Investigating the Impact of Polymers on Clay Flocculation and Residual Oil Behaviour Using a 2.5D Model

Abstract

1. Introduction

2. The Phenomenon of Particle Migration After Binary Composite Flooding

2.1. The Advantages of Binary Composite Flooding for Oil Recovery

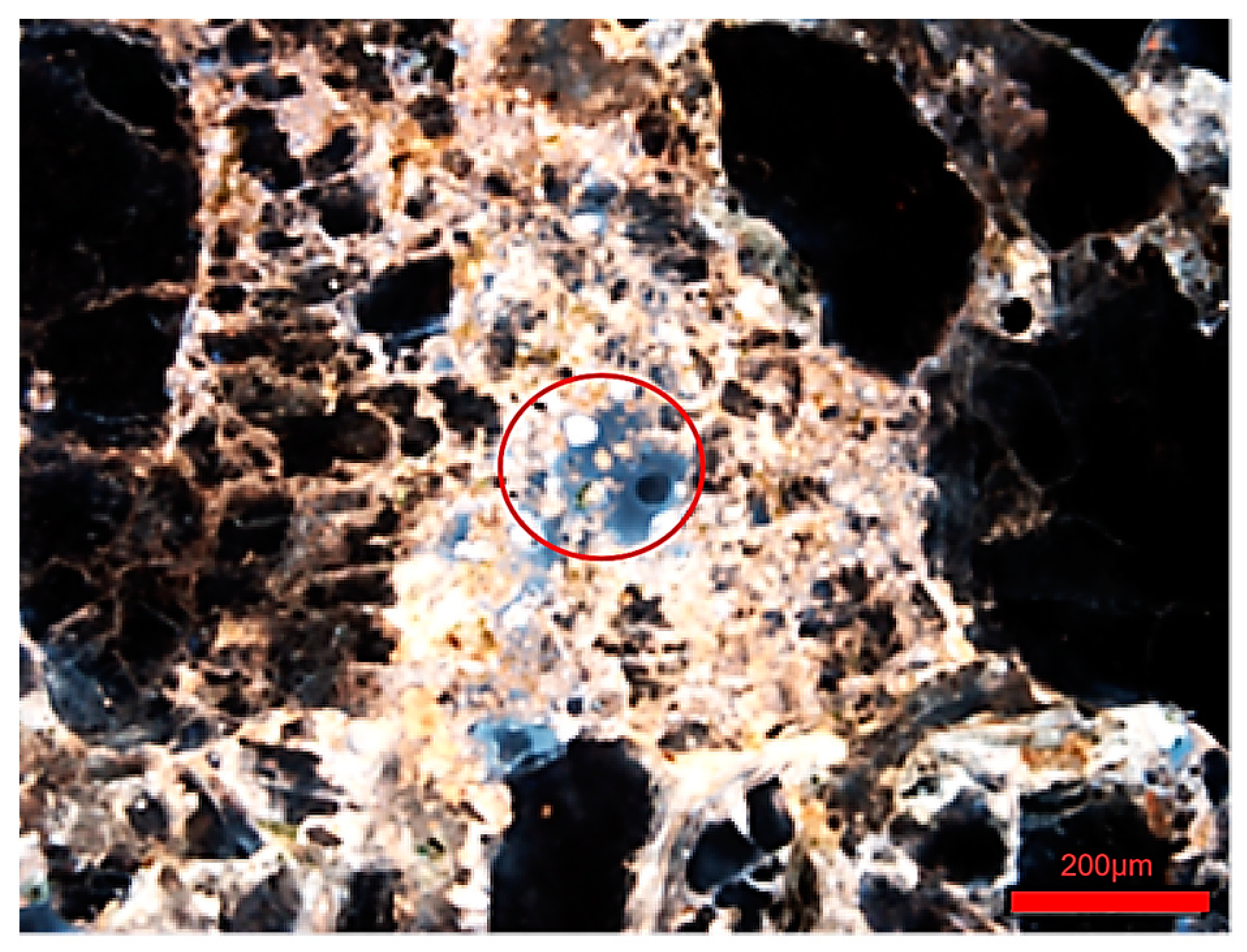

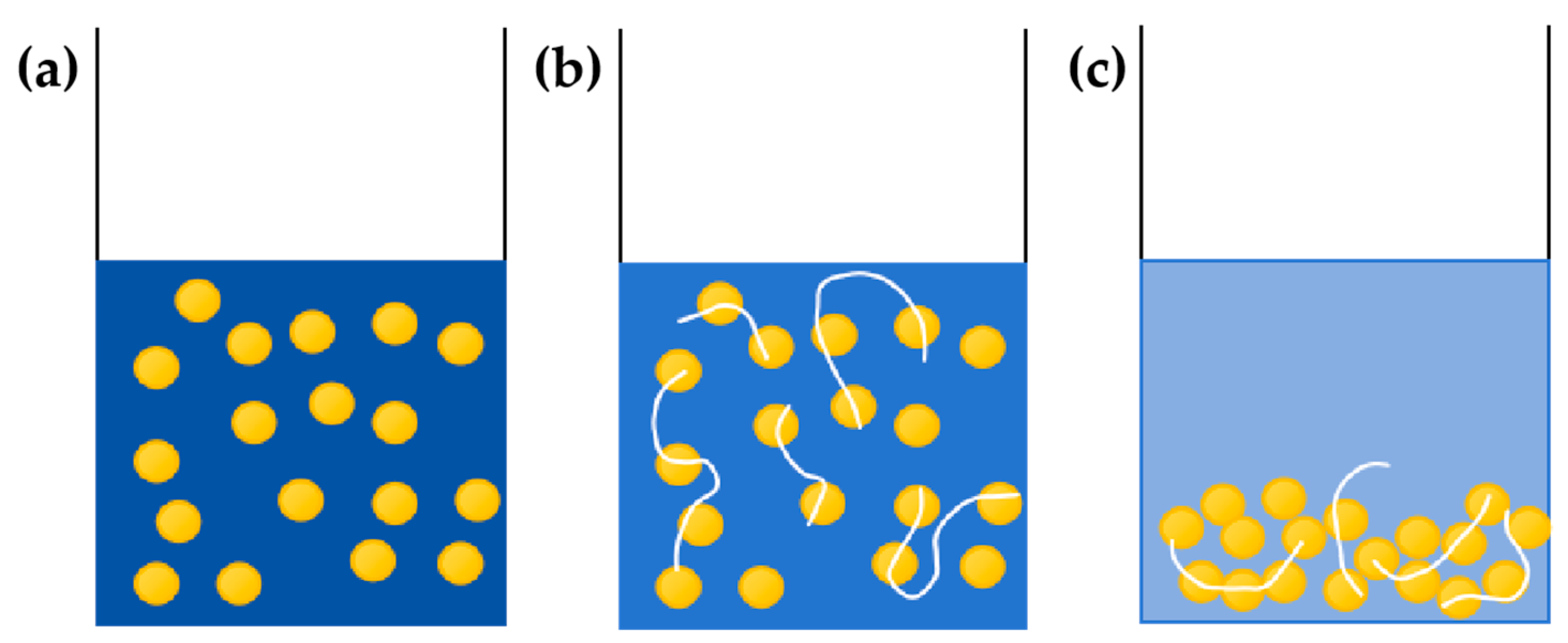

2.2. Particle Migration Phenomenon

2.3. The Mechanism of the Particle Migration Phenomenon

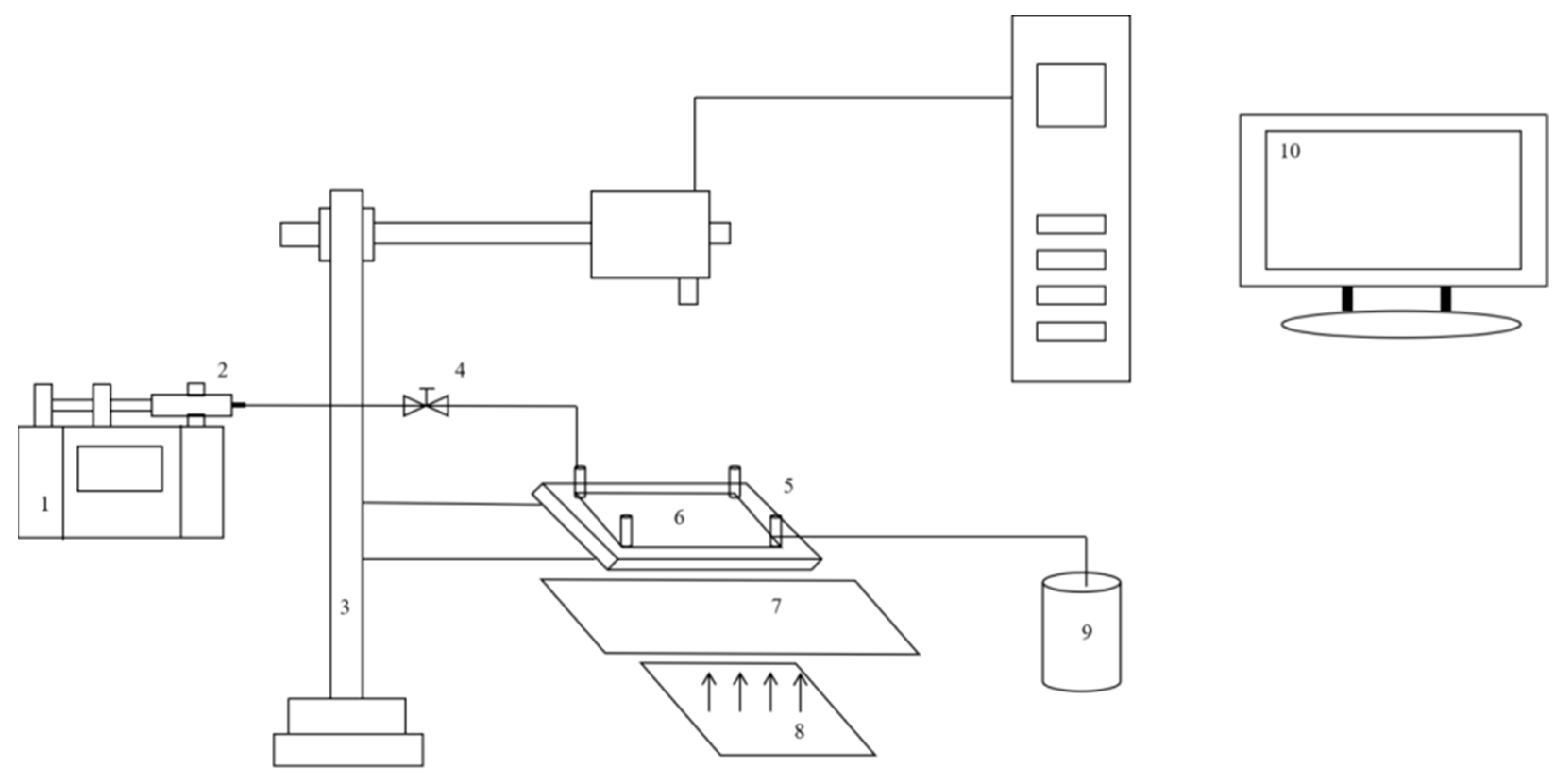

3. Micro-Visualization Experiment

3.1. Experimental Chemicals

3.2. Experimental Apparatus

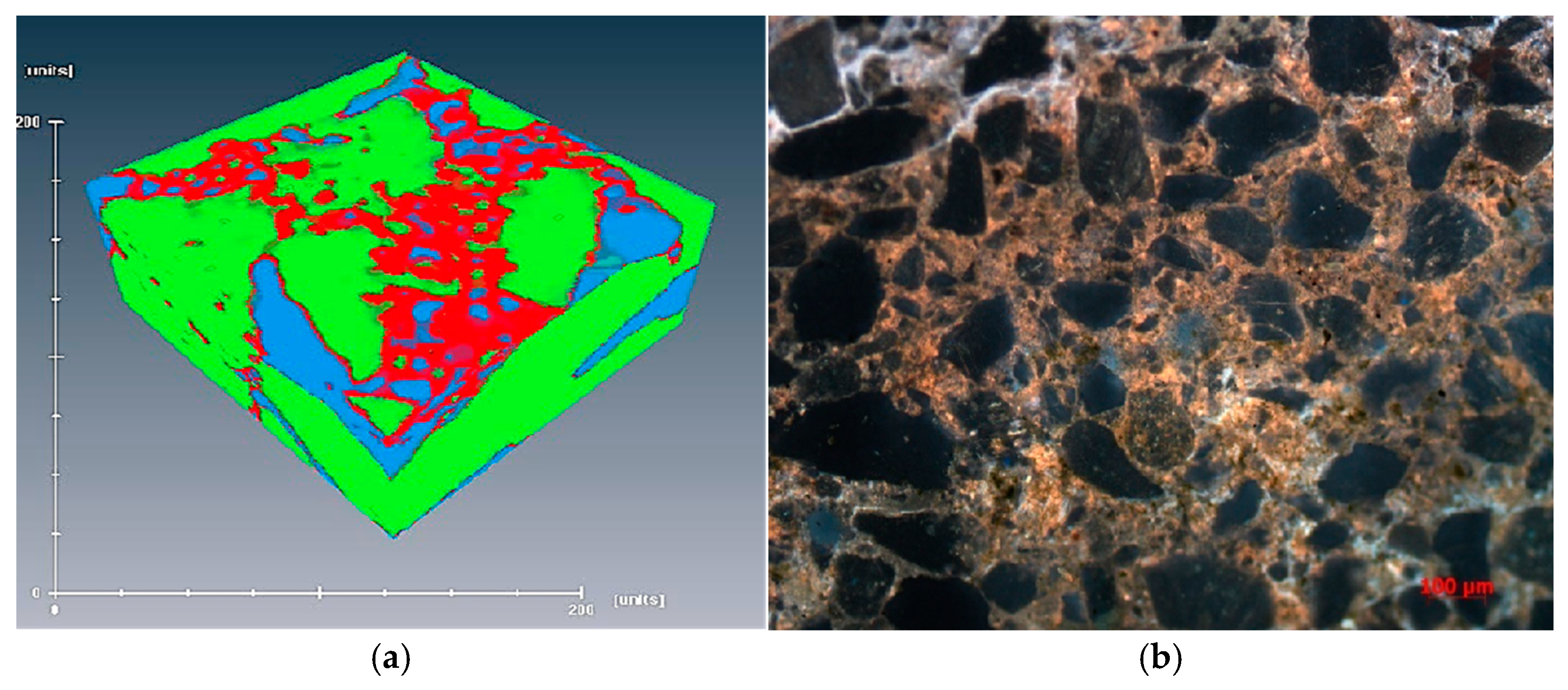

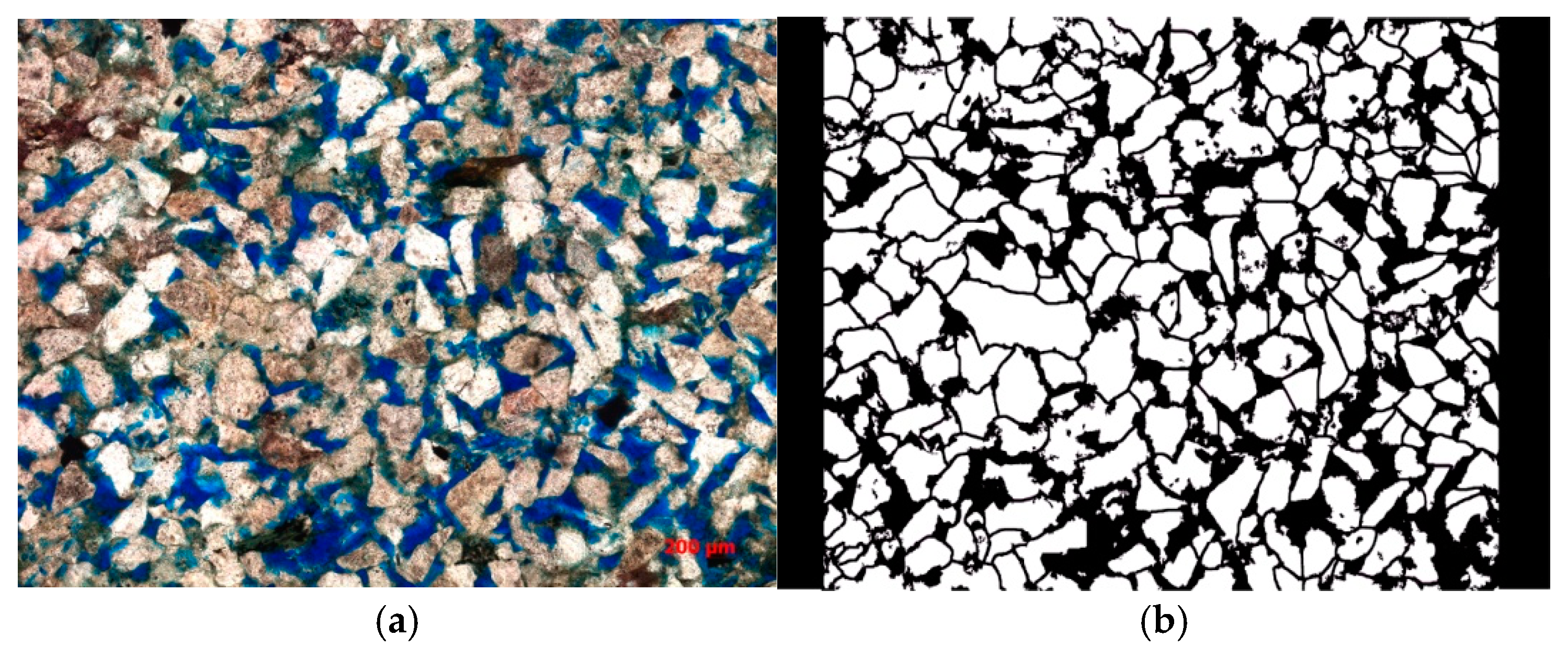

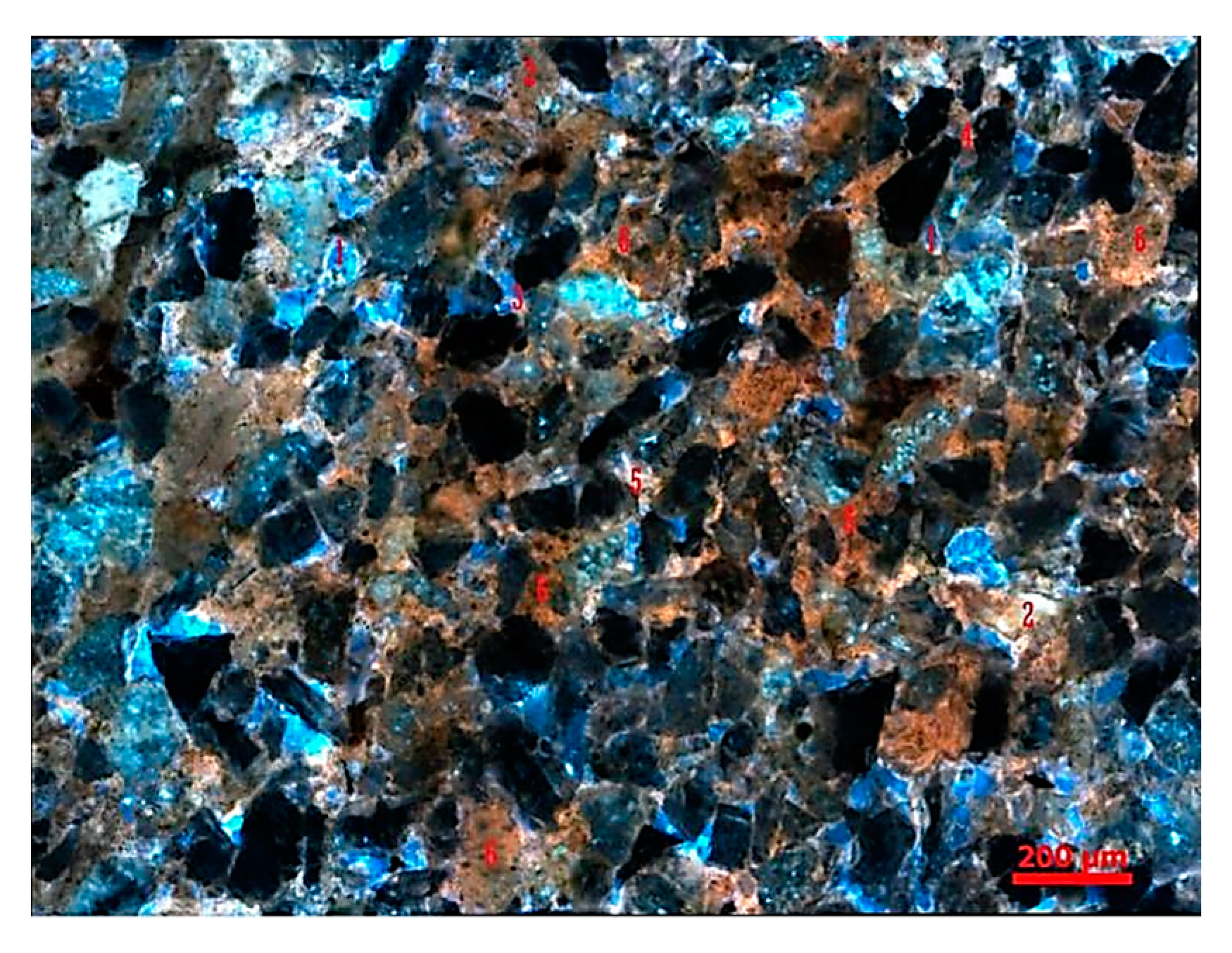

3.3. Preparation of Micro-Visualization Model

3.4. Preparation of Experimental Reagents

3.5. Microscopic Visualization Displacement Experiment

4. Results Analysis

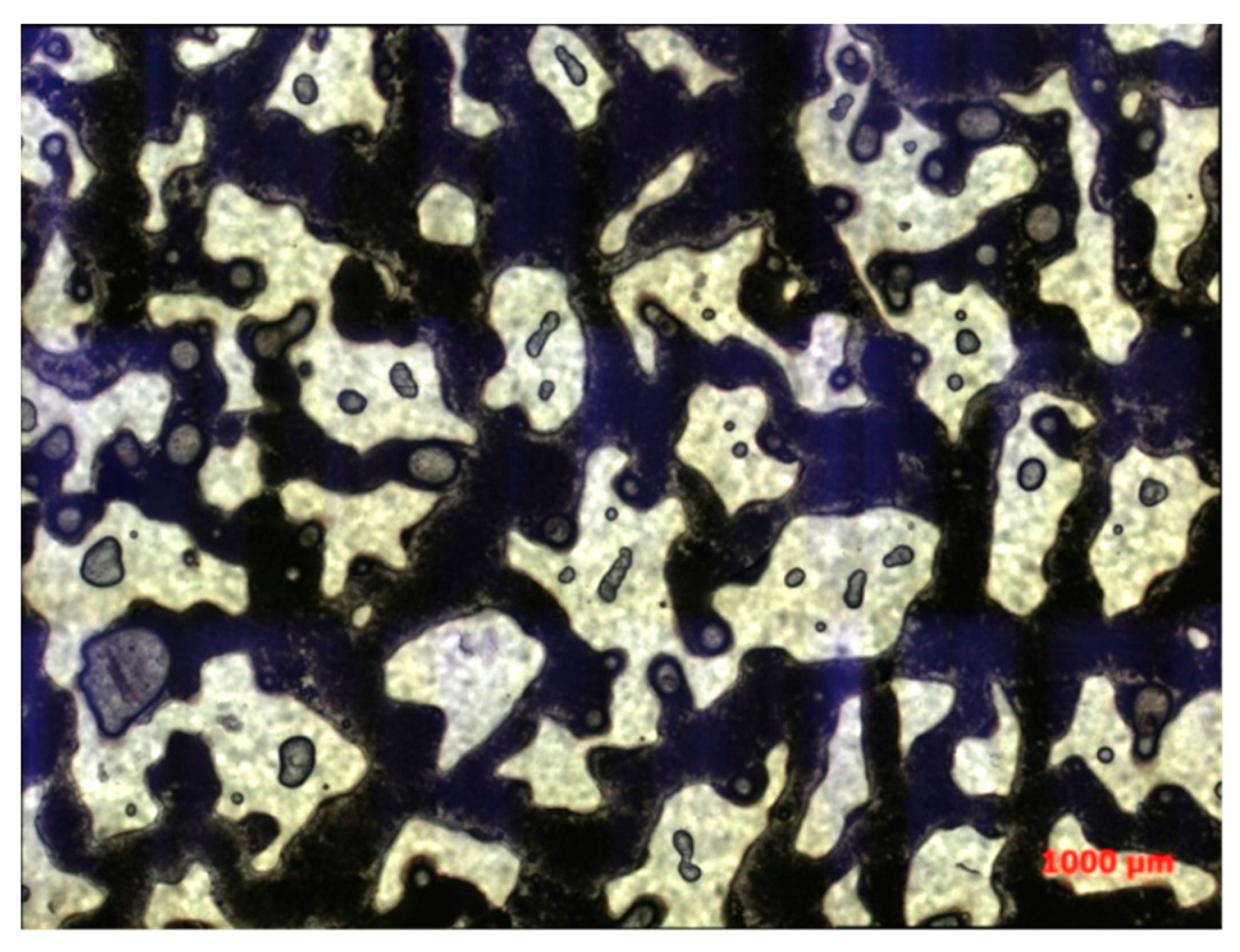

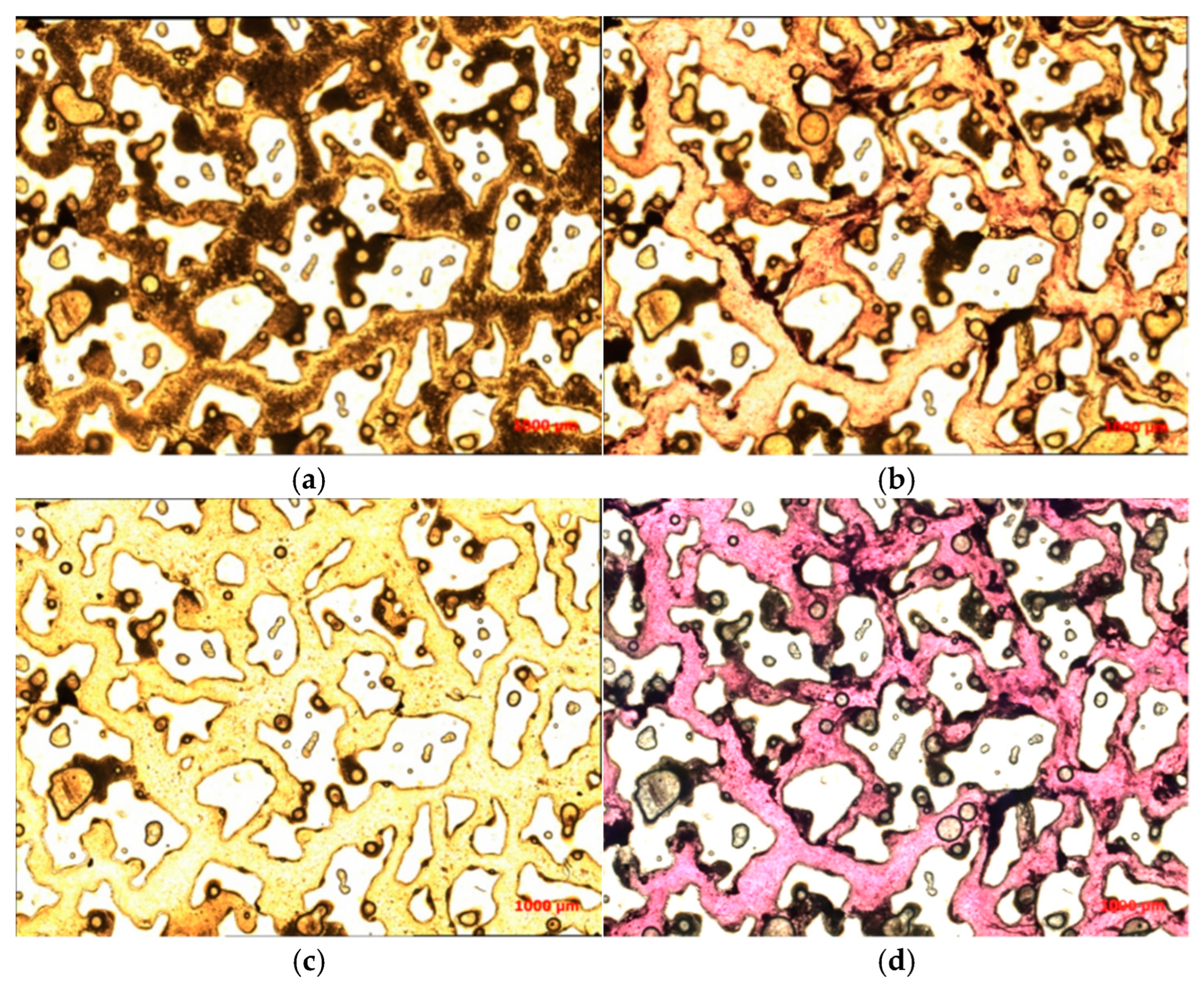

4.1. Experimental Results Analysis

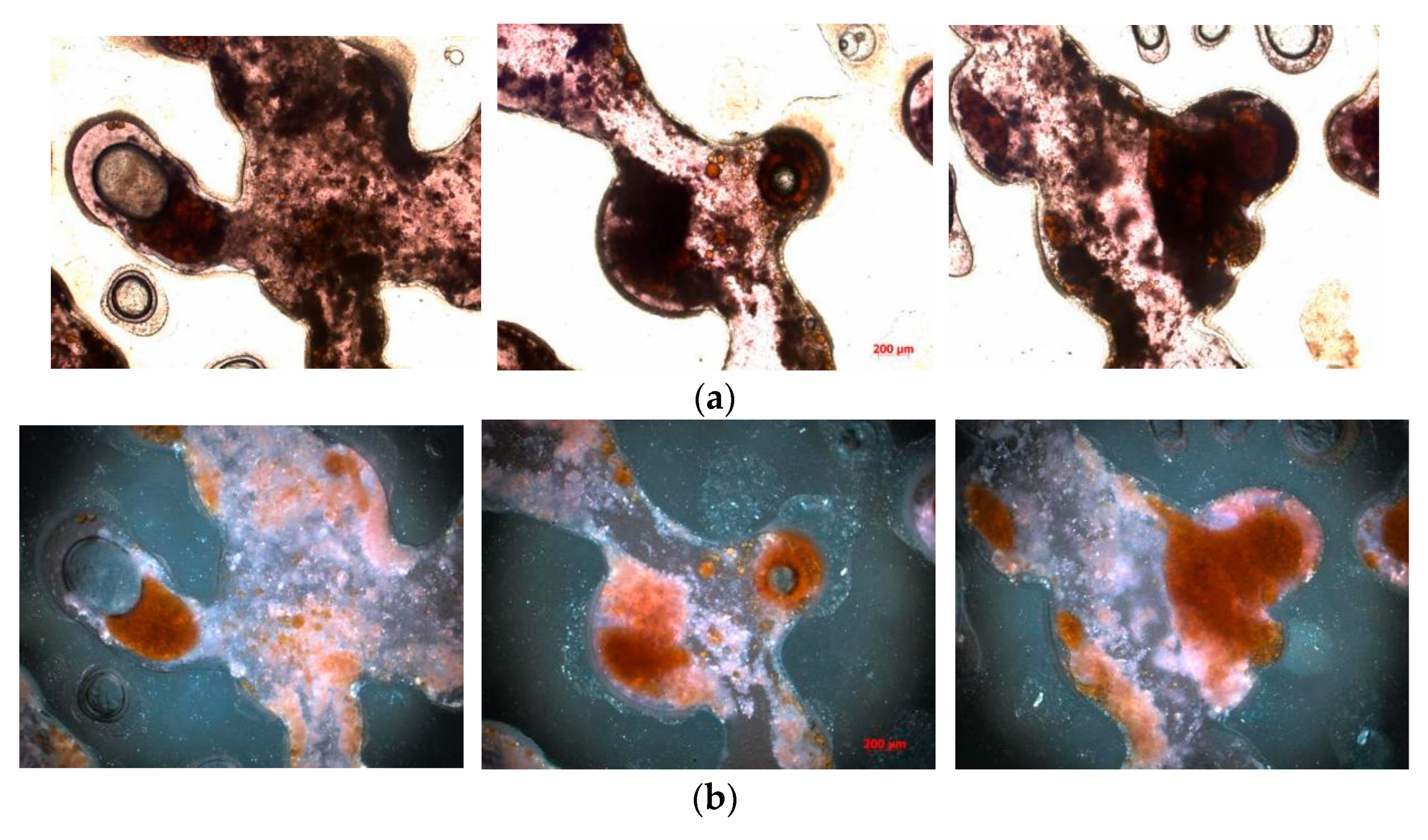

4.2. Impact of Flocculation Reactions on the Oil Displacement Process and Solutions

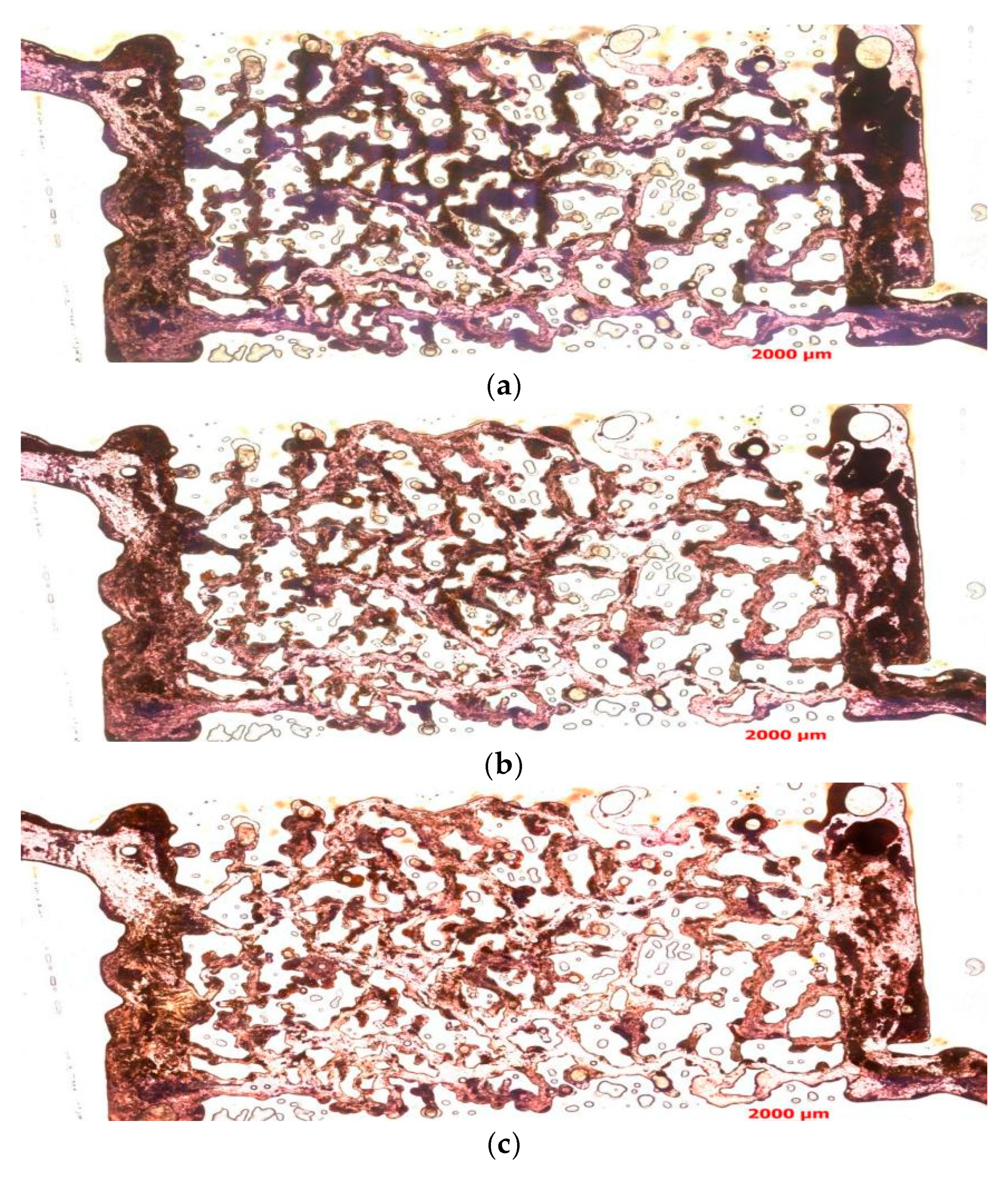

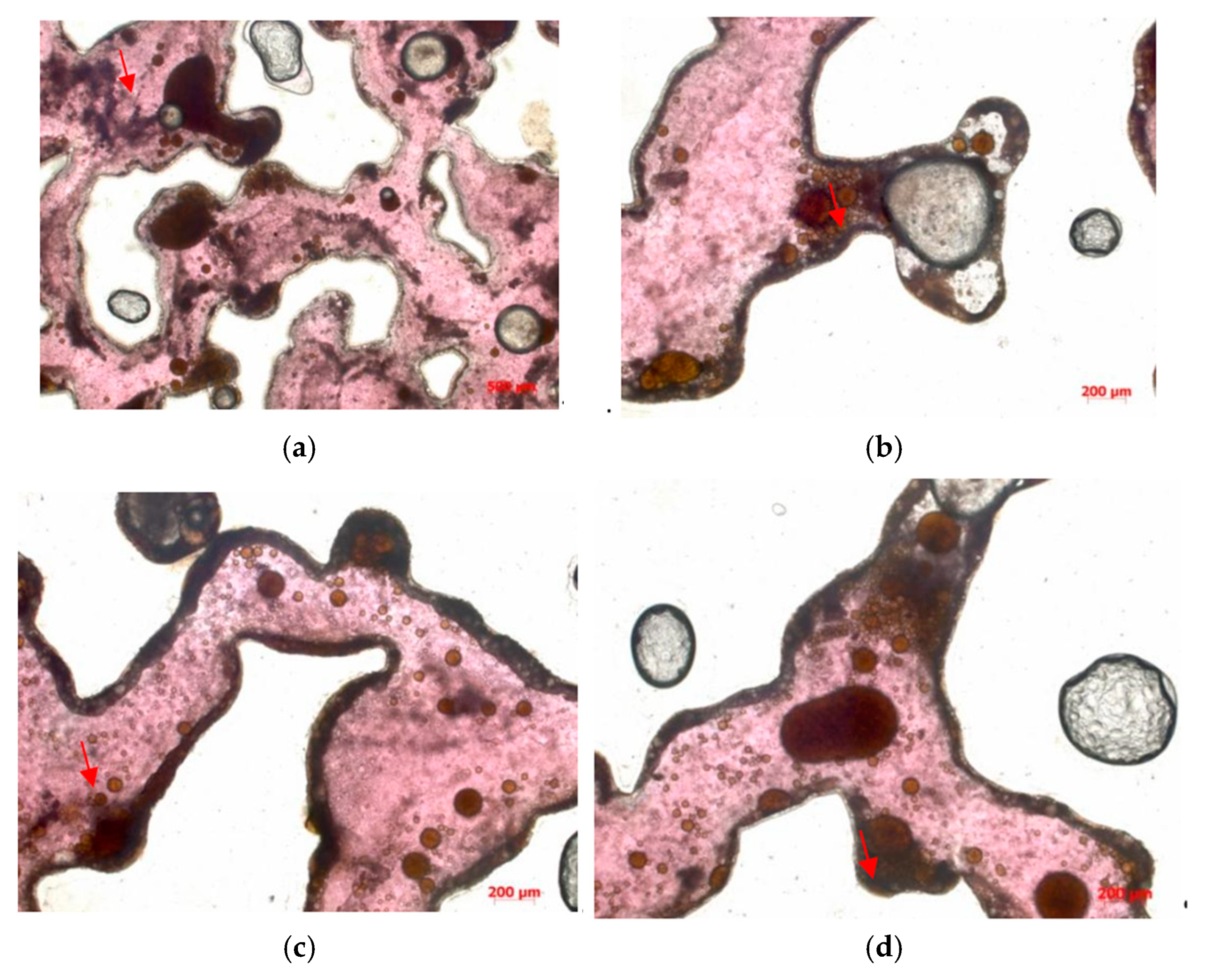

5. The Distribution of Residual Oil After Binary Composite Flooding

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Li, G.; Zhu, R. Progress, challenges and key issues in the unconventional oil and gas development of CNPC. China Pet. Explor. 2020, 25, 1–13. [Google Scholar]

- Liao, G.; He, D.; Wang, G.; Wang, L.; Wang, Z.; Su, C.; Qin, Q.; Bai, J.; Hu, Z.; Huang, Z.; et al. Discussion on the limit recovery factor of carbon dioxide flooding in a permanent sequestration scenario. Pet. Explor. Dev. 2022, 49, 1463–1470. [Google Scholar] [CrossRef]

- Lake, L.W.; Johns, R.; Rossen, B.; Pope, G.A. Fundamentals of Enhanced Oil Recovery; Society of Petroleum Engineers: Richardson, TX, USA, 2014. [Google Scholar]

- Mokheimer, E.M.; Hamdy, M.; Abubakar, Z.; Shakeel, M.R.; Habib, M.A.; Mahmoud, M. A comprehensive review of thermal enhanced oil recovery: Techniques evaluation. J. Energy Resour. Technol. 2019, 141, 030801. [Google Scholar] [CrossRef]

- Patel, J.; Borgohain, S.; Kumar, M.; Rangarajan, V.; Somasundaran, P.; Sen, R. Recent developments in microbial enhanced oil recovery. Renew. Sustain. Energy Rev. 2015, 52, 1539–1558. [Google Scholar] [CrossRef]

- Xia, X.; Deng, Q.; Sang, P.; Tan, L.; Yan, L.; Bao, J.; Li, W. Low-carbon oil exploitation: Carbon dioxide flooding technology. Front. Earth Sci. 2023, 10, 1035771. [Google Scholar] [CrossRef]

- Sorbie, K.S. Polymer-Improved Oil Recovery; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2013. [Google Scholar]

- Zhu, Y.; Hou, Q.; Jian, G.; Ma, D.; Wang, Z. Current development and application of chemical combination flooding technique. Pet. Explor. Dev. 2013, 40, 96–103. [Google Scholar] [CrossRef]

- Liu, Z.; Shi, B.; Ge, T.; Sui, F.; Wang, Y.; Zhang, P.; Chang, X.; Liu, Y.; Wang, Y.; Wang, Z. Tight sandstone reservoir sensitivity and damage mechanism analysis: A case study from Ordos Basin, China and implications for reservoir damage prevention. Energy Geosci. 2022, 3, 394–416. [Google Scholar] [CrossRef]

- Zou, Y.; Ning, S.; He, P. Study on flocculation properties of amphoteric polyacrylamide. Chin. J. Colloid Polym. 2013, 31, 115–117. [Google Scholar]

- Yu, X.-W.; Fu, C.-L.; Gu, A.-Q.; Han, Y.; Wang, J.-M.; Yu, Z.-L. Study on the synthesis process conditions and flocculation properties of cationic polyacrylamide. Chem. Res. Appl. 2017, 29, 319–324. [Google Scholar]

- Zhao, X. Synthesis of Acrylamide Polymers and Their Application in Wastewater Treatment. Master’s Thesis, Wuhan University of Science and Technology, Wuhan, China, 2019. [Google Scholar]

- Xu, F.; Chen, Q.; Ma, M.; Wang, Y.; Yu, F.; Li, J. Displacement mechanism of polymeric surfactant in chemical cold flooding for heavy oil based on microscopic visualization experiments. Adv. Geo-Energy Res. 2020, 4, 77–85. [Google Scholar] [CrossRef]

- Gu, Z.; Li, Z.; Xu, Z.; Zhang, C. Microscopic mechanical model analysis and visualization investigation of SiO2 nanoparticle/HPAM polymer foam liquid film displacing heavy oil. Langmuir 2022, 38, 9166–9185. [Google Scholar] [CrossRef] [PubMed]

- Voroniak, A.; Bryan, J.; Hejazi, H.; Kantzas, A. Two-Dimensional Visualization of Heavy Oil Displacement Mechanism During Chemical Flooding. In Proceedings of the SPE Annual Technical Conference and Exhibition, Dubai, United Arab Emirates, 26–28 September 2016; p. D031S045R001. [Google Scholar]

- Lei, W.; Lu, X.; Wu, T.; Yang, H.; Wang, M. High-performance displacement by microgel-in-oil suspension in heterogeneous porous media: Microscale visualization and quantification. J. Colloid Interface Sci. 2022, 627, 848–861. [Google Scholar] [CrossRef]

- Conn, C.A.; Ma, K.; Hirasaki, G.J.; Biswal, S.L. Visualizing oil displacement with foam in a microfluidic device with permeability contrast. Lab Chip 2014, 14, 3968–3977. [Google Scholar] [CrossRef]

- Bajgiran, K.R.; Hymel, H.C.; Sombolestani, S.; Dante, N.; Safa, N.; Dorman, J.A.; Rao, D.; Melvin, A.T. Fluorescent visualization of oil displacement in a microfluidic device for enhanced oil recovery applications. Analyst 2021, 146, 6746–6752. [Google Scholar] [CrossRef] [PubMed]

- Zhu, H.; Zhou, J.; Wang, Y.; Huang, L. Microscopic mechanism study of gas-water flow in porous media. Pet. Geol. Exp. 2004, 26, 571–573. [Google Scholar]

- Liu, Z.; Li, Y.; Luan, H.; Gao, W.; Guo, Y.; Chen, Y. Pore scale and macroscopic visual displacement of oil-in-water emulsions for enhanced oil recovery. Chem. Eng. Sci. 2019, 197, 404–414. [Google Scholar] [CrossRef]

- Li, D.; Zhang, L.; Zhou, K.; Guo, L.-P. Gas-water two-phase flow mechanism in visual microscopic pore model. J. China Univ. Pet. (Ed. Nat. Sci.) 2008, 32, 80–83. [Google Scholar]

- Donaldson, E.C.; Thomas, R.D. Microscopic observations of oil displacement in water-wet and oil-wet systems. In Proceedings of the SPE Annual Technical Conference and Exhibition, New Orleans, LA, USA, 3 October 1971; p. SPE-3555-MS. [Google Scholar]

- Mehranfar, A.; Ghazanfari, M.H. Investigation of the microscopic displacement mechanisms and macroscopic behavior of alkaline flooding at different wettability conditions in shaly glass micromodels. J. Pet. Sci. Eng. 2014, 122, 595–615. [Google Scholar] [CrossRef]

- Sun, X.; Suo, L.; Zhang, M.; Wang, P. New progress of laser confocal scanning microscopy in the study of reservoir analysis in Daqing exploration area. Acta Petrol. Sin. 2005, 21, 1479–1488. [Google Scholar]

- Zhong, H.; He, Y.; Yang, E.; Bi, Y.; Yang, T. Modeling of microflow during viscoelastic polymer flooding in heterogenous reservoirs of Daqing Oilfield. J. Pet. Sci. Eng. 2022, 210, 110091. [Google Scholar] [CrossRef]

- Yi, X.; Zhang, M.; Mu, G. Microscopic Distribution and Development Strategy of Residual Oil in Tight Sandstone. Processes 2023, 11, 1907. [Google Scholar] [CrossRef]

- Fu, H.; Bai, Z.; Guo, H.; Yang, K.; Guo, C.; Liu, M.; Liang, L.; Song, K. Remaining oil distribution law and development potential analysis after polymer flooding based on reservoir architecture in Daqing Oilfield, China. Polymers 2023, 15, 2137. [Google Scholar] [CrossRef]

- Sirivithayapakorn, S.; Keller, A. Transport of colloids in saturated porous media: A pore-scale observation of the size exclusion effect and colloid acceleration. Water Resour. Res. 2003, 39, 1109. [Google Scholar] [CrossRef]

- Xia, H.; Wang, L.; Han, P.; Cao, R.; Zhang, S.; Sun, X. Microscopic residual oil distribution characteristics and quantitative characterization of producing degree based on core fluorescence analysis technology. Geofluids 2021, 2021, 8827721. [Google Scholar] [CrossRef]

- Sun, C.; Wang, X.; Zhao, J.; Zhang, J.; Wu, X.; Wang, W.; Yan, X. Study on the Mobilization Mechanisms of Microscopic Residual Oil in High-Water-Cut Sandstone Reservoirs. Processes 2024, 12, 1608. [Google Scholar] [CrossRef]

- Li, J.; Liu, Y.; Gao, Y.; Cheng, B.; Meng, F.; Xu, H. Effects of microscopic pore structure heterogeneity on the distribution and morphology of remaining oil. Pet. Explor. Dev. 2018, 45, 1112–1122. [Google Scholar] [CrossRef]

- Gao, H.; Liu, Y.; Zhang, Z.; Niu, B.; Li, H. Impact of secondary and tertiary floods on microscopic residual oil distribution in medium-to-high permeability cores with NMR technique. Energy Fuels 2015, 29, 4721–4729. [Google Scholar] [CrossRef]

- Sun, X.; Zhao, M.; Fan, X.; Zhang, Y.; Xu, C.; Wang, L.; Sang, G. Study on micro production mechanism of corner residual oil after polymer flooding. Polymers 2022, 14, 878. [Google Scholar] [CrossRef] [PubMed]

- Druetta, P.; Picchioni, F. Influence of physical and rheological properties of sweeping fluids on the residual oil saturation at the micro-and macroscale. J. Non-Newton. Fluid Mech. 2020, 286, 104444. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, X.; Wang, Y.; Guo, Q.; Ouyang, Z.; Xu, C.; Cao, Y.; Liu, T.; Ma, W. Investigating the Impact of Polymers on Clay Flocculation and Residual Oil Behaviour Using a 2.5D Model. Polymers 2024, 16, 3494. https://doi.org/10.3390/polym16243494

Sun X, Wang Y, Guo Q, Ouyang Z, Xu C, Cao Y, Liu T, Ma W. Investigating the Impact of Polymers on Clay Flocculation and Residual Oil Behaviour Using a 2.5D Model. Polymers. 2024; 16(24):3494. https://doi.org/10.3390/polym16243494

Chicago/Turabian StyleSun, Xianda, Yuchen Wang, Qiansong Guo, Zhaozhuo Ouyang, Chengwu Xu, Yangdong Cao, Tao Liu, and Wenjun Ma. 2024. "Investigating the Impact of Polymers on Clay Flocculation and Residual Oil Behaviour Using a 2.5D Model" Polymers 16, no. 24: 3494. https://doi.org/10.3390/polym16243494

APA StyleSun, X., Wang, Y., Guo, Q., Ouyang, Z., Xu, C., Cao, Y., Liu, T., & Ma, W. (2024). Investigating the Impact of Polymers on Clay Flocculation and Residual Oil Behaviour Using a 2.5D Model. Polymers, 16(24), 3494. https://doi.org/10.3390/polym16243494