Enhancing Mechanical Performance of High-Lignin-Filled Polypropylene via Reactive Extrusion

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of PP/Lignin Blends

2.3. Characterization

2.3.1. Scanning Electron Microscopy (SEM) Observations

2.3.2. Mechanical Tests

2.3.3. Density and Melt Flow Index (MFI)

2.3.4. Heat Deflection Temperature (HDT)

2.3.5. Thermal Analysis

2.3.6. Rheological Test

3. Results and Discussion

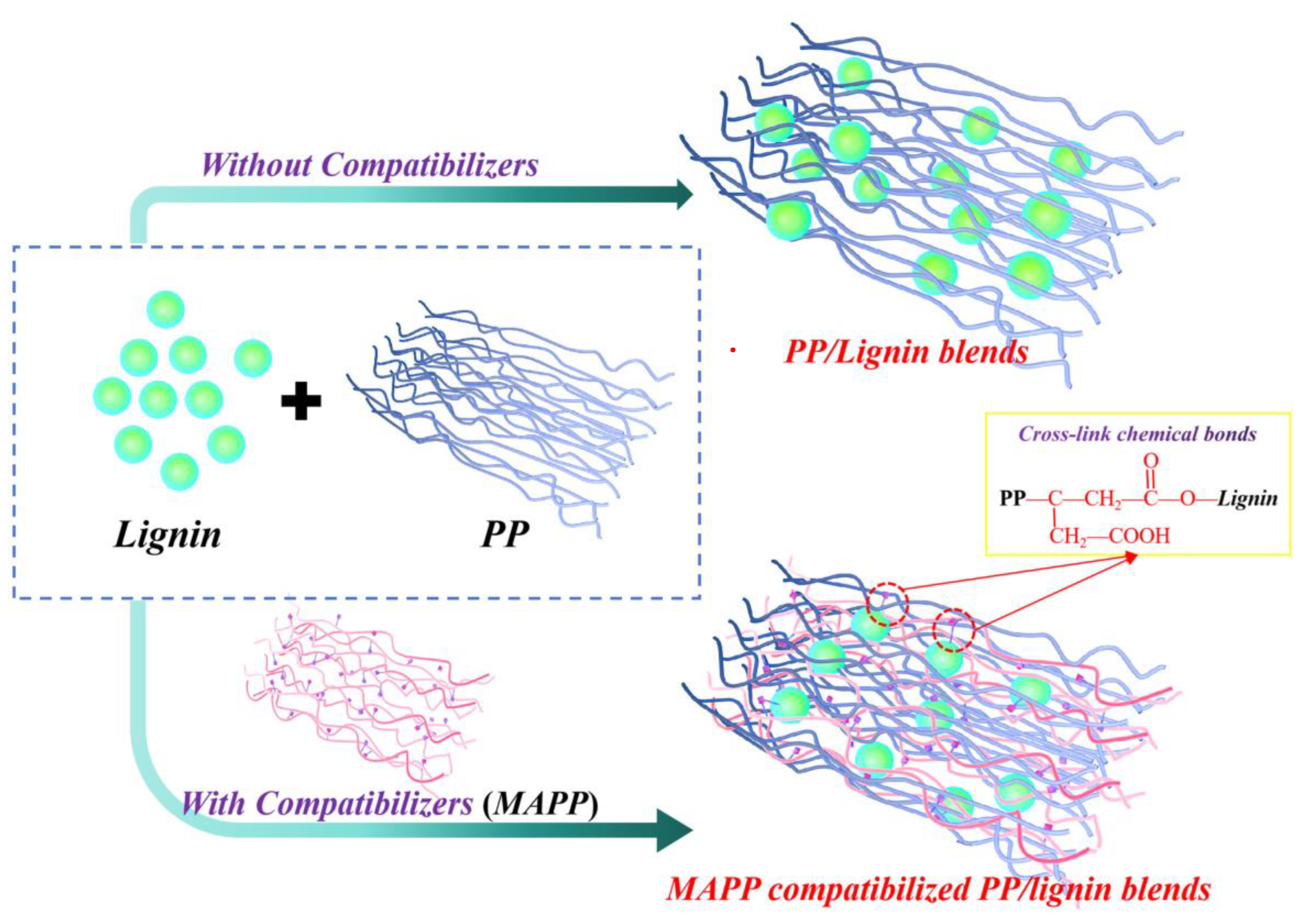

3.1. Morphological Observations

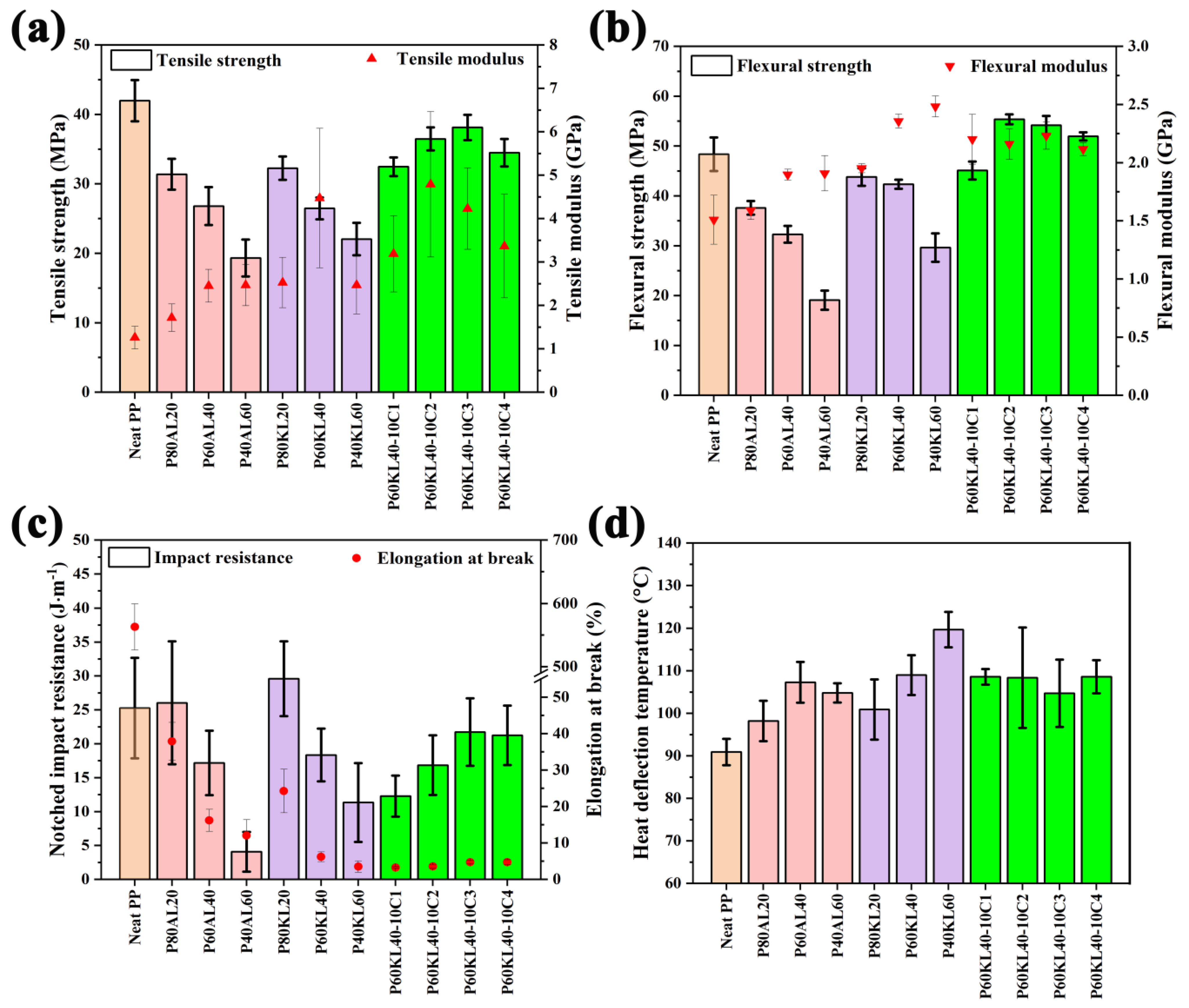

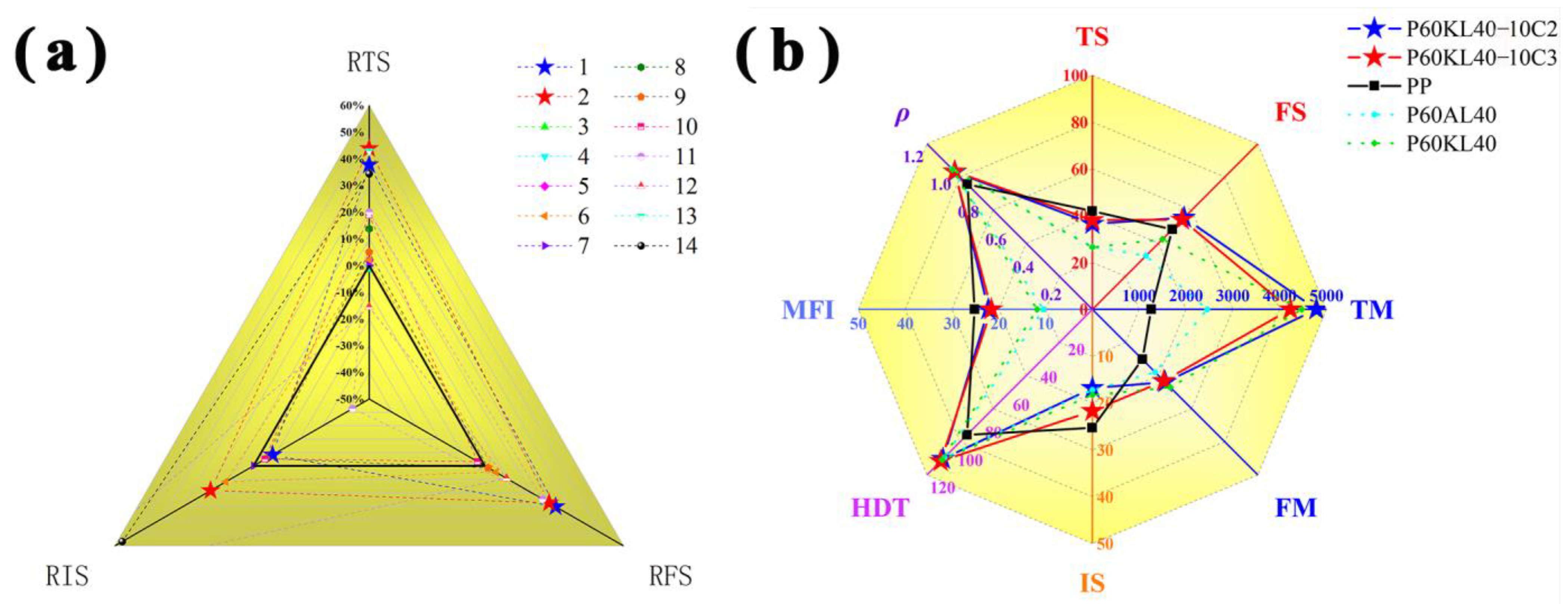

3.2. Mechanical Properties

3.3. Thermal Analysis

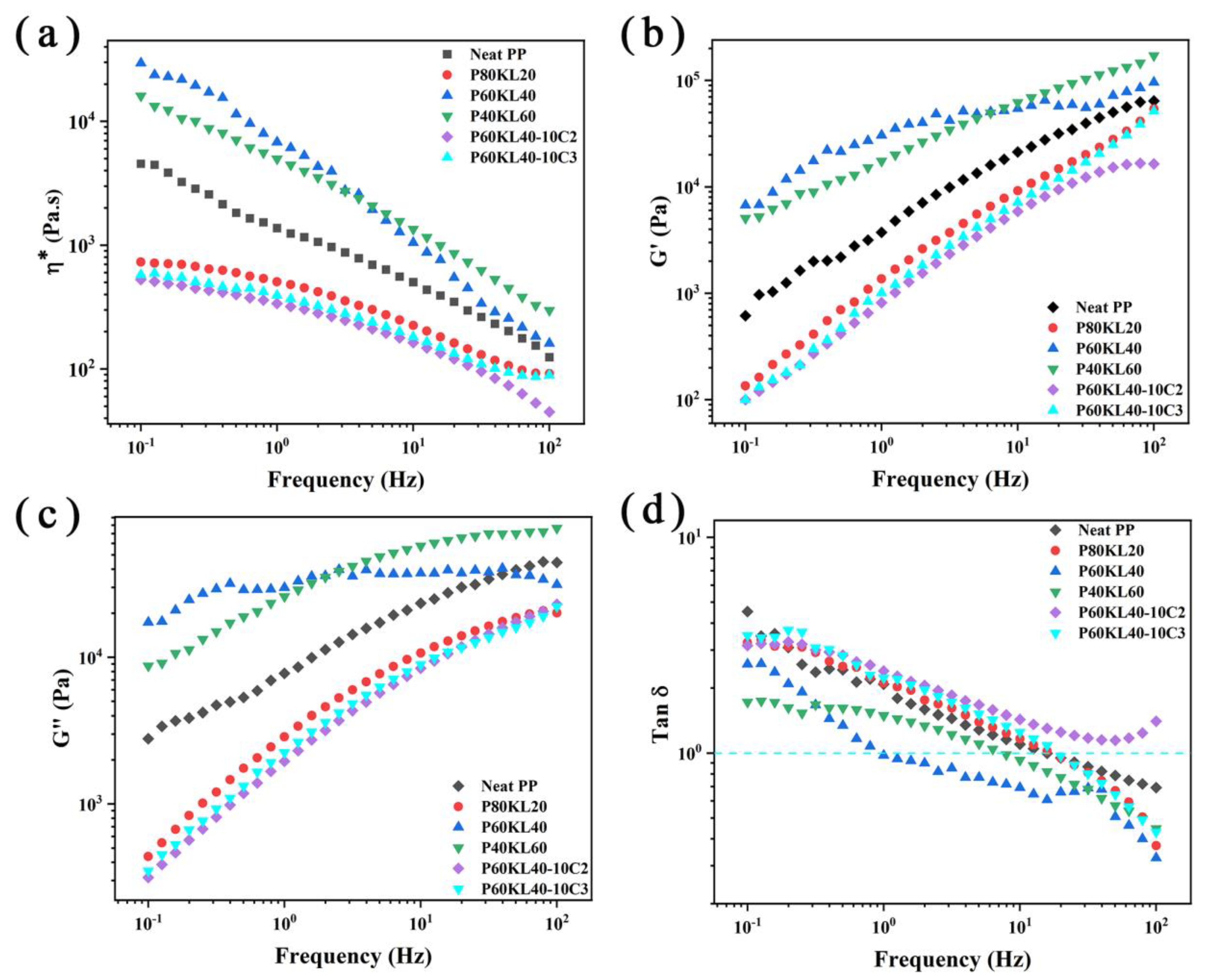

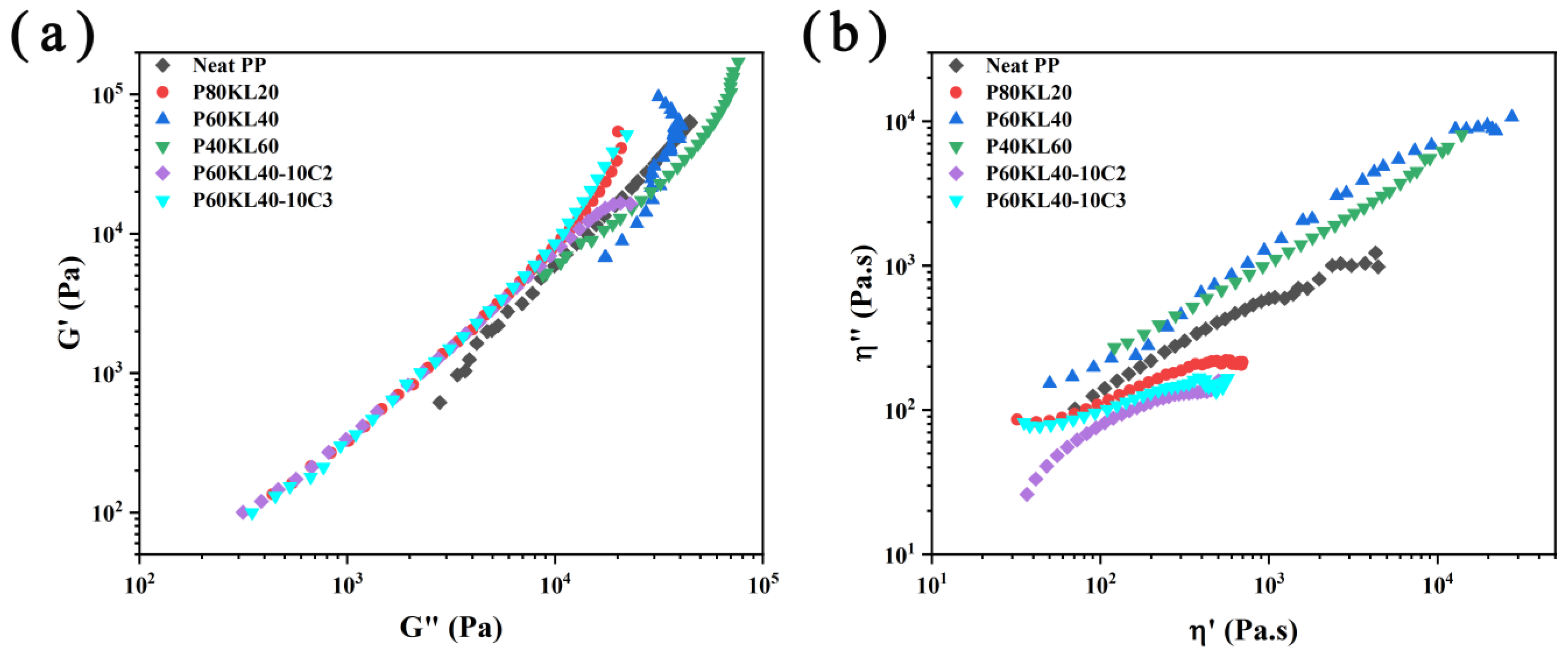

3.4. Rheological Characterization

3.5. Comparative Analysis of Research

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Tolinski, M. Additives for Polyolefins Getting the Most out of Polypropylene, Polyethylene and TPO, 2nd ed.; Elsevier: Oxford, UK, 2015; pp. 8–16. [Google Scholar]

- Talarico, G.; De Rosa, C.; Auriemma, F. Polypropylene Handbook: Morphology, Blends and Composites, 1st ed.; Springer: Cham, Switzerland, 2019; pp. 1–35. [Google Scholar]

- Company, T.B.R. Propylene-Petrochemicals Global Market Report 2023. 2023. Available online: https://www.thebusinessresearchcompany.com/report/propylene-petrochemicals-global-market-report (accessed on 25 September 2023).

- Stegmann, P.; Daioglou, V.; Londo, M.; van Vuuren, D.P.; Junginger, M. Plastic futures and their CO2 emissions. Nature 2022, 612, 272–276. [Google Scholar] [CrossRef]

- Edmonton. Plastic—What the Numbers Mean, How Many Times They Are Recycled, and What They Are Recycled into. 2021. Available online: https://earthwarriorlifestyle.com/blogs/news/plastic-recycling (accessed on 20 January 2024).

- Ojima, D.S.; Melillo, J.M. Looking Beyond Stockholm+ 50. Bull. Ecol. Soc. Am. 2022, 103, 1–3. [Google Scholar]

- Liao, Y.; Koelewijn, S.-F.; Van den Bossche, G.; Van Aelst, J.; Van den Bosch, S.; Renders, T.; Navare, K.; Nicolaï, T.; Van Aelst, K.; Maesen, M. A sustainable wood biorefinery for low–carbon footprint chemicals production. Science 2020, 367, 1385–1390. [Google Scholar] [CrossRef] [PubMed]

- Huang, J.; Fu, S.; Gan, L. Lignin Chemistry and Applications, 1st ed.; Elsevier: Oxford, UK, 2019; pp. 1–24. [Google Scholar]

- Haq, I.; Mazumder, P.; Kalamdhad, A.S. Recent advances in removal of lignin from paper industry wastewater and its industrial applications—A review. Bioresour. Technol. 2020, 312, 123636. [Google Scholar] [CrossRef]

- Sharma, S.; Sharma, A.; Mulla, S.I.; Pant, D.; Sharma, T.; Kumar, A. Lignin: Biosynthesis and Transformation for Industrial Applications, 1st ed.; Springer: Cham, Switzerland, 2020; pp. 1–15. [Google Scholar]

- Imlimthan, S.; Figueiredo, P.; Santos, H.A.; Sarparanta, M. Lignin-Based Materials for Biomedical Applications Preparation, Characterization, and Implementation, 1st ed.; Elsevier: Oxford, UK, 2021; pp. 1–34. [Google Scholar]

- Nadányi, R.; Ház, A.; Lisý, A.; Jablonský, M.; Šurina, I.; Majová, V.; Baco, A. Lignin Modifications, Applications, and Possible Market Prices. Energies 2022, 15, 6520. [Google Scholar] [CrossRef]

- Trading Economics. Polypropylene 2023 Data—2013–2022 Historical—2024 Forecast—Price—Quote. 2023. Available online: https://tradingeconomics.com/commodity/polypropylene#:~:text=Polypropylene%20is%20expected%20to%20trade,7611.31%20in%2012%20months%20time (accessed on 25 February 2023).

- Ye, D.; Kong, J.; Gu, S.; Zhou, Y.; Huang, C.; Xu, W.; Zhang, X. Selective aminolysis of acetylated lignin: Toward simultaneously improving thermal-oxidative stability and maintaining mechanical properties of polypropylene. Int. J. Biol. Macromol. 2018, 108, 775–781. [Google Scholar] [CrossRef] [PubMed]

- Pregi, E.; Kun, D.; Faludi, G.; Móczó, J.; Pukánszky, B. Modeling the mechanical properties of polypropylene/lignin/flax hybrid composites. Mater. Des. 2022, 220, 110833. [Google Scholar] [CrossRef]

- Pregi, E.; Faludi, G.; Kun, D.; Móczó, J.; Pukánszky, B. Three-component polypropylene/lignin/flax composites with high natural additive content for structural applications. Ind. Crops Prod. 2022, 182, 114890. [Google Scholar] [CrossRef]

- Dias, O.A.T.; Sain, M.; Cesarino, I.; Leao, A.L. Development of high bio-content polypropylene composites with different industrial lignins. Polym. Adv. Technol. 2019, 30, 70–78. [Google Scholar] [CrossRef]

- Abdelwahab, M.A.; Misra, M.; Mohanty, A.K. Injection molded biocomposites from polypropylene and lignin: Effect of compatibilizers on interfacial adhesion and performance. Ind. Crops Prod. 2019, 132, 497–510. [Google Scholar] [CrossRef]

- ASTM D638-14:2014; Standard Test Method for Tensile Properties of Plastics; ASTM International: West Conshohocken, PA, USA, 2014.

- ASTM D790-17; Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials. ASTM: West Conshohocken, PA, USA, 2017.

- ASTM D256-10; Standard Test Methods for Determining the Izod Pendulum Impact Resistance of Plastics. ASTM: West Conshohocken, PA, USA, 2010.

- ASTM D1238-13; Standard Test Method for Melt Flow Rates of Thermoplastics by Extrusion Plastometer. ASTM: West Conshohocken, PA, USA, 2020.

- ASTM-D648; Standard Test Method for Deflection Temperature of Plastics Under Flexural Load in the Edgewise Position. ASTM International: West Conshohocken, PA, USA, 2018.

- Şahin, K.; Clawson, J.K.; Singletary, J.; Horner, S.; Zheng, J.; Pelegri, A.; Chasiotis, I. Limiting role of crystalline domain orientation on the modulus and strength of aramid fibers. Polymer 2018, 140, 96–106. [Google Scholar] [CrossRef]

- Novais, R.M.; Simon, F.; Paiva, M.C.; Covas, J.A. The influence of carbon nanotube functionalization route on the efficiency of dispersion in polypropylene by twin-screw extrusion. Compos. Part A: Appl. Sci. Manuf. 2012, 43, 2189–2198. [Google Scholar] [CrossRef]

- Xu, X.; He, Z.; Lu, S.; Guo, D.; Yu, J. Enhanced thermal and mechanical properties of lignin/polypropylene wood-plastic composite by using flexible segment-containing reactive compatibilizer. Macromol. Res. 2014, 22, 1084–1089. [Google Scholar] [CrossRef]

- Lu, S.; Li, S.; Yu, J.; Guo, D.; Ling, R.; Huang, B. The effect of hyperbranched polymer lubricant as a compatibilizer on the structure and properties of lignin/polypropylene composites. Wood Mater. Sci. Eng. 2013, 8, 159–165. [Google Scholar] [CrossRef]

- Ogunsona, E.O.; Codou, A.; Misra, M.; Mohanty, A.K. Thermally Stable Pyrolytic Biocarbon as an Effective and Sustainable Reinforcing Filler for Polyamide Bio-composites Fabrication. J. Polym. Environ. 2018, 26, 3574–3589. [Google Scholar] [CrossRef]

- Lotz, B. α and β phases of isotactic polypropylene: A case of growth kinetics ‘phase reentrency’ in polymer crystallization. Polymer 1998, 39, 4561–4567. [Google Scholar] [CrossRef]

- Altay, L.; Sarikanat, M.; Sağlam, M.; Uysalman, T.; Seki, Y. The effect of various mineral fillers on thermal, mechanical, and rheological properties of polypropylene. Res. Eng. Struct. Mater. 2021, 7, 361–373. [Google Scholar] [CrossRef]

- Benz, J.; Bonten, C. Influence of polymer-particle-interaction on the flow behavior of highly filled plastics. In Proceedings of the PPS-34: The 34th International Conference of the Polymer Processing Society—Conference Papers, Taipei, Taiwan, 21–25 May 2018. [Google Scholar]

- Doumbia, A.S.; Castro, M.; Jouannet, D.; Kervoëlen, A.; Falher, T.; Cauret, L.; Bourmaud, A. Flax/polypropylene composites for lightened structures: Multiscale analysis of process and fibre parameters. Mater. Des. 2015, 87, 331–341. [Google Scholar] [CrossRef]

- Tian, B.; Li, J.; Li, Z.; Xu, N.; Yao, G.; Zhang, N.; Dong, W.; Liu, Y.; Di, M. Synergistic lignin construction of a long-chain branched polypropylene and its properties. RSC Adv. 2020, 10, 38120–38127. [Google Scholar] [CrossRef]

- Li, Y.; Jia, S.; Du, S.; Wang, Y.; Lv, L.; Zhang, J. Improved properties of recycled polypropylene by introducing the long chain branched structure through reactive extrusion. Waste Manag. 2018, 76, 172–179. [Google Scholar] [CrossRef]

- Wu, F.; Misra, M.; Mohanty, A.K. Sustainable green composites from biodegradable plastics blend and natural fibre with bal-anced performance: Synergy of nano-structured blend and reactive extrusion. Compos. Sci. Technol. 2020, 200, 108369. [Google Scholar] [CrossRef]

- Ebadi-Dehaghani, H.; Khonakdar, H.A.; Barikani, M.; Jafari, S.H.; Wagenknecht, U.; Heinrich, G. An Investigation on Compatibilization Threshold in the Interface of Polypropylene/Polylactic Acid Blends Using Rheological Studies. J. Vinyl Addit. Technol. 2016, 22, 19–28. [Google Scholar] [CrossRef]

- Liu, Y.; Tian, B.; Liu, X. Preparation of polypropylene blends with the long chain branched behavior through reactive blending induced by pre-irradiation. Radiat. Phys. Chem. 2020, 177, 109188. [Google Scholar] [CrossRef]

- Chen, F.; Zhang, M. Maleic anhydride-modified polyolefins as compatibilizer for lignin-reinforced polypropylene composites. Polym. Compos. 2018, 40, 2594–2601. [Google Scholar] [CrossRef]

- Chen, F.; Liu, W.; Shahabadi, S.I.S.; Xu, J.; Lu, X. Sheet-Like Lignin Particles as Multifunctional Fillers in Polypropylene. ACS Sustain. Chem. Eng. 2016, 4, 4997–5004. [Google Scholar] [CrossRef]

- Klapiszewski, Ł.; Grząbka-Zasadzińska, A.; Borysiak, S.; Jesionowski, T. Preparation and characterization of polypropylene composites reinforced by functional ZnO/lignin hybrid materials. Polym. Test. 2019, 79. [Google Scholar] [CrossRef]

- Dias, O.; Negrão, D.; Silva, R.; Funari, C.; Cesarino, I.; Leao, A. Studies of lignin as reinforcement for plastics composites. Mol. Cryst. Liq. Cryst. 2016, 628, 72–78. [Google Scholar] [CrossRef]

- Maldhure, A.V.; Ekhe, J.D.; Deenadayalan, E. Mechanical properties of polypropylene blended with esterified and alkylated lignin. J. Appl. Polym. Sci. 2012, 125, 1701–1712. [Google Scholar] [CrossRef]

- Abdelwahab, M.; Misra, M.; Mohanty, A. Effect of maleated polypropylene emulsion on the mechanical and thermal properties of lignin-polypropylene blends. In Proceedings of the PPS-34: The 34th International Conference of the Polymer Processing Society—Conference Papers, Taipei, Taiwan, 21–25 May 2018; p. 150006. [Google Scholar]

- Sameni, J.; Jaffer, S.A.; Sain, M. Thermal and mechanical properties of soda lignin/HDPE blends. Compos. Part A: Appl. Sci. Manuf. 2018, 115, 104–111. [Google Scholar] [CrossRef]

- Hong, S.-H.; Hwang, S.-H. Construction and foamability of lignin-reinforced low-density polyethylene biocomposites. Mater. Today Commun. 2021, 28, 102696. [Google Scholar] [CrossRef]

| Sample Names | PP (wt.%) | AAL (wt.%) | KL (wt.%) | CPA1 (pph) a | CPA2 (pph) a | CPA3 (pph) a | CPA4 (pph) a |

|---|---|---|---|---|---|---|---|

| neat PP | 100 | ||||||

| P80AL20 | 80 | 20 | |||||

| P60AL40 | 60 | 40 | |||||

| P40AL60 | 40 | 60 | |||||

| P80KL20 | 80 | 20 | |||||

| P60KL40 | 60 | 40 | |||||

| P40KL60 | 40 | 60 | |||||

| P60KL40-10C1 | 60 | 40 | 10 | ||||

| P60KL40-10C2 | 60 | 40 | 10 | ||||

| P60KL40-10C3 | 60 | 40 | 10 | ||||

| P60KL40-10C4 | 60 | 40 | 10 |

| Sample | 1st Heat | 2nd Heat | 1st Cool | |||||

|---|---|---|---|---|---|---|---|---|

| Tm (°C) | ΔHm (J g−1) | Xc (%) | Tm (°C) | ΔHm (J g−1) | Xc (%) | Tc (°C) | ΔHc (J g−1) | |

| neat PP | 165.51 | 99.79 | 48.18 | 161.49 | 121.5 | 58.67 | 119.79 | 118.80 |

| P80AL20 | 164.78 | 84.21 | 50.83 | 161.15 | 99.11 | 59.82 | 120.30 | 97.07 |

| P60AL40 | 163.44 | 59.92 | 48.22 | 160.56 | 69.39 | 55.84 | 119.05 | 68.04 |

| P40AL60 | 161.88 | 42.04 | 50.75 | 160.77 | 40.42 | 48.79 | 116.32 | 39.25 |

| P80KL20 | 164.43 | 91.07 | 54.97 | 161.17 | 106.80 | 64.46 | 120.20 | 105.00 |

| P60KL40 | 161.99 | 64.64 | 52.02 | 160.86 | 75.20 | 60.52 | 119.51 | 76.91 |

| P40KL60 | 163.74 | 55.44 | 66.92 | 161.32 | 57.91 | 69.91 | 118.21 | 58.54 |

| P60KL40-10C2 | 165.04 | 73.72 | 65.26 | 160.83 | 83.18 | 73.63 | 120.96 | 82.21 |

| P60KL40-10C3 | 164.60 | 67.49 | 59.74 | 160.76 | 70.34 | 62.27 | 120.62 | 71.16 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, R.; You, X.; Qi, S.; Tian, R.; Zhang, H. Enhancing Mechanical Performance of High-Lignin-Filled Polypropylene via Reactive Extrusion. Polymers 2024, 16, 520. https://doi.org/10.3390/polym16040520

Wang R, You X, Qi S, Tian R, Zhang H. Enhancing Mechanical Performance of High-Lignin-Filled Polypropylene via Reactive Extrusion. Polymers. 2024; 16(4):520. https://doi.org/10.3390/polym16040520

Chicago/Turabian StyleWang, Ruichen, Xiangyu You, Shijie Qi, Ruiyun Tian, and Huijie Zhang. 2024. "Enhancing Mechanical Performance of High-Lignin-Filled Polypropylene via Reactive Extrusion" Polymers 16, no. 4: 520. https://doi.org/10.3390/polym16040520

APA StyleWang, R., You, X., Qi, S., Tian, R., & Zhang, H. (2024). Enhancing Mechanical Performance of High-Lignin-Filled Polypropylene via Reactive Extrusion. Polymers, 16(4), 520. https://doi.org/10.3390/polym16040520