Effects of Carbon Black on Mechanical Properties and Oil Resistance of Liquid Silicone Rubber

Abstract

1. Introduction

2. Experimental Section

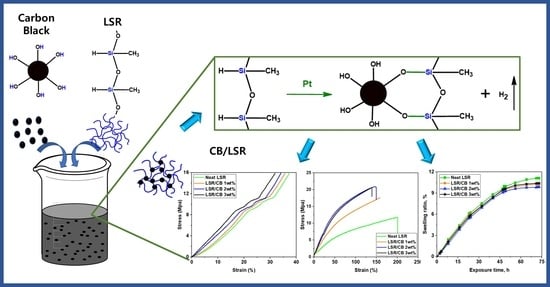

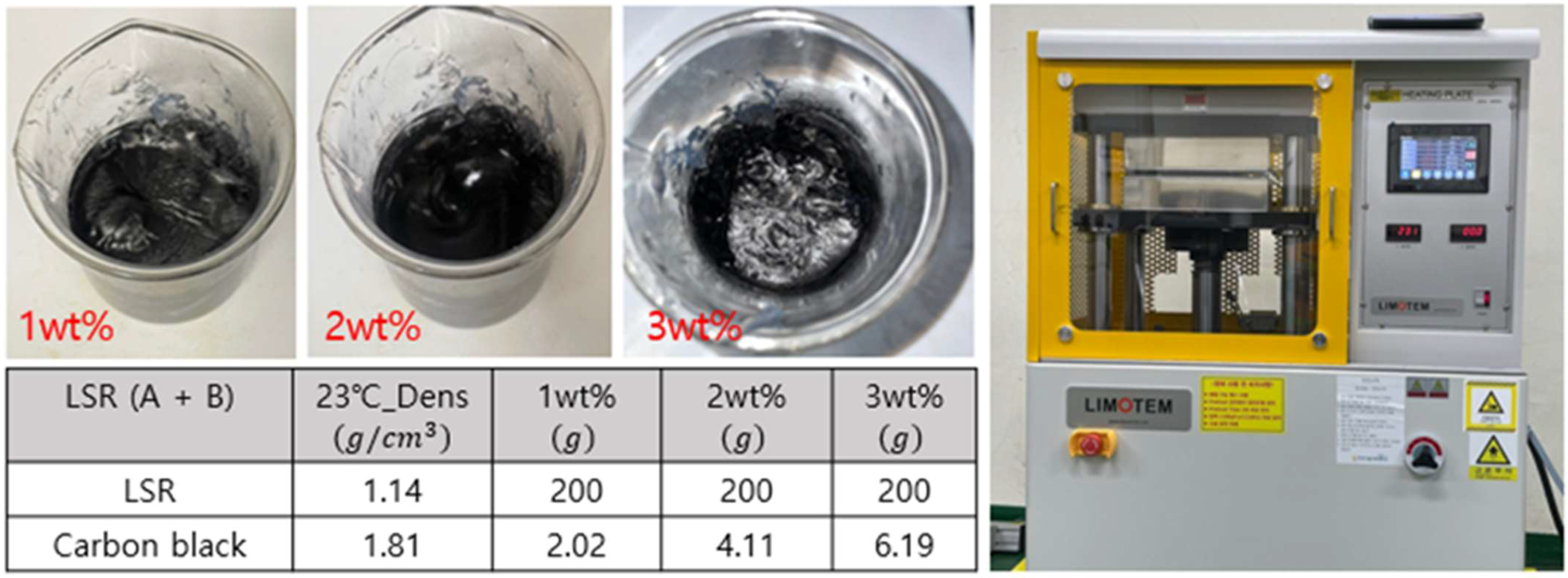

2.1. Preparation of CB/LSR Composite Specimen

2.2. Measurements

2.2.1. Tensile and Compression Tests

2.2.2. Swelling Test

2.2.3. Scanning Electron Microscopy (SEM) Measurement

2.2.4. Compression Set Test

3. Results and Discussion

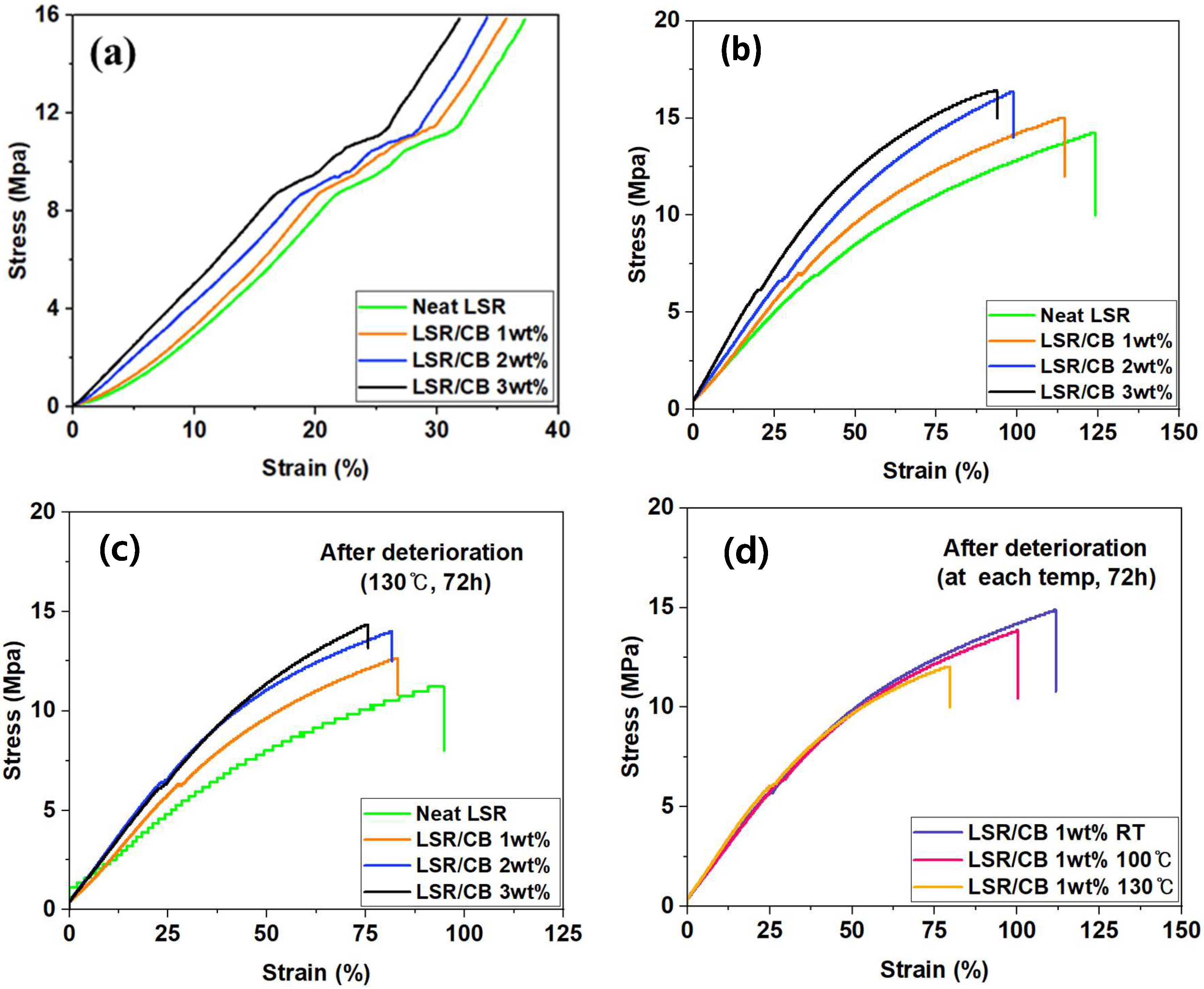

3.1. Tensile and Compression Properties

3.2. Swelling Characteristics

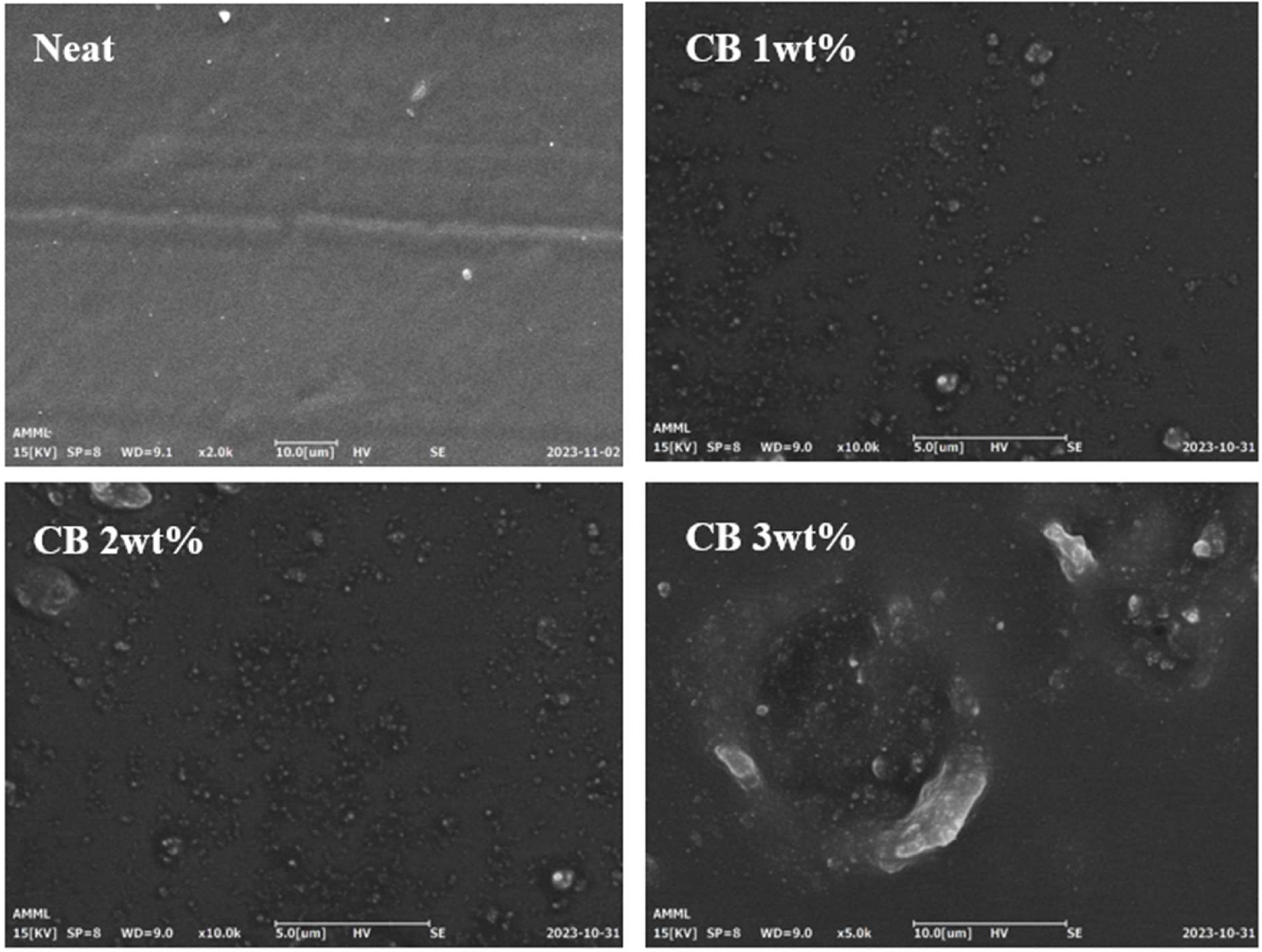

3.3. Morphological and Surface Characterization

3.4. Compression Set Property

3.5. The Mechanism of CB Effect on LSR

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Etienne, D.; Ganachaud, F. Looking over Liquid Silicone Rubbers: (1) Network Topology vs. Chemical Formulations. ACS Appl. Mater. Interfaces 2012, 4, 3340–3352. [Google Scholar]

- Matthew, B.; Barry, C.; Johnston, S. A review of liquid silicone rubber injection molding: Process variables and process molding. Polym. Eng. Sci. 2021, 61, 331–347. [Google Scholar]

- Haberstroh, E.; Michaeli, W.; Henze, E. Simulation of the Filling and Curing Phase in Injection Molding of Liquid Silicone Rubber (LSR). J. Compos. Mater. 2002, 21, 461–471. [Google Scholar] [CrossRef]

- Delebecq, E.; Hermeline, N.; Flers, A.; Ganachaud, F. Looking over Liquid Silicone Rubbers: (2) Mechanical Properties vs. Network Topology. ACS Appl. Mater. Interfaces 2012, 4, 3353–3363. [Google Scholar] [CrossRef] [PubMed]

- Shit, S.C.; Shah, P. A Review on Silicone Rubber. Natl. Acad. Sci. Lett. 2013, 36, 355–365. [Google Scholar] [CrossRef]

- Li, P.; Jiang, S. Biomaterial characteristics and application of silicone rubber and PVA hydrogels mimicked in organ groups for prostate brachytherapy. J. Mech. Behav. Biomed. Mater. 2015, 49, 220–234. [Google Scholar] [CrossRef] [PubMed]

- Yun, Y.J.; Ju, J.; Lee, J.H.; Moon, S.H.; Park, S.J.; Kim, Y.H.; Hong, W.G.; Ha, D.H.; Jang, H.; Lee, G.H. Highly elastic graphenebased electronics toward electronic skin. Adv. Funct. Mater. 2017, 27, 1701513. [Google Scholar] [CrossRef]

- Min, S.H.; Lee, G.Y.; Ahn, S.H. Direct printing of highly sensitive, stretchable, and durable strain sensor based on silver nanoparticles/multi-walled carbon nanotubes composites. Compos. B Eng. 2019, 161, 395–401. [Google Scholar] [CrossRef]

- Fink, J.K. Liquid Silicone Rubber: Chemistry, Materials, and Processing; John Wiley & Sons: Hoboken, NJ, USA, 2019. [Google Scholar]

- Mostafa, A.; Abouel-Kasem, A.; Bayoumi, M.R.; El-Sebaie, M.G. Effects of carbon black loading on the swelling and compression set behavior of SBR and NBR rubber compounds. Mater. Des. 2009, 30, 1561–1568. [Google Scholar] [CrossRef]

- Pehilivan-Davis, S.; Clarke, J.; Armour, S. Comparison of accelerated aging of silicone rubber gasket material with aging in a fuel cell environment. J. Appl. Polym. Sci. 2013, 129, 1446–1454. [Google Scholar] [CrossRef]

- Widodo, W.S.; Soenoko, R.; Choiron, M.A.; Sonief, A.A. Sealing performance analysis of composite gaskets made of silicone rubber filled with ramie natural fibers. J. Mech. Eng. Sci. 2019, 13, 6178–6194. [Google Scholar]

- Nakano, M.; Sasaki, H.; Hanashima, K. The prediction of long-term and emergency sealability of silicone and EPDM gaskets. In Proceedings of the 18th International Conference on Nuclear Engineering, Xi’an, China, 17–21 May 2010; Volume 49330, pp. 309–316. [Google Scholar]

- Jie, Z.; Feng, S. Temperature effects of electrical resistivity of conductive silicone rubber filled with carbon blacks. J. Appl. Polym. Sci. 2003, 90, 3889–3895. [Google Scholar]

- Li, Z.H.; Zhang, J.; Chen, S.J. Effects of carbon blacks with various structures on vulcanization and reinforcement of filled ethylene-propylene-diene rubber. Express Polym. Lett. 2008, 2, 695–704. [Google Scholar] [CrossRef]

- Stübler, N.; Fritzsche, J.; Klüppel, M. Mechanical and electrical analysis of carbon black networking in elastomers under strain. Polym. Eng. Sci. 2011, 51, 1206–1217. [Google Scholar] [CrossRef]

- Kumar, V.; Alam, M.N.; Manikkavel, A.; Song, M.; Lee, D.J.; Park, S.S. Silicone rubber composites reinforced by carbon nanofillers and their hybrids for various applications: A review. Polymers 2021, 13, 2322. [Google Scholar] [CrossRef]

- Song, P.; Song, J.; Zhang, Y. Stretchable conductor based on carbon nanotube/carbon black silicone rubber nanocomposites with highly mechanical, electrical properties and strain sensitivity. Compos. B Eng. 2020, 191, 107979. [Google Scholar] [CrossRef]

- Boonstra, B.B.; Medalia, A.I. Effect of carbon black dispersion on the mechanical properties of rubber vulcanizates. Rubber Chem. Technol. 1963, 36, 115–142. [Google Scholar] [CrossRef]

- Rwei, S.P.; Ku, F.H.; Cheng, K.C. Dispersion of carbon black in a continuous phase: Electrical, rheological, and morphological studies. Colloid. Polym. Sci. 2002, 280, 1110–1115. [Google Scholar]

- Sau, K.P.; Khastgir, D.; Chaki, T.K. Electrical conductivity of carbon black and carbon fibre filled silicone rubber composites. Macromol. Mater. Eng. 1998, 258, 11–17. [Google Scholar] [CrossRef]

- Grunert, F.; Wehmeier, A.; Blume, A. New insights into the morphology of silica and carbon black based on their different dispersion behavior. Polymers 2020, 12, 567. [Google Scholar] [CrossRef]

- Shivashankar, H.; Sangamesh, R.; Kulkarni, S.M. Processing and investigation of mechanical characteristics on the polydimethylsiloxane/carbon black composites. Mater. Res. Express 2019, 6, 105340. [Google Scholar] [CrossRef]

- Schubert, D.W.; Werner, S.; Hahn, I.; Solovieva, V. Effect of particle size and size distribution on the permeability of soft magnetic liquid silicone rubber composites. Compos. Sci. Technol. 2019, 177, 26–33. [Google Scholar] [CrossRef]

- Liu, P.; Liu, C.; Huang, Y.; Wang, W.; Fang, D.; Zhang, Y.; Ge, Y. Transfer function and working principle of a pressure/temperature sensor based on carbon black/silicone rubber composites. J. Appl. Polym. Sci. 2016, 133, 42979. [Google Scholar] [CrossRef]

- Song, P.; Wang, G.; Zhang, Y. Enhanced positive temperature coefficient effect by crosslinking reaction for silicone rubber/carbon black composites with high pressure sensitivity. J. Appl. Polym. Sci. 2022, 139, 51682. [Google Scholar] [CrossRef]

- Jeddi, J.; Katbab, A.A. The Electrical Conductivity and EMI Shielding Properties of Polyurehane Foam/Silicone Rubber/Carbon Black/Nanographite Hybrid Composites. Polym. Compos. 2018, 39, 3452–3460. [Google Scholar] [CrossRef]

- Jie, Z.; Feng, S.; Ma, Q. Kinetics of the thermal degradation and thermal stability of conductive silicone rubber filled with conductive carbon black. J. Appl. Polym. Sci. 2003, 89, 1548–1554. [Google Scholar]

- Ding, T.; Wang, L. Changes in electrical resistance of carbon-black-filled silicone rubber composite during compression. J. Polym. Sci. B Polym. Phys. 2007, 45, 2700–2706. [Google Scholar] [CrossRef]

- Hussain, R.; Moxter, J.; Hinrichsen, V. Influence of temperature and electric field strength on the space charge behavior of liquid silicone rubber with carbon black nanofillers. IEEE Trans. Dielectr. Electr. Insul. 2020, 27, 427–432. [Google Scholar] [CrossRef]

- Wang, S.; Wang, P.; Ding, T. Resistive viscoelasticity of silicone rubber/carbon black composite. Polym. Compos. 2011, 32, 29–35. [Google Scholar] [CrossRef]

- ASTM D412-16; Standard Test Methods for Vulcanized Rubber and Thermoplastic Elastomer Tension. ASTM International: West Conshohocken, PA, USA, 2021.

- ASTM D1229-03; Standard Test Methods for Rubber Property-Compresion Set at Low Temperatures. ASTM International: West Conshohocken, PA, USA, 2019.

- ASTM D471-16a; Standard Test Methods for Rubber Property-Effect of Liquids. ASTM International: West Conshohocken, PA, USA, 2021.

- ASTM D395-18; Standard Test Methods for Rubber Property-Compreession Set. ASTM International: West Conshohocken, PA, USA, 2018.

- Omnes, B.; Thuillier, S.; Pilvin, P.; Grohens, Y.; Gillet, S. Effective properties of carbon black filled natural rubber: Experiments and modeling. Compos. Part. A Appl. Sci. Manuf. 2008, 39, 1141–1149. [Google Scholar] [CrossRef]

- Herd, C.R.; McDonald, G.C.; Hess, W.M. Morphology of Carbon-Black Aggregates: Fractal Versus Euclidean Geometry. Rubber Chem. Technol. 1992, 65, 107–129. [Google Scholar] [CrossRef]

- Dou, Y.; Sun, S.; Lu, S.; Yao, W.; Guan, D. Preparation of carbon black/silicone rubber composites with large-area-homogeneous-low electrical-resistance used as electroplating matrix. RSC Adv. 2012, 12, 32448. [Google Scholar] [CrossRef] [PubMed]

- Zhu, X.; Li, W. Research on Dynamic Compression Testing of Silicone Rubber under Different Temperatures. J. Phys. Conf. Ser. 2021, 2002, 012047. [Google Scholar] [CrossRef]

- Luis, E.; Pan, H.M.; Sing, S.L.; Bastola, A.K.; Goh, G.D.; Goh, G.L.; Tan, H.K.J.; Bajpai, R.; Song, J.; Yong, W.Y. Silicone 3D printing: Process optimization, product biocompatibility, and reliability of silicone meniscus implants. 3D Print. Addit. Manuf. 2019, 6, 319–332. [Google Scholar] [CrossRef]

- VLitvinov, V.M.; Steeman, P.A.M. EPDM-Carbon Black Interactions and the Reinforcement Mechanisms, As Studied by Low-Resolution 1H NMR. Macromolecules 1999, 32, 8476–8490. [Google Scholar] [CrossRef]

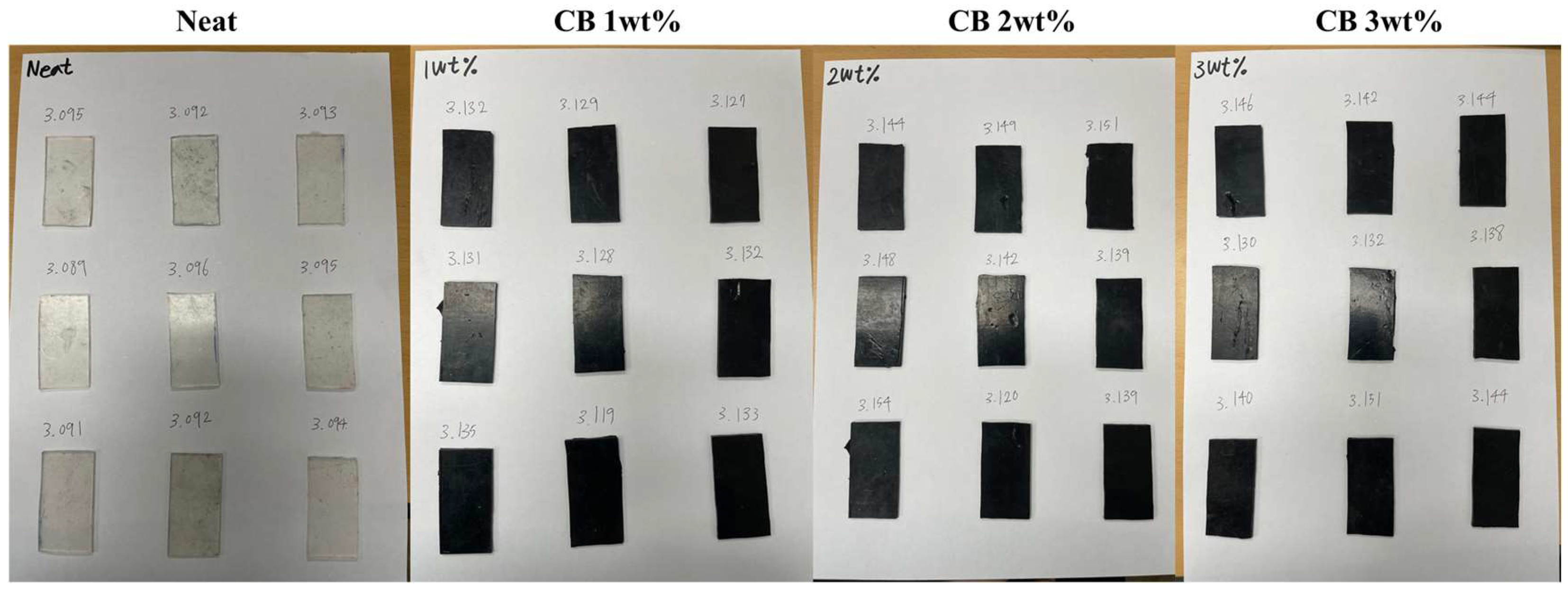

| Material | Ultimate Tensile Strength-before Deterioration (MPa) | Ultimate Tensile Strength-after Deterioration (MPa) | Deterioration Rate (%) |

|---|---|---|---|

| Neat | 14.22 | 11.21 | 21.67 |

| CB 1 wt% | 14.99 | 12.62 | 15.81 |

| CB 2 wt% | 16.34 | 14.57 | 10.83 |

| CB 3 wt% | 16.35 | 14.32 | 12.42 |

| Material | Tensile Modulus—before Deterioration (MPa) | Tensile Modulus— after Deterioration (MPa) | Deterioration Rate (%) |

|---|---|---|---|

| Neat | 16.53 | 13.35 | 19.24 |

| CB 1 wt% | 19.79 | 17.72 | 10.46 |

| CB 2 wt% | 24.05 | 22.48 | 6.53 |

| CB 3 wt% | 29.03 | 23.69 | 18.39 |

| Time (h) | 0 | 8 | 16 | 24 | 32 | 40 | 48 | 56 | 64 | 72 | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Neat | RT | 3.095 | 3.112 | 3.133 | 3.146 | 3.164 | 3.201 | 3.226 | 3.250 | 3.252 | 3.256 |

| 100 | 3.092 | 3.135 | 3.182 | 3.223 | 3.262 | 3.302 | 3.334 | 3.353 | 3.364 | 3.371 | |

| 130 | 3.093 | 3.167 | 3.229 | 3.286 | 3.326 | 3.365 | 3.401 | 3.417 | 3.431 | 3.437 | |

| CB 1 wt% | RT | 3.132 | 3.149 | 3.163 | 3.184 | 3.194 | 3.229 | 3.254 | 3.285 | 3.289 | 3.294 |

| 100 | 3.129 | 3.289 | 3.204 | 3.244 | 3.276 | 3.315 | 3.343 | 3.348 | 3.377 | 3.389 | |

| 130 | 3.127 | 3.196 | 3.258 | 3.314 | 3.352 | 3.392 | 3.424 | 3.437 | 3.444 | 3.449 | |

| CB 2 wt% | RT | 3.144 | 3.160 | 3.171 | 3.194 | 3.200 | 3.241 | 3.271 | 3.289 | 3.292 | 3.302 |

| 100 | 3.149 | 3.182 | 3.297 | 3.240 | 3.289 | 3.306 | 3.354 | 3.373 | 3.391 | 3.397 | |

| 130 | 3.151 | 3.209 | 3.272 | 3.327 | 3.369 | 3.411 | 3.442 | 3.452 | 3.459 | 3.462 | |

| CB 3 wt% | RT | 3.146 | 3.163 | 3.178 | 3.198 | 3.206 | 3.240 | 3.273 | 3.302 | 3.306 | 3.307 |

| 100 | 3.142 | 3.168 | 3.199 | 3.246 | 3.294 | 3.335 | 3.370 | 3.390 | 3.396 | 3.397 | |

| 130 | 3.144 | 3.211 | 3.274 | 3.326 | 3.367 | 3.409 | 3.427 | 3.462 | 3.467 | 3.471 | |

| Material | RT 72 h | 100 °C 72 h | 130 °C 72 h | |||||

|---|---|---|---|---|---|---|---|---|

| Neat | (g) | 3.095 | 3.256 | 3.092 | 3.371 | 3.093 | 3.437 | |

| swelling ratio (%) | 5.202 | 9.238 | 11.121 | |||||

| CB 1 wt% | (g) | 3.132 | 3.294 | 3.129 | 3.389 | 3.127 | 3.449 | |

| swelling ratio (%) | 5.172 | 8.309 | 10.297 | |||||

| CB 2 wt% | (g) | 3.144 | 3.302 | 3.149 | 3.397 | 3.151 | 3.462 | |

| swelling ratio (%) | 5.025 | 7.876 | 9.858 | |||||

| CB 3 wt% | (g) | 3.146 | 3.307 | 3.142 | 3.397 | 3.144 | 3.471 | |

| swelling ratio (%) | 5.118 | 8.116 | 10.407 | |||||

| Material | RT 72 h | 130 °C 72 h | ||||

|---|---|---|---|---|---|---|

| Neat | (cm) | 12.471 | 12.450 | 12.469 | 12.444 | |

| Compression set (%) | 4.44 | 5.43 | ||||

| CB 1 wt% | (cm) | 12.454 | 12.433 | 12.452 | 12.426 | |

| Compression set (%) | 4.62 | 5.83 | ||||

| CB 2 wt% | (cm) | 12.478 | 12.455 | 12.481 | 12.452 | |

| Compression set (%) | 4.72 | 6.12 | ||||

| CB 3 wt% | (cm) | 12.499 | 12.474 | 12.503 | 12.469 | |

| Compression set (%) | 5.01 | 6.81 | ||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, B.-J.; Yoo, H.-M. Effects of Carbon Black on Mechanical Properties and Oil Resistance of Liquid Silicone Rubber. Polymers 2024, 16, 933. https://doi.org/10.3390/polym16070933

Lee B-J, Yoo H-M. Effects of Carbon Black on Mechanical Properties and Oil Resistance of Liquid Silicone Rubber. Polymers. 2024; 16(7):933. https://doi.org/10.3390/polym16070933

Chicago/Turabian StyleLee, Beom-Joo, and Hyeong-Min Yoo. 2024. "Effects of Carbon Black on Mechanical Properties and Oil Resistance of Liquid Silicone Rubber" Polymers 16, no. 7: 933. https://doi.org/10.3390/polym16070933

APA StyleLee, B.-J., & Yoo, H.-M. (2024). Effects of Carbon Black on Mechanical Properties and Oil Resistance of Liquid Silicone Rubber. Polymers, 16(7), 933. https://doi.org/10.3390/polym16070933