The Effect of Carbon-Based Nanofillers on Cryogenic Temperature Mechanical Properties of CFRPs

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

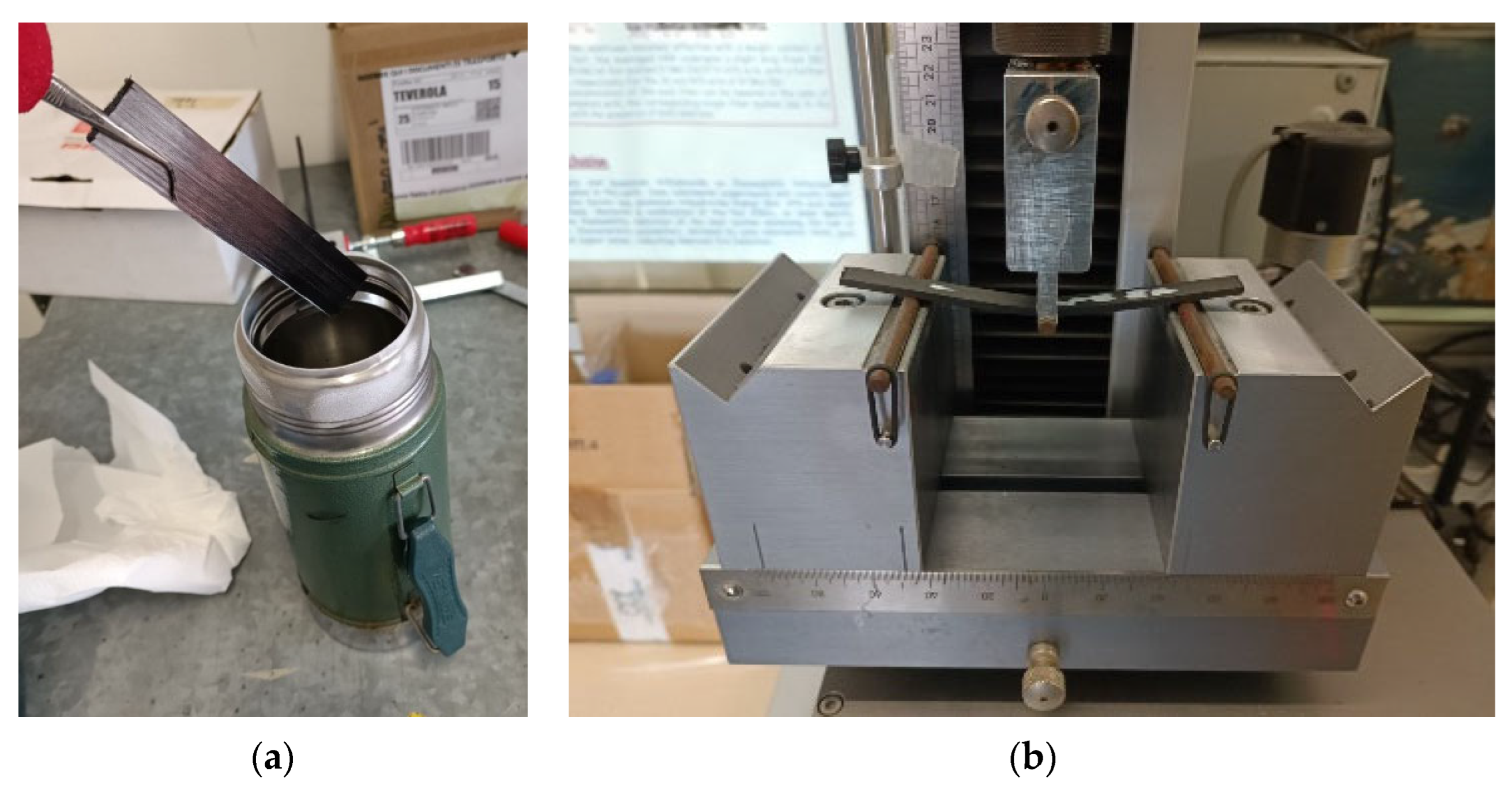

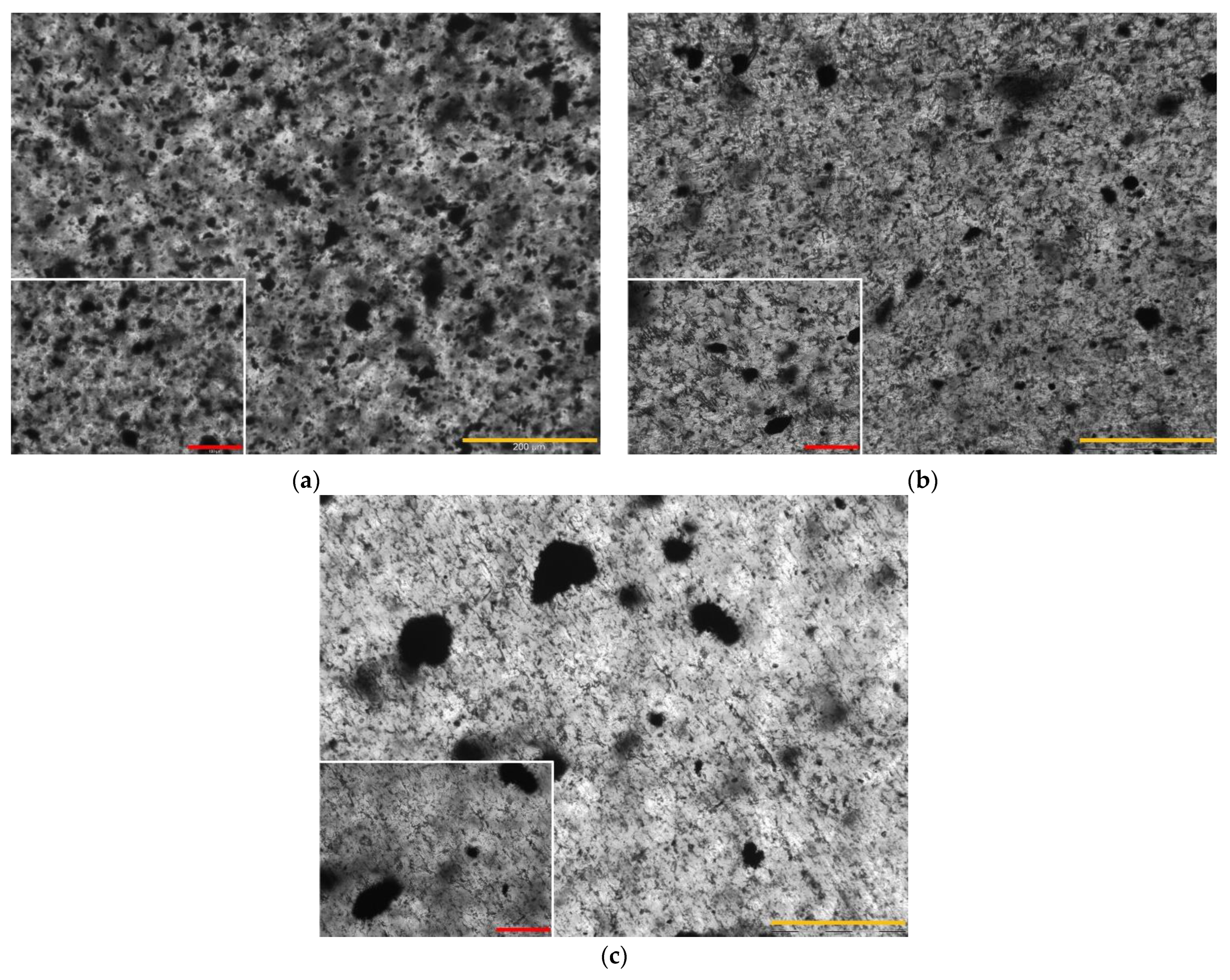

2.2. Nanocomposite and Composite Manufacturing

2.3. Experimental Characterization

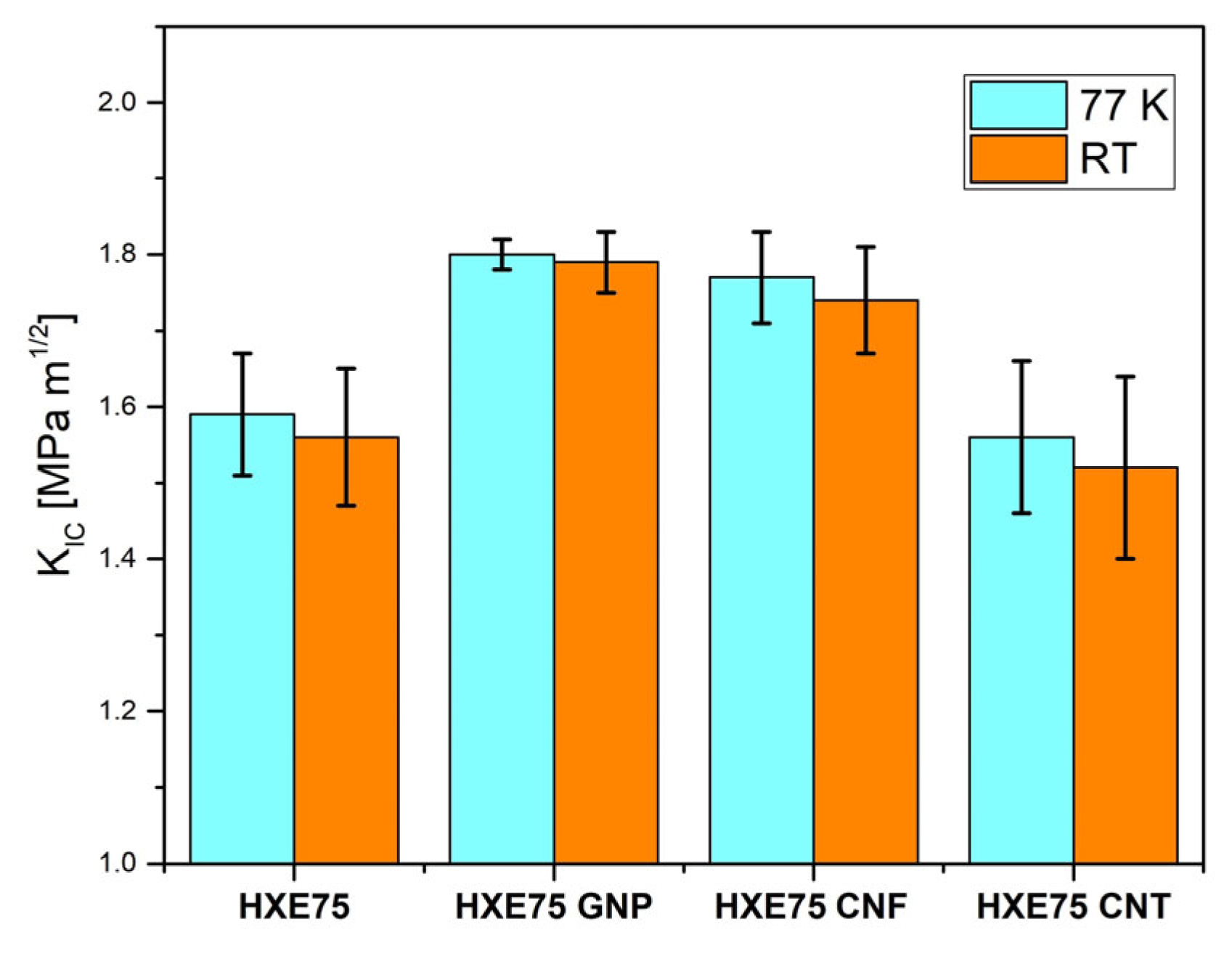

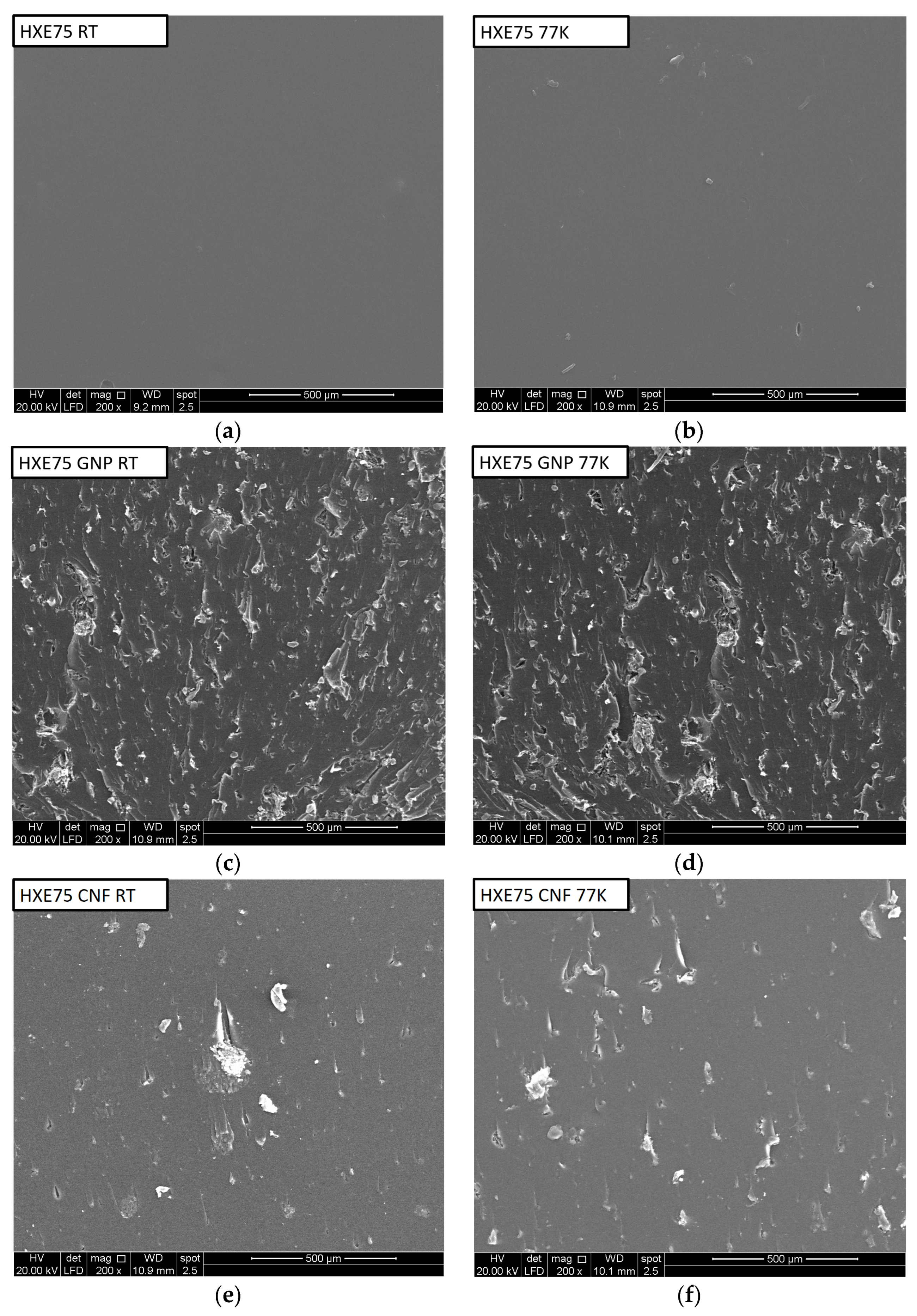

3. Results

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Soutis, C. Carbon fiber reinforced plastics in aircraft construction. Mater. Sci. Eng. A 2005, 412, 171–176. [Google Scholar] [CrossRef]

- Elmahdy, A.; Zotti, A.; Zuppolini, S.; Zarrelli, M.; Borriello, A.; Verleysen, V. Effect of Strain Rate and Silica Filler Content on the Compressive Behavior of RTM6 Epoxy-Based Nanocomposites. Polymers 2021, 13, 3735. [Google Scholar] [CrossRef]

- Friedrich, K.; Almajid, A.A. Manufacturing aspects of advanced polymer composites for automotive applications. Appl. Compos. Mater. 2013, 20, 107–128. [Google Scholar] [CrossRef]

- Garcia-Espinel, J.D.; Castro-Fresno, D.; Gayo, P.P.; Ballester-Muñoz, F. Effects of sea water environment on glass fiber reinforced plastic materials used for marine civil engineering constructions. Mater. Des. 2015, 66, 46–50. [Google Scholar] [CrossRef]

- Qian, D. Fiber-reinforced polymer composite materials with high specific strength and excellent solid particle erosion resistance. Wear 2010, 268, 637–642. [Google Scholar] [CrossRef]

- Ning, Z.; Liu, R.; El Hajjar, R.F.; Wang, F. Micro-modeling of thermal properties in carbon fibers reinforced polymer composites with fiber breaks or delamination. Compos. Part B Eng. 2017, 114, 247–255. [Google Scholar] [CrossRef]

- Liu, L.; Jia, C.; He, J. Interfacial characterization, control and modification of carbon fiber reinforced polymer composites. Compos. Sci. Technol. 2015, 121, 56–72. [Google Scholar] [CrossRef]

- Zotti, A.; Borriello, A.; Ricciardi, M.; Antonucci, V.; Giordano, M.; Zarrelli, M. Effects of sepiolite clay on degradation and fire behaviour of a bisphenol A-based epoxy. Compos. Part B Eng. 2015, 73, 139–148. [Google Scholar] [CrossRef]

- Kaw, A.K. Mechanics of Composite Materials, 2nd ed.; CRC Press: Boca Raton, FL, USA, November 2005. [Google Scholar]

- Xian, G.; Guo, R.; Li, C. Combined effects of sustained bending loading, water immersion and fiber hybrid mode on the mechanical properties of carbon/glass fiber reinforced polymer composite. Compos. Struct. 2022, 281, 115060. [Google Scholar] [CrossRef]

- Timmerman, J.F.; Tillman, M.S.; Hayes, B.S.; Seferis, J.C. Matrix and fiber influences on the cryogenic microcracking of carbon fiber/epoxy composites. Compos. Part A Appl. Sci. Manuf. 2002, 33, 323–329. [Google Scholar] [CrossRef]

- Sápi, Z.; Butler, R. Properties of cryogenic and low temperature composite materials—A review. Cryogenics 2020, 111, 103190. [Google Scholar] [CrossRef]

- Hung, P.Y.; Lau, K.T.; Fox, B.; Hameed, N.; Jia, B.; Lee, J.H. Effect of graphene oxide concentration on the flexural properties of CFRP at low temperature. Carbon 2019, 152, 556–564. [Google Scholar] [CrossRef]

- Yang, L.; Li, Z.; Xu, H.; Wu, Z. Prediction on Residual Stresses of Carbon/Epoxy Composite at Cryogenic Temperature. Polym. Compos. 2019, 40, 3369–3786. [Google Scholar] [CrossRef]

- Ward, I.M.; Sweeney, J. Mechanical Properties of Solid Polymers, 3rd ed.; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2013. [Google Scholar]

- Zhao, Y.; Chen, Z.K.; Liu, Y.; Xiao, H.M.; Feng, Q.P.; Fu, S.Y. Simultaneously enhanced cryogenic tensile strength and fracture toughness of epoxy resins by carboxylic nitrile-butadiene nano-rubber. Compos. Part A Appl. Sci. Manuf. 2013, 55, 178–187. [Google Scholar] [CrossRef]

- Zhang, Y.; Xu, F.; Zhang, C.; Wang, J.; Jia, Z.; Hui, D. Tensile and interfacial properties of polyacrylonitrile-based carbon fiber after different cryogenic treated condition. Compos. Part B Eng. 2016, 99, 358–365. [Google Scholar] [CrossRef]

- Shi, H.Q.; Sun, B.G.; Liu, Q.; Yang, Z.Y.; Zhang, Y. Properties of cryogenic Epoxy Resin Matrix Composites prepared by RTM Process. In Proceedings of the 20th International Conference on Composite Materials, Copenhagen, Denmark, 19–24 July 2015. [Google Scholar]

- Qu, C.B.; Huang, Y.; Li, F. Enhanced cryogenic mechanical properties of carbon fiber reinforced epoxy composites by introducing graphene oxide. Compos. Commun. 2020, 22, 100480. [Google Scholar] [CrossRef]

- Zotti, A.; Zuppolini, S.; Borriello, A.; Trinchillo, L.; Vinti, V.; Zarrelli, M. Hierarchical aerospace epoxy composites of carbon fiber and hyperbranched filler: Toughening behavior from nanocomposites to composites. Compos. Struct. 2024, 327, 117719. [Google Scholar] [CrossRef]

- Zotti, A.; Zuppolini, S.; Borriello, A.; Zarrelli, M. Polymer nanocomposites based on Graphite Nanoplatelets and amphiphilic graphene platelets. Compos. Part B Eng. 2022, 246, 110223. [Google Scholar] [CrossRef]

- Chen, D.; Li, J.; Yuan, Y. A Review of the Polymer for Cryogenic Application: Methods, Mechanisms and Perspectives. Polymers 2021, 13, 320. [Google Scholar] [CrossRef]

- Chen, Z.K.; Yang, J.P.; Ni, Q.Q.; Fu, S.Y.; Huang, Y.G. Reinforcement of epoxy resins with multi-walled carbon nanotubes for enhancing cryogenic mechanical properties. Polymer 2009, 50, 4753–4759. [Google Scholar] [CrossRef]

- Hung, P.Y.; Lau, K.T.; Qiao, K.; Fox, B.; Hameed, N. Property enhancement of CFRP composites with different graphene oxide employment methods at a cryogenic temperature. Compos. Part A 2019, 120, 56–63. [Google Scholar] [CrossRef]

- Nobelen, M.; Hayes, B.S.; Seferis, J.C. Influence of elastomer distribution on the cryogenic microcracking of carbon fiber/epoxy composites. J. Appl. Polym. Sci. 2003, 90, 2268–2275. [Google Scholar] [CrossRef]

- Di Cosmo, A.; D’andrea, B.; Vinti, V. Polymeric Formulations with Chemically Adjustable Rheology for the Manufacture of Prepregs and Articles Made of Composite Material. U.S. Patent 9217082B2, 22 December 2015. [Google Scholar]

- Zotti, A.; Zuppolini, S.; Borriello, A.; Vinti, V.; Trinchillo, L.; Borrelli, D.; Caraviello, A.; Zarrelli, M. Effect of the Mixing Technique of Graphene Nanoplatelets and Graphene Nanofibers on Fracture Toughness of Epoxy Based Nanocomposites and Composites. Polymers 2022, 14, 5105. [Google Scholar] [CrossRef] [PubMed]

- Ma, H.I.; Jia, Z.; Lau, K.; Leng, J.; Hui, D. Impact properties of glass fiber/epoxy composites at cryogenic environment. Compos. Part B 2016, 92, 210–217. [Google Scholar] [CrossRef]

- ASTM D5045; Standard Test Methods for Plane-Strain Fracture Toughness and Strain Energy Release Rate of Plastic Materials. ASTM International: West Conshohocken, PA, USA, 2022.

- ASTM D2344; Standard Test Method for Short-Beam Strength of Polymer Matrix Composite Materials and Their Laminates. ASTM International: West Conshohocken, PA, USA,, 2022.

- ASTM D790; Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials. ASTM International: West Conshohocken, PA, USA, 2017.

- Schulz, S.C.; Faiella, G.; Buschhorn, S.T.; Prado, L.A.S.A.; Giordano, M.; Schulte, K.; Bauhofer, W. Combined electrical and rheological properties of shear induced multiwall carbon nanotube agglomerates in epoxy suspensions. Eur. Polym. J. 2011, 47, 2069–2077. [Google Scholar] [CrossRef]

- Nishijima, S.; Honda, Y.; Okada, T. Application of the positron annihilation method for evaluation of organic materials for cryogenic use. Cryogenics 1995, 35, 779–781. [Google Scholar] [CrossRef]

- Zotti, A.; Zuppolini, S.; Zarrelli, M.; Borriello, A. Fracture toughening mechanisms in epoxy adhesives. In Adhesives-Applications and Properties; InTech: London, UK, 2016; Volume 1, p. 257. [Google Scholar]

- Zotti, A.; Zuppolini, S.; Tábi, T.; Grasso, M.; Ren, G.; Borriello, A.; Zarrelli, M. Effects of 1D and 2D nanofillers in basalt/poly (lactic acid) composites for additive manufacturing. Compos. Part B Eng. 2016, 153, 364–375. [Google Scholar] [CrossRef]

- Islam, M.S.; Melendez-Soto, E.; Castellanos, A.G.; Prabhakar, P. Investigation of Woven Composites as Potential Cryogenic Tank Materials. Cryogenics 2015, 72, 82–89. [Google Scholar] [CrossRef]

- Sethi, S.; Rathore, D.K.; Ray, B.C. Effects of temperature and loading speed on interface-dominated strength in fibre/polymer composites: An evaluation for in-situ environment. Mater. Des. 2015, 65, 617–625. [Google Scholar] [CrossRef]

- Takeda, T.; Shindo, Y.; Fukuzaki, T.; Narita, F. Short beam interlaminar shear behaviour and electrical resistance-based damage self-sensing of woven carbon/epoxy composite laminates in a cryogenic environment. J. Compos. Mater. 2014, 48, 119–128. [Google Scholar] [CrossRef]

- Kumar, M.S.; Sharma, N.; Ray, B.C. Microstructural and Mechanical Aspects of Carbon/Epoxy Composites at Liquid Nitrogen Temperature. J. Reinf. Plast. Compos. 2009, 28, 2013–2023. [Google Scholar] [CrossRef]

- Shukla, M.J.; Kumar, D.S.; Mahato, K.K.; Rathore, D.K.; Prusty, R.K.; Ray, B.C. A comparative study of the mechanical performance of Glass and Glass/Carbon hybrid polymer composites at different temperature environments. IOP Conf. Ser. Mater. Sci. Eng. 2015, 75, 012002. [Google Scholar]

| Sample ID | Filler Typology | Filler Content [wt%] | Carbon Fiber Reinforcement |

|---|---|---|---|

| HXE75 | - | 0 | - |

| HXE75 GNP | GNPs | 0.5 | - |

| HXE75 CNF | CNFs | 0.5 | - |

| HXE75 CNT | CNTs | 0.1 | - |

| HXE75-UD | - | 0 | T700 UD |

| HXE75 GNP-UD | GNPs | 0.5 | T700 UD |

| HXE75 CNF-UD | CNFs | 0.5 | T700 UD |

| HXE75 CNT-UD | CNTs | 0.1 | T700 UD |

| 77 K | RT | |||

|---|---|---|---|---|

| KIC [MPa m1/2] | ΔKIC [%] | KIC [MPa m1/2] | ΔKIC [%] | |

| HXE75 | 1.59 ± 0.08 | - | 1.56 ± 0.09 | - |

| HXE75 GNP | 1.80 ± 0.02 | 13.2 | 1.79 ± 0.04 | 14.7 |

| HXE75 CNF | 1.77 ± 0.06 | 11.3 | 1.74 ± 0.06 | 11.5 |

| HXE75 CNT | 1.56 ± 0.10 | −1.9 | 1.52 ± 0.11 | −2.6 |

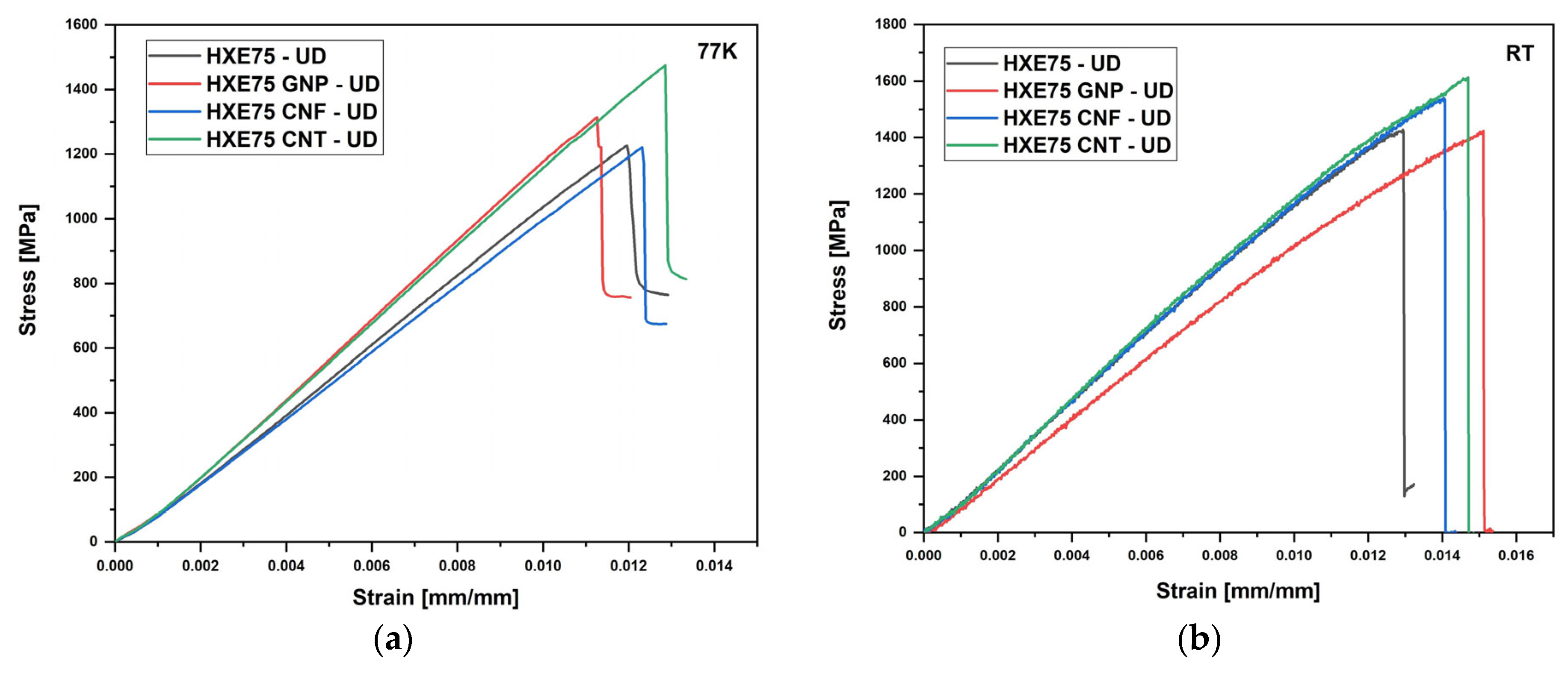

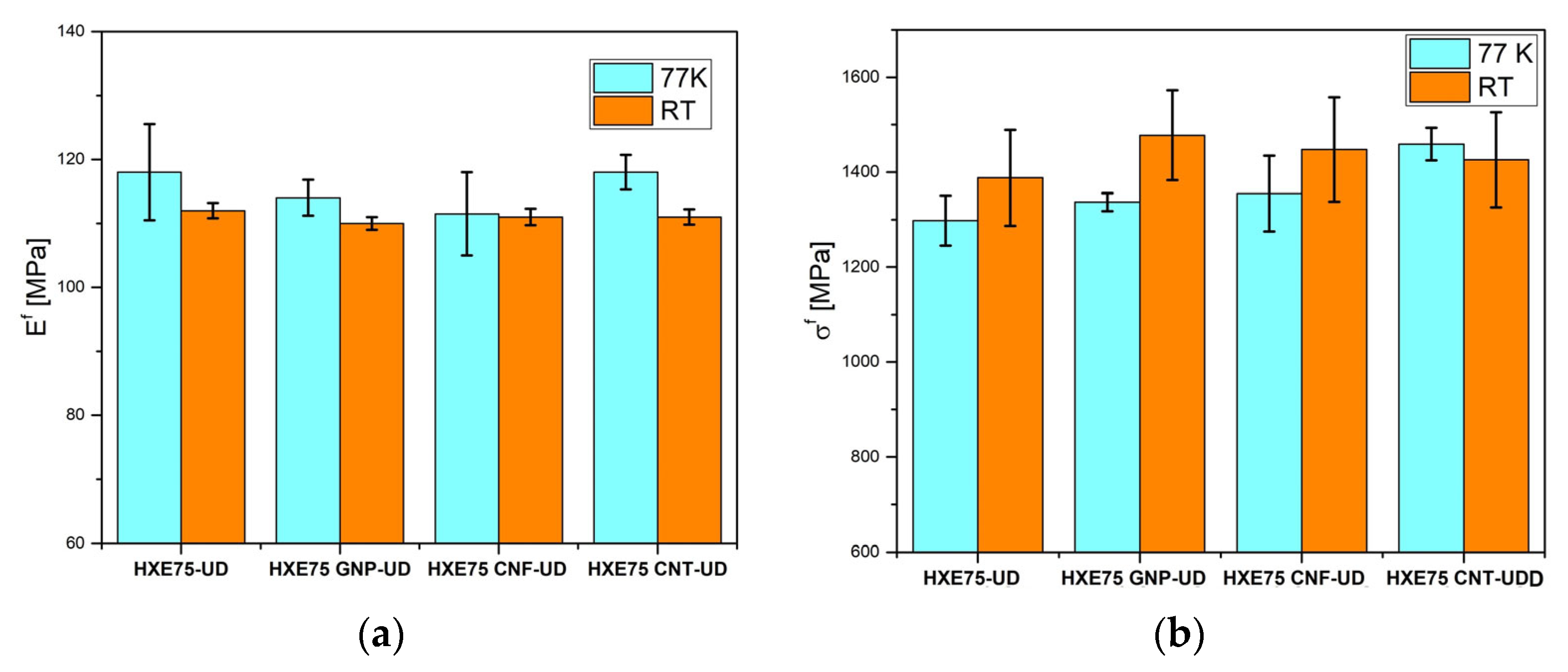

| Ef [MPa] | σf [MPa] | ILSS [MPa] | ||||

|---|---|---|---|---|---|---|

| 77 K | RT | 77 K | RT | 77 K | RT | |

| HXE75-UD | 118.3 ± 7.5 | 112 ± 1.2 | 1298 ± 53 | 1388 ± 101 | 64.4 ± 4.2 | 75.5 ± 4.5 |

| HXE75 GNP-UD | 114.1 ± 2.8 | 110 ± 1.0 | 1337 ± 19 | 1478 ± 95 | 62.0 ± 1.8 | 68.0 ± 3.2 |

| HXE75 CNF-UD | 111.5 ± 6.5 | 111 ± 1.3 | 1355 ± 80 | 1448 ± 110 | 59.9 ± 2.3 | 70.1 ± 2.4 |

| HXE75 CNT-UD | 118.2 ± 2.7 | 111 ± 1.2 | 1459 ± 34 | 1426 ± 100 | 65.6 ± 1.6 | 68.6 ± 4.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zotti, A.; Zuppolini, S.; Borriello, A.; Vinti, V.; Trinchillo, L.; Zarrelli, M. The Effect of Carbon-Based Nanofillers on Cryogenic Temperature Mechanical Properties of CFRPs. Polymers 2024, 16, 638. https://doi.org/10.3390/polym16050638

Zotti A, Zuppolini S, Borriello A, Vinti V, Trinchillo L, Zarrelli M. The Effect of Carbon-Based Nanofillers on Cryogenic Temperature Mechanical Properties of CFRPs. Polymers. 2024; 16(5):638. https://doi.org/10.3390/polym16050638

Chicago/Turabian StyleZotti, Aldobenedetto, Simona Zuppolini, Anna Borriello, Valeria Vinti, Luigi Trinchillo, and Mauro Zarrelli. 2024. "The Effect of Carbon-Based Nanofillers on Cryogenic Temperature Mechanical Properties of CFRPs" Polymers 16, no. 5: 638. https://doi.org/10.3390/polym16050638

APA StyleZotti, A., Zuppolini, S., Borriello, A., Vinti, V., Trinchillo, L., & Zarrelli, M. (2024). The Effect of Carbon-Based Nanofillers on Cryogenic Temperature Mechanical Properties of CFRPs. Polymers, 16(5), 638. https://doi.org/10.3390/polym16050638