Transient Viscosity Adjustment Using a Coaxial Nozzle for Electrospinning Nanofibers from Non-Spinnable Pure m-Poly(hydroxyamide)

Abstract

1. Introduction

2. Materials and Methods

2.1. m-PHA Synthesis

2.2. Polymer Solution Preparation

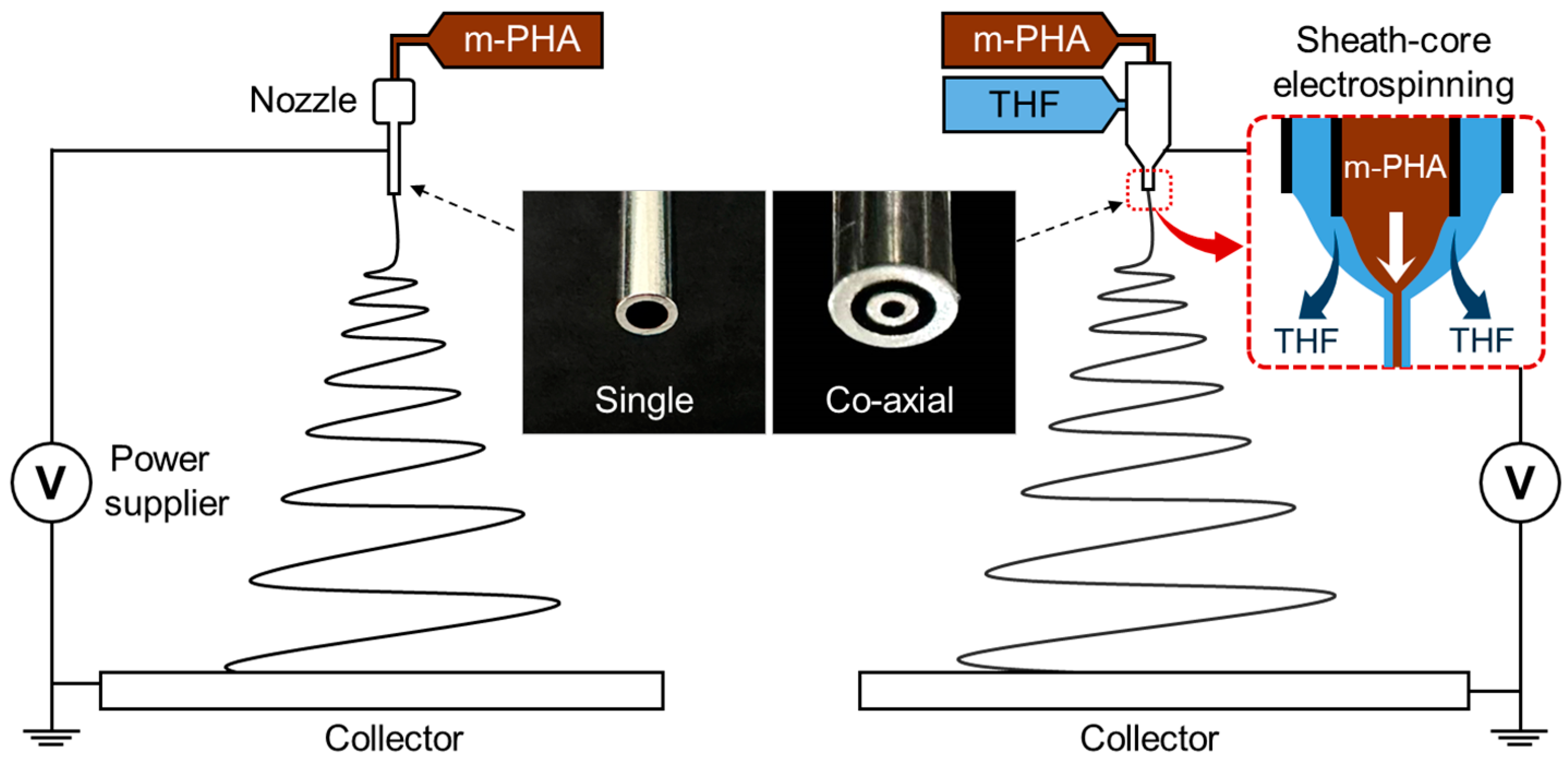

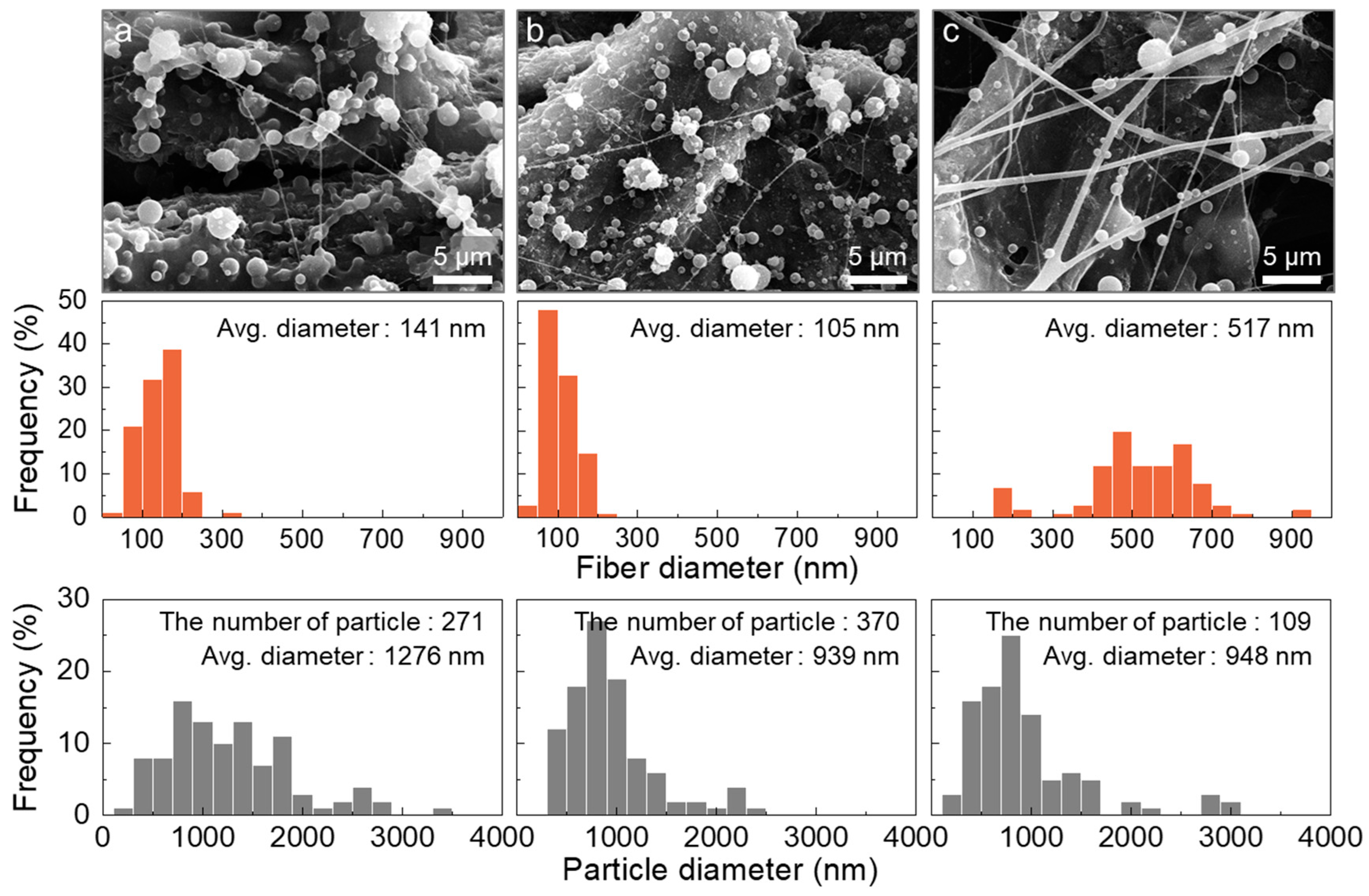

2.3. Electrospinning the m-PHA

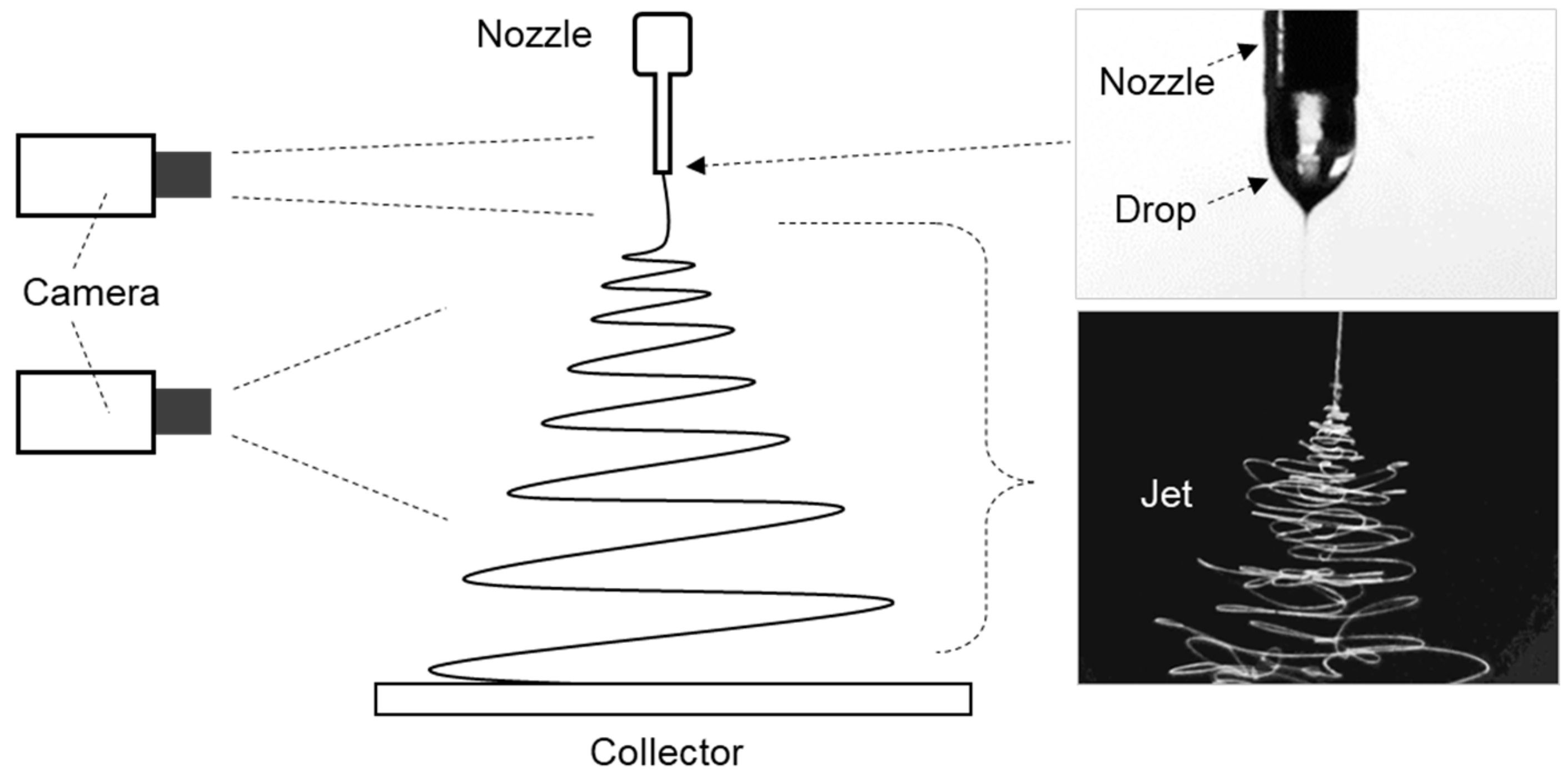

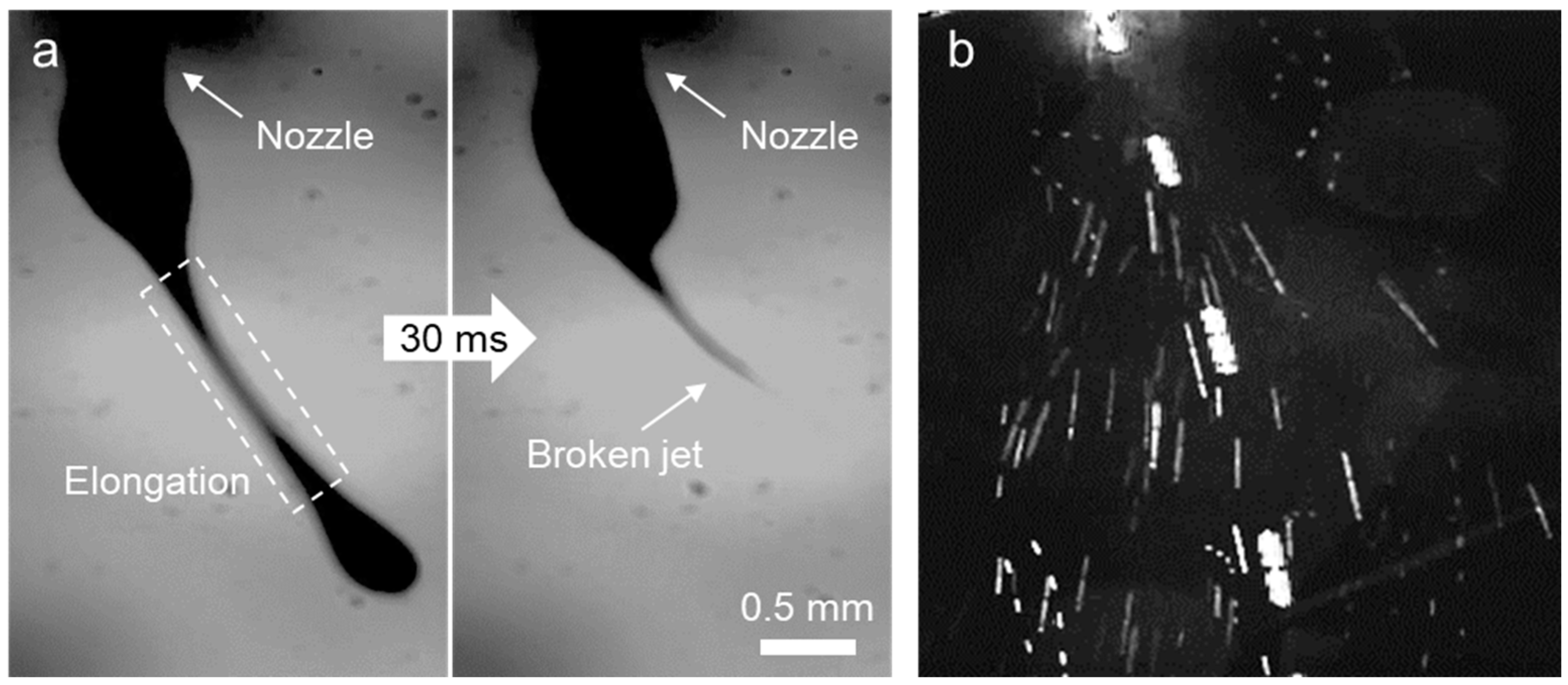

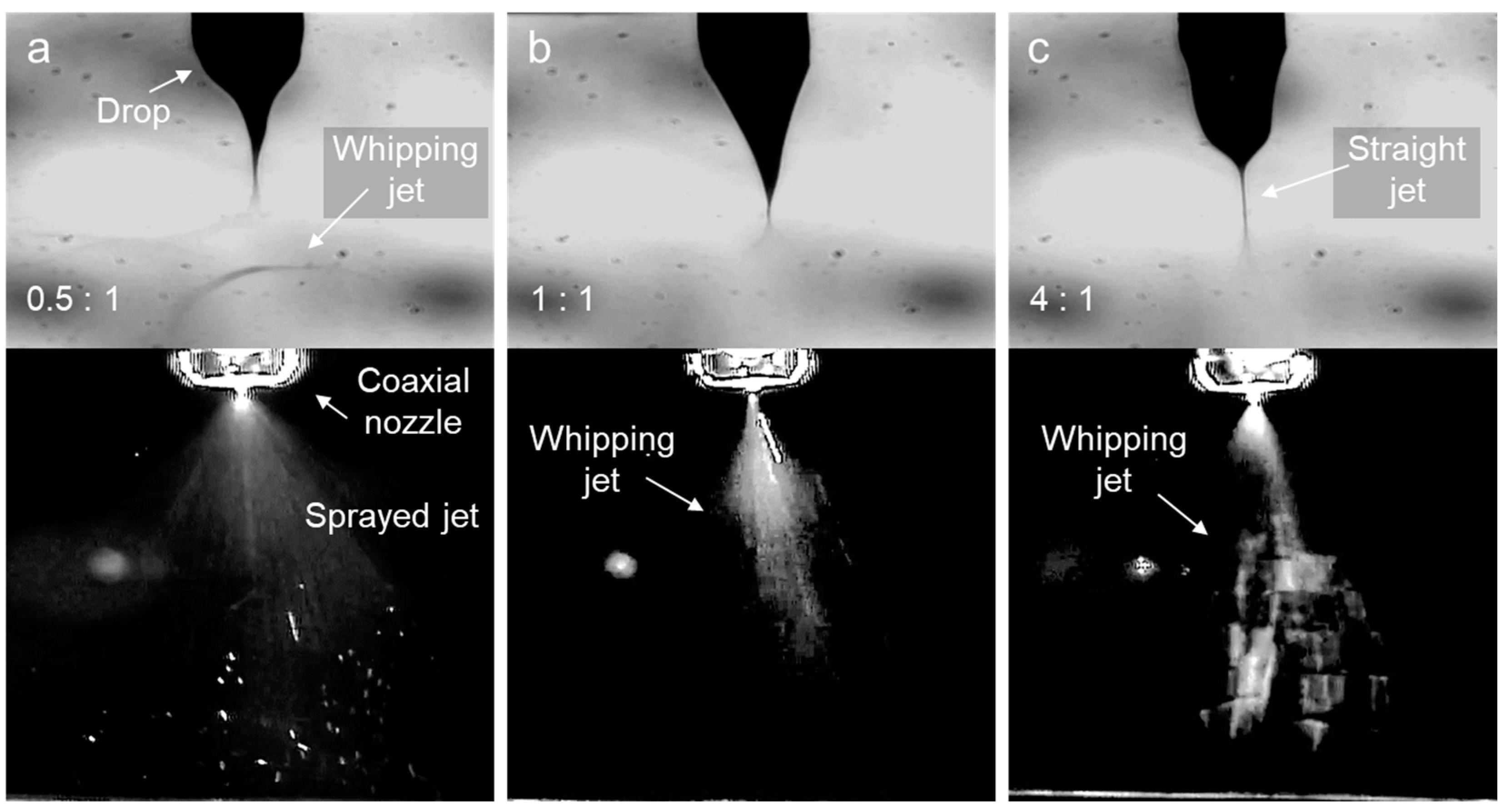

2.4. Dynamic Behavior of the Electrospinning

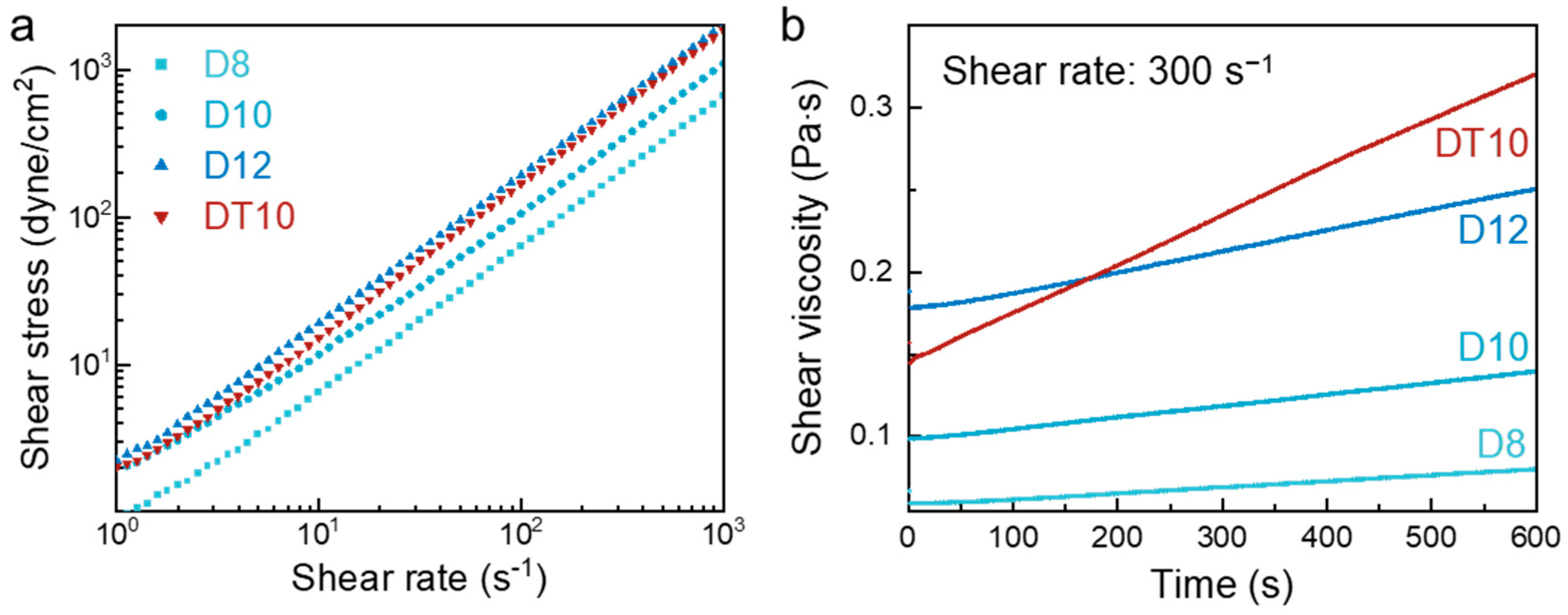

2.5. Rheological Characteristics

2.6. Morphological Characteristics

3. Results and Discussion

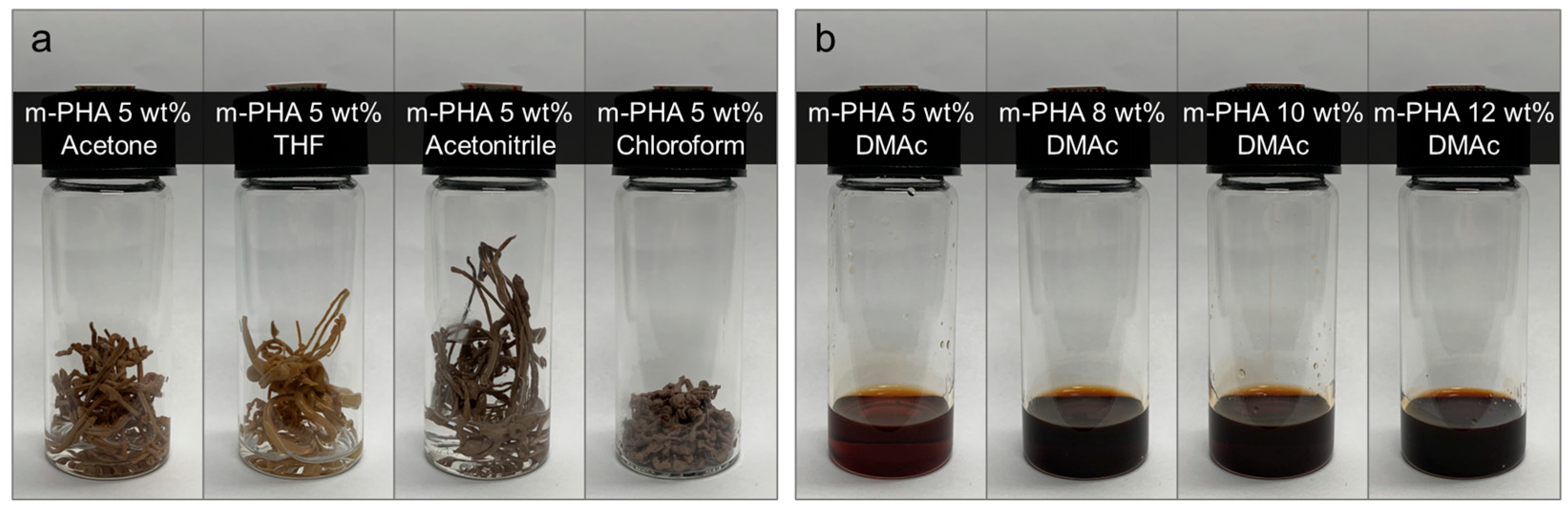

3.1. Solubility of the m-PHA in the Organic Solvents

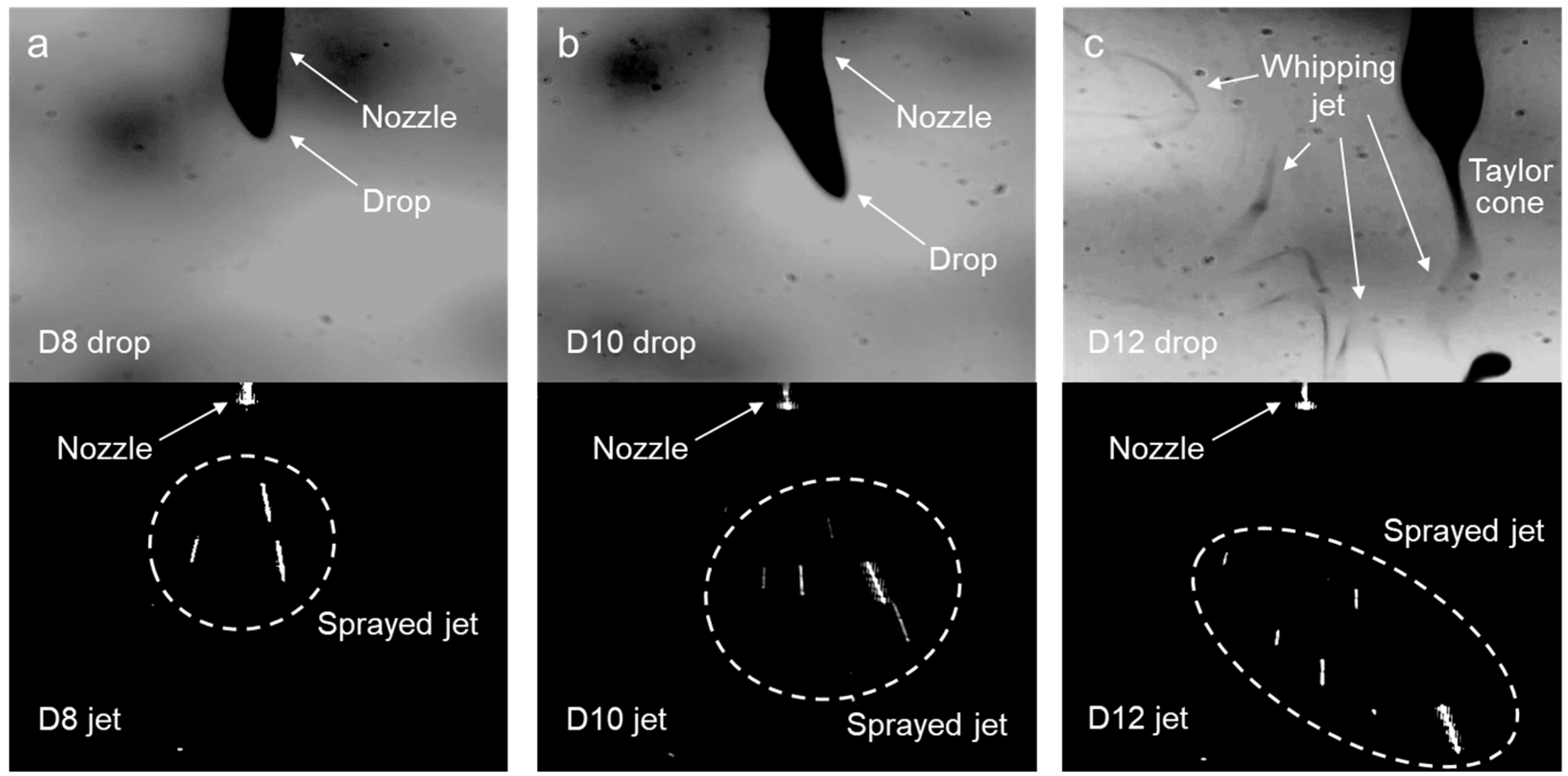

3.2. Effect of the Solution Properties on Nanofiber Formation

3.3. Modifications to the Electrospinning Setup

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Han, S.H.; Lee, E.J.; Choi, J.K. Synthesis and Properties of Polybenzoxazole Copolymers Having Non Linear Units. Elastomers Compos. 2019, 54, 321–329. [Google Scholar]

- Chang, J.-H.; Chen, M.J.; Farris, R.J. Effect of heat treatment on the thermal and mechanical properties of a precursor polymer: Polyhydroxyamide. Polymer 1998, 39, 5649–5654. [Google Scholar] [CrossRef]

- Chokai, M.; Taniguchi, M.; Moriya, S.; Matsubayashi, K.; Shinoda, T.; Nabae, Y.; Kuroki, S.; Hayakawa, T.; Kakimoto, M.-A.; Ozaki, J.-I. Preparation of carbon alloy catalysts from a polyhydroxyamide with iron phthalocyanine via a poly-biphenylenebisoxazole composite. J. Photopolym. Sci. Technol. 2010, 23, 459–464. [Google Scholar] [CrossRef]

- Wee, D.-Y.; Choi, J.-K.; Lee, C.-H. Synthesis and Thermal Properties of Aromatic Polyhydroxyamides Containing Imide Ring in the Main Chain. Elastomers Compos. 2011, 46, 295–303. [Google Scholar]

- Wee, D.-Y.; Han, J.-W.; Choi, J.-K. Preparation and Characteristics of the Blends of Polyimide and Polybenzoxazole Having Imide Ring. Polymer 2013, 37, 420–430. [Google Scholar] [CrossRef]

- Hsu, S.L.-C.; Chang, K.-C. Synthesis and properties of polybenzoxazole–clay nanocomposites. Polymer 2002, 43, 4097–4101. [Google Scholar] [CrossRef]

- Lim, J.; Kim, M.-C.; Goh, M.; Yeo, H.; Shin, D.G.; Ku, B.-C.; You, N.-H. Synthesis and characterization of polybenzoxazole/graphene oxide composites via in situ polymerization. Carbon Lett. 2013, 14, 251–254. [Google Scholar] [CrossRef]

- Iwashita, K. Study of Low Temperature Curable Polybenzoxazole Precursors Containing Aliphatic Dicarboxylic Acid Structures. J. Photopolym. Sci. Technol. 2017, 30, 225–230. [Google Scholar] [CrossRef]

- Duan, G.; Jiang, S.; Chen, S.; Hou, H. Heat and Solvent Resistant Electrospun Polybenzoxazole Nanofibers from Methoxy-Containing Polyaramide. J. Nanomater. 2010, 2010, 219562. [Google Scholar] [CrossRef]

- Park, C.H.; Tocci, E.; Lee, Y.M.; Drioli, E. Thermal treatment effect on the structure and property change between hydroxy-containing polyimides (HPIs) and thermally rearranged polybenzoxazole (TR-PBO). J. Phys. Chem. B 2012, 116, 12864–12877. [Google Scholar] [CrossRef]

- Zhang, H.; Jiang, S.; Duan, G.; Li, J.; Liu, K.; Zhou, C.; Hou, H. Heat-resistant polybenzoxazole nanofibers made by electrospinning. Eur. Polym. J. 2014, 50, 61–68. [Google Scholar] [CrossRef]

- Hsu, S.L.C.; Lin, K.S.; Wang, C. Preparation of polybenzoxazole fibers via electrospinning and postspun thermal cyclization of polyhydroxyamide. J. Polym. Sci. Part A Polym. Chem. 2008, 46, 8159–8169. [Google Scholar] [CrossRef]

- Lee, E.H.; Jee, M.H.; Kang, C.S.; Baik, D.H. Preparation and characterization of polyhydroxyamide hybrid nanocomposite films containing MWCNTs and clay as reinforcing materials. Fibers Polym. 2019, 20, 832–838. [Google Scholar] [CrossRef]

- Xia, Y.; Yang, P.; Sun, Y.; Wu, Y.; Mayers, B.; Gates, B.; Yin, Y.; Kim, F.; Yan, H. One-dimensional nanostructures: Synthesis, characterization, and applications. Adv. Mater. 2003, 15, 353–389. [Google Scholar] [CrossRef]

- Choi, S.; Eom, Y.; Kim, S.M.; Jeong, D.W.; Han, J.; Koo, J.M.; Hwang, S.Y.; Park, J.; Oh, D.X. A self-healing nanofiber-based self-responsive time-temperature indicator for securing a cold-supply chain. Adv. Mater. 2020, 32, 1907064. [Google Scholar] [CrossRef]

- Senthil, R.; Sumathi, V.; Tamilselvi, A.; Kavukcu, S.B.; Aruni, A.W. Funtionalized electrospun nanofibers for high efficiency removal of particulate matter. Sci. Rep. 2022, 12, 8411. [Google Scholar] [CrossRef]

- Meng, Z.; Zhu, L.; Wang, X.; Zhu, M. Electrospun Nanofibrous Composite Membranes for Separations. Acc. Mater. Res. 2023, 4, 180–192. [Google Scholar] [CrossRef]

- Wu, L.; Song, Y.; Xing, S.; Li, Y.; Xu, H.; Yang, Q.; Li, Y. Advances in electrospun nanofibrous membrane sensors for ion detection. RSC Adv. 2022, 12, 34866. [Google Scholar] [CrossRef]

- Kibria, F.; Rahman, W.; Patra, S.N. Detection of high sensitive acoustic region for sensible applications of electrospinning based PVDF-TrFE nanofiber sensor. Nano Express 2020, 1, 020027. [Google Scholar] [CrossRef]

- Simko, M.; Lukas, D. Mathematical modeling of a whipping instability of an electrically charged liquid jet. Appl. Math. Model. 2016, 40, 9565–9583. [Google Scholar] [CrossRef]

- Brown, T.D.; Dalton, P.D.; Hutmacher, D.W. Melt electrospinning today: An opportune time for an emerging polymer process. Prog. Polym. Sci. 2016, 56, 116–166. [Google Scholar] [CrossRef]

- Vasilyev, G.; Burman, M.; Arinstein, A.; Zussman, E. Estimating the degree of polymer stretching during electrospinning: An experimental imitation method. Macromol. Mater. Eng. 2017, 302, 1600554. [Google Scholar] [CrossRef]

- Lim, J.; Choi, S.; Kim, H.S. Hybrid processing of melt electrospinning/blowing for polypropylene/polyethylene glycol fiber fabrication with various diameter distribution. J. Text. Inst. 2024, in press. [Google Scholar] [CrossRef]

- Wang, C.; Hashimoto, T.; Wang, Y. Extension Rate and Bending Instability of Electrospinning Jets: The Role of the Electric Field. Macromolecules 2021, 54, 7193–7209. [Google Scholar] [CrossRef]

- Wang, C.; Wang, Y.; Hashimoto, T. Impact of Entanglement Density on Solution Electrospinning: A Phenomenological Model for Fiber Diameter. Macromolecuels 2016, 49, 7985–7996. [Google Scholar] [CrossRef]

- Choi, S.; Lee, H.M.; Kim, H.S. Effect of molecular weight on humidity-sensitive characteristics of electrospun polyethylene oxide. Sens. Actuators A Phys. 2019, 294, 194–202. [Google Scholar] [CrossRef]

- Kriegel, C.; Kit, K.; McClements, D.; Weiss, J. Influence of surfactant type and concentration on electrospinning of chitosan–poly(ethylene oxide) blend nanofibers. Food Biophys. 2009, 4, 213–228. [Google Scholar] [CrossRef]

- Bachs-Herrera, A.; Yousefzade, O.; del Valle, L.J.; Puiggali, J. Melt electrospinning of polymers: Blends, nanocomposites, additives and applications. Appl. Sci. 2021, 11, 1808. [Google Scholar] [CrossRef]

- Topuz, F.; Uyar, T. Influence of hydrogen-bonding additives on electrospinning of cyclodextrin nanofibers. ACS Omega 2018, 3, 18311–18322. [Google Scholar] [CrossRef]

- Wang, C.; Wang, J.; Zeng, L.; Qiao, Z.; Liu, X.; Liu, H.; Zhang, J.; Ding, J. Fabrication of electrospun polymer nanofibers with diverse morphologies. Molecules 2019, 24, 834. [Google Scholar] [CrossRef]

- Rathore, P.; Schiffman, J.D. Beyond the single-nozzle: Coaxial electrospinning enables innovative nanofiber chemistries, geometries, and applications. ACS Appl. Mater. Interfaces 2020, 13, 48–66. [Google Scholar] [CrossRef] [PubMed]

- Deitzel, J.M.; Kleinmeyer, J.D.; Hirvonen, J.K.; Tan, N.B. Controlled deposition of electrospun poly(ethylene oxide) fibers. Polymer 2001, 42, 8163–8170. [Google Scholar] [CrossRef]

- Perez-Puyana, V.M.; Romero, A.; Guerrero, A.; Moroni, L.; Wieringa, P.A. Enabling low molecular weight electrospinning through binary solutions of polymer blends. Next Mater. 2025, 6, 100306. [Google Scholar] [CrossRef]

- Pirzada, T.; Farias, B.V.D.; Chu, H.M.A.; Khan, S.A. Fabrication of Guar-Only Electrospun Nanofibers by Exploiting a High- and Low-Molecular Weight Blend. ACS Omega 2019, 4, 10767–10774. [Google Scholar] [CrossRef]

- Wang, X.; Pellerin, C.; Bazuin, C.G. Enhancing the Electrospinnability of Low Molecular Weight Polymers Using Small Effective Cross-Linkers. Macromolecules 2016, 49, 891–899. [Google Scholar] [CrossRef]

- Dong, S.; Maciejewska, B.M.; Schofield, R.M.; Hawkins, N.; Siviour, C.R.; Grobert, N. Electrospinning Nonspinnable Sols to Ceramic Fibers and Springs. ACS Nano 2024, 18, 13538–13550. [Google Scholar] [CrossRef]

| Nozzle Type | Solvent Type | Solution Concentration (wt%) | Solution Name | Applied Voltage (kV) | Flow Rate (mL h−1) | Others | |

|---|---|---|---|---|---|---|---|

| Core | Sheath | ||||||

| Single (ID: 0.26 mm) | DMAc only | 8 | D8 | 10–11 | 0.5 | - | Distance 170 mm |

| 10 | D10 | ||||||

| 12 | D12 | ||||||

| DMAc:THF = 8:2 (w/w) | 10 | DT10 | 18 | 0.5 | - | Room Temp | |

| Coaxial (ID: 0.25 mm) | DMAc only | 10 | D10 | 22–24 | 0.5 | 0.25, 0.5, 2.0, 8.0, 10.0, and 20.0 | 25% RH |

| 12 | D12 | ||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, Y.; Lim, J.; Kim, H.S.; Lee, J.; Chun, Y.; Cho, D.-H.; Kang, C.S.; Choi, S. Transient Viscosity Adjustment Using a Coaxial Nozzle for Electrospinning Nanofibers from Non-Spinnable Pure m-Poly(hydroxyamide). Polymers 2024, 16, 3414. https://doi.org/10.3390/polym16233414

Kim Y, Lim J, Kim HS, Lee J, Chun Y, Cho D-H, Kang CS, Choi S. Transient Viscosity Adjustment Using a Coaxial Nozzle for Electrospinning Nanofibers from Non-Spinnable Pure m-Poly(hydroxyamide). Polymers. 2024; 16(23):3414. https://doi.org/10.3390/polym16233414

Chicago/Turabian StyleKim, Yerim, Jihwan Lim, Han Seong Kim, Jaejun Lee, Youngsang Chun, Dong-Hyun Cho, Chan Sol Kang, and Sejin Choi. 2024. "Transient Viscosity Adjustment Using a Coaxial Nozzle for Electrospinning Nanofibers from Non-Spinnable Pure m-Poly(hydroxyamide)" Polymers 16, no. 23: 3414. https://doi.org/10.3390/polym16233414

APA StyleKim, Y., Lim, J., Kim, H. S., Lee, J., Chun, Y., Cho, D.-H., Kang, C. S., & Choi, S. (2024). Transient Viscosity Adjustment Using a Coaxial Nozzle for Electrospinning Nanofibers from Non-Spinnable Pure m-Poly(hydroxyamide). Polymers, 16(23), 3414. https://doi.org/10.3390/polym16233414