Interlaminar Shear Strength Change and Storage Life Prediction of Carbon Fiber/Epoxy Composites with Hygrothermal Accelerated Aging

Abstract

1. Introduction

2. Experimental Specimens and Experimental Methods

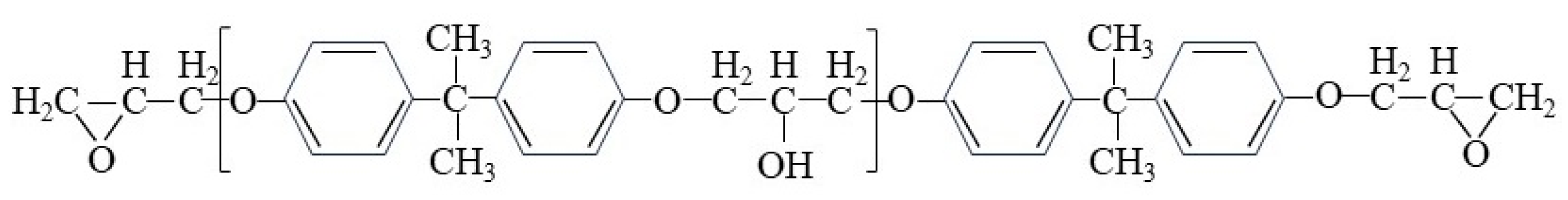

2.1. Specimens

2.2. Hygrothermal Accelerated Aging Test

2.3. Interlayer Shear Test

2.4. Mechanism Analysis of Hygrothermal Accelerated Aging

2.5. Storage Life Prediction

3. Results Analysis and Discussion

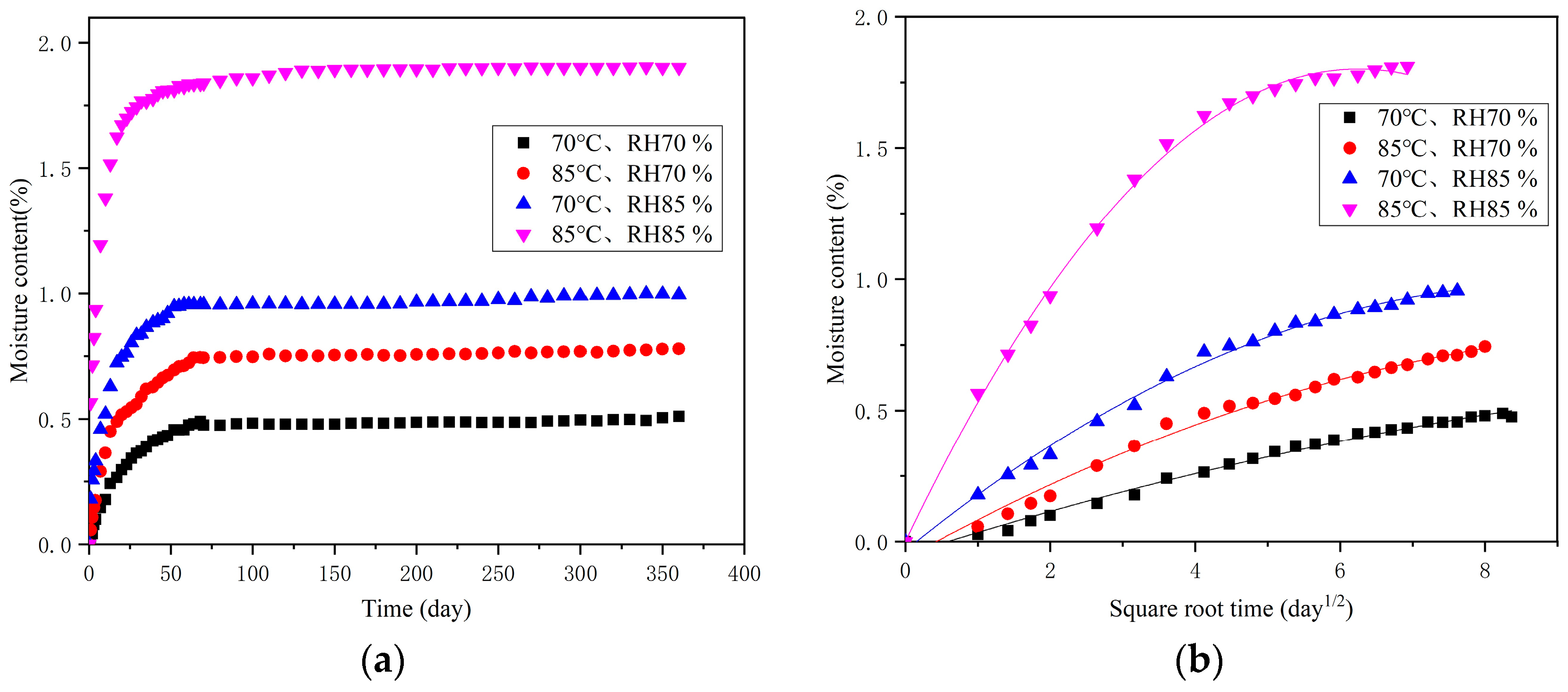

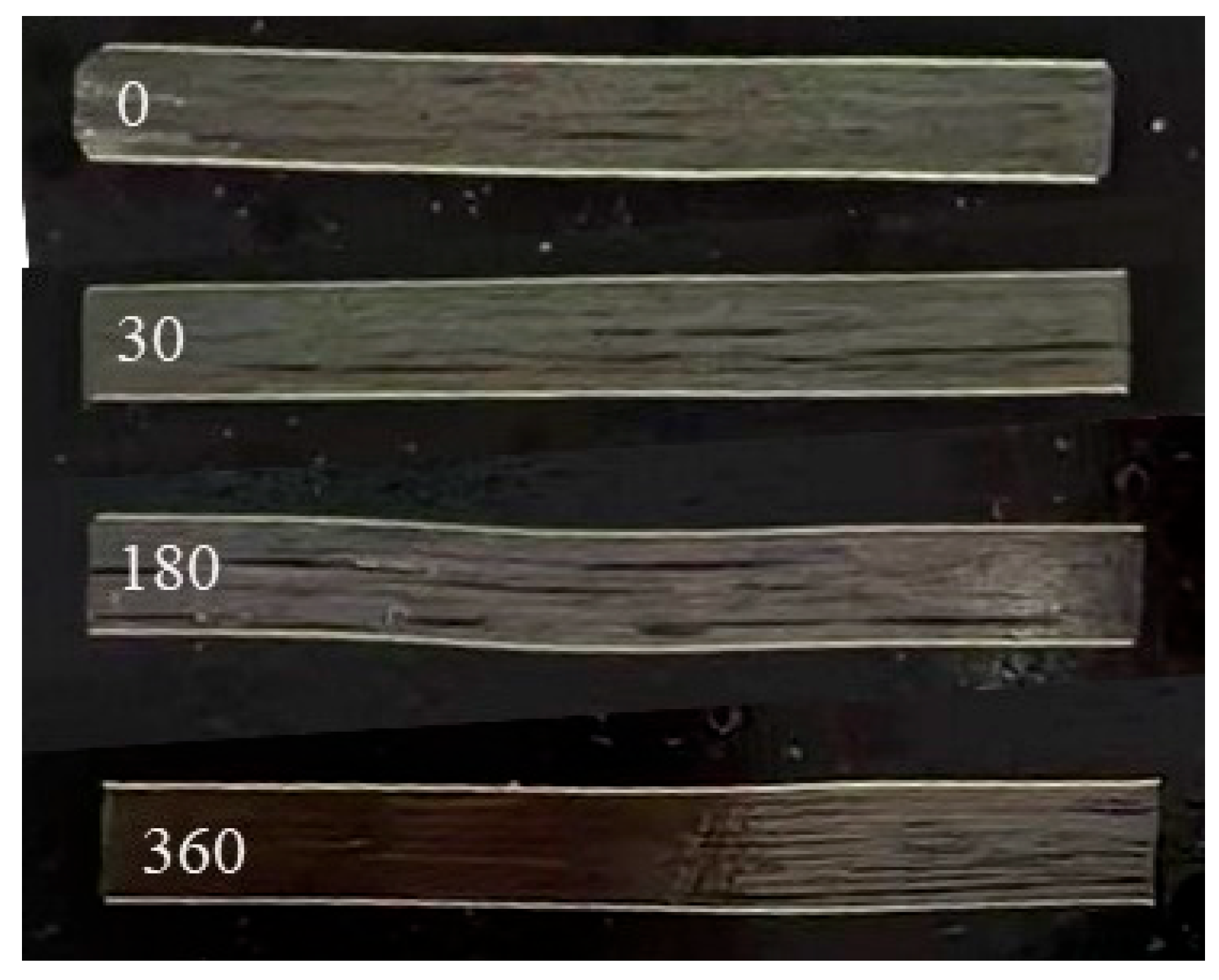

3.1. Moisture Content

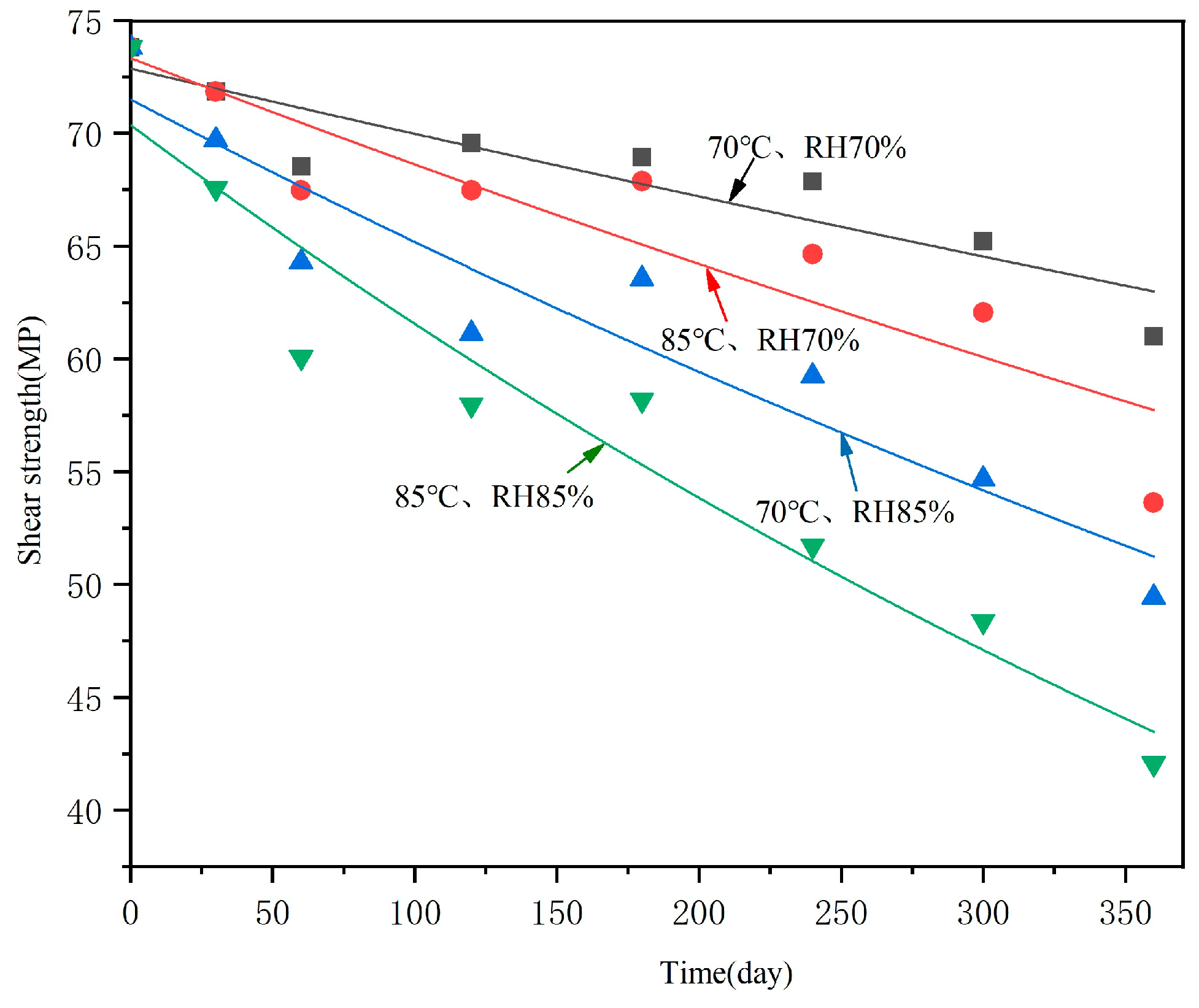

3.2. Interlayer Shear Strength under Different Hygrothermal Conditions

3.3. Failure Mechanism of Hygrothermal Accelerated Aging

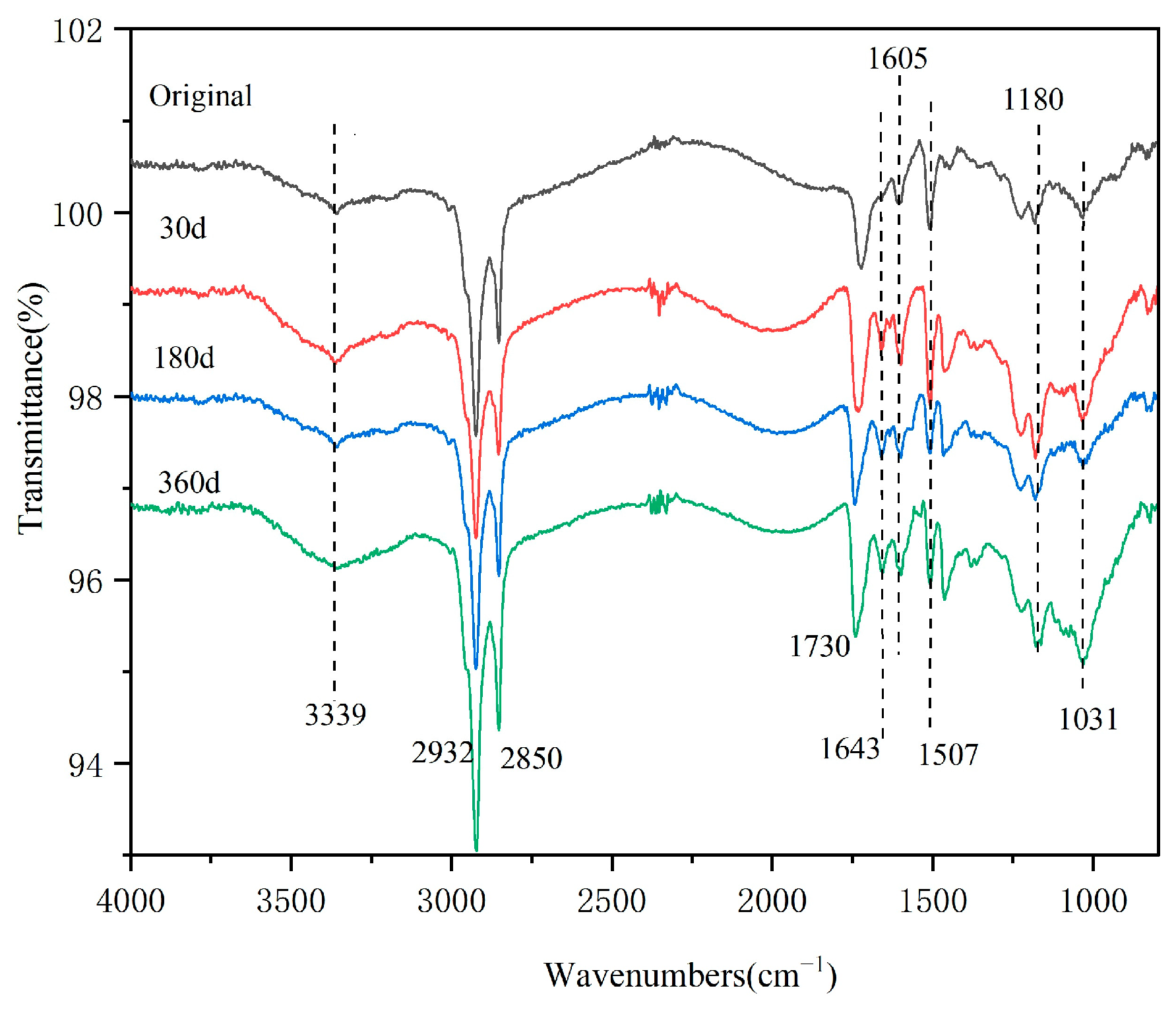

3.3.1. Fourier Transform Infrared Analysis

3.3.2. DSC Analysis of Resin Matrix

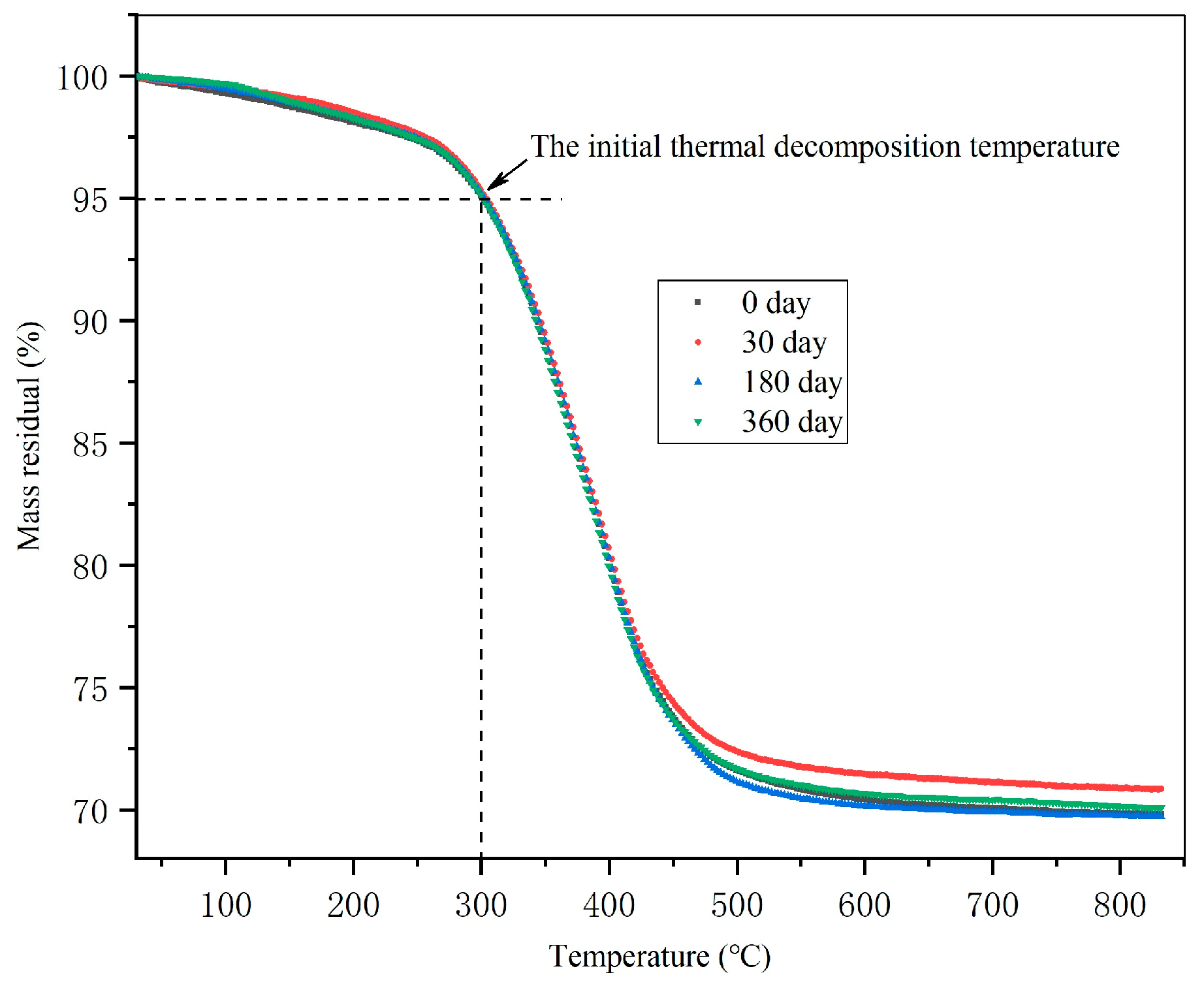

3.3.3. TGA Results of Composites

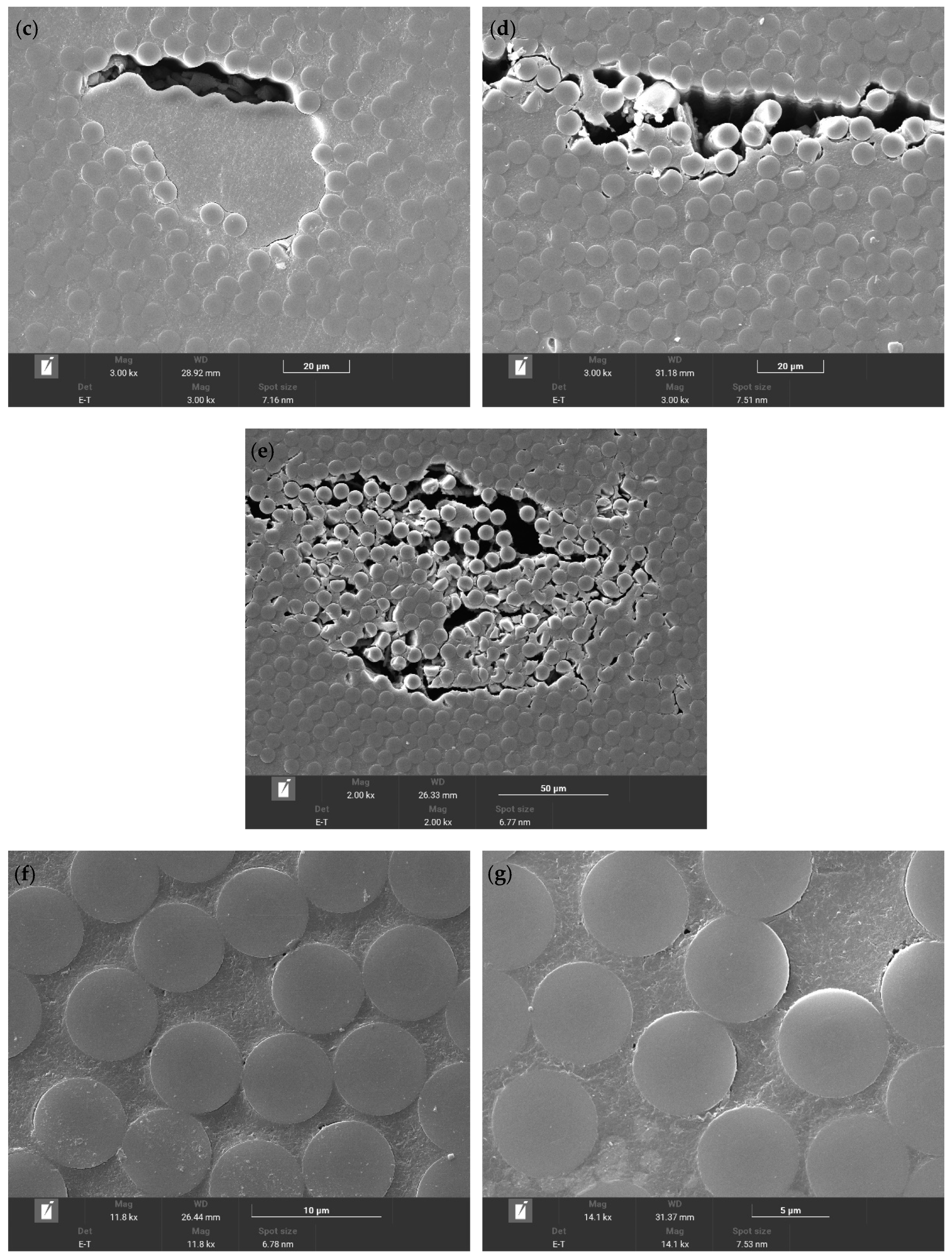

3.3.4. Interlaminar Cracks and Interface Analysis

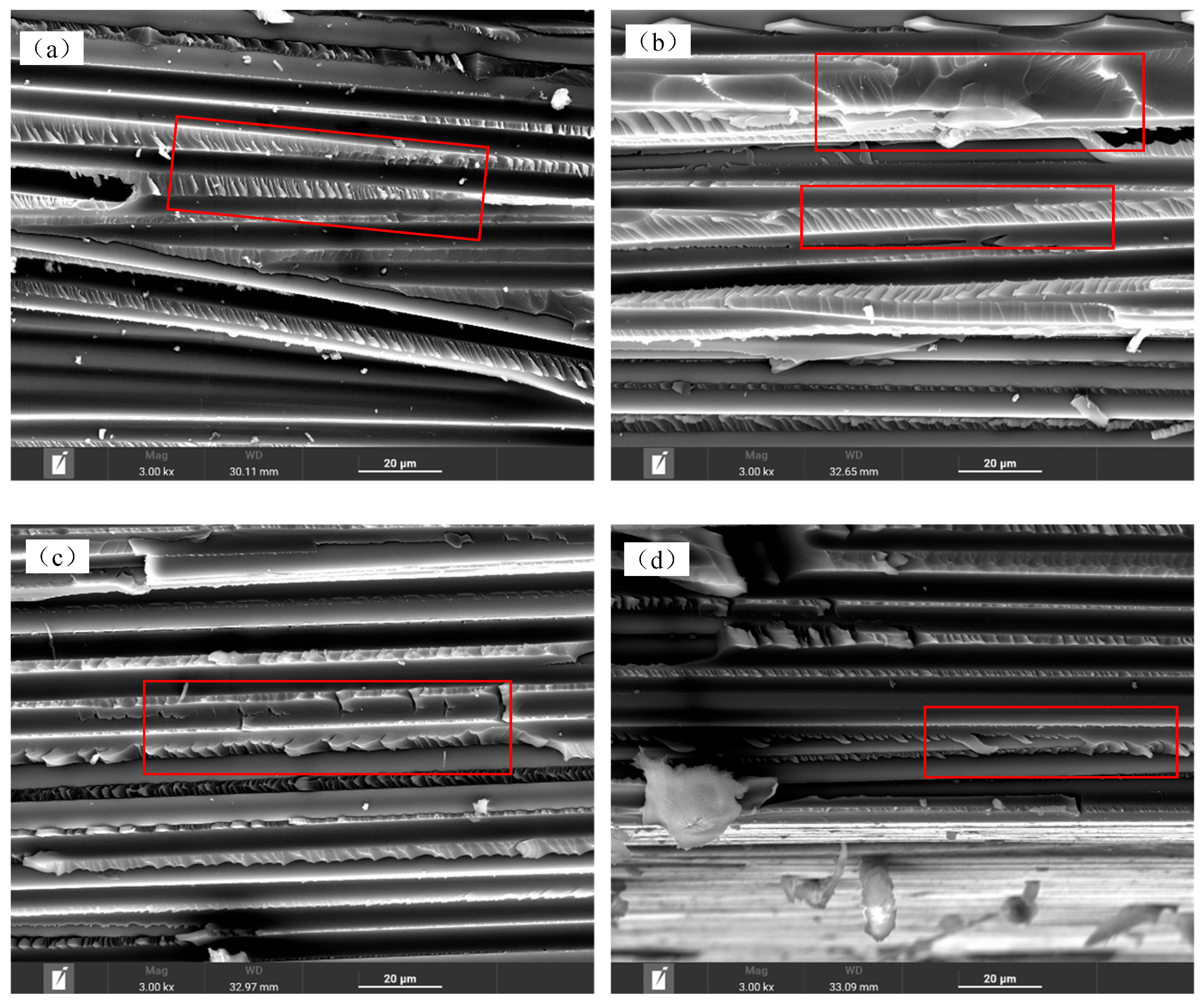

3.3.5. Fracture Morphology Analysis

3.4. Storage Life Estimation

4. Conclusions

- (1)

- The order of moisture absorption rates, moisture absorption contents, and the severity effect order on the interlaminar shear strength is RH85%; 85 °C > 70 °C, RH85% > 85 °C, RH70% > 70 °C, RH70%. The times to achieve effective moisture absorption balance were opposite to this.

- (2)

- The moisture absorption rate satisfies Fick’s law before the effective moisture absorption balance, then shows a linear trend. The interlayer shear strength still decreases exponentially with aging time, which is mainly caused by the resin plasticization and interface weakening.

- (3)

- With the increase in hygrothermal accelerated aging time, the resin matrix fracture gradually changes from a brittle fracture to a plastic fracture. The main reasons for the interlayer shear strength decreasing are resin moisture plasticization and interface weakening.

- (4)

- A dual stress storage life prediction model and the equivalent relationship between natural storage and hygrothermal acceleration were established. According to the model, based on the failure criterion of the interlayer shear strength decreasing to 77% of the initial value, the storage life of T700/epoxy resin in Guangzhou, China was calculated to be 14.4661 years. The effectiveness of the model was verified by actual storage data for 2 years.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Xing, L.; Li, Y.; Chen, X. The status and role of advanced composite materials in the development of aviation equipment. Acta Mater. Compos. Sin. 2022, 39, 8–15. [Google Scholar] [CrossRef]

- Nakada, M.; Miyano, Y. Accelerated testing for long-term durability of FRP laminates for Marine Use. Compos. Sci. Technol. 2009, 69, 805–813. [Google Scholar] [CrossRef]

- Frigione, M.; Rodriguez-Prieto, A. Can Accelerated Aging Procedures Predict the Long Term Behavior of Polymers Exposed to Different Environments? Polymers 2021, 13, 2688. [Google Scholar] [CrossRef] [PubMed]

- Starkova, O.; Gagani, A.I.; Karl, C.W.; Rocha, I.B.; Burlakovs, J.; Krauklis, A.E. Modelling of environmental ageing of polymers and polymer composites-durability prediction methods. Polymer 2022, 14, 907. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Wang, J.; Wei, J.; Liu, M.; Li, X.; Ding, A. Long-term mechanical properties of carbon fiber reinforced vinyl resin composites in hygrothermal environment. Acta Mater. Compos. Sin. 2023, 40, 1406–1416. [Google Scholar] [CrossRef]

- Wang, D.X.; Sun, Y.; Xie, K.Y.; Li, H.; Wang, X.B.; Duan, J.; Shao, M. Long term aging and failure behaviors of carbon fiber reinforced polymer composites in simulated marine environments. Acta Mater. Compos. Sin. 2022, 39, 1353–1362. [Google Scholar] [CrossRef]

- Bauer, H.; Ilie, N. Effects of aging and irradiation time on the properties of a highly translucent resin-based composite. Dent. Mater. J. 2013, 32, 592–599. [Google Scholar] [CrossRef] [PubMed]

- Rao, R.M.V.G.K.; Kumari, H.V.S.; Raju, K.S. Moisture Diffusion Behavior of T300-914C Laminates. J. Reinf. Plast. Compos. 1995, 14, 513–522. [Google Scholar] [CrossRef]

- Burks, B. The effect of atmospheric aging on a hybrid polymer matrix composites material properties. Diss. Theses—Gradworks 2012, 72, 1803–1811. [Google Scholar] [CrossRef]

- Park, S.Y.; Choi, W.J.; Choi, C.H.; Choi, H.S. An experimental study into aging unidirectional carbon fiber epoxy composite under thermal cycling and moisture absorption. Compos. Struct. 2019, 207, 81–92. [Google Scholar] [CrossRef]

- Xu, L.; Jia, Y.; Zhou, S.; Li, H. Effect of Aging Environment on the Properties of T800 Carbon Fiber/Epoxy Resin Composites. Polym. Mater. Sci. Eng. 2021, 37, 7. [Google Scholar] [CrossRef]

- Wang, W.; Wei, C.; Tian, J. Research on hygrothermal ageing models of carbon fiber composites. Compos. Sci. Eng. 2023, 11, 44–48. [Google Scholar] [CrossRef]

- Devine, M.; Bajpai, A.; Obande, W.; Conchur, M.O.; Bradaigh, D.R. Seawater ageing of thermoplastic acrylic hybrid matrix composites for marine applications. Compos. Part B Eng. 2023, 15, 263. [Google Scholar] [CrossRef]

- Zhao, Y.Q.; Zhou, Y.; Huang, Z.M.; Batra, R.C. Experimental and micromechanical investigation of T300/7901 unidirectional composite strength. Polym. Compos. 2019, 40, 2639–2652. [Google Scholar] [CrossRef]

- Das, S. Life cycle assessment of carbon fiber-reinforced polymer composites. Int. J. Life Cycle Assess 2011, 16, 268–282. [Google Scholar] [CrossRef]

- Yang, X.; An, T.; Zou, T. Effect of hygrothermal environment on mechanical properties and damage mechanism of CFRP. J. Mater. Eng. 2019, 47, 84–91. [Google Scholar] [CrossRef]

- Peret, T.; Clement, A.; Freour, S.; Jacquemin, F. Effect of mechanical states on water diffusion based on the free volume theory: Numerical study of polymers and laminates used in marine application. Compos. Part B Eng. 2017, 118, 54–66. [Google Scholar] [CrossRef]

- Almeida, J.H.S.; Souza, S.D.; Botelho, E.C.; Amico, S.C. Carbon fiber-reinforced epoxy filament-wound composite laminates exposed to hygrothermal conditioning. J. Mater. Sci. 2016, 51, 4697–4708. [Google Scholar] [CrossRef]

- Sui, X.; Xiong, S.; Zhu, L.; Li, Y.; Li, N. Hygrothermal properties of domestic T800 carbonfiber/expoxy composites. J. Aeronaut. Mater. 2019, 39, 88–93. [Google Scholar]

- Kesentini, Z.; El Mahi, A.; Rebiere, J.L.; El Guerjouma, R.; Beyaoui, M.; Haddar, M. Static and Fatigue Tensile Behavior and Damage Mechanisms Analysis in Aged Flax Fiber/PLA Composite. Int. J. Appl. Mech. 2022, 14, 2250080. [Google Scholar] [CrossRef]

- Wu, R.; Li, Y.; Yu, T. Comparative study on the hygrothermal durability of different fiber reinforced composites. Acta Mater. Compos. Sin. 2022, 39, 4406–4419. [Google Scholar] [CrossRef]

- Niu, Y.; Li, Z.; Zhu, X. Flexural properties and life-time estimation of carbon fiber/epoxy composite under hygrothermal conditions. Acta Mater. Compos. Sin. 2020, 37, 104–112. [Google Scholar]

- Niu, Y.; Li, Z.; Zhu, X. Interlaminar shear strength of carbon fiber/epoxy composites under hygrothermal conditions. Polym. Mater. Sci. Eng. 2021, 37, 113–120. [Google Scholar] [CrossRef]

- Liu, S.; Cheng, X.; Bao, J. Hygrothermal Effects on Properties of Composite Materials. Polym. Mater. Sci. Eng. 2014, 30, 183–189. [Google Scholar]

- Wani, V.; M, M.; Jain, S.; Singh, P.; Bhattacharya, B. Prediction of storage life of propellants having different burning rates using dynamic mechanical analysis. Def. Sci. J. 2012, 62, 290–294. [Google Scholar] [CrossRef][Green Version]

- Krauklis, A.E.; Akulichev, A.G.; Gagani, A.; Echtermeyer, A.T. Time-Temperature Plasticization Superpositon principle: Predicting creep of a Plasticized Epoxy. Polymers 2019, 11, 1848. [Google Scholar] [CrossRef] [PubMed]

- Gagani, A.I.; Monsas, A.B.; Krauklis, A.E. The effect of temperature and water immersion on the interlaminar shear fatigue of glass fiber epoxy composites using the I-beam method. Compos. Sci. Technol. 2019, 181, 107703. [Google Scholar] [CrossRef]

- Ishisaka, A.; Kawagoe, M. Examination of the time–water content superposition on the dynamic viscoelasticity of moistened polyamide 6 and epoxy. J. Appl. Polym. Sci. 2004, 93, 560–567. [Google Scholar] [CrossRef]

- Yu, Z.G.; Yang, S.C.; Song, B.F. Comparison of Wet and Hot Aging Resistance of T700 and T300 Carbon Fiber Strengthened Epoxy Resin Composites. Mater. Mech. Eng. 2009, 33, 48–51. [Google Scholar]

- Wang, S.; Zhang, W.F.; Chen, Y.; Wu, Y.F. Hygrothermal Behavior of T700 and T300 BMI Used for Advanced Polymeric Composite. Adv. Mater. Res. 2012, 476–478, 632–635. [Google Scholar] [CrossRef]

- Li, C.; Cui, R.; Lei, C. Comparison of Structure and Properties in Different Polyacrylonitrile-based Carbon Fibers. Mater. Rev. 2011, 16, 51–55. [Google Scholar]

- HB 7401-2021; Test Methods for Moisture Absorption of Polymer Matrix Composites for Aerospace Applications. Ministry of Industry and Information Technology of the People’s Republic of China: Beijing, China, 2021. Available online: http://www.biaozhun8.cn/biaozhun51930/ (accessed on 1 July 2021).

- JC/T773-2010; Fiber-Reinforced Plastics Composites-Determination of Apparent Interlaminar Shear Strength by Short-Beam Method. Ministry of Industry and Information Technology of the People’s Republic of China: Beijing, China, 2010. Available online: http://www.standardcnjc.com/index/standard/detail/id/320.html (accessed on 1 March 2011).

- ASTM D 3418-15; Standard Test Method for Transition Temperatures and Enthalpies of Fusion and Crystallization of Polymers by Differential Scanning Calorimetry. American Society for Testing and Materials: West Conshohocken, PA, USA, 2015. [CrossRef]

- Yan, F.F. Performance of Composite Material Dispersion and Safety Coefficient; Nanjing University of Aeronautics and Astronautics: Nanjing, China, 2009. [Google Scholar] [CrossRef]

| Storage Time | Average Temperature and Humidity |

|---|---|

| Spring (From March to May) | 21 °C ± 0.5 °C, RH65% ± RH 2% |

| Summer (From June to August) | 29 °C ± 0.5 °C, RH 75% ± RH 2% |

| Autumn (From September to November) | 25 °C ± 0.5 °C, RH60% ± RH 2% |

| Winter (From December to February) | 18 °C ± 0.5 °C, RH58% ± RH 2% |

| Interlayer Shear Strength (MPa) | Average Value (MPa) | Coefficient of Variation (%) |

|---|---|---|

| 68.3 | 68.6 | 1.6 |

| 69.0 | ||

| 70.0 | ||

| 67.0 | ||

| 68.5 |

| Hygrothermal Accelerated Aging Conditions | Degradation Rate k |

|---|---|

| 70 °C, RH70% | 0.0004 |

| 85 °C, RH70% | 0.00066 |

| 70 °C, RH85% | 0.00092 |

| 85 °C, RH85% | 0.00134 |

| Storage Conditions | Degradation Rate k |

|---|---|

| Spring (From March to May) | 0.000034 |

| Summer (From June to August) | 0.000121 |

| Autumn (From September to November) | 0.000028 |

| Winter (From December to February) | 0.000015 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fan, J.; Zhang, Q.; Chen, X.; He, Y. Interlaminar Shear Strength Change and Storage Life Prediction of Carbon Fiber/Epoxy Composites with Hygrothermal Accelerated Aging. Polymers 2024, 16, 1109. https://doi.org/10.3390/polym16081109

Fan J, Zhang Q, Chen X, He Y. Interlaminar Shear Strength Change and Storage Life Prediction of Carbon Fiber/Epoxy Composites with Hygrothermal Accelerated Aging. Polymers. 2024; 16(8):1109. https://doi.org/10.3390/polym16081109

Chicago/Turabian StyleFan, Jinjuan, Qin Zhang, Xinwen Chen, and Yuhuai He. 2024. "Interlaminar Shear Strength Change and Storage Life Prediction of Carbon Fiber/Epoxy Composites with Hygrothermal Accelerated Aging" Polymers 16, no. 8: 1109. https://doi.org/10.3390/polym16081109

APA StyleFan, J., Zhang, Q., Chen, X., & He, Y. (2024). Interlaminar Shear Strength Change and Storage Life Prediction of Carbon Fiber/Epoxy Composites with Hygrothermal Accelerated Aging. Polymers, 16(8), 1109. https://doi.org/10.3390/polym16081109