Study on Bearing Strength and Failure Modes of Single Bolted Joint Carbon/Epoxy Composite Materials

Abstract

1. Introduction

2. Test Materials and Methods

2.1. Test Materials

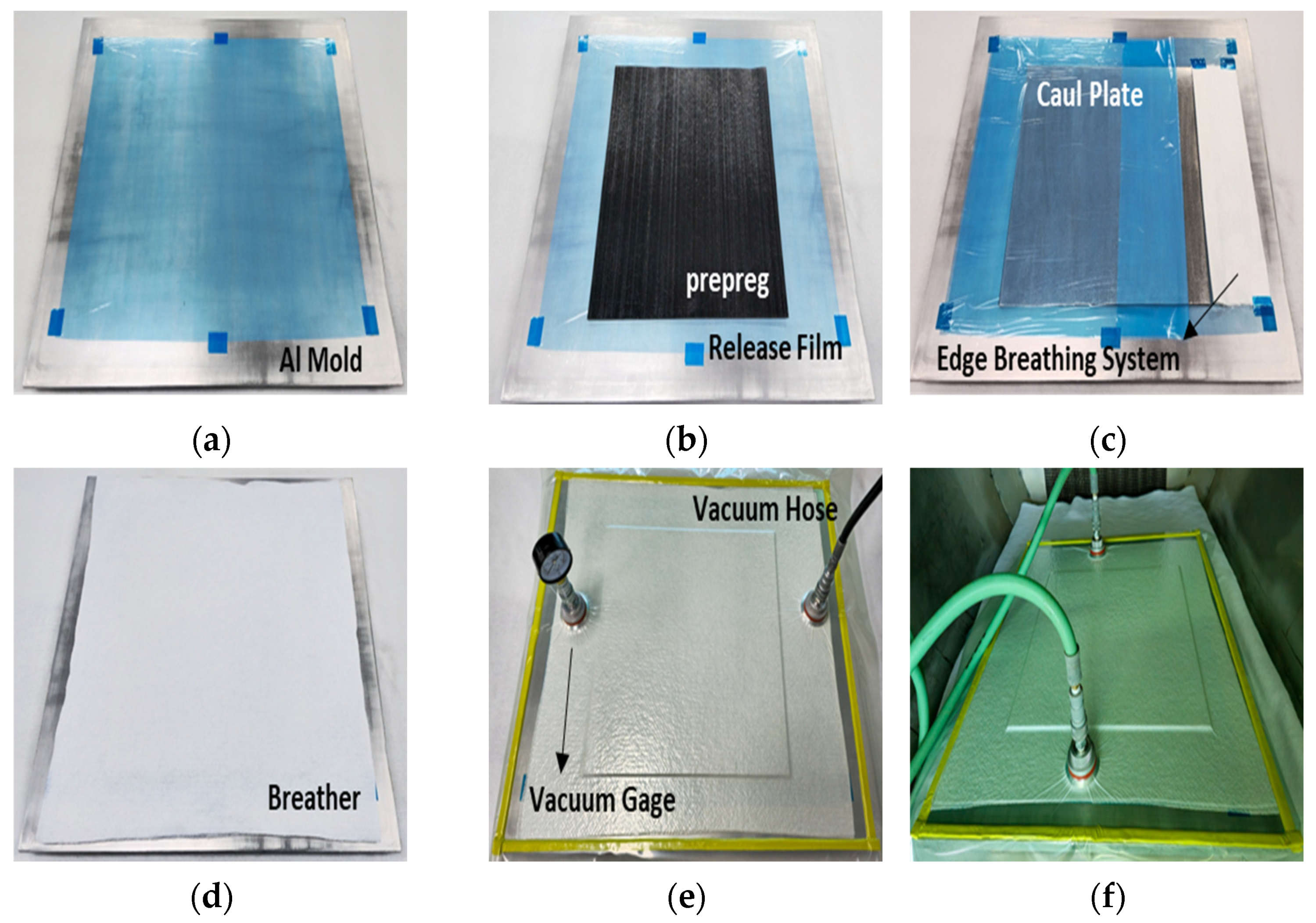

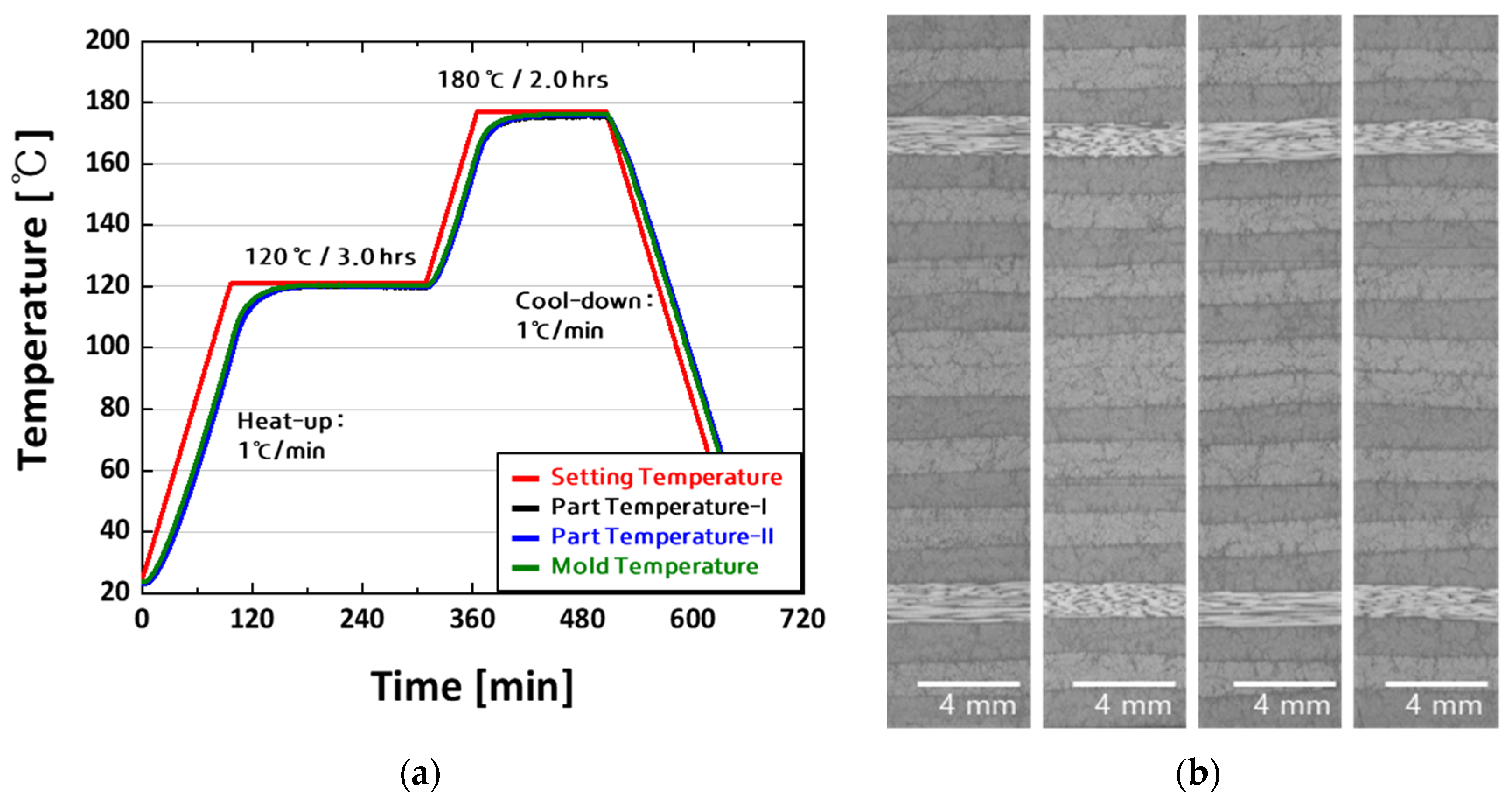

2.2. Specimen Fabrication

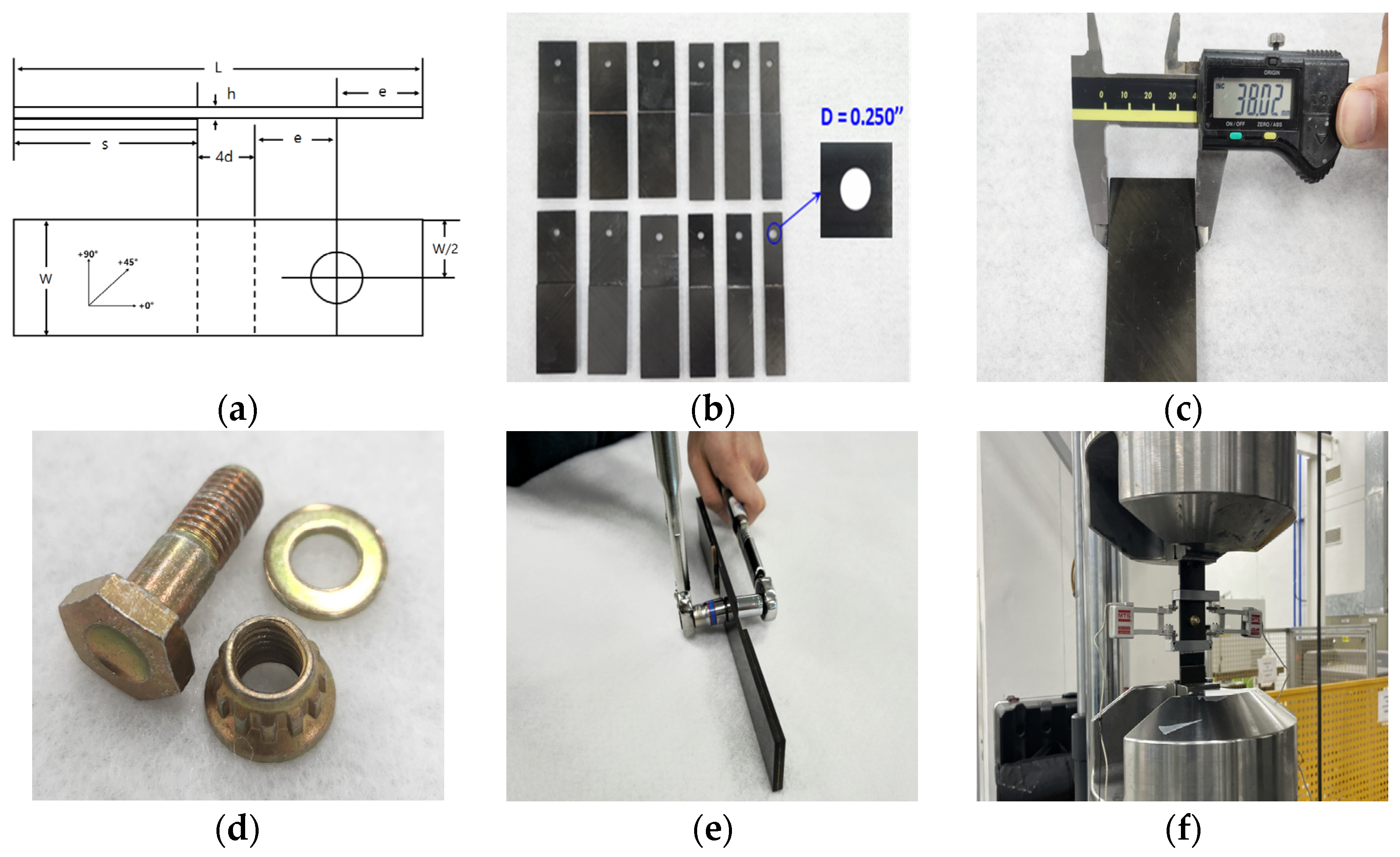

2.3. Experimental Set-Up

2.4. Calculation of Bearing Strength

3. Test Results

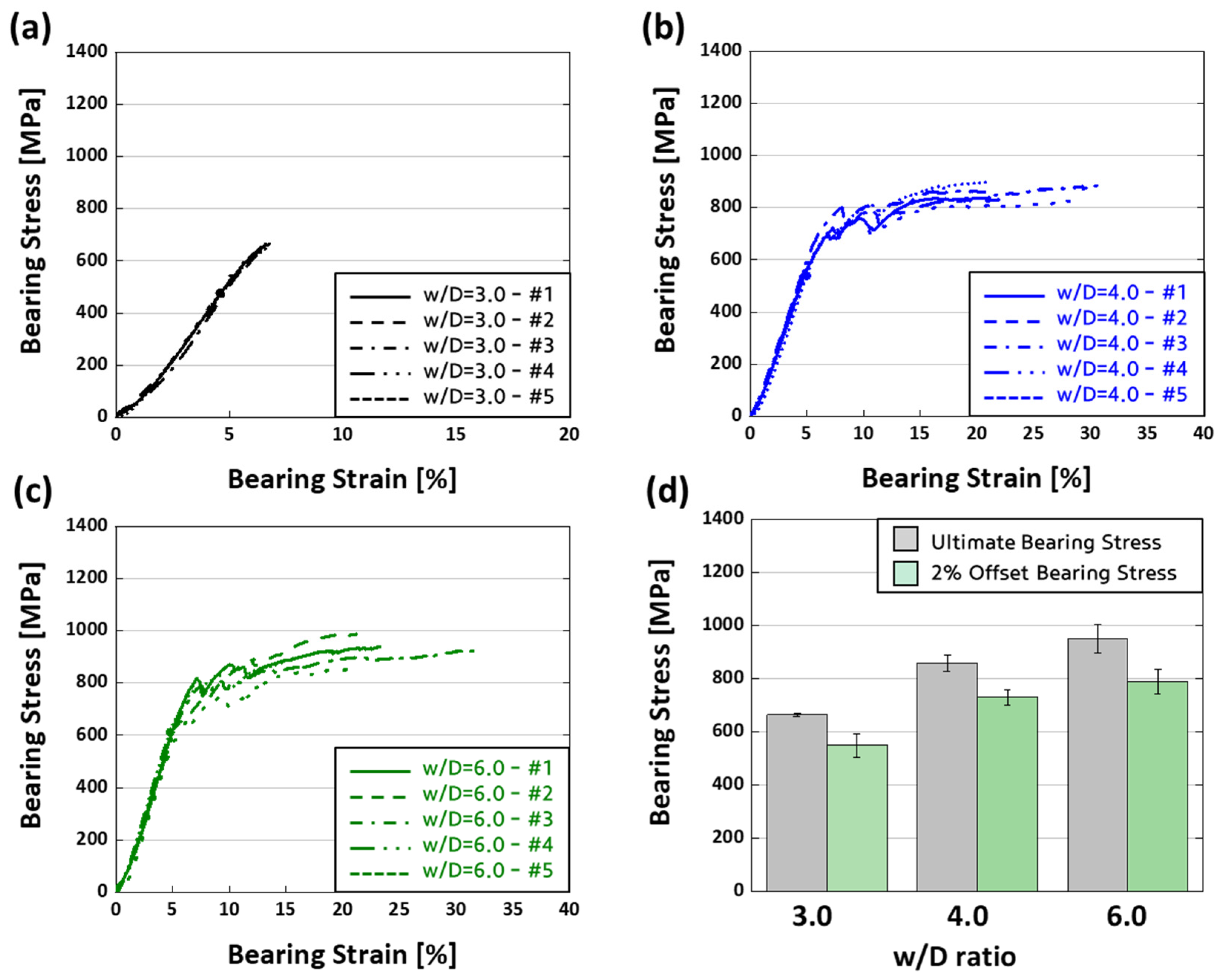

3.1. Bearing Strength

3.2. Failure Mode

4. Discussion

4.1. Bearing Strength

4.2. Failure Mode

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Niu, M.C.Y.; Niu, M. Composite Airframe Structures: Practical Design Information and Data, 3rd ed.; Conmilit Press Ltd.: Hong Kong, China, 2010. [Google Scholar]

- Kwon, H. Out-Of-Autoclave Process Using a Novel Semi-Preg System for Aircraft Structures. Ph.D. Thesis, Korea Aerospace University, Goyang, Republic of Korea, 2014. [Google Scholar]

- Jawaid, M.; Thariq, M. Sustainable Composites for Aerospace Applications; Woodhead Publishing: Cambridge, UK, 2018. [Google Scholar]

- Campbell, F.C. Manufacturing Technology for Aerospace Structural Materials; Elsevier: New York, NY, USA, 2006. [Google Scholar]

- Campbell, F.C. Manufacturing Processes for Advanced Composites; Elsevier: New York, NY, USA, 2004. [Google Scholar]

- Min, P.S. Development Promotion Policy of Next-Generation Leisure Lightweight Aircraft. J. Aviat. Dev. Korea 2010, 53, 27–43. [Google Scholar]

- Thompson, J.E. Compaction and Cure of Resin Film Infusion Prepregs. Master’s Thesis, Virginia Polytechnic Institute and State University, Blacksburg, VA, USA, 2004. [Google Scholar]

- Chen, B.; Chou, T. Compaction of Woven-Fabric Preforms: Nesting and Multi-Layer Deformation. Compos. Sci. Technol. 2000, 60, 2223–2231. [Google Scholar] [CrossRef]

- Chen, B.; Chou, T. Compaction of Woven-Fabric Preforms in Liquid Composite Molding Processes: Single-Layer Deformation. Compos. Sci. Technol. 1999, 59, 1519–1526. [Google Scholar] [CrossRef]

- Lee, J.M.; Kim, B.M.; Ko, D.C. CFRP Compression Forming Technology. Trans. Mater. Process. 2016, 25, 203–208. [Google Scholar]

- Pasco, C.; Kendall, K. Characterisation of the thermoset prepreg compression moulding process. In Proceedings of the SPE Automotive and Composites Divisions-16th Annual Automotive Composites Conference and Exhibition, Novi, MI, USA, 7 September 2016. [Google Scholar]

- Lee, J.M.; Kim, B.M.; Ko, D.C. Development of vacuum-assisted prepreg compression molding for production of automotive roof panels. Compos. Struct. 2019, 213, 144–152. [Google Scholar] [CrossRef]

- Kim, H.S.; Lee, W.G.; Lee, C.H.; Lee, K.D. Optimization for the prepreg compression molding of notebook computer cover using design of experiment and finite element method. SN Appl. Sci. 2020, 2, 1619. [Google Scholar] [CrossRef]

- Michel, C. Solvay Launches CYCOM EP2750, High-Rate Compression Molding Prepreg for Aerospace Primary Structures; Solvay News and Press Releases: Brussels, Belgium, 2020. [Google Scholar]

- Repecka, L.; Boyd, J. Vacuum-bag-only-curable prepregs that produce void-free parts. In Proceedings of the SAMPE Symposium and Exhibition, Long Beach, CA, USA, 12–16 May 2002. [Google Scholar]

- Ridgard, C. Advances in low temperature curing prepregs for aerospace structures. In Proceedings of the SAMPE Symposium and Exhibition, Long Beach, CA, USA, 21–25 May 2000. [Google Scholar]

- Ridgard, C. Out of Autoclave Composite Technology for Aerospace, Defense and Space Structures. In Proceedings of the SAMPE Symposium and Exhibition, Baltimore, MD, USA, 18–21 May 2009. [Google Scholar]

- Ridgard, C. Next generation out of autoclave systems. In Proceedings of the SAMPE Symposium and Exhibition, Seattle, WA, USA, 17–20 May 2010. [Google Scholar]

- Lucas, S.; Howard, S.; Senger, J. Vacuum bag only processing: Improving prepreg out-time and porosity for large composite structure. In Proceedings of the SAMPE Symposium and Exhibition, Seattle, WA, USA, 17–20 May 2010. [Google Scholar]

- Centea, T.; Grunenfelder, L.K.; Nutt, S.R. A review of out-of-autoclave prepregs–Material properties, process phenomena, and manufacturing considerations. Compos. Part A Appl. Sci. Manuf. 2015, 70, 132–154. [Google Scholar] [CrossRef]

- El-Sisi, A.; Hassanin, A.; Alsharari, F.; Galustanian, N.; Salim, H. Failure Behavior of Composite Bolted Joints: Review. Civil. Eng. 2022, 3, 60. [Google Scholar] [CrossRef]

- Gao, G.; An, L.; Giannopoulos, I.K.; Han, N.; Ge, E.; Hu, G. Progressive Damage Numerical Modelling and Simulation of Aircraft Composite Bolted Joints Bearing Response. Materials 2020, 13, 5606. [Google Scholar] [CrossRef]

- Yan, L.; Jiang, R.; Zuo, Y. Damage Analysis of CFRP Hybrid Bonded-Bolted Joint during Insertion of Interference-Fit Bolt. Materials 2023, 16, 3753. [Google Scholar] [CrossRef]

- Liu, G.; Li, C.; Luo, W.; Liao, F.; Zhang, Y.; Zeng, S. Investigation on the Progressive Damage and Bearing Failure Behavior of Composite Laminated Bolted Joints under Tension. Crystals 2023, 13, 729. [Google Scholar] [CrossRef]

- Kwon, J.S.; Kim, J.S.; Lee, S.Y.; Bae, J.S. A mechanically fastened composite laminate joint and progressive failure analysis. Adv. Compos. Mater. 2018, 27, 439–456. [Google Scholar] [CrossRef]

- Li, X.; Wang, L.; Zhao, W.; Wu, H.; Xu, B. Selection and analysis of optimum stacking sequence and geometry dimensions on bismaleimides composite joints under tensile loading. Polym. Test. 2022, 105, 107421. [Google Scholar] [CrossRef]

- Qi, Z.; Zhang, Z.; Xiao, Y.; Wang, X. Analysis of Plastic Improvement and Interference Behavior in Current-Assisted Riveting of CFRP Laminates. Materials 2022, 15, 1673. [Google Scholar] [CrossRef] [PubMed]

- Torres-Arellano, M.; Bolom-Martínez, M.D.J.; Franco-Urquiza, E.A.; Pérez-Mora, R.; Jiménez-Arévalo, O.A.; Olivier, P. Bearing Strength and Failure Mechanisms of Riveted Woven Carbon Composite Joints. Aerospace 2021, 8, 105. [Google Scholar] [CrossRef]

- Borba, N.Z.; Afonso, C.R.M.; Blaga, L.; Dos Santos, J.F.; Canto, L.B.; Amancio-Filho, S.T. On the Process-Related Rivet Microstructural Evolution, Material Flow and Mechanical Properties of Ti-6Al-4V/GFRP Friction-Riveted Joints. Materials 2017, 10, 184. [Google Scholar] [CrossRef] [PubMed]

- Di Bella, G.; Alderucci, T.; Favaloro, F.; Borsellino, C. The Effect of Thickness on Strength of Single Lap Orbital Riveted Aluminum/Composite Joints Used in Marine Environments. Metals 2022, 12, 2068. [Google Scholar] [CrossRef]

- Mariga, L.P.D.; Silva, E.; Pêcego, F.; Menezes, W.; Sales, R. Analysis of parallelism tolerances and its influence on Bearing tension tests on structural composite performance according to ASTM D5961. Rev. Bras. Apl. Vácuo 2018, 37, 17–22. [Google Scholar] [CrossRef]

- Huang, Y.; Guan, Z.; Yi, X.; Ni, Z.; Ouyang, T.; Li, Z. Experimental and Numerical Investigation of Intact, Defective and Repaired Countersunk Composite Joints under Tensile Loading. Materials 2022, 15, 4677. [Google Scholar] [CrossRef]

- Zhang, J.; Chen, X.; Tian, A.; Fan, Y. Tests and Numerical Study of Single-Lap Thermoplastic Composite Joints Bolted by Countersunk. Materials 2022, 15, 2386. [Google Scholar] [CrossRef]

- Chishti, M.; Wang, C.H.; Thomson, R.S.; Orifici, A.C. Experimental investigation of damage progression and strength of countersunk composite joints. Compos. Struct. 2012, 94, 865–873. [Google Scholar] [CrossRef]

- Qin, Z.; He, Y.; Wang, S.; Meng, C. Investigation of CFRP-Countersunk Bolted Assembly Fatigue Damage under Three-Point Bending via Experimental and Numerical Analysis. Polymers 2023, 15, 1648. [Google Scholar] [CrossRef]

- Anderson, E.; Gunawan, B.; Nicholas, J.; Ingraham, M.; Hernandez-Sanchez, B.A. A Multicontinuum-Theory-Based Approach to the Analysis of Fiber-Reinforced Polymer Composites with Degraded Stiffness and Strength Properties Due to Moisture Absorption. J. Mar. Sci. Eng. 2023, 11, 421. [Google Scholar] [CrossRef]

- Calabrese, L.; Fiore, V.; Bruzzaniti, P.G.; Scalici, T.; Valenza, A. An Aging Evaluation of the Bearing Performances of Glass Fiber Composite Laminate in Salt Spray Fog Environment. Fibers 2019, 7, 96. [Google Scholar] [CrossRef]

- Fiore, V.; Calabrese, L. Effect of Glass Fiber Hybridization on the Durability in Salt-Fog Environment of Pinned Flax Composites. Polymers 2021, 13, 4201. [Google Scholar] [CrossRef]

- Calabrese, L.; Fiore, V.; Bruzzaniti, P.; Scalici, T.; Valenza, A. Pinned Hybrid Glass-Flax Composite Laminates Aged in Salt-Fog Environment: Mechanical Durability. Polymers 2020, 12, 40. [Google Scholar] [CrossRef]

- Pearce, G.M.; Tao, C.; Quek, Y.H.; Chowdhury, N.T. Chowdhury. A modified Arcan test for mixed-mode loading of bolted joints in composite structures. Compos. Struct. 2018, 187, 203–211. [Google Scholar] [CrossRef]

- Song, M.H.; Kweo, J.H.; Kim, S.K.; Kim, C.; Lee, T.J.; Choi, S.M.; Seong, M.S. An experimental study on the failure of carbon/epoxy single lap, riveted joints after thermal exposure. Compos. Struct. 2008, 86, 125–134. [Google Scholar] [CrossRef]

- Kaybal, H.B.; Ulus, H.; Avci, A. Seawater Aged Basalt/Epoxy Composites: Improved Bearing Performance with Halloysite Nanotube Reinforcement. Fibers Polym. 2021, 22, 1643–1652. [Google Scholar] [CrossRef]

- Kim, D.U.; Seo, H.S.; Jang, H.Y. Study on Mechanical Bearing Strength and Failure Modes of Composite Materials for Marine Structures. J. Mar. Sci. Eng. 2021, 9, 726. [Google Scholar] [CrossRef]

- Sivakumar, D.; Ng, L.F.; Salmi, N.S. Eco-Hybrid Composite Failure Behavior of Two Serial Bolted Joint Holes. J. Eng. Technol. 2016, 7, 114–124. [Google Scholar]

- Alshahrani, H.; Sebaey, T.A. Bearing Properties of CFRP Composite Laminates Containing Spread-Tow Thin-Plies. Polymers 2022, 14, 2076. [Google Scholar] [CrossRef] [PubMed]

- Sajid, Z.; Karuppanan, S.; Shah, S.Z.H. Effect of Washer Size and Tightening Torque on Bearing Performance of Basalt Fiber Composite Bolted Joints. J. Nat. Fibers 2022, 19, 5910–5927. [Google Scholar] [CrossRef]

- Wang, A.; Wang, Z.; Zhao, M.; Zhao, Y.; Chang, Z. Effects of ply thickness and interference-fit on the bearing strength of single-lap countersunk composite joints. Thin-Walled Struct. 2023, 189, 110878. [Google Scholar] [CrossRef]

- Hu, J.; Zhang, K.; Cheng, H.; Qi, Z. An experimental investigation on interfacial behavior and preload response of composite bolted interference-fit joints under assembly and thermal conditions. Aerosp. Sci. Technol. 2020, 103, 105971. [Google Scholar] [CrossRef]

- Dickson, A.N.; Dowling, D.P. Enhancing the bearing strength of woven carbon fibre thermoplastic composites through additive manufacturing. Compos. Struct. 2019, 212, 381–388. [Google Scholar] [CrossRef]

- Paliwal, I.; Ramji, M.; Khaderi, S.N. Experimental characterization of CFRP single lap joints under tension at various loading rates. Compos. Part A Appl. Sci. Manuf. 2023, 173, 107636. [Google Scholar] [CrossRef]

- Qu, L.; Tian, A.; Xin, Y.; Su, C.; Wang, D.; Xi, Y.; Chang, Z. Mechanical properties analysis of carbon fiber composite bond-rivet hybrid joints of maglev train body in different service environments. J. Phys. Conf. Ser. 2023, 1, 2510. [Google Scholar] [CrossRef]

- Solvay. CYCOM 5320-1 Prepreg Technical Data Sheet; Solvay: Brussels, Belgium, 2017. [Google Scholar]

- ASTM D5229/5229M-20; Standard Test Method for Moisture Absorption Properties and Equilibrium Conditioning of Polymer Matrix Composite Materials. ASTM International: West Conshohocken, PA, USA, 2020.

- Clarkson, E. Cytec Cycom 5320-1 T650 Unitape Gr 145 Qualification Statistical Analysis Report; Wichita State University: Wichita, KS, USA, 2017. [Google Scholar]

- ASTM D5961/5961M-17; Standard Test Method for Bearing Response of Polymer Matrix Composite Laminates. ASTM International: West Conshohocken, PA, USA, 2017.

- Turvey, G.J. Single-bolt tension joint tests on pultruded GRP plate—Effects of tension direction relative to pultrusion direction. Compos. Struct. 1998, 42, 341–351. [Google Scholar] [CrossRef]

- Zhou, S.; Wang, Z.; Zhou, J.; Wu, X. Experimental and numerical investigation on bolted composite joint made by vacuum assisted resin injection. Compos. Part B Eng. 2013, 45, 1620–1628. [Google Scholar] [CrossRef]

- Liu, F.; Yao, W.; Shi, X.; Zhao, L.; Zhang, J. Bearing failure optimization of composite double-lap bolted joints based on a three-step strategy marked by feasible region reduction and model decoupling. Comput. Mater. Contin. 2020, 62, 977–999. [Google Scholar] [CrossRef]

- Ataş, A.; Soutis, C. Strength prediction of bolted joints in CFRP composite laminates using cohesive zone elements. Compos. Part B Eng. 2014, 58, 25–34. [Google Scholar] [CrossRef]

- Wang, H.S.; Hung, C.L.; Chang, F.K. Bearing Failure of Bolted Composite Joints. Part I: Experimental Characterization. J. Compos. Mater. 1996, 30, 1284–1313. [Google Scholar] [CrossRef]

- Aktaş, A.; Uzun, I. Sea water effect on pinned-joint glass fibre composite materials. Compos. Struct. 2008, 85, 59–63. [Google Scholar] [CrossRef]

- Aktaş, A. Statistical Analysis of Bearing Strength of Glass—Fiber Composite Materials. J. Reinf. Plast. Compos. 2007, 26, 555–564. [Google Scholar] [CrossRef]

- Aktas, A.; Dirikolu, M. The effect of stacking sequence of carbon epoxy composite laminates on pinned-joint strength. Compos. Struct. 2003, 62, 107–111. [Google Scholar] [CrossRef]

- Okutan, B. The effects of geometric parameters on the failure strength for pin-loaded multi-directional fiber-glass reinforced epoxy laminate. Compos. Part B Eng. 2002, 33, 567–578. [Google Scholar] [CrossRef]

- Calabrese, L.; Fiore, V.; Scalici, T.; Bruzzaniti, P.; Valenza, A. Failure maps to assess bearing performances of glass composite laminates. Polym. Compos. 2019, 40, 1087–1096. [Google Scholar] [CrossRef]

- Giorleo, L.; Papa, I.; Silvestri, A.T.; Squillace, A. Pin-bearing mechanical behaviour of composites fabricated via fused filament fabrication as a function of reinforcing, pin diameter and W/D ratio. Compos. Struct. 2023, 321, 117227. [Google Scholar] [CrossRef]

- Karakuzu, R.; Gülem, T.; İçten, B.M. Failure analysis of woven laminated glass–vinylester composites with pin-loaded hole. Compos. Struct. 2006, 72, 27–32. [Google Scholar] [CrossRef]

- Kumar, S.; Wu, C.-M.; Lai, W.-Y.; Lin, P.-C. Pin hole tensile and fatigue properties of self-reinforced PET composites. Compos. Struct. 2020, 255, 112981. [Google Scholar] [CrossRef]

- Aktas, A.; Karakuzu, R. Failure analysis of two-dimensional carbon-epoxy composite plate pinned joint. Mech. Adv. Mater. Struct. 1999, 6, 347–361. [Google Scholar] [CrossRef]

- Aktaş, A. Failure analysis of serial pinned joints in composite materials. Indian J. Eng. Mater. Sci. 2011, 18, 102–110. [Google Scholar]

- Okutan, B.; Aslan, Z.; Karakuzu, R. A study of the effects of various geometric parameters on the failure strength of pin-loaded woven-glass-fiber reinforced epoxy laminate. Compos. Sci. Technol. 2001, 61, 1491–1497. [Google Scholar] [CrossRef]

- Baba, B.O. Behavior of pin-loaded laminated composites. Exp. Mech. 2006, 46, 589–600. [Google Scholar] [CrossRef]

- McCarthy, C.T.; McCarthy, A.M.; Gilchrist, M.D.; Ostachowicz, W.M.; Dulieu Barton, J.M.; Holford, K.M.; Krawczuk, M.; Żak, A.J. Predicting Failure in Multi-Bolt Composite Joints Using Finite Element Analysis and Bearing-Bypass Diagrams. Key Eng. Mater. 2005, 293–294, 591–598. [Google Scholar] [CrossRef]

- McCarthy, C.T.; McCarthy, M.A. Experimental and Computational Studies of Mechanically Fastened Joints in Composite Aircraft Structures. In Proceedings of the 1st International CEAS (Council of the European Aerospace Societies) European Air and Space Conference, Berlin, Germany, 10 September 2007. [Google Scholar] [CrossRef]

| Ratio | Width | Edge Distance | Thickness | Diameter |

|---|---|---|---|---|

| w/D = 3.0 | 19.07 ± 0.03 | 19.05 ± 0.01 | 2.19 ± 0.02 | 6.36 ± 0.01 |

| w/D = 4.0 | 25.38 ± 0.02 | 19.05 ± 0.01 | 2.20 ± 0.03 | 6.36 ± 0.02 |

| w/D = 6.0 | 38.11 ± 0.01 | 19.05 ± 0.02 | 2.19 ± 0.02 | 6.36 ± 0.01 |

| e/D = 1.5 | 38.04 ± 0.01 | 9.51 ± 0.03 | 2.21 ± 0.01 | 6.36 ± 0.01 |

| e/D = 2.0 | 38.02 ± 0.02 | 12.72 ± 0.01 | 2.19 ± 0.02 | 6.36 ± 0.01 |

| e/D = 3.0 | 38.07 ± 0.01 | 19.05 ± 0.02 | 2.19 ± 0.02 | 6.36 ± 0.01 |

| Ratio | 2% Offset Bearing Strength (MPa) | Ultimate Bearing Strength (MPa) |

|---|---|---|

| w/D = 3.0 | 548 ± 45 | 664 ± 7 |

| w/D = 4.0 | 730 ± 29 | 859 ± 31 |

| w/D = 6.0 | 789 ± 46 | 949 ± 54 |

| Ratio | 2% Offset Bearing Stress (MPa) | Ultimate Bearing Stress (MPa) |

|---|---|---|

| e/D = 1.5 | 668 ± 25 | 721 ± 27 |

| e/D = 2.0 | 774 ± 13 | 901 ± 47 |

| e/D = 3.0 | 789 ± 46 | 949 ± 54 |

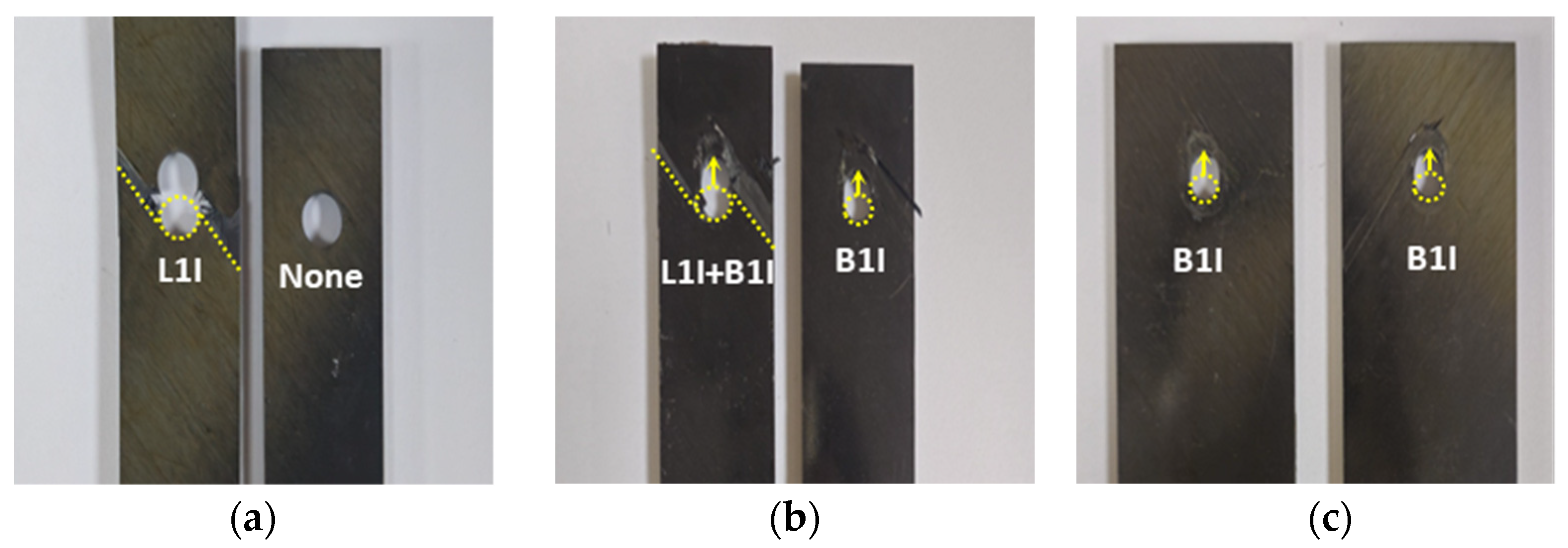

| Ratio | 1st Piece | 2nd Piece | Fastener |

|---|---|---|---|

| w/D = 3.0 | L1I | - | S3T |

| w/D = 4.0 | L1I + B1I | B1I | S3T |

| w/D = 6.0 | B1I | B1I | S3T |

| e/D = 1.5 | S1I | - | S3T |

| e/D = 2.0 | S1I + B1I | B1I | S3T |

| e/D = 3.0 | B1I | B1I | S3T |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Park, S.M.; Jeon, J.H.; Choi, W.J. Study on Bearing Strength and Failure Modes of Single Bolted Joint Carbon/Epoxy Composite Materials. Polymers 2024, 16, 847. https://doi.org/10.3390/polym16060847

Park SM, Jeon JH, Choi WJ. Study on Bearing Strength and Failure Modes of Single Bolted Joint Carbon/Epoxy Composite Materials. Polymers. 2024; 16(6):847. https://doi.org/10.3390/polym16060847

Chicago/Turabian StylePark, Sang Min, Jin Hwan Jeon, and Won Jong Choi. 2024. "Study on Bearing Strength and Failure Modes of Single Bolted Joint Carbon/Epoxy Composite Materials" Polymers 16, no. 6: 847. https://doi.org/10.3390/polym16060847

APA StylePark, S. M., Jeon, J. H., & Choi, W. J. (2024). Study on Bearing Strength and Failure Modes of Single Bolted Joint Carbon/Epoxy Composite Materials. Polymers, 16(6), 847. https://doi.org/10.3390/polym16060847