Numerical Simulation for Durability of a Viscoelastic Polymer Material Subjected to Variable Loadings Fatigue Based on Entropy Damage Criterion

Abstract

1. Introduction

2. Numerical Methodologies

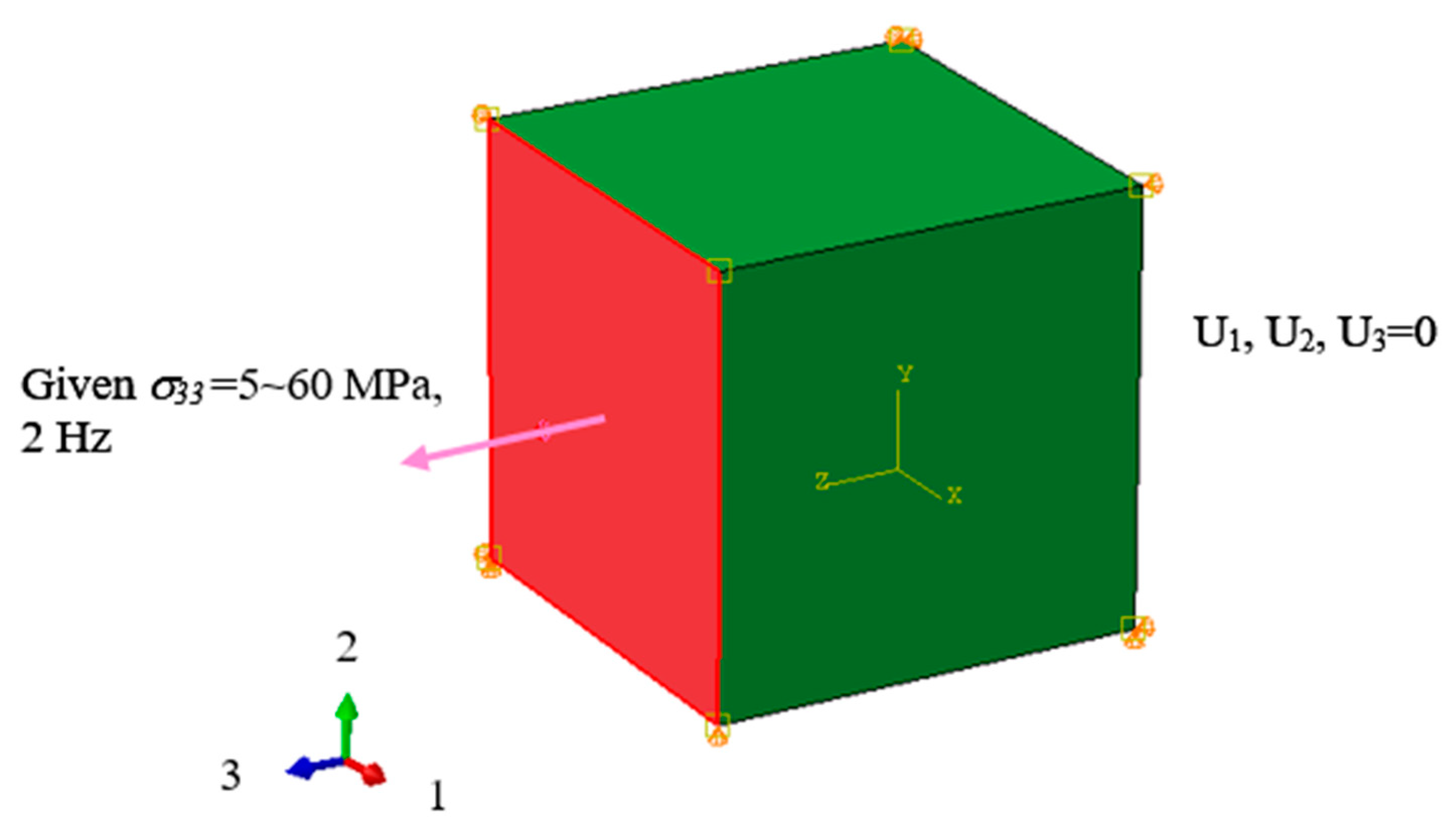

2.1. Finite Element Simulation

2.2. Constitutive Equation Considering Entropy Damage Criterion

3. Numerical Results

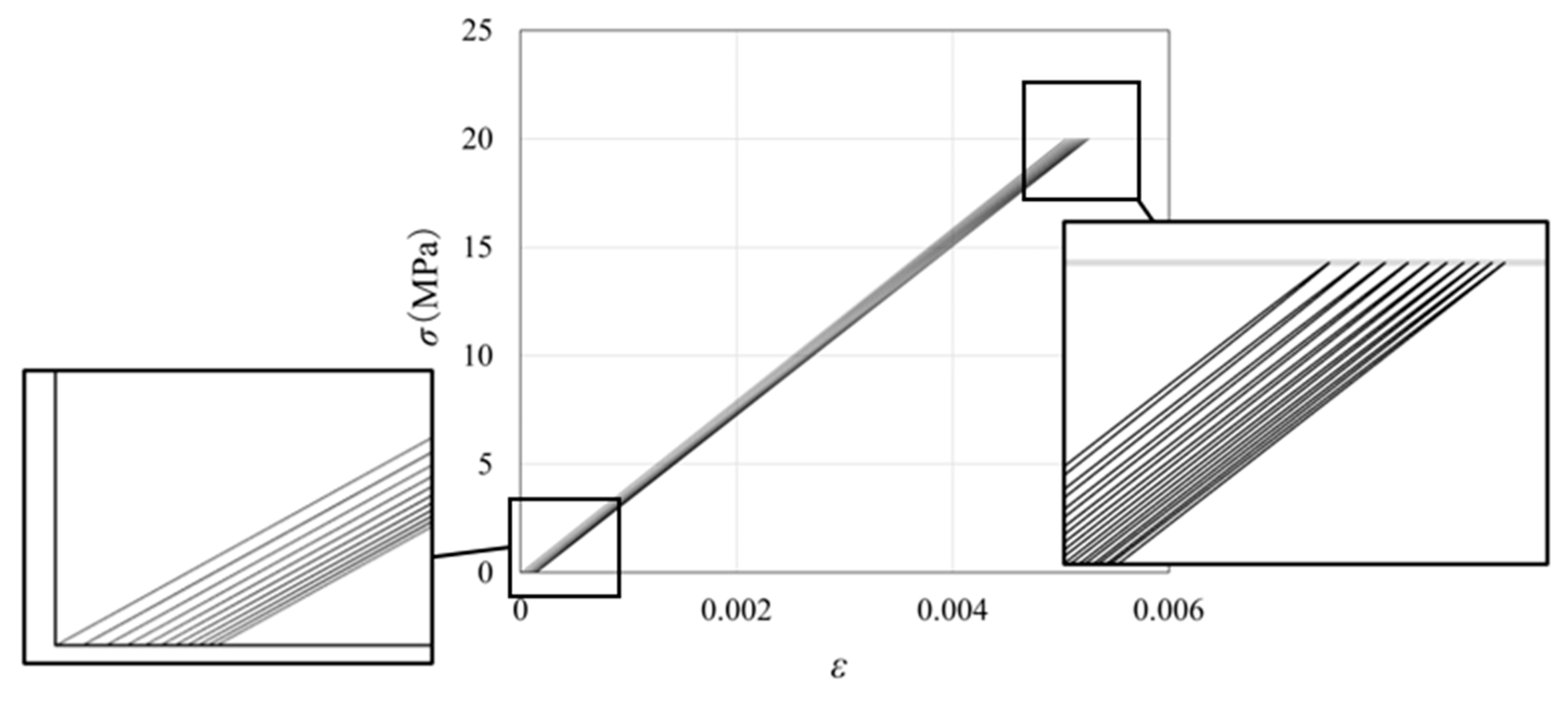

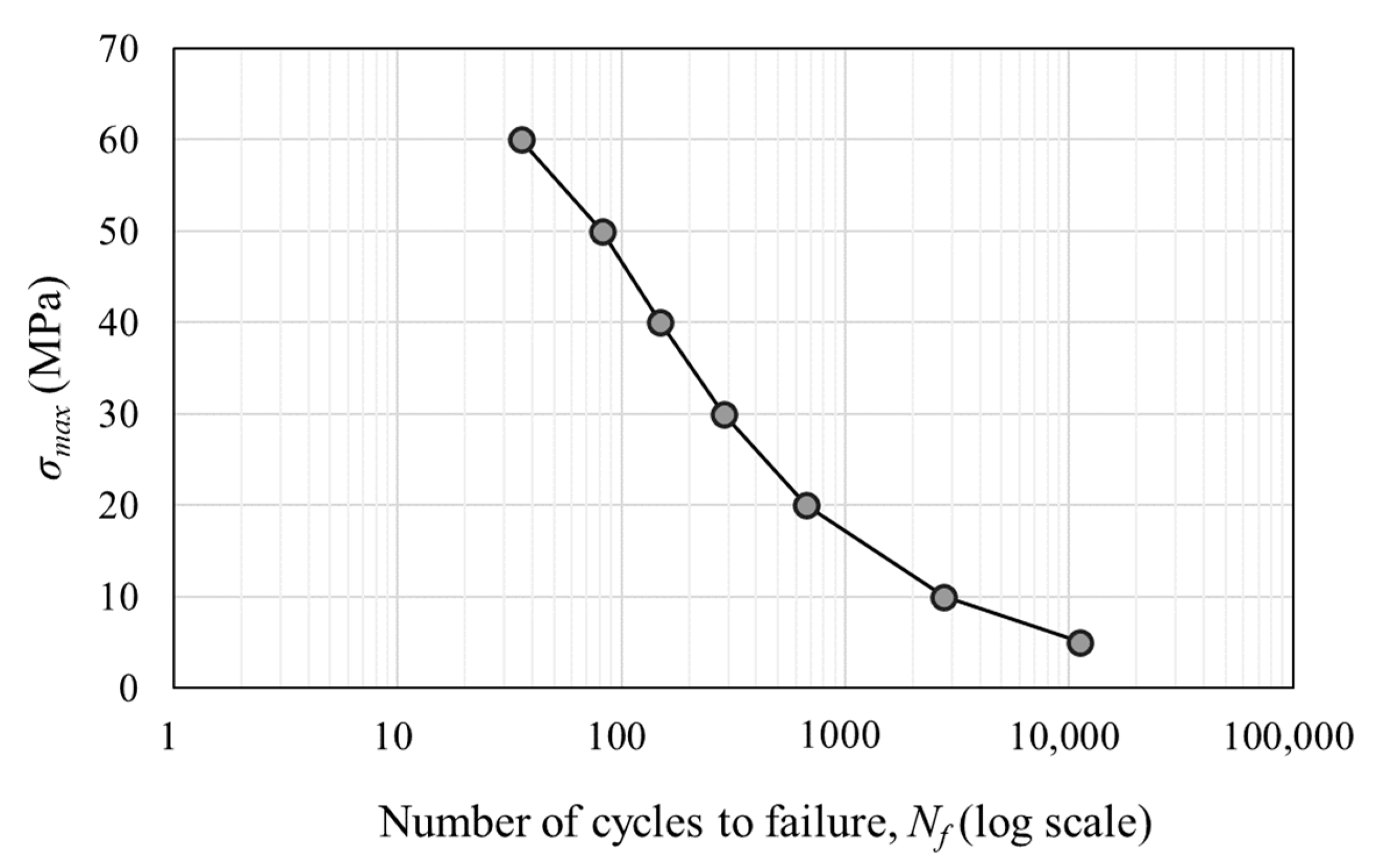

3.1. S–N Curve

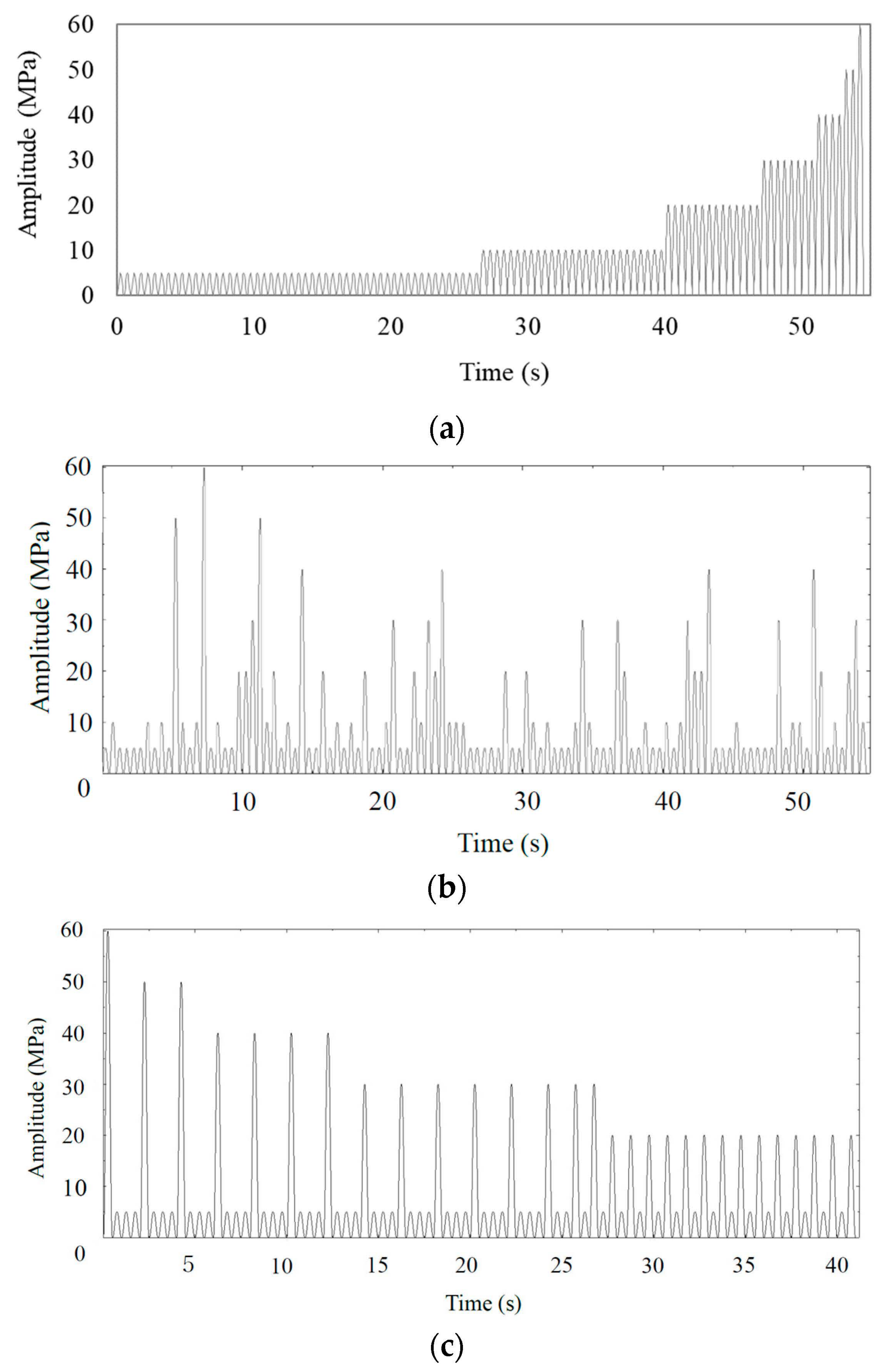

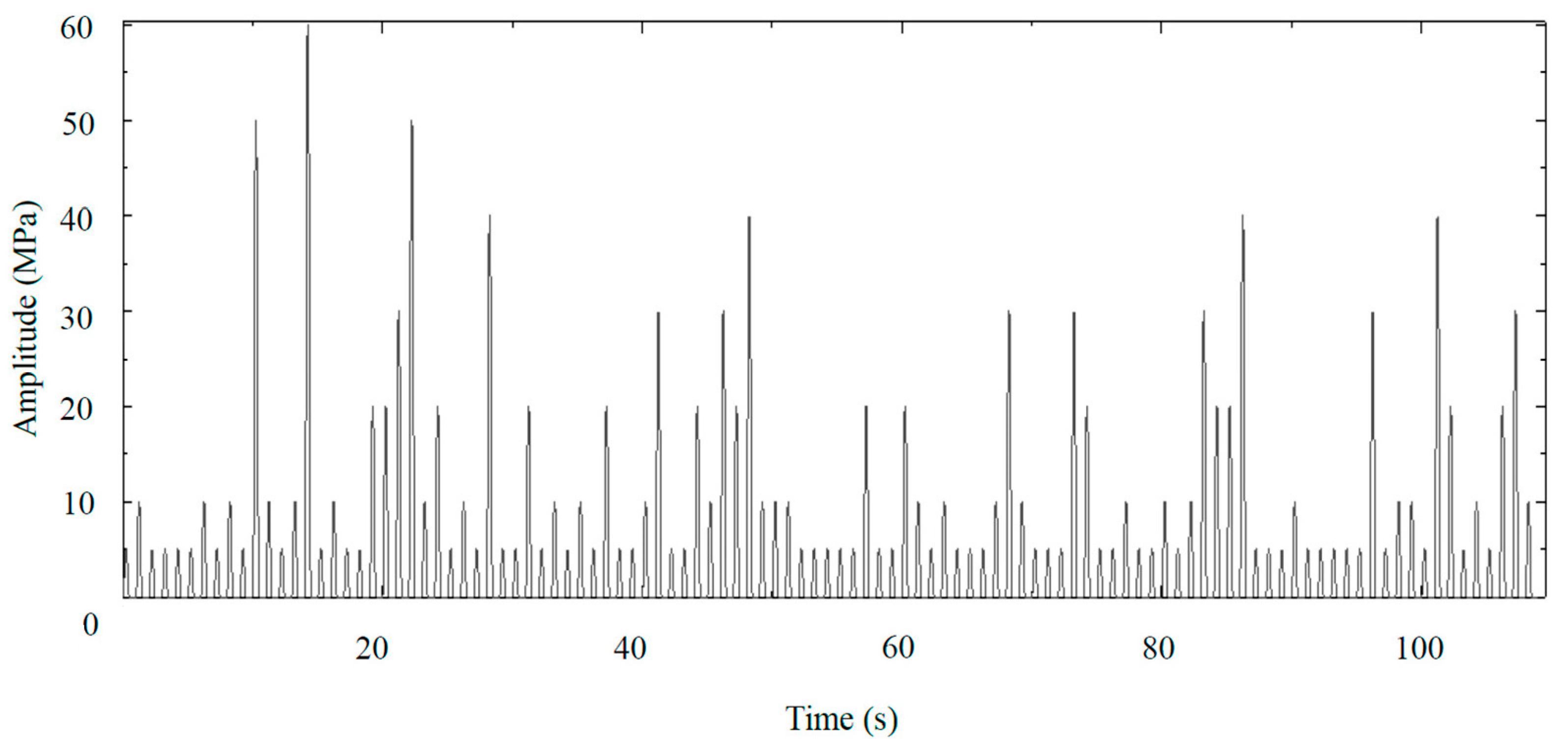

3.2. Variable Loading Patterns

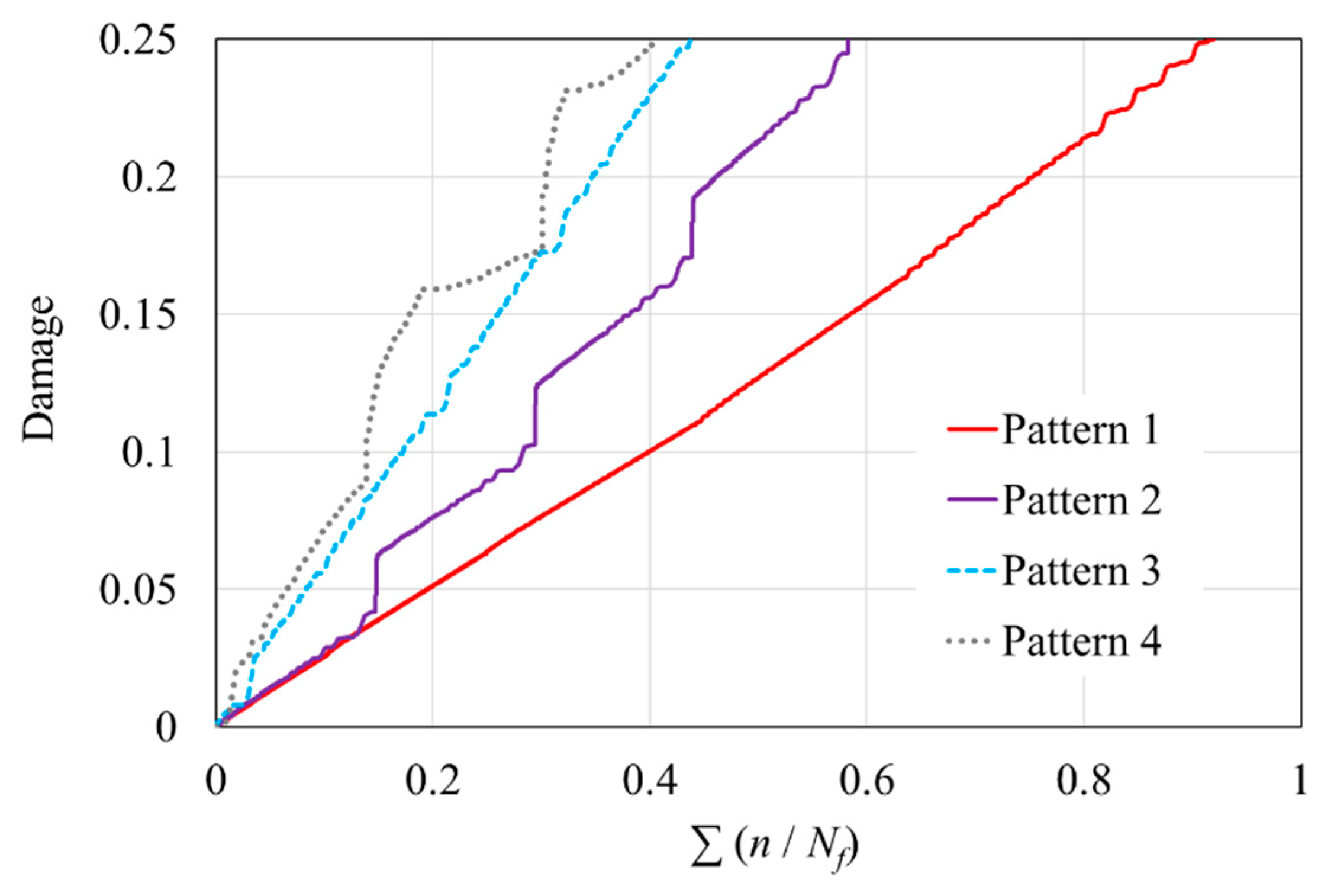

3.3. Fatigue Failure under Variable Loading Patterns Compared with the P-M Rule

4. Discussion

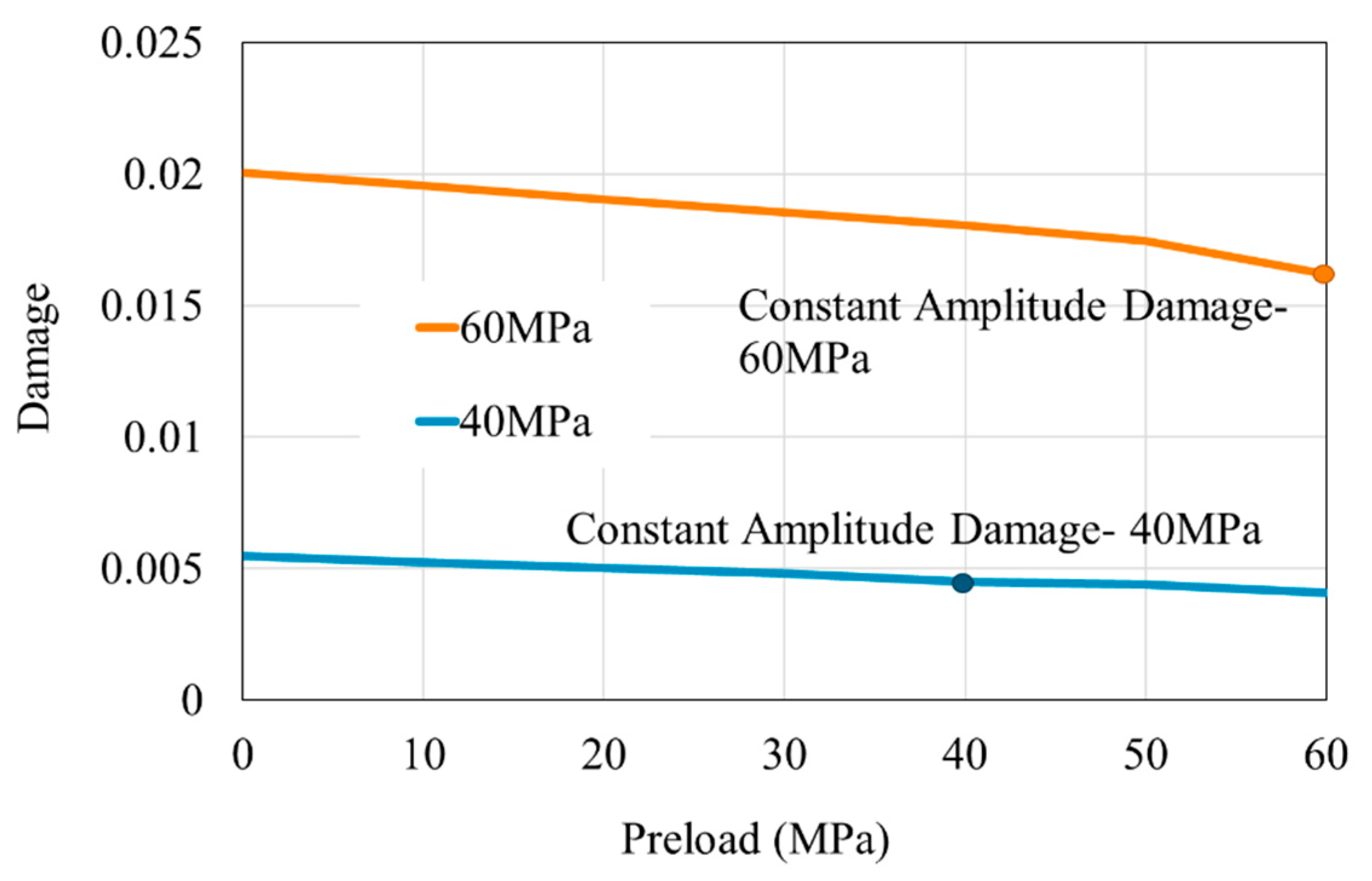

4.1. Impact of Historical Load on Damage

4.2. Interrupted Fatigue Simulation

5. Conclusions

- Frequent changes in stress amplitude accelerate damage accumulation to some extent; applying an initial high stress leads to more rapid failure compared to applying low stress first.

- As the preload increases, the damage caused by subsequent loads decreases. The effect of different preloads on subsequent loads depends on the amplitude of the latter, with higher amplitudes showing a more pronounced damage-reducing effect. When there is no preload, the load causes maximum damage.

- Intermittent pauses further reduce the proportion of fatigue life expended.

- Pauses also delay fatigue, such there is a maximum pause time leading to the fastest failure, which is closely related to material properties.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Miner, M.A. Cumulative Damage in Fatigue. J. Appl. Mech. 1945, 12, 159–164. [Google Scholar] [CrossRef]

- Fatemi, A.; Yang, L. Cumulative Fatigue Damage and Life Prediction Theories: A Survey of the State of the Art for Homogeneous Materials. Int. J. Fatigue 1998, 20, 9–34. [Google Scholar] [CrossRef]

- Santecchia, E.; Hamouda, A.M.S.; Musharavati, F.; Zalnezhad, E.; Cabibbo, M.; El Mehtedi, M.; Spigarelli, S. A Review on Fatigue Life Prediction Methods for Metals. Adv. Mater. Sci. Eng. 2016, 2016, 9573524. [Google Scholar] [CrossRef]

- Huang, T.; Ding, R.-C.; Li, Y.-F.; Zhou, J.; Huang, H.-Z. A Modified Model for Nonlinear Fatigue Damage Accumulation of Turbine Disc Considering the Load Interaction Effect. Metals 2019, 9, 919. [Google Scholar] [CrossRef]

- Post, N.; Case, S.; Lesko, J. Modeling the Variable Amplitude Fatigue of Composite Materials: A Review and Evaluation of the State of the Art for Spectrum Loading. Int. J. Fatigue 2008, 30, 2064–2086. [Google Scholar] [CrossRef]

- Post, N.L.; Cain, J.; McDonald, K.J.; Case, S.W.; Lesko, J.J. Residual Strength Prediction of Composite Materials: Random Spectrum Loading. Eng. Fract. Mech. 2008, 75, 2707–2724. [Google Scholar] [CrossRef]

- Jensen, S.M.; Bak, B.L.V.; Bender, J.J.; Carreras, L.; Lindgaard, E. Transient Delamination Growth in GFRP Laminates with Fibre Bridging under Variable Amplitude Loading in G-Control. Compos. B Eng. 2021, 225, 109296. [Google Scholar] [CrossRef]

- Lin, J.-X.; Huang, P.-Y.; Guo, Y.-C.; Guo, X.-Y.; Zeng, J.-J.; Zhao, C.; Chen, Z.-B. Fatigue Behavior of RC Beams Strengthened with CFRP Laminate under Hot-Wet Environments and Vehicle Random Loads Coupling. Int. J. Fatigue 2020, 131, 105329. [Google Scholar] [CrossRef]

- Lin, J.; Huang, P.; Guo, X.; Zheng, X.; Zhao, C. Fatigue Performance of RC Beams Strengthened with CFRP under Coupling Action of Temperatures and Vehicle Random Loads. Fatigue Fract. Eng. Mater. Struct. 2019, 42, 31–44. [Google Scholar] [CrossRef]

- Strizhius, V. Fatigue life prediction of CFRP laminate under quasi-random loading. In Proceedings of the 30th Symposium of the International Committee on Aeronautical Fatigue, ICAF 2019, Krakow, Poland, 2–7 June 2019; pp. 423–431. [Google Scholar]

- Sasaki, K.; Kawai, M. Random Fatigue Test Method for Woven CFRP Laminates and Life Prediction. Proc. Ibaraki Dist. Conf. 2017, 25, 806. [Google Scholar] [CrossRef]

- Takeda, N. OS0524 Accuracy Improvement in Frequency Domain Prediction of Fatigue Life under Random Loading. Proc. Mater. Mech. Conf. 2011, 2011, _OS0524-1_–_OS0524-3_. [Google Scholar] [CrossRef]

- Gomez, J.; Basaran, C. A Thermodynamics Based Damage Mechanics Constitutive Model for Low Cycle Fatigue Analysis of Microelectronics Solder Joints Incorporating Size Effects. Int. J. Solids Struct. 2005, 42, 3744–3772. [Google Scholar] [CrossRef]

- Basaran, C.; Nie, S. An Irreversible Thermodynamics Theory for Damage Mechanics of Solids. Int. J. Damage Mech. 2004, 13, 205–223. [Google Scholar] [CrossRef]

- Amiri, M.; Khonsari, M.M. Life Prediction of Metals Undergoing Fatigue Load Based on Temperature Evolution. Mater. Sci. Eng. A 2010, 527, 1555–1559. [Google Scholar] [CrossRef]

- Amiri, M.; Naderi, M.; Khonsari, M.M. An Experimental Approach to Evaluate the Critical Damage. Int. J. Damage Mech. 2011, 20, 89–112. [Google Scholar] [CrossRef]

- Basaran, C.; Nie, S.; Gomez, J.; Gunel, E.; Li, S.; Lin, M.; Tang, H.; Yan, C.; Yao, W.; Ye, H. Thermodynamic Theory for Damage Evolution in Solids. In Handbook of Damage Mechanics; Springer: New York, NY, USA, 2014; pp. 1–39. [Google Scholar]

- Amiri, M.; Modarres, M. An Entropy-Based Damage Characterization. Entropy 2014, 16, 6434–6463. [Google Scholar] [CrossRef]

- Mehdizadeh, M.; Khonsari, M.M. On the Application of Fracture Fatigue Entropy to Variable Frequency and Loading Amplitude. Theor. Appl. Fract. Mech. 2018, 98, 30–37. [Google Scholar] [CrossRef]

- Ellyin, F.; El-Kadi, H. A Fatigue Failure Criterion for Fiber Reinforced Composite Laminae. Compos. Struct. 1990, 15, 61–74. [Google Scholar] [CrossRef]

- Morrow, J. Cyclic Plastic Strain Energy and Fatigue of Metals. In Internal Friction, Damping, and Cyclic Plasticity; ASTM International: West Conshohocken, PA, USA, 1965; pp. 45–87. [Google Scholar]

- Park, J. Evaluation of an Energy-Based Approach and a Critical Plane Approach for Predicting Constant Amplitude Multiaxial Fatigue Life. Int. J. Fatigue 2000, 22, 23–39. [Google Scholar] [CrossRef]

- Bryant, M.D.; Khonsari, M.M.; Ling, F.F. On the Thermodynamics of Degradation. Proc. R. Soc. A Math. Phys. Eng. Sci. 2008, 464, 2001–2014. [Google Scholar] [CrossRef]

- Naderi, M.; Amiri, M.; Khonsari, M.M. On the Thermodynamic Entropy of Fatigue Fracture. Proc. R. Soc. A Math. Phys. Eng. Sci. 2010, 466, 423–438. [Google Scholar] [CrossRef]

- Naderi, M.; Khonsari, M.M. A Thermodynamic Approach to Fatigue Damage Accumulation under Variable Loading. Mater. Sci. Eng. A 2010, 527, 6133–6139. [Google Scholar] [CrossRef]

- Liakat, M.; Khonsari, M.M. On the Anelasticity and Fatigue Fracture Entropy in High-Cycle Metal Fatigue. Mater. Des. 2015, 82, 18–27. [Google Scholar] [CrossRef]

- Mahmoudi, A.; Khonsari, M.M. Investigation of Metal Fatigue Using a Coupled Entropy-Kinetic Model. Int. J. Fatigue 2022, 161, 106907. [Google Scholar] [CrossRef]

- Wang, J.; Yao, Y. An Entropy Based Low-Cycle Fatigue Life Prediction Model for Solder Materials. Entropy 2017, 19, 503. [Google Scholar] [CrossRef]

- Moghanlou, M.R.; Khonsari, M.M. On the Kinetic Formulation of Fracture Fatigue Entropy of Metals. Fatigue Fract. Eng. Mater. Struct. 2022, 45, 565–577. [Google Scholar] [CrossRef]

- Amooie, M.A.; Lijesh, K.P.; Mahmoudi, A.; Azizian-Farsani, E.; Khonsari, M.M. On the Characteristics of Fatigue Fracture with Rapid Frequency Change. Entropy 2023, 25, 840. [Google Scholar] [CrossRef]

- Mehdizadeh, M.; Khonsari, M.M. On the Application of Fracture Fatigue Entropy to Multiaxial Loading. Int. J. Fatigue 2021, 150, 106321. [Google Scholar] [CrossRef]

- Sakai, T.; Takase, N.; Oya, Y.; Koyanagi, J. A Possibility for Quantitative Detection of Mechanically-Induced Invisible Damage by Thermal Property Measurement via Entropy Generation for a Polymer Material. Materials 2022, 15, 737. [Google Scholar] [CrossRef]

- Takase, N.; Koyanagi, J.; Mori, K.; Sakai, T. Molecular Dynamics Simulation for Evaluating Fracture Entropy of a Polymer Material under Various Combined Stress States. Materials 2021, 14, 1884. [Google Scholar] [CrossRef]

- Naderi, M.; Khonsari, M.M. A Comprehensive Fatigue Failure Criterion Based on Thermodynamic Approach. J. Compos. Mater. 2012, 46, 437–447. [Google Scholar] [CrossRef]

- Naderi, M.; Khonsari, M.M. On the Role of Damage Energy in the Fatigue Degradation Characterization of a Composite Laminate. Compos. B Eng. 2013, 45, 528–537. [Google Scholar] [CrossRef]

- Movahedi-Rad, A.V.; Eslami, G.; Keller, T. A Novel Fatigue Life Prediction Methodology Based on Energy Dissipation in Viscoelastic Materials. Int. J. Fatigue 2021, 152, 106457. [Google Scholar] [CrossRef]

- Mohammadi, B.; Shokrieh, M.M.; Jamali, M.; Mahmoudi, A.; Fazlali, B. Damage-Entropy Model for Fatigue Life Evaluation of off-Axis Unidirectional Composites. Compos. Struct. 2021, 270, 114100. [Google Scholar] [CrossRef]

- Mohammadi, B.; Mahmoudi, A. Developing a New Model to Predict the Fatigue Life of Cross-Ply Laminates Using Coupled CDM-Entropy Generation Approach. Theor. Appl. Fract. Mech. 2018, 95, 18–27. [Google Scholar] [CrossRef]

- Shimizu, S.; Sato, M.; Koyanagi, J.; Suemasu, H.; Kogo, Y. Numerical Simulation for Compressive Failure of CFRP Laminates with Various Shaped Holes. J. Jpn. Soc. Compos. Mater. 2019, 45, 205–213. [Google Scholar] [CrossRef]

- Koyanagi, J.; Kiyota, G.; Kamiya, T.; Kawada, H. Prediction of Creep Rupture in Unidirectional Composite: Creep Rupture Model with Interfacial Debonding and Its Propagation. Adv. Compos. Mater. 2004, 13, 199–213. [Google Scholar] [CrossRef]

- Sato, M.; Shirai, S.; Koyanagi, J.; Ishida, Y.; Kogo, Y. Numerical Simulation for Strain Rate and Temperature Dependence of Transverse Tensile Failure of Unidirectional Carbon Fiber-Reinforced Plastics. J. Compos. Mater. 2019, 53, 4305–4312. [Google Scholar] [CrossRef]

- Deng, H.; Toda, K.; Sato, M.; Koyanagi, J. Micro-Scale Numerical Simulation of Fatigue Failure for CFRP Subjected to Multiple-Amplitude Cyclic Loadings Based on Entropy Damage Criterion. Materials 2023, 16, 6120. [Google Scholar] [CrossRef]

- Sato, M.; Hasegawa, K.; Koyanagi, J.; Higuchi, R.; Ishida, Y. Residual Strength Prediction for Unidirectional CFRP Using a Nonlinear Viscoelastic Constitutive Equation Considering Entropy Damage. Compos. Part. A Appl. Sci. Manuf. 2021, 141, 106178. [Google Scholar] [CrossRef]

- Jang, J.Y.; Khonsari, M.M. On the Evaluation of Fracture Fatigue Entropy. Theor. Appl. Fract. Mech. 2018, 96, 351–361. [Google Scholar] [CrossRef]

- Kagawa, H.; Umezu, Y.; Sakaue, K.; Koyanagi, J. Numerical Simulation for the Tensile Failure of Randomly Oriented Short Fiber Reinforced Plastics Based on a Viscoelastic Entropy Damage Criterion. Compos. Part C Open Access 2023, 10, 100342. [Google Scholar] [CrossRef]

| n | Elasticity | |||

|---|---|---|---|---|

| 1 | 284 | 4.5 × 102 | * | 4260 |

| 2 | 284 | 3.3 × 103 | ν * | 0.3 |

| 3 | 284 | 1.2 × 105 | Nonlinearity | |

| 4 | 284 | 1.9 × 106 | 70 | |

| 5 | 284 | 1.8 × 107 | α | 2 |

| 6 | 284 | 1.4 × 108 | m | 7 |

| 7 | 284 | 8.5 × 108 | Entropy-relating | |

| 8 | 284 | 5.0 × 109 | sf | 0.1 J/m3 · K |

| 9 | 284 | 3.0 × 1010 | Dcr | 0.25 |

| 10 | 284 | 1.9 × 1011 | T | 303 K |

| 11 | 284 | 1.4 × 1016 | ||

| 12 | 284 | 1.3 × 1019 | ||

| 13 | 284 | 2.1 × 1022 | ||

| 14 | 284 | 1.3 × 1026 | Damage acceleration parameter | |

| 15 | 284 | 2.5 × 1029 | 4 | |

| σmax (MPa) | Number of Cycles to Failure (Cycle) | 1/Nf |

|---|---|---|

| 5 | 11,169 | 0.01% |

| 10 | 2760 | 0.04% |

| 20 | 671 | 0.15% |

| 30 | 286 | 0.35% |

| 40 | 150 | 0.67% |

| 50 | 82 | 1.22% |

| 60 | 36 | 2.81% |

| σmax (MPa) | Number of Cycles (Cycle) |

|---|---|

| 5 | 371 |

| 10 | 189 |

| 20 | 98 |

| 30 | 56 |

| 40 | 28 |

| 50 | 14 |

| 60 | 7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Y.; Fikry, M.J.M.; Koyanagi, J. Numerical Simulation for Durability of a Viscoelastic Polymer Material Subjected to Variable Loadings Fatigue Based on Entropy Damage Criterion. Polymers 2024, 16, 2857. https://doi.org/10.3390/polym16202857

Li Y, Fikry MJM, Koyanagi J. Numerical Simulation for Durability of a Viscoelastic Polymer Material Subjected to Variable Loadings Fatigue Based on Entropy Damage Criterion. Polymers. 2024; 16(20):2857. https://doi.org/10.3390/polym16202857

Chicago/Turabian StyleLi, Yutong, M. J. Mohammad Fikry, and Jun Koyanagi. 2024. "Numerical Simulation for Durability of a Viscoelastic Polymer Material Subjected to Variable Loadings Fatigue Based on Entropy Damage Criterion" Polymers 16, no. 20: 2857. https://doi.org/10.3390/polym16202857

APA StyleLi, Y., Fikry, M. J. M., & Koyanagi, J. (2024). Numerical Simulation for Durability of a Viscoelastic Polymer Material Subjected to Variable Loadings Fatigue Based on Entropy Damage Criterion. Polymers, 16(20), 2857. https://doi.org/10.3390/polym16202857