Synergistic Improvement of Strength Characteristics in Recycled Aggregates Using Nano-Clay and Polypropylene Fiber

Abstract

1. Introduction

2. Experiment Materials and Scheme

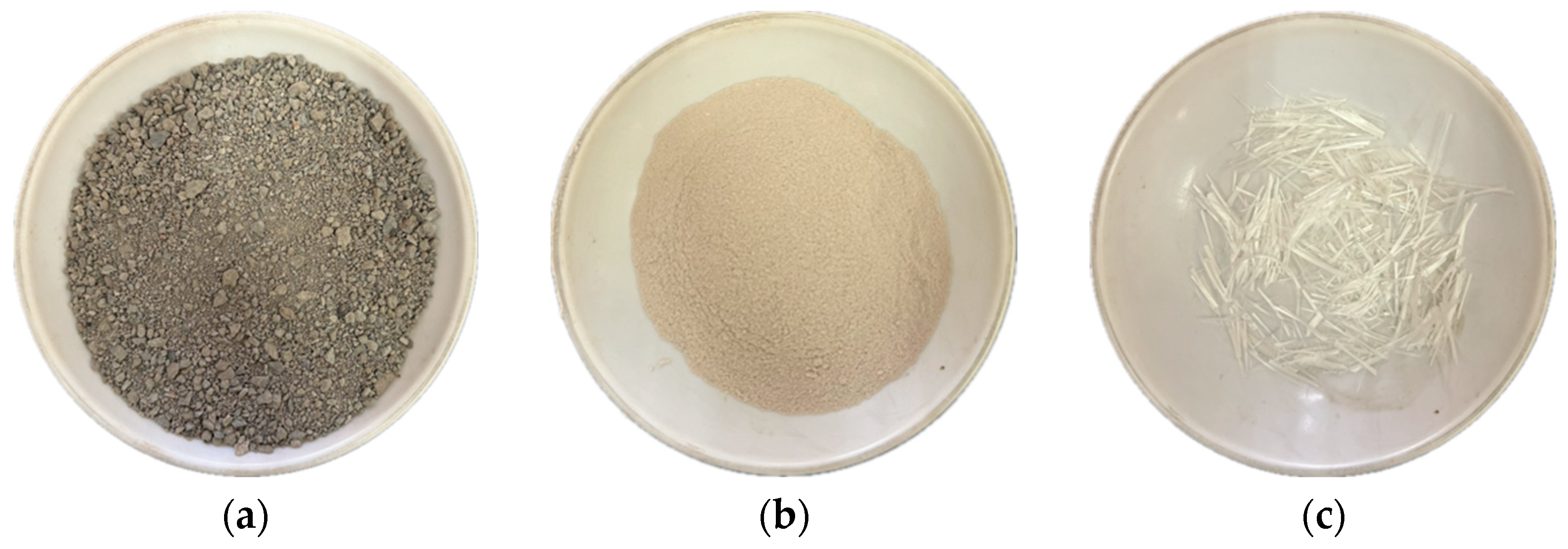

2.1. Experiment Materials

2.2. Experiment Scheme

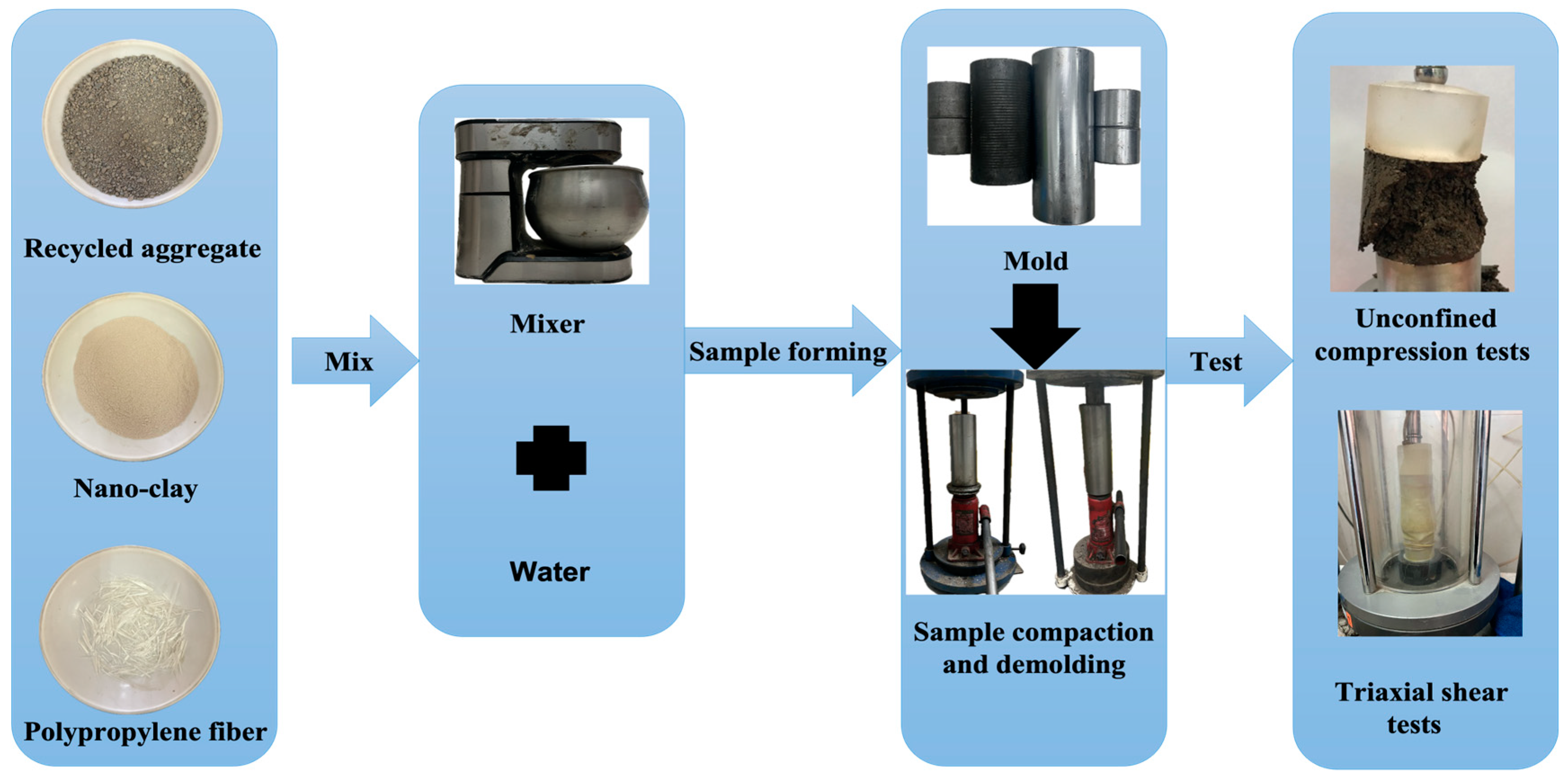

2.3. Specimen Preparation

- (1)

- Recycled aggregate treatment. The recycled aggregate block is placed into an oven with a temperature of 105 °C for drying. At the end of the drying process, the fine-grained recycled aggregate used in the test is obtained by removing the large particles from the recycled aggregate block through a 2 mm sieve.

- (2)

- Nano-clay treatment. The nano-clay is dried in a vacuum freeze dryer for 5 h to obtain the nano-clay used in the test.

- (3)

- Mixed mixture. Firstly, the recycled aggregates are mixed with polypropylene fibers and nano-clay until they are evenly blended. Then, water is added, and the mixture is stirred for 6 min. Throughout the mixing process, observations are made every 2 min to ensure that the recycled aggregates, polypropylene fibers, and nano-clay are dispersed as much as possible and clumping is avoided. Finally, after stirring, the mixture is allowed to stand for 2 h [29,34].

- (4)

- Specimen forming. Firstly, the mixture is divided into three equal parts and added to the hollow cylindrical mold. (The unconfined compressive strength test mold has a 65 mm outer diameter, 50 mm inner diameter, and 130 mm height, while the three-axis shear test mold features an outer diameter of 65 mm, an inner diameter of 39.1 mm, and a height of 180 mm.) After each pouring, the mixture should be evenly inserted and vibrated with a tamping rod. Subsequently, a jack is employed to compact the specimen, and the pressure is maintained for 10 min. Finally, utilizing a reaction frame and a jack, the specimen is removed from the mold and shaped into the cylindrical specimens.

- (5)

3. Analysis of Unconfined Compression Test Results

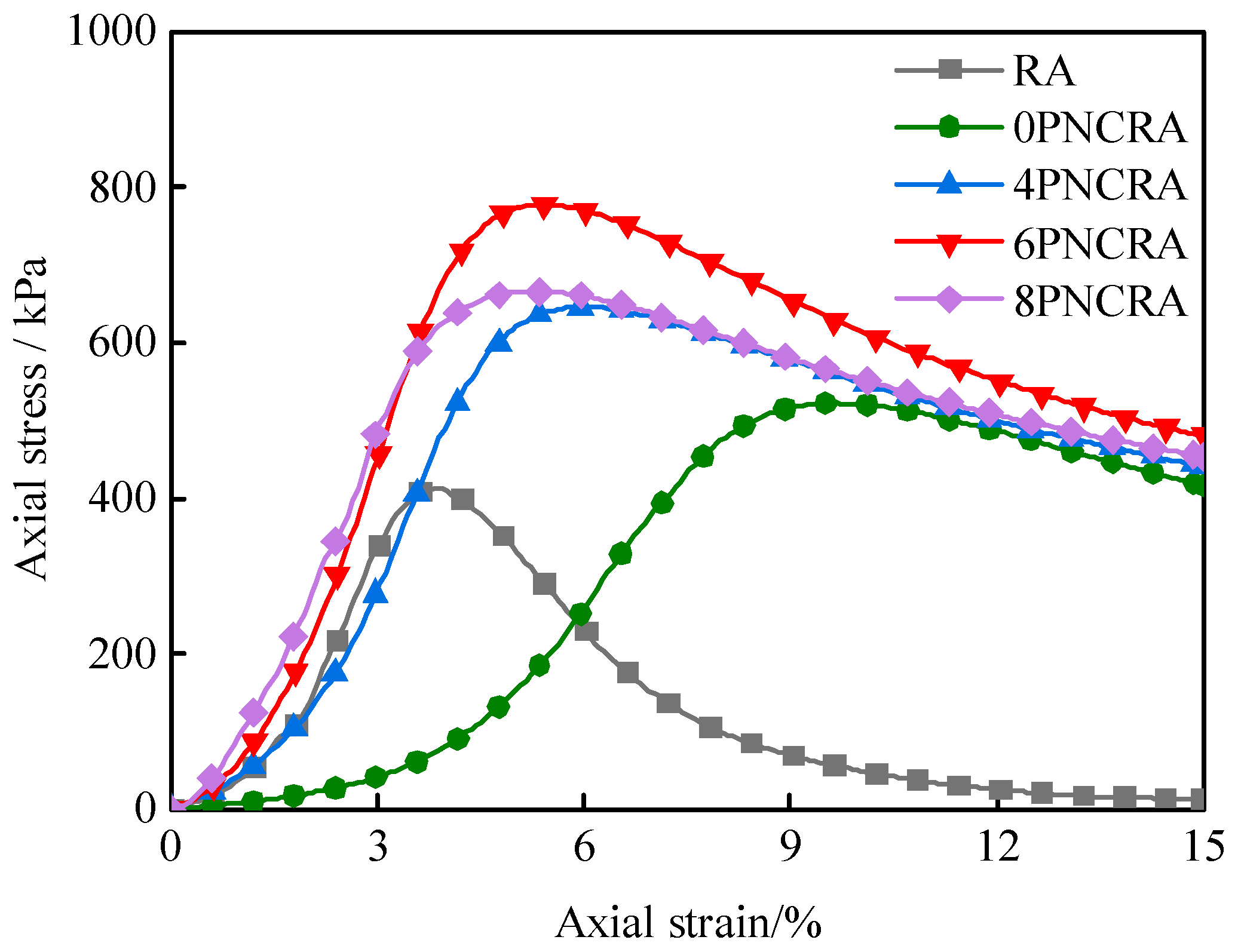

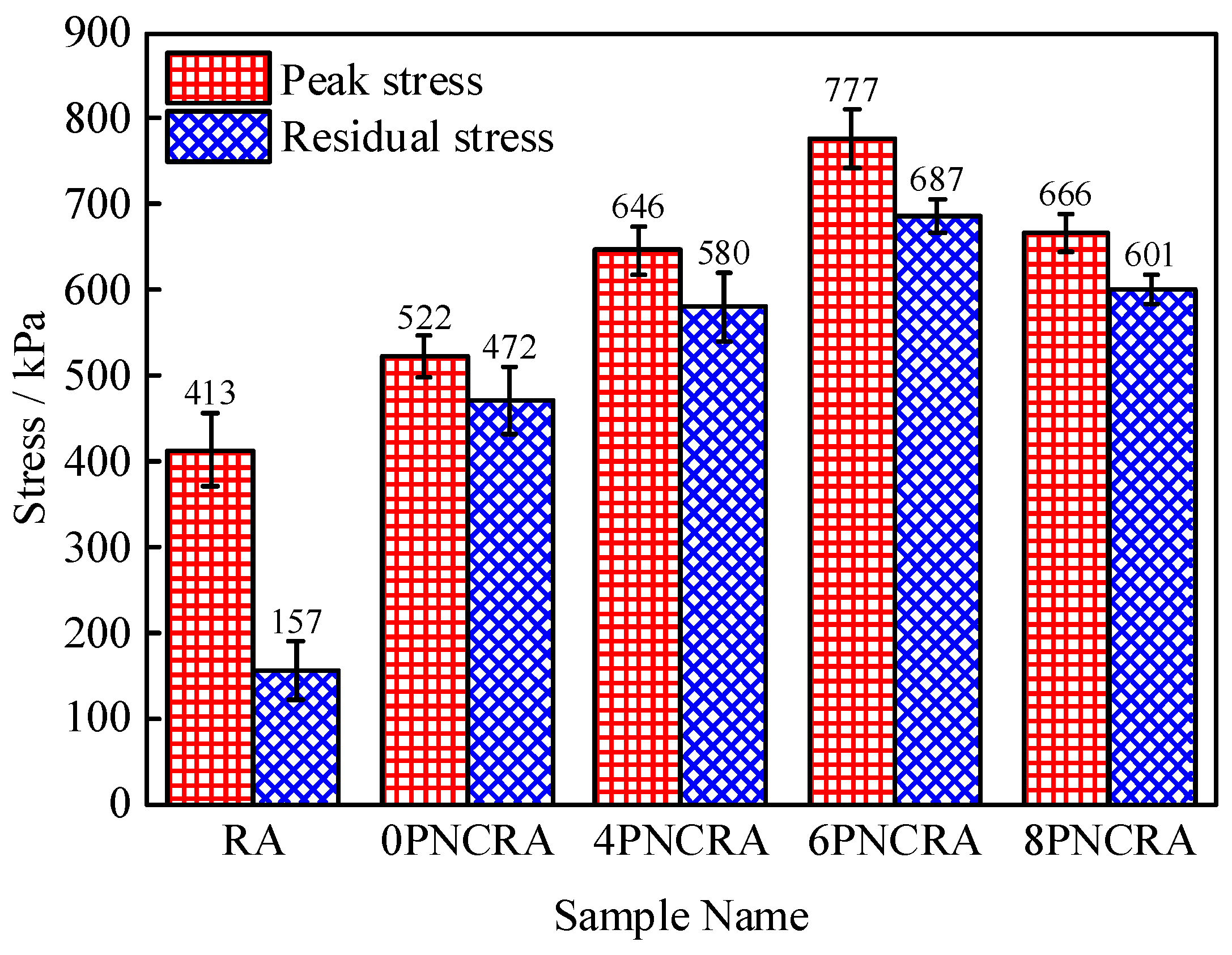

3.1. Unconfined Compressive Strength

3.2. Residual Stress

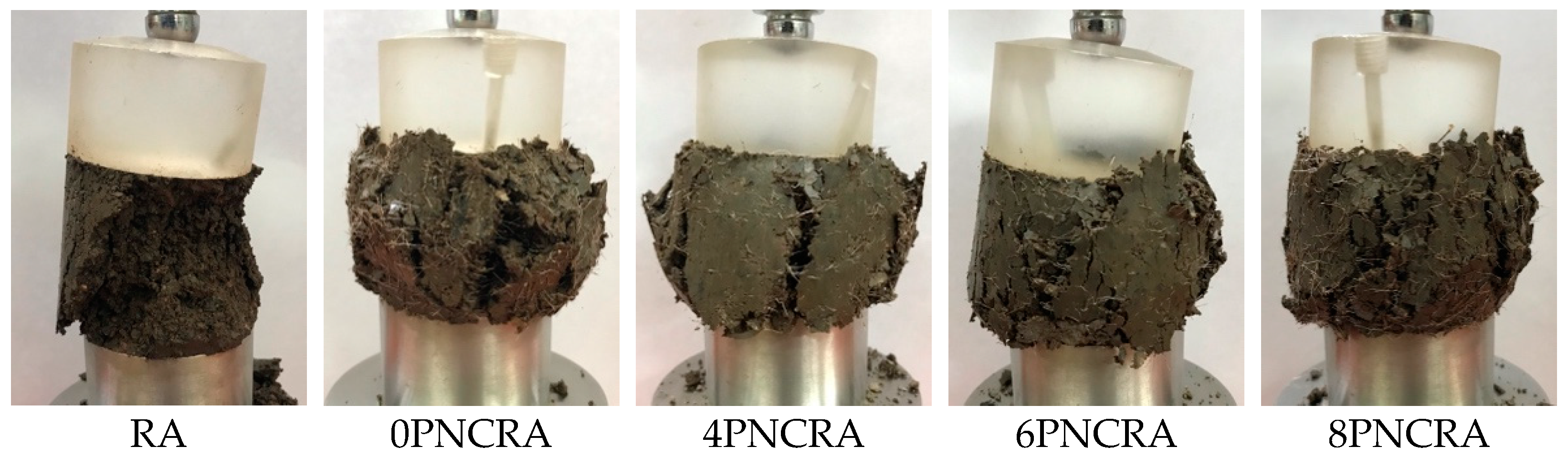

3.3. Failure Mode

4. Analysis of Triaxial Shear Test Results

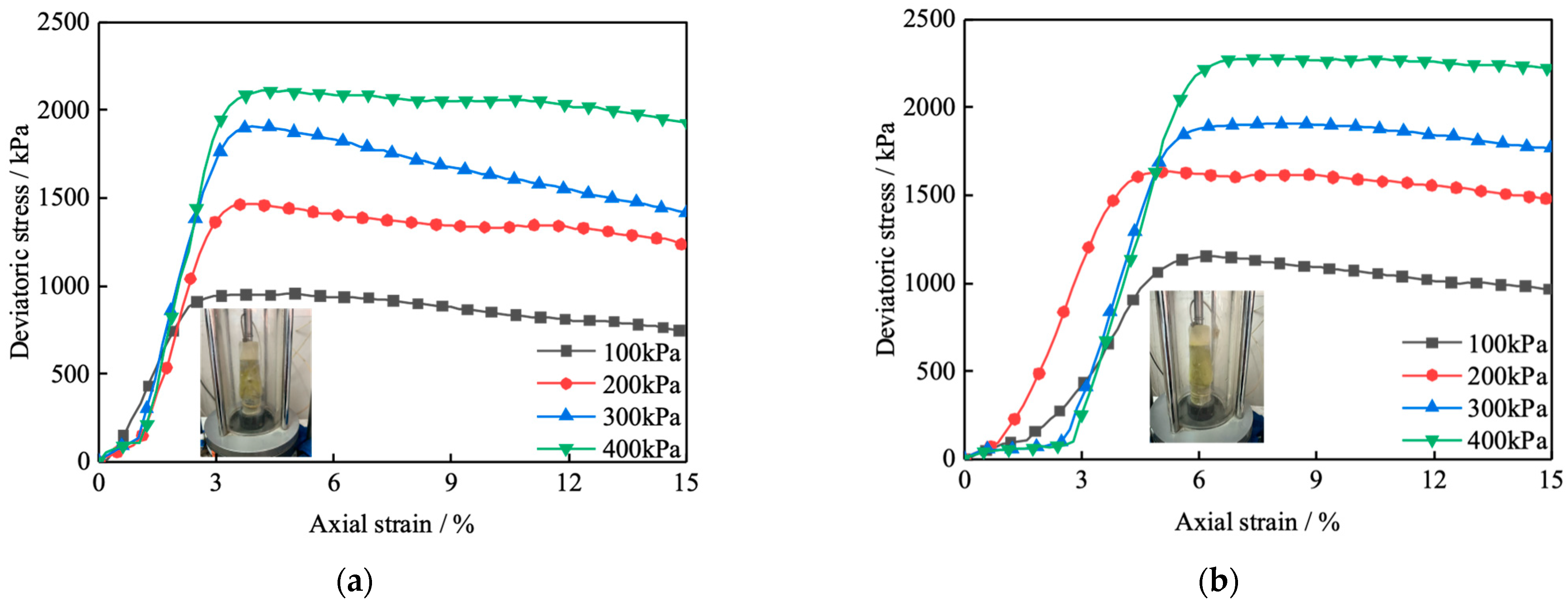

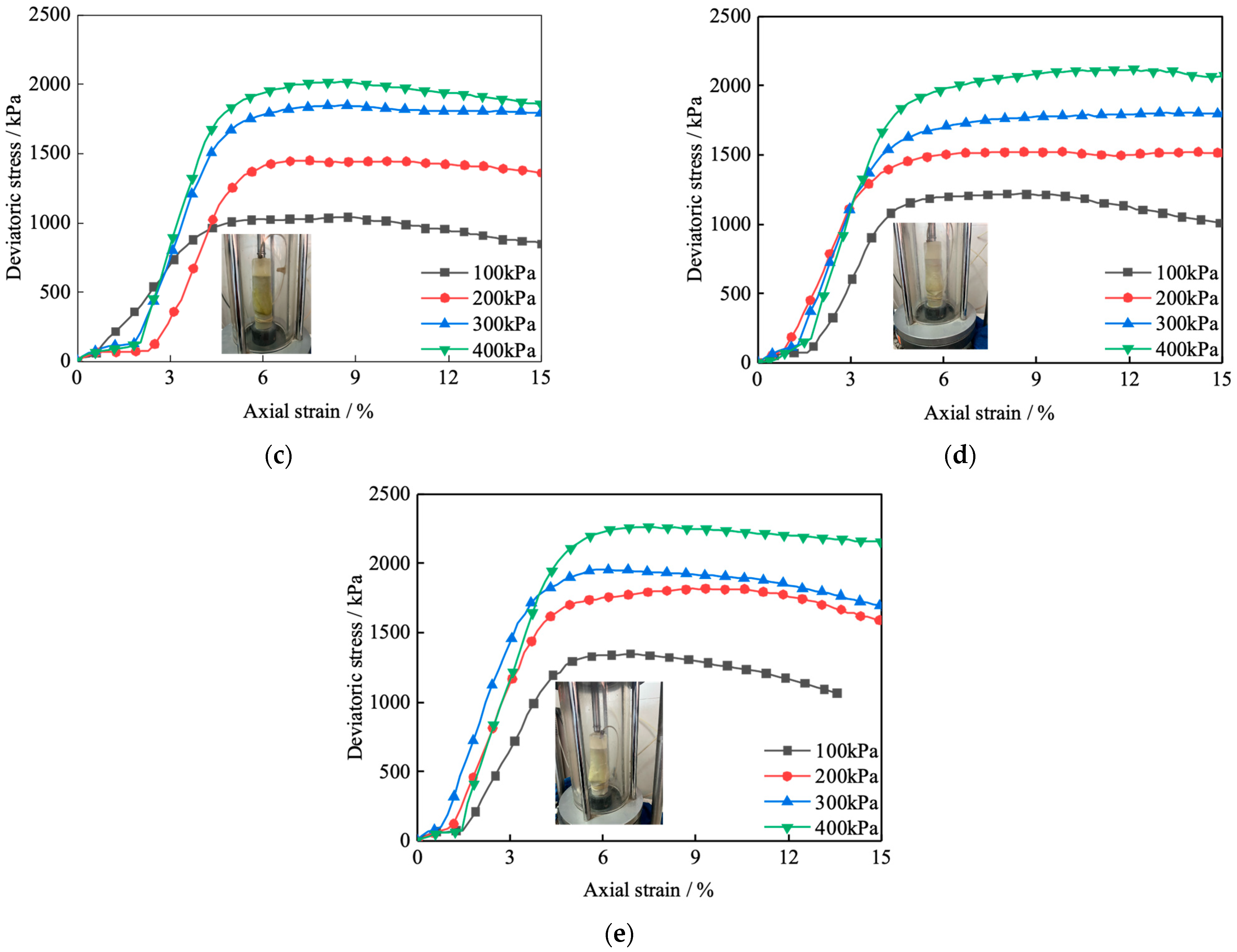

4.1. Deviatoric Stress

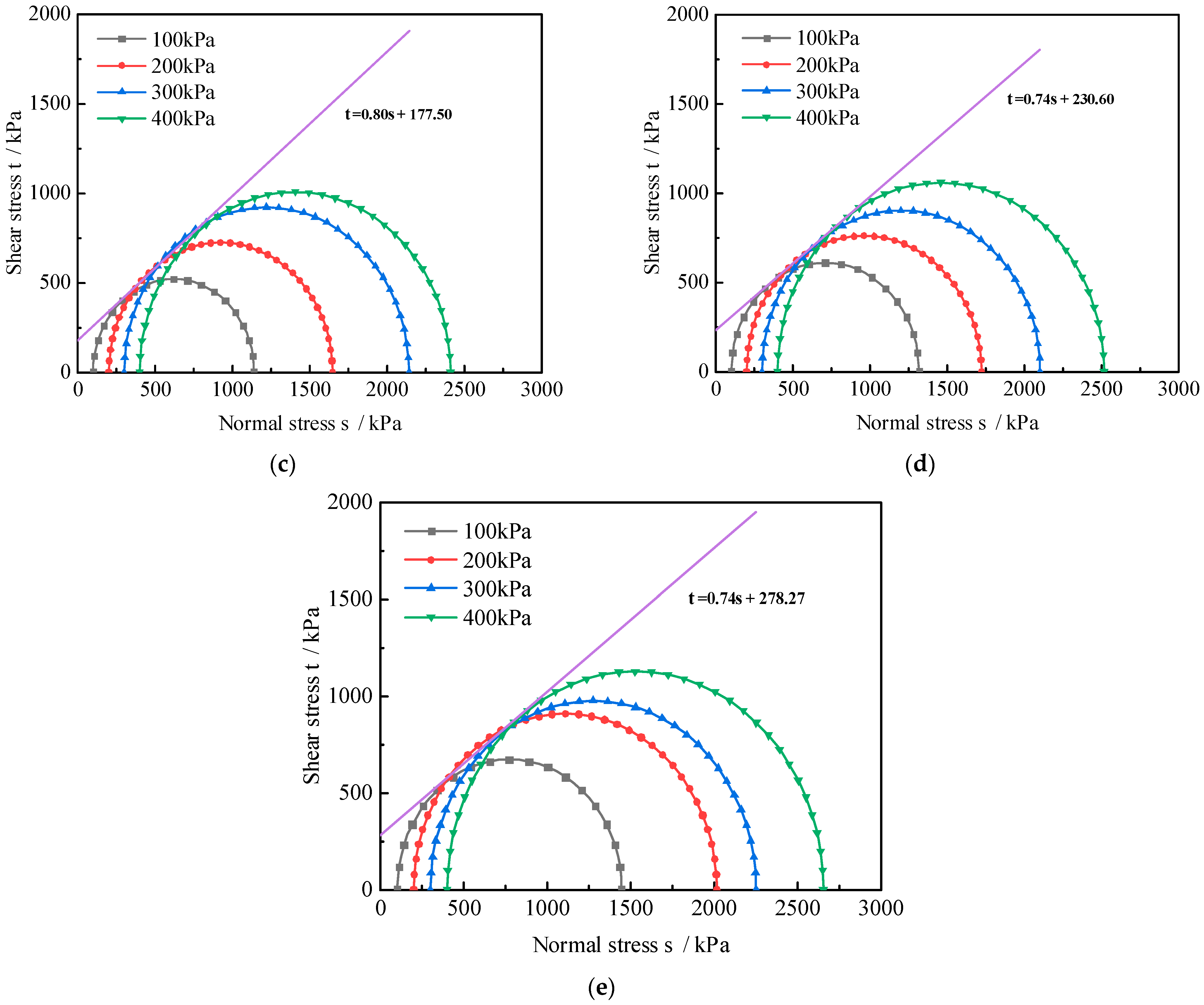

4.2. Shear Strength Parameters

5. Conclusions

- (1)

- A fiber content of 0.6% enhances the compressive strength, residual strength, and ductility of recycled aggregates. Furthermore, the performance of the fiber-reinforced recycled aggregate is further improved by adding nano-clay. When the fiber content reaches 6%, both the compressive strength and residual strength are maximized. Additionally, the incorporation of fibers and nano-clay improves the failure morphology of recycled aggregates.

- (2)

- Under the confining pressures of 100 kPa and 200 kPa, the deviatoric stress strength of PNCRA specimens significantly increases after the addition of nano-clay with an optimal amount of 8%. However, under the confining pressures of 300 kPa and 400 kPa, there is no significant improvement in the deviatoric stress strength observed upon the addition of fibers and nano-clay to recycled aggregates.

- (3)

- In terms of shear strength enhancement, the addition of fibers and nano-clay reduces the internal friction angle of the recycled aggregate, but increases its cohesion. In addition, as the nano-clay content increases, so does cohesion.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Tsai, C.Y.; Chang, A.S. Framework for developing construction sustainability items: The example of highway design. J. Clean. Prod. 2012, 20, 127–136. [Google Scholar] [CrossRef]

- Ahmed, W.; Lim, C. Production of sustainable and structural fiber reinforced recycled aggregate concrete with improved fracture properties: A review. J. Clean. Prod. 2021, 279, 123832. [Google Scholar] [CrossRef]

- Akhtar, A.; Sarmah, A.K. Construction and demolition waste generation and properties of recycled aggregate concrete: A global perspective. J. Clean. Prod. 2018, 186, 262–281. [Google Scholar] [CrossRef]

- Wang, J.; Li, Z.; Tam, V.W. Critical factors in effective construction waste minimization at the design stage: A Shenzhen case study, China. Resour. Conserv. Recycl. 2014, 82, 1–7. [Google Scholar] [CrossRef]

- Silva, R.; De Brito, J.; Dhir, R. Properties and composition of recycled aggregates from construction and demolition waste suitable for concrete production. Constr. Build. Mater. 2014, 65, 201–217. [Google Scholar] [CrossRef]

- Arulrajah, A.; Disfani, M.M.; Horpibulsuk, S.; Suksiripattanapong, C.; Prongmanee, N. Physical properties and shear strength responses of recycled construction and demolition materials in unbound pavement base/subbase applications. Constr. Build. Mater. 2014, 58, 245–257. [Google Scholar] [CrossRef]

- Patel, S.K.; Singh, B. Shear strength response of glass fibre-reinforced sand with varying compacted relative density. Int. J. Geotech. Eng. 2019, 13, 339–351. [Google Scholar] [CrossRef]

- Sobhan, K.; Mashnad, M. Mechanical stabilization of cemented soil–fly ash mixtures with recycled plastic strips. J. Environ. Eng. 2003, 129, 943–947. [Google Scholar] [CrossRef]

- Yetimoglu, T.; Salbas, O. A study on shear strength of sands reinforced with randomly distributed discrete fibers. Geotext. Geomembr. 2003, 21, 103–110. [Google Scholar] [CrossRef]

- Hughes, B.; Fattuhi, N. Stress-strain curves for fibre reinforced concrete in compression. Cem. Concr. Res. 1977, 7, 173–183. [Google Scholar] [CrossRef]

- Cai, Y.; Shi, B.; Ng, C.W.; Tang, C.-S. Effect of polypropylene fibre and lime admixture on engineering properties of clayey soil. Eng. Geol. 2006, 87, 230–240. [Google Scholar] [CrossRef]

- Tingle, J.S.; Santoni, R.L.; Webster, S.L. Full-scale field tests of discrete fiber-reinforced sand. J. Transp. Eng. 2002, 128, 9–16. [Google Scholar] [CrossRef]

- Guo, Y.; Zhang, J.; Chen, G.; Chen, G.; Xie, Z. Fracture behaviors of a new steel fiber reinforced recycled aggregate concrete with crumb rubber. Constr. Build. Mater. 2014, 53, 32–39. [Google Scholar] [CrossRef]

- Hanumesh, B.; Harish, B.; Ramana, N.V. Influence of polypropylene fibres on recycled aggregate concrete. Mater. Today Proc. 2018, 5, 1147–1155. [Google Scholar] [CrossRef]

- Afroughsabet, V.; Biolzi, L.; Ozbakkaloglu, T. Influence of double hooked-end steel fibers and slag on mechanical and durability properties of high performance recycled aggregate concrete. Compos. Struct. 2017, 181, 273–284. [Google Scholar] [CrossRef]

- Mohseni, E.; Saadati, R.; Kordbacheh, N.; Parpinchi, Z.S.; Tang, W. Engineering and microstructural assessment of fibre-reinforced self-compacting concrete containing recycled coarse aggregate. J. Clean. Prod. 2017, 168, 605–613. [Google Scholar] [CrossRef]

- Singh, D.; Senthil, K.; Emmanuel, P. Mechanical and durability properties of recycled aggregate self-compacting concrete along with basalt fibers. In Recycled Waste Materials: Proceedings of EGRWSE 2018; Springer: Singapore, 2019; pp. 199–211. [Google Scholar]

- Das, C.S.; Dey, T.; Dandapat, R.; Mukharjee, B.B.; Kumar, J. Performance evaluation of polypropylene fibre reinforced recycled aggregate concrete. Constr. Build. Mater. 2018, 189, 649–659. [Google Scholar] [CrossRef]

- Ahmed, T.W.; Ali, A.A.M.; Zidan, R.S. Properties of high strength polypropylene fiber concrete containing recycled aggregate. Constr. Build. Mater. 2020, 241, 118010. [Google Scholar] [CrossRef]

- Mansi, A.; Sor, N.H.; Hilal, N.; Qaidi, S.M. The impact of nano clay on normal and high-performance concrete characteristics: A review. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2022; p. 012085. [Google Scholar]

- Tabarsa, A.; Latifi, N.; Meehan, C.L.; Manahiloh, K.N. Laboratory investigation and field evaluation of loess improvement using nanoclay—A sustainable material for construction. Constr. Build. Mater. 2018, 158, 454–463. [Google Scholar] [CrossRef]

- Fadzil, A.M.; Muhd Norhasri, M.; Hamidah, M.; Zaidi, M.; Mohd Faizal, J. In Alteration of nano metakaolin for ultra high performance concrete. In CIEC 2013: Proceedings of the International Civil and Infrastructure Engineering Conference 2013; Springer: Singapore, 2014; pp. 887–894. [Google Scholar]

- Staub de Melo, J.V.; Trichês, G. Study of the influence of nano-TiO2 on the properties of Portland cement concrete for application on road surfaces. Road Mater. Pavement Des. 2018, 19, 1011–1026. [Google Scholar] [CrossRef]

- Iranpour, B.; Haddad, A. The influence of nanomaterials on collapsible soil treatment. Eng. Geol. 2016, 205, 40–53. [Google Scholar] [CrossRef]

- Mohsen, S.; Javad, T. Laboratory assessing of the liquefaction potential and strength properties of Sand soil treated with mixture of nanoclay and glass fiber under dynamic and static loading. J. Mater. Res. Technol. 2020, 9, 12661–12684. [Google Scholar]

- Ibrahem, A.M.; Al-Mishhadani, S.A.; Naji, Z.H. The effect of nano metakaolin material on some properties of concrete. Diyala J. Eng. Sci. 2013, 6, 50–61. [Google Scholar] [CrossRef]

- Wang, W.-C. Compressive strength and thermal conductivity of concrete with nanoclay under Various High-Temperatures. Constr. Build. Mater. 2017, 147, 305–311. [Google Scholar] [CrossRef]

- Toghroli, A.; Mehrabi, P.; Shariati, M.; Trung, N.T.; Jahandari, S.; Rasekh, H. Evaluating the use of recycled concrete aggregate and pozzolanic additives in fiber-reinforced pervious concrete with industrial and recycled fibers. Constr. Build. Mater. 2020, 252, 118997. [Google Scholar] [CrossRef]

- GB/T 50123—2019; Ministry of Housing and Urban-Rural Development of the People’s Republic of China. Standard for Soil Test Methods. China Planning Press: Beijing, China, 2019.

- Hu, Y.; Ma, L. Effect of surface treatment of polypropylene (PP) fiber on the sulfate corrosion resistance of cement mortar. Materials 2021, 14, 3690. [Google Scholar] [CrossRef] [PubMed]

- Dawood, E.T.; Hamad, A.J. Toughness behaviour of high-performance lightweight foamed concrete reinforced with hybrid fibres. Struct. Concr. 2015, 16, 496–507. [Google Scholar] [CrossRef]

- Gao, B.; Cao, S.; Yilmaz, E. Effect of content and length of polypropylene fibers on strength and microstructure of cementitious tailings-waste rock fill. Minerals 2023, 13, 142. [Google Scholar] [CrossRef]

- Ye, P.; Chen, Z.; Su, W. Mechanical properties of fully recycled coarse aggregate concrete with polypropylene fiber. Case. Stud. Constr. Mat. 2022, 17, e01352. [Google Scholar] [CrossRef]

- JTG E51-2009; Test Methods of Materials Stabilized with Inorganic Binders for Highway Engineering. Ministry of Transport PR China: Beijing, China, 2009.

- Jiang, P.; Zhou, L.; Zhang, W.Q.; Wang, W.; Li, N. Unconfined Compressive Strength and Splitting Tensile Strength of Lime Soil Modified by Nano Clay and Polypropylene Fiber. Crystals 2022, 12, 285. [Google Scholar] [CrossRef]

- Zare, Y. Study of nanoparticles aggregation/agglomeration in polymer particulate nanocomposites by mechanical properties. Compos. Part A 2016, 84, 158–164. [Google Scholar] [CrossRef]

- Wang, W.; Kang, H.; Li, N.; Guo, J.; Girma, D.Y.; Liu, Y. Experimental investigations on the mechanical and microscopic behavior of cement-treated clay modified by nano-MgO and fibers. Int. J. Geomech. 2022, 22, 04022059. [Google Scholar] [CrossRef]

- Bekhiti, M.; Trouzine, H.; Rabehi, M. Influence of waste tire rubber fibers on swelling behavior, unconfined compressive strength and ductility of cement stabilized bentonite clay soil. Constr. Build. Mater. 2019, 208, 304–313. [Google Scholar] [CrossRef]

- Zhang, P.; Yang, Y.; Wang, J.; Hu, S.; Jiao, M.; Ling, Y. Mechanical properties and durability of polypropylene and steel fiber-reinforced recycled aggregates concrete (FRRAC): A review. Sustainability 2020, 12, 9509. [Google Scholar] [CrossRef]

- Kachouh, N.; El-Hassan, H.; El-Maaddawy, T. Effect of steel fibers on the performance of concrete made with recycled concrete aggregates and dune sand. Constr. Build. Mater. 2019, 213, 348–359. [Google Scholar] [CrossRef]

- Tomar, A.; Sharma, T.; Singh, S. Strength properties and durability of clay soil treated with mixture of nano silica and Polypropylene fiber. Mater. Today Proc. 2020, 26, 3449–3457. [Google Scholar] [CrossRef]

- Ahmadi, M.; Farzin, S.; Hassani, A.; Motamedi, M. Mechanical properties of the concrete containing recycled fibers and aggregates. Constr. Build. Mater. 2017, 144, 392–398. [Google Scholar] [CrossRef]

- Kayali, O.; Haque, M.; Zhu, B. Some characteristics of high strength fiber reinforced lightweight aggregate concrete. Cem. Concr. Compos. 2003, 25, 207–213. [Google Scholar] [CrossRef]

- Liu, J.-L.; Hou, T.-S.; Luo, Y.-S.; Cui, Y.-X. Experimental study on unconsolidated undrained shear strength characteristics of synthetic cotton fiber reinforced soil. Geotech. Geol. Eng. 2020, 38, 1773–1783. [Google Scholar] [CrossRef]

- Qian, B.; Yu, W.; Lv, B.; Kang, H.; Shu, L.; Li, N.; Wang, W. Mechanical properties and micro mechanism of nano-clay-modified soil cement reinforced by recycled sand. Sustainability 2021, 13, 7758. [Google Scholar] [CrossRef]

| Natural Moisture Content/% | Specific Gravity | Liquid Limit/% | Plastic Limit/% | Maximum Dry Density/g/cm3 | Optimum Moisture Content/% |

|---|---|---|---|---|---|

| 5 | 2.69 | 18.95 | 10.29 | 2.04 | 10 |

| Composition | Appearance | Montmorillonite Content/% | Density/g/cm3 | Diameter–Thickness Ratio | Stacking Thickness/nm | Moisture Content/% |

|---|---|---|---|---|---|---|

| Montmorillonite Derivatives | Light-Pink Powder | 96–98 | 0.45 | 200 | ≤25 | 2 |

| Fiber Type | Specific Gravity | Diameter/μm | Length/mm | Tensile Strength/MPa | Melting Point/°C | Elastic Modulus/MPa | Elongation/% | Tensile Limit |

|---|---|---|---|---|---|---|---|---|

| Bundle Monofilament | 0.91 | 18–48 | 9 | >3850 | 160–180 | >165 | 10–28 | >150% |

| Specimen Type | Water Content/% | Specimen Density/g/cm3 | Fiber Content/% | Nano-Clay Content/% |

|---|---|---|---|---|

| RA | 10 | 2.1 | 0 | 0 |

| 0PNCRA | 0.6 | 0 | ||

| 4PNCRA | 0.6 | 4 | ||

| 6PNCRA | 0.6 | 6 | ||

| 8PNCRA | 0.6 | 8 |

| Shear Strength Parameters | RA | 0PNCRA | 4PNCRA | 6PNCRA | 8PNCRA |

|---|---|---|---|---|---|

| Internal Friction Angle φ/° | 41.9 | 40.4 | 38.9 | 36.8 | 36.6 |

| Cohesive Force c/kPa | 133 | 190 | 178 | 231 | 278 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, T.; Wang, C.; Zhang, D.; Yu, Y.; Luo, J.; Li, C. Synergistic Improvement of Strength Characteristics in Recycled Aggregates Using Nano-Clay and Polypropylene Fiber. Polymers 2024, 16, 374. https://doi.org/10.3390/polym16030374

Zhao T, Wang C, Zhang D, Yu Y, Luo J, Li C. Synergistic Improvement of Strength Characteristics in Recycled Aggregates Using Nano-Clay and Polypropylene Fiber. Polymers. 2024; 16(3):374. https://doi.org/10.3390/polym16030374

Chicago/Turabian StyleZhao, Tieyong, Chenjun Wang, De Zhang, Yanfei Yu, Jiale Luo, and Cuihong Li. 2024. "Synergistic Improvement of Strength Characteristics in Recycled Aggregates Using Nano-Clay and Polypropylene Fiber" Polymers 16, no. 3: 374. https://doi.org/10.3390/polym16030374

APA StyleZhao, T., Wang, C., Zhang, D., Yu, Y., Luo, J., & Li, C. (2024). Synergistic Improvement of Strength Characteristics in Recycled Aggregates Using Nano-Clay and Polypropylene Fiber. Polymers, 16(3), 374. https://doi.org/10.3390/polym16030374