Effect of Star-like Polymer on Mechanical Properties of Novel Basalt Fibre-Reinforced Composite with Bio-Based Matrix

Abstract

1. Introduction

2. Materials and Methods

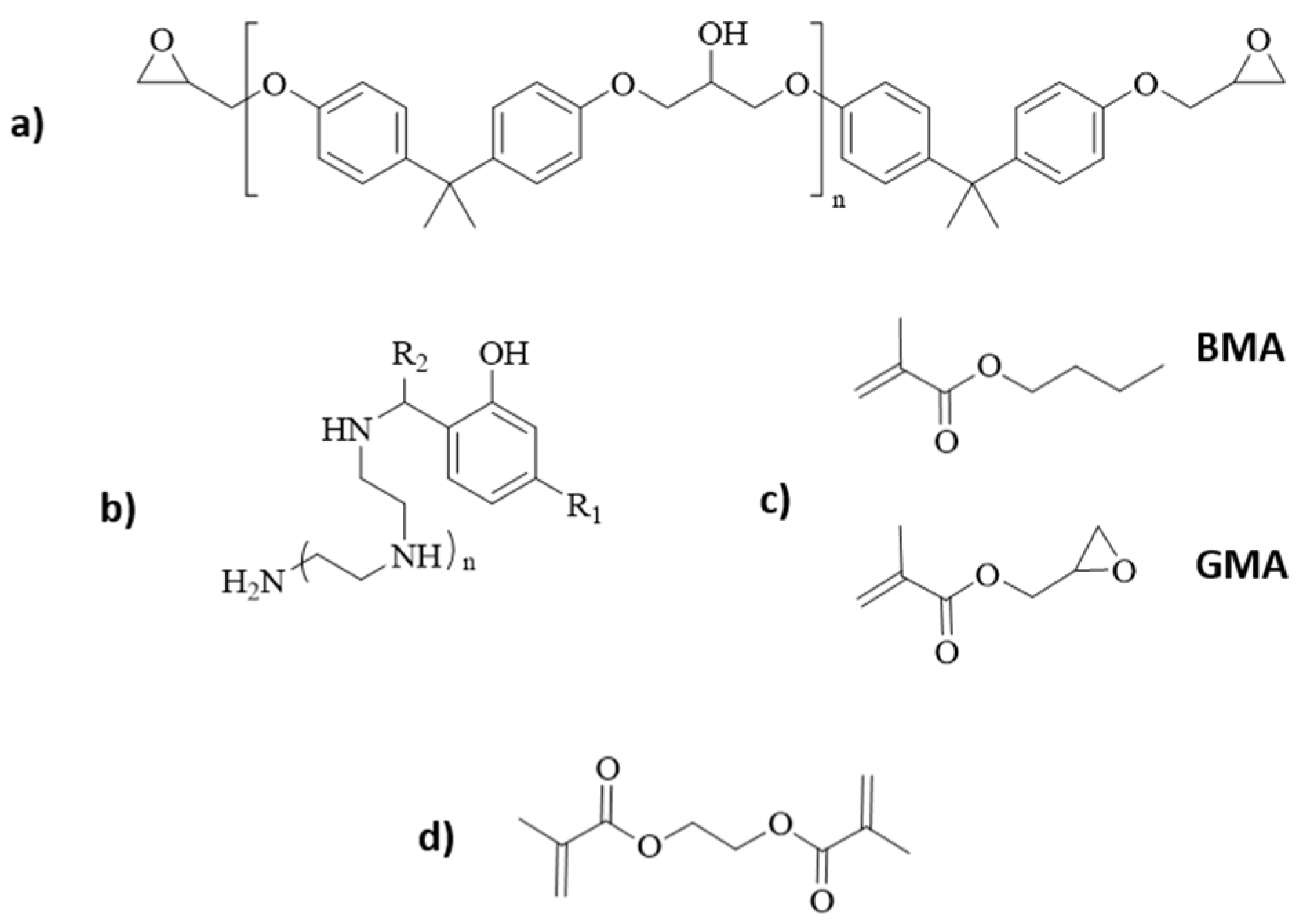

2.1. Materials

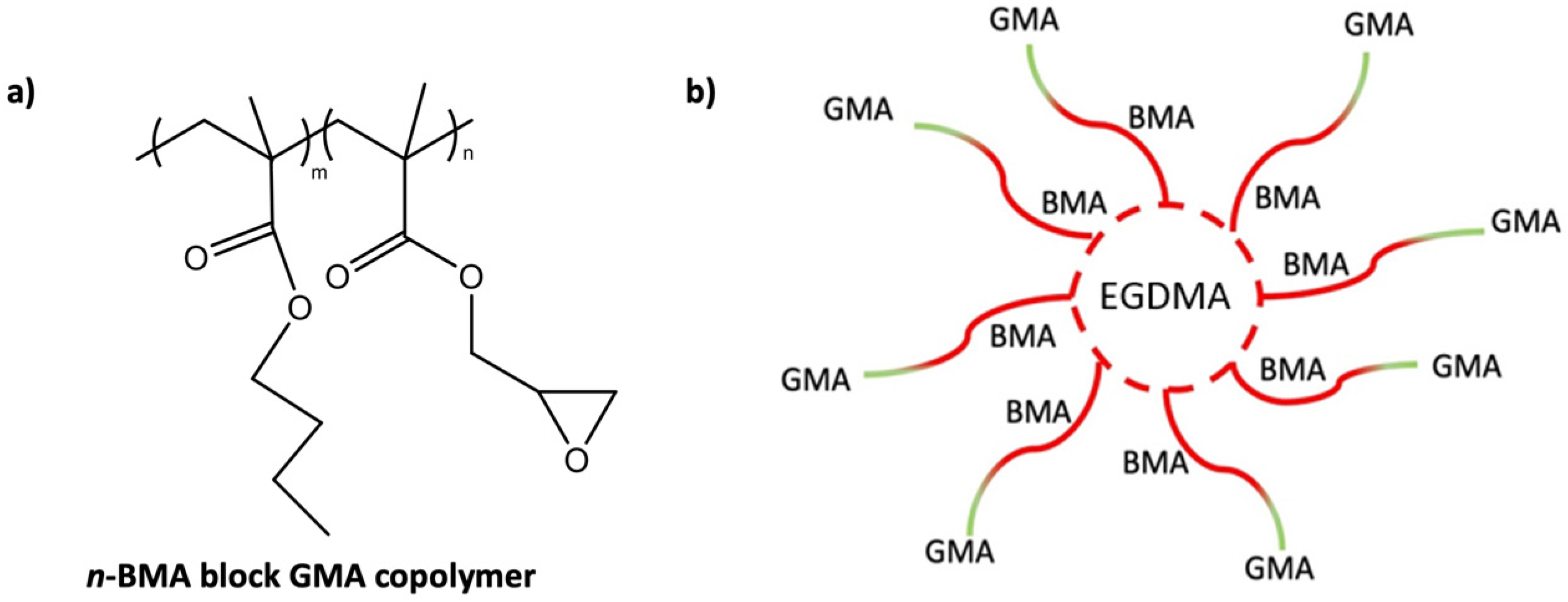

2.2. Synthesis of Star-like Polymer

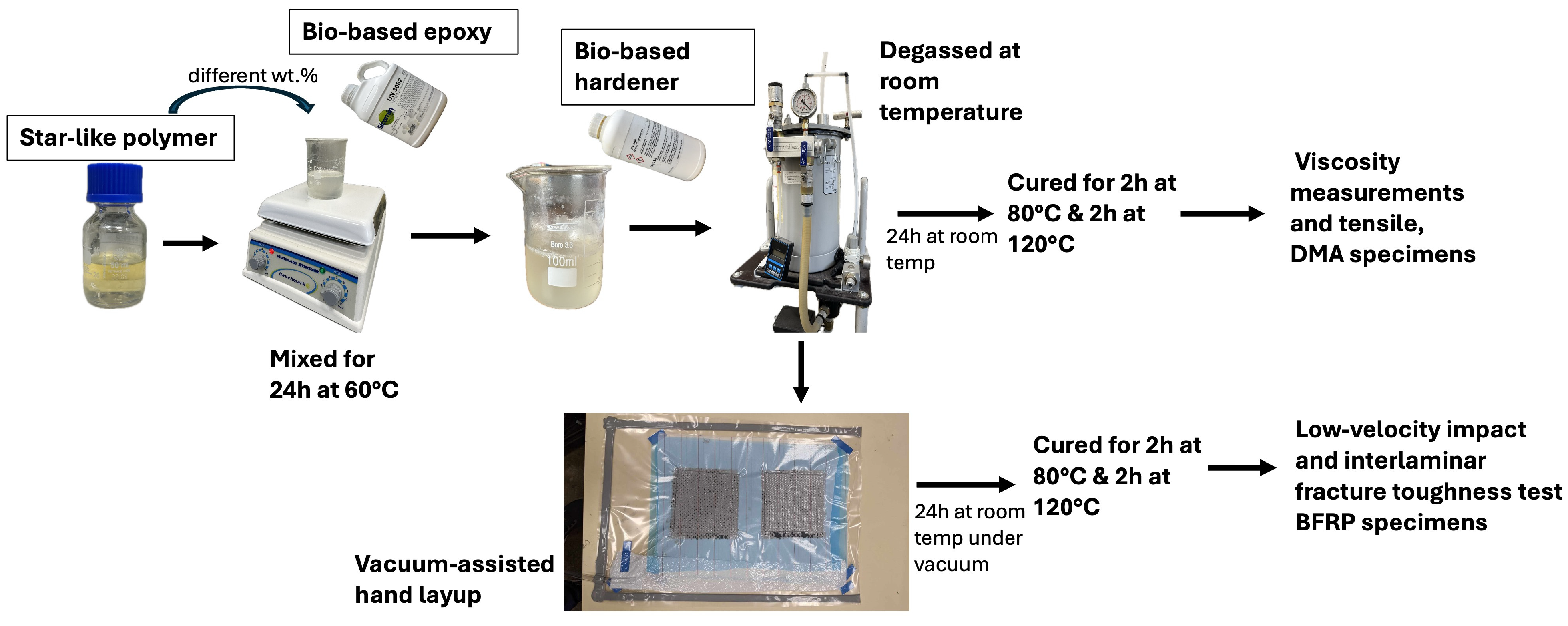

2.3. Material Preparation

2.4. Fabrication of Specimens

2.5. Materials Testing

3. Results and Discussion

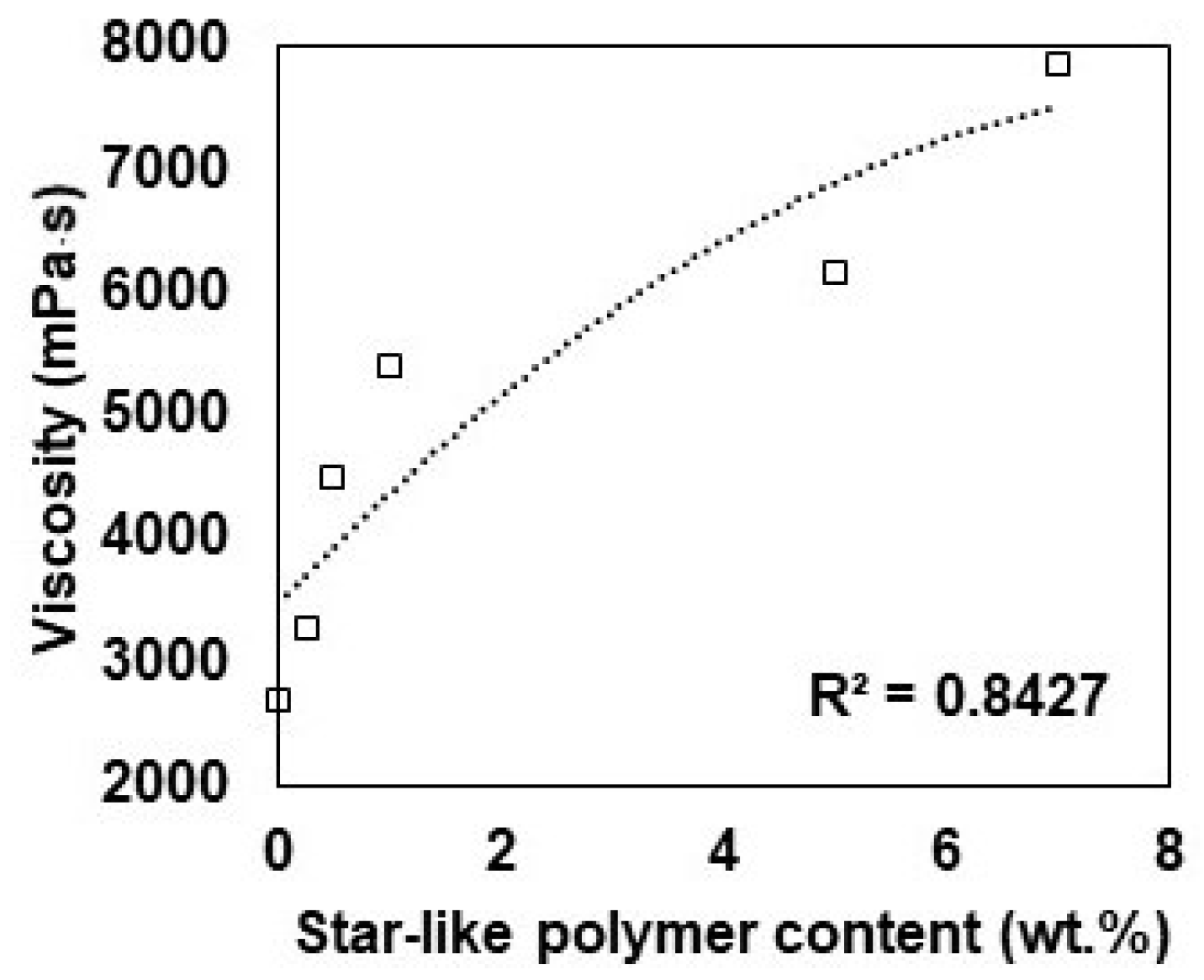

3.1. Effect of Star-like Polymer Content on Viscosity of Bio-Based Epoxy

3.2. Tensile Properties of Star-like Polymer-Modified Bio-Based Matrix

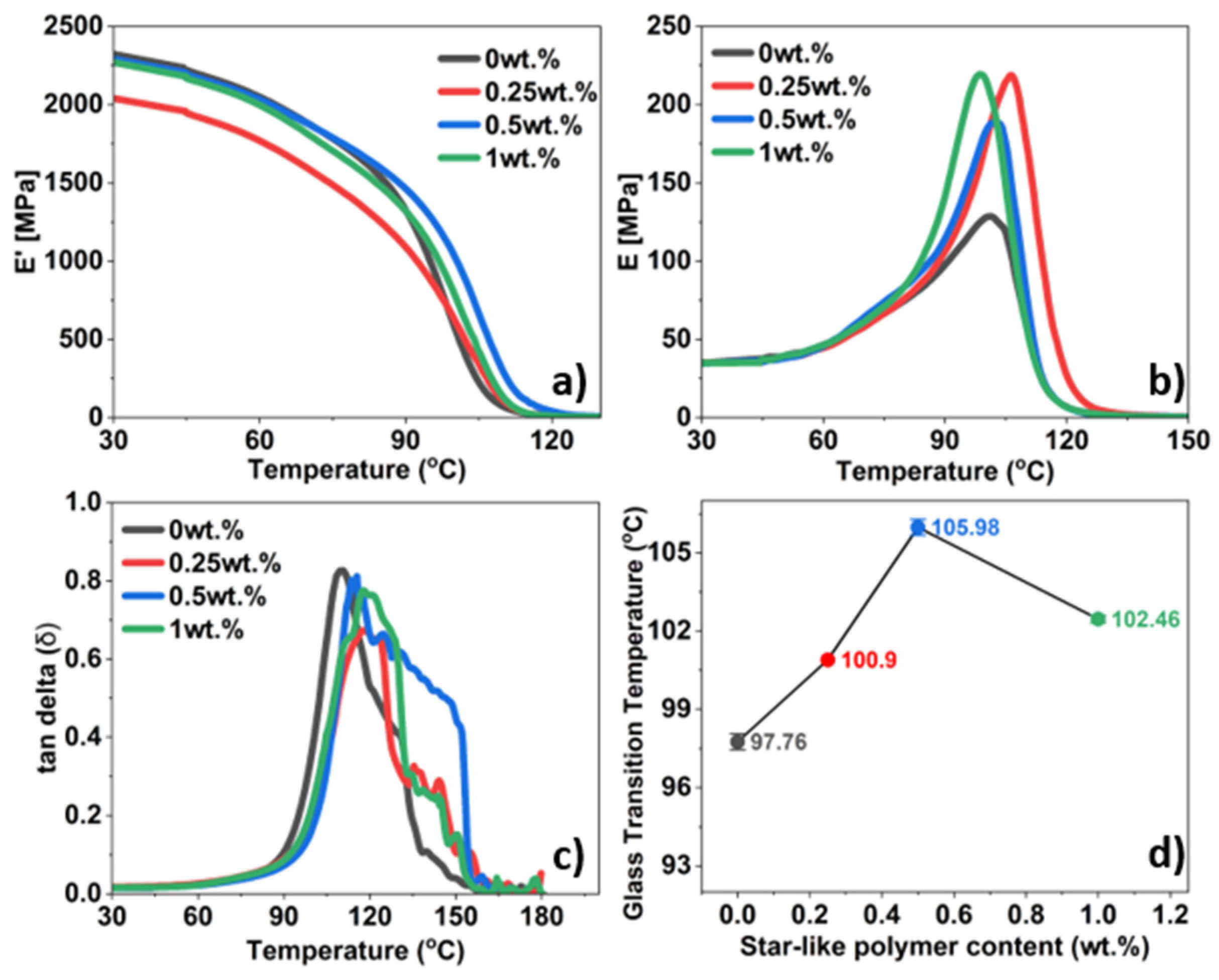

3.3. Visco-Elastic Properties of Star-like Polymer-Modified Bio-Based Matrix

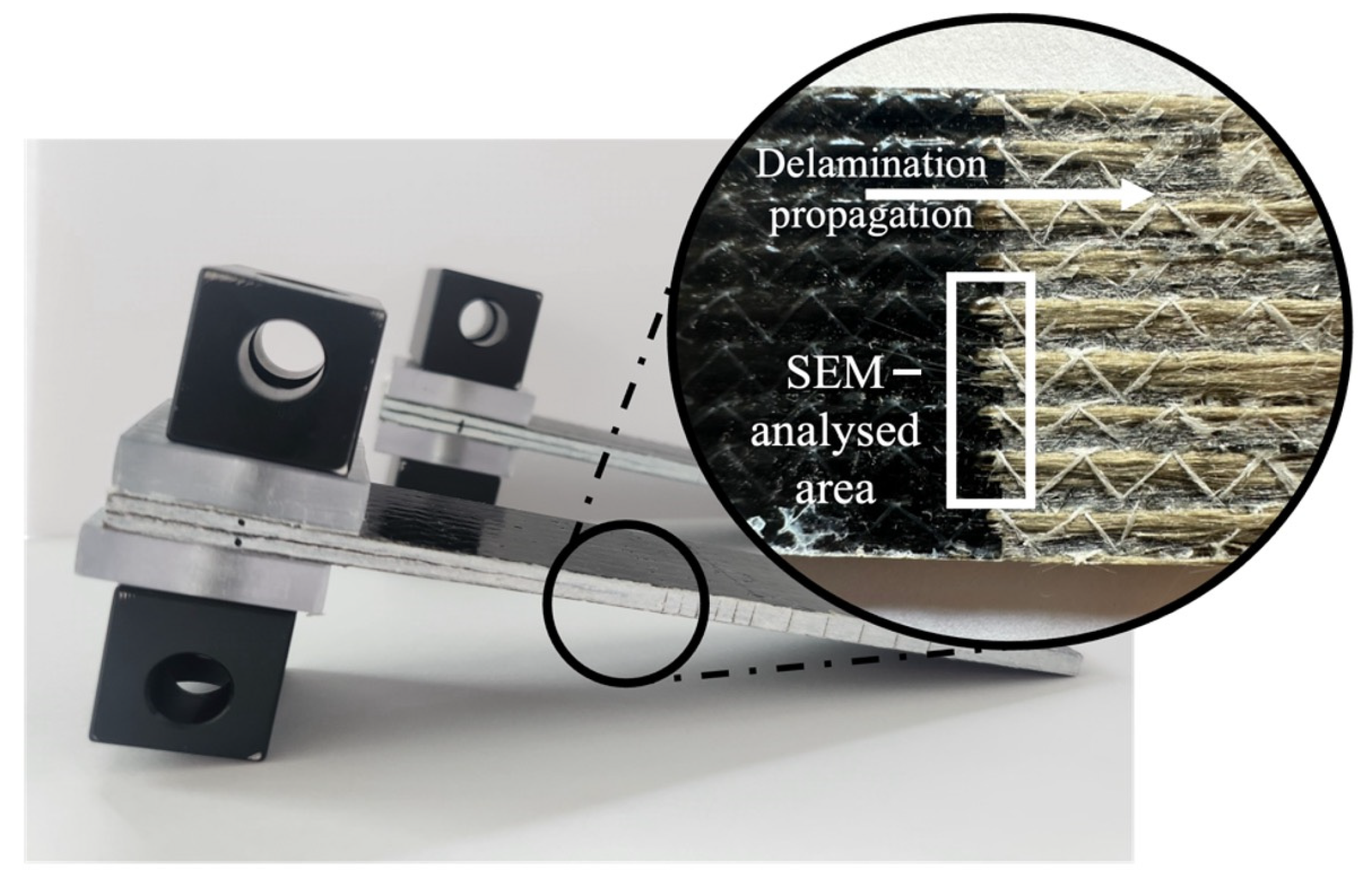

3.4. Interlaminar Fracture Toughness of BFRP Laminates

3.5. Low-Velocity Impact Properties of BFRP Laminates

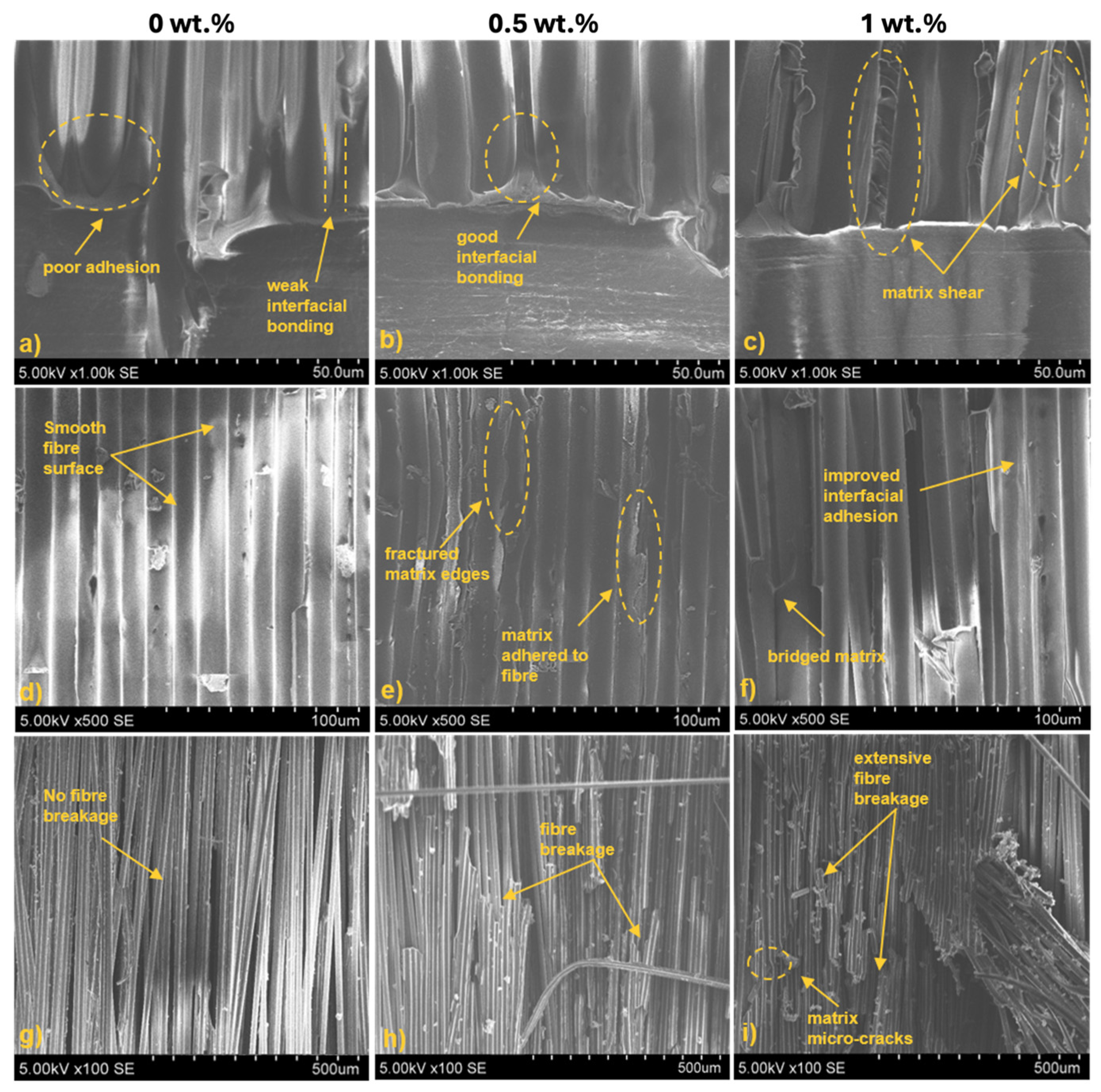

3.6. Scanning Electron Microscopy Characterization

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Singha, K. A Short Review on Basalt Fiber. Int. J. Text. Sci. 2012, 4, 19–28. [Google Scholar]

- Bhatt, P.; Goe, A. Carbon fibres: Production, properties and potential use. Mater. Sci. Res. India 2017, 14, 52–57. [Google Scholar] [CrossRef]

- Hancu, B.D.; Pop, M. Assessment of health effects related to fiber glass exposure in fiber glass workers: Exhaled biomarkers eCO, FENO and their usefulness in the occupational environment testing. Clujul Med. 2013, 86, 114–116. [Google Scholar] [PubMed]

- Barbarino, M.; Giordano, A. Assessment of the Carcinogenicity of Carbon Nanotubes in the Respiratory System. Cancers 2021, 13, 1318. [Google Scholar] [CrossRef]

- Fiore, V.; Scalici, T.; Di Bella, G.; Valenza, A. A review on basalt fibre and its composites. Compos. Part B Eng. 2015, 74, 74–94. [Google Scholar] [CrossRef]

- Meyer, L.O.; Schulte, K.; Grove-Nielsen, E. CFRP-Recycling Following a Pyrolysis Route: Process Optimization and Potentials. J. Compos. Mater. 2009, 43, 1121–1132. [Google Scholar] [CrossRef]

- Dauguet, M.; Mantaux, O.; Perry, N.; Zhao, Y.F. Recycling of CFRP for High Value Applications: Effect of Sizing Removal and Environmental Analysis of the SuperCritical Fluid Solvolysis. Procedia CIRP 2015, 29, 734–739. [Google Scholar] [CrossRef]

- Deng, J.; Xu, L.; Zhang, L.; Peng, J.; Guo, S.; Liu, J.; Koppala, S. Recycling of Carbon Fibers from CFRP Waste by Microwave Thermolysis. Processes 2019, 7, 207. [Google Scholar] [CrossRef]

- More, A.P. Flax fiber–based polymer composites: A review. Adv. Compos. Hybrid Mater. 2022, 5, 1–20. [Google Scholar] [CrossRef]

- Shahzad, A. Hemp fiber and its composites—A review. J. Compos. Mater. 2012, 46, 973–986. [Google Scholar] [CrossRef]

- Chandekar, H.; Chaudhari, V.; Waigaonkar, S. A review of jute fiber reinforced polymer composites. Mater. Today Proc. 2020, 26, 2079–2082. [Google Scholar] [CrossRef]

- Väisänen, T.; Das, O.; Tomppo, L. A review on new bio-based constituents for natural fiber-polymer composites. J. Clean. Prod. 2017, 149, 582–596. [Google Scholar] [CrossRef]

- Chaishome, J.; Rattanapaskorn, S. The influence of alkaline treatment on thermal stability of flax fibres. IOP Conf. Ser. Mater. Sci. Eng. 2017, 191, 012007. [Google Scholar] [CrossRef]

- Mwaikambo, L.Y.; Ansell, M.P. Mechanical properties of alkali treated plant fibres and their potential as reinforcement materials. I. hemp fibres. J. Mater. Sci. 2006, 41, 2483–2496. [Google Scholar] [CrossRef]

- Kabir, M.M.; Wang, H.; Lau, K.T.; Cardona, F. Chemical treatments on plant-based natural fibre reinforced polymer composites: An overview. Compos. Part B Eng. 2012, 43, 2883–2892. [Google Scholar] [CrossRef]

- Li, Z.; Xiao, T.; Pan, Q.; Cheng, J.; Zhao, S. Corrosion behaviour and mechanism of basalt fibres in acidic and alkaline environments. Corros. Sci. 2016, 110, 15–22. [Google Scholar] [CrossRef]

- Azimpour-Shishevan, F.; Akbulut, H.; Mohtadi-Bonab, M.A. Effect of thermal cycling on mechanical and thermal properties of basalt fibre-reinforced epoxy composites. Bull. Mater. Sci. 2020, 43, 88. [Google Scholar] [CrossRef]

- Chowdhury, I.R.; Pemberton, R.; Summerscales, J. Developments and Industrial Applications of Basalt Fibre Reinforced Composite Materials. J. Compos. Sci. 2022, 6, 367. [Google Scholar] [CrossRef]

- Matykiewicz, D.; Lewandowski, K.; Dudziec, B. Evaluation of thermomechanical properties of epoxy–basalt fibre composites modified with zeolite and silsesquioxane. Compos. Interfaces 2017, 24, 489–498. [Google Scholar] [CrossRef]

- Jia, H.; Liu, C.; Zhang, Y.; Qiao, Y.; Zhao, W.; Chen, X.; Jian, X. Electrophoretic deposition for the interfacial enhancement of BF/PPENK composite: GO vs. Ti3C2Tx MXene. Compos. Part Appl. Sci. Manuf. 2024, 181, 108115. [Google Scholar] [CrossRef]

- Chen, W.; Shen, H.; Auad, M.L.; Huang, C.; Nutt, S. Basalt fiber–epoxy laminates with functionalized multi-walled carbon nanotubes. Compos. Part Appl. Sci. Manuf. 2009, 40, 1082–1089. [Google Scholar] [CrossRef]

- Sukur, E.F.; Onal, G. Graphene nanoplatelet modified basalt/epoxy multi-scale composites with improved tribological performance. Wear 2020, 460–461, 203481. [Google Scholar] [CrossRef]

- Patil, R.A.; Aloorkar, N.H.; Kulkarni, A.S.; Ingale, D.J. Star Polymers: An Overview. Int. J. Pharm. Sci. Nanotechnol. 2012, 5, 1675–1684. [Google Scholar] [CrossRef]

- Aboelanin, H.M.; Podzimek, S.; Spacek, V. Synthesis and molecular structure of highly compact star-like poly(methyl methacrylate) and poly(butyl methacrylate). Eur. Polym. J. 2023, 194, 112119. [Google Scholar] [CrossRef]

- Pinto, R.; Monastyreckis, G.; Aboelanin, H.M.; Spacek, V.; Zeleniakiene, D. Mechanical properties of carbon fibre reinforced composites modified with star-shaped butyl methacrylate. J. Compos. Mater. 2022, 56, 951–959. [Google Scholar] [CrossRef]

- Ma, Y.; Yang, Y.; Sugahara, T.; Hamada, H. A study on the failure behavior and mechanical properties of unidirectional fiber reinforced thermosetting and thermoplastic composites. Compos. Part B Eng. 2016, 99, 162–172. [Google Scholar] [CrossRef]

- Ramakrishna, M.; Girigoswami, A.; Chakraborty, S.; Girigoswami, K. Bisphenol A-an Overview on its Effect on Health and Environment. Biointerface Res. Appl. Chem. 2021, 12, 105–119. [Google Scholar] [CrossRef]

- Tkachuk, A.I.; Zagora, A.G.; Terekhov, I.V.; Mukhametov, R.R. Isophorone Diamine—A Curing Agent for Epoxy Resins: Production, Application, Prospects. A Review. Polym. Sci. Ser. D 2022, 15, 171–176. [Google Scholar] [CrossRef]

- Dornburg, V.; Lewandowski, I.; Patel, M. Comparing the Land Requirements, Energy Savings, and Greenhouse Gas Emissions Reduction of Biobased Polymers and Bioenergy: An Analysis and System Extension of Life-Cycle Assessment Studies. J. Ind. Ecol. 2003, 7, 93–116. [Google Scholar] [CrossRef]

- Gerbase, A.E.; Petzhold, C.L.; Costa, A.P.O. Dynamic mechanical and thermal behavior of epoxy resins based on soybean oil. J. Am. Oil Chem. Soc. 2002, 79, 797–802. [Google Scholar] [CrossRef]

- Pin, J.; Sbirrazzuoli, N.; Mija, A. From Epoxidized Linseed Oil to Bioresin: An Overall Approach of Epoxy/Anhydride Cross-Linking. ChemSusChem 2015, 8, 1232–1243. [Google Scholar] [CrossRef] [PubMed]

- Fernandes, F.C.; Kirwan, K.; Lehane, D.; Coles, S.R. Epoxy resin blends and composites from waste vegetable oil. Eur. Polym. J. 2017, 89, 449–460. [Google Scholar] [CrossRef]

- Campaner, P.; D’Amico, D.; Longo, L.; Stifani, C.; Tarzia, A. Cardanol-based novolac resins as curing agents of epoxy resins. J. Appl. Polym. Sci. 2009, 114, 3585–3591. [Google Scholar] [CrossRef]

- Andrew, J.J.; Dhakal, H.N. Sustainable biobased composites for advanced applications: Recent trends and future opportunities—A critical review. Compos. Part C Open Access 2022, 7, 100220. [Google Scholar] [CrossRef]

- Saleem, A.; Medina, L.; Skrifvars, M. Mechanical performance of hybrid bast and basalt fibers reinforced polymer composites. J. Polym. Res. 2020, 27, 61. [Google Scholar] [CrossRef]

- Shishevan, F.A.; Akbulut, H.; Mohtadi-Bonab, M.A. Low Velocity Impact Behavior of Basalt Fiber-Reinforced Polymer Composites. J. Mater. Eng. Perform. 2017, 26, 2890–2900. [Google Scholar] [CrossRef]

- Lopresto, V.; Leone, C.; De Iorio, I. Mechanical characterisation of basalt fibre reinforced plastic. Compos. Part B Eng. 2011, 42, 717–723. [Google Scholar] [CrossRef]

- Sarasini, F.; Tirillò, J.; Valente, M.; Valente, T.; Cioffi, S.; Iannace, S.; Sorrentino, L. Effect of basalt fiber hybridization on the impact behavior under low impact velocity of glass/basalt woven fabric/epoxy resin composites. Compos. Part Appl. Sci. Manuf. 2013, 47, 109–123. [Google Scholar] [CrossRef]

- Almansour, F.A.; Dhakal, H.N.; Zhang, Z.Y. Effect of water absorption on Mode I interlaminar fracture toughness of flax/basalt reinforced vinyl ester hybrid composites. Compos. Struct. 2017, 168, 813–825. [Google Scholar] [CrossRef]

- Zhao, G.; Li, M.; Wang, S.; Peng, X.; Wang, L.; Li, X.; Zhao, Y.; Gao, Y.; Zhang, Y.; Zheng, J. Effect of interlaminar basalt fiber veil reinforcement on mode I fracture toughness of basalt fiber composites. Polym. Compos. 2024, 45, 4985–4993. [Google Scholar] [CrossRef]

- Don, D.K.; Reiner, J.; Jennings, M.; Subhani, M. Basalt Fibre-Reinforced Polymer Laminates with Eco-Friendly Bio Resin: A Comparative Study of Mechanical and Fracture Properties. Polymers 2024, 16, 2056. [Google Scholar] [CrossRef] [PubMed]

- Hameed, N.; Guo, Q.; Xu, Z.; Hanley, T.L.; Mai, Y.-W. Reactive block copolymer modified thermosets: Highly ordered nanostructures and improved properties. Soft Matter 2010, 6, 6119. [Google Scholar] [CrossRef]

- D638; Standard Test Method for Tensile Properties of Plastics. ASTM International: West Conshohocken, PA, USA, 2014. [CrossRef]

- D4065-20; Standard Practice for Plastics: Dynamic Mechanical Properties: Determination and Report of Procedures. ASTM International: West Conshohocken, PA, USA, 2020. [CrossRef]

- D5528-13; D30 Committee Test Method for Mode I Interlaminar Fracture Toughness of Unidirectional Fiber-Reinforced Polymer Matrix Composites. ASTM International: West Conshohocken, PA, USA, 2022. [CrossRef]

- ISO 6603-2:2023; Plastics—Determination of Puncture Impact Behaviour of Rigid Plastics Part 2: Instrumented Impact Testing. International Organization for Standardization: Vernier, Switzerland, 2023.

- ISO 527-1:2019; Plastics—Determination of Tensile Properties Part 1: General Principles. International Organization for Standardization: Vernier, Switzerland, 2019.

- Shokrieh, M.M.; Heidari-Rarani, M.; Ayatollahi, M.R. Interlaminar fracture toughness of unidirectional DCB specimens: A novel theoretical approach. Polym. Test. 2012, 31, 68–75. [Google Scholar] [CrossRef]

- Michels, J.; Widmann, R.; Czaderski, C.; Allahvirdizadeh, R.; Motavalli, M. Glass transition evaluation of commercially available epoxy resins used for civil engineering applications. Compos. Part B Eng. 2015, 77, 484–493. [Google Scholar] [CrossRef]

- ISO 6721-11; Plastics—Determination of Dynamic Mechanical Properties—Part 1: General Principles. Available online: https://www.iso.org/standard/73142.html (accessed on 2 October 2024).

- Karvanis, K.; Rusnáková, S.; Krejčí, O.; Žaludek, M. Preparation, Thermal Analysis, and Mechanical Properties of Basalt Fiber/Epoxy Composites. Polymers 2020, 12, 1785. [Google Scholar] [CrossRef]

- Zheng, X.; Guo, Y.; Douglas, J.F.; Xia, W. Understanding the role of cross-link density in the segmental dynamics and elastic properties of cross-linked thermosets. J. Chem. Phys. 2022, 157, 064901. [Google Scholar] [CrossRef]

- Starkova, O.; Buschhorn, S.T.; Mannov, E.; Schulte, K.; Aniskevich, A. Water transport in epoxy/MWCNT composites. Eur. Polym. J. 2013, 49, 2138–2148. [Google Scholar] [CrossRef]

- Glaskova-Kuzmina, T.; Aniskevich, A.; Sevcenko, J.; Borriello, A.; Zarrelli, M. Cyclic Moisture Sorption and its Effects on the Thermomechanical Properties of Epoxy and Epoxy/MWCNT Nanocomposite. Polymers 2019, 11, 1383. [Google Scholar] [CrossRef]

- De Morais, A.B. A new fibre bridging based analysis of the Double Cantilever Beam (DCB) test. Compos. Part Appl. Sci. Manuf. 2011, 42, 1361–1368. [Google Scholar] [CrossRef]

- Sridharan, S.B.; Fangueiro, R. Low velocity impact behaviour of textile reinforced composites. Indian J. Fibre Text Res. 2008, 33, 189–202. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pinto, R.; Glaskova-Kuzmina, T.; Zukiene, K.; Monastyreckis, G.; Novakova, M.; Spacek, V.; Kovalovs, A.; Aniskevich, A.; Zeleniakiene, D. Effect of Star-like Polymer on Mechanical Properties of Novel Basalt Fibre-Reinforced Composite with Bio-Based Matrix. Polymers 2024, 16, 2909. https://doi.org/10.3390/polym16202909

Pinto R, Glaskova-Kuzmina T, Zukiene K, Monastyreckis G, Novakova M, Spacek V, Kovalovs A, Aniskevich A, Zeleniakiene D. Effect of Star-like Polymer on Mechanical Properties of Novel Basalt Fibre-Reinforced Composite with Bio-Based Matrix. Polymers. 2024; 16(20):2909. https://doi.org/10.3390/polym16202909

Chicago/Turabian StylePinto, Rochele, Tatjana Glaskova-Kuzmina, Kristina Zukiene, Gediminas Monastyreckis, Marie Novakova, Vladimir Spacek, Andrejs Kovalovs, Andrey Aniskevich, and Daiva Zeleniakiene. 2024. "Effect of Star-like Polymer on Mechanical Properties of Novel Basalt Fibre-Reinforced Composite with Bio-Based Matrix" Polymers 16, no. 20: 2909. https://doi.org/10.3390/polym16202909

APA StylePinto, R., Glaskova-Kuzmina, T., Zukiene, K., Monastyreckis, G., Novakova, M., Spacek, V., Kovalovs, A., Aniskevich, A., & Zeleniakiene, D. (2024). Effect of Star-like Polymer on Mechanical Properties of Novel Basalt Fibre-Reinforced Composite with Bio-Based Matrix. Polymers, 16(20), 2909. https://doi.org/10.3390/polym16202909