The Aging of Polymers under Electromagnetic Radiation

Abstract

1. Introduction

- To explore the key theoretical positions on the range of UV radiation that affects the polymers and the radiation that generates heat for polymer decomposition;

- To review the testing procedures used for polymer aging evaluation and real-world applications that are impacted by the aging of polymers, especially agricultural plastics;

- To appraise the available technical methods for improving the performance of polymers under UV radiation and other radiation mediums to identify whether there are any promising technologies for meeting this need.

2. Materials and Methods

2.1. Research Philosophy

2.2. Research Approach

2.3. Research Design

2.4. Search Strategy

2.5. Data Analysis

2.6. Ethical Considerations

2.7. Limitations

3. Results

3.1. Theoretical Background of Aging

3.2. The Stability of 3D Printed Polymers under UV

3.3. Methods of Improving Polymer Performance

3.4. The Effect of Polymer Aging in Real-World Applications and Agricultural Plastics

3.5. Experimental Methods of Determining the Aging Process of Polymers Exposed to UV Radiation

4. Discussion

4.1. Interpretation and Implications of the Findings

4.2. The Key Theoretical Positions on the Range of the UV Radiation That Affects Polymers

4.3. The Testing Procedures Used for Polymer Aging Evaluation and Real-World Applications

4.4. Available Technical Methods for Improving the Performance of Polymers under UV Radiation

4.5. Research Gaps

4.6. Future Research Needs

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| UV | Ultraviolet rays |

| ABS-PC | Acrylonitrile Butadiene Styrene Polycarbonate |

| 3D polymer | Three-dimensional polymer |

| (μ-POF) | Micro-polymer optical fibers |

| SBS | Styrene–butadiene–styrene |

| LDPE | Low-density polyethylene |

| UVA | Ultraviolet radiations with long wavelengths of between 400 and 320 nm |

| UVB | Ultraviolet radiations with a medium wavelength of between 320 and 290 nm |

| UVC | Short wavelength radiation with radiations of between 290 and 200 nm |

| PO | Polyolefin |

| CI | Carbonyl indexes |

| TiO2 | Titanium dioxide |

| PLA | Polylactide |

| PISA | Porosity-Induced Sidechain Adsorption |

| PAF-1 | A porous aromatic framework |

| PMMA | Poly(methyl methacrylate) |

| PANI | Polyaniline |

| PS | Polystyrene |

| PE | Polyethylene |

| CLSM | Confocal laser scanning microscopy |

| Tg | Transition temperature |

Appendix A. Summary of Literature Analysis

| Number | Authors | Title | Methodology | Findings | Conclusion/Recommendation |

| [53] | Zhang et al. | Investigation of polymer aging mechanisms using molecular simulations: a review | Literature review | Polymer aging can be explained through the theory of reaction. | The theory of diffusion suggests that free permeating molecules react with polymer compounds, causing degradation |

| [54] | Liu and Li | Progress in study of polymer degradation behaviors and mechanisms in various environment conditions | A literature review study | Polymer aging differs from one environment to the other. A secondary bond change occurs during physical aging, although it is reversible. | Photo, thermal and chemical media influence polymer degradation |

| [55] | Scott | Initiation processes in polymer degradation. | A quantitative study was utilized | In thermal degradation of vinyl polymeric materials, free radicals are propagated through thermooxidative degradation. | Free radicals have a participatory role in polymer aging as they interact with oxidative agents |

| [56] | Day et al. | Degradation of contaminated plastics: A kinetic study | An experimental study focusing on four polymeric materials was implemented | The thermal degradation rate is even higher in polymers with metal contamination as that catalyzes their aging behavior. | Contamination increases the rate of polymer degradation |

| [57] | Troev et al. | Chemical degradation of polyurethanes. II. Degradation of microporous polyurethane elastomer by phosphoric acid esters | An experimental research design was implemented to test the degradation of microporous polyurethane elastome | phosphoric acid added to polyurethane was found to speed up degradation by breaking the free radicals, leading to the breaking up of the compound and making the trialkyl esters in this polymer. | The aging properties of polymers can be sped up the reactive agents that release free radicals |

| [58] | Barrer | Some properties of diffusion coefficients in polymers | A quantitative study using factor analysis and experimental observations was used | Through thermal fluctuation, fragments of polymers absorb energy, loosen and reshuffle themselves, making permeating molecules take new positions. | The study supports the theory of polymer reaction as free radicals react with permeating molecules |

| [59] | Arya et al. | Glassy Polymers—diffusion, sorption, ageing and applications | Quantitative research using diffusion models to explain polymer aging | Minute molecules of polymers diffuse with changes in temperature and concentrations. | Changes in the external conditions lead to reactions with polymer molecules |

| [60] | Enomoto et al. | The role of hydroperoxides as a precursor in the radiation-induced graft polymerization of methyl methacrylate to ultra-high-molecular-weight polyethylene | A quantitative research method using grafting technique was implemented | Solvents increase the free volumes of polymers as diffusion progresses through the free-volume chains. | Hydroperoxides can be used as solvents to increase the diffusion of polymer molecules through free volumes |

| [61] | Ching et al. | Effects of high temperature and ultraviolet radiation on polymer composites | A literature review methodology was used | High thermal conditions and UV radiations weaken the mechanical properties of polymer composites. | Exposing polymers to extreme thermal conditions causes them to age faster |

| [62] | Henry et al. | White LED induced photooxidation aging of epoxy/carbon fibre reinforced polymer and its implications for cleanroom cleanliness and contamination control | An experimental research design was implemented | Polymer degradation is caused by a photooxidation process of a UV source with up to 500 nm irradiation wavelengths. It affects the first microns of an irradiated surface. | Photooxidation polymer resins should be limited and avoided in some circumstances to deter the risks of aging |

| [63] | Lu et al. | Particle removal mechanisms in synergistic aging of polymers and glass-reinforced polymer composites under combined UV and water | Quantitative research was conducted through hydrodynamic analysis | The extra total mass that is unoccupied causes mass transport within the polymer structure. | The hydrothermal environments speed up the process of polymer degradation |

| [64] | Amza et al. | Effect of UV-C radiation on 3D-printed ABS-PC polymers | A quantitative study using experimentation to determine the impact of UV radiation on 3D polymer samples | 3D polymers are more stable and withstand UV radiationbetter than other polymer types. 3D polymers can withstand UV radiations of wavelengths 200 nm to 280, making them resistant to UV aging. | 3D polymers are more stable when exposed to aging conditions than normal polymer composites |

| [65] | Amza et al. | Aging of 3D-printed polymers under sterilizing UV-C radiation | Experimental research was conducted to determine the stability of normal 3D PLA when exposed to UV aging | 3D-printed parts of a polycarbonate and acrylonitrile butadiene styrene polymer (ABS-PC) exposed to UV radiation experience minimal degradation. | 3D parts can be used to sterilize polymers |

| [66] | Afshar and Mihut | Enhancing durability of 3D-printed polymer structures by metallization | Experimental study that used ABS specimens that were 3D-printed using fused deposition modeling (FDM) technique as well as metalized through DC magnetron sputtering | 3D polymers lose their stiffness and retain their tensile strength following exposure. | 3D polymers are more durable |

| [67] | Amza et al. | Accelerated aging effect on mechanical properties of common 3D-printing polymers | Quantitative study that entailed conducting scanning electron microscopy (SEM) fractographic analysis | 3D parts did not lose stiffness after the UV-B exposure. Creep behavior was closely linked to the decline in mechanical properties | UV-B exposure substantially reduces 3D polymers’ tensile strength |

| [68] | Franco et al. | Accelerated ultraviolet aging of a PET nonwoven geotextile and thermoanalytical evaluation | The study used an experimental design to test the thermal behavior of commercial nonwoven polyester geotextiles exposed to accelerated UV aging | UV aging induced mechanical deterioration on polyester fibers. | Additives can be used to improve the stability of polymers during manufacturing |

| [69] | D’Urso et al. | PLA melt stabilization by high-surface-area graphite and carbon black | Experimental study using rheological measurements and gel permeation chromatography (GPC) | Carbon black can be used in small amounts to improve the resistance of polymers against aging. | Additives can improve the resistivity of plastic materials against thermal-induced aging |

| [70] | Dubey et al. | Carbon black-filled PE/PP/EPDM blends: phase-selective localization of carbon black and EPDM-induced phase stabilization | An experimental study using the melt compounding of PE, PP, ethylene propylene diene monomer (EPDM) as well as CB in different proportions | This additive helps absorb UV radiation and, therefore, protects the polymer component against degradation. | The percolation of carbon black in various phases emphasizes its role in reducing polymer degradation |

| [71] | CABOT. | Carbon blacks for protection of plastics exposed to ultraviolet light | Literature review study | Small particles of carbon black are more effective in shielding polymers from UV radiation. | Carbon black is effective in stabilizing polyethylene against UV radiation |

| [72] | Hachicha and Overmeyer | Investigation on aging of metallic surface-integrated micro-POFs | Quantitative research using optimal communication to test the mechanical features of polymers with micro-POFs | Improving the communication structures of polymers through integrated waveguides is also suggested. | Such novel methods provide another suitable approach for improving the properties of polymer aging |

| [73] | Hoghoghifard et al. | Improving EMI shielding effectiveness and dielectric properties of polyaniline-coated polyester fabric by effective doping and redoping procedures | Experimentation using X-band frequency range analysis | Doping and redoping procedures can improve the efficacy and dielectric features of polymer fabrics. Double and triple layers have attenuated shielding effects due to the absorption mechanism. | The redoping process compensates for the increase in surface resistivity as polymer samples are washed |

| [74] | Egghe et al. | Comparative study of the aging behavior of plasma-activated hexamethyldisiloxane-based plasma polymers and silicone elastomer thin films | A quantitative comparative study was conducted through experimentation | Enhancing the mobility of oxidized short-chain fragments has been reported as effective in polymer stability. | Some aging processes get reduced in crosslinked plasma activated films |

| [75] | Vasylius et al. | Degradation of mechanical properties of A-PET films after UV aging. | The study conducted an experiment with A-PET films exposed to UV aging for varying lengths of time | Extensive exposure can, however, make A-PET films lose tensile strength. | The duration of exposure determines the degree of deterioration |

| [76] | He et al. | Profile monitoring-based quality control method for fused deposition modeling process. | Quantitative research based on a non-contact measurement method was implemented, coupled with a statistical process control method | 3D printing can utilize profile monitoring techniques to improve the quality of polymer performance. | The performance of polymeric materials in withstanding UV aging significantly differs from one material to the other |

| [77] | Mondal et al. | Effect of thermal–air aging treatment on mechanical properties and electromagnetic interference shielding effectiveness of low-cost nano-structured carbon-filled chlorinated polyethylene | A quantitative study using FESEM analysis was conducted | Low-cost CPE composites can be filled with VXC particles through a strategy of melting and mixing them to suppress EM pollution. | This method enhanced the interfacial polarization of the polymer, causing outstanding polymer–filler interaction |

| [78] | Lajić et al. | Accelerated and natural aging of offset prints covered with different varnishes. | Experiments of natural aging and accelerated aging were conducted | Polymers are used in manufacturing plastics across various industries, such as varnishes. | Polymeric materials have broad industrial uses |

| [79] | Cantero-Chinchilla et al. | Robust optimized design of 3D-printed elastic metastructures: A trade-off between complexity and vibration attenuation | An experimental study using a transfer matrix approach was conducted | 3D-printed metastructures can be optimized strategically through the robust design of mechanical metamaterials. | Smaller variabilities in material properties impact the robustness of the metamaterials |

| [80] | Mantada et al. | Parameters influencing the precision of various 3D printing technologies | Experimental research comparing the precision of 3D printing technologies | 3D printing precision can be improved through Fused Deposition Modeling (FDM), Stereolithography (SLA), Polyjet Matrix and Selective Laser Sintering (SLS). | With such high precision, these 3D printing technologies can be used across various industries |

| [81] | Lin et al. | Effects of ultraviolet aging on properties of wood flour–poly(lactic acid) 3D printing filaments | A comparative study using experimental research to determine polymer aging through color, tensile strength, scanning electron micrographs, as well as water absorption rate of polymer filaments | Polymers are also utilized in making PLA 3D printing filaments due to the aging resistance of these filaments. | Adding UV absorbent into polymer filaments improves their aging resistance |

| [82] | Sousa et al. | Mechanical properties of 3D printed mouthguards: Influence of layer height and device thickness | Experimental study focusing on the thickness and printing quality (layer height) | There was a decline in the tensile strength as specimen thickness increased, with the exception of TPU because of its highest level of deformation capacity. | Customizing mouthguards with thinner walls through additive processing techniques can hinder injurious outcomes |

| [83] | Ferreira et al. | Ageing effect on the low-velocity impact response of 3D printed continuous fiber reinforced composites | An experimental study using low-velocity impact tests across varying numbers of days was conducted | The initial elastic part of 3D-printed continuous fiber-reinforced composites slightly reduces as the polymer ages. | The severity of visual damage to the polymer specimens varied with age |

| [84] | Najvani et al. | Early-age strength and failure characteristics of 3D printable polymer concrete. | The study was based on a rheology analysis | The rheological data could be integrated into the Herschel–Bulkley model. The flow index for the polymer concrete decreased with time, while the static yield stress, thixotropy, as well as consistency were observed to increase. | Polymer concretes are also used in construction instead of cement |

| [85] | House et al. | Case report of asthma associated with 3D printing | Case study design | 3D polymers, however useful in many industries, can cause asthmatic and other health challenges. | There is a need for further research to determine whether 3D polymers have health detriments |

| [86] | Bedi et al. | Reviewing some properties of polymer concrete | Secondary research methodology based on a literature review | Polymer concretes’ characteristics differ greatly based on their conditions of preparation. | Precast polymer concrete is being used to manufacture various products such as acid tanks, manholes, drains, and highway median barriers |

| [87] | Krčma et al. | Use of polymer concrete for large-scale 3D printing | The quantitative study used the deposition modeling process and computed tomography of polymer samples | The 3D-printed samples showed high levels of porosity. | The new polymer material is useful in 3D printing, with negligible to no degradation resulting from the process |

| [88] | Furet et al. | 3D printing for construction based on a complex wall of polymer-foam and concrete | An experimental study was conducted | Polymer concretes are mixed with fillers, resins, and aggregates to provide a substitute binder for cement in additive manufacturing. | Additive manufacturing uses 3D printing to create foam and extrude the concrete with a robotic system to jointly form both the structure as well as thermal elements of the structure/building |

| [89] | Kozicki et al. | Measurement of the radiation dose and radiation isocenter of the truebeam accelerator using 3D polymer gel dosimeters from the VIPAR family with different chemical history | Experimental research using three-dimensional polymer gel dosimeters was conducted | N-vinylpyrrolidone acts as a stabilizing agent for dosimeters. | Ionized dosimeters are also products of 3D polymers |

| [90] | Chapiro | Radiation effects in polymers | Quantitative study | Ionizing radiation causes polymer aging. | The crosslinking of shaped polymers coupled with the curing of coatings comprise broader applications of polymeric materials |

| [91] | Lebedev et al. | Radiation aging of polymer composite materials. | Experimental study | Polymer composites exposed to UV radiation deteriorate due to the weakening of their mechanical properties. | Physicochemical as well as structural changes in polymer matrices are observable when these composites are exposed to UV aging |

| [92] | Davenas et al. | Stability of polymers under ionizing radiation: the many faces of radiation interactions with polymers | Experimental research | As the polymer interacts with UV radiations, its mechanical properties weaken, causing aging. | Polymer stability is challenged under ionization agents |

| [93] | Feldman and Zezin | The 13th International Symposium on Ionizing Radiation and Polymers (IRaP, 2018) | Conference publication with n = 100 contributors drawn from 20 countries | The ionizing impacts of radiation can, at times, cause polymer degradation. | Despite ionization’s impacts, polymers are crucial in making composites with thermoplastic and thermoset matrices |

| [94] | Hakamivala et al. | Parametric process optimization to improve the accuracy and mechanical properties of 3D printed parts | A quantitative study using parametric analysis | Adding interactive 3D features to the polymer can improve scaffolding. | Parametric analysis can be used to enhance 3D-printed polymers’ accuracy and mechanical properties |

| [95] | Sun et al. | Oxidation and polymer degradation characteristics of high viscosity modified asphalts under various aging environments | Experimental study | Polymer aging through exposure to oxidized environments ruins the stability of plastics. | Exposing polymer resins and high-viscosity modified asphalts to oxidized environments accelerates their aging mechanisms |

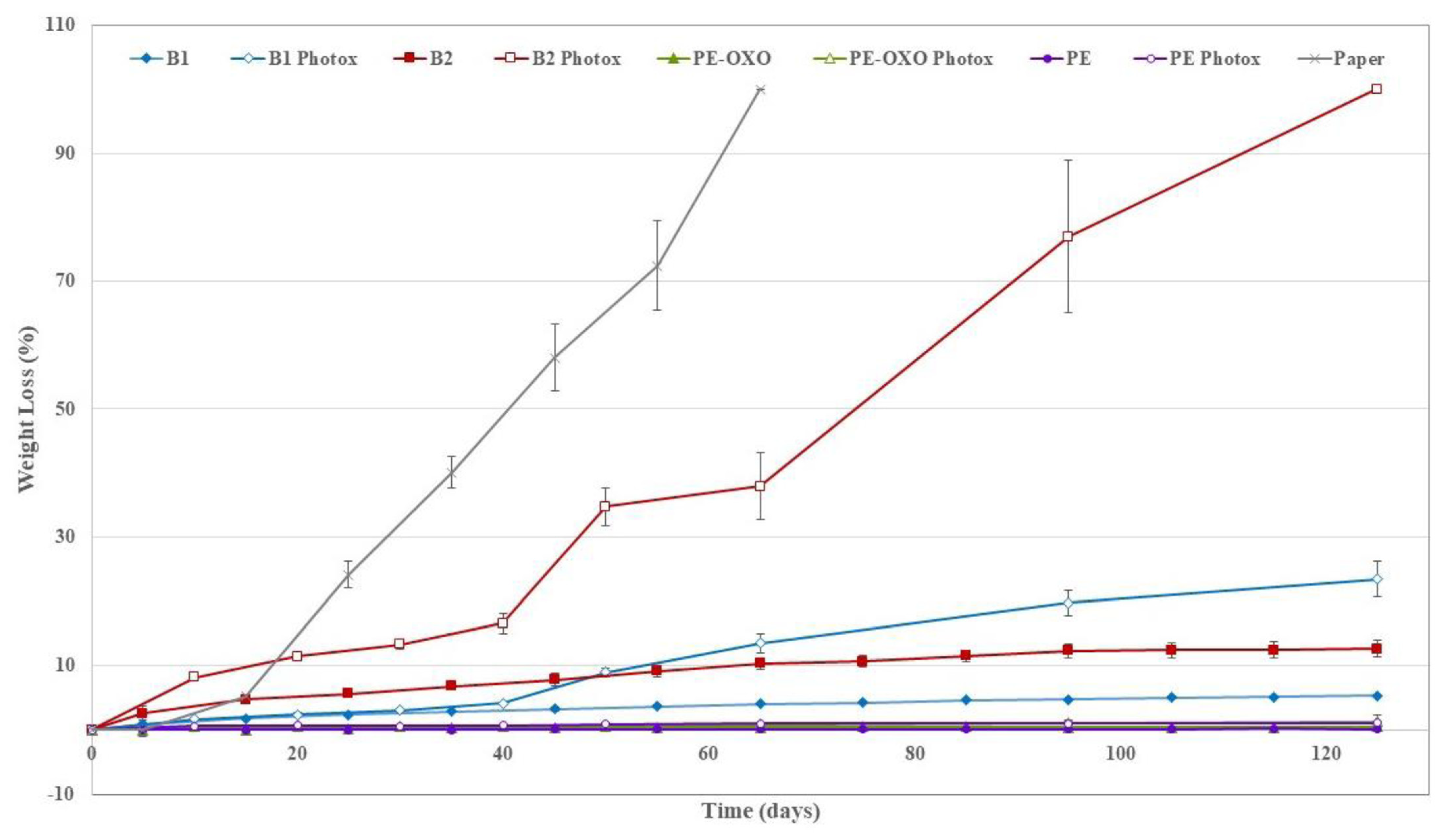

| [96] | Lin et al. | Unraveling the influence of fibers on aging susceptibility and performance of high content polymer modified asphalt mixtures. | Case study research methodology based on lignin and polyester polymers as representative samples. Tests on Cantabro loss, SCB strength, SCB fatigue and Hamburg Wheel-Tracking were performed | Exposure of polymers to aging sources reduces their lifespans in real-life use. However, polymers can improve their porosity if combined with fiber mixtures. | High-Content SBS Polymer-Modified Bitumen (HCPMB) has excellent features in its original state that mask the enhancement impact of fibers |

| [97] | Makki et al. | Micromechanical modeling of the visco-hyperelastic-viscoplastic behavior and fracture of aged semicrystalline polymers. | Experimental study based on modeling analysis | The aspect of polymer degradation affects the longevity of high-viscosity modified asphalt. | Polymer aging accelerates the period within which polymeric materials have a useful economic life |

| [98] | Desidery and Lanotte | Identification of undisclosed modifiers and their effects on chemical, thermal, and microstructural properties of unaged and aged industrial high polymer-modified asphalt binders | Experimental study | The aging processes of polymeric materials affect the properties of the base bitumen, undisclosed crystalline modifiers, and SBS. | Modifiers perform better when the base characteristics of polymers have not been altered |

| [99] | Hu et al. | Performance study on anti-weather aging combinations for high-content polymer modified asphalt and comparison by improved multi-scale mathematical TOPSIS method | Experimental research based on TOPSIS calculations | Unique combinations of novel materials for light absorption and antioxidation, as well as those for shielding light, can provide a shielding effect against the aging of asphalt polymers. | Combining these materials appropriately can equip polymers with anti-aging characteristics |

| [100] | Goncalves Bardi et al. | Behavior of UV-cured print inks on LDPE and PBAT/TPS blend substrates during curing, postcuring, and accelerated degradation | Experimental research method | Polymer reactions generate curative blend substrates. | Using print inks improves the stability of polymer substrates and polymer composites against UV aging |

| [101] | Wang et al. | Waterborne polyurethane composite coatings as UV-light converter and directional infrared light barrier for light and heat management in greenhouse | Experimental | Composite coatings on the greenhouse plastics increased pepper yield by 35%, while each fruit added 8 g in weight. | These coatings can be used to increase agricultural yield |

| [102] | Vijayalakshmi and Baek | Conversion of UV light to dazzling reddish orange light with robust color purity for plant growth in biocompatible glasses | Experimental design | Adding Gd3+ to red emissions of Eu3+ optimized glass productivity in agricultural production. | There is a profound applicability of plastics in agriculture since they convert UV light to the needed conditions for agricultural production |

| [103] | Al-Helal et al. | Effect of shape, orientation and aging of a plastic greenhouse cover on the degradation rate of the optical properties in arid climates | Experimental research was conducted on four greenhouses with two shapes | The shape and orientation of greenhouses with small sizes did not significantly impact the rate of degradation of the cover’s optical properties. The four corners examined had reduced global solar radiation transmittance (T) by 27–31% after one year of exposure relative to the new film. | These plastics can also degrade if exposed to intense conditions |

| [104] | Dehbi et al. | Degradation assessment of LDPE multilayer films used as a greenhouse cover: Natural and artificial aging impacts | Experimental research | The rate of aging is influenced by surface location and the orientation of the cover. | The degree of degradation differs based on the surface location of the LDPE multilayer films |

| [105] | Bonyadinejad et al. | Investigating the sustainability of agricultural plastic products, combined influence of polymer characteristics and environmental conditions on microplastics aging | Experimental | Low-molecular weight-microplastics have less photostability. | Covering LDPE with soil made them experience limited photo-degradation |

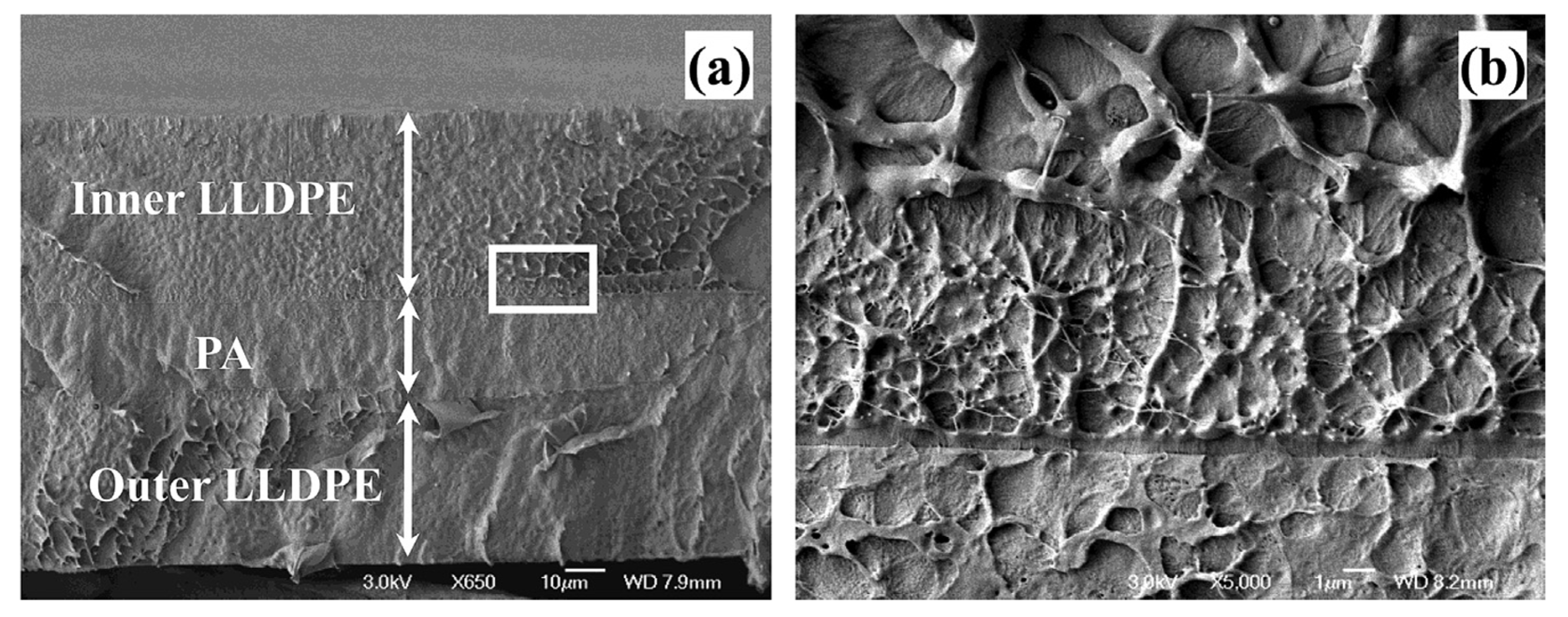

| [106] | Rabaev et al. | Long term aging of LLDPE based multi-layer film by exposure to light hydrocarbons. | Experimental study | Photo-degradation is particularly reported for LDPE green-house plastics due to their interaction with UV radiation. | The longest container stayed for 10 years before degradation |

| [107] | Ji et al. | Composition identification and UV-C irradiation growth inhibition effect of green shading on the greenhouse cover | Experimental study | Shading has a shielding effect on the inhibition of UV-C irradiation. | Shading through the correct anti-aging components can increase the longevity of LDPE covers |

| [108] | Tuasikal et al. | Influence of natural and accelerated weathering on the mechanical properties of low-density polyethylene films | Experimental study | Adding anti-oxidants helps reduce the aging effect of UV radiation on LPDE covers. | Natural and accelerated aging can be inhibited through anti-oxidants |

| [109] | Amin et al. | Natural weather ageing of the low-density poly-ethylene: Effect of polystarch N | Experimental study | The degree of photo-degradation is affected by the disposition of soil particles. | If the soil particles are correctly dispositioned, then polymers used for agriculture can have an extended lifespan |

| [110] | Picuno | Innovative material and improved technical design for a sustainable exploitation of agricultural plastic film | Literature review methodology | Improving the technical design of agricultural plastics can elevate their antiaging performance. | Agricultural plastic films can be recycled and reused to prevent externalities |

| [111] | Djakhdane et al. | The effect of sand wind, temperature and exposure time on tri-layer polyethylene film used as greenhouse roof | Experimental research | PE film is highly degradable after exposure to extreme heat and sand wind. | Sand wind and high temperatures are factors that facilitate polymer degradation |

| [112] | Dehbi et al. | Degradation of thermomechanical performance and lifetime estimation of multilayer greenhouse polyethylene films under simulated climatic conditions | Experimental study | The highest level of degradation was noted for plastics exposed to the combined impacts of temperature and UV radiation. | Thermal–oxidative conditions significantly deteriorate the performance and functionality of plastics |

| [113] | Bonhomme et al. | Environmental biodegradation of polyethylene | Experimental research | Microorganisms and oxidative products facilitate polymer aging. | Extreme temperatures and humidity accelerate polymer aging |

| [114] | Garnai Hirsch et al. | Characterization of surface phenomena: probing early stage degradation of low-density polyethylene films. | Experimental study | The contact angles of the plastics were sensitive to nanoscale surface roughening as well as composition changes. | At early aging there is poor sensitivity to the deterioration of mechanical properties |

| [115] | Hirsch et al. | Correlating chemical and physical changes of photo-oxidized low-density polyethylene to the activation energy of water release. | Experimental study | Release of water correlated with accelerated LDPE photo-oxidation. | Exposure to high humidity lowers the surface changes on the plastics |

| [116] | Picuno et al. | Agrochemical contamination and ageing effects on greenhouse plastic film for recycling. | Experimental research | Agrochemicals increased the aging properties of greenhouse plastics. | Agrochemicals reduce the lifespan of agricultural plastics |

| [117] | Schettini et al. | Interaction between agrochemical contaminants and UV stabilizers for greenhouse EVA plastic films | Experimental research | The interaction of agrochemicals with greenhouse plastics contaminates them. | Agrochemicals also speed up the degradation of agricultural plastics |

| [118] | Lamnatou and Chemisana | Solar radiation manipulations and their role in greenhouse claddings: Fresnel lenses, NIR-and UV-blocking materials. | Experimental research | UV radiation is very destructive for greenhouse plastics. However, using UV-blocking materials reduces the adverse impacts of solar radiation. | Solar radiations weaken the mechanical strength of agricultural plastics |

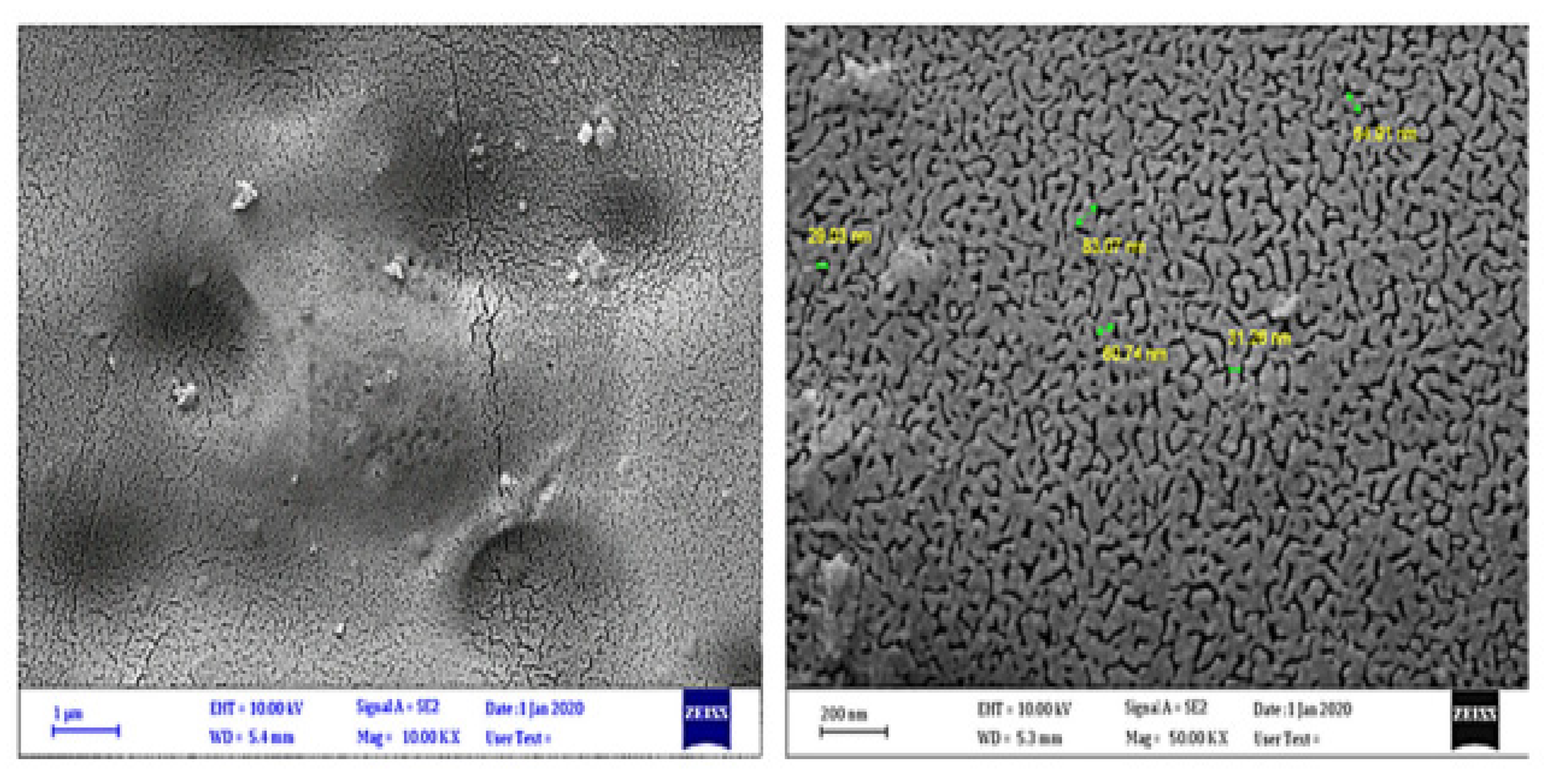

| [119] | Hamzah et al. | Surface chemistry changes and microstructure evaluation of low-density nanocluster polyethylene under natural weathering: A spectroscopic investigation | Experimental research | Natural weathering gradually degrades the mechanical properties of polyethylene. | Natural weathering reacts with the polymer surface; thus, the plastics’ mechanical properties are weakened, and their useful lives are reduced |

| [120] | Dehbi et al. | Artificial ageing of tri-layer polyethylene film used as greenhouse cover under the effect of the temperature and the UV-A simultaneously. | Experimental research | Carboxyl groups begin to degrade after extensive exposure to UV radiation. | Artificial aging shows how the degradation parameters in the natural environment cause polymer aging |

| [121] | Dehbi et al. | Impact of degradation of polyethylene films under simulated climatic conditions on their mechanical behavior and thermal stability and lifetime | Quantitative study based on simulations | Climatic conditions significantly cause the deterioration of agricultural films. | The film’s mechanical properties and material structure were significantly altered when the experiment was performed in a simulated environment |

| [122] | Lycoskoufis et al. | Ultraviolet radiation management in greenhouse to improve red lettuce quality and yield | The study employed two experiments to determine how UV light improved quality and productivity | The study determined that using supplemental UV lighting of dosage 425 kJ m−2 d−1 for 10 days prior to harvesting produced red lettuces of similar quality as those grown in UV-open greenhouses. Lettuce yield increased by 30% without any adverse effects. | UV light is converted by greenhouse plastics into favorable light conditions for maximizing productivity |

| [123] | Zou et al. | . Solar spectrum management and radiative cooling film for sustainable greenhouse production in hot climates | Literature review | Greenhouse management provides a viable solution to tackling the global food crisis | The UV radiation entering greenhouses must be managed within 400–700 nm to avoid degrading the agricultural plastics used to promote crop production in hot climates |

| [124] | Elanmugilan et al. | Natural weather aging of low-density polyethylene: effect of prodegradant additive | A quantitative study using rheological and Fourier transform infrared spectroscopy (FTIR) and scanning electron microscope (SEM) was implemented | In natural weathering processes, degradation of LDPE occurs as a result of chain scission and crosslinking. | Electromagnetic radiation of 300 and 400 nm wavelengths causes the natural aging of LDPE plastics. Adding additives elongates the lifespan of these plastic materials |

| [125] | Siti et al. | Mechanical properties of UV irradiated bio polymer thin films doped with titanium dioxide | The study used an experimental research design whereby film samples were irradiated in a UV-accelerated weatherometer at temperatures of 50 °C with varying durations of exposure | The study discovered that as the wavelengths increased, more free radicals were released from the polymer structure. | Neat BPF coupled with BPF doped with 10% TiO2 and then subjected to UV radiation showed higher ductility than the unexposed BPF. The longer BPF was exposed to UV light, the more it had a systematic increment in tensile strength because of the heightened crosslink between isocyanate as well as the hydroxyl group |

| [126] | Katsoulas et al. | Plant responses to UV blocking greenhouse covering materials: A review | The study conducted a literature review based on a sample of representative studies to show the impact of UV-blocking materials on different crops’ agronomic factors | The results show that UV shielding materials had a positive impact on the physiological functions of different plants. These functions included the transpiration rate as well as photosynthesis, thus contributing to plants’ growth characteristics. | Anthocyanins and total phenolics are used to block UV radiation in greenhouses |

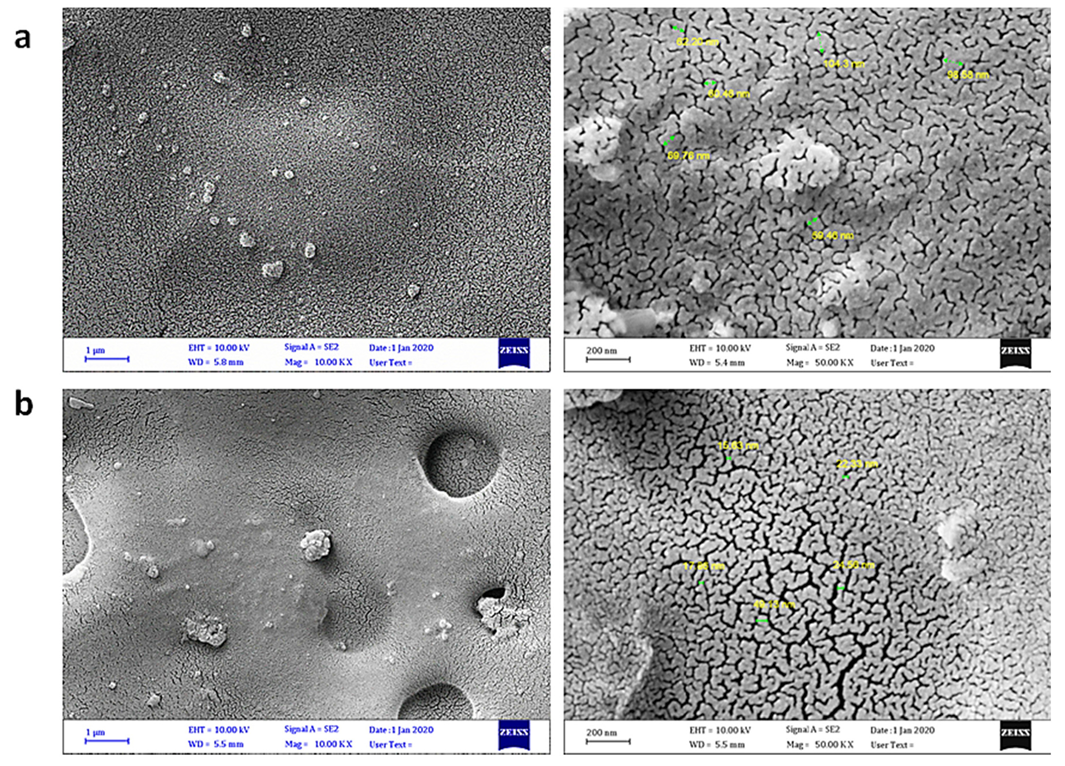

| [127] | Al-Salem et al. | Study of the degradation profile for virgin linear low-density polyethylene (LLDPE) and polyolefin (PO) plastic waste blends | The properties of LLDPE and PO were studied experimentally. The techniques used included thermogravimetry, differential scanning calorimetry (DSC), as well as infrared spectroscopy and scanning electron microscopy (SEM). | The polymers underwent crystallinity because of losing weight to weathering, leading to a change in the crystal size. | Polymers exhibit immiscibility as well as polydispersity when contextualized within the blending matrix as a consequence of chain scission and oxidation following UV exposure |

| [128] | Feldman | Polymer weathering: photo-oxidation | The study reviews the literature on polymer weathering | Weathering of polymers is severe since it merges photophysical and photochemical impacts of UV radiation with oxidative as well as hydrolytic impacts of the outdoor environment. | Photooxidation of polymers results from the degradation of their mechanical properties due to outdoor factors |

| [129] | Andrady et al. | Consequences of stratospheric ozone depletion and climate change on the use of materials | A literature review was conducted to describe technical advances in the techniques of stabilization and degradation of polymers | Weather-induced degradation of plastic and wood materials reduces their service life. | The interaction of polymers with UV-B causes them to have shorter lifespans |

| [130] | Chen et al. | A flexible UV–Vis–NIR photodetector based on a perovskite/conjugated-polymer composite. | Experimental research design | The conjugated polymer composite developed had outstanding mechanical flexibility coupled with improved environmental stability. | The paper inspired the development of diverse perovskite-based polymer composite systems that deliver superior performance at low costs and elevated-performance flexible broadband photodetectors |

| [131] | Al-Salem et al. | Effect of die head temperature at compounding stage on the degradation of linear low density polyethylene/plastic film waste blends after accelerated weathering | Experimental study that tested accelerated weathering of LLDPE | It was observed that exceeding the melting point of polymeric blends did not always lead to their synergistic behavior. | Once subjected to UV exposure under the conditions of weathering, polyolefin polymers lose their amorphousness due to the impact of plastic waste components |

| [132] | Hu et al. | Understanding the aging depth gradient distribution of high viscosity modified asphalt under the effect of solar radiation and diffuse oxygen. | An experimental study on the aging of high-viscosity modified asphalt (HVMA) was performed | The impact of UV radiation deterioration diffused from the surface of the asphalt to the asphalt inside in a gradual manner. | As the intensity of the solar radiation increased and aging time advanced, the aging depth of HVMA also increased continuously |

| [133] | Ni et al. | Degradation characteristics of SBS polymer and its contribution to weathering aging of modified asphalt | The study used shear rheology experiments (DSR) to determine the aging behaviors of SBS polymers | The findings illustrate that the deterioration pattern of weathering SBS obeys a single function of exponential decay function. | The effective content of the SBS decreased to 66.7%, 50%, as well as 33.3% post-accelerated weathering for 5.8, 10.5 and 14.5 h, respectively. |

| [134] | Garg et al. | Melamine–Formaldehyde Polymer-Based Nanocomposite for Sunlight-Driven Photo-degradation of Multiple Dyes and Their Mixture. | The study applied a comparative quantitative study methodology through nuclear magnetic resonance (NMR) analysis of polymer composites | A breakdown of organic dyes’ aromatic framework through the MFP-CdS in sunlight was observed. | Organic dyes undergoing photodegradation under UV radiation due to the substantial involvement of superoxide radicals and their holes. |

| [135] | Ávila-López et al. | Photo-degradation of air and water contaminants using 3D-printed TiO2 nanoparticle scaffolds | Experimental research | The addition of water and air contaminated the polymer, thus accelerating its aging process. | The susceptibility of polymers to aging stems from the weak carbon bonds that UV radiation breaks |

| [136] | Cacuro et al. | Demonstration of polymer photo-degradation using a simple apparatus | Quantitative research based on simple tests was conducted in four classes with n = 25 students | Photodegradation can use recent technology to functionalize non-polar polymer surfaces. | Exposure of polymer surfaces to photodegrading elements causes them to deteriorate in terms of their mechanical properties |

| [137] | Garg et al. | Ag3PO4 nanoparticles-decorated melamine–formaldehyde polymer nanocomposite as a catalyst for the photo-degradation of bisphenol a and its antibacterial activity | Experimental research design | The polymer nanocomposites fractured their molecular weight upon photodegradation and released free radicals. | The nanocomposite showed effective antibacterial activity |

| [138] | Lei et al. | Aerosol acidity sensing via polymer degradation | Experimental research based on pH measurement | As the size of the particle decreased, there was an increase in polymer degradation, showing a rise in aerosol acidity at smaller diameters of the particle. | This new approach can be used in the determination of particle acidity |

| [139] | Palkar and Kuksenok | Controlling degradation and erosion of polymer networks: insights from mesoscale modeling | Experimental study utilizing reverse gel point measurement | This approach was able to prevent polymer percolation within the network | Nanoscale modeling can help prevent polymer degradation |

| [140] | Cheng et al. | Hyper cross-linked additives that impede aging and enhance permeability in thin polyacetylene films for organic solvent nano-filtration | The experimental method was conducted through organic solvent nanofiltration | The study was able to develop scalable, thin film nanocomposite membranes that were supported on polymer substrates that resist physical aging while at the same time having high permeability rates to alcohols. | Thus, developing resistant membranes in polymers is can enhance the durability of polymer composites |

| [141] | Fraga Dominguez et al. | Unravelling the photo-degradation mechanisms of a low bandgap polymer by combining experimental and modeling approaches | Experimental research | The method was effective in determining the photodegradation properties of polymers. | Combining experimental methods with modeling offers a superior approach to polymer aging |

| [142] | Rivas Aiello et al. | Magnetic nanoparticle–polymer composites loaded with hydrophobic sensitizers for photo-degradation of azoic dyes | Experimental study design | There was a 76% efficiency of the dye decomposition at the pH value of 6. | Similar approaches could be applied in encapsulating hydrophobic photosensitizers |

| [143] | Tian et al. | Amphiphilic polymer micellar disruption based on main-chain photo-degradation | Experimental research | The N–O photocleavage can accelerate the release of DOX in aqueous media. | There is a rapid degradation of polymers in hydrophobic environments |

| [144] | Xiu et al. | Simultaneously improving toughness and UV-resistance of polylactide/titanium dioxide nanocomposites by adding poly (ether) urethane | Experimental research | Adding TiO2 to PLA can enhance its resistance to aging. | Poly(ether) urethane can be added to polymer surfaces to improve their UV resistance |

| [145] | Zhou et al. | Photocatalytic degradation by TiO2-conjugated/coordination polymer heterojunction: Preparation, mechanisms, and prospects. | Experimental study | Conjugated polymer with TiO2 exhibited improved resistivity to photocatalytic degradation. | The addition of TiO2 to conjugated polymers improves their anti-aging properties |

| [146] | Smith et al. | Control of physical aging in super-glassy polymer mixed matrix membranes. | Experimental study | PISA can enhance polymer stability against physical aging. | The addition of PISA can improve the resistance of super-glassy polymers against physical deterioration |

| [147] | El-Hiti et al. | Modifications of polymers through the addition of ultraviolet absorbers to reduce the aging effect of accelerated and natural irradiation | Experimental study | The absorbent material applied to the polymer surface helped modify its ability to withstand UV-induced weathering. | Absorbers are suggested for use to enhance polymer stabilization |

| [148] | Zemke et al. | Applications of the Tachiya fluorescence quenching model to describe the kinetics of solid-state polymer photo-degradation | Experimental study | The Tachiya model provided improved fits to the experimental kinetics data when considering the short reaction time. | Polymers with metal–metal bonds are also helpful in circumventing photodegradation |

| [149] | Auras et al. | Poly (lactic acid): synthesis, structures, properties, processing, applications, and end of life, | A book series providing a series of experimental and literature reviews | Eco-friendly PLA polymers have numerous industrial uses ranging from packaging to medical implants as well as wastewater treatment. | Polymeric materials require end-of-life management to ensure that they are used properly in their diverse use functions |

| [150] | Wallnöfer-Ogris et al. | Main degradation mechanisms of polymer electrolyte membrane fuel cell stacks–Mechanisms, influencing factors, consequences, and mitigation strategies | Review of literature | Operating conditions cause voltage decay in fuel cells as the polymer surfaces degrade. | Initial degradation influences further deterioration of the fuel cell |

| [151] | Karlsson and Albertsson | Techniques and mechanisms of polymer degradation | Literature review | Exposing polymer materials to complex outdoor environments makes them susceptible to decay. | A combination of oxidative agents causes polymer degradation |

| [152] | He et al. | Polymer degradation: category, mechanism and development prospect | Literature review | Degradation methods such as photo-, oxidative, catalytic, and biodegradation can help address the problem of white pollution. | An understanding of polymer degradation methods provides integral details on how to manage plastics |

| [153] | Ray and Cooney | Thermal degradation of polymer and polymer composites | Literature | Thermal environments accelerate the process of polymer decomposition. | With the increase in the commercial use of polymers, it is crucial to determine effective aging mechanisms for proper end-of-life management |

| [154] | La Mantia et al. | Degradation of polymer blends: A brief review | A literature review | Degradability and durability define the usefulness of polymeric materials. | The generation of free radicals by polymers once exposed to thermal and oxidative environments causes polymer aging |

| [155] | Ricci et al. | Linear stress relaxation and probe reorientation: comparison of the segmental dynamics of two glassy polymers during physical aging | Experimental research | The study used optical probe reorientation as a method for determining polymer aging. | Various methods can be applied during experimentation |

| [156] | Hebert and Ediger | Reversing strain deformation probes mechanisms for enhanced segmental mobility of polymer glasses | Experimental study | Enhanced segmental mobility can be applied to reverse deformations in polymers. | After reversal, deformations reaching 60% of the yield strain were observed |

| [157] | Hodgson et al. | Studying thermally induced chemical and physical transformations in common synthetic polymers: A laboratory project. | Laboratory experimentation | Polymer analysis and polymer characterization are useful in indicating the changes in aged polymers. | Common synthetic fibers experience both physical and chemical aging due to thermal influence |

| [158] | Han et al. | Metalloporphyrin-based DA type conjugated organic polymer nanotube for efficient photocatalytic degradation | Experimental study | The transfer and removal of photo-induced carriers were greatly improved through metal-to-ligand charge transfer (MLCT) | New methods can provide valuable ways through which photocatalytic activities can be enhanced in polymer aging experiments |

| [159] | Dinoop lal et al. | Accelerated photo-degradation of polystyrene by TiO2-polyaniline photocatalyst under UV radiation | Experimental study | UV radiation caused the faster degradation of the polymer. | Nano-TiO2 and PANI are also used to establish the aging features of polymers and their composites. |

| [160] | Mohammed et al. | Protection of poly(vinyl chloride) films against photo-degradation using various valsartan tin complexes | Experimental study | Lifespan elongation of polymers uses field-emission scanning electron microscopy. | Non-desirable transformations were lower in films with tin complexes compared to blank polymeric films |

| [161] | Ding et al. | Investigation of the thermal degradation of SBS polymer in long-term aged asphalt binder using confocal laser scanning microscopy (CLSM) | Experimental research | Confocal laser scanning microscopy (CLSM) characterized the morphological alterations of the SBS polymer. | Increasing the aging temperature accelerated the degradation of the SBS polymer while maintaining the same rheological level |

| [162] | Verney et al. | Melt viscoelastic assessment of poly (lactic acid) composting: influence of UV ageing. | Experimental research | Melt viscoelastic assessment helped establish the influence of UV aging on the polymer. | When this method is applied in polymer aging the specimens undergo deep molecular evolutions |

| [163] | Lesiak et al. | UV sensor based on fiber Bragg grating covered with graphene oxide embedded in composite materials. | Experimental study | Using UV sensors cause epoxy resins to undergo degradation. | UV lamps with wavelengths 290–400 nm also experimentally determine how the epoxy matrices of polymers age under UV exposure |

| [164] | Zhang et al. | 3D printed lignin/polymer composite with enhanced mechanical and anti-thermal-aging performance | The study applied an experimental research design to perform the demethylation of hardwood organosolv lignin | 3D-printed lignin had better aging performance against mechanical and thermal aging | Modifying lignin through the phenolic enhancement of its structure improved its interfacial adhesion. |

| [165] | Glaskova-Kuzmina et al. | Durability of biodegradable polymer nanocomposites | Literature review | Incorporating nanofillers into biodegradable polymers could attenuate the loss of mechanical properties as well as improve durability. | It is crucial to note that, at times, nanofillers can contribute to substantial polymer degradation |

| [166] | Biale et al. | A systematic study on the degradation products generated from artificially aged microplastics | An experimental study was conducted to artificially age five microplastics to understand their degradation behavior. The experiments used absorption spectroscopy to monitor how polymers’ physical and chemical properties are transformed after exposure | The photo-aged microplastics had remained with about 18 wt. % of extractable and low-molecular-weight fraction. The remaining fraction differed from one polymer to the other depending on the type. | There was a marked decline in the mean molecular weight of the polymer chains of PP, while PS had crosslinking |

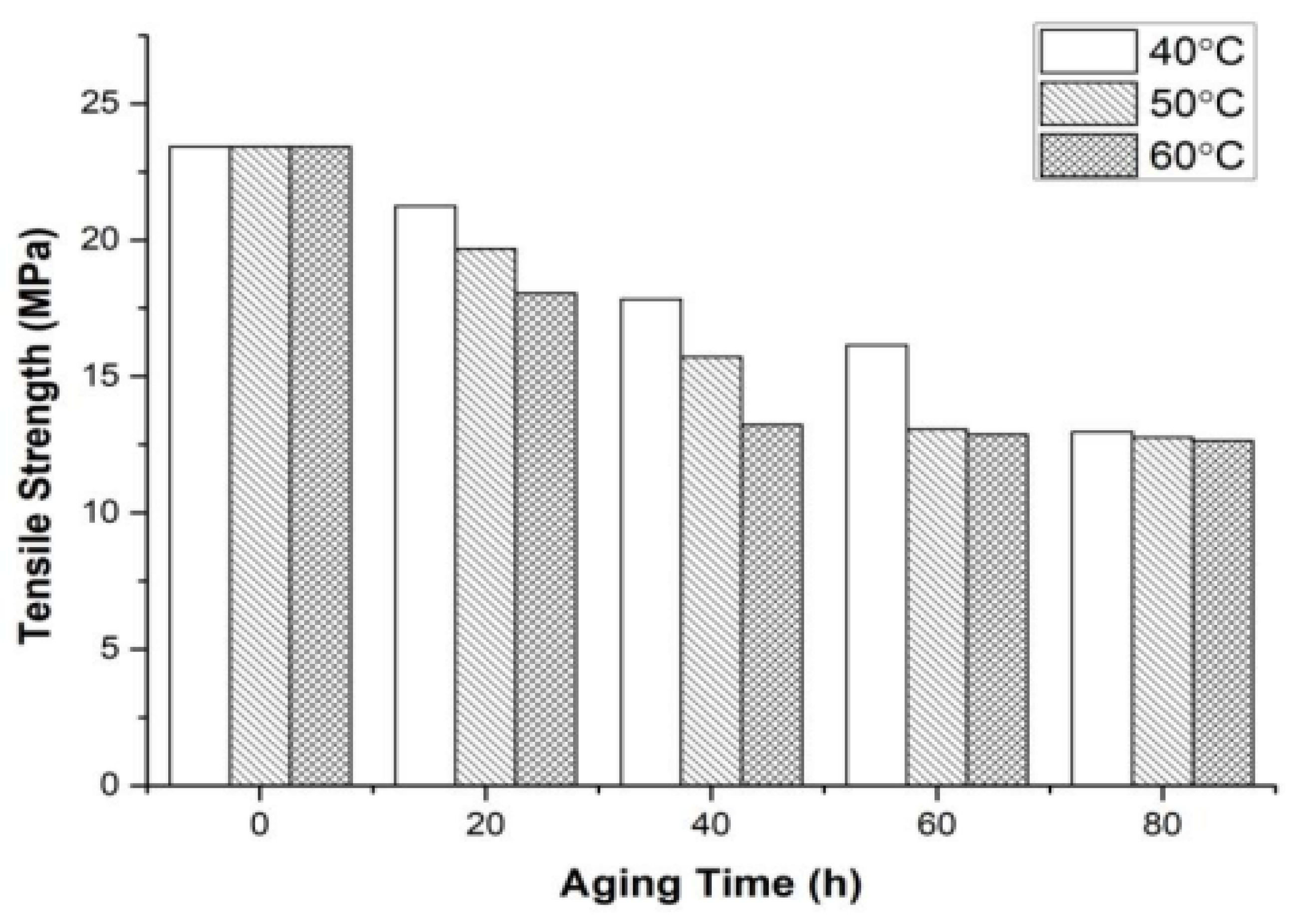

| [167] | Suraci et al. | Degradation assessment of polyethylene-based material through electrical and chemical-physical analyses | The study conducted experimental research whereby two LDPE flat specimens were subjected to thermal aging under different temperature conditions. The temperatures applied were 90 °C and 110 °C for the two polymers | The mechanisms of degradation were found to be deeply affected by the aging temperatures used. | There is a possibility of performing polymer aging development via non-destructive techniques that use electricity |

| [168] | Karimi et al. | A review on graphene’s light stabilizing effects for reduced photo-degradation of polymers | The paper reviewed existing knowledge about graphene | Using graphene, which is the latest member of the carbon group of metals, provides higher efficiency in increasing the shielding effect of polymers against photo-degradation. This superior performance of graphene is even possible at low loads of 1 wt. % or less. The protective role of graphene entails several complementary mechanisms that are aligned with the unique geometry as well as chemistry of the metal. | The findings showed that graphene’s free radical scavenging impact partially comes from the functional hydroxyl groups on its surfaces. Graphene also acts as a nucleating agent and can, therefore, enhance polymeric materials’ photostability |

| [169] | Urso et al. | Breaking polymer chains with self-propelled light-controlled navigable hematite microrobots | Experimental research design was applied | The method was effective in degrading polymers with high molecular weights through matrix-assisted laser desorption. | The effectiveness of the method was attributed to the microrobots’ active motion, improved capture of polymer chains through electrostatics and better charge separation |

| [170] | Giron and Celina | High temperature polymer degradation: Rapid IR flow-through method for volatile quantification. | The study used a quantitative research methodology | The rapid mid-IR gas analytical technique developed was useful in quantifying the volatiles contained in minute ampoules following exposure to the aging process. | The changes in the polymers’ mean molecular weights can be used to monitor changes |

| [171] | Plota and Masek | Lifetime prediction methods for degradable polymeric materials—A short review | The paper utilized a literature review methodology | The environmental factors causing the degradation of polymers are humidity and sunlight, which create thermal oxidative conditions. The polymers’ aging mechanisms can be predicted through lifetime analysis methods like the Arrhenius model and time–temperature superposition. | Accelerated aging tests and data extrapolation from induced thermal aging can determine the shelf life of polymers |

| [172] | Hebner and Maurer-Jones | Characterizing microplastic size and morphology of photodegraded polymers placed in simulated moving water conditions | An experimental research design was applied | When the polymers were irradiated for 1, 2, and 3 days, the results showed that an extensive period of irradiation correlated with the formation of more microplastics by the polypropylene films. | Thus, the changes in the polymer’s microplastics correlated with alterations in the glass transition temperatures. Irradiating the polymer at 300 nm generated fewer microplastics as a result of slower phototransformation kinetics. |

| [173] | Rånby | Photo-degradation and photo-oxidation of synthetic polymers | An exploratory study that examined the process of polymer aging through photooxidation | UV radiation damages polymer networks, which is determined through crosslinking. | Electron spectroscopy, infrared, and electron spin resonance spectroscopy can conduct chemical analyses of photoinitiated reactions |

| [174] | Kyrikou et al. | Analysis of photo-chemical degradation behavior of polyethylene mulching film with pro-oxidants | An experimental study was conducted | Declined weight of the polymer molecule and production of free radicals show that changes have occurred. | The combined impact of critical factors of pro-oxidants on the predefined photochemical degradation of LLDPE films is significant. |

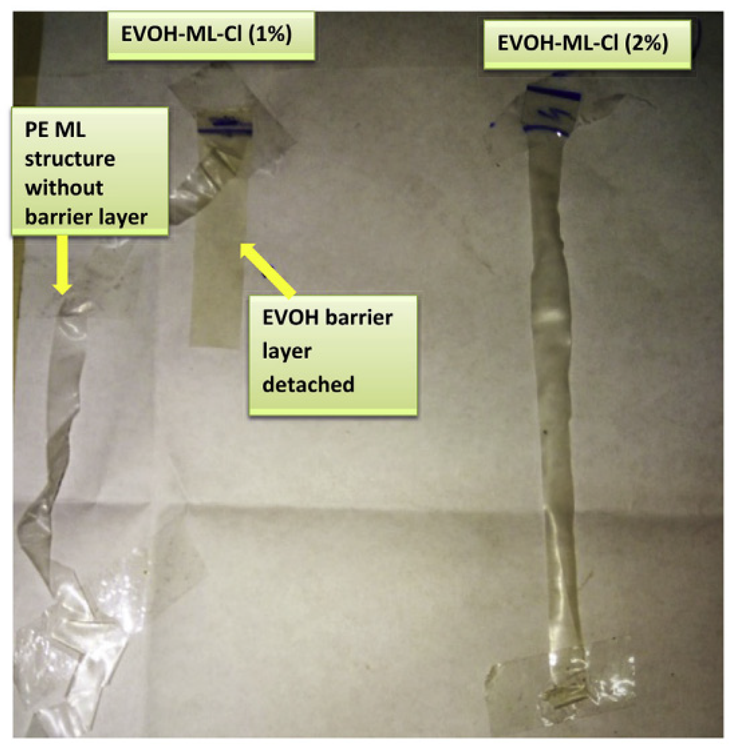

| [175] | Briassoulis et al. | Combined effect of UVA radiation and agrochemicals on the durability of agricultural multilayer films | The study involved an experimental design for multi-layered films of 180–200 μm thick | Combining agrochemicals with UV radiation leads to the early failure of barring layers, which compromises the longevity of the whole polymer film | The study recommended the elimination of barrier layers in agricultural multilayer films to enhance their durability |

| [176] | Maraveas | Environmental sustainability of greenhouse covering materials | Literature review article | Polymeric materials can be recycled through mechanical as well as chemical means, closed-loop cycling and the polymerization of biodegradable feedstock. | Plastic films that have gone past the consumption phase do not have the same optical or energy characteristics as virgin polymers. The combined advantages of diverse polymeric materials underscore that they can be embraced on a large scale in the long run. |

| [177] | Maraveas et al. | Sustainable greenhouse covering materials with nano- and micro-particle additives for enhanced radiometric and thermal properties and performance | Literature review | Future innovations on the macro and micro synthesis of nanomaterials can provide an improvement in using them for greenhouse coverings. | These materials are, however, highly sensitive to external climatic as well as meteorological conditions |

| [178] | Maraveas et al. | Smart and solar greenhouse covers: Recent developments and future perspectives | Literature review | Greenhouses embedded with transparent polymers as roofs embrace sustainable approaches whereby the energy generated is fully renewable as well as economical. | The new use of polymer films that have tailored light absorbance as well as emission features regulates solar radiation. These materials also help regulate the internal and external temperatures of greenhouse agricultural projects |

| [179] | Zhong and Zhang | 3D printing geopolymers: a review. | Literature review | 3D printing technology, premised on the concept of additive manufacturing, fosters increased productivity of construction works | Geopolymers’ printability can potentially be optimized by blending fly ash, silica fume, solid activator, and river sand. |

| [180] | Rapisarda et al. | Photo-oxidative and soil burial degradation of irrigation tubes based on biodegradable polymer blends. | Experimental research design | Elevated temperatures or UV-induced aging led to the deterioration of the Bio-Flex®-based irrigation tubes in soil. | UV radiation sources cause the release of free radicals and a reduction in the molecular weight of polymers |

| [181] | Zaaba and Jaafar | A review on degradation mechanisms of polylactic acid: Hydrolytic, photodegradative, microbial, and enzymatic degradation. | Literature review | Other tests on degradation mechanisms use pyrolysis to determine how main chain polymer scission and polymer molecules unzip. | PLA has broader industrial applications, ranging from packaging to agriculture, textile, and biomedical uses, among others |

| [182] | Maléchaux et al. | Influence of gamma irradiation on electric cables models: study of additive effects by mid-infrared spectroscopy | Experimental research design | Models of insulation using crosslinked polyethylene (XLPE) and structural modification are discussed in relation to the impacts of additives. The results show the impacts of aging based on the dose rate as well as material formulation. | A low dose rate was found to cause elevated polymer degradation compared to a high dose rate |

| [183] | Ali et al. | Degradation of conventional plastic wastes in the environment: a review on the current status of knowledge and future perspectives of disposal | Literature review | Exposure of conventional plastics to the environment weakens their mechanical properties. | Plastic degradation can be improved by merging diverse degradation techniques. However, plastic degradation needs further research to establish biodegradation processes |

| [184] | La Mantia et al. | Comparative investigation on the soil burial degradation behavior of polymer films for agriculture before and after photo-oxidation. | A causal comparative study using experimentation was conducted | Biodegradable polymer films in soil experienced more degradation than PE-based polymers. UV irradiation increases polymers’ surface wettability coupled with its disintegration in the soil. | Photooxidation caused a reduction in the polymers’ molar mass as well as their hydrophilic end groups. This aspect increases the loss of weight and erosion of the surface by the polymer samples |

| [185] | Bhandari et al. | Degradation of fundamental polymers/plastics used in daily life: a review. | Literature review | Bio-based polymers degrade comparatively faster into fragments that are environmentally compatible than petro-based polymers. | It is crucial to produce bio-based polymers instead of petro-based ones to provide a sustainable solution that addresses plastic-related environmental concerns around the globe |

| [186] | Yu et al. | Impact of ultraviolet radiation on the aging properties of SBS-modified asphalt binders | This experimental study conducted 16 different tests to determine the impact | Consistent exposure to UV radiation increased the shrinkage stress in the polymer samples, making their surfaces crack. | The lab conditions mirror the usual natural conditions that cause polymer aging |

| [187] | Kaczmarek et al. | Effect of short wavelength UV-irradiation on ageing of polypropylene/cellulose compositions | Experimental study | As the epoxy resins are exposed to thermal extremities, with temperatures surpassing the glass transition temperatures, they age. | Reflectance infrared spectroscopy (ATR-FTIR) can be merged with SEM to provide a faster estimation of changes occurring in polymers during ecological degradation |

| [188] | Vašíˇcek et al. | Degradation of polylactic acid polymer and biocomposites exposed to controlled climatic ageing: mechanical and thermal properties and structure | Experimental research | Tensile and flexural tests showed that the biocomposites weakened their mechanical properties after exposure to thermal conditions due to the fragmentation of their chemical structure. | The fragmentation of biocomposites’ chemical structure in controlled aging experiments can be determined by differential scanning calorimetry |

| [189] | Odegard and Bandyopadhyay | Physical aging of epoxy polymers and their composites | Literature review | The physically aged epoxy polymers lost weight due to the deprivation of residual volatiles as well as moisture. | The physical properties of epoxy polymers are affected by mechanisms that can undermine their reliability in terms of engineering components as well as structure |

References

- Namazi, H. Polymers in our daily life. BioImpacts BI 2017, 7, 73–74. [Google Scholar] [CrossRef]

- White, J.R. Polymer ageing: Physics, chemistry or engineering? Time to reflect. Comptes Rendus Chim. 2006, 9, 1396–1408. [Google Scholar] [CrossRef]

- Yousif, E.; Haddad, R. Photodegradation and photostabilization of polymers, especially polystyrene. SpringerPlus 2013, 2, 398. [Google Scholar] [CrossRef]

- Tocháček, J.; Vrátníčková, Z. Polymer lifetime prediction: The role of temperature in UV accelerated ageing of polypropylene and its copolymers. Polym. Test. 2014, 36, 182–187. [Google Scholar] [CrossRef]

- Frigione, M.; Rodríguez-Prieto, A. Can accelerated aging procedures predict the long term behavior of polymers exposed to different environments? Polymers 2021, 13, 2688. [Google Scholar] [CrossRef]

- Pickett, J.E.; Gibson, D.A.; Gardner, M.M. Effects of irradiation conditions on the weathering of engineering thermoplastics. Polym. Degrad. Stab. 2008, 93, 1597–1606. [Google Scholar] [CrossRef]

- Kockott, D. Shorter test times for thermal and radiation induced aging of polymer material: 2: Early recognition of molecular alterations by measurement of chemiluminescence. Polym. Test. 2001, 20, 725–727. [Google Scholar] [CrossRef]

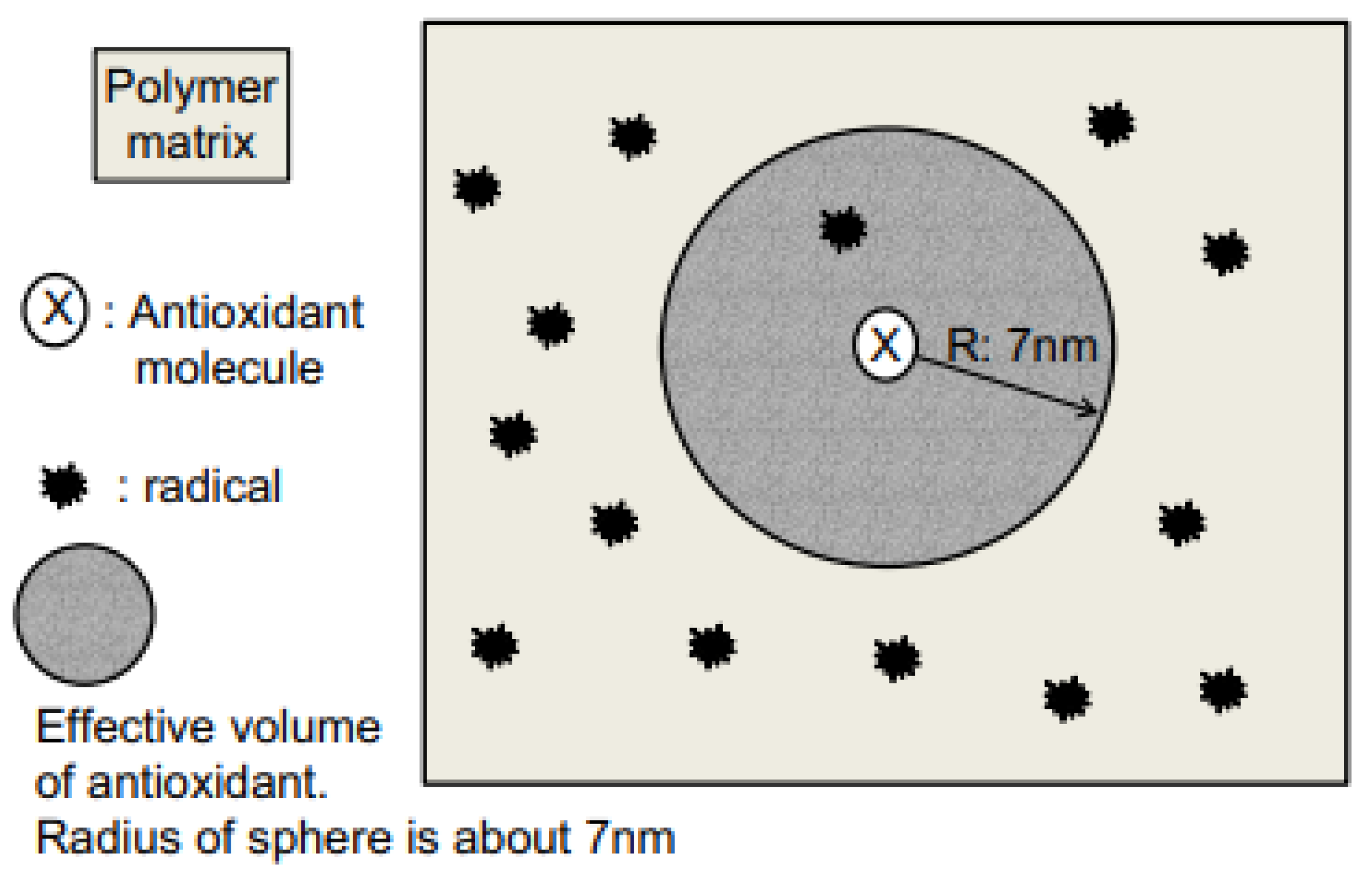

- Seguchi, T.; Tamura, K.; Shimada, A.; Sugimoto, M.; Kudoh, H. Mechanism of antioxidant interaction on polymer oxidation by thermal and radiation ageing. Radiation Phys. Chem. 2012, 81, 1747–1751. [Google Scholar] [CrossRef]

- Liu, H.; Zhang, X.; Ji, B.; Qiang, Z.; Karanfil, T.; Liu, C. UV aging of microplastic polymers promotes their chemical transformation and byproduct formation upon chlorination. Sci. Total Environ. 2023, 858, 159842. [Google Scholar] [CrossRef] [PubMed]

- Kockott, D. New method for accelerated testing of the aging behavior of polymeric materials as a function of radiation and temperature. Polym. Test. 2022, 110, 107550. [Google Scholar] [CrossRef]

- Diab, A.; Enieb, M.; Singh, D. Influence of aging on properties of polymer-modified asphalt. Constr. Build. Mater. 2019, 196, 54–65. [Google Scholar] [CrossRef]

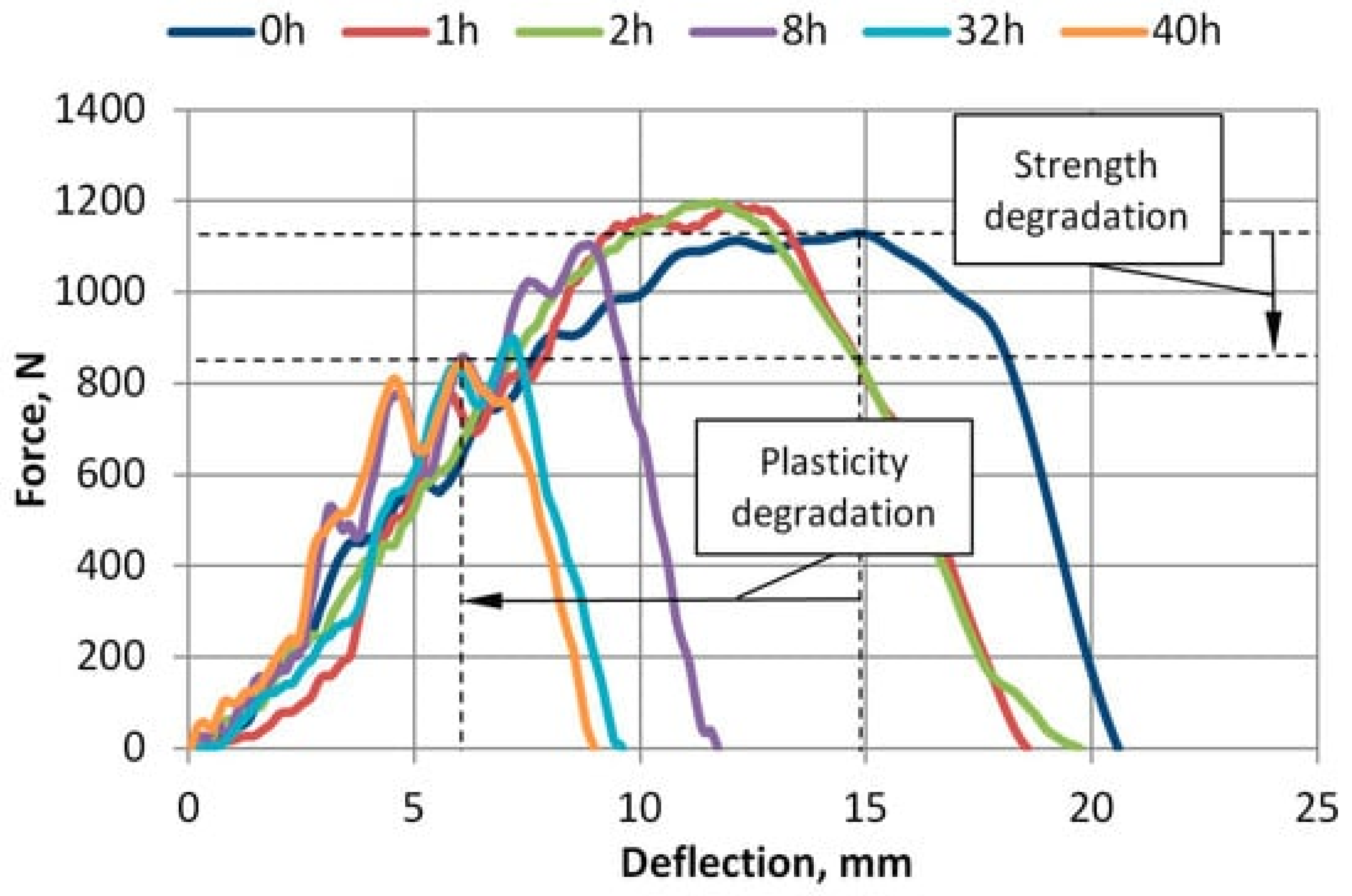

- Arhant, M.; Le Gall, M.; Le Gac, P.Y. Fracture test to accelerate the prediction of polymer embrittlement during aging–Case of PET hydrolysis. Polym. Degrad. Stab. 2022, 196, 109848. [Google Scholar] [CrossRef]

- Fiorio, R.; Villanueva Díez, S.; Sánchez, A.; D’hooge, D.R.; Cardon, L. Influence of different stabilization systems and multiple ultraviolet A (UVA) aging/recycling steps on physicochemical, mechanical, colorimetric, and thermal-oxidative properties of ABS. Materials 2020, 13, 212. [Google Scholar] [CrossRef]

- Feng, Z.; Cai, F.; Yao, D.; Li, X. Aging properties of ultraviolet absorber/SBS modified bitumen based on FTIR analysis. Constr. Build. Mater. 2021, 273, 121713. [Google Scholar] [CrossRef]

- Ma, D.; Pan, Z.; Liu, Y.; Jiang, Z.; Liu, Z.; Zhou, L.; Tang, L. Residual flexural performance of epoxy polymer concrete under hygrothermal conditions and ultraviolet aging. Materials 2019, 12, 3472. [Google Scholar] [CrossRef] [PubMed]

- Ayoub, G.; Makki, M.; Kadri, R.; Dargazany, R.; Nait Abdelaziz, M. Micromechanical modeling of the effects of crystal content on the visco-hyperelastic-viscoplastic behavior and fracture of semi-crystalline polymers. Mech. Mater. 2024, 189, 104897. [Google Scholar] [CrossRef]

- 104897Baklan, D.; Bilousova, A.; Myronyuk, O. UV aging of styrene-acrylic polymer SiO2 and TiO2 composites. Mater. Today Commun. 2023, 38, 107990. [Google Scholar]

- Moraczewski, K.; Stepczy’nska, M.; Malinowski, R.; Karasiewicz, T.; Jagodziński, B.; Rytlewski, P. Modification of Polycaprolactone with Plant Extracts to Improve the Aging Resistance. Materials 2023, 16, 5154. [Google Scholar] [CrossRef] [PubMed]

- Rodriguez, A.K.; Mansoor, B.; Ayoub, G.; Colin, X.; Benzerga, A.A. Effect of UV-aging on the mechanical and fracture behavior of low density polyethylene. Polym. Degrad. Stab. 2020, 180, 109185. [Google Scholar] [CrossRef]

- Cosnita, M.; Cazan, C.; Pop, M.A.; Cristea, D. Aging resistance under short time ultraviolet (UV) radiations of polymer wood composites entirely based on wastes. Environ. Technol. Innov. 2023, 31, 103208. [Google Scholar] [CrossRef]

- Ghosh, J.; Hait, S.; Ghorai, S.; Mondal, D.; Wießner, S.; Das, A.; De, D. Cradle-to-cradle approach to waste tyres and development of silica based green tyre composites. Resour. Conserv. Recycl. 2020, 154, 104629. [Google Scholar] [CrossRef]

- Qi, X.; Tian, J.; Xian, G. Hydrothermal ageing of carbon fiber reinforced polymer composites applied for construction: A review. J. Mater. Res. Technol. 2023, 27, 1017–1045. [Google Scholar] [CrossRef]

- Zhumadilova, Z.O.; Selyaev, V.P.; Nurlybayev, R.E.; Orynbekov, Y.S.; Sangulova, I.B.; Kuldeyev, E.I. Prediction of Durability of Thermal Insulating Epoxy Coatings with Regard to Climatic Ageing. Polymers 2022, 14, 1650. [Google Scholar] [CrossRef]

- Starkova, O.; Gagani, A.I.; Karl, C.W.; Rocha, I.B.C.M.; Burlakovs, J.; Krauklis, A.E. Modelling of Environmental Ageing of Polymers and Polymer Composites—Durability Prediction Methods. Polymers 2022, 14, 907. [Google Scholar] [CrossRef]

- Celauro, C.; Saroufim, E.; Mistretta, M.C.; La Mantia, F.P. Influence of short-term aging on mechanical properties and morphology of polymer-modified bitumen with recycled plastics from waste materials. Polymers 2020, 12, 1985. [Google Scholar] [CrossRef] [PubMed]

- Zhu, X.; Wang, Y.; Miljković, M.; Li, R.; Hao, G. Effects of polymer structure on the physicochemical and performance-related properties of SBS-modified asphalt binders subjected to short-term aging. Constr. Build. Mater. 2024, 411, 134446. [Google Scholar] [CrossRef]

- Brandt, J.; Kanaki, E.; Fischer, D.; Herm, C. Evaluation of the composition, thermal and mechanical behavior, and color changes of artificially and naturally aged polymers for the conservation of stained glass windows. Polymers 2023, 15, 2595. [Google Scholar] [CrossRef] [PubMed]

- Celina, M.; Linde, E.; Brunson, D.; Quintana, A.; Giron, N. Overview of accelerated aging and polymer degradation kinetics for combined radiation-thermal environments. Polym. Degrad. Stab. 2019, 166, 353–378. [Google Scholar] [CrossRef]

- Krauklis, A.E.; Karl, C.W.; Rocha, I.B.C.M.; Burlakovs, J.; Ozola-Davidane, R.; Gagani, A.I.; Starkova, O. Modelling of environmental ageing of polymers and polymer composites—Modular and multiscale methods. Polymers 2022, 14, 216. [Google Scholar] [CrossRef] [PubMed]

- Čubrić, I.S.; Čubrić, G.; Katić Križmančić, I.; Kovačević, M. Evaluation of Changes in Polymer Material Properties Due to Aging in Different Environments. Polymers 2022, 14, 1682. [Google Scholar] [CrossRef] [PubMed]

- Markovičová, L.; Zatkalíková, V. The effect of UV aging on structural polymers. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Pavlov, Czech Republic, 3–7 September 2019. [Google Scholar]

- Sen, T.; Rai, R.N.; Paul, A. Damage and degradability study of pretreated natural fiber-reinforced polymers composites and its comparative analysis with artificial fiber-reinforced polymers composites. Ref. Modul. Mater. Sci. Mater. Eng. 2016, 105356. [Google Scholar] [CrossRef]

- Ryan, G. Introduction to positivism, interpretivism and critical theory. Nurse Res. 2018, 25, 41–49. [Google Scholar] [CrossRef] [PubMed]

- Žukauskas, P.; Vveinhardt, J.; Andriukaitienė, R. Philosophy and paradigm of scientific research. Manag. Cult. Corp. Soc. Responsib. 2018, 121, 506–518. [Google Scholar]

- Kim, S.M. Inductive or deductive? Research by maxillofacial surgeons. J. Korean Assoc. Oral Maxillofac. Surg. 2021, 47, 151–152. [Google Scholar] [CrossRef]

- Bonner, C.; Tuckerman, J.; Kaufman, J.; Costa, D.; Durrheim, D.N.; Trevena, L.; Thomas, S.; Danchin, M. Comparing inductive and deductive analysis techniques to understand health service implementation problems: A case study of childhood vaccination barriers. Implement. Sci. Commun. 2021, 2, 100. [Google Scholar] [CrossRef] [PubMed]

- Azungah, T. Qualitative research: Deductive and inductive approaches to data analysis. Qual. Res. J. 2018, 18, 383–400. [Google Scholar] [CrossRef]

- Hunter; McCallum, J.; Howes, D. Defining exploratory-descriptive qualitative (EDQ) research and considering its application to healthcare. J. Nurs. Health Care 2019, 4, 1–8. [Google Scholar]

- Dash, P. Analysis of literature review in cases of exploratory research. SSRN Electron. J. 2019, 3555628. [Google Scholar] [CrossRef]

- Mbaka, N.; Isiramen, O.M. The changing role of an exploratory research in modern organisation. GPH-Int. J. Bus. Manag. 2021, 4, 27–36. [Google Scholar]

- Reiter, B. Theory and Methodology of Exploratory Social Science Research. Int. J. Sci. Res. Methodol. 2017, 5, 129. [Google Scholar]

- Gusenbauer, M.; Haddaway, N.R. Which academic search systems are suitable for systematic reviews or meta-analyses? Evaluating retrieval qualities of Google Scholar, PubMed, and 26 other resources. Res. Synth. Methods 2020, 11, 181–217. [Google Scholar] [CrossRef] [PubMed]

- Bramer, W.M.; De Jonge, G.B.; Rethlefsen, M.L.; Mast, F.; Kleijnen, J. A systematic approach to searching: An efficient and complete method to develop literature searches. J. Med. Libr. Assoc. JMLA 2018, 106, 531–541. [Google Scholar] [CrossRef] [PubMed]

- Halevi, G.; Moed, H.; Bar-Ilan, J. Suitability of Google Scholar as a source of scientific information and as a source of data for scientific evaluation—Review of the literature. J. Informetr. 2017, 11, 823–834. [Google Scholar] [CrossRef]

- Wohlin, C.; Kalinowski, M.; Felizardo, K.R.; Mendes, E. Successful combination of database search and snowballing for identification of primary studies in systematic literature studies. Inf. Softw. Technol. 2022, 147, 106908. [Google Scholar] [CrossRef]

- Aliyu, M.B. Efficiency of Boolean search strings for Information retrieval. Am. J. Eng. Res. 2017, 6, 216–222. [Google Scholar]

- Clarke, V.; Braun, V. Thematic analysis. J. Posit. Psychol. 2017, 12, 297–298. [Google Scholar] [CrossRef]

- Nowell, L.S.; Norris, J.; White, D.E.; Moules, N.J. Thematic analysis: Striving to meet the trustworthiness criteria. Int. J. Qual. Methods 2017, 16, 1609406917733847. [Google Scholar] [CrossRef]

- Tripathy, J.P. Secondary data analysis: Ethical issues and challenges. Iran. J. Public Health 2013, 42, 1478–1479. [Google Scholar]

- Jol, G.; Stommel, W. Ethical considerations of secondary data use: What about informed consent? Dutch J. Appl. Linguist. 2016, 5, 180–195. [Google Scholar] [CrossRef]

- Baldwin, J.R.; Pingault, J.B.; Schoeler, T.; Sallis, H.M.; Munafò, M.R. Protecting against researcher bias in secondary data analysis: Challenges and potential solutions. Eur. J. Epidemiol. 2022, 37, 1–10. [Google Scholar] [CrossRef]

- Wickham, R.J. Secondary analysis research. J. Adv. Pract. Oncol. 2019, 10, 395–400. [Google Scholar]

- Zhang, F.; Yang, R.; Lu, D. Investigation of polymer aging mechanisms using molecular simulations: A review. Polymers 2023, 15, 1928. [Google Scholar] [CrossRef]

- Liu, J.; Li, X. Progress in study of polymer degradation behaviors and mechanisms in various environment conditions. Polym. Bull. 2005, 3, 62–69. [Google Scholar]

- Scott, G. Initiation processes in polymer degradation. Polym. Degrad. Stab. 1995, 48, 315–324. [Google Scholar] [CrossRef]

- Day, M.; Cooney, J.D.; Mackinnon, M. Degradation of contaminated plastics: A kinetic study. Polym. Degrad. Stab. 1995, 48, 341–349. [Google Scholar] [CrossRef]

- Troev, K.; Atanassov, V.; Tzevi, R. Chemical degradation of polyurethanes. II. Degradation of microporous polyurethane elastomer by phosphoric acid esters. J. Appl. Polym. Sci. 2000, 76, 886–893. [Google Scholar]

- Barrer, R.M. Some properties of diffusion coefficients in polymers. J. Phys. Chem. 1957, 61, 178–189. [Google Scholar] [CrossRef]

- Arya, R.K.; Thapliyal, D.; Sharma, J.; Verros, G.D. Glassy Polymers—Diffusion, sorption, ageing and applications. Coatings 2021, 11, 1049. [Google Scholar] [CrossRef]

- Enomoto, I.; Katsumura, Y.; Kudo, H.; Sekiguchi, M. The role of hydroperoxides as a precursor in the radiation-induced graft polymerization of methyl methacrylate to ultra-high molecular weight polyethylene. Radiat. Phys. Chem. 2010, 79, 718–724. [Google Scholar] [CrossRef]

- Ching, Y.C.; Gunathilake, T.U.; Ching, K.Y.; Chuah, C.H.; Sandu, V.; Singh, R.; Liou, N.S. Effects of high temperature and ultraviolet radiation on polymer composites. In Durability and Life Prediction in Biocomposites, Fibre-Reinforced Composites and Hybrid Composites; Mohammad, J., Mohamed, T., Naheed, S., Eds.; Woodhead Publishing: Sawston, UK, 2019; Volume 1, pp. 407–426. [Google Scholar]

- Henry, T.; Lafont, U.; Hołyńska, M. White LED induced photooxidation aging of epoxy/carbon fibre reinforced polymer and its implications for cleanroom cleanliness and contamination control. Polym. Degrad. Stab. 2023, 218, 110588. [Google Scholar] [CrossRef]

- Lu, T.; Solis-Ramos, E.; Yi, Y.B.; Kumosa, M. Particle removal mechanisms in synergistic aging of polymers and glass reinforced polymer composites under combined UV and water. Compos. Sci. Technol. 2017, 153, 273–281. [Google Scholar] [CrossRef]

- Amza, C.G.; Zapciu, A.; Baciu, F.; Radu, C. Effect of UV-C radiation on 3D printed ABS-PC polymers. Polymers 2023, 15, 1966. [Google Scholar] [CrossRef] [PubMed]

- Amza, C.G.; Zapciu, A.; Baciu, F.; Vasile, M.I.; Popescu, D. Aging of 3D printed polymers under sterilizing UV-C radiation. Polymers 2021, 13, 4467–4483. [Google Scholar] [CrossRef]

- Afshar, A.; Mihut, D. Enhancing durability of 3D printed polymer structures by metallization. J. Mater. Sci. Technol. 2020, 53, 185–191. [Google Scholar] [CrossRef]

- Amza, C.G.; Zapciu, A.; Baciu, F.; Vasile, M.I.; Nicoara, A.I. Accelerated aging effect on mechanical properties of common 3D-printing polymers. Polymers 2021, 13, 4132. [Google Scholar] [CrossRef]

- Franco, Y.B.; Valentin, C.A.; Kobelnik, M.; Lins da Silva, J.; Ribeiro, C.A.; da Luz, M.P. Accelerated aging ultraviolet of a PET nonwoven geotextile and thermoanalytical evaluation. Materials 2022, 15, 4157. [Google Scholar] [CrossRef]

- D’Urso, L.; Acocella, M.R.; Guerra, G.; Iozzino, V.; De Santis, F.; Pantani, R. PLA melt stabilization by high-surface-area graphite and carbon black. Polymers 2018, 10, 139. [Google Scholar] [CrossRef]

- Dubey, K.A.; Sinha, S.K.; Bhardwaj, Y.K.; Panicker, L.; Varshney, L. Carbon black-filled PE/PP/EPDM blends: Phase selective localization of carbon black and EPDM-induced phase stabilization. Polym.-Plast. Technol. Eng. 2014, 53, 442–450. [Google Scholar] [CrossRef]

- CABOT. Carbon Blacks for Protection of Plastics Exposed to Ultraviolet Light; CABOT Technical Report S-114; CABOT: Billerica, MA, USA, 1990. [Google Scholar]

- Hachicha, B.; Overmeyer, L. Investigation on aging of metallic surface integrated micro-POFs. Procedia Technol. 2016, 26, 413–418. [Google Scholar] [CrossRef]

- Hoghoghifard, S.; Mokhtari, H.; Dehghani, S. Improving EMI shielding effectiveness and dielectric properties of polyaniline-coated polyester fabric by effective doping and redoping procedures. J. Ind. Text. 2018, 47, 587–601. [Google Scholar] [CrossRef]

- Egghe, T.; Ghobeira, R.; Morent, R.; Hoogenboom, R.; De Geyter, N. Comparative study of the aging behavior of plasma activated hexamethyldisiloxane-based plasma polymers and silicone elastomer thin films. Prog. Org. Coat. 2022, 172, 107091. [Google Scholar] [CrossRef]

- Vasylius, M.; Tadžijevas, A.; Šapalas, D.; Kartašovas, V.; Janutėnienė, J.; Mažeika, P. Degradation of mechanical properties of A-PET films after UV aging. Polymers 2023, 15, 4166. [Google Scholar] [CrossRef]

- He, K.; Zhang, Q.; Hong, Y. Profile monitoring based quality control method for fused deposition modeling process. J. Intell. Manuf. 2019, 30, 947–958. [Google Scholar] [CrossRef]

- Mondal, S.; Ganguly, S.; Das, P.; Bhawal, P.; Das, T.K.; Ravindren, R.; Ghosh, S.; Das, N.C. Effect of thermal-air ageing treatment on mechanical properties and electromagnetic interference shielding effectiveness of low-cost nano-structured carbon filled chlorinated polyethylene. Mater. Sci. Eng. B 2017, 225, 140–149. [Google Scholar] [CrossRef]

- Lajić, B.; Majnarić, I.; Mirković, I.B. Accelerated and natural ageing of offset prints covered with different varnishes. Nord. Pulp Pap. Res. J. 2013, 28, 101–110. [Google Scholar] [CrossRef]

- Cantero-Chinchilla, S.; Fabro, A.T.; Meng, H.; Yan, W.J.; Papadimitriou, C.; Chronopoulos, D. Robust optimised design of 3D printed elastic metastructures: A trade-off between complexity and vibration attenuation. J. Sound Vib. 2022, 529, 116896. [Google Scholar] [CrossRef]

- Mantada, P.; Mendricky, R.; Safka, J. Parameters influencing the precision of various 3d printing technologies. MM Sci. J. 2017, 5, 2004–2012. [Google Scholar] [CrossRef]

- Lin, W.; Xie, G.; Qiu, Z. Effects of ultraviolet aging on properties of wood flour–poly (lactic acid) 3D printing filaments. BioResources 2019, 14, 8689–86700. [Google Scholar] [CrossRef]

- Sousa, A.M.; Pinho, A.C.; Piedade, A.P. Mechanical properties of 3D printed mouthguards: Influence of layer height and device thickness. Mater. Des. 2021, 203, 109624. [Google Scholar] [CrossRef]

- Ferreira, L.M.; Aranda, M.T.; Muñoz-Reja, M.; Coelho, C.A.; Távara, L. Ageing effect on the low-velocity impact response of 3D printed continuous fibre reinforced composites. Compos. Part B Eng. 2023, 267, 111031. [Google Scholar] [CrossRef]

- Najvani, M.A.; Murcia, D.H.; Soliman, E.; Taha, M.M. Early-age strength and failure characteristics of 3D printable polymer concrete. Constr. Build. Mater. 2023, 394, 132119. [Google Scholar] [CrossRef]

- House, R.; Rajaram, N.; Tarlo, S.M. Case report of asthma associated with 3D printing. Occup. Med. 2017, 67, 52–54. [Google Scholar] [CrossRef]

- Bedi, R.; Chandra, R.; Singh, S.P. Reviewing some properties of polymer concrete. Indian Concr. J. 2014, 88, 47–68. [Google Scholar]

- Krčma, M.; Škaroupka, D.; Vosynek, P.; Zikmund, T.; Kaiser, J.; Palousek, D. Use of polymer concrete for large-scale 3D printing. Rapid Prototyp. J. 2021, 27, 465–474. [Google Scholar] [CrossRef]

- Furet, B.; Poullain, P.; Garnier, S. 3D printing for construction based on a complex wall of polymer-foam and concrete. Addit. Manuf. 2019, 28, 58–64. [Google Scholar] [CrossRef]

- Kozicki, M.; Jaszczak, M.; Maras, P.; Kadlubowski, S. Measurement of the radiation dose and radiation isocenter of the truebeam accelerator using 3D polymer gel dosimeters from the VIPAR family with different chemical history. Measurement 2023, 221, 113452. [Google Scholar] [CrossRef]

- Chapiro, A. Radiation Effects in Polymers. Encycl. Mater. Sci. Technol. 2004, 1–8. [Google Scholar]