Accelerated Weathering Testing (AWT) and Bacterial Biodegradation Effects on Poly(3-hydroxybutyrate-co-3-hydroxyvalerate) (PHBV)/Rapeseed Microfiber Biocomposites Properties

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Fiber Alkali Treatment (Mercerization)

2.3. Fiber NMMO Treatment

2.4. Preperation of Composites

2.5. Composite Characterization

2.5.1. Weathering

2.5.2. Fourier Transform Infrared Spectroscopy (FTIR)

2.5.3. Colorimetry

2.5.4. Differential Scanning Calorimetry (DSC)

2.5.5. Tensile Properties

2.5.6. Bacterial Biodegradation

3. Results and Discussion

3.1. Accelerated Weathering Impact on Properties

3.1.1. Surface Chemistry (FTIR)

3.1.2. Colorimetry

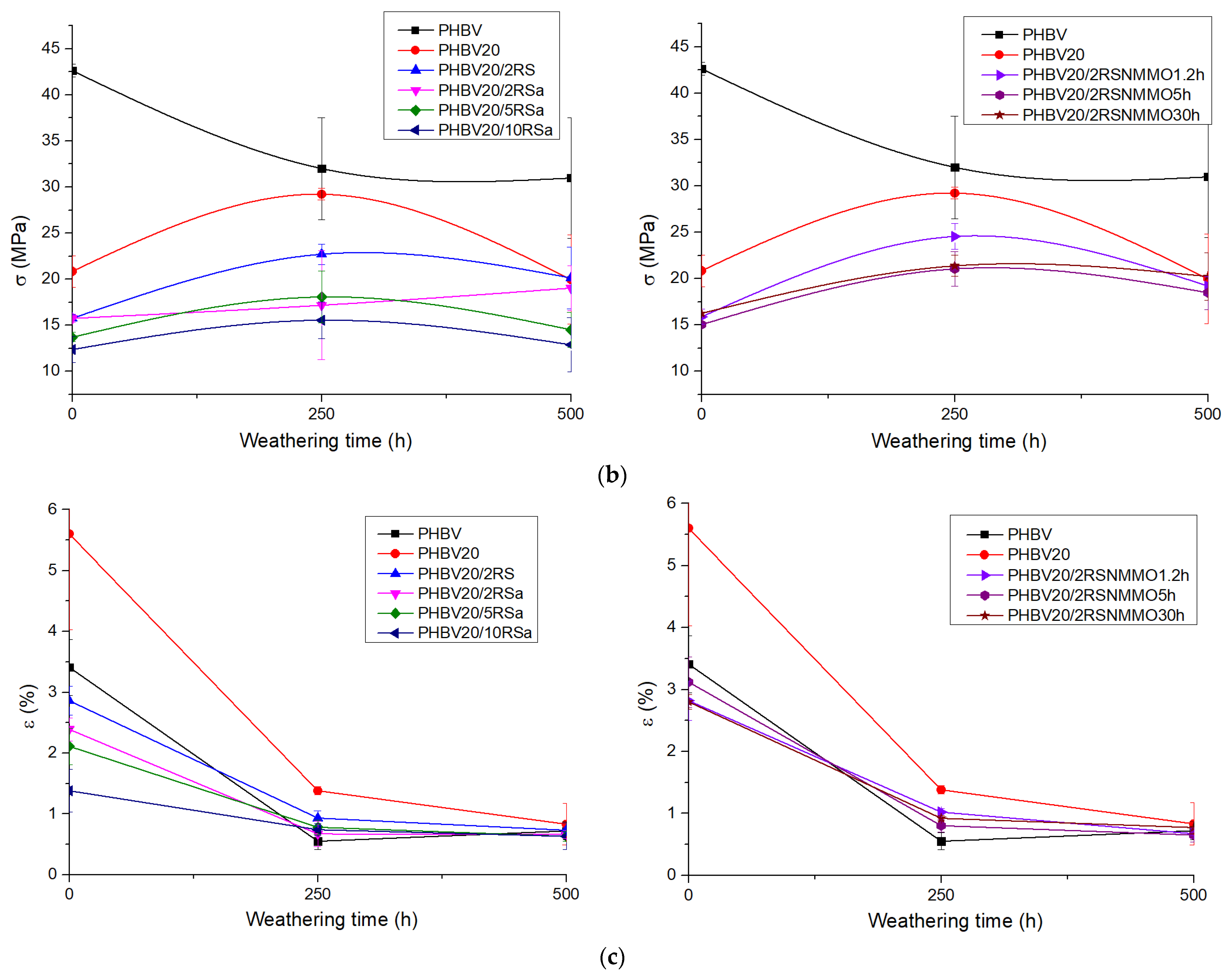

3.1.3. Thermal Properties (DSC)

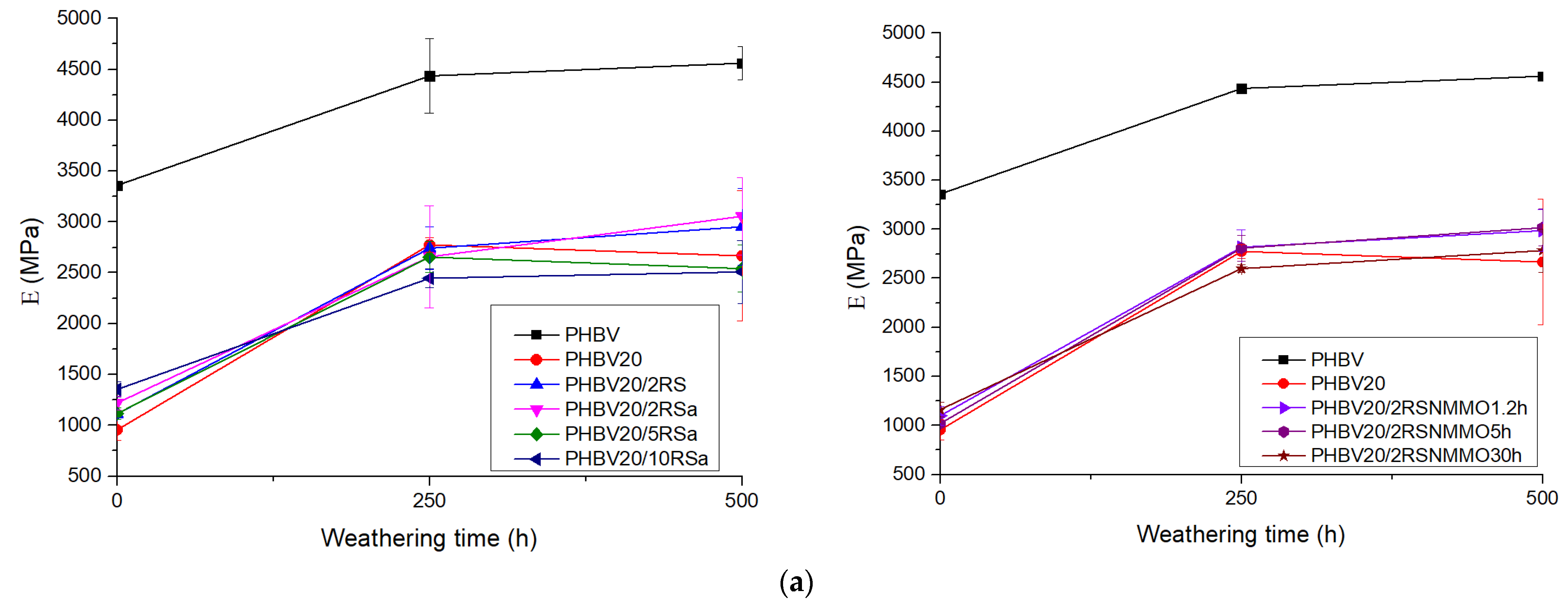

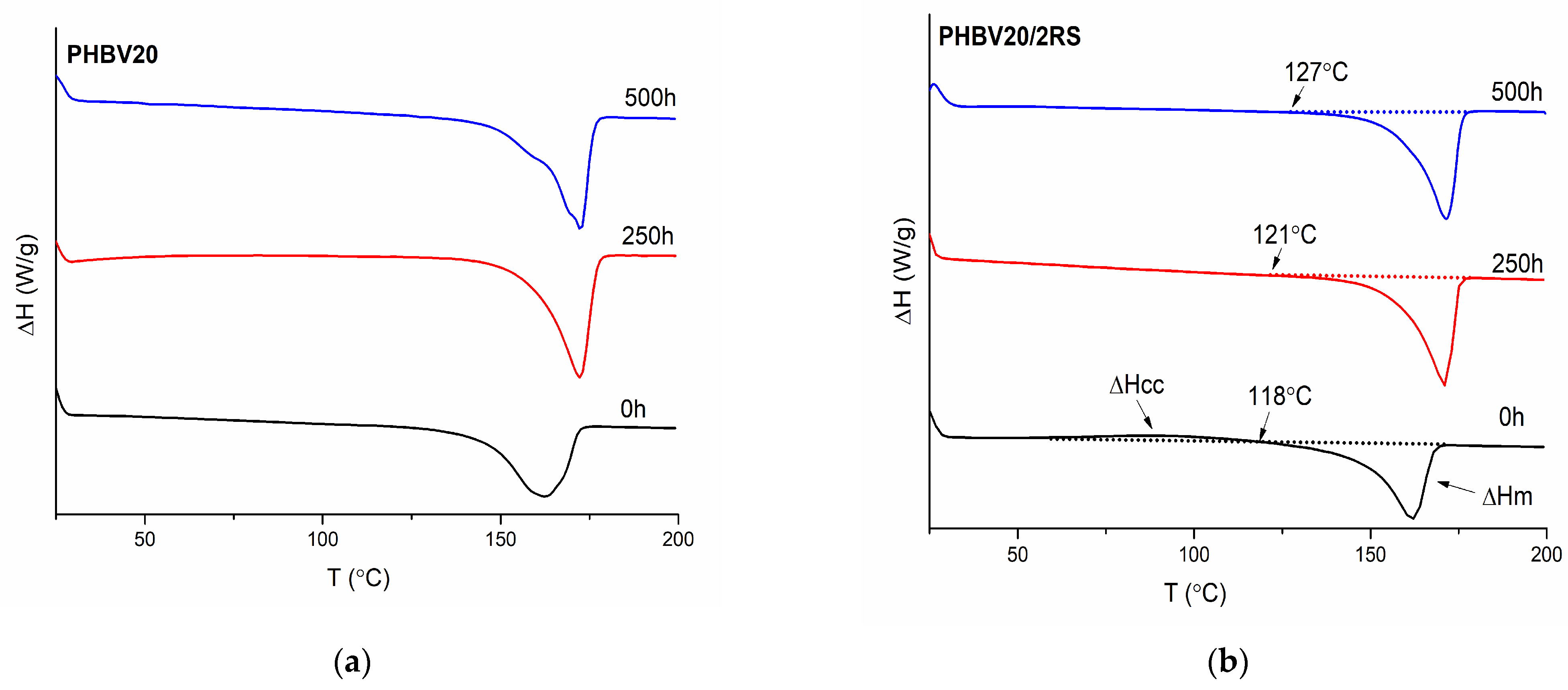

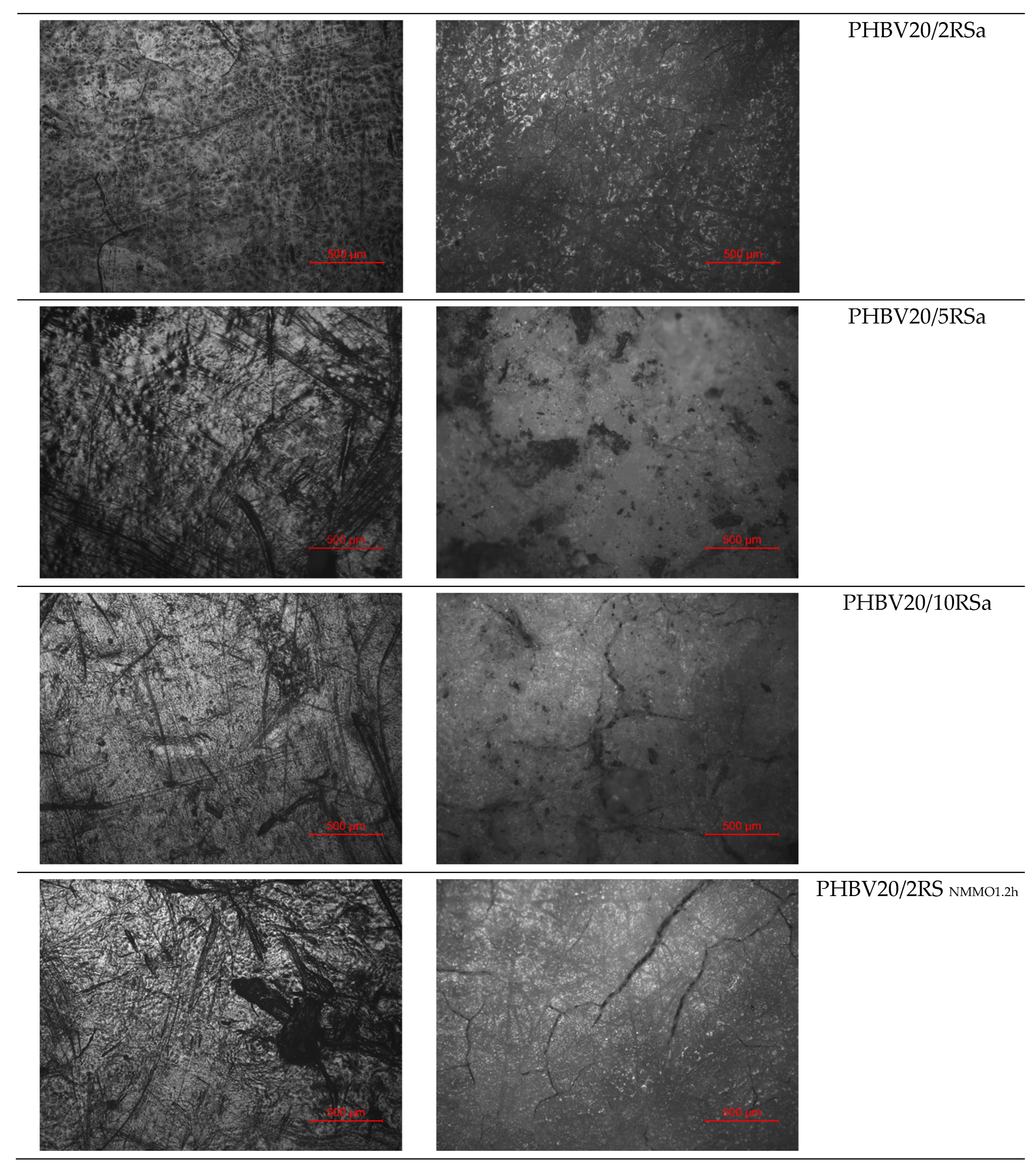

3.1.4. Tensile Properties

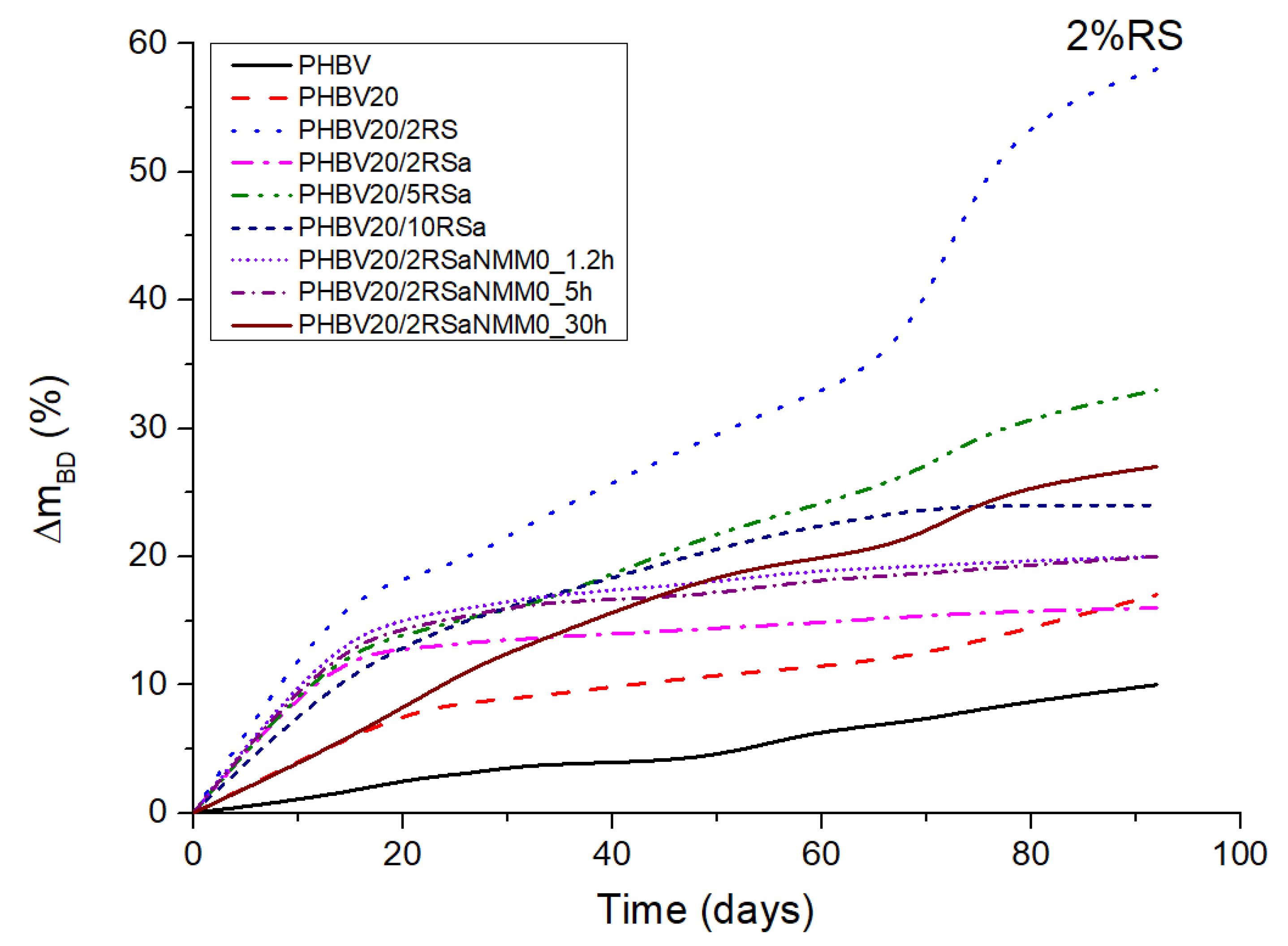

3.2. Biodegradation in Soil

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- European Parliament. How the EU Wants to Achieve a Circular Economy by 2050. 2023. Available online: https://www.europarl.europa.eu/news/en/headlines/priorities/circular-economy/20210128STO96607/how-the-eu-wants-to-achieve-a-circular-economy-by-2050 (accessed on 20 October 2023).

- Vu, D.H.; Åkesson, D.; Taherzadeh, M.J.; Ferreira, J.A. Recycling strategies for polyhydroxyalkanoate-based waste materials: An overview. Bioresour. Technol. 2020, 298, 122393. [Google Scholar] [CrossRef] [PubMed]

- Sharma, V.; Shegal, R.; Reena, G. Polyhydroxyalkanoate (PHA): Properties and Modifications. Polymers 2021, 212, 123161. [Google Scholar] [CrossRef]

- Kaniuk, Ł.; Stachewicz, U. Development and Advantages of Biodegradable PHA Polymers Based on Electrospun PHBV Fibers for Tissue Engineering and Other Biomedical Applications. ACS Biomater. Sci. Eng. 2021, 7, 5339–5362. [Google Scholar] [CrossRef] [PubMed]

- Rivera-Briso, A.L.; Serrano-Aroca, Á. Poly(3-Hydroxybutyrate-co-3-Hydroxyvalerate): Enhancement Strategies for Advanced Applications. Polymers 2018, 10, 732. [Google Scholar] [CrossRef] [PubMed]

- Zhao, X.; Lawal, T.; Rodrigues, M.M.; Geib, T.; Vodovotz, Y. Value-Added Use of Invasive Plant-Derived Fibers as PHBV Fillers for Biocomposite Development. Polymers 2021, 13, 1975. [Google Scholar] [CrossRef]

- Berthet, M.A.; Angellier-Coussy, H.; Chea, V.; Guillard, V.; Gastaldi, E.; Gontard, N. Sustainable food packaging: Valorising wheat straw fibres for tuning PHBV-based composites properties. Compos. Part A Appl. Sci. Manuf. 2015, 72, 139–147. [Google Scholar] [CrossRef]

- Umemura, R.T.; Felisberti, M.I. Plasticization of poly(3-hydroxybutyrate) with triethyl citrate: Thermal and mechanical properties, morphology, and kinetics of crystallization. J. Appl. Polym. Sci. 2021, 138, 49990. [Google Scholar] [CrossRef]

- Bertheta, M.A.; Angellier-Coussya, H.; Machadob, D.; Hillioub, L.; Staeblerc, A.; Vicented, A.; Gontard, N. Exploring the potentialities of using lignocellulosic fibres derived from three food by-products as constituents of biocomposites for food packaging. Ind. Crops Prod. 2015, 69, 110–122. [Google Scholar] [CrossRef]

- Frącz, W.; Janowski, G.; Smusz, R.; Szumski, M. The Influence of Chosen Plant Fillers in PHBV Composites on the Processing Conditions, Mechanical Properties and Quality of Molded Pieces. Polymers 2021, 13, 3934. [Google Scholar] [CrossRef] [PubMed]

- Singh, S.; Mohanty, A.K. Wood fiber reinforced bacterial bioplastic composites: Fabrication and performance evaluation. Compos. Sci. Technol. 2007, 67, 1753–1763. [Google Scholar] [CrossRef]

- Rout, A.K.; Kar, J.; Jesthi, D.K.; Sutar, A.K. Effect of Surface Treatment on the Physical, Chemical, and Mechanical Properties of Palm Tree Leaf Stalk Fibers. BioResources 2016, 11, 4432–4445. [Google Scholar] [CrossRef]

- Hashim, M.Y.; Amin, A.M.; Marwah, O.M.F.; Othman, M.H.; Yunus, M.R.M.; Chuan Huat, N. The effect of alkali treatment under various conditions on physical properties of kenaf fiber. J. Phys. Conf. Ser. 2017, 914, 1. [Google Scholar] [CrossRef]

- Norul Izani, M.A.; Paridah, M.T.; Anwar, U.M.K.; Mohd Nor, M.Y.; H’ng, P.S. Effects of fiber treatment on morphology, tensile and thermogravimetric analysis of oil palm empty fruit bunches fibers. Compos. Part B Eng. 2013, 45, 1251–1257. [Google Scholar] [CrossRef]

- Santos, E.B.C.; Moreno, C.G.; Barros, J.J.P.; de Moura, D.A.; de Carvalho Fim, F.; Ries, A.; Wellen, R.M.R.; da Silva, L.B. Effect of alkaline and hot water treatments on the structure and morphology of piassava fibers. Mater. Res. 2018, 21, 0365. [Google Scholar] [CrossRef]

- Stelte, W. Steam Explosion for Biomass Pre-Treatment; Danish Technological Institute: Taastrup, Denmark, 2013; pp. 1–15. [Google Scholar] [CrossRef]

- Merijs-Meri, R.; Zicans, J.; Ivanova, T.; Bochkov, I.; Varkale, M.; Franciszczak, P.; Bledzki, A.K.; Danilovas, P.P.; Gravitis, J.; Rubenis, K.; et al. Development and characterization of grain husks derived lignocellulose filler containing polypropylene composites. Polym. Eng. Sci. 2019, 59, 2467–2473. [Google Scholar] [CrossRef]

- Rosenau, T.; Potthast, A.; Sixta, H.; Kosma, P. The chemistry of side reactions and byproduct formation in the system NMMO/cellulose (Lyocell process). Prog. Polym. Sci. 2001, 26, 1763–1837. [Google Scholar] [CrossRef]

- Ābele, A.; Bērziņš, R.; Bērziņa, R.; Merijs-Meri, R.; Žiganova, M.; Zicāns, J. Potential uses of N-methylmorpholine N-oxide for the treatment of agricultural waste biomass. Proc. Estonian Acad. Sci. 2023, 72, 176–183. [Google Scholar] [CrossRef]

- Batista, K.C.; Silva, D.A.K.; Coelho, L.A.F.; Pezzin, S.H.; Pezzin, A.P.T. Soil Biodegradation of PHBV/Peach Palm Particles Biocomposites. J. Polym. Environ. 2010, 18, 346–354. Available online: https://link.springer.com/article/10.1007/s10924-010-0238-4 (accessed on 5 November 2023). [CrossRef]

- Wei, L.; Liang, S.; McDonald, A.G. Thermophysical properties and biodegradation behavior of green composites made from polyhydroxybutyrate and potato peel waste fermentation residue. Ind. Crops Prod. 2015, 69, 91–103. [Google Scholar] [CrossRef]

- Žiganova, M.; Merijs-Meri, R.; Zicāns, J.; Ivanova, T.; Bochkov, I.; Kalniņš, M.; Błędzki, A.K.; Danilovas, P.P. Characterisation of Nanoclay and Spelt Husk Microfiller-Modified Polypropylene Composites. Polymers 2022, 14, 4332. [Google Scholar] [CrossRef]

- Žiganova, M.; Merijs-Meri, R.; Zicāns, J.; Bochkov, I.; Ivanova, T.; Vīgants, A.; Ence, E.; Štrausa, E. Visco-Elastic and Thermal Properties of Microbiologically Synthesized Polyhydroxyalkanoate Plasticized with Triethyl Citrate. Polymers 2023, 15, 2896. [Google Scholar] [CrossRef]

- ISO 4892–3:2016; Plastics—Methods of Exposure to Laboratory Light Sources—Part 3: Fluorescent UV Lamps. International Organization for Standardization (ISO): Geneva, Switzerland, 2016.

- ASTM D 2244-02; Standard Practice for Calculation of Color Tolerances and Color Differences from Instrumentally Measured Color Coordinates. ASTM: West Conshohocken, PA, USA, 2002.

- Stanley, A.; Murthy, P.S.K.; Vijayendra, S.V.N. Characterization of Polyhydroxyalkanoate Produced by Halomonas venusta KT832796. J. Polym. Environ. 2020, 28, 973–983. Available online: https://link.springer.com/article/10.1007/s10924-020-01662-6 (accessed on 5 September 2023). [CrossRef]

- EN ISO 527; Plastics—Determination of Tensile Properties—Part 1: General Principles (ISO 527-1:2019). International Organization for Standardization (ISO): Geneva, Switzerland, 2019.

- Nabels-Sneiders, M.; Platnieks, O.; Grase, L.; Gaidukovs, S. Lamination of Cast Hemp Paper with Bio-Based Plastics for Sustainable Packaging: Structure-Thermomechanical Properties Relationship and Biodegradation Studies. J. Compos. Sci. 2022, 6, 246. [Google Scholar] [CrossRef]

- Kann, Y.; Shurgalin, M.; Krishnaswamy, R.K. FTIR Spectroscopy for Analysis of Crystallinity of Poly(3-hydroxybutyrate-co-4 -hydroxybutyrate) Polymers and Its Utilization in Evaluation of Aging, Orientation and Composition. Polym. Test. 2014, 40, 218–224. [Google Scholar] [CrossRef]

- Antunes, A.; Popelka, A.; Aljarod, O.; Hassan, M.K.; Kasak, P.; Luyt, A.S. Accelerated Weathering Effects on Poly(3-hydroxybutyrate-co-3-hydroxyvalerate) (PHBV) and PHBV/TiO2 Nanocomposites. Polymers 2020, 12, 1743. [Google Scholar] [CrossRef]

- Iggui, K.; Kaci, M.; Le Moigne, N.; Bergeret, A. Effects of hygrothermal aging on chemical, physical, and mechanical properties of poly(3-hydroxybutyrate-co-3-hydroxyvalerate)/Cloisite 30B bionanocomposite. Polym. Compos. 2021, 42, 1878–1890. [Google Scholar] [CrossRef]

- Tor-Świątek, A.; Garbacz, T. Effect of Abiotic Degradation on the Colorimetric Analysis, Mechanical Properties and Morphology of PLA Composites with Linen Fibers. Adv. Sci. Technol. Res. J. 2021, 15, 99–109. [Google Scholar] [CrossRef]

- Czerniecka-Kubicka, A.; Frącz, W.; Jasiorski, M.; Pilch-Pitera, B.; Pyda, M.; Zarzyka, I. Thermal Properties of poly(3-hydroxybutyrate) Modified by Nanoclay. J. Therm. Anal. Calorim. 2017, 128, 1513–1526. Available online: https://link.springer.com/article/10.1007/s10973-016-6039-9 (accessed on 13 January 2024). [CrossRef]

- Lee, S.Y. Plastic bacteria? Progress and prospects for polyhydroxyalkanoate production in bacteria. Trends Biotechnol. 1996, 14, 431–438. [Google Scholar] [CrossRef]

- Boopathy, R. Factors limiting bioremediation technologies. Bioresour. Technol. 2000, 74, 63–67. [Google Scholar] [CrossRef]

| Code | PHBV (wt %) | RS (wt %) | RSa (wt %) | RSNMMO (h) | TEC (wt %) |

|---|---|---|---|---|---|

| PHBV | 100 | − | − | − | 0 |

| PHBV20 | 80 | − | − | − | 20 |

| PHBV20/2RS | 78 | 2 | − | − | 20 |

| PHBV20/2RSa | 78 | − | 2 | − | 20 |

| PHBV20/5RSa | 75 | − | 5 | − | 20 |

| PHBV20/10RSa | 70 | − | 10 | − | 20 |

| PHBV20/2RSNMMO1.2h | 78 | − | − | 1 h 20 min | 20 |

| PHBV20/2RSNMMO5h | 78 | − | − | 5 h | 20 |

| PHBV20/2RSNMMO30h | 78 | − | − | 30 h | 20 |

| Code | Carbonyl Index I1718/1379 | Crystallinity Index I1718/1735 | Crystallinity Index I1225/1180 |

|---|---|---|---|

| PHBV 0 h | 3.3 | 3.4 | 1.3 |

| PHBV 250 h | 3.3 | 3.1 | 1.2 |

| PHBV 500 h | 3.2 | 3.1 | 1.2 |

| PHBV20 0 h | 3.8 | 3.3 | 1.0 |

| PHBV20 250 h | 3.6 | 3.4 | 1.3 |

| PHBV20 500 h | 3.2 | 3.2 | 1.2 |

| PHBV20/2RS 0 h | 3.5 | 2.6 | 0.9 |

| PHBV20/2RS 250 h | 3.0 | 3.2 | 1.2 |

| PHBV20/2RS 500 h | 3.0 | 3.1 | 1.2 |

| PHBV20/2RSa 0 h | 4.2 | 3.0 | 0.8 |

| PHBV20/2RSa 250 h | 3.1 | 3.2 | 1.2 |

| PHBV20/2RSa 500 h | 2.6 | 2.9 | 1.1 |

| PHBV20/5RSa 0 h | 4.3 | 3.1 | 0.8 |

| PHBV20/5RSa 250 h | 3.0 | 3.2 | 1.1 |

| PHBV20/5RSa 500 h | 3.0 | 3.2 | 1.2 |

| PHBV20/10RSa 0 h | 4.0 | 2.9 | 0.9 |

| PHBV20/10RSa 250 h | 3.3 | 3.3 | 1.2 |

| PHBV20/10RSa 500 h | 3.1 | 3.2 | 1.1 |

| PHBV20/2RSNMMO1.2h 0 h | 4.2 | 3.0 | 0.8 |

| PHBV20/2RSNMMO1.2h 250 h | 3.3 | 3.0 | 1.2 |

| PHBV20/2RSNMMO1.2h 500 h | 3.4 | 3.5 | 1.2 |

| PHBV20/2RSNMMO5h 0 h | 4.3 | 2.9 | 0.8 |

| PHBV20/2RSNMMO5h 250 h | 3.0 | 3.3 | 1.1 |

| PHBV20/2RSNMMO5h 500 h | 3.0 | 2.9 | 1.2 |

| PHBV + 20/2RSNMMO30h 0 h | 3.9 | 3.7 | 0.8 |

| PHBV20/2RSNMMO30h 250 h | 3.4 | 3.4 | 1.2 |

| PHBV20/2RSNMMO30h 500 h | 2.4 | 2.6 | 1.1 |

| Sample Code |  |

|---|---|

| PHBV |  |

| PHBV20 |  |

| PHBV20/2RS |  |

| PHBV20/2RSa |  |

| PHBV20/5RSa |  |

| PHBV20/10RSa |  |

| PHBV20/2RSNMMO1.2h |  |

| PHBV20/2RSNMMO5h |  |

| PHBV20/2RSNMMO30h |  |

| Calorimetric Parameter– Aging Time | Tcc | Tm | χ, % | ||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Sample Code | 0 h | 250 h | 500 h | 0 h | 250 h | 500 h | 0 h | 250 h | 500 h | ||||||||||||||||||||||||||||

| PHBV | - | - | - | 175 | 175 | 172 | 64 | 55 | 55 | ||||||||||||||||||||||||||||

| PHBV20 | - | - | - | 163 | 172 | 173 | 57 | 63 | 63 | ||||||||||||||||||||||||||||

| PHBV20/2RS | 90 | - | - | 162 | 171 | 171 | 54 | 65 | 71 | ||||||||||||||||||||||||||||

| PHBV20/2RSa | 91 | - | - | 162 | 172 | 171 | 55 | 68 | 67 | ||||||||||||||||||||||||||||

| PHBV20/5RSa | 91 | - | - | 167 | 175 | 172 | 47 | 70 | 66 | ||||||||||||||||||||||||||||

| PHBV20/10RSa | 91 | - | - | 165 | 172 | 172 | 47 | 70 | 75 | ||||||||||||||||||||||||||||

| PHBV20/2RSNMMO1.2h | 99 | - | - | 165 | 171 | 173 | 47 | 69 | 69 | ||||||||||||||||||||||||||||

| PHBV20/2RSNMMO5h | 102 | - | - | 164 | 170 | 174 | 42 | 68 | 70 | ||||||||||||||||||||||||||||

| PHBV20/2RSNMMO30h | 104 | - | - | 168 | 176 | 172 | 52 | 67 | 69 | ||||||||||||||||||||||||||||

| (Cooling) | |||||||||||||||||||||||||||||||||||||

| Calorimetric Parameter– Aging Time | Tm | χ, % | |||||||||||||||||||||||||||||||||||

| Sample Code | 0 h | 250 h | 500 h | 0 h | 250 h | 500 h | |||||||||||||||||||||||||||||||

| PHBV | 83 | 89 | 91 | 47 | 46 | 38 | |||||||||||||||||||||||||||||||

| PHBV20 | 75 | 82 | 73 | 44 | 50 | 47 | |||||||||||||||||||||||||||||||

| PHBV20/2RS | 76 | 85 | 82 | 45 | 54 | 59 | |||||||||||||||||||||||||||||||

| PHBV20/2RSa | 74 | 87 | 77 | 45 | 56 | 56 | |||||||||||||||||||||||||||||||

| PHBV20/5RSa | 74 | 91 | 88 | 44 | 58 | 59 | |||||||||||||||||||||||||||||||

| PHBV20/10RSa | 77 | 92 | 92 | 47 | 61 | 63 | |||||||||||||||||||||||||||||||

| PHBV20/2RSNMMO1.2h | 73 | 88 | 82 | 44 | 77 | 59 | |||||||||||||||||||||||||||||||

| PHBV20/2RSNMMO5h | 71 | 86 | 77 | 41 | 55 | 57 | |||||||||||||||||||||||||||||||

| PHBV20/2RSNMMO30h | 70 | 89 | 81 | 44 | 56 | 59 | |||||||||||||||||||||||||||||||

| (second heating run) | |||||||||||||||||||||||||||||||||||||

| Calorimetric Parameter–Aging Time | Tcc | Tm1 | Tm2 | χ, % | |||||||||||||||||||||||||||||||||

| Sample Code | 0 h | 250 h | 500 h | 0 h | 250 h | 500 h | 0 h | 250 h | 500 h | 0 h | 250 h | 500 h | |||||||||||||||||||||||||

| PHBV | 95 | 103 | 99 | 167 | 168 | 166 | 172 | 174 | 172 | 56 | 48 | 49 | |||||||||||||||||||||||||

| PHBV20 | 91 | 92 | 91 | 154 | 164 | 156 | 165 | 172 | 168 | 58 | 57 | 52 | |||||||||||||||||||||||||

| PHBV20/2RS | 90 | 97 | 96 | 154 | 163 | 162 | 165 | 171 | 171 | 54 | 52 | 58 | |||||||||||||||||||||||||

| PHBV20/2RSa | 91 | 97 | 90 | 155 | 162 | 160 | 166 | 171 | 170 | 55 | 57 | 57 | |||||||||||||||||||||||||

| PHBV20/5RSa | 94 | 100 | 97 | 154 | 166 | 164 | 165 | 172 | 171 | 44 | 62 | 58 | |||||||||||||||||||||||||

| PHBV20/10RSa | 95 | 97 | 100 | 155 | 165 | 165 | 165 | 171 | 171 | 49 | 66 | 62 | |||||||||||||||||||||||||

| PHBV20/2RSNMMO1.2h | 90 | 97 | 94 | 154 | 164 | 163 | 165 | 171 | 170 | 53 | 67 | 64 | |||||||||||||||||||||||||

| PHBV20/2RSNMMO5h | 91 | 101 | 91 | 153 | 163 | 161 | 165 | 171 | 170 | 49 | 55 | 59 | |||||||||||||||||||||||||

| PHBV20/2RSNMMO30h | 94 | 94 | 93 | 154 | 165 | 162 | 165 | 171 | 170 | 50 | 65 | 65 | |||||||||||||||||||||||||

| Sample Code | Time (Days) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 0 | 13 | 21 | 27 | 33 | 49 | 58 | 69 | 76 | 92 | |

| PHBV |  | |||||||||

| PHBV20 | ||||||||||

| PHBV20/2RS | ||||||||||

| PHBV20/2RSa | ||||||||||

| PHBV20/5RSa | ||||||||||

| PHBV20/10RSa | ||||||||||

| PHBV20/2RSNMM0_1.2h | ||||||||||

| PHBV20/2RSNMM0_5h | ||||||||||

| PHBV20/2RSNMM0_30h | ||||||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Žiganova, M.; Merijs-Meri, R.; Zicāns, J.; Ābele, A.; Bochkov, I.; Ivanova, T. Accelerated Weathering Testing (AWT) and Bacterial Biodegradation Effects on Poly(3-hydroxybutyrate-co-3-hydroxyvalerate) (PHBV)/Rapeseed Microfiber Biocomposites Properties. Polymers 2024, 16, 622. https://doi.org/10.3390/polym16050622

Žiganova M, Merijs-Meri R, Zicāns J, Ābele A, Bochkov I, Ivanova T. Accelerated Weathering Testing (AWT) and Bacterial Biodegradation Effects on Poly(3-hydroxybutyrate-co-3-hydroxyvalerate) (PHBV)/Rapeseed Microfiber Biocomposites Properties. Polymers. 2024; 16(5):622. https://doi.org/10.3390/polym16050622

Chicago/Turabian StyleŽiganova, Madara, Remo Merijs-Meri, Jānis Zicāns, Agnese Ābele, Ivan Bochkov, and Tatjana Ivanova. 2024. "Accelerated Weathering Testing (AWT) and Bacterial Biodegradation Effects on Poly(3-hydroxybutyrate-co-3-hydroxyvalerate) (PHBV)/Rapeseed Microfiber Biocomposites Properties" Polymers 16, no. 5: 622. https://doi.org/10.3390/polym16050622

APA StyleŽiganova, M., Merijs-Meri, R., Zicāns, J., Ābele, A., Bochkov, I., & Ivanova, T. (2024). Accelerated Weathering Testing (AWT) and Bacterial Biodegradation Effects on Poly(3-hydroxybutyrate-co-3-hydroxyvalerate) (PHBV)/Rapeseed Microfiber Biocomposites Properties. Polymers, 16(5), 622. https://doi.org/10.3390/polym16050622