Abstract

Herein, wheat straw residue and pulping waste liquid were collected from pulping mill and mixed to prepare bio-based granular fuels by using compression molding technology, and to explore the comprehensive utilization of the industrial waste of pulping and papermaking. The effects of pulping waste liquid on granular fuel properties were analyzed systemically. Further study of the function of pulping waste liquid, cellulose and hemicellulose was used to replace wheat straw residue and avoid the interference factors. Therefore, the prediction models of granular fuels were established with influencing factors that included cellulose, hemicellulose and pulping waste liquid. The granular fuels had the best performance with 18.30% solid content of pulping waste liquid. The highest transverse compressive strength of granular fuel was 102.61 MPa, and the activation energy was 81.71 KJ·mol−1. A series of curve fitting prediction models were established to clarify the forming process of granular fuel, and it turned out that the pulping waste liquid could improve the adhesion between solid particles and increase their compression resistance.

1. Introduction

Biomass granular fuel, as a renewable and environmentally friendly energy, is produced and expected to replace coal, oil, electricity and natural gas [1,2]. Therefore, the development of biomass granular fuel technology could compensate the shortage of conventional energy and provide significant environmental benefits. However, the traditional granular fuels made by molding technology has low quality, and various pollutants are released during the combustion process [3,4]. Consequently, selecting suitable additives is a crucial solution to improve the quality of granular fuels and reduce power consumption during granularizing processes [5].

Several industrial wastes as additives have been reported to improve the properties of biomass granular fuel and the physical properties and combustion characteristics of biomass granular fuel. It was discovered that using coal tar residue (CTR) as a binder for biomass/lignite granular fuel significantly enhances the granular fuel’ mechanical strength and heating value [6]. With an increase in the proportion of CTR, the ignition temperature and activation energy of wheat straw granular fuel increased gradually. At the same time, the maximum burning rate and maximum weight loss percentage decreased. The bio-waste could be successfully densified into good-quality granular fuel by drum granulation using silicate-based binders, and the link between the properties of granules and the conditions of granulation process was established [7]. Meanwhile, the combustion behaviors of sludge–biomass mixed granular fuel with different sludge ratios in air atmosphere are investigated by thermogravimetric analysis [8]. Four main stages are dehydration, volatile oxidation, char burning, and burnout during the thermal decomposition of granular fuel. The reactivities of sludge–biomass granular fuels are improved by the increment of the mixing ratio of biomass. However, the above experiments have high emission pollution and ash slagging potential, so further research is needed. The co-granularization of agricultural and forestry waste using refuse-derived fuel lowered energy consumption during granularization slightly improved particle and bulk densities, which resulted in a significant increase in the breaking load and tensile strength of the granular fuel and reduced the ash content of the roasted biomass granular fuel. However, the durability, net calorific value, and energy density were impoverished as the refuse-derived fuel in the blend increased [9,10]. The effect of paper sludge was studied as an additive to the quality of granular fuels [11]. They observed that it improved the characteristic ash melting temperature of straw granular fuel and the mechanical properties of wheat straw granular fuel. In our previous work, the effect of pulping waste liquid on forming effect and performance of wheat straw granular fuel were studied [12]. The proper amount of pulping waste liquid is added to improve the relaxed density and durability of the fuel. However, the compositional variables in the selected natural biomass materials may interfere with the experimental results to a certain extent, and the forming process of industrial waste to granular fuel has not been fully explained. Therefore, a granular fuel model was prepared for this experiment to explore this problem. The forming process of the solid content of pulping waste liquid on biomass granular fuel was explored by changing the amount of pulping waste liquid.

The pulping waste liquid is constituted with lignin, hemicellulose, sugars, organic acids, inorganic salts, etc. [13,14], which can be considered to be used as binder to be incorporated with wheat straw residues and to prepare granular fuels. In this study, cellulose, hemicellulose, and pulping waste liquid were used as raw materials to prepare biomass granular fuel models, so the function of pulping waste liquid on the properties of granular fuels was explored systemically. Thereafter, the granular fuels were characterized by the thermogravimetric analysis method and the Coats-Redfern method to analyze their combustion performance. Based on the data relationship between the granular fuel and prediction models, the function of pulping waste liquid was clarified. These research results provide good guidance to their practical utilization, and will provide a theoretical basis for the further development of biomass granular fuel.

2. Materials and Methods

2.1. Experimental Materials

Wheat straws residues with a particle size of >0.22 mm were attained from a pulp and paper mill in Weifang, China. The wheat straws were pre-treated with pectinase and lipase for 4 h at 55 °C, and then transferred in digester with 4% of NaOH, liquid ratio of 1:4 at 100 °C for 20 min; cellulose was filtered for papermaking, and the pulping waste liquid was attained. Cellulose (particle size:180 μm) was purchased from Shanghai Aladdin Co., Ltd. (Shanghai, China). Hemicellulose (xylan, 85%, Corncob) was purchased from Shanghai Yuanye Bio-Technology Co. Ltd. (Shanghai, China).

2.2. Detection of Pulping Waste Liquid

The lignin content in the pulping waste liquid was measured according to GB/T 2677.8-1994 and 72% sulfuric acid method. An ion chromatograph (ICS-5000+, Thermo Fisher Scientific, Waltham, MA, USA) was applied to determine the sugar content in the pulping waste liquid. A revolving rheometer (ARES-G2, TA Instruments, New Castle, DE, USA) was used to determine the viscosity of the pulping waste liquid.

2.3. Sample Preparation

Preparation of Wheat Straws Granular Fuel and Granular Fuel Model

The granular fuels with pulping waste liquid were prepared as Granular Fuel-1 in Table 1: (1) The oven dry wheat straws residue and pulping waste liquid were mixed, and then dried in an oven at 60 °C for 24 h; (2) 1.00 g of the mixed materials was molded by powder compressing machine (FW-4A, Tianjin Botian Shengda Technology Development Co., Ltd., Tianjin, China) at room temperature with a pressure of 8 MPa and a diameter of 13 mm. As a control group, the granular fuels with water were prepared as Granular Fuel-2 in Table 1: the oven dry wheat straws residue and water were mixed, and then molded by powder compressing machine and marked as A, B, C, D, E.

Table 1.

The material balance of granular fuels.

In this material balance, the preparing parameters before drying were listed, the applied pulping waste liquid has a solid content of pulping waste liquid of 4.45%. After drying, the mass fraction of pulping waste liquid were 4.26%, 18.30%, 30.94%, 40.19% and 47.26%, which were corresponded to 1, 2, 3, 4, 5.

The granular fuel models with pulping waste liquid were prepared as follows: (1) The mixture of cellulose and hemicellulose with a mass ratio of 30.15:27.06 was prepared and corresponded to the mass ratio in wheat straw residues [9]; (2) and then the mixtures were mixed with pulping waste liquid as Granular Fuel Model-1 in Table 1, and dried in an oven at 60 °C for 24 h; (3) 1.00 g of the mixed materials was molded by powder compressing machine. The samples were marked as 1#, 2#, 3#, 4#, 5#. As a control group, the granular fuels model with water were prepared with the mixture of cellulose and hemicellulose as Granular Fuel Model-2 in Table 1; the preparing process was the same as above mentioned, and the samples were marked as A#, B#, C#, D#, E#, respectively.

2.4. Physicochemical Performance Testing

2.4.1. Density

The cylindrical granular fuels were measured after setting 0 and 12 h using a thickness gauge. The diameter of the cylindrical granular fuels was kept at 13 mm, but their height was changed and recorded to calculate the relaxed densities of d (ρ = m/V).

2.4.2. Compressive Strength

An electronic universal testing machine (WDW-10E, Jinan Wenteng Testing Instrument Co., Ltd., Jinan, China) was used to measure the transverse and longitudinal compressive strengths of granular fuel with a compressing rate of 10 mm/min. When the first crack occurred, the corresponding pressure was rendered as the maximum compression resistance.

2.4.3. X-ray Micro-Tomography

The microstr uctural properties of the granular fuel model were investigated using X-ray microCT (Sky Scan-2211, Bruker, Ettlingen, DE, USA) with a non-destructive method. The scaled image pixel size of 1 μm was settled, which was sufficient to detect the large features within the granular fuel model.

2.5. Combustion Performance Test

2.5.1. Calorific Value

Wheat straws residue granular fuel and granular fuel model were measured using an automatic calorimeter (ZDHW-5, Hebi Huifa Instrument Co., Ltd., Hebi, China) with the Oxygen bomb method, and the test unit was recorded with J/g.

2.5.2. Thermogravimetric Experiments

The sample heating thermogravimetric curve (TG) and derivative thermogravimetric curve (DTG) of the samples were achieved using a TGA thermogravimetric analyzer (Rigaku TG-DTA8122 model, Japan TG-DTA Instruments, Kyoto, Japan). This test was performed under air atmosphere with a flow of 50 mL/min, and the temperature ranged from 25 °C to 800 °C with a heating rate of 10 °C/min. The TG–DTG standard definition method was used to analyze the igniting temperature Ti (°C), the maximum combustion rate vmax (%/min) and temperature Tmax (°C); the average combustion rate v (%/min) and the burn-out temperature Tf (°C).

The index S of comprehensive combustion characteristic [15] can be calculated with the Equation (1):

where, S—the comprehensive combustion characteristics, %2·min−2·°C−3; vmax—the maximum combustion rate, %/min; v—the average combustion rate, %/min; Ti—the ignition temperature, °C; Tf—the burn-out temperature, °C.

The index Rv of volatile components precipitation characteristics can be calculated with the Equation (2):

where, Rv—the volatile components precipitation characteristics, %·min−1·K−2; vmax—the maximum combustion rate, %/min; Tmax—the temperature of maximum combustion rate, K; Ti—the ignition temperature, K.

The fire index Di [16] can be calculated with the Equation (3):

where, Di—the fire index, %·min−1·°C−2; vmax—the maximum combustion rate, %/min; Tmax—the temperature of maximum combustion rate, °C; Ti—the ignition temperature, °C.

In this experiment, the combustion thermogravimetric experiment was carried out under a constant heating rate. The Coats-Redfern method was used to fit the kinetic parameters of the first-stage reaction. Calculation was based on the Alenius formula (4), which reflected the relationship between the chemical reaction rate constant and temperature [17]:

where, k—the reaction constant, min−1; A—the pre-exponential factor, min−1; E—the activation energy of reaction, J/mol; R—the universal gas constant, 8.314 J/(mol·K); T—the absolute temperature, K; α—the conversion rate of reaction process, %; n—the reaction order.

where, m0—the mass of sample at the initial moment of pyrolysis, mg; mt—the mass of sample at the moment t of pyrolysis, mg; mf—the quality of sample at the time when the solution is terminated, mg.

For biomass fuels, ≈1, the formula can be simplified to:

Let , , build a model according to the first-level reaction y = ax + b, make , , according to slope a and intercept b of the fitted curve; the activation energy and the pre-exponential factor can then be obtained.

2.6. The Analysis of Performance Index Equation

The performance indexes of granular fuel like S, Rv, Di and initial density, are calculated to establish equations with the following steps:

Firstly, the solid content of pulp waste liquid was set as x, and the performance index of the granular fuel model was labelled with ym. The x-ym curve was fitted to obtain Equation (1) according to experimental data of S, Rv, Di and initial density of granular fuel model, respectively. Therefore, the relationship between the x and ym can be expressed as following:

ym = f(x)

The performance index of the granular fuel model was set as ym, the performance index of the granular fuel was labelled with y. The ym-y curve was fitted to obtain Equation (2) according to experimental data of S, Rv, Di and initial density of granular fuel. Therefore, the relationship between the ym and y can be expressed as following:

y = g(ym)

Equation (1) was integrated with Equation (2) to obtain Equation (3). Therefore, the relationship between the x and y could be expressed as following:

y = g(f(x))

Finally, the prediction accuracy of the granular model was evaluated by the relative error value.

3. Results and Discussion

3.1. The Composition and Adhesion of Pulping Waste Liquid

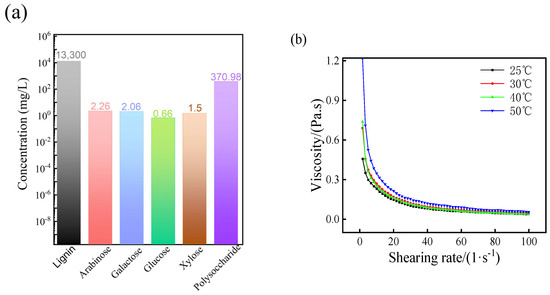

As is shown in Figure 1a, the pulping waste liquid contains a variety of chemical components, in which lignin has the highest concentration of 13,300 mg/L followed by, polysaccharide, which has a concentration of 370.98 mg/L, and then some other sugars like arabinose, galactose, glucose and xylose, which have a concentration below 10 mg/L. In the cooking process, lignin, cellulose and hemicellulose can be hydrolyzed as small molecular carbohydrates, which have a relatively small proportion. It is known to all that lignin and sugars are natural adhesive polymers in plants, and can act as adhesive binder in molding granule. Furthermore, lignin has a high heating value of 27,000 J/g due to its rich content of carbon and hydrogen [18], so lignin can also be used to provide the quality of heat for granular fuels. So pulping waste liquid can be used to improve the performance of granular fuels.

Figure 1.

(a) Composition and (b) viscosity of pulping waste liquid.

The influence of shearing rate and temperature on pulping waste liquid are shown in Figure 1b. With the increasing shear rate, the viscosity of pulping waste liquor has a decreasing tendency, which shows a shearing–thinning behavior. Meanwhile, the viscosity of pulping waste liquid increases with the increasing temperature, the pulping waste liquid has the highest initial viscosity at 50 °C of about 5.32 Pa·s, and lowest initial viscosity at 25 °C of about 0.51 Pa·s. Lignin could dissolve in solvents at low temperature, but lignin would become soft with increasing temperature, along with the increasing viscosity. Actually, the natural adhesives like lignin, hydrolysates and other resins, waxes, are sensitive to temperature and pressure, and so they would also play binding role in the pressing process. With the increasing shearing rate, all the sample with various temperatures showed a similar viscosity of about 0.15 Pa·s, in which all the chains of the molecules have a similar directional arrangement under the shear force.

3.2. Effect of Pulping Waste Liquid on the Physical Properties of Wheat Straw Residue Granular Fuel

The manufactured granular fuels are influenced by many factors, like additives, moisture content, dimensions, densities, compressive strength, heating value, etc. As the important constituents and main adhesives of granular fuels, the effect of pulping waste liquid would be studied systemically.

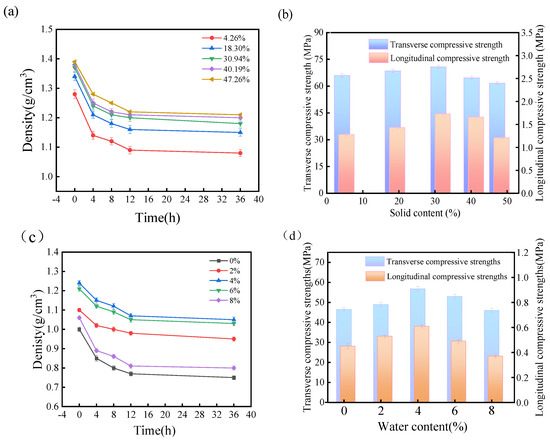

The relationship between the pulping waste liquid and the physical properties of granular fuel is displayed in Figure 2a. When the solid content of the pulping waste liquid increases from 4.26% to 30.94%, the density of granular fuel increases significantly, and the initial density reaches 1.37 g/cm3. It turns out that the solids in the pulping waste liquid can fill the gap between the wheat straw residue particles. When the solid content of waste liquid increases by 47.26%, the initial density of granular fuels decreases by 1.38 g/cm3, so the addition of pulping waste liquid would lead to more complicated mechanical engagement and intermolecular binding force, and finally result in a dense structure. However, the internal structure undergoes stress deformation over time, so the density of all granular fuels shows decreasing tendency with ongoing, time and the relaxation density tends to a constant after 4 h. In addition, the results show that the granular fuels with high addition of pulping waste liquid have a low reduction amplitude, and further demonstrate that the addition of pulping waste liquid improves the binding force of the granular fuels.

Figure 2.

The physical properties of granular fuel with different pulping waste liquid: Density (a) and Compressive strength (b); and with water (c,d).

As shown in Figure 2b, the compressive strength of wheat straw residue granular fuel initially increases and then decreases with the increasing content of pulping waste liquid. Compared with the granular fuel with 4% water content (56.82 MPa), the best transverse compressive strength of the granular fuel increases by 9.27% with the adding of pulping waste liquid. It can be seen that pulping waste liquid has a more substantial enhancement effect on the compressive strength of straw residue granular fuel. When the solid content of pulping waste liquid is 30.94%, the transverse compressive strength reaches 62.09 MPa, which is 25.79% higher than the transverse compressive strength, with 4.26% pulping waste liquid. With the further increase of pulping waste liquid by 47.26%, the transverse compressive strength decreases to 58.40 MPa. The excessive solid content of pulping waste liquid has increased the lubricity of the internal structure [19], and thus wheat straw residue granular fuel cannot effectively support the higher external force.

Compared with the granular fuels with pulping waste liquid, the control group has low density and low physical strength and the results are listed in Figure 2c,d. Water is important in the molding process,. with increasing water proportion, water works as free radical and promotes the binding among particles, even with less external pressure. As can be seen in Figure 2c, the granular fuels have increasing transverse and longitudinal compressive strengths with increasing water content that then decreases after 4%.

3.3. Effect of Pulping Waste Liquid on the Physicochemical Properties of Granular Fuel Model

The granular fuels with wheat straw residue have complicate constituents, and it is hard to tell the function of pulping waste liquid clearly. Thereafter, the granular fuel models are prepared, and their physicochemical properties are analyzed and compared to clarify the forming process.

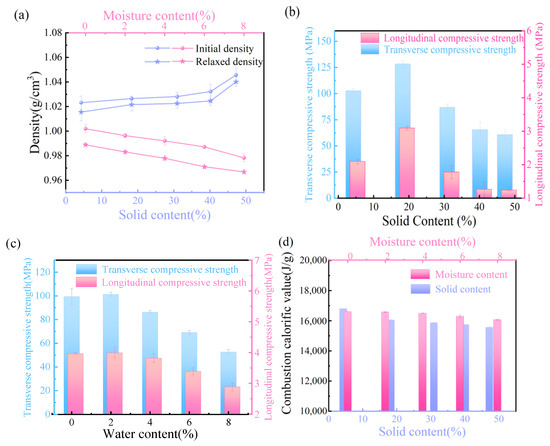

It can be seen from Figure 3a that the initial density and relaxation density show a downward tendency with the increasing moisture content. Meanwhile, the initial density and relaxation density (after 24 h) show an increasing tendency with the increasing pulping waste liquid solid content. The particle size of cellulose and hemicellulose powder is small, and their internal gap reduces without any additives. Adding water to the mixture to make the granules, the hydrogen bonding forms among cellulose, hemicellulose and water, which strengths the binding force of granular fuels. But the density decreases with increasing moisture content, and water becomes attached to the surface of particles and forms a layer of water film, which hinders the tight binding between the particles [20]. Adding the pulping waste liquid with the solid content of 4.29%, the initial density is 1.02 g/cm3. The initial density then increases by 1.05 g/cm3 with the solid content of 47.26%. Compared with the granules with water, the granules with pulping waster liquid have a smaller difference between initial and relaxed density. Lignin and sugars in the pulping waste liquid has good adhesive function [21,22] and elastic performance; they can produce plastic deformation after compression molding process, and have a fast stress transmission speed [23,24].

Figure 3.

Effect of pulping waste liquor on physicochemical properties of granular fuel. (a) Density, (b,c) compressive strength and (d) combustion calorific value.

Figure 3b,c show that the transverse compressive strength is obviously higher than the longitudinal compressive strength of granular fuels, and they all show a descending tendency with increasing moisture. Excessive water (>2%) has a weakening effect on the compressive strength of granular fuel. However, the transverse and longitudinal compressive strength show the same tendency, which increases with increasing solid content and then decreases, and shows a maximum at 20%. The lignin and sugars in the pulping waste liquid show good bonding effect and contribute to an improved compressive strength. When the pulping waste liquid content exceeds 20%, too many spaces are filled with lignin and sugars, which creates great connectivity with cellulose and hemicellulose, and results in bad skeleton stability of the granule fuels. Therefore, the amount of pulping waste liquid should be kept at a suitable dosage.

The combustion calorific value of granular fuel model shows a downward trend with the increasing water content and pulping waste liquid solid content (Figure 3d). The pulping waste liquid containing lignin, polysaccharide etc. has a value of calorific value but is lower than cellulose/hemicellulose, which explains the reason for the decreasing tendency. Furthermore, the granular fuels with pulping waste liquid are higher than water, due to the existence of organic compounds.

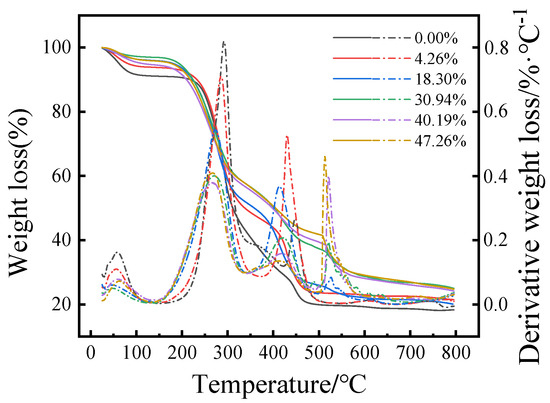

3.4. Effect of Pulping Waste Liquid on the Combustion Characteristics of Granular Fuel Model

As shown in Figure 4, the evaporation temperature range of water is between 25 and 150 °C, the degradation temperature range of cellulose and hemicellulose is between 175 and 400 °C, while lignin degrades in the range from 350 to 600 °C. The higher the content of pulping waste liquid, the lower the combustion and decomposition rate of granular fuel. It is observed that the residual weight of wheat straws residue granular fuel with the most solid content (27.65%) is higher than that of wheat straws residue granular fuel without pulping waste liquor (18.96%). This is because of the presence of higher inorganic mineral content and ash in the pulping waste liquor.

Figure 4.

TG and DTG curves of wheat straws granular fuel with different pulping waste liquid content.

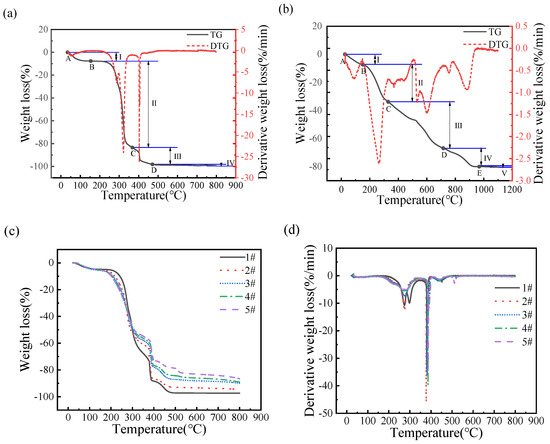

It can be seen from Figure 5a that the TG curve of granular fuel mainly have four stages. They can be concluded as follows: the water evaporation stage (I), the volatile component combustion stage (II), the fixed carbon combustion stage (III) and the burn-out stage (IV); the specific data are listed in Table 2. The evaporation temperature range of water is between 25 and 150 °C, the degradation temperature of volatile components ranges from 220 to 360 °C, the fixed carbon combustion temperature ranges from 360 to 570 °C, and granular fuels burn out at 600 °C. It is known that hemicellulose pyrolysis occurs from 220 to 315 °C, and cellulose pyrolysis from 315 to 360 °C [25]. Meanwhile, CO2, CO and some small organic matter [26,27,28] are generated and a high weight loss of 75.45% occurs from 220 to 360 °C. At the third stage, the pyrolysis of the organic matter in the granular fuel is completed. At the last stage, the combustion is completed, and the residues are kept at 1.23%.

Figure 5.

TG and DTG curves of granular fuel models with different pulping waste liquid content. (a) TG–DTG curves of the granular fuel model with water. (b) TG–DTG curves of the pulping waste liquid solids. (c) TG curves of granular fuel models with different pulping waste liquid content. (d) DTG curves of granular fuel models with different pulping waste liquid content.

Table 2.

The combustion process analysis of the model without adding waste liquid fuel or solid content of waste liquid; granular fuel model with different solid content of the waste liquid.

In referring to Figure 5b, it can be seen that the pyrolysis of pulping waste liquid mainly includes five stages. They can be concluded as follows: the water evaporation stage (I), the volatile component combustion stage (II), the fixed carbon combustion stage (III), the fourth stage (IV), and the burn-out stage (V); the detailed temperature range is listed in Table 3. At the fourth stage (480–560 °C), the oxidation and decomposition of inorganic salt in the pulping waste liquid occurs, and alkali metal salts melt, evaporate, decompose, and burn to produce volatile components such as CO and CO2 [29,30]. As can be seen from Table 3, with the increasing solid content of pulping waste liquid, the combustion residues of the granular fuel model also increase. The sample of A# is prepared without pulping waste liquid, and the burning residues amount of the granular fuel model is 1.23%. When the solid content of pulping waste liquid increases to 47.26%, the burning residues amount of granular fuel model increases to the maximum of 17.30%. Cellulose/hemicellulose granular fuel model with water can be completely burned, and the inorganic substances within pulping waste liquid result in residue. Therefore, when the more solid content of the pulping waste liquid is retained in the granular fuel model, more combustion residues are produced.

Table 3.

Analysis table of the thermodynamic parameters of the volatile stage combustion.

Figure 5c,d show the pyrolysis of granular fuel models with different pulping waste liquid content. The volatile combustion stage of granular fuel models range from 150 to 350 °C, in which the granular fuels form the initial carbon layer. With the increasing pulping waste liquid solid content, the inorganic substances proportion in the fuel model increases, followed by the melt reduction reaction recording a high initial temperature. The more inorganic substances lower the combustion temperature of the fuel model, indicating that the pulping waste liquid solid content has a synergistic effect on the combustion of the granular fuel model.

Table 3 shows that the ignition temperature of granular fuel model decreases with the increasing waste liquid solid contents. As inorganic substances are incombustible, they will decrease the ignition temperature of granular fuel model. For the granular fuel model, vmax1 and vmax2 show a downward trend with increasing pulping waste liquid solid content; the v of the A#, 1#, and 5# models are 4.64%·min−1, 3.36%·min−1 and 2.53%·min−1, respectively. The inorganic substances reduce the calorific value of the granular fuel, which results in the decrease of combustion releasing heat. Furthermore, the inorganic substances cover the unburned organic matter during the combustion process, which increases the resistance to the flame spread and decreases the combustion rate [30,31].

Table 4 shows that increasing the pulping waste liquid solid content decreases the ignition index of the granular fuel model, and weakens the ignition performance. The Di of 1# fuel model is 3.91 × 10−5%·min−1·°C−2, and it has relatively good ignition performance; the Di of 5# fuel model is 1.89 × 10−5%·min−1·°C −2 with the worst ignition performance. The comprehensive combustion characteristic index of the 1# fuel model is 1.69 × 10−7%2·min−2·°C−3. The S of granular fuel decreases as the pulping waste liquid solid content increases. The Rv of the 1# and 5# fuel models are 2.12 × 10−4 and 0.65 × 10−4%·min−1·K−2, respectively. Therefore, the increasing waste liquid solid contents result in decreasing Rv of granular fuel, and a decreasing rate of the volatile components precipitation and combustion.

Table 4.

Analysis table of the combustion characteristics of the granular fuel model.

The kinetic parameters of granular fuel model are obtained by the first-order reaction equation in each combustion stage, and the correlation coefficients are all above 0.95, indicating that the fitting results are feasible. The activation energy E and frequency factor A of granular fuel model are calculated by fitting the slope and intercept of linear equation in each combustion stage. Herein, E is the difference between the activated molecules’ average energy and all molecules’ energy in the combustion process. The combustion process of the granular fuel is easier with lower value of E. A is the frequency factor, which is a constant determined only by the chemical substance and used to measure the intensity of the combustion process of granular fuel.

Table 5 shows that the E of the A# granular fuel model in the volatile and fixed carbon combustion stages are 124.70 and 283.99 KJ·mol−1, which are 136.35% and 561.67% higher than that of the waste liquid solid. The A of the A# granular fuel model in the volatile and fixed carbon combustion stages are 4.25 × 1010 and 3.69 × 1021 min−1, which are 1.41 × 106 and 7.62 × 1019 times that of the waste liquid solid. Thus, under the same conditions, the volatile and fixed carbon in the waste liquid solid are more flammable than those in the A# granular fuel model, and the combustion process is milder and less prone to deflagration. The E of the 5# granular fuel model in the volatile and fixed carbon combustion stages are 55.42 and 216.86 KJ·mol−1, which are 55.56% and 23.64% lower than those of the A# model. This is because of the catalytic role of metal oxides in the pyrolysis process [32,33]. As the waste liquid solid content increases, metal oxides’ content in the granular fuel model increase, the catalytic pyrolysis is strengthened, the energy required for the reaction decreases, and the activation energy decreases. The A of A# granular fuel model in the volatile and fixed carbon combustion stages are 9.79 × 105 times and 1.24 × 105 times that of the 5# granular fuel model. This indicates that the volatile and fixed carbon of the granular fuel combined with waste liquid is more flammable, more stable, and less prone to deflagration than those without the addition of waste liquid.

Table 5.

Combustion kinetic parameters of the granular fuel model.

3.5. Analysis of the Molding Process of Granular Fuel

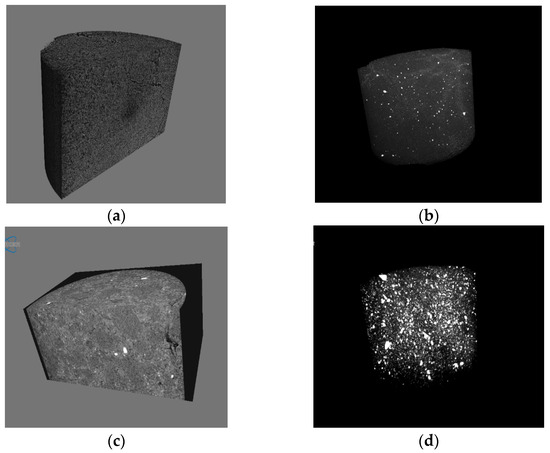

Figure 6 shows the 3D images of the internal and external microstructure of granular fuel. The granular fuel with 2% moisture shows a regular section with small pores and cracks, and the distribution of water is shown in Figure 6b. In comparison, the granular fuel with 18.30% pulping waste liquid has a denser structure, and the liquid is closely distributed with the solid particles. It is concluded that the pulping waste liquid makes a good fusion between particles, and a strengthened binding force is formed. This can be used to directly explain the strengthened physical properties and deduced density obtained with pulping waste liquid.

Figure 6.

3D images of micro-CT reconstructed granular fuel model with (a) 2% moisture content and (c) 18.30% pulping waste liquid solid content; Distribution of water (b) and pulping waste liquid solids (d) in the granular fuel model.

The granular fuel and granular fuel model with pulping waste liquid solid content of 4.26%, 18.30%, 30.94, 40.19%, 47.26% were calculated to obtain prediction models by curve fitting and equation simplifying, with their S, Rv, Di and density listed in the following:

In Equation (8), x refers to solid content of pulping waste liquid, and y refers to S. As is shown in Table 6, the relative error between measured data and predicated data are lower than 0.20, which means a high fitting degree exists. And then the derivation was calculated:

in which, x ∈ [0, 50], and y′ < 0. So, the value of S is negatively associated with the solid content of pulping waste liquid.

Table 6.

Prediction models of the comprehensive combustion characteristic index.

In Equation (11), x refers to solid content of pulping waste liquid and y refers to Rv. As is shown in Table 7, the relative error between measured data and predicated data are also lower than 0.20, which means a high fitting degree exists. And then the derivation was calculated:

in which, x ∈ [0, 50] and (3.41 × 10−4 − 6.00 × 10 − 5∙x0.39) > 0, so y′ < 0. So, the value of Rv is negatively associated with the solid content of pulping waste liquid.

Table 7.

Prediction models of the volatile component precipitation characteristic index.

In Equation (15), x refers to solid content of pulping waste liquid and y refers to Di. As is shown in Table 8, the relative error between measured data and predicated data are also lower than 0.20, which means a high fitting degree exists. And then the derivation was calculated:

in which, , and . So, the value of Di is negatively associated with the solid content of pulping waste liquid.

Table 8.

Prediction models of the ignition index.

In Equation (18), x refers to solid content of pulping waste liquid, and y refers to initial density. As is shown in Table 9, the relative error between measured data and predicated data are also lower than 0.20 with the range of solid content at 4.26–47.26%. With the high fitting degree of the equation, its derivation was calculated:

in which, and . So, the value of initial density is positively associated with the solid content of pulping waste liquid.

Table 9.

Prediction models of the initial density.

In Equation (21), x refers to solid content of pulping waste liquid and y refers to relaxed density. As is shown in Table 10, the relative error between measured data and predicated data are also lower than 0.20, and the equation has high fitting degree. And then the derivation was calculated:

in which, x ∈ [0, 50], and y′ > 0. So, the value of relaxed density is positively associated with the solid content of pulping waste liquid.

Table 10.

Prediction models of the relaxed density.

According to the above data, the initial density and relaxed density are positively associated with the solid content of pulping waste liquid, whereas, the S, Rv, Di are all negatively associated with the solid content of pulping waste liquid. Therefore, the addition of pulping waste liquid increased the tightness and physical performance of the granular fuels, but decreased the combustion. Combined with the characteristic of pulping waste liquid and the structure of granular fuels, this confirmed the binding function of pulping waste liquid; Meanwhile, within the same quantity, pulping waste liquid has inferior combustion performance than wheat straw resides and reduced the whole combustion performance.

4. Conclusions

In this study, the function of pulping waste liquid on the forming process and properties of granular fuel were investigated systemically.

- (1)

- Lignin and sugars in the pulping waste liquid were natural adhesives, and the addition of pulping waste liquid could improve the mechanical strength of granular fuels. The granular fuels had the best performance with 18.30% solid content of pulping waste liquid, the highest transverse compressive strength was up to 102.61 MPa, and the activation energy was 81.71 KJ·mol−1 at the volatile carbon combustion stage.

- (2)

- The predicated models were established to study the forming process, and the pulping waste liquid were evenly distributed in granular fuels. The addition of pulping waste liquid improved their density and density combustion indexes.

Author Contributions

L.X.: Conceptualization, software, validation, investigation, writing—original draft preparation. G.Y.: conceptualization, methodology, validation, resources, writing—review and editing, project administration, funding acquisition. Z.L.: methodology, writing—review and editing, visualization. J.C.: validation, supervision. J.L.: formal analysis. B.H.: data curation. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Key Research and Development Program of China (grant number 2019YFC1905900); Jinan Science and Technology Bureau Project (grant number 20233046); Pilot Project for Integrating Science, Education and Industry (grant number 2022JBZ01-05, 2022PY057).

Institutional Review Board Statement

The study was conducted in accordance with the Declaration of Helsinki, and approved by the Ethics Committee.

Data Availability Statement

All data are contained within the article.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Arulprakasajothi, M.; Beemkumar, N.; Parthipan, J.; Battu, N. Investigating the Physio-chemical Properties of Densified Biomass Pellet Fuels from Fruit and Vegetable Market Waste. Arab. J. Sci. Eng. 2020, 45, 563–574. [Google Scholar] [CrossRef]

- Costa, S.; Barcelos, R.; Magnago, R. Solid biofuel from glycerol and agricultural waste as a source of energy. Cellul. Chem. Technol. 2017, 51, 765–774. [Google Scholar]

- Nesterovic, A.; Djatkov, D.; Viskovic, M.; Martinov, M.; Adamovic, D. Air pollutants emissions from biomass combustion in the City of Novi Sad, Serbia. Biomass Convers. Biorefinery 2023, 13, 10935–10946. [Google Scholar] [CrossRef]

- Woolley, K.E.; Dickinson-Craig, E.; Bartington, S.E.; Oludotun, T.; Kirenga, B.; Mariga, S.T.; Kabera, T.; Coombe, A.; Pope, F.D.; Singh, A.; et al. Effectiveness of interventions to reduce household air pollution from solid biomass fuels and improve maternal and child health outcomes in low- and middle-income countries: A systematic review protocol. Syst. Rev. 2021, 10, 33. [Google Scholar] [CrossRef]

- Mohamed, O.; Zuaiter, H. Fresh Properties, Strength, and Durability of Fiber-Reinforced Geopolymer and Conventional Concrete: A Review. Polymers 2024, 16, 141. [Google Scholar] [CrossRef]

- Cheng, J.; Zhou, F.; Si, T. Mechanical strength and combustion properties of biomass pellets prepared with coal tar residue as a binder. Fuel Process. Technol. 2018, 179, 229–237. [Google Scholar] [CrossRef]

- Chen, H.; Mangwandi, C.; Rooney, D. Production of solid biofuel granules from drum granulation of bio-waste with silicate-based binders. Powder Technol. 2019, 354, 231–239. [Google Scholar] [CrossRef]

- Jiang, L.; Yuan, X.; Li, H. Co-pelletization of sewage sludge and biomass: Thermogravimetric analysis and ash deposits. Fuel Process. Technol. 2016, 145, 109–115. [Google Scholar] [CrossRef]

- García, R.; González, M.P.; Rubiera, F. Co-pelletization of pine sawdust and refused derived fuel (RDF) to high-quality waste-derived pellets. J. Clean. Prod. 2021, 328, 129635. [Google Scholar] [CrossRef]

- Gnoffo, C.; Frache, A. Identification of plastics in mixtures and blends through pyrolysis-gas chromatography/mass spectrometry. Polymers 2024, 16, 71. [Google Scholar] [CrossRef]

- Matúš, M.; Križan, P.; Šooš, Ľ. The effect of papermaking sludge as an additive to biomass pellets on the final quality of the fuel. Fuel 2018, 219, 196–204. [Google Scholar] [CrossRef]

- Yang, G.; Hou, H.; Lin, Z. Effects of waste liquid on the formation and properties of wheat slag pellet fuel. Trans. Chin. Soc. Agric. Eng. 2022, 38, 197–203. [Google Scholar]

- Zhao, L.; Wang, Y.; Wang, Q.; Liu, S.; Ji, X. Lignin Nanoparticles Produced from Wheat Straw Black Liquor Using γ-Valerolactone. Polymers 2024, 16, 49. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Zhang, J.; Zhang, B. Study on the Composition and Evaporation Characteristics of Pulping Black Liquor. Trans. China Pulp Pap. 2018, 33, 35–39. [Google Scholar]

- Jia, G. Combustion Characteristics and Kinetic Analysis of Biomass Pellet Fuel Using Thermogravimetric Analysis. Clean Combust. Emiss. Veh. Power Syst. 2021, 9, 868. [Google Scholar] [CrossRef]

- Li, B.; Liu, G.; Bi, M.; Li, Z.; Han, B.; Shu, C. Self-ignition risk classification for coal dust layers of three coal types on a hot surface. Energy 2021, 216, 119197. [Google Scholar] [CrossRef]

- Raza, M.; Abu-Jdayil, B.; Al-Marzouqi, A.H.; Inayat, A. Kinetic and thermodynamic analyses of date palm surface fibers pyrolysis using Coats-Redfern method. Renew. Energy 2022, 183, 67–77. [Google Scholar] [CrossRef]

- Maksimuk, Y.; Antonava, Z.; Krouk, V. Prediction of higher heating value based on elemental composition for lignin and other fuels. Fuel 2020, 263, 116727. [Google Scholar] [CrossRef]

- Priyabrata, P.; Sanjay, M.M.; Amit, A. Production and utilization of fuel pellets from biomass: A review. Fuel Process. Technol. 2018, 181, 215–232. [Google Scholar]

- Xu, Y.; Li, J.; Liu, Y.; Wu, W. Construction and Curing Behavior of Underwater In Situ Repairing Coatings for Offshore Structures. Polymers 2024, 16, 306. [Google Scholar] [CrossRef] [PubMed]

- Anthony, A.; Jonas, B.; Gunnar, H.; Stefan, F.; Magnus, S. A review of the mechanism of bonding in densified biomass pellets. Renew. Sustain. Energy Rev. 2021, 148, 111249. [Google Scholar]

- Rossi, L.; Wechsler, L.; Peltzer, M.A.; Ciannamea, E.M.; Ruseckaite, R.A.; Stefani, P.M. Sustainable Particleboards Based on Brewer’s Spent Grains. Polymers 2024, 16, 59. [Google Scholar] [CrossRef] [PubMed]

- Sadeq, A.; Heinrich, D.; Pietsch-Braune, S.; Heinrich, S. Influence of oscillating water content on the structure of biomass pellets. Powder Technol. 2023, 426, 118631. [Google Scholar] [CrossRef]

- Akkenzheyeva, A.; Haritonovs, V.; Bussurmanova, A.; Merijs-Meri, R.; Imanbayev, Y.; Riekstins, A.; Serikbayeva, A.; Sydykov, S.; Aimova, M.; Mustapayeva, G. Study of the Viscoelastic and Rheological Properties of Rubber-Bitumen Binders Obtained from Rubber Waste. Polymers 2024, 16, 114. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Shen, B.; Kang, D.; Yuan, P.; Wu, C. Investigate the interactions between biomass components during pyrolysis using in-situ DRIFTS and TGA. Chem. Eng. Sci. 2019, 195, 767–776. [Google Scholar] [CrossRef]

- Guo, F.; He, Y.; Hassanpour, A.; Gardy, J.; Zhong, Z. Thermogravimetric analysis on the co-combustion of biomass pellets with lignite and bituminous coal. Energy 2020, 197, 117147. [Google Scholar] [CrossRef]

- Li, C.; Zou, Y.; Li, G.; Lu, Y.; Wang, W.; Duan, J. Hydrodynamic characteristics of pyrolyzing biomass particles in a multi-chamber fluidized bed. Powder Technol. 2023, 421, 118403. [Google Scholar] [CrossRef]

- Sobek, S.; Tran, Q.K.; Junga, R.; Werle, S. Hydrothermal carbonization of the waste straw: A study of the biomass transient heating behavior and solid products combustion kinetics. Fuel 2022, 314, 122725. [Google Scholar] [CrossRef]

- Ozgen, S.; Cernuschi, S.; Caserini, S. An overview of nitrogen oxides emissions from biomass combustion for domestic heat production. Renew. Sustain. Energy Rev. 2021, 135, 110113. [Google Scholar] [CrossRef]

- Yang, W.; Pudasainee, D.; Gupta, R.; Li, W.; Wang, B.; Sun, L. An overview of inorganic particulate matter emission from coal/biomass/MSW combustion: Sampling and measurement, formation, distribution, inorganic composition and influencing factors. Fuel Process. Technol. 2021, 213, 106657. [Google Scholar] [CrossRef]

- Kleinhans, U.; Wieland, C.; Frandsen, J.F.; Spliethoff, H. Ash formation and deposition in coal and biomass fired combustion systems: Progress and challenges in the field of ash particle sticking and rebound behavior. Prog. Energy Combust. Sci. 2018, 68, 65–168. [Google Scholar] [CrossRef]

- Téllez-Salazar, W.N.; Ovalle-Encinia, O.; Ramírez-Rosales, D.; Ma, X.; Dorantes-Rosales, H.J.; Lara-García, H.A.; Ortiz-Landeros, J. Chemical synthesis and evaluation of Co3O4/Ce0.9Zr0.05Y0.05O2-δ mixed oxides for the catalytic-assisted combustion of soot. Chem. Eng. Sci. 2021, 234, 116443. [Google Scholar] [CrossRef]

- Sheth, M.M.; Sigdel, S.; Harichandan, A.B.; Bhoraniya, R. Performance of fuel reactor in Chemical Looping Combustion system with various metal oxide particle size and operating temperature. Int. J. Thermofluids 2023, 17, 100295. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).