Properties of Heat-Treated Wood Fiber–Polylactic Acid Composite Filaments and 3D-Printed Parts Using Fused Filament Fabrication

Abstract

1. Introduction

2. Materials and Methods

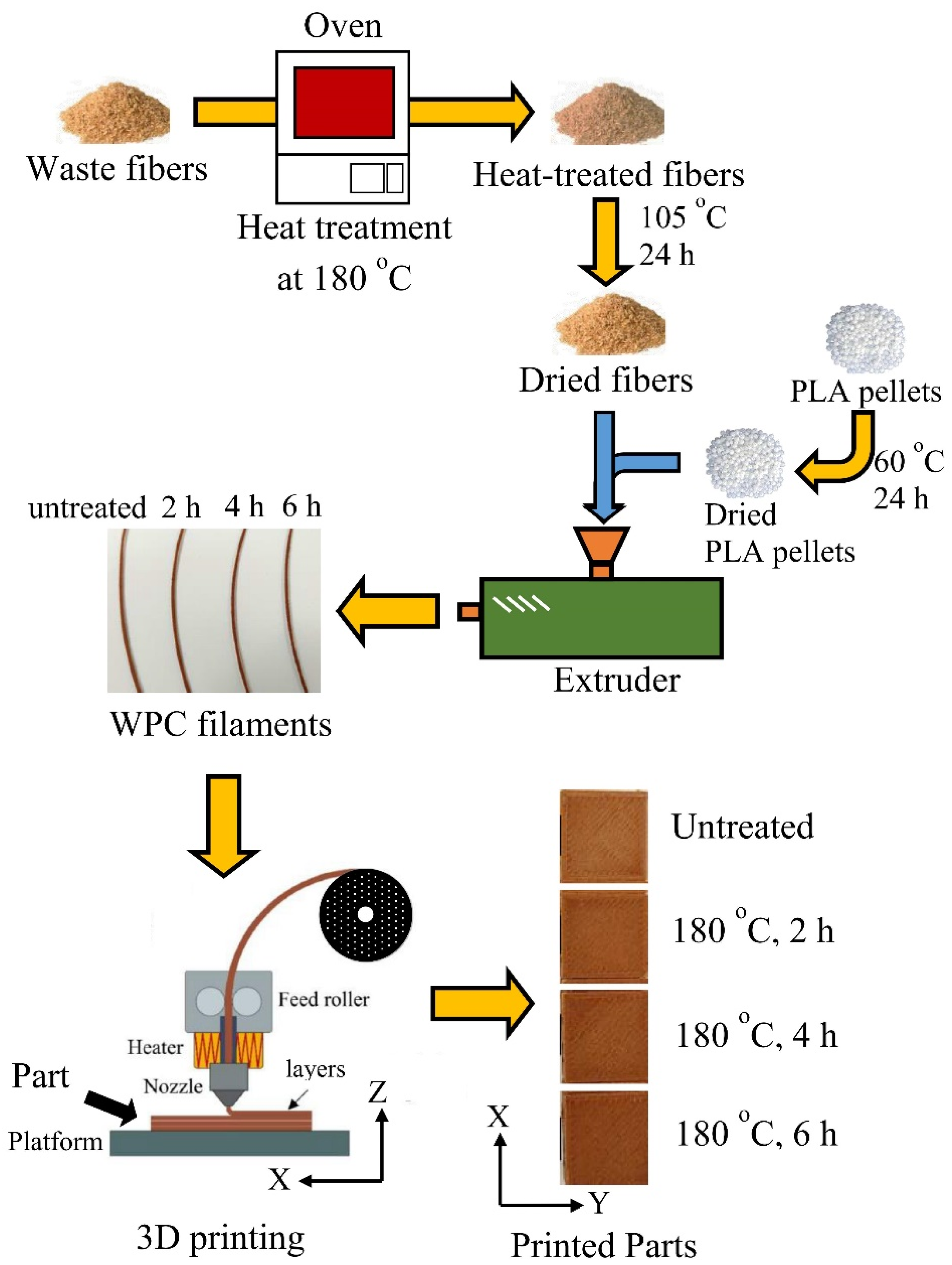

2.1. Materials and Heat Treatment Process

2.2. WPC Filaments and 3D-Printed WPC Parts

2.3. Properties of WPC Filaments

2.4. Properties of 3D-Printed WPC Parts

2.4.1. Surface Color

2.4.2. Physical and Mechanical Properties

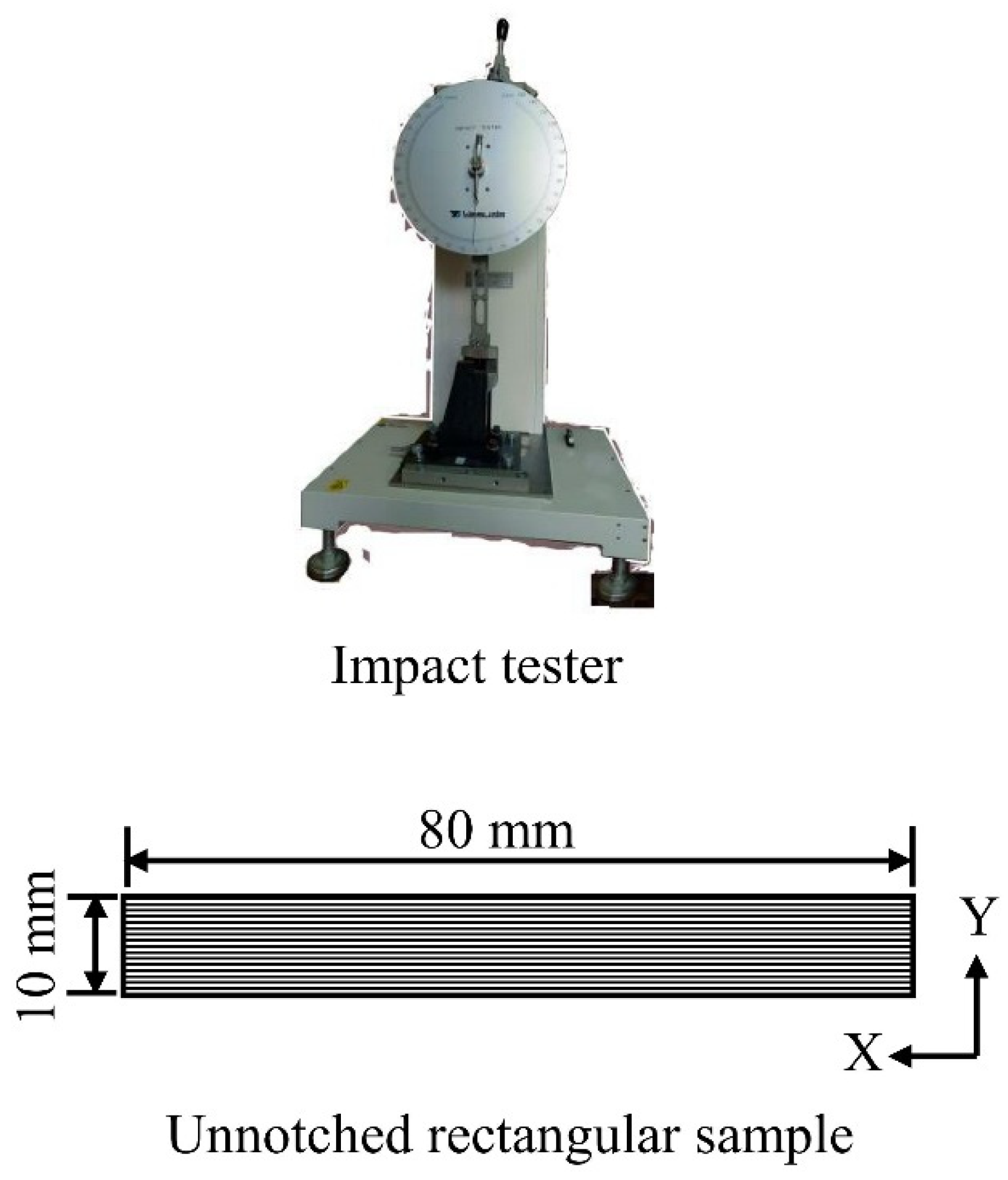

2.4.3. Impact Strength

2.5. Analysis of Variance

3. Results and Discussion

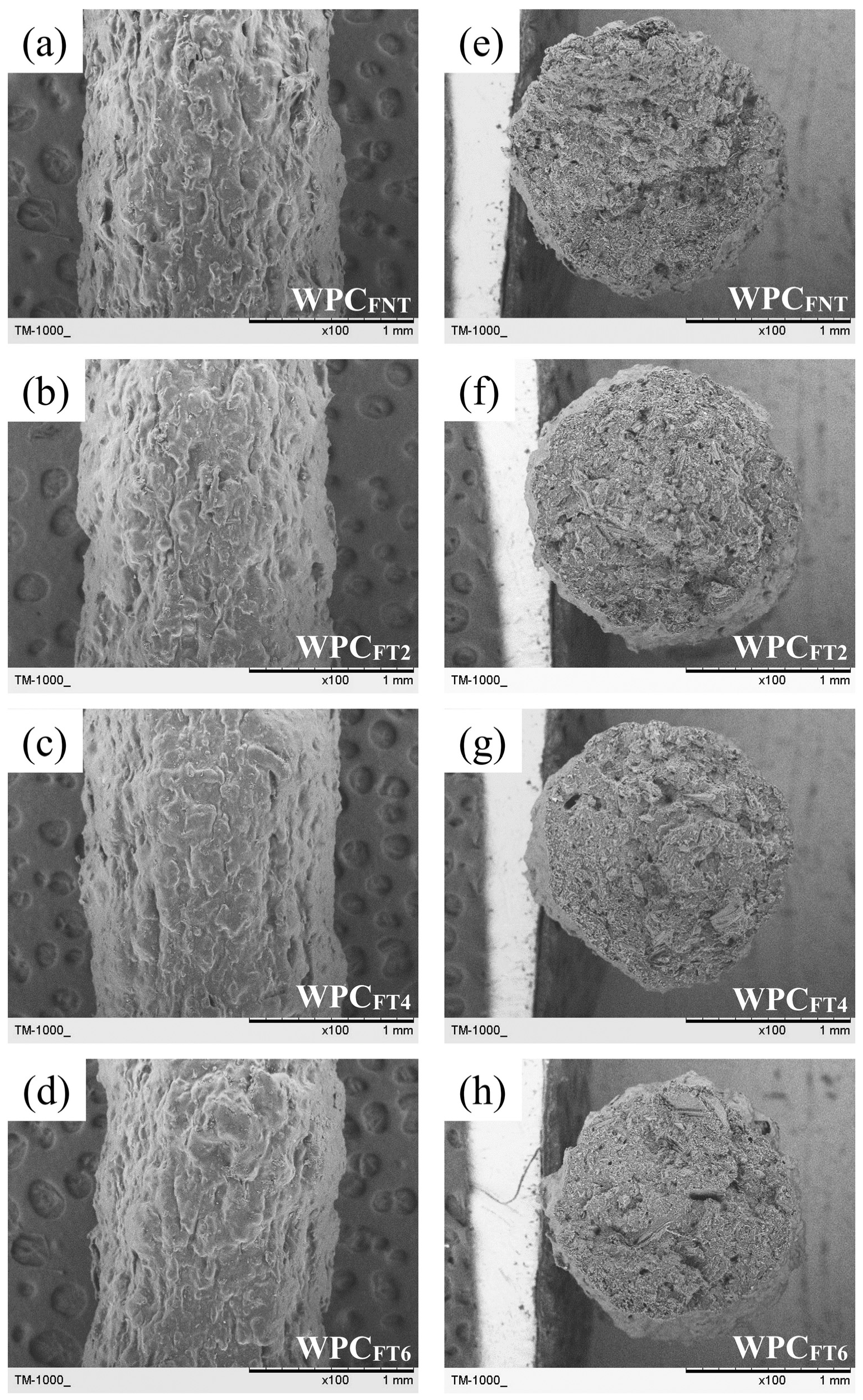

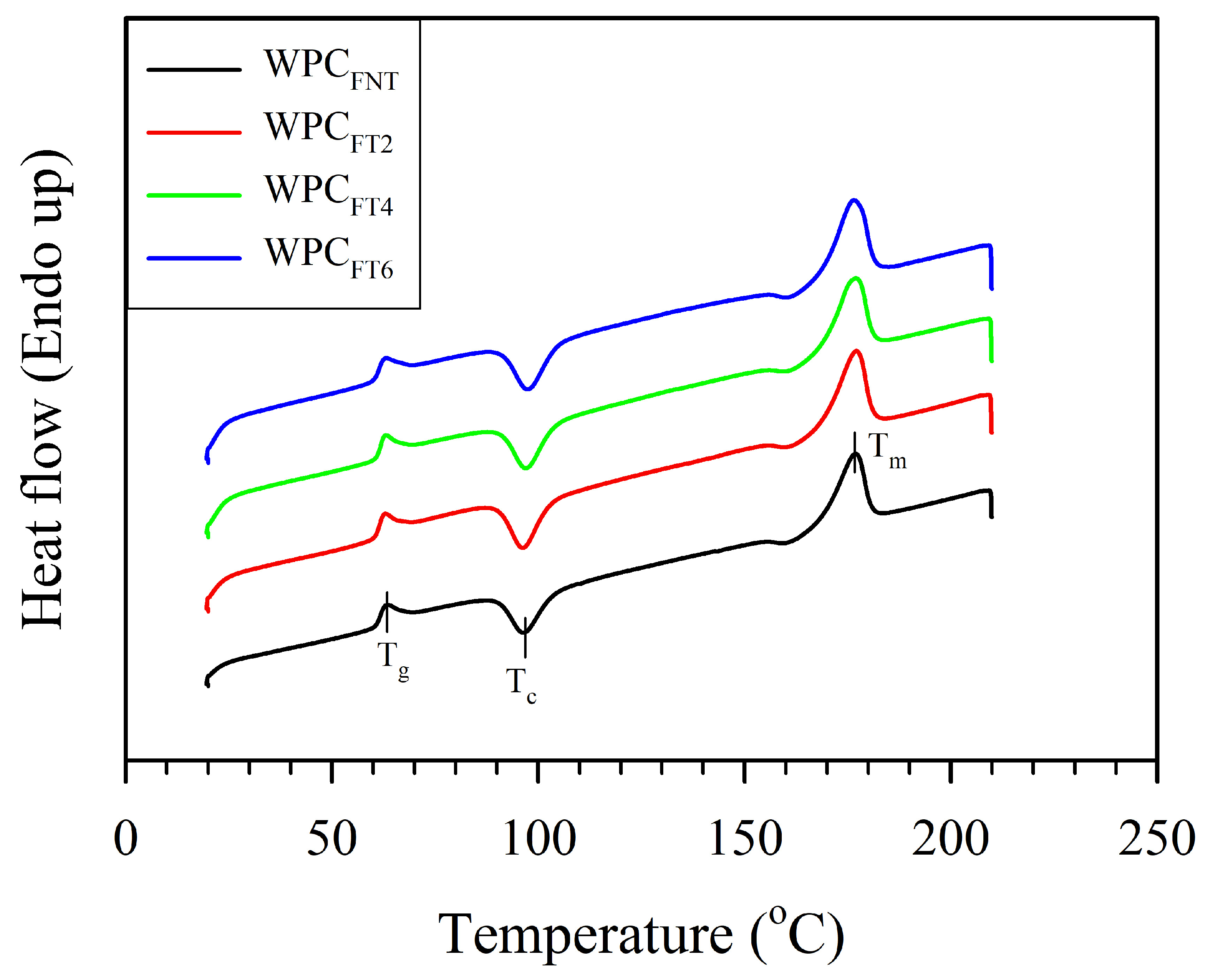

3.1. Properties of WPC Filaments with Heat-Treated WFs

3.2. Properties of 3D-Printed WPC Parts

3.2.1. Surface Color

3.2.2. Physical Properties

3.2.3. Mechanical Properties and Impact Strength

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Syed, A.M.T.; Elias, P.K.; Amit, B.; Susmita, B.; Lisa, O.; Charitidis, C. Additive manufacturing: Scientific and technological challenges, market uptake and opportunities. Mater. Today 2017, 21, 22–37. [Google Scholar] [CrossRef]

- Shahrubudin, N.; Lee, T.C.; Ramlan, R. An overview on 3D printing technology: Technological, materials, and applications. Procedia Manuf. 2019, 35, 1286–1296. [Google Scholar] [CrossRef]

- Kafle, A.; Luis, E.; Silwal, R.; Pan, H.M.; Shrestha, P.L.; Bastola, A.K. 3D/4D printing of polymers: Fused Deposition Modelling (FDM), Selective Laser Sintering (SLS), and Stereolithography (SLA). Polymers 2021, 13, 3101. [Google Scholar] [CrossRef]

- Anwajler, B.; Zdybel, E.; Tomaszewska-Ciosk, E. Innovative polymer composites with natural fillers produced by additive manufacturing (3D Printing)—A literature review. Polymers 2023, 15, 3534. [Google Scholar] [CrossRef]

- Ahmad, M.N.; Ishak, M.R.; Mohammad Taha, M.; Mustapha, F.; Leman, Z. A review of natural fiber-based filaments for 3D printing: Filament fabrication and characterization. Materials 2023, 16, 4052. [Google Scholar] [CrossRef]

- Ni, Z.; Shi, J.; Li, M.; Lei, W.; Yu, W. FDM 3D printing and soil-burial-degradation behaviors of residue of astragalus particles/thermoplastic starch/Poly(lactic acid) biocomposites. Polymers 2023, 15, 2382. [Google Scholar] [CrossRef]

- Jian, B.; Mohrmann, S.; Li, H.; Li, Y.; Ashraf, M.; Zhou, J.; Zheng, X. A review on flexural properties of wood-plastic composites. Polymers 2022, 14, 3942. [Google Scholar] [CrossRef]

- Das, A.K.; Agar, D.A.; Rudolfsson, M.; Larsson, S.H. A review on wood powders in 3D printing: Processes, properties and potential applications. J. Mater. Res. Technol. 2021, 15, 241–255. [Google Scholar] [CrossRef]

- Kariz, M.; Sernek, M.; Obućina, M.; Kuzman, M.K. Effect of wood content in FDM filament on properties of 3D printed parts. Mater. Today Commun. 2018, 14, 135–140. [Google Scholar] [CrossRef]

- Le Duigou, A.; Castro, M.; Bevan, R.; Martin, N. 3D printing of wood fibre biocomposites: From mechanical to actuation functionality. Mater. Des. 2016, 96, 106–114. [Google Scholar] [CrossRef]

- Le Guen, M.J.; Hill, S.; Smith, D.; Theobald, B.; Gaugler, E.; Barakat, A.; Mayer-Laigle, C. Influence of rice husk and wood biomass properties on the manufacture of filaments for fused deposition modeling. Front. Chem. 2019, 7, 15–20. [Google Scholar] [CrossRef]

- Fico, D.; Rizzo, D.; De Carolis, V.; Montagna, F.; Palumbo, E.; Corcione, C.E. Development and characterization of sustainable PLA/Olive wood waste composites for rehabilitation applications using fused filament fabrication (FFF). J. Build. Eng. 2022, 56, 104673. [Google Scholar] [CrossRef]

- Forestry and Nature Conservation Agency in Taiwan, Forestry Statistics Yearbook. 2020. Available online: https://www.forest.gov.tw/EN/0004346 (accessed on 25 November 2023).

- Yang, T.-C.; Chien, Y.-C.; Wu, T.-L.; Hung, K.-C.; Wu, J.-H. Effects of heat-treated wood particles on the physico-mechanical properties and extended creep behavior of wood/recycled-HDPE composites using the time–temperature superposition principle. Materials 2017, 10, 365. [Google Scholar] [CrossRef] [PubMed]

- Kabir, M.M.; Wang, H.; Lau, K.T.; Cardona, F. Chemical treatments on plant-based natural fibre reinforced polymer composites: An overview. Compo. Part B-Eng. 2012, 43, 2883–2892. [Google Scholar] [CrossRef]

- Joseph, P.V.; Joseph, K.; Thomas, S.; Pillai, C.K.S.; Prasad, V.S.; Groeninckx, G.; Sarkissova, M. The thermal and crystallisation studies of short sisal fibre reinforced polypropylene composites. Compos. Part A-Appl. Sci. Manuf. 2003, 34, 253–266. [Google Scholar] [CrossRef]

- Wang, B.; Panigrahi, S.; Tabil, L.; Crerar, W. Pre-treatment of flax fibres for use in rotationally molded biocomposites. J. Reinf. Plast. Compos. 2007, 26, 447–463. [Google Scholar] [CrossRef]

- Li, X.; Tabil, L.G.; Panigrahi, S. Chemical treatment of natural fibre for use in natural fibre-reinforced composites: A review. Polym. Environ. 2007, 15, 25–33. [Google Scholar] [CrossRef]

- Ayrilmis, N.; Jarusombuti, S.; Fuengvivat, V.; Bauchongkol, P. Effect of thermal treatment of rubber wood fibres on physical and mechanical properties of medium density fibreboard. J. Trop. Forest Sci. 2011, 23, 10–16. [Google Scholar]

- Ayrilmis, N.; Jarusombuti, S.; Fuengvivat, V.; Bauchongkol, P. Effect of thermal-treatment of wood fibres on properties of flat-pressed wood plastic composites. Polym. Degrad. Stabil. 2011, 96, 818–822. [Google Scholar] [CrossRef]

- Chien, Y.-C.; Yang, T.-C.; Hung, K.-C.; Li, C.-C.; Xu, J.-W.; Wu, J.-H. Effects of heat treatment on the chemical compositions and thermal decomposition kinetics of Japanese cedar and beech wood. Polym. Degrad. Stabil. 2018, 158, 220–227. [Google Scholar] [CrossRef]

- Yang, T.-C.; Chung, M.-J.; Wu, T.-L.; Yeh, C.-H. Physicomechanical properties and water resistance of heat-modified moso bamboo (Phyllostachys pubescens) as a function of density. Constr. Build. Mater. 2021, 306, 124897. [Google Scholar] [CrossRef]

- CNS 13333-1; Plastics−Methods for Determining the Density of Non-Cellular Plastics−Part 1: Immersion Method, Liquid Pycnometer Method and Titration Method. National Standards of the Republic of China: Taipei, Taiwan, 2015.

- ASTM D4442-20; Standard Test Methods for Direct Moisture Content Measurement of Wood and Wood-Based Materials. ASTM International: West Conshohocken, PA, USA, 2020.

- ASTM D1037-12; Standard Test Methods for Evaluating Properties of Wood-Base Fiber and Particle Panel Materials. ASTM International: West Conshohocken, PA, USA, 2020.

- ASTM D638-14; Standard Test Method for Tensile Properties of Plastics. ASTM International: West Conshohocken, PA, USA, 2022.

- ASTM D790-17; Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials. ASTM International: West Conshohocken, PA, USA, 2017.

- CNS 5846-1; Plastics−Determination of Charpy Impact Properties−Part 1: Noninstrumented Impact Test. National Standards of the Republic of China: Taipei, Taiwan, 2019.

- Yang, T.-C. Effect of extrusion temperature on the physico-mechanical properties of unidirectional wood fiber-reinforced Polylactic acid composite (WFRPC) components using fused deposition modeling. Polymers 2018, 10, 976. [Google Scholar] [CrossRef] [PubMed]

- Yang, T.-C.; Yeh, C.-H. Morphology and mechanical properties of 3D printed wood fiber/Polylactic acid composite parts using fused deposition modeling (FDM): The effects of printing speed. Polymers 2020, 12, 1334. [Google Scholar] [CrossRef]

- Filgueira, D.; Holmen, S.; Melbø, J.K.; Moldes, D.; Echtermeyer, A.T.; Chinga-Carrasco, G. Enzymatic-assisted modification of thermomechanical pulp fibers to improve the interfacial adhesion with Poly(lactic acid) for 3D printing. ACS Sustain. Chem. Eng. 2017, 5, 9338–9346. [Google Scholar] [CrossRef]

- Odalanowska, M.; Borysiak, S. Influence of wood thermal modification on the supermolecular structure of polypropylene composites. Polym. Compos. 2021, 42, 2087–2100. [Google Scholar] [CrossRef]

- Guinault, A.; Sollogoub, C.; Domenek, S.; Grandmontagne, A.; Ducruet, V. Influence of crystallinity on gas barrier and mechanical properties of PLA food packaging films. Int. J. Mater. Form. 2010, 3, 603–606. [Google Scholar] [CrossRef]

- Yang, D.; Cao, Y.; Zhang, Z.; Yin, Y.; Li, D. Effects of crystallinity control on mechanical properties of 3D-printed short-carbon-fiber-reinforced polyether ether ketone composites. Polym. Test. 2021, 97, 107149. [Google Scholar] [CrossRef]

- Yang, T.-H.; Lee, C.-H.; Lee, C.-J.; Cheng, Y.-W. Effects of different thermal modification media on physical and mechanical properties of moso bamboo. Constr. Build. Mater. 2016, 119, 251–259. [Google Scholar] [CrossRef]

- Gaff, M.; Kubovský, I.; Sikora, A.; Kačíková, D.; Li, H.; Kubovský, M.; Kačík, F. Impact of thermal modification on color and chemical changes of African padauk, merbau, mahogany, and iroko wood species. Rev. Adv. Mater. Sci. 2023, 62, 20220277. [Google Scholar] [CrossRef]

- Sikora, A.; Kačík, F.; Gaff, M.; Vondrová, V.; Bubeníková, T.; Kubovský, I. Impact of thermal modification on color and chemical changes of spruce and oak wood. J. Wood Sci. 2018, 64, 406–416. [Google Scholar] [CrossRef]

- Bekhta, P.; Niemz, P. Effect of high temperature on the change in color, dimensional stability and mechanical properties of spruce wood. Holzforschung 2003, 57, 539–546. [Google Scholar] [CrossRef]

- Bourgois, P.J.; Janin, G.; Guyonnet, R. The color measurement: A fast method to study and to optimize the chemical transformations undergone in the thermically treated wood. Holzforschung 1991, 45, 377–382. [Google Scholar] [CrossRef]

- Ashori, A.; Sheshmani, S. Hybrid composites made from recycled materials: Moisture absorption and thickness swelling behavior. Bioresour. Technol. 2010, 101, 4717–4720. [Google Scholar] [CrossRef] [PubMed]

- Tumuluru, J.S.; Sokhansanj, S.; Hess, J.R.; Wright, C.T.; Boardman, R.D. A review on biomass torrefaction process and product properties for energy applications. Ind. Biotechnol. 2011, 7, 384–401. [Google Scholar] [CrossRef]

- Windeisen, E.; Bächle, H.; Zimmer, B.; Wegener, G. Relations between chemical changes and mechanical properties of thermally treated wood. Holzforschung 2009, 63, 773–778. [Google Scholar] [CrossRef]

- Tokoro, R.; Vu, D.M.; Okubo, K.; Tanaka, T.; Fujii, T.; Fujiura, T. How to improve mechanical properties of polylactic acid with bamboo fibers. J. Mater. Sci. 2008, 43, 775–787. [Google Scholar] [CrossRef]

- Mazur, K.E.; Borucka, A.; Kaczor, P.; Gądek, S.; Bogucki, R.; Mirzewiński, D.; Kuciel, S. Thermal and microstructural characteristic of 3D printed Polylactide composites with natural fibers: Wood, Bamboo and Cork. J. Polym. Environ. 2022, 30, 2341–2354. [Google Scholar] [CrossRef]

| Code | Treatment Temperature (°C) | Treatment Time (h) | TSF (MPa) | TMF (GPa) | EBF (%) |

|---|---|---|---|---|---|

| WPCFNT | - | - | 44.3 ± 4.5 a | 3.2 ± 0.2 b | 3.0 ± 0.3 a |

| WPCFT2 | 180 | 2 | 44.7 ± 4.7 ans | 3.3 ± 0.5 a,bns | 2.2 ± 0.4 a,b,* |

| WPCFT4 | 180 | 4 | 47.0 ± 6.9 ans | 3.7 ± 0.2 a,** | 2.2 ± 0.7 a,b,* |

| WPCFT6 | 180 | 6 | 41.4 ± 6.7 ans | 3.6 ± 0.1 a,b,** | 1.9 ± 0.6 b,* |

| Code | Treatment Temperature (°C) | Treatment Time (h) | Tg (°C) | Tcc (°C) | Tm (°C) | Xc (%) |

|---|---|---|---|---|---|---|

| WPCFNT | - | - | 61.7 | 96.7 | 176.8 | 23.4 |

| WPCFT2 | 180 | 2 | 61.6 | 96.5 | 176.9 | 34.0 |

| WPCFT4 | 180 | 4 | 61.9 | 97.1 | 176.8 | 40.5 |

| WPCFT6 | 180 | 6 | 61.5 | 97.6 | 176.4 | 43.9 |

| Code | Treatment Temperature (°C) | Treatment Time (h) | L* | a* | b* | ΔE* |

|---|---|---|---|---|---|---|

| WPCPNT | - | - | 54.3 ± 0.3 a | 10.0 ± 0.3 c | 25.2 ± 0.4 a,b | - |

| WPCPT2 | 180 | 2 | 50.0 ± 0.2 b | 11.3 ± 0.1 b | 26.1 ± 0.3 a | 4.6 ± 0.2 b |

| WPCPT4 | 180 | 4 | 48.8 ± 0.6 b | 10.9 ± 0.2 a,b | 25.2 ± 0.3 a,b | 5.6 ± 0.6 b |

| WPCPT6 | 180 | 6 | 45.6 ± 0.6 c | 11.9 ± 0.5 a | 24.3 ± 0.6 b | 8.9 ± 0.7 a |

| Code | Treatment Temperature (°C) | Treatment Time (h) | Density (g/cm3) | MC (%) | 24 h of Soaking | |

|---|---|---|---|---|---|---|

| WA (%) | TKS (%) | |||||

| WPCPNT | - | - | 1.06 ± 0.02 a | 1.1 ± 0.0 a | 3.9 ± 0.4 a | 0.52 ± 0.18 a |

| WPCPT2 | 180 | 2 | 0.99 ± 0.04 ans | 1.1 ± 0.0 ans | 4.0 ± 0.2 ans | 0.51 ± 0.30 ans |

| WPCPT4 | 180 | 4 | 1.04 ± 0.03 ans | 1.1 ± 0.0 ans | 3.5 ± 0.3 a,b,* | 0.25 ± 0.31 ans |

| WPCPT6 | 180 | 6 | 1.02 ± 0.04 ans | 1.0 ± 0.1 a,* | 3.2 ± 0.3 b,*** | 0.10 ± 0.22 ans |

| Code | Treatment Temperature (°C) | Treatment Time (h) | Tensile Properties | Flexural Properties | IS (kJ/m2) | |||

|---|---|---|---|---|---|---|---|---|

| TS (MPa) | TM (GPa) | EB (%) | MOR (MPa) | MOE (GPa) | ||||

| WPCPNT | - | - | 25.5 ± 1.8 b | 2.7 ± 0.2 a | 1.9 ± 0.1 a | 50.3 ± 2.0 a | 2.6 ± 0.1 a | 7.7 ± 1.1 a |

| WPCPT2 | 180 | 2 | 29.0 ± 0.8 a,* | 2.6 ± 0.5 ans | 2.0 ± 0.1 ans | 50.6 ± 2.9 ans | 2.6 ± 0.1 ans | 6.8 ± 0.4 a,bns |

| WPCPT4 | 180 | 4 | 30.5 ± 1.5 a,* | 2.7 ± 0.5 ans | 1.9 ± 0.1 ans | 52.3 ± 1.1 ans | 2.6 ± 0.2 ans | 7.1 ± 0.3 a,bns |

| WPCPT6 | 180 | 6 | 30.4 ± 0.6 a,* | 3.1 ± 0.1 a,* | 1.9 ± 0.1 ans | 48.7 ± 3.3 ans | 2.4 ± 0.3 ans | 6.3 ± 0.4 bns |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chien, Y.-C.; Yang, T.-C. Properties of Heat-Treated Wood Fiber–Polylactic Acid Composite Filaments and 3D-Printed Parts Using Fused Filament Fabrication. Polymers 2024, 16, 302. https://doi.org/10.3390/polym16020302

Chien Y-C, Yang T-C. Properties of Heat-Treated Wood Fiber–Polylactic Acid Composite Filaments and 3D-Printed Parts Using Fused Filament Fabrication. Polymers. 2024; 16(2):302. https://doi.org/10.3390/polym16020302

Chicago/Turabian StyleChien, Yu-Chen, and Teng-Chun Yang. 2024. "Properties of Heat-Treated Wood Fiber–Polylactic Acid Composite Filaments and 3D-Printed Parts Using Fused Filament Fabrication" Polymers 16, no. 2: 302. https://doi.org/10.3390/polym16020302

APA StyleChien, Y.-C., & Yang, T.-C. (2024). Properties of Heat-Treated Wood Fiber–Polylactic Acid Composite Filaments and 3D-Printed Parts Using Fused Filament Fabrication. Polymers, 16(2), 302. https://doi.org/10.3390/polym16020302