Tensile and Interfacial Mechanical Properties for Single Aramid III Fibers under Dynamic Loading

Abstract

1. Introduction

2. Experiment

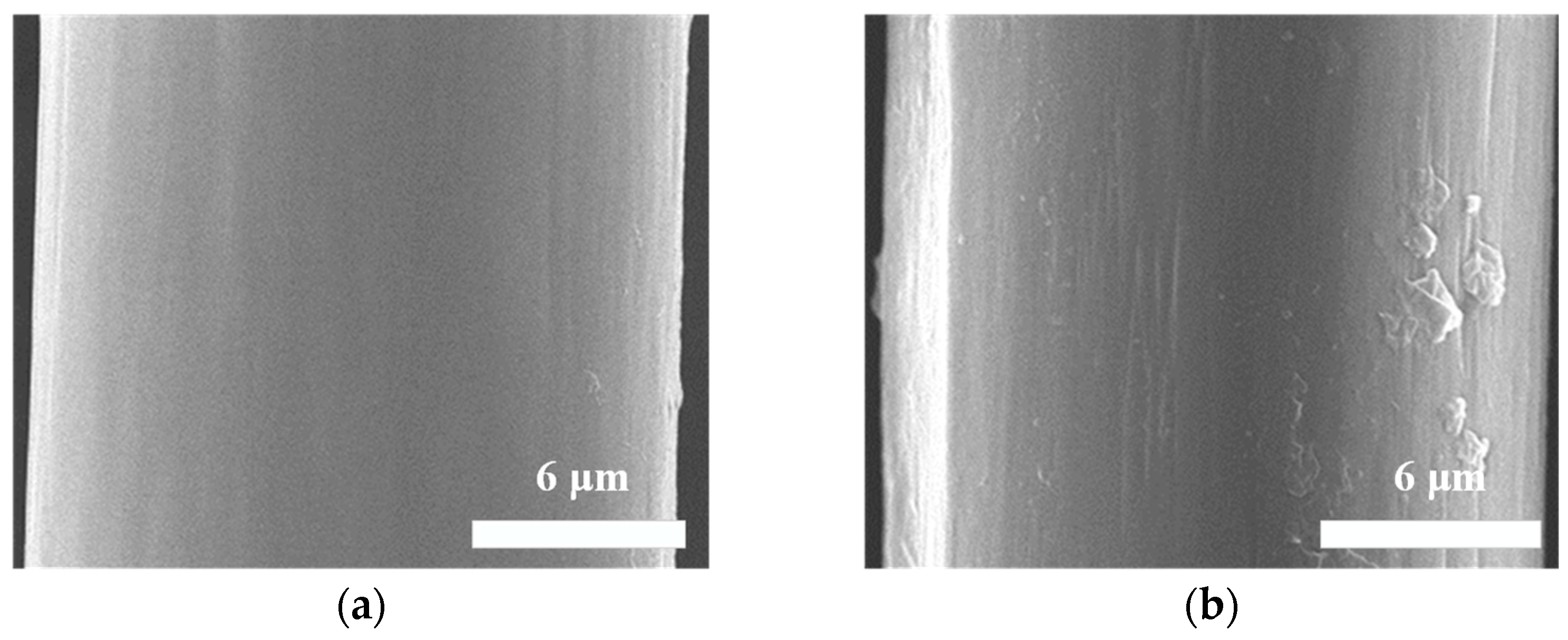

2.1. Materials and Polyamine Modification of Aramid III Fibers

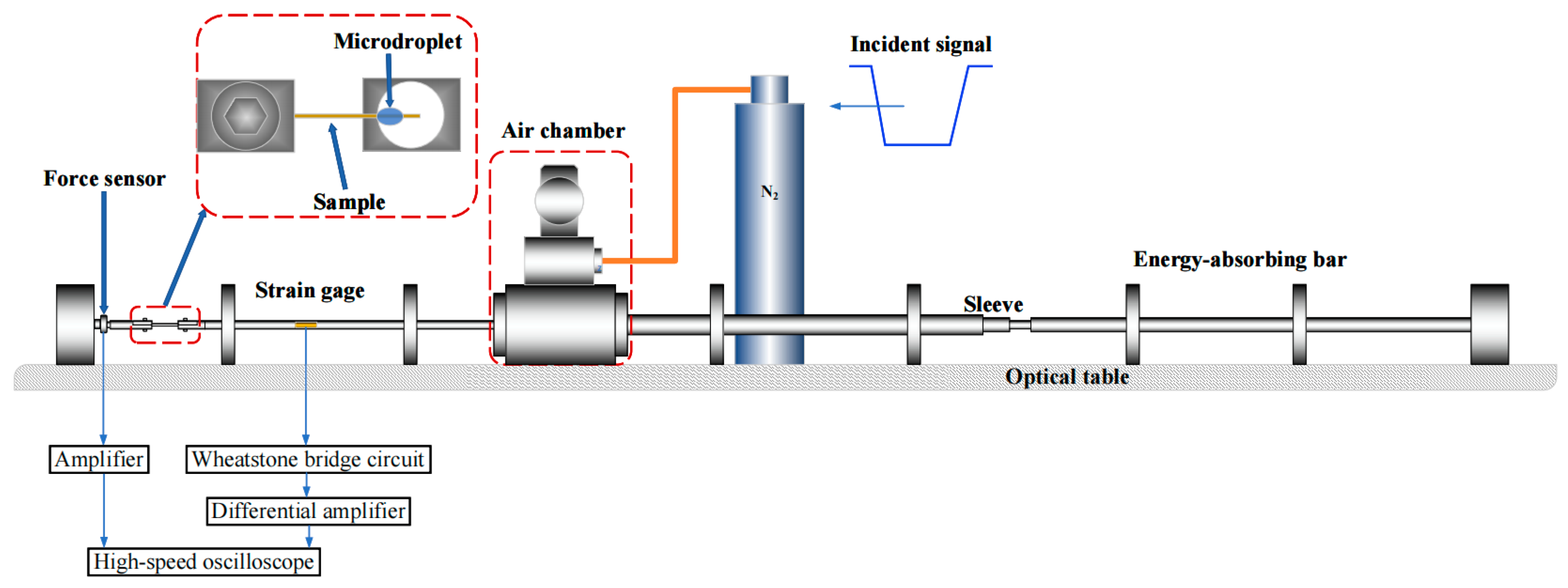

2.2. Tensile Test of Single Aramid III Fibers

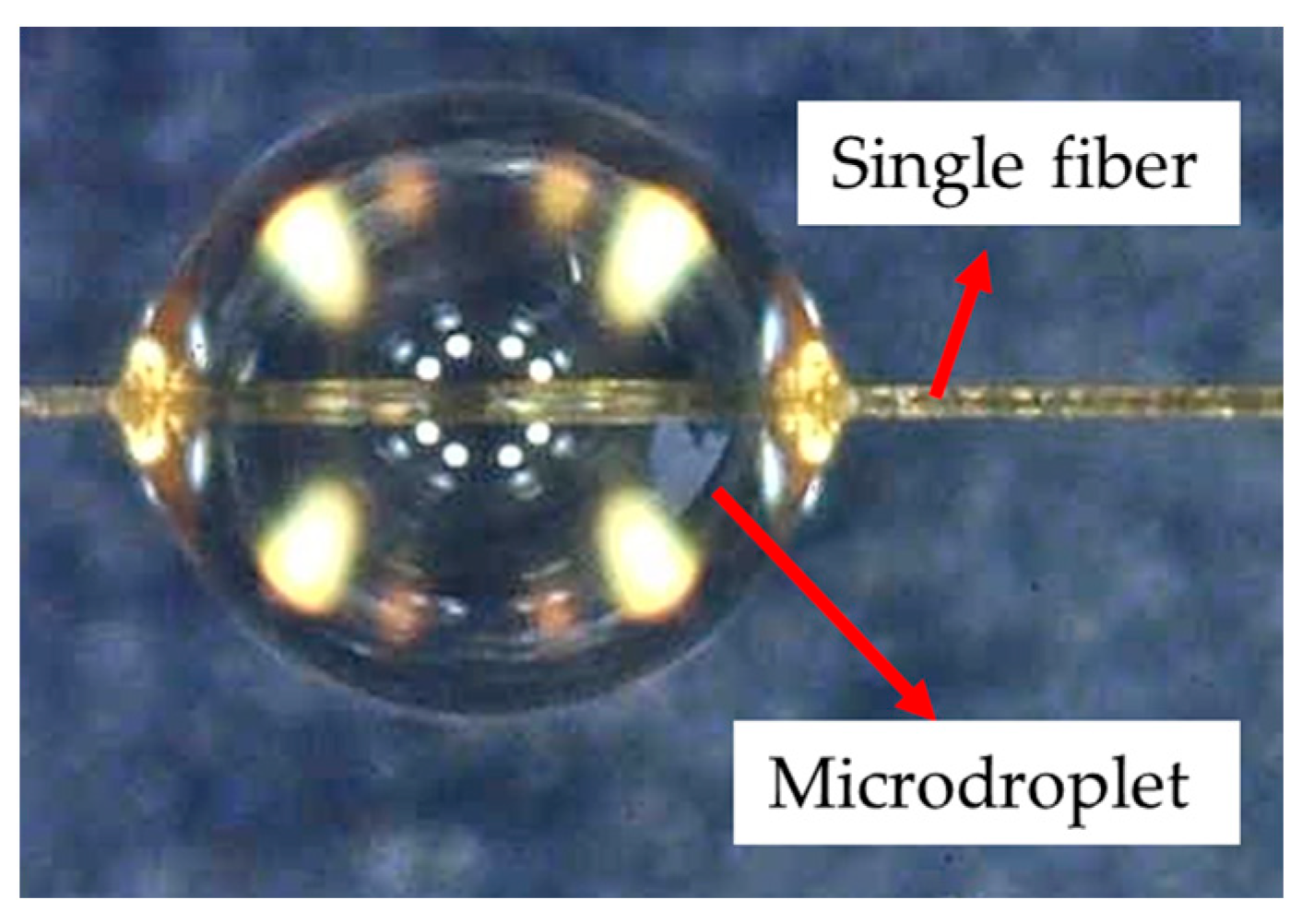

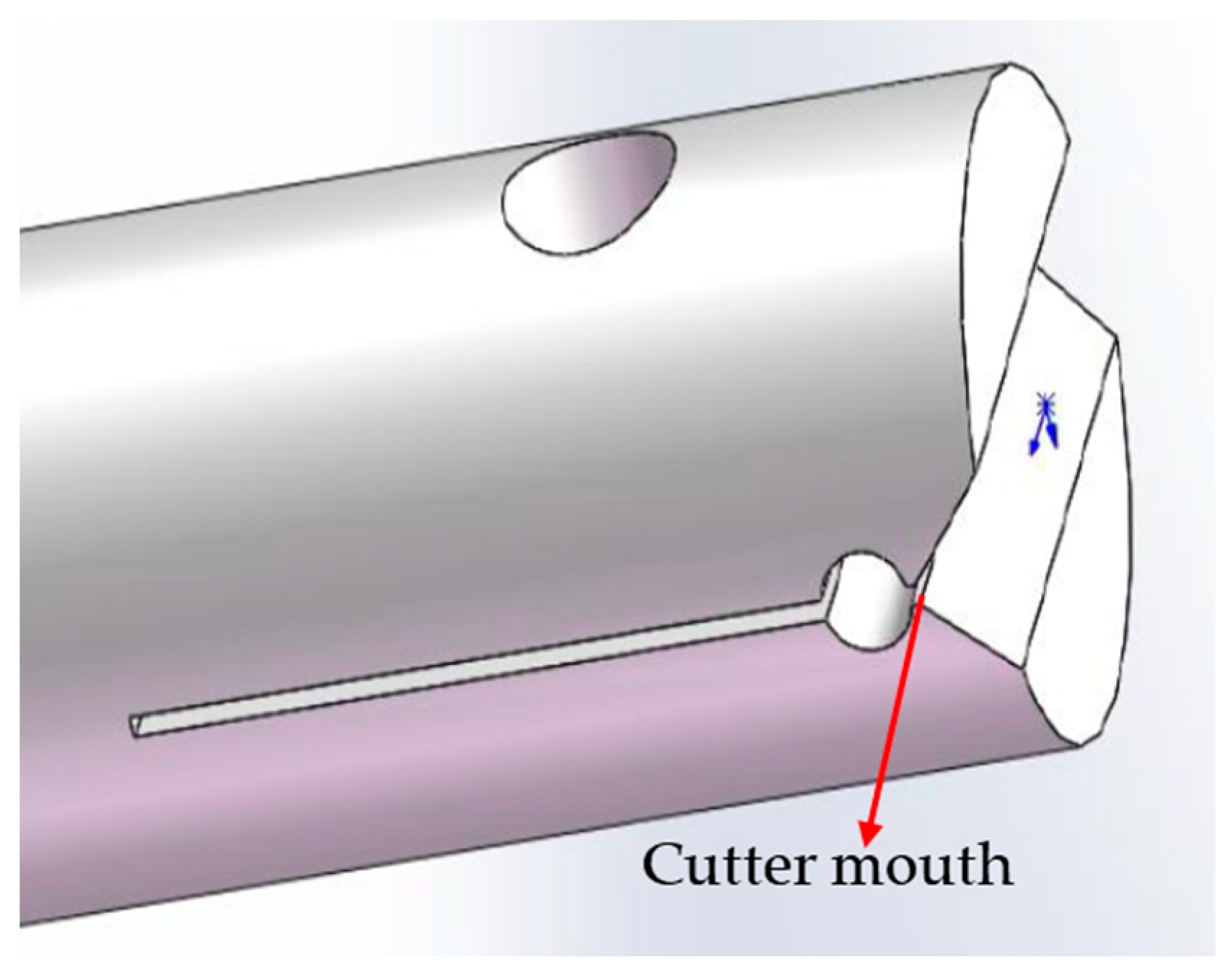

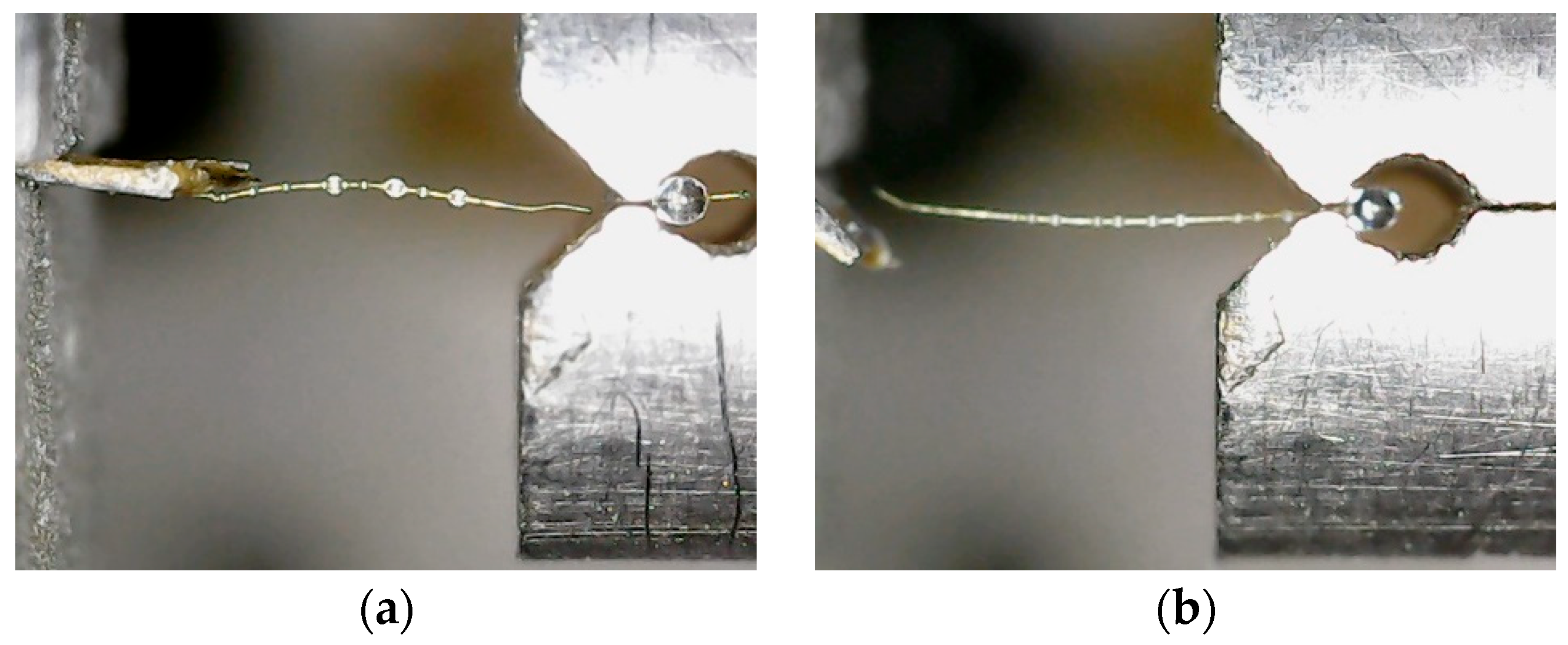

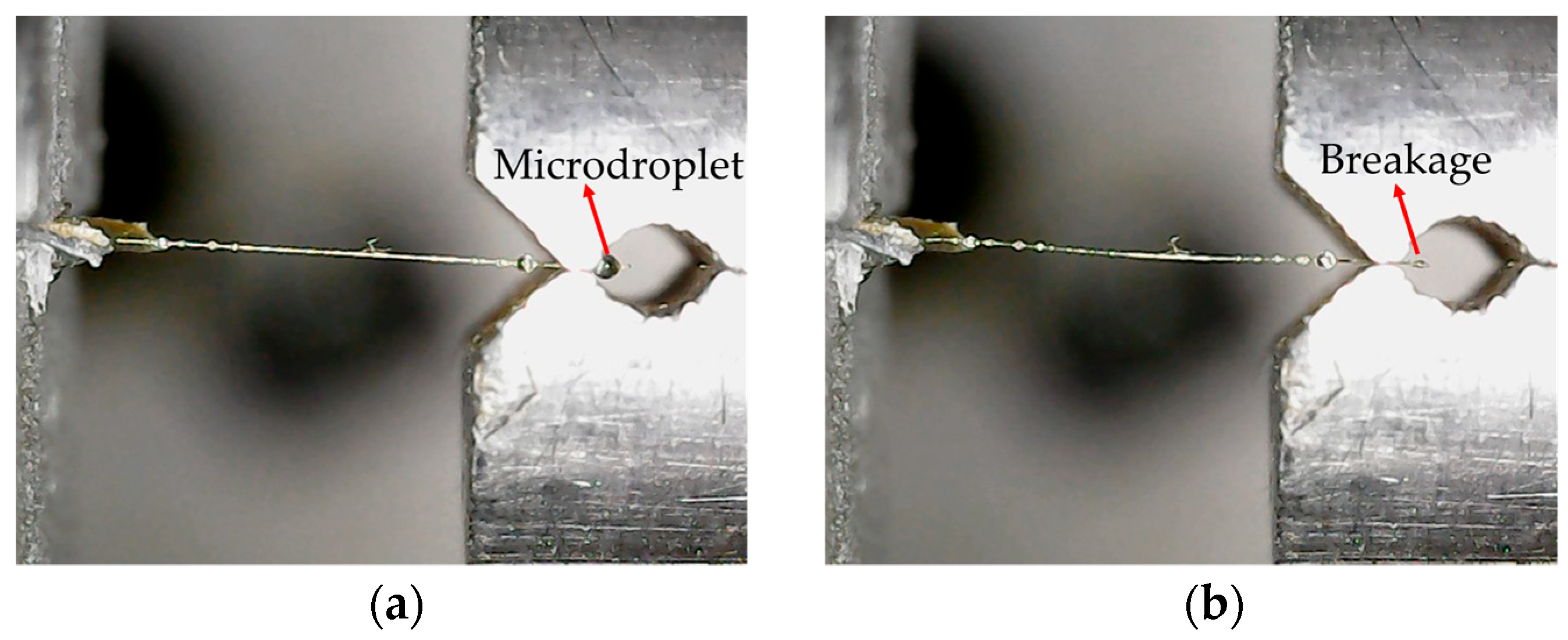

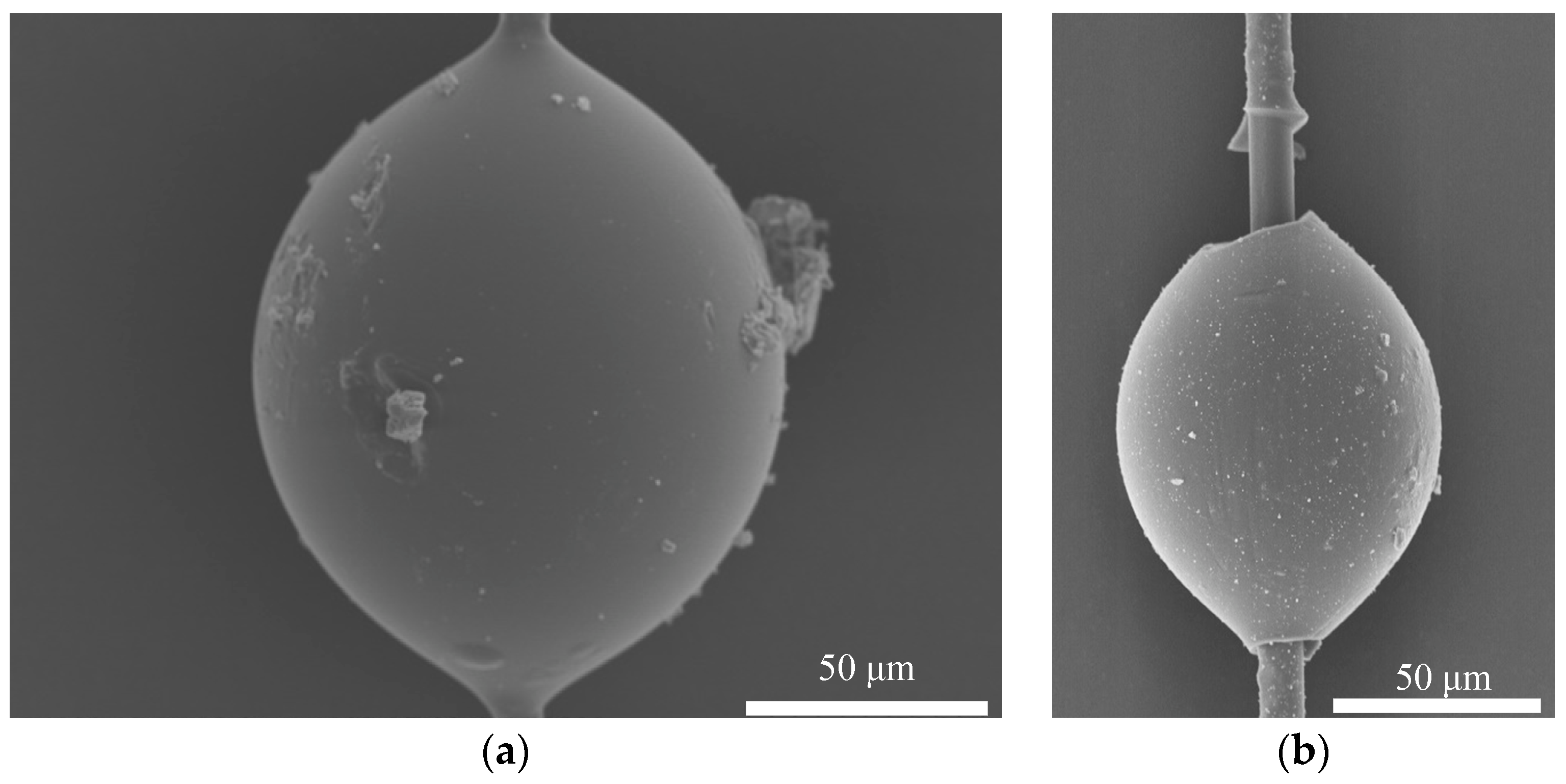

2.3. Shear Strength Test of Aramid III Fiber/Resin Interface

3. Results and Discussion

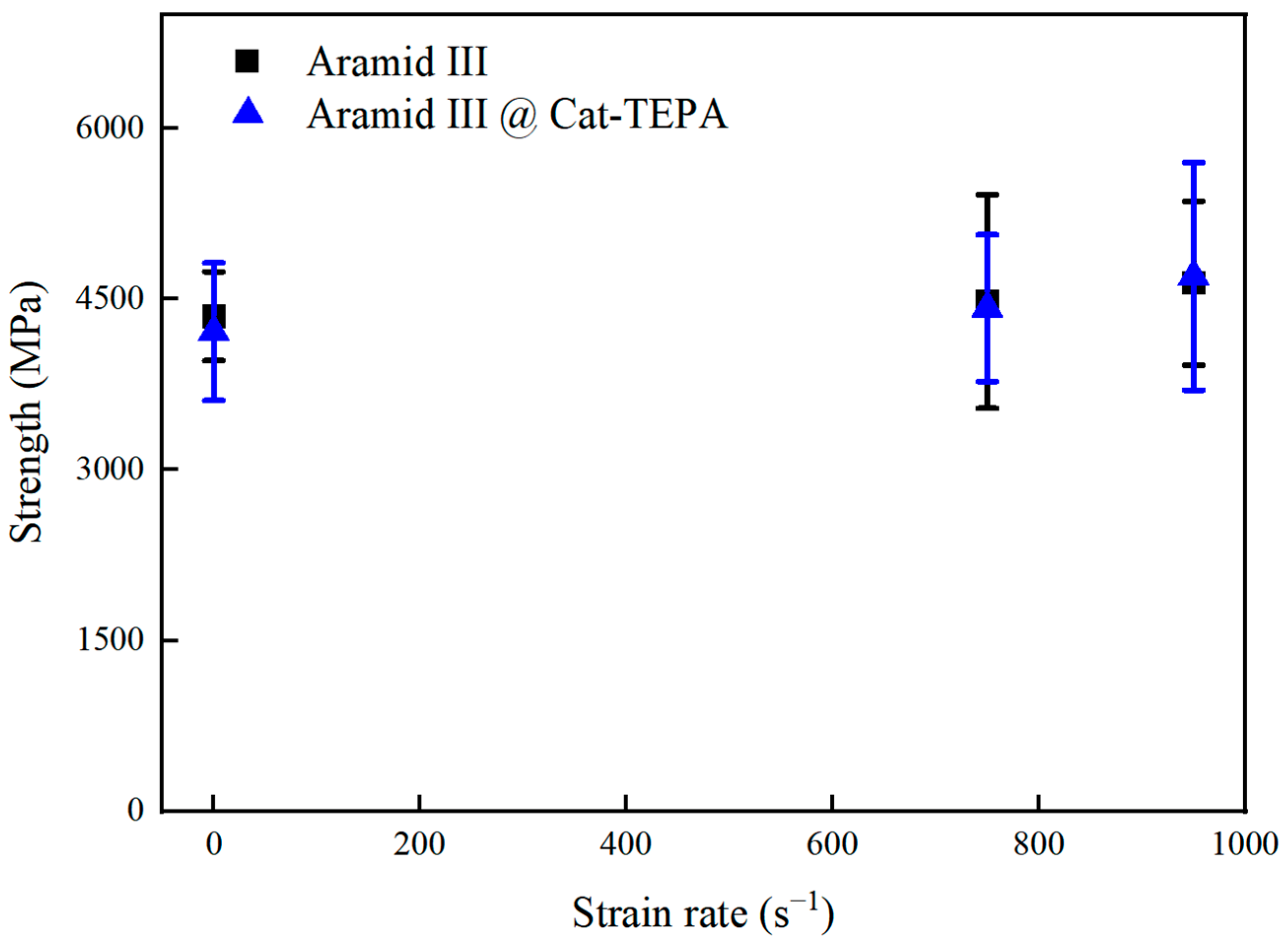

3.1. Tensile Strength of Single Aramid III @ Cat-TEPA Fibers

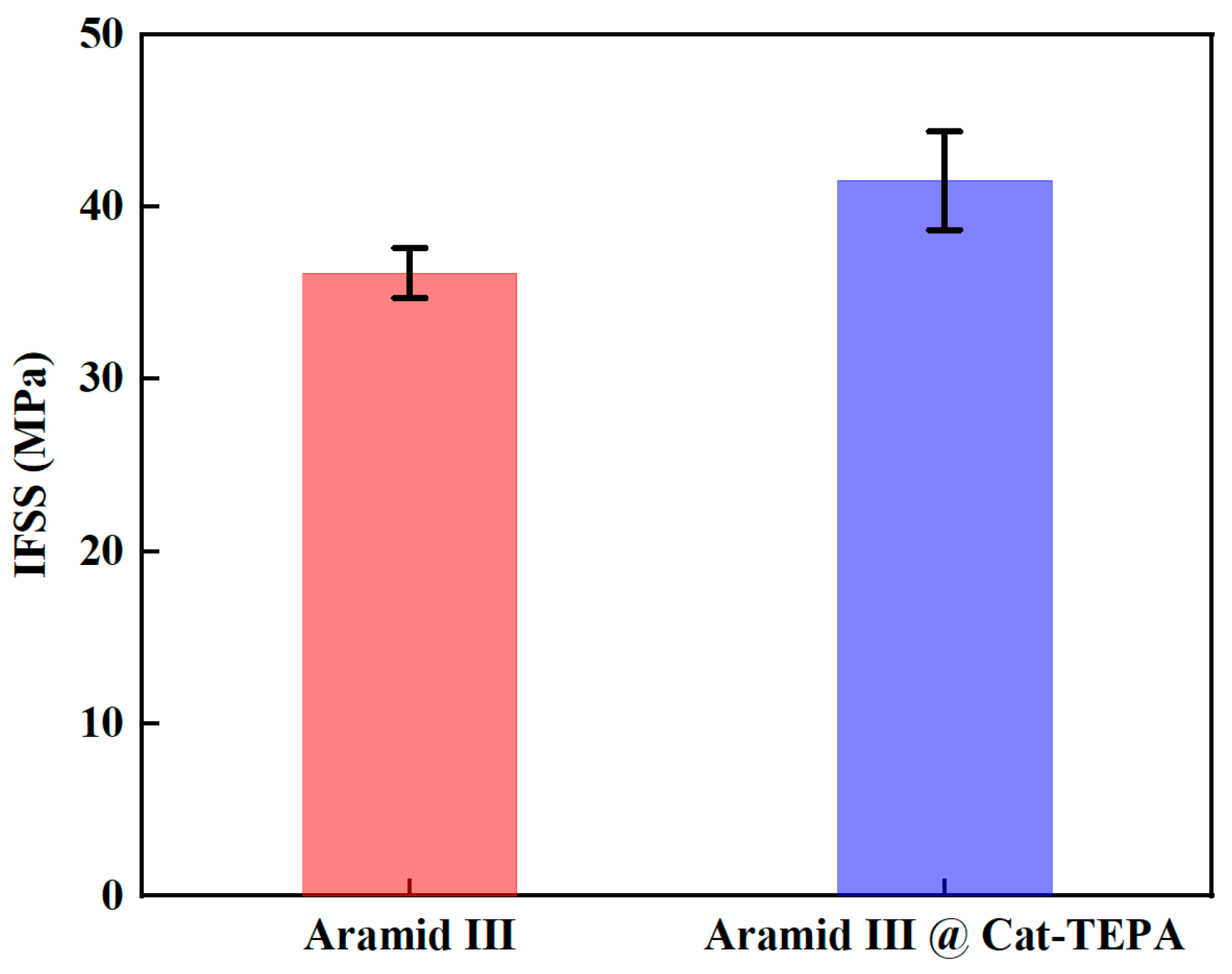

3.2. Interfacial Performance of Single Aramid III @ Cat-TEPA Fibers

4. Conclusions

- (1)

- By incorporating a fixed energy-absorbing bar and an incident bar with a cutter device, improvements have been made to the mini SHTB, enabling the precise characterization of the dynamic mechanical properties of fiber/resin interfaces.

- (2)

- The Cat-TEPA co-deposition method was utilized to prepare single Aramid III fibers, introducing amino functional groups on the fiber surface via the Cat-TEPA coating. This enhanced the properties of the fiber/resin interface.

- (3)

- Quasi-static and dynamic tensile test results indicate that the Cat-TEPA modification method does not significantly affect the tensile strength of a single Aramid III fiber itself.

- (4)

- A testing device based on the microdroplet technique for evaluating the dynamic mechanical properties of the fiber/resin interface was designed. The test results revealed that the dynamic shear strength of the fiber/resin interface of Aramid III @ Cat-TEPA was 41.51 MPa, representing a 14.8% increase compared to the strength before modification.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Singh, T.J.; Samanta, S. Characterization of Kevlar fiber and its composites: A review. Mater. Today Proc. 2015, 2, 1381–1387. [Google Scholar] [CrossRef]

- Rodríguez-Millán, M.; Ito, T.; Loya, J.; Olmedo, A.; Miguélez, M. Development of numerical model for ballistic resistance evaluation of combat helmet and experimental validation. Mater. Des. 2016, 110, 391–403. [Google Scholar] [CrossRef]

- Li, Z.; Xue, Y.; Sun, B.; Gu, B. Ballistic penetration damages of hybrid plain-woven laminates with carbon, Kevlar and UHMWPE fibers in different stacking sequences. Def. Technol. 2023, 26, 23–38. [Google Scholar] [CrossRef]

- Tham, C.; Tan, V.; Lee, H.-P. Ballistic impact of a KEVLAR® helmet: Experiment and simulations. Int. J. Impact Eng. 2008, 35, 304–318. [Google Scholar] [CrossRef]

- Cantwell, W.J.; Morton, J. The impact resistance of composite materials—A review. Composites 1991, 22, 347–362. [Google Scholar] [CrossRef]

- Gholizadeh, S. A review of impact behaviour in composite materials. Int. J. Mech. Prod. Eng. 2019, 7, 28–39. [Google Scholar]

- Yao, Y.; Zhu, D.; Zhang, H.; Li, G.; Mobasher, B. Tensile behaviors of basalt, carbon, glass, and aramid fabrics under various strain rates. J. Mater. Civ. Eng. 2016, 28, 04016081. [Google Scholar] [CrossRef]

- Tan, V.; Zeng, X.; Shim, V. Characterization and constitutive modeling of aramid fibers at high strain rates. Int. J. Impact Eng. 2008, 35, 1303–1313. [Google Scholar] [CrossRef]

- Lim, J.; Zheng, J.Q.; Masters, K.; Chen, W.W. Mechanical behavior of A265 single fibers. J. Mater. Sci. 2010, 45, 652–661. [Google Scholar] [CrossRef]

- Cheng, M.; Chen, W.; Weerasooriya, T. Mechanical properties of Kevlar® KM2 single fiber. J. Eng. Mater. Technol. 2005, 127, 197–203. [Google Scholar] [CrossRef]

- Lei, X.; Xiao, K.; Wu, X.; Huang, C. Dynamic mechanical properties of several high-performance single fibers. Materials 2021, 14, 3574. [Google Scholar] [CrossRef]

- Cruz, J.; Fangueiro, R. Surface modification of natural fibers: A review. Procedia Eng. 2016, 155, 285–288. [Google Scholar] [CrossRef]

- LaBarre, E.; Calderon-Colon, X.; Morris, M.; Tiffany, J.; Wetzel, E.; Merkle, A.; Trexler, M. Effect of a carbon nanotube coating on friction and impact performance of Kevlar. J. Mater. Sci. 2015, 50, 5431–5442. [Google Scholar] [CrossRef]

- Jin, X.; Wang, W.; Xiao, C.; Lin, T.; Bian, L.; Hauser, P. Improvement of coating durability, interfacial adhesion and compressive strength of UHMWPE fiber/epoxy composites through plasma pre-treatment and polypyrrole coating. Compos. Sci. Technol. 2016, 128, 169–175. [Google Scholar] [CrossRef]

- Lee, W.; Lee, J.U.; Byun, J.-H. Catecholamine polymers as surface modifiers for enhancing interfacial strength of fiber-reinforced composites. Compos. Sci. Technol. 2015, 110, 53–61. [Google Scholar] [CrossRef]

- Lee, H.; Dellatore, S.M.; Miller, W.M.; Messersmith, P.B. Mussel-inspired surface chemistry for multifunctional coatings. Science 2007, 318, 426–430. [Google Scholar] [CrossRef]

- Sa, R.; Wei, Z.; Yan, Y.; Wang, L.; Wang, W.; Zhang, L.; Ning, N.; Tian, M. Catechol and epoxy functionalized ultrahigh molecular weight polyethylene (UHMWPE) fibers with improved surface activity and interfacial adhesion. Compos. Sci. Technol. 2015, 113, 54–62. [Google Scholar] [CrossRef]

- Wang, H.; Wu, J.; Cai, C.; Guo, J.; Fan, H.; Zhu, C.; Dong, H.; Zhao, N.; Xu, J. Mussel inspired modification of polypropylene separators by catechol/polyamine for Li-ion batteries. ACS Appl. Mater. Interfaces 2014, 6, 5602–5608. [Google Scholar] [CrossRef]

- Zhao, H.; Shang, Q.; Yang, M.; Jin, S.; Wang, Y.; Zhao, N.; Yin, X.; Ding, C.; Xu, J. Surface modification of ultra-high molecular weight polyethylene fiber by catechol-tetraethylenepentamine. Acta Polym. Sin. 2020, 51, 287–294. [Google Scholar]

- Hutchinson, J.W.; Jensen, H.M. Models of fiber debonding and pullout in brittle composites with friction. Mech. Mater. 1990, 9, 139–163. [Google Scholar] [CrossRef]

- Piggott, M.R. The single-fibre pull-out method: Its advantages, interpretation and experimental realization. Compos. Interfaces 1993, 1, 211–223. [Google Scholar] [CrossRef]

- Awal, A.; Cescutti, G.; Ghosh, S.; Müssig, J. Interfacial studies of natural fibre/polypropylene composites using single fibre fragmentation test (SFFT). Compos. Part A Appl. Sci. Manuf. 2011, 42, 50–56. [Google Scholar] [CrossRef]

- Ramirez, F.; Carlsson, L.; Acha, B. A method to measure fracture toughness of the fiber/matrix interface using the single-fiber fragmentation test. Compos. Part A Appl. Sci. Manuf. 2009, 40, 679–686. [Google Scholar] [CrossRef]

- You, J.; Lutz, W.; Gerger, H.; Siddiq, A.; Brendel, A.; Höschen, C.; Schmauder, S. Fiber push-out study of a copper matrix composite with an engineered interface: Experiments and cohesive element simulation. Int. J. Solids Struct. 2009, 46, 4277–4286. [Google Scholar] [CrossRef]

- Zhang, L.; Ren, C.; Zhou, C.; Xu, H.; Jin, X. Single fiber push-out characterization of interfacial mechanical properties in unidirectional CVI-C/SiC composites by the nano-indentation technique. Appl. Surf. Sci. 2015, 357, 1427–1433. [Google Scholar] [CrossRef]

- Sharma, M.; Gao, S.; Mäder, E.; Sharma, H.; Wei, L.Y.; Bijwe, J. Carbon fiber surfaces and composite interphases. Compos. Sci. Technol. 2014, 102, 35–50. [Google Scholar] [CrossRef]

- Li, Z.; Bi, X.; Lambros, J.; Geubelle, P.H. Dynamic fiber debonding and frictional push-out in mode composite systems: Experimental observations. Exp. Mech. 2002, 42, 417–425. [Google Scholar] [CrossRef]

- Chu, J.; Claus, B.; Parab, N.; O’Brien, D.; Sun, T.; Fezzaa, K.; Chen, W. Visualization of dynamic fiber-matrix interfacial shear debonding. J. Mater. Sci. 2018, 53, 5845–5859. [Google Scholar] [CrossRef]

- Tamrakar, S.; Haque, B.Z.; Gillespie, J.W. High rate test method for fiber-matrix interface characterization. Polym. Test. 2016, 52, 174–183. [Google Scholar] [CrossRef]

- Zhang, X.; Fan, X.; Yan, C.; Li, H.; Zhu, Y.; Li, X.; Yu, L. Interfacial microstructure and properties of carbon fiber composites modified with graphene oxide. ACS Appl. Mater. Interfaces 2012, 4, 1543–1552. [Google Scholar] [CrossRef]

- Miller, B.; Muri, P.; Rebenfeld, L. A microbond method for determination of the shear strength of a fiber/resin interface. Compos. Sci. Technol. 1987, 28, 17–32. [Google Scholar] [CrossRef]

- Gaur, U.; Miller, B. Microbond method for determination of the shear strength of a fiber/resin interface: Evaluation of experimental parameters. Compos. Sci. Technol. 1989, 34, 35–51. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, F.; Li, F.; Li, X.; Tian, H.; Lei, X. Tensile and Interfacial Mechanical Properties for Single Aramid III Fibers under Dynamic Loading. Polymers 2024, 16, 804. https://doi.org/10.3390/polym16060804

Liu F, Li F, Li X, Tian H, Lei X. Tensile and Interfacial Mechanical Properties for Single Aramid III Fibers under Dynamic Loading. Polymers. 2024; 16(6):804. https://doi.org/10.3390/polym16060804

Chicago/Turabian StyleLiu, Fu, Fangfang Li, Xuelei Li, Haobin Tian, and Xudong Lei. 2024. "Tensile and Interfacial Mechanical Properties for Single Aramid III Fibers under Dynamic Loading" Polymers 16, no. 6: 804. https://doi.org/10.3390/polym16060804

APA StyleLiu, F., Li, F., Li, X., Tian, H., & Lei, X. (2024). Tensile and Interfacial Mechanical Properties for Single Aramid III Fibers under Dynamic Loading. Polymers, 16(6), 804. https://doi.org/10.3390/polym16060804