 134622. [Google Scholar] [CrossRef]

- Andoko, A.; Gapsari, F.; Wijatmiko, I.; Diharjo, K.; Rangappa, S.M.; Siengchin, S. Performance of carbon fiber (CF)/Ceiba petandra fiber (CPF) reinforced hybrid polymer composites for lightweight high-performance applications. J. Mater. Res. Technol. 2023, 27, 7636–7644. [Google Scholar] [CrossRef]

- Kawasaki, S.; Naito, K.; Ishida, O.; Shirai, T.; Uzawa, K. Infrared-thermography measurement of temperature distribution in carbon fiber–reinforced polypropylene during ultrasonic welding. Compos. Part A Appl. Sci. Manuf. 2024, 177, 107887. [Google Scholar] [CrossRef]

- Kwon, D.-J.; Kim, N.-S.-R.; Jang, Y.-J.; Yang, S.-B.; Yeum, J.-H.; Jung, J.-H.; Nam, S.Y.; Park, Y.-B.; Ji, W. Investigation of impact resistance performance of carbon fiber reinforced polypropylene composites with different lamination to applicate fender parts. Compos. Part B Eng. 2021, 215, 108767. [Google Scholar] [CrossRef]

- Li, C.-Q.; Zha, J.-W.; Long, H.-Q.; Wang, S.-J.; Zhang, D.-L.; Dang, Z.-M. Mechanical and dielectric properties of graphene incorporated polypropylene nanocomposites using polypropylene-graft-maleic anhydride as a compatibilizer. Compos. Sci. Technol. 2017, 153, 111–118. [Google Scholar] [CrossRef]

- Chen, X.; Wang, Y.; He, D.; Deng, Y. Enhanced dielectric performances of polypropylene films via polarity adjustment by maleic anhydride-grafted polypropylene. J. Appl. Polym. Sci. 2017, 134, 45029. [Google Scholar] [CrossRef]

- ISO 527-2:2012; Plastics—Determination of Tensile Properties—Part 2: Test Conditions for Moulding and Extrusion Plastics. ISO: Geneva, Switzerland, 2012.

- Wunderlich, B. Macromolecular Physics; Academic Press: Cambridge, MA, USA, 1976. [Google Scholar]

- Lin, T.A.; Lin, J.-H.; Bao, L. A study of reusability assessment and thermal behaviors for thermoplastic composite materials after melting process: Polypropylene/thermoplastic polyurethane blends. J. Clean. Prod. 2021, 279, 123473. [Google Scholar] [CrossRef]

- Watanabe, R.; Sugahara, A.; Hagihara, H.; Sato, H.; Mizukado, J.; Shinzawa, H. Study of matrix-filler interaction of polypropylene/silica composite by combined infrared (IR) spectroscopic imaging and disrelation mapping. Compos. Part A Appl. Sci. Manuf. 2020, 128, 105658. [Google Scholar] [CrossRef]

- Karaoui, M.; Hsissou, R.; Alami, M.; Assouag, M. Thermal, mechanical, morphological, and structural properties of composites based on polyolefin and biofiller produced from snail shell (PP/SSP). Mater. Today Proc. 2023; in press. [Google Scholar]

- Franco, P.; Incarnato, L.; De Marco, I. Supercritical CO2 impregnation of α-tocopherol into PET/PP films for active packaging applications. J. CO2 Util. 2019, 34, 266–273. [Google Scholar] [CrossRef]

- Zhang, S.; Hull, T.R.; Horrocks, A.R.; Smart, G.; Kandola, B.K.; Ebdon, J.; Joseph, P.; Hunt, B. Thermal degradation analysis and XRD characterisation of fibre-forming synthetic polypropylene containing nanoclay. Polym. Degrad. Stab. 2007, 92, 727–732. [Google Scholar] [CrossRef]

- Bai, H.; Wang, Y.; Song, B.; Han, L. Synergistic toughening effects of nucleating agent and ethylene–octene copolymer on polypropylene. J. Appl. Polym. Sci. 2008, 108, 3270–3280. [Google Scholar] [CrossRef]

- Li, X.; Wu, H.; Wang, Y.; Bai, H.; Liu, L.; Huang, T. Study on the β to α transformation of PP/POE blends with β-phase nucleating agent during the tensile deformation process. Mater. Sci. Eng. A 2010, 527, 531–538. [Google Scholar] [CrossRef]

- Niu, H.; Wang, N.; Li, Y. Influence of β-nucleating agent dispersion on the crystallization behavior of isotactic polypropylene. Polymer 2018, 150, 371–379. [Google Scholar] [CrossRef]

- Brachet, P.; Høydal, L.T.; Hinrichsen, E.L.; Melum, F. Modification of mechanical properties of recycled polypropylene from post-consumer containers. Waste Manag. 2008, 28, 2456–2464. [Google Scholar] [CrossRef]

- Yu, B.; Geng, C.; Zhou, M.; Bai, H.; Fu, Q.; He, B. Impact toughness of polypropylene/glass fiber composites: Interplay between intrinsic toughening and extrinsic toughening. Compos. Part B Eng. 2016, 92, 413–419. [Google Scholar] [CrossRef]

- Yokoi, D.; Takamura, M.; Takahashi, T. Mechanical properties of carbon fiber/polypropylene composites using carboxylic-acid-modified polypropylene without and with oxazoline-containing polymer coated on carbon fiber. Compos. Sci. Technol. 2023, 242, 110213. [Google Scholar] [CrossRef]

- Tiwari, S.K.; Umamaheswara Rao, A.; Reddy, N.; Sharma, H.; Pandey, J.K. Synthesis, characterization and finite element analysis of polypropylene composite reinforced by jute and carbon fiber. Mater. Today Proc. 2021, 46, 10884–10891. [Google Scholar] [CrossRef]

- Kore, S.; Spencer, R.; Ghossein, H.; Slaven, L.; Knight, D.; Unser, J.; Vaidya, U. Performance of hybridized bamboo-carbon fiber reinforced polypropylene composites processed using wet laid technique. Compos. Part C Open Access 2021, 6, 100185. [Google Scholar] [CrossRef]

- Almeshari, B.; Junaedi, H.; Baig, M.; Almajid, A. Development of 3D printing short carbon fiber reinforced polypropylene composite filaments. J. Mater. Res. Technol. 2023, 24, 16–26. [Google Scholar] [CrossRef]

- Fernández, A.; Santangelo-Muro, M.; Fernández-Blázquez, J.P.; Lopes, C.S.; Molina-Aldareguia, J.M. Processing and properties of long recycled-carbon-fibre reinforced polypropylene. Compos. Part B Eng. 2021, 211, 108653. [Google Scholar] [CrossRef]

- Wong, K.H.; Syed Mohammed, D.; Pickering, S.J.; Brooks, R. Effect of coupling agents on reinforcing potential of recycled carbon fibre for polypropylene composite. Compos. Sci. Technol. 2012, 72, 835–844. [Google Scholar] [CrossRef]

- Li, R.; Wang, N.; Bai, Z.; Chen, S.; Guo, J.; Chen, X. Microstructure design of polypropylene/expandable graphite flame retardant composites toughened by the polyolefin elastomer for enhancing its mechanical properties. RSC Adv. 2021, 11, 6022–6034. [Google Scholar] [CrossRef]

- Wang, G.; Li, S.; Feng, Y.; Hu, Y.; Zhao, G.; Jiang, W. Effectively toughening polypropylene with in situ formation of core-shell starch-based particles. Carbohydr. Polym. 2020, 249, 116795. [Google Scholar] [CrossRef]

| Sample Code | R-PP/POE/PP-g-MAH/CF [wt.%] |

|---|---|

| R-PP (A0) | 100/0/0/0 |

| R-PP/POE/CF (C1) | 50/45/5/0 |

| R-PP/POE/CF (C2) | 50/42/5/3 |

| R-PP/POE/CF (C3) | 50/40/5/5 |

| R-PP/POE/CF (C4) | 50/38/5/7 |

| R-PP/POE/CF (C5) | 50/36/5/9 |

| Sample [wt.%] | Tensile Strength [MPa] | Impact Strength [KJ/m2] | Bending Strength [MPa] | Reference |

|---|---|---|---|---|

| PP/CF + JF | 92.34 | 2.65 ± 0.5 J/m | 44.77 | [37] |

| PP 50/BF 50 | 7.1 | 8.9 ± 1.0 J/m | 43.3 ± 2.6 | [38] |

| PP/22 SCF | 30 | 285 J/m | - | [39] |

| PP/30 rCF | - | 37 | - | [40] |

| PP/30 RCF | 50.62 ± 2.00 | 12.69 ± 1.14 | 91.34 ± 1.82 | [41] |

| PP/nEG 20/POE 5 | 30.0 ± 0.3 | 10.4 ± 0.3 | - | [42] |

| PP/nEG 20/POE 20 | 19.7 ± 0.2 | 22.9 ± 0.3 | - | [42] |

| PP 7/POE-MA 15/TPAS 15 | 22.6 | 68.1 | - | [43] |

| R-PP/36 POE/9 CF | 29.95 ± 0.57 | 46.96 ± 1.97 | 20.01 | This work |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wei, J.; Abdurexit, A.; Jamal, R.; Abdiryim, T.; You, J.; Li, Z.; Shang, J.; Cheng, Q. Carbon Fiber Reinforced Recycled Polypropylene/Polyolefin Elastomer Composites with High Mechanical Properties. Polymers 2024, 16, 972. https://doi.org/10.3390/polym16070972

Wei J, Abdurexit A, Jamal R, Abdiryim T, You J, Li Z, Shang J, Cheng Q. Carbon Fiber Reinforced Recycled Polypropylene/Polyolefin Elastomer Composites with High Mechanical Properties. Polymers. 2024; 16(7):972. https://doi.org/10.3390/polym16070972

Chicago/Turabian StyleWei, Jin, Abdukeyum Abdurexit, Ruxangul Jamal, Tursun Abdiryim, Jiangan You, Zhiwei Li, Jin Shang, and Qian Cheng. 2024. "Carbon Fiber Reinforced Recycled Polypropylene/Polyolefin Elastomer Composites with High Mechanical Properties" Polymers 16, no. 7: 972. https://doi.org/10.3390/polym16070972

APA StyleWei, J., Abdurexit, A., Jamal, R., Abdiryim, T., You, J., Li, Z., Shang, J., & Cheng, Q. (2024). Carbon Fiber Reinforced Recycled Polypropylene/Polyolefin Elastomer Composites with High Mechanical Properties. Polymers, 16(7), 972. https://doi.org/10.3390/polym16070972