High-Throughput Additive Manufacturing of Continuous Carbon Fiber-Reinforced Plastic by Multifilament

Abstract

1. Introduction

2. Materials and Methods

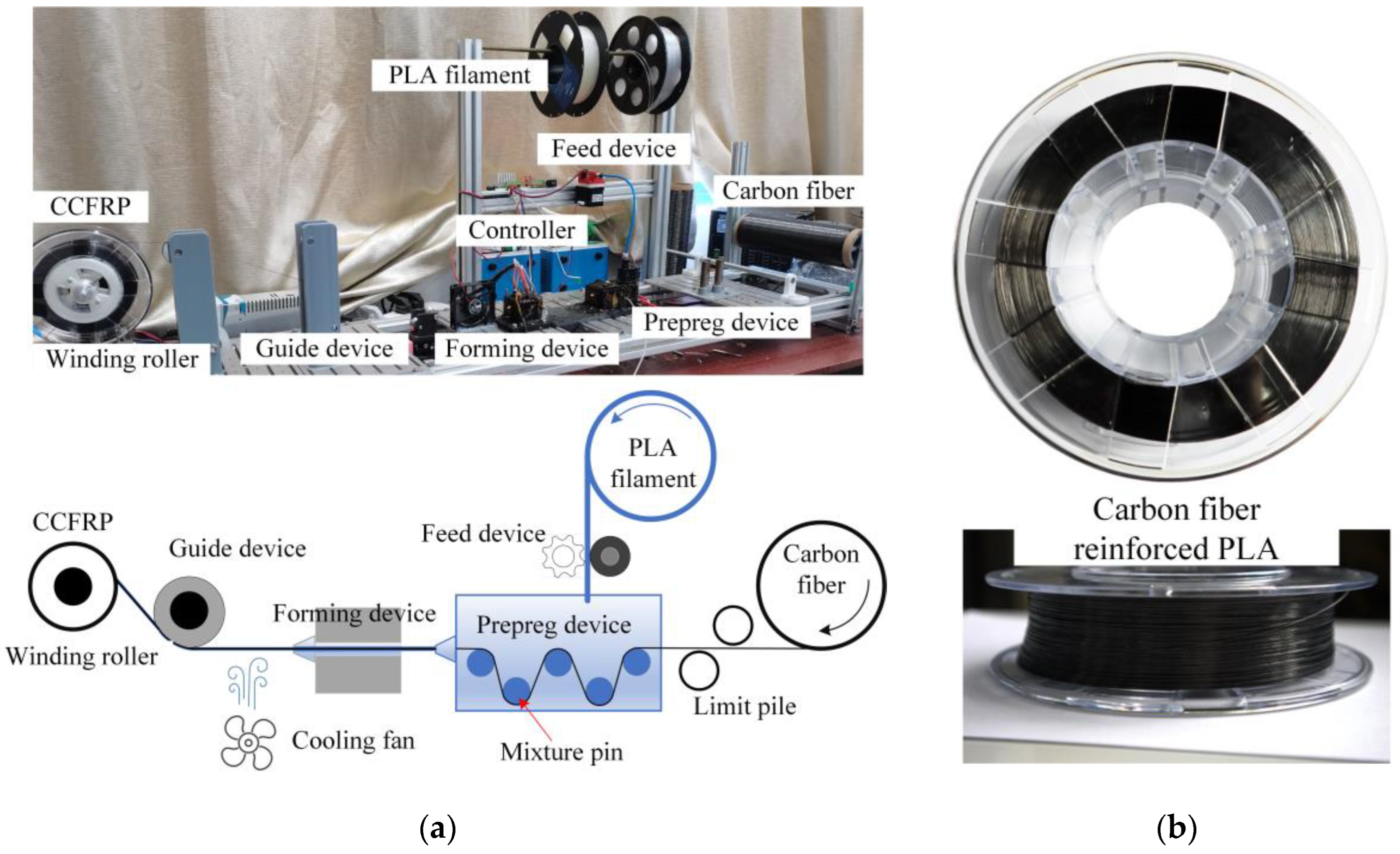

2.1. Materials

2.2. Additive Manufacturing System

2.2.1. Hardware Setup

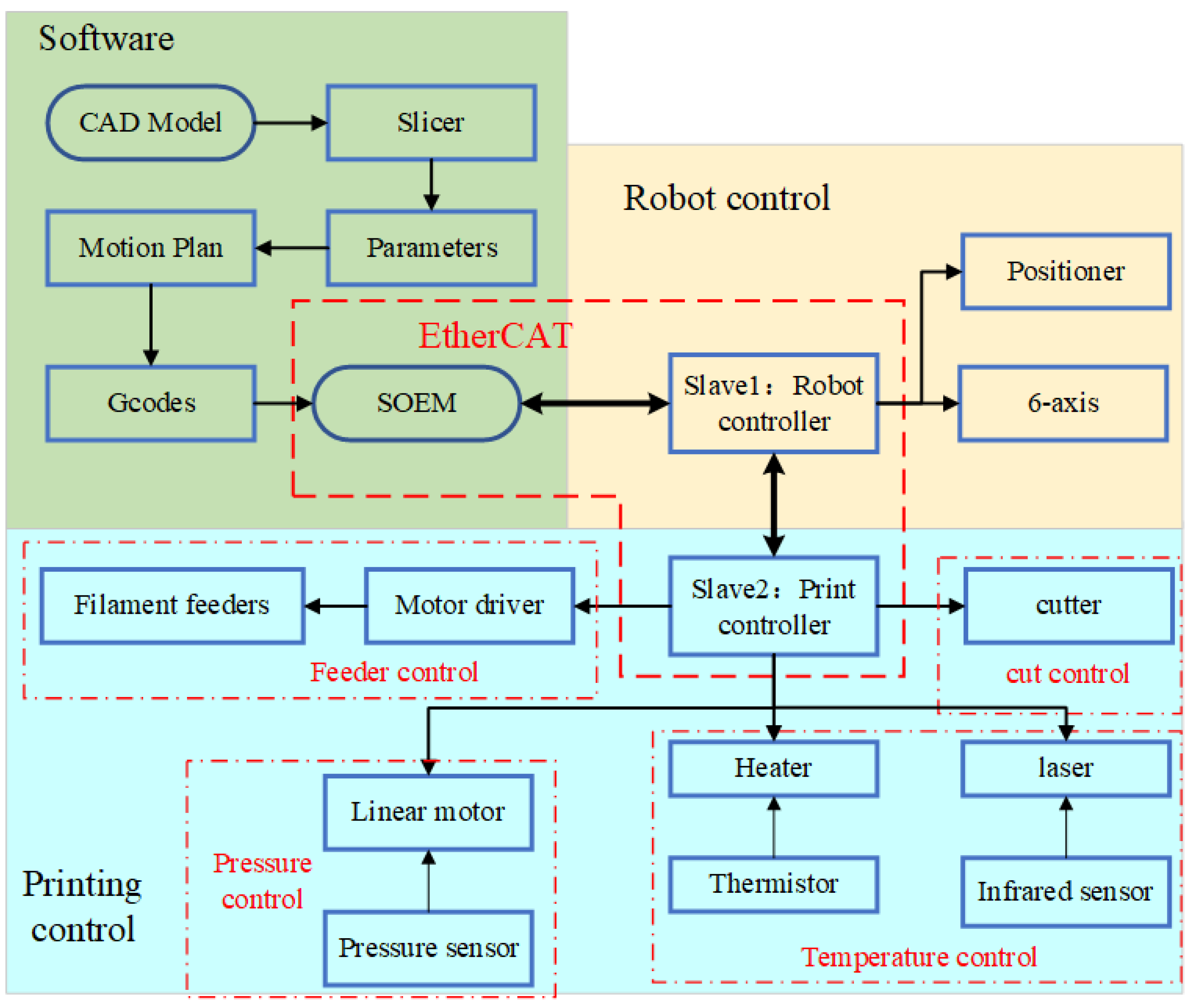

2.2.2. Software and Control System

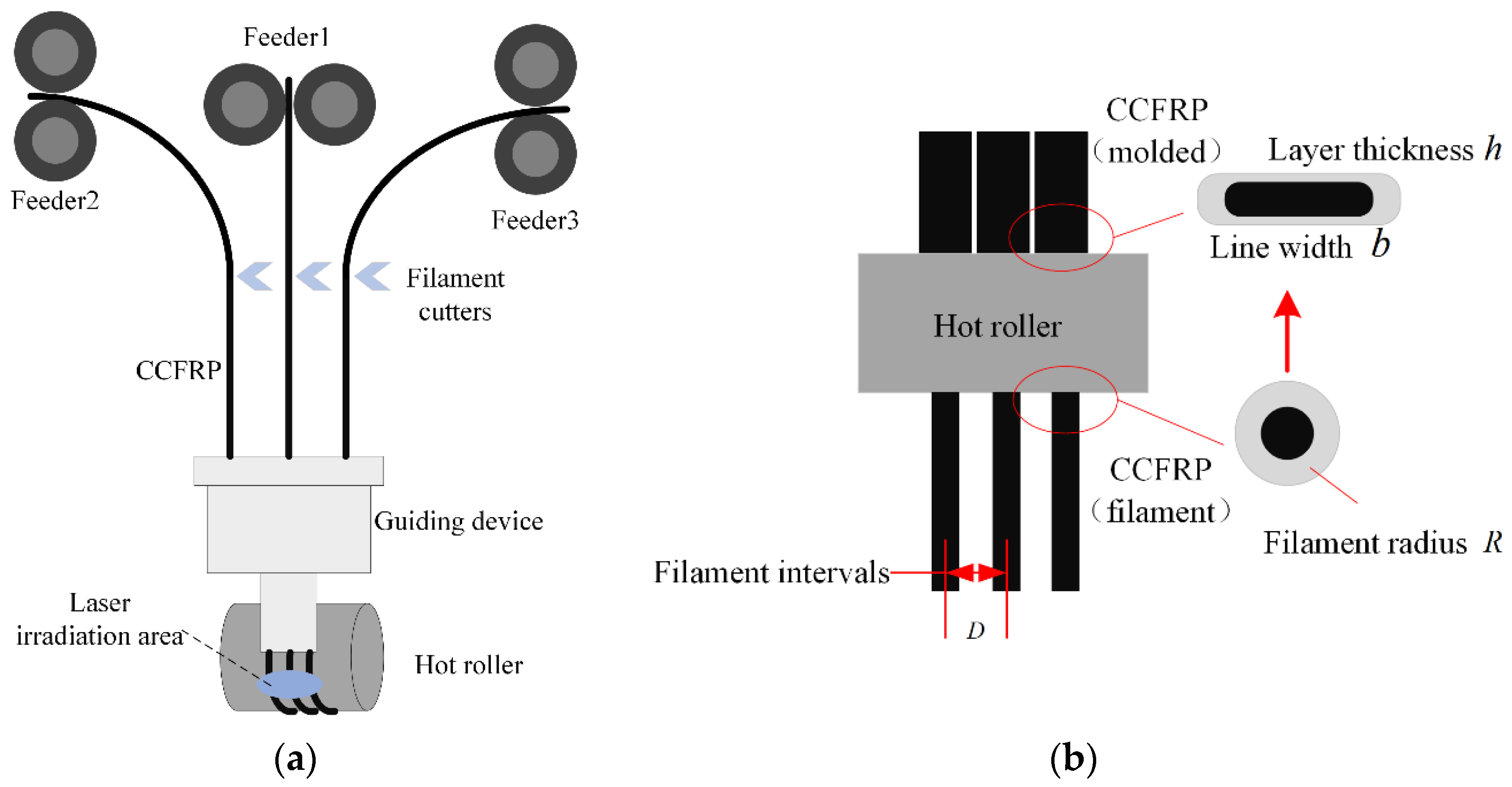

2.2.3. Prototyping Principle

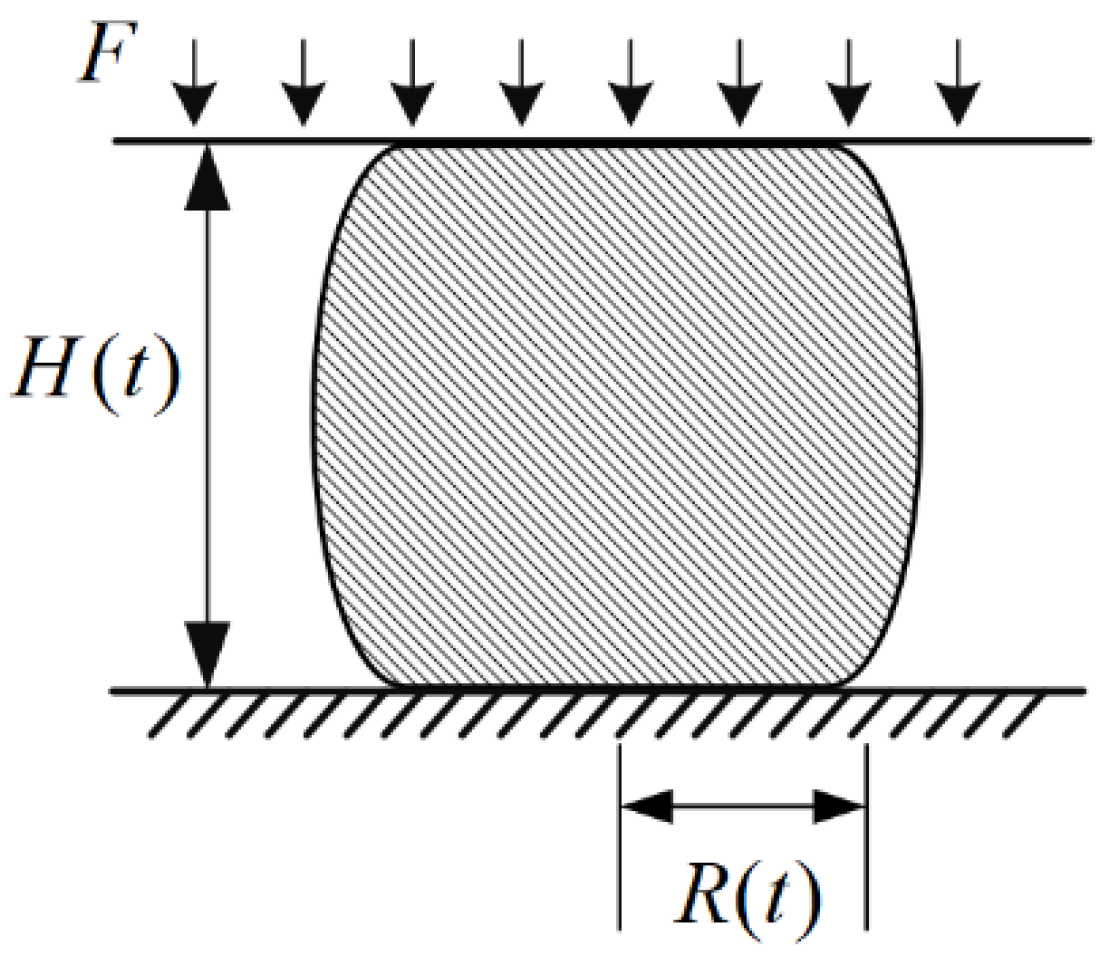

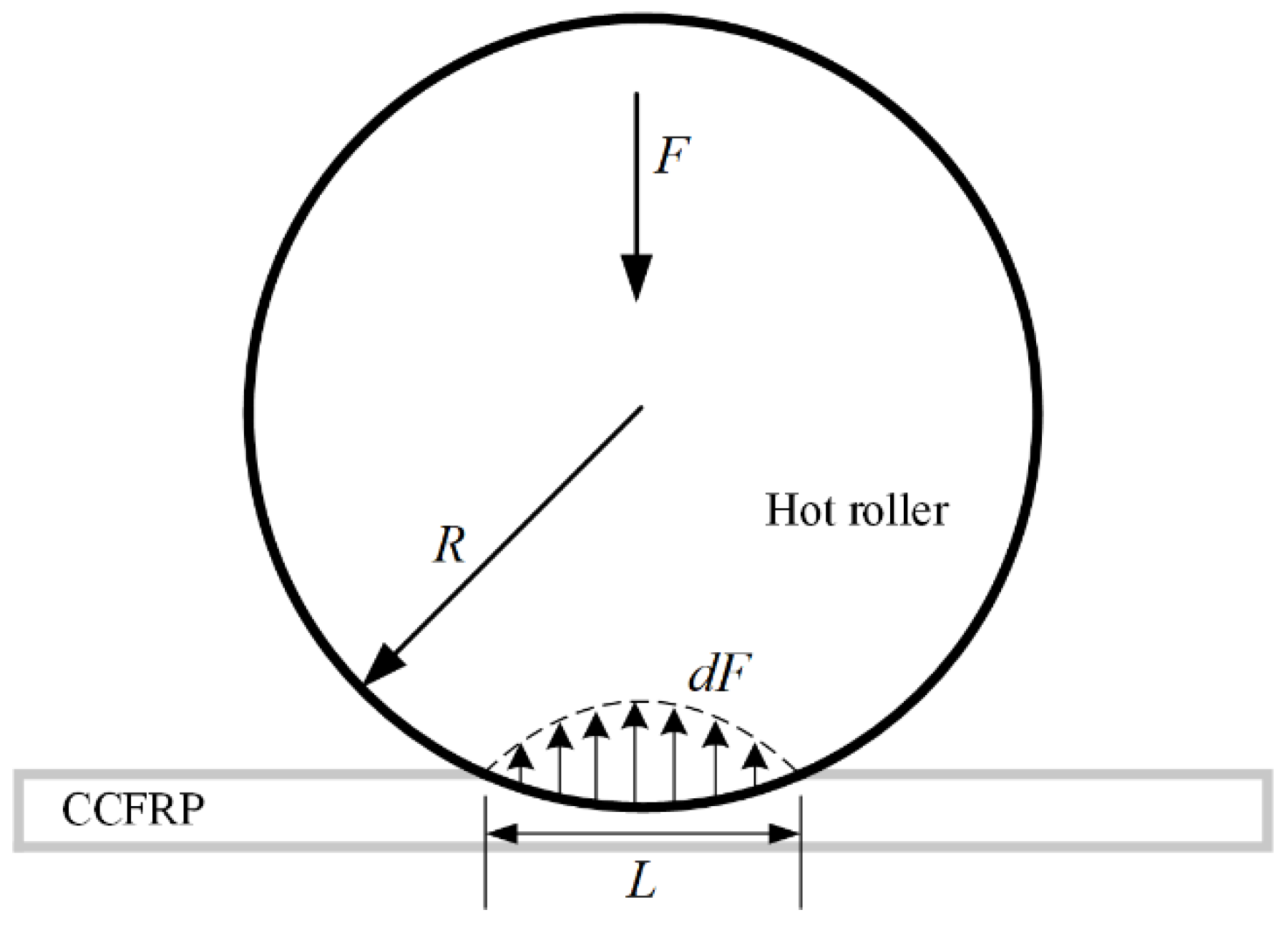

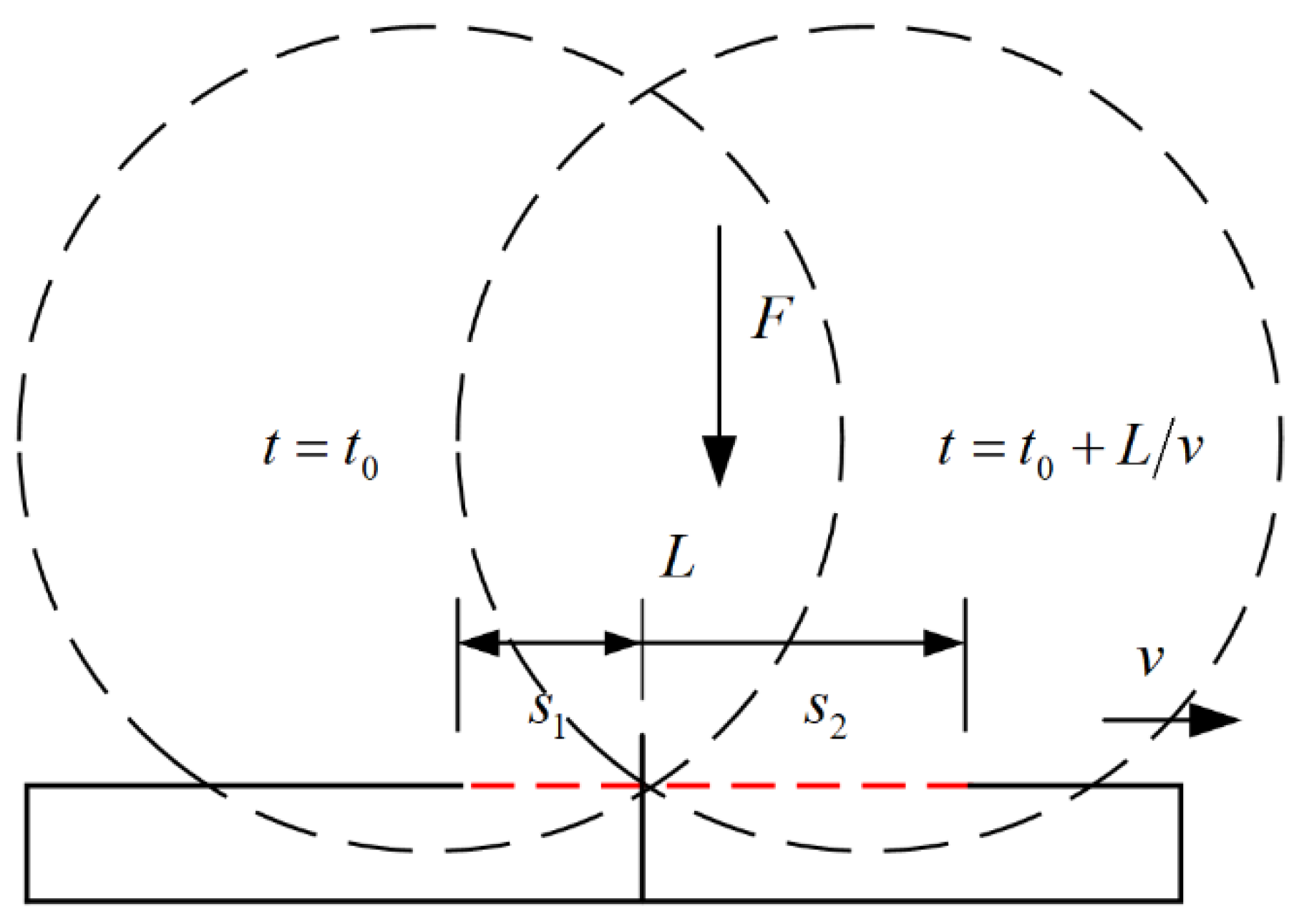

2.3. Filament Deformation Coupled Thermal-Mechanical Model

2.4. Mathematical Model of Filament Deformation and Printing Parameters

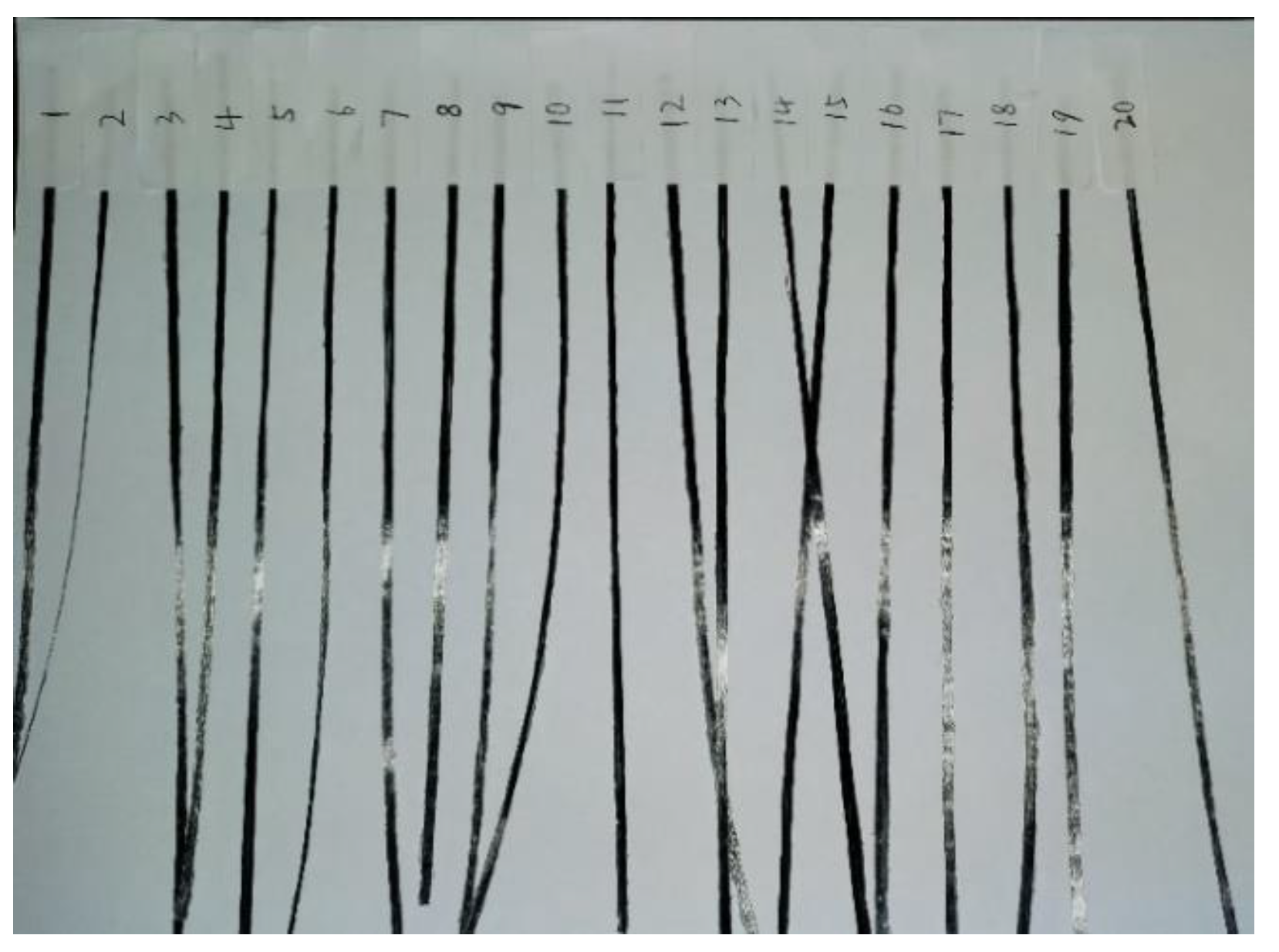

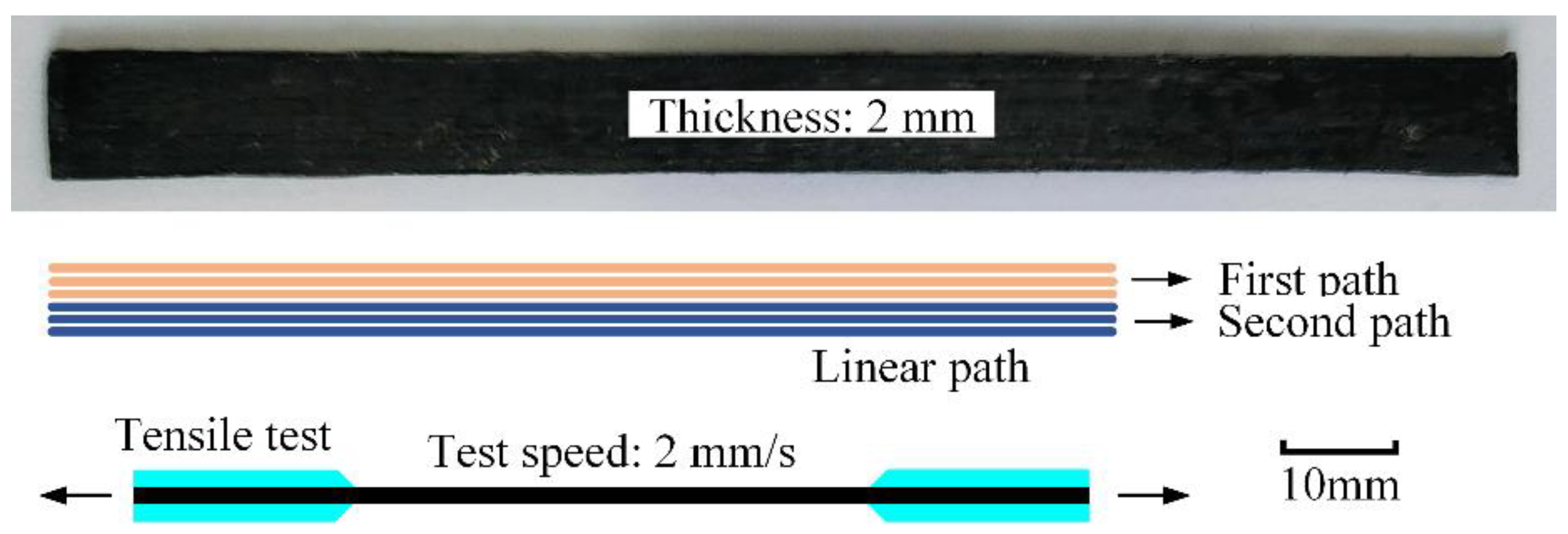

2.5. Printing Experiments and Tensile Properties Test

2.6. Void Determination and Scanning Electron Microscopy

3. Results and Discussion

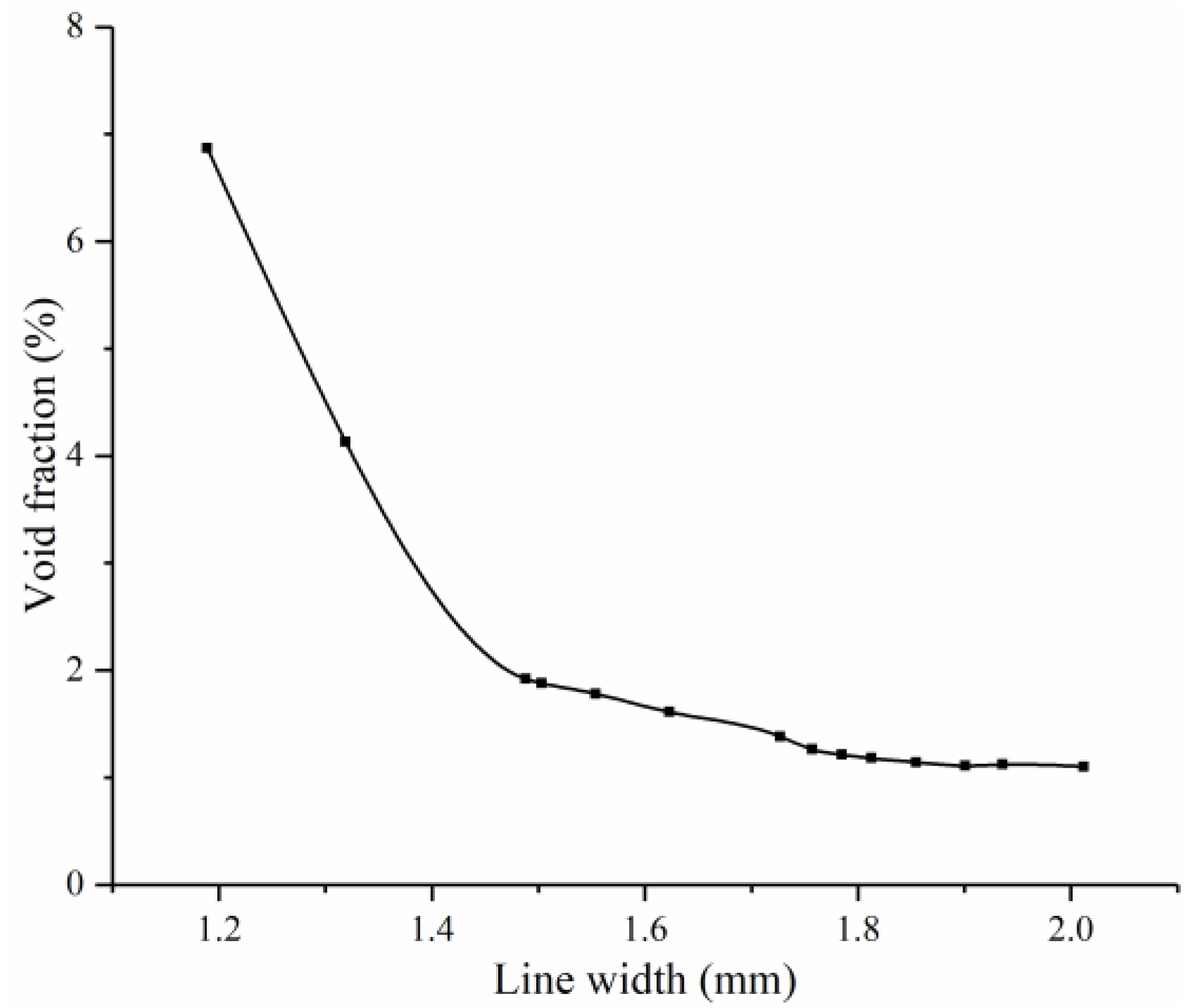

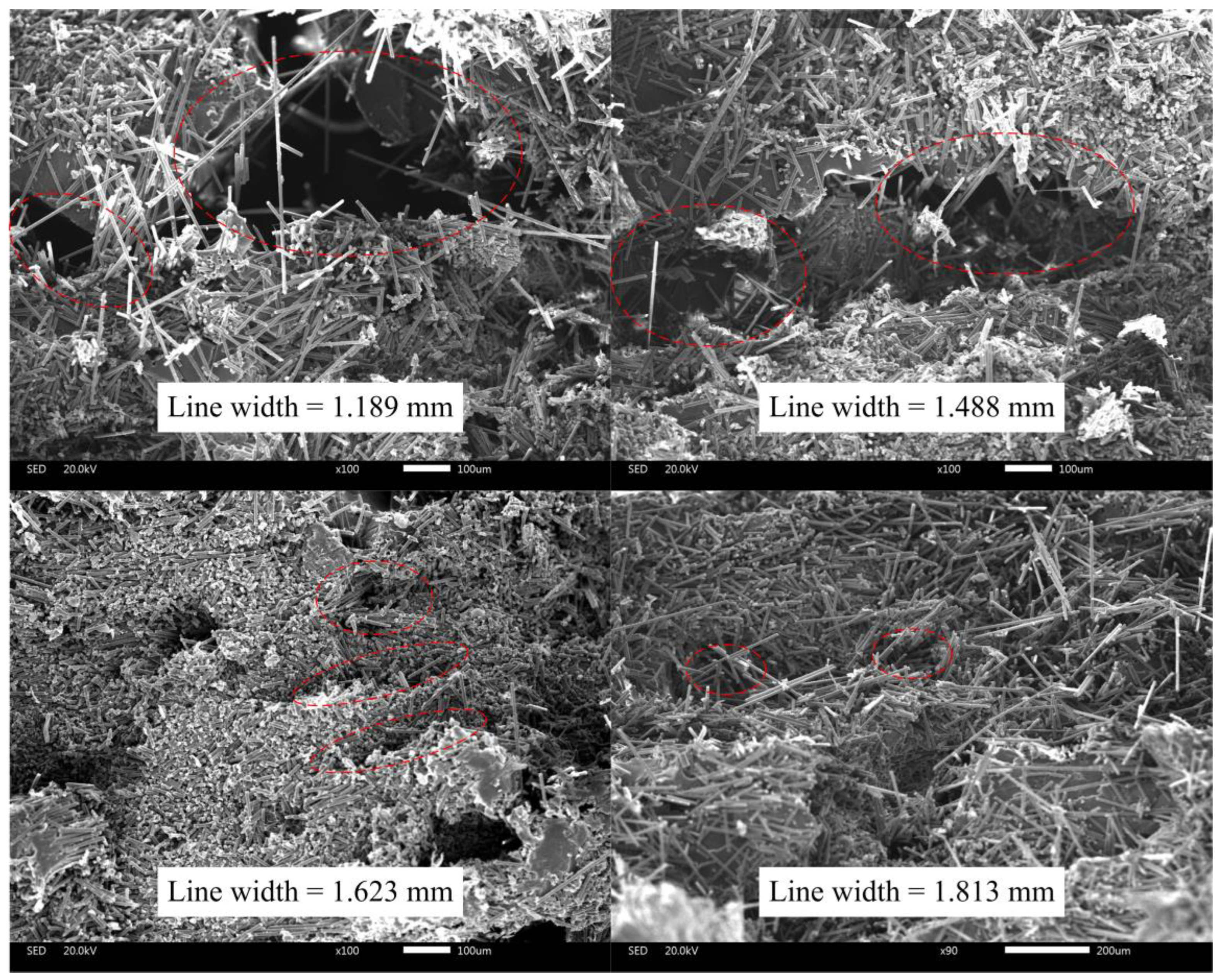

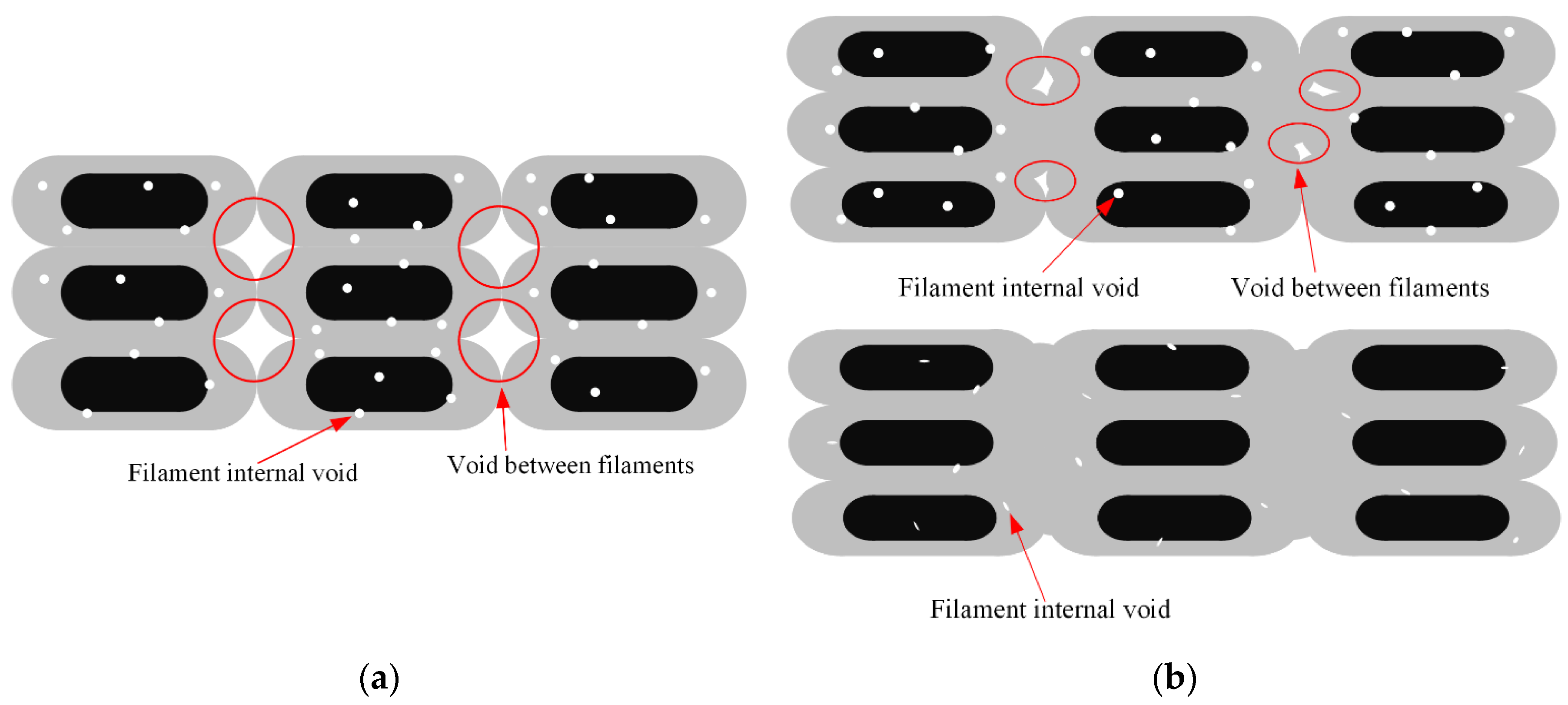

3.1. Void Fraction and Cross-Sectional Observation

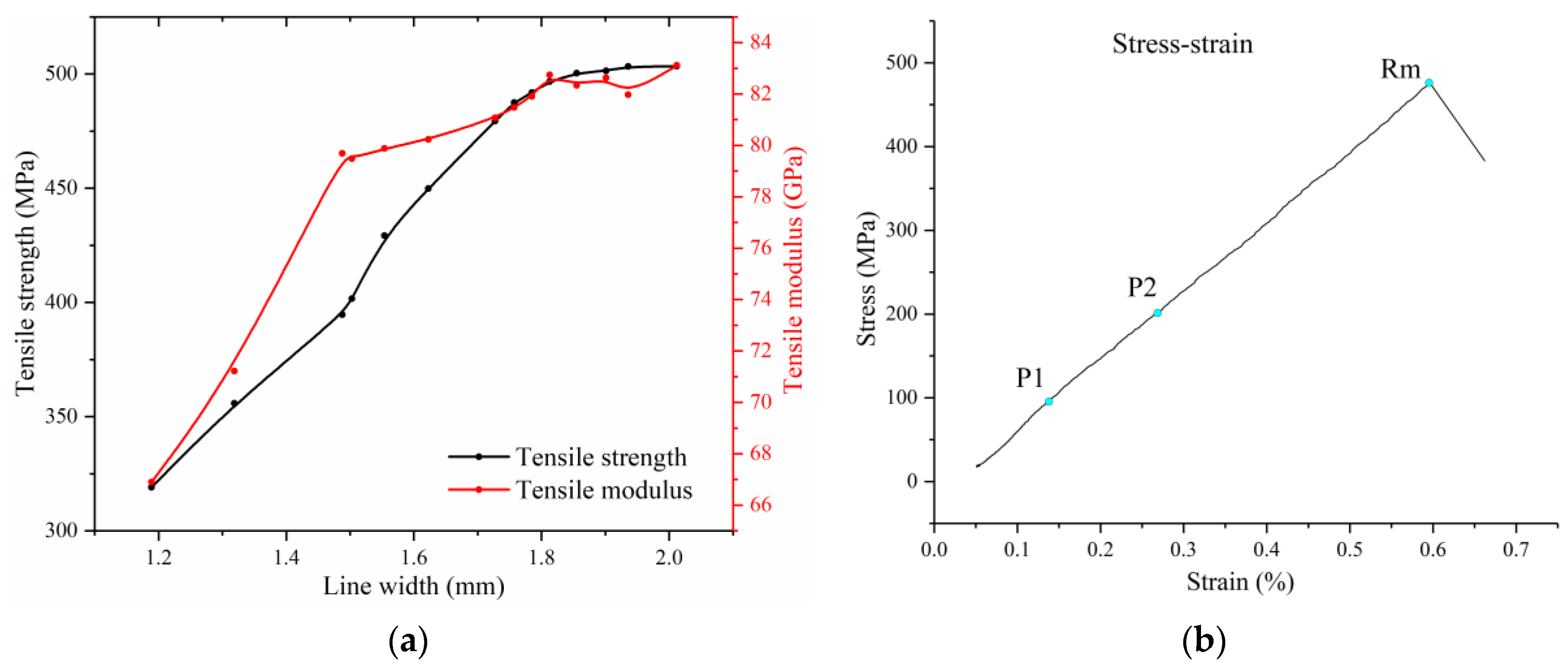

3.2. Tensile Properties

3.3. Comparison and Printed Parts Demonstration

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Parandoush, P.; Lin, D. A review on additive manufacturing of polymer-fiber composites. Compos. Struct. 2017, 182, 36–53. [Google Scholar] [CrossRef]

- Pan, L.; Yapici, U. A comparative study on mechanical properties of carbon fiber/PEEK composites. Adv. Compos. Mater. 2016, 25, 359–374. [Google Scholar] [CrossRef]

- Zhang, Z.; Long, Y.; Yang, Z.; Fu, K.; Li, Y. An investigation into printing pressure of 3D printed continuous carbon fiber reinforced composites. Compos. Part A Appl. Sci. Manuf. 2022, 162, 107162. [Google Scholar] [CrossRef]

- Van de Werken, N.; Tekinalp, H.; Khanbolouki, P.; Ozcan, S.; Williams, A.; Tehrani, M. Additively manufactured carbon fiber-reinforced composites: State of the art and perspective. Addit. Manuf. 2020, 31, 100962. [Google Scholar] [CrossRef]

- Uşun, A.; Gümrük, R. The mechanical performance of the 3D printed composites produced with continuous carbon fiber reinforced filaments obtained via melt impregnation. Addit. Manuf. 2021, 46, 102112. [Google Scholar] [CrossRef]

- Kabir, S.F.; Mathur, K.; Seyam, A.F.M. A critical review on 3D printed continuous fiber-reinforced composites: History, mechanism, materials and properties. Compos. Struct. 2020, 232, 111476. [Google Scholar] [CrossRef]

- Cheng, P.; Peng, Y.; Li, S.; Rao, Y.; Le Duigou, A.; Wang, K.; Ahzi, S. 3D printed continuous fiber reinforced composite lightweight structures: A review and outlook. Compos. Part B Eng. 2023, 250, 110450. [Google Scholar] [CrossRef]

- Tian, X.; Todoroki, A.; Liu, T.; Wu, L.; Hou, Z.; Ueda, M.; Lu, B. 3D printing of continuous fiber reinforced polymer composites: Development, application, and prospective. Chin. J. Mech. Eng. Addit. Manuf. Front. 2022, 1, 100016. [Google Scholar] [CrossRef]

- O’Connor, H.J.; Dowling, D.P. Low-pressure additive manufacturing of continuous fiber-reinforced polymer composites. Polym. Compos. 2019, 40, 4329–4339. [Google Scholar] [CrossRef]

- Luo, M.; Tian, X.; Shang, J.; Zhu, W.; Li, D.; Qin, Y. Impregnation and interlayer bonding behaviours of 3D-printed continuous carbon-fiber-reinforced poly-ether-ether-ketone composites. Compos. Part A Appl. Sci. Manuf. 2019, 121, 130–138. [Google Scholar] [CrossRef]

- Bhandari, S.; Lopez-Anido, R.A.; Gardner, D.J. Enhancing the interlayer tensile strength of 3D printed short carbon fiber reinforced PETG and PLA composites via annealing. Addit. Manuf. 2019, 30, 100922. [Google Scholar] [CrossRef]

- Zhang, J.; Zhou, Z.; Zhang, F.; Tan, Y.; Tu, Y.; Yang, B. Performance of 3D-printed continuous-carbon-fiber-reinforced plastics with pressure. Materials 2020, 13, 471. [Google Scholar] [CrossRef]

- Ueda, M.; Kishimoto, S.; Yamawaki, M.; Matsuzaki, R.; Todoroki, A.; Hirano, Y.; Le Duigou, A. 3D compaction printing of a continuous carbon fiber reinforced thermoplastic. Compos. Part A Appl. Sci. Manuf. 2020, 137, 105985. [Google Scholar] [CrossRef]

- Blok, L.G.; Longana, M.L.; Yu, H.; Woods, B.K. An investigation into 3D printing of fibre reinforced thermoplastic composites. Addit. Manuf. 2018, 22, 176–186. [Google Scholar] [CrossRef]

- Ye, W.; Lin, G.; Wu, W.; Geng, P.; Hu, X.; Gao, Z.; Zhao, J. Separated 3D printing of continuous carbon fiber reinforced thermoplastic polyimide. Compos. Part A Appl. Sci. Manuf. 2019, 121, 457–464. [Google Scholar] [CrossRef]

- Azarov, A.V.; Antonov, F.K.; Golubev, M.V.; Khaziev, A.R.; Ushanov, S.A. Composite 3D printing for the small size unmanned aerial vehicle structure. Compos. Part B Eng. 2019, 169, 157–163. [Google Scholar] [CrossRef]

- Dou, H.; Cheng, Y.; Ye, W.; Zhang, D.; Li, J.; Miao, Z.; Rudykh, S. Effect of process parameters on tensile mechanical properties of 3D printing continuous carbon fiber-reinforced PLA composites. Materials 2020, 13, 3850. [Google Scholar] [CrossRef] [PubMed]

- Pappas, J.M.; Thakur, A.R.; Leu, M.C.; Dong, X. A parametric study and characterization of additively manufactured continuous carbon fiber reinforced composites for high-speed 3D printing. Int. J. Adv. Manuf. Technol. 2021, 113, 2137–2151. [Google Scholar] [CrossRef]

- Li, N.; Link, G.; Jelonnek, J. Rapid 3D microwave printing of continuous carbon fiber reinforced plastics. CIRP Ann. 2020, 69, 221–224. [Google Scholar] [CrossRef]

- Yiwen, T.; Yuegang, T.; Fan, Z.; Jun, Z. Laser assisted rapid 3D printing of continuous carbon fiber reinforced plastics: Simulation, characterization, and properties. Polym. Compos. 2023, 44, 3084–3094. [Google Scholar] [CrossRef]

- Kozaczuk, K. Automated fiber placement systems overview. Pr. Inst. Lotnictwa 2016, 4, 52–59. [Google Scholar] [CrossRef]

- Frketic, J.; Dickens, T.; Ramakrishnan, S. Automated manufacturing and processing of fiber-reinforced polymer (FRP) composites: An additive review of contemporary and modern techniques for advanced materials manufacturing. Addit. Manuf. 2017, 14, 69–86. [Google Scholar] [CrossRef]

- Oromiehie, E.; Prusty, B.G.; Compston, P.; Rajan, G. Automated fibre placement based composite structures: Review on the defects, impacts and inspections techniques. Compos. Struct. 2019, 224, 110987. [Google Scholar] [CrossRef]

- Brasington, A.; Sacco, C.; Halbritter, J.; Wehbe, R.; Harik, R. Automated fiber placement: A review of history, current technologies, and future paths forward. Compos. Part C Open Access 2021, 6, 100182. [Google Scholar] [CrossRef]

- Ueda, M.; Nakayama, D.; Katsuta, N.; Okoshi, M. High-throughput 3D printing of continuous carbon fiber–reinforced Polyamide 6/Maleic Anhydride-modified Polypropylene/polypropylene composite by a multifilament feeder. Compos. Adv. Mater. 2023, 32, 26349833231158395. [Google Scholar] [CrossRef]

- Tu, Y.; Tan, Y.; Zhang, F.; Zhang, J.; Ma, G. Shearing algorithm and device for the continuous carbon fiber 3D printing. J. Adv. Mech. Des. Syst. Manuf. 2019, 13, JAMDSM0016. [Google Scholar] [CrossRef]

- Tadmor, Z.; Gogos, C.G. Principles of Polymer Processing; John Wiley & Sons: Hoboken, NJ, USA, 2013. [Google Scholar]

- Scott, J.R. Theory and Application of the Parallel-Plate Plastimeter. Trans. Inst. Rubber Ind. 1931, 7, 169–186. [Google Scholar] [CrossRef]

- Leider, P.J.; Bird, R.B. Squeezing flow between parallel disks. I. Theoretical analysis. Ind. Eng. Chem. Fundam. 1974, 13, 336–341. [Google Scholar] [CrossRef]

- Biao, Y.; Fujun, P.; Jun, X. Hot-press bonding mechanism and mechanism designing for prepreg. Acta Mater. Compos. Sin. 2016, 33, 1033–1039. (In Chinese) [Google Scholar]

- GB/T 1447-2005; Fiber-Reinforced Plastics Composite—Determination of Tensile Properties. The Standardization Administration of China: Beijing, China, 2005.

- He, Q.; Wang, H.; Fu, K.; Ye, L. 3D printed continuous CF/PA6 composites: Effect of microscopic voids on mechanical performance. Compos. Sci. Technol. 2020, 191, 108077. [Google Scholar] [CrossRef]

- Van Der Klift, F.; Koga, Y.; Todoroki, A.; Ueda, M.; Hirano, Y.; Matsuzaki, R. 3D printing of continuous carbon fibre reinforced thermo-plastic (CFRTP) tensile test specimens. Open J. Compos. Mater. 2015, 6, 18–27. [Google Scholar] [CrossRef]

- Matsuzaki, R.; Ueda, M.; Namiki, M.; Jeong, T.K.; Asahara, H.; Horiguchi, K.; Hirano, Y. Three-dimensional printing of continuous-fiber composites by in-nozzle impregnation. Sci. Rep. 2016, 6, 23058. [Google Scholar] [CrossRef] [PubMed]

- Li, N.; Li, Y.; Liu, S. Rapid prototyping of continuous carbon fiber reinforced polylactic acid composites by 3d printing—Sciencedirect. J. Mater. Process. Technol. 2016, 238, 218–225. [Google Scholar] [CrossRef]

- Heidari-Rarani, M.; Rafiee-Afarani, M.; Zahedi, A.M. Mechanical characterization of FDM 3D printing of continuous carbon fiber reinforced PLA composites. Compos. Part B Eng. 2019, 175, 107147. [Google Scholar] [CrossRef]

- Markforged. 2020. Available online: https://markforged.com/materials/continuous-fibers/continuous-carbon-fiber (accessed on 14 March 2020).

- Mosleh, N.; Rezadoust, A.M.; Dariushi, S. Determining process-window for manufacturing of continuous carbon fiber-reinforced composite Using 3D-printing. Mater. Manuf. Process. 2021, 36, 409–418. [Google Scholar] [CrossRef]

- Yang, C.; Tian, X.; Liu, T.; Cao, Y.; Li, D. 3d printing for continuous fiber reinforced thermoplastic composites: Mechanism and performance. Rapid Prototyp. J. 2017, 23, 209–215. [Google Scholar] [CrossRef]

- Omuro, R.; Ueda, M.; Matsuzaki, R.; Todoroki, A.; Hirano, Y. Three-dimensional printing of continuous carbon fiber reinforced thermoplastics by in-nozzle impregnation with compaction roller. In Proceedings of the 21st International Conference on Composite Materials, Xi’an, China, 20–25 August 2017. [Google Scholar]

- Goh, G.D.; Dikshit, V.; Nagalingam, A.P.; Goh, G.L.; Agarwala, S.; Sing, S.L.; Yeong, W.Y. Characterization of mechanical properties and fracture mode of additively manufactured carbon fiber and glass fiber reinforced thermoplastics. Mater. Des. 2018, 137, 79–89. [Google Scholar] [CrossRef]

- Ouyang, Z.; Yang, L.; Pi, Z.; Wang, Z.; Yan, C.; Shi, Y. Robot-assisted laser additive manufacturing for high-strength/low-porosity continuous fiber-reinforced thermoplastic composites. Compos. Sci. Technol. 2024, 247, 110397. [Google Scholar] [CrossRef]

- Lu, L.; Hou, J.; Yuan, S.; Yao, X.; Li, Y.; Zhu, J. Deep learning-assisted real-time defect detection and closed-loop adjustment for additive manufacturing of continuous fiber-reinforced polymer composites. Robot. Comput.-Integr. Manuf. 2023, 79, 102431. [Google Scholar] [CrossRef]

- Abedi, K.; Miri, S.; Gregorash, L.; Fayazbakhsh, K. Evaluation of electromagnetic shielding properties of high-performance continuous carbon fiber composites fabricated by robotic 3D printing. Addit. Manuf. 2022, 54, 102733. [Google Scholar] [CrossRef]

- Miri, S.; Kalman, J.; Canart, J.P.; Spangler, J.; Fayazbakhsh, K. Tensile and thermal properties of low-melt poly aryl ether ketone reinforced with continuous carbon fiber manufactured by robotic 3D printing. Int. J. Adv. Manuf. Technol. 2022, 122, 1041–1053. [Google Scholar] [CrossRef]

- Ghnatios, C.; Fayazbakhsh, K. Warping estimation of continuous fiber-reinforced composites made by robotic 3d printing. Addit. Manuf. 2022, 55, 102796. [Google Scholar] [CrossRef]

- İpekçi, A.; Ekici, B. Experimental and statistical analysis of robotic 3D printing process parameters for continuous fiber reinforced composites. J. Compos. Mater. 2021, 55, 2645–2655. [Google Scholar] [CrossRef]

- Li, N.; Link, G.; Ma, J.; Jelonnek, J. LiDAR based multi-robot cooperation for the 3D printing of continuous carbon fiber reinforced composite structures. In Advances in Manufacturing Technology XXXIV; IOS Press: Amsterdam, The Netherlands, 2021; pp. 125–132. [Google Scholar]

| Parameters | Trends | Mechanization | Line Width | Layer Thickness |

|---|---|---|---|---|

| Printing temperature | Up | Reduces resin viscosity | Widen | Reduction |

| Printing speed | Up | Reduced compaction time | Narrow | Increase |

| Pressure | Up | Improved compaction | Widen | Reduction |

| No. | Printing Temperature (°C) | Printing Speed (mm/s) | Pressure (N) | Layer Thickness (mm) | Line Width (mm) |

|---|---|---|---|---|---|

| 1 | 220 | 10 | 0.5 | 0.148 | 1.327 |

| 2 | 220 | 10 | 2 | 0.126 | 1.554 |

| 3 | 200 | 5 | 2 | 0.1210 | 1.623 |

| 4 | 190 | 2.5 | 0.5 | 0.133 | 1.478 |

| 5 | 190 | 10 | 2 | 0.139 | 1.409 |

| 6 | 220 | 5 | 1 | 0.114 | 1.727 |

| 7 | 200 | 5 | 2 | 0.123 | 1.602 |

| 8 | 190 | 2.5 | 1.5 | 0.122 | 1.615 |

| 9 | 200 | 10 | 1 | 0.147 | 1.338 |

| 10 | 210 | 7.5 | 0.5 | 0.149 | 1.319 |

| 11 | 220 | 5 | 1 | 0.112 | 1.757 |

| 12 | 210 | 2.5 | 0.5 | 0.119 | 1.65 |

| 13 | 200 | 10 | 1 | 0.153 | 1.283 |

| 14 | 210 | 2.5 | 1.5 | 0.110 | 1.785 |

| 15 | 210 | 7.5 | 1.5 | 0.132 | 1.483 |

| 16 | 220 | 2.5 | 2 | 0.098 | 2.012 |

| 17 | 200 | 5 | 1 | 0.132 | 1.488 |

| 18 | 210 | 7.5 | 1.5 | 0.131 | 1.503 |

| 19 | 190 | 7.5 | 1.5 | 0.145 | 1.357 |

| 20 | 190 | 7.5 | 0.5 | 0.165 | 1.189 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tu, Y.; Tan, Y.; Zhang, F.; Zou, S.; Zhang, J. High-Throughput Additive Manufacturing of Continuous Carbon Fiber-Reinforced Plastic by Multifilament. Polymers 2024, 16, 704. https://doi.org/10.3390/polym16050704

Tu Y, Tan Y, Zhang F, Zou S, Zhang J. High-Throughput Additive Manufacturing of Continuous Carbon Fiber-Reinforced Plastic by Multifilament. Polymers. 2024; 16(5):704. https://doi.org/10.3390/polym16050704

Chicago/Turabian StyleTu, Yiwen, Yuegang Tan, Fan Zhang, Shulin Zou, and Jun Zhang. 2024. "High-Throughput Additive Manufacturing of Continuous Carbon Fiber-Reinforced Plastic by Multifilament" Polymers 16, no. 5: 704. https://doi.org/10.3390/polym16050704

APA StyleTu, Y., Tan, Y., Zhang, F., Zou, S., & Zhang, J. (2024). High-Throughput Additive Manufacturing of Continuous Carbon Fiber-Reinforced Plastic by Multifilament. Polymers, 16(5), 704. https://doi.org/10.3390/polym16050704