Evaluation of Starch–Garlic Husk Polymeric Composites through Mechanical, Thermal, and Thermo-Mechanical Tests

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Obtaining Reinforcer

2.3. Composites Preparation

2.4. Composites Characterization

3. Results

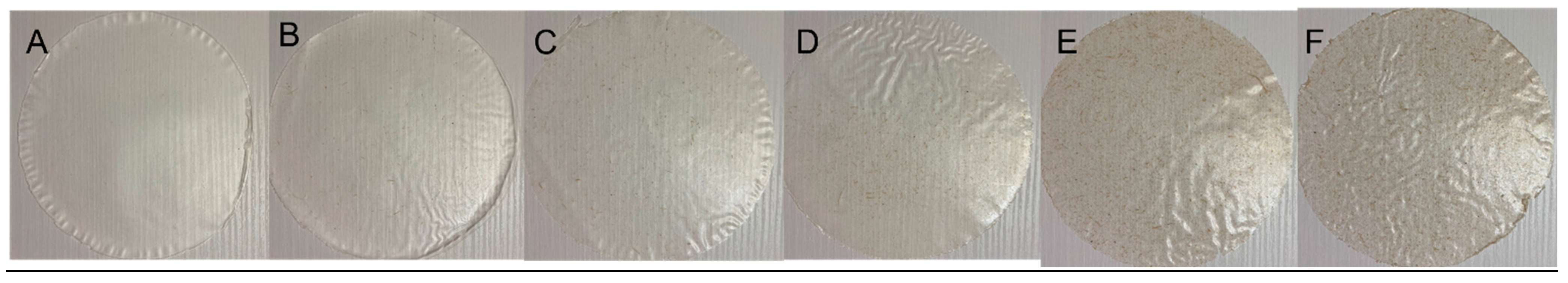

3.1. Garlic Husk(GH) Dispersion and Physical Appearance of Composites

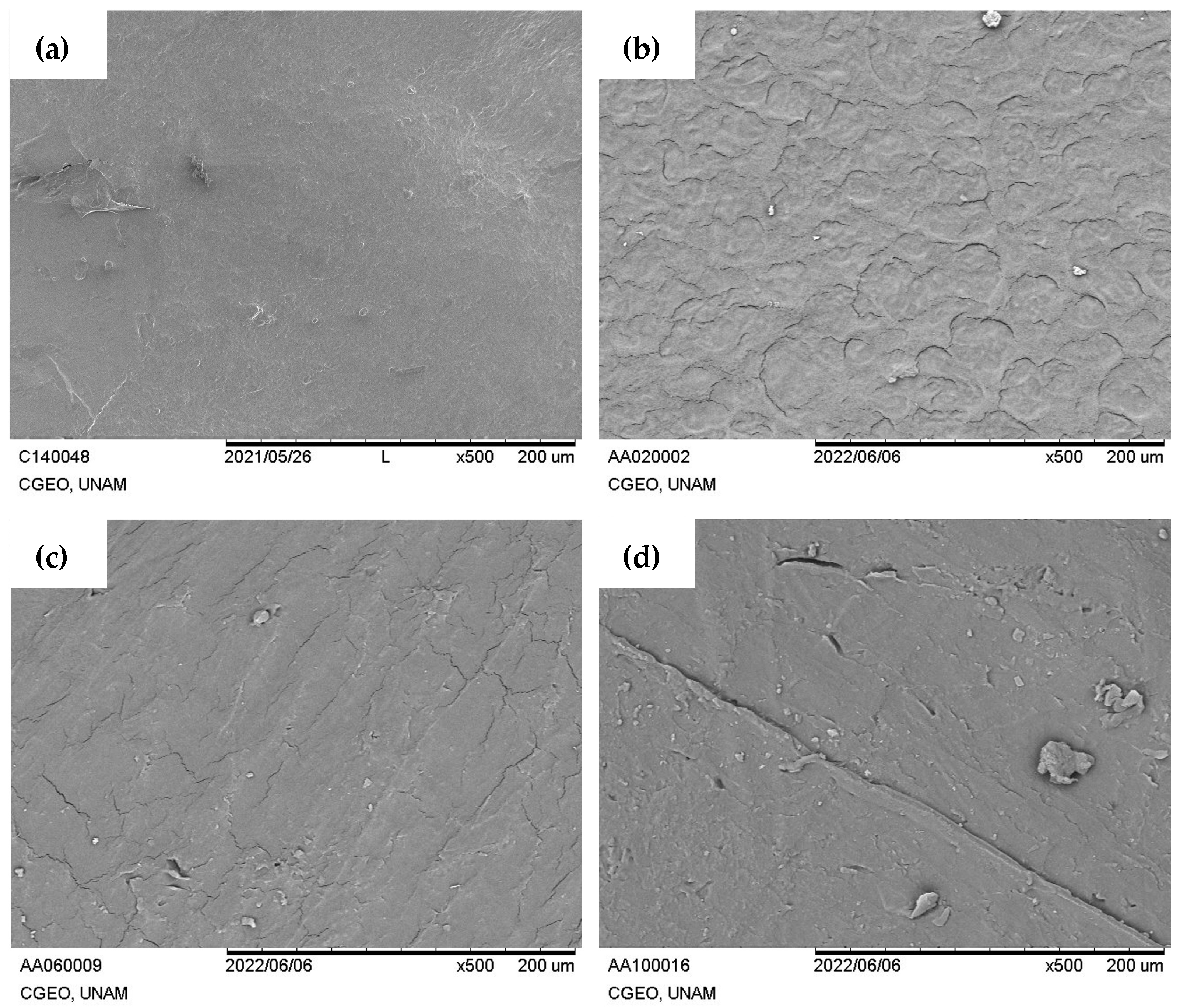

3.2. Morphology of Composites Studied by SEM

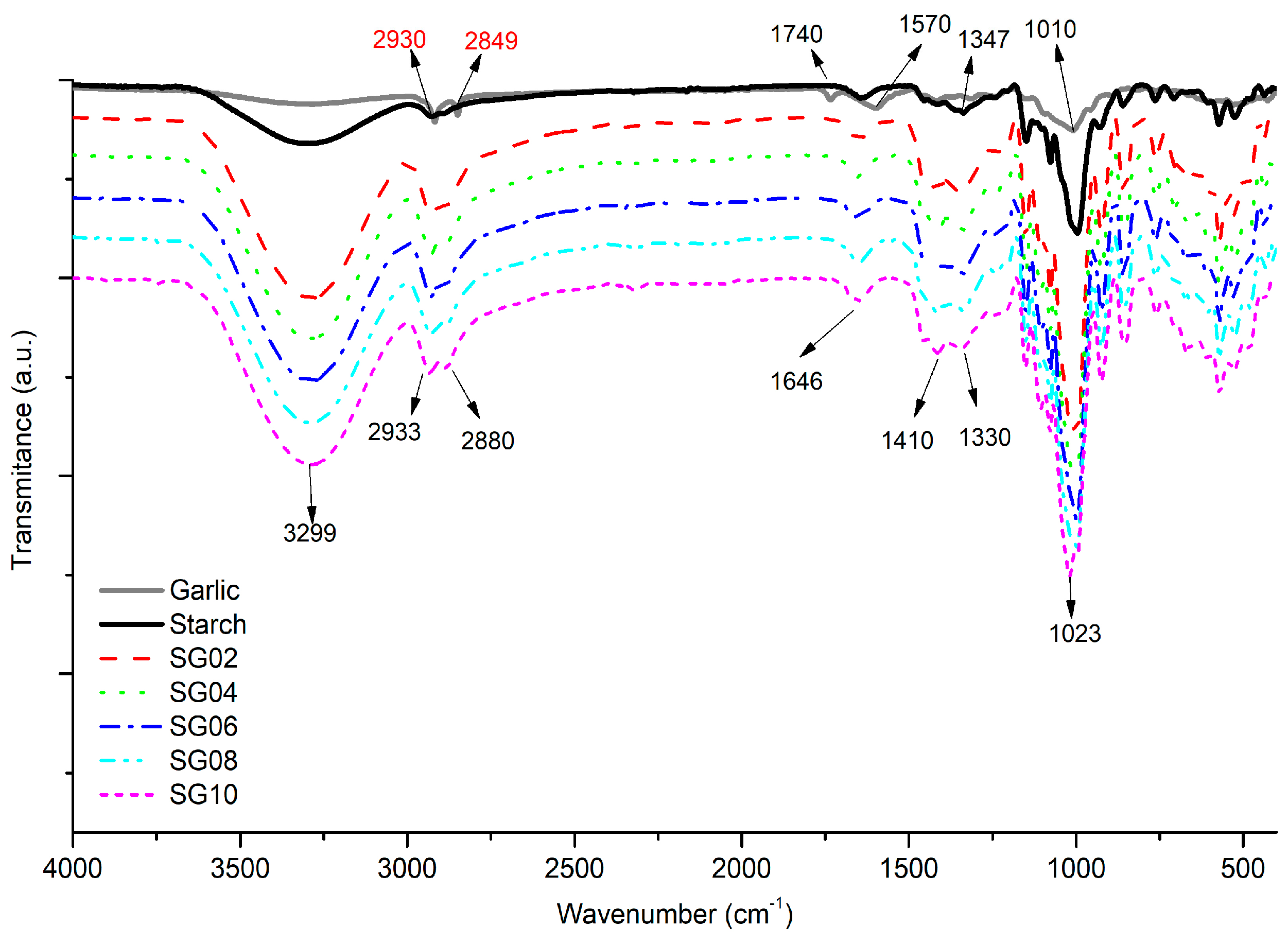

3.3. FTIR Analysis

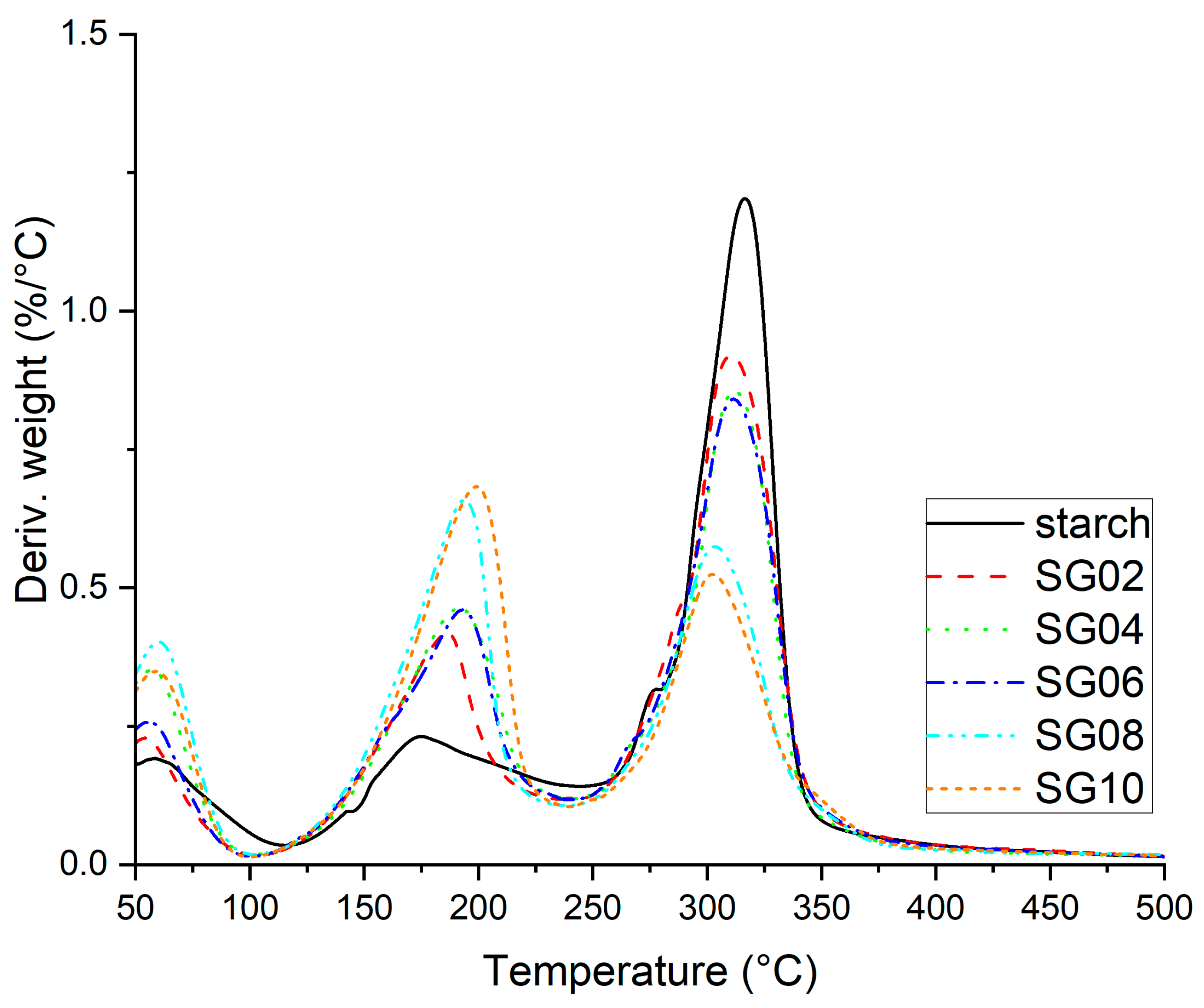

3.4. TGA Analysis

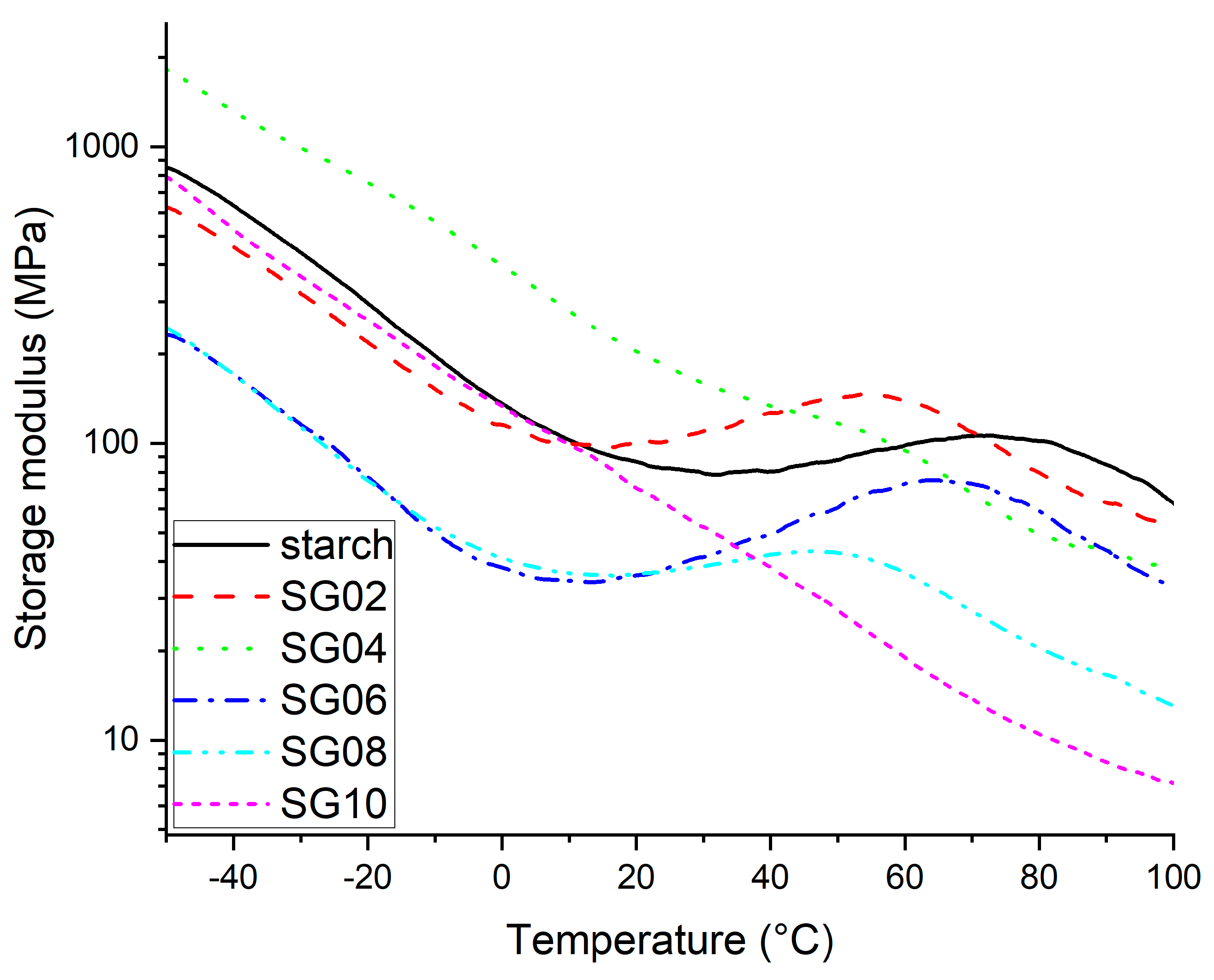

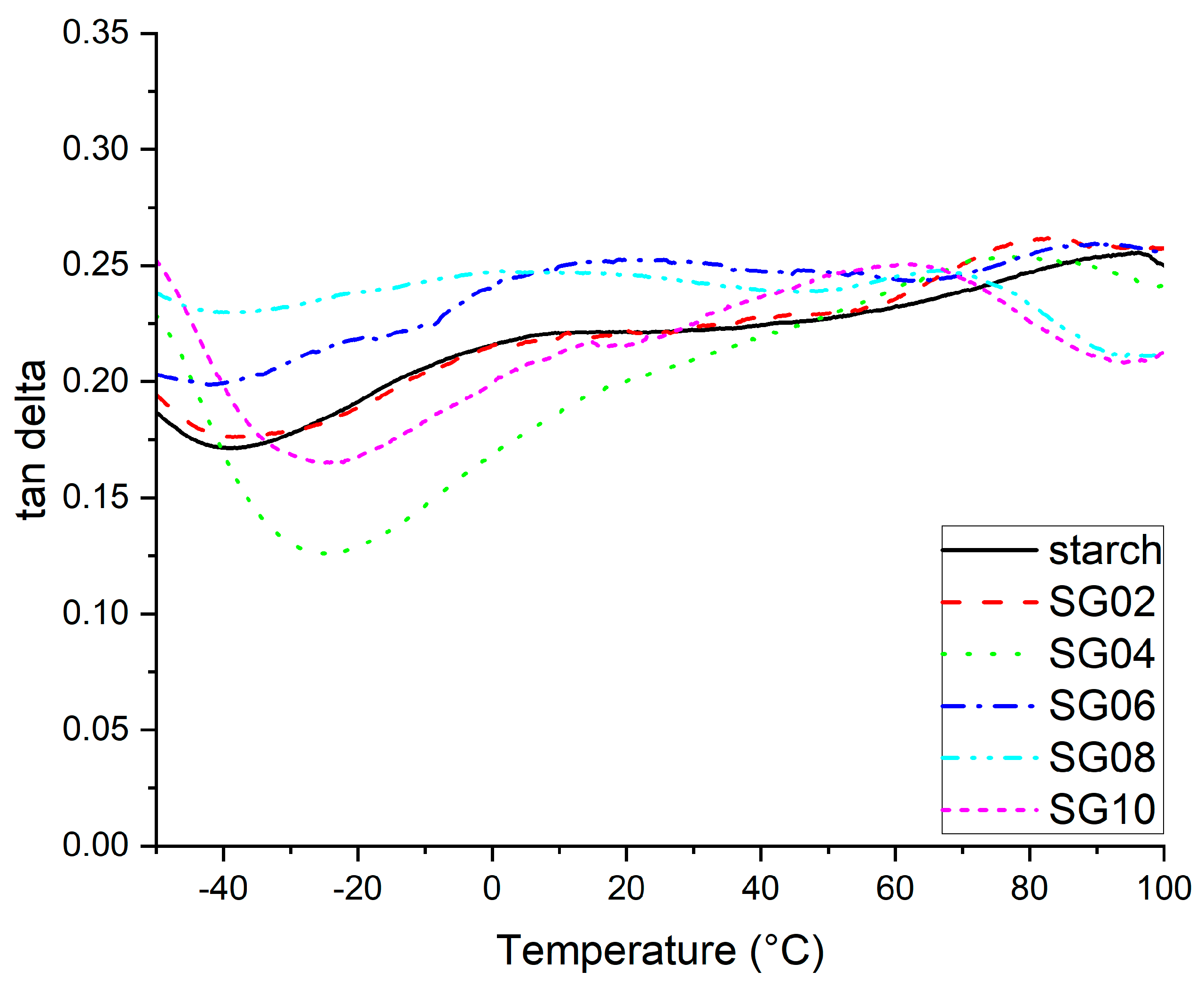

3.5. DMA Analysis

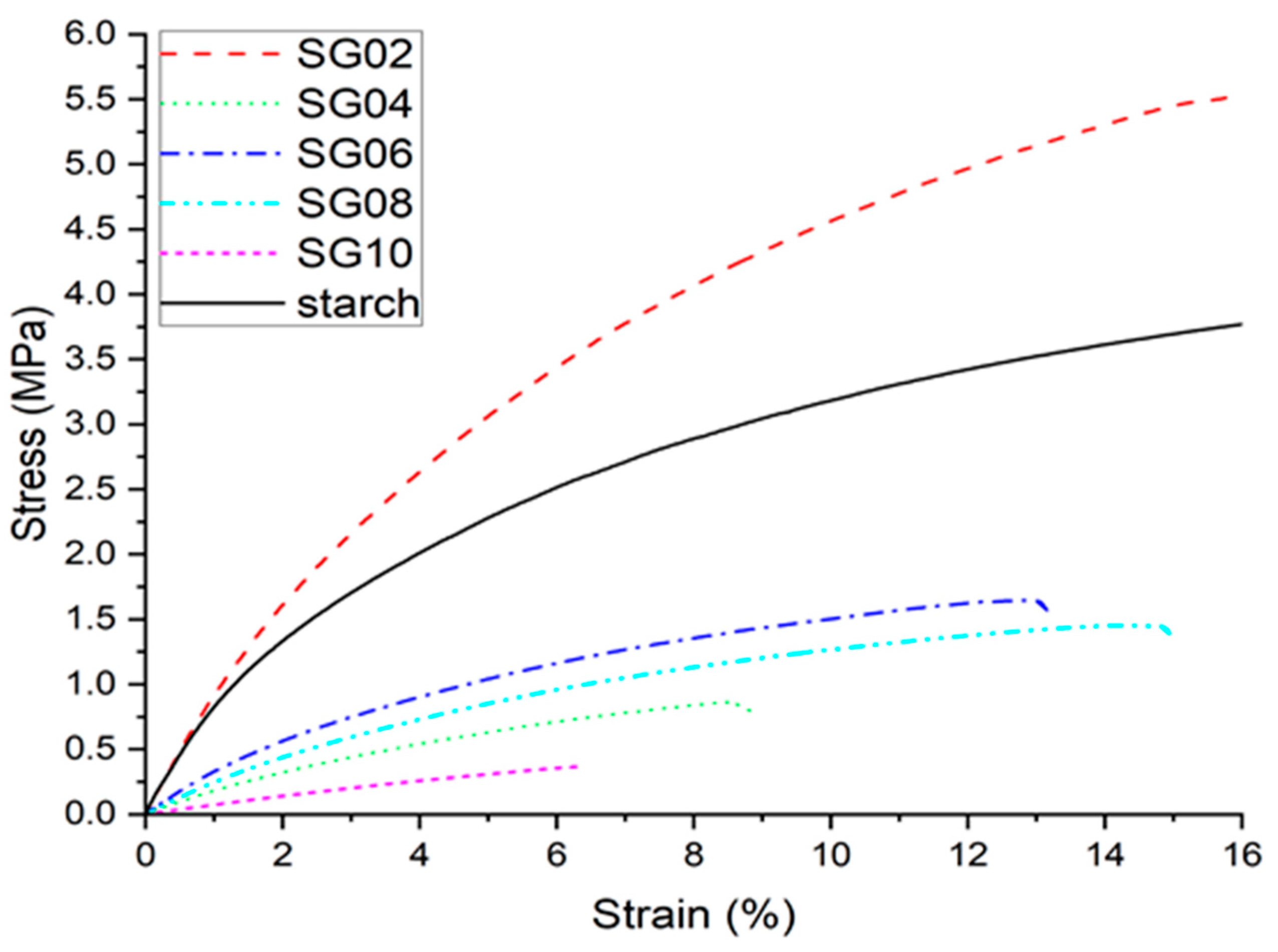

3.6. Tensile Tests

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- de Las Heras, R.B.; Ayala, S.F.; Salazar, E.M.; Carrillo, F.; Cañavate, J.; Colom, X. Circular Economy Insights on the Suitability of New Tri-Layer Compostable Packaging Films after Degradation in Storage Conditions. Polymers 2023, 15, 4154. [Google Scholar] [CrossRef] [PubMed]

- Almeida, S.; Ozkan, S.; Gonçalves, D.; Paulo, I.; Queirós, C.S.; Ferreira, O.; Bordado, J.; Galhano dos Santos, R. A Brief Evaluation of Antioxidants, Antistatics, and Plasticizers Additives from Natural Sources for Polymers Formulation. Polymers 2023, 15, 6. [Google Scholar] [CrossRef] [PubMed]

- Muñoz-Gimena, P.F.; Oliver-Cuenca, V.; Peponi, L.; López, D. A review on reinforcements and additives in starch-based composites for food packaging. Polymers 2023, 15, 2972. [Google Scholar] [CrossRef] [PubMed]

- Cui, C.; Zhao, S.; Zhang, Z.; Li, M.; Shi, R.; Sun, Q. Preparation, and characterization of corn starch straws with strong mechanical properties by extrusion and retrogradation. Ind. Crops Prod. 2023, 191, 115991. [Google Scholar] [CrossRef]

- Melo, P.M.A.; Macêdo, O.B.; Barbosa, G.P.; Santos, A.S.F.; Silva, L.B. Reuse of natural waste to improve the thermal stability, stiffness, and toughness of postconsumer polypropylene composites. J. Polym. Environ. 2021, 29, 538–555. [Google Scholar] [CrossRef]

- Teacă, C.A.; Shahzad, A.; Duceac, I.A.; Tanasă, F. The Re-/Up-Cycling of Wood Waste in Wood–Polymer Composites (WPCs) for Common Applications. Polymers 2023, 15, 3467. [Google Scholar] [CrossRef] [PubMed]

- Brunšek, R.; Kopitar, D.; Schwarz, I.; Marasović, P. Biodegradation Properties of Cellulose Fibers and PLA Biopolymer. Polymers 2023, 15, 3532. [Google Scholar] [CrossRef] [PubMed]

- Wandosell, G.; Parra-Meroño, M.C.; Alcayde, A.; Baños, R. Green Packaging from Consumer and Business Perspectives. Sustainability 2021, 13, 1356. [Google Scholar] [CrossRef]

- Zhu, Z.; Liu, W.; Ye, S.; Batista, L. Packaging design for the circular economy: A systematic review. Sustain. Prod. Consum. 2022, 32, 817–832. [Google Scholar] [CrossRef]

- Li, Z.; Guan, J.; Yan, C.; Chen, N.; Wang, C.; Liu, T.; Cheng, F.; Guo, Q.; Zhang, X.; Ye, X.; et al. Corn straw core/cellulose nanofibers composite for food packaging: Improved mechanical, bacteria blocking, ultraviolet and water vapor barrier properties. Food Hydrocoll. 2023, 143, 108884. [Google Scholar] [CrossRef]

- Flores-Hernández, C.G.; Cornejo-Villegas, M.D.L.A.; Moreno-Martell, A.; Del Real, A. Synthesis of a biodegradable polymer of poly (sodium alginate/ethyl acrylate). Polymers 2021, 13, 504. [Google Scholar] [CrossRef] [PubMed]

- Ortuño-López, M.B.; Salazar-Cruz, B.A.; del Real, A.; Almendarez-Camarillo, A.; López-Barroso, J.; Rivera-Armenta, J.L.; Flores-Hernández, C.G. Physical properties of thermoplastic cornstarch/Hibiscus sabdariffa fiber obtained by evaporation casting. Starch-Stärke 2023, 75, 2200242. [Google Scholar] [CrossRef]

- Hernández-Varela, J.D.; Chanona-Pérez, J.J.; Resendis-Hernández, P.; Victoriano, L.G.; Méndez-Méndez, J.V.; Cárdenas-Pérez, S.; Benavides, H.C. Development, and characterization of biopolymers films mechanically reinforced with garlic skin waste for fabrication of compostable dishes. Food Hydrocoll. 2022, 124, 107252. [Google Scholar] [CrossRef]

- Castro-Yobal, M.A.; Contreras-Oliva, A.; Saucedo-Rivalcoba, V.; Rivera-Armenta, J.L.; Hernández-Ramírez, G.; Salinas-Ruiz, J.; Herrera-Corredor, A. Evaluation of physicochemical properties of film-based alginate for food packing applications. e-Polymers 2021, 21, 82–95. [Google Scholar] [CrossRef]

- Koo, S.H.; Lee, K.Y.; Lee, H.G. Effect of cross-linking on the physicochemical and physiological properties of corn starch. Food Hydrocoll. 2021, 24, 619–625. [Google Scholar] [CrossRef]

- Nordin, N.; Othman, S.H.; Rashid, S.A.; Basha, R.K. Effects of glycerol and thymol on physical, mechanical, and thermal properties of corn starch films. Food Hydrocoll. 2020, 106, 105884. [Google Scholar] [CrossRef]

- Wang, B.; Gao, W.; Kang, X.; Dong, Y.; Liu, P.; Yan, S.; Yu, B.; Guo, L.; Abd El-Aty, A.M. Structural changes in corn starch granules treated at different temperatures. Food Hydrocoll. 2021, 118, 106760. [Google Scholar] [CrossRef]

- Fabra, M.J.; López-Rubio, A.; Ambrosio-Martín, J.; Lagaron, J.M. Improving the barrier properties of thermoplastic corn starch-based films containing bacterial cellulose nanowhiskers by means of PHA electrospun coatings of interest in food packaging. Food Hydrocoll. 2016, 61, 261–268. [Google Scholar] [CrossRef]

- Wang, S.; Zhang, P.; Li, Y.; Li, J.; Li, X.; Yang, J.; Ji, M.; Li, F.; Zhang, C. Recent Advances and Future Challenges of the Starch-Based Bio-Composites for Engineering Applications. Carbohydr. Polym. 2023, 307, 120627. [Google Scholar] [CrossRef]

- Pradeep, M.; Binoy, R.F.; Yaswanth, S.; Pullan, T.T.; Joseph, M. Investigations on chitin and coconut fiber reinforcements on mechanical and moisture absorption properties of corn starch bioplastics. Mater. Today Proc. 2022, 58, 65–70. [Google Scholar] [CrossRef]

- Cruz-Balaz, M.I.; Bósquez-Cáceres, M.F.; Delgado, A.D.; Arjona, N.; Morera Córdova, V.; Álvarez-Contreras, L.; Tafur, J.P. Green Energy Storage: Chitosan-Avocado Starch Hydrogels for a Novel Generation of Zinc Battery Electrolytes. Polymers 2023, 15, 4398. [Google Scholar] [CrossRef] [PubMed]

- Othman, S.H.; Nordin, N.; Azman, N.A.A.; Tawakkal, I.S.M.A.; Basha, R.K. Effects of nanocellulose fiber and thymol on mechanical, thermal, and barrier properties of corn starch films. Int. J. Biol. Macromol. 2021, 183, 1352–1361. [Google Scholar] [CrossRef] [PubMed]

- Zhang, W.; Roy, S.; Ezati, P.; Yang, D.P.; Rhim, J.W. Tannic acid: A green crosslinker for biopolymer-based food packaging films. Trends Food Sci. Technol. 2023, 136, 11–23. [Google Scholar] [CrossRef]

- Chhatariya, H.F.; Srinivasan, S.; Choudhary, P.M.; Begum, S.S. Corn starch biofilm reinforced with orange peel powder: Characterization of physicochemical and mechanical properties. Mater. Today Proc. 2022, 59, 884–892. [Google Scholar] [CrossRef]

- Naidu, M.; Bhosale, A.; Munde, Y.; Salunkhe, S.; Hussein, H.M.A. Wear and Friction Analysis of Brake Pad Material Using Natural Hemp Fibers. Polymers 2022, 15, 188. [Google Scholar] [CrossRef] [PubMed]

- Versino, F.; Lopez, O.V.; Garcia, M.A.; Zaritzky, N.E. Starch-based films and food coatings: An overview. Starch-Stärke 2016, 68, 1026–1037. [Google Scholar] [CrossRef]

- Kallel, F.; Driss, D.; Chaari, F.; Belghith, L.; Bouaziz, F.; Ghorbel, R.; Chaabouni, S.E. Garlic (Allium sativum L.) husk waste as a potential source of phenolic compounds: Influence of extracting solvents on its antimicrobial and antioxidant properties. Ind. Crops Prod. 2014, 62, 34–41. [Google Scholar] [CrossRef]

- Roy, S.; Das, T.; Goh, K.L.; Verma, C.; Maji, P.K.; Sharma, K.; Chang, Y.W. Synergistic effects of fresh garlic juice in cellulose based antimicrobial food packaging film. Mater. Lett. 2022, 324, 132538. [Google Scholar] [CrossRef]

- Ding, Y.; Jiang, Y.; Zhong, Y.; Wang, D.; Deng, Y.; Meng, F.; Li, Y.; Zhang, M.; Zhang, C. Preparation of garlic stem cellulose nanocrystal/leaf extract/chitosan film for black garlic preservation by electrostatic spraying. Int. J. Biol. Macromol. 2023, 225, 518–525. [Google Scholar] [CrossRef]

- Abid, M.A.; Abid, D.A.; Aziz, W.J.; Rashid, T.M. Iron oxide nanoparticles synthesized using garlic and onion peel extracts rapidly degrade methylene blue dye. Phys. B 2021, 622, 413277. [Google Scholar] [CrossRef]

- Kumar, A.; Patel, G.; Dwivedi, M.; Hashmi, S.; Pradhan, R.C. Synthesis and Characterization of Edible Films from Garlic (Allium sativum) Husk Components. J. Sci. Ind. Res. 2022, 81, 455–461. [Google Scholar]

- Senthilkumar, A.; Muthuswamy, R.; Maheshwari-Nallal, U.; Ramaiyan, S.; Kannan, P.; Muthupandi, S.; Lakshminarayanan, S.P.; Sambasivm, S.; Ayyar, M. Green Synthesis of copper nanoparticles from agro-waste garlic husk. Int. J. Chem. Phys. 2023, 238, 0291. [Google Scholar] [CrossRef]

- Gao, X.; Jia, Y.; Chen, Z.; Santhanam, R.K.; Zhang, M.; He, C.; Chen, H. Synthesis of hydrogels based on nanocellulose from garlic straw and regulating the release of allicin and its cytotoxicity. Food Sci. Tech. 2022, 42, 43422. [Google Scholar] [CrossRef]

- Villalobos-Neri, E.E.; Macchlesh Del Pino-Perez, L.A.; Velasco-Ocejo, H.A.; Rivera-Armenta, J.L.; Espindola-Flores, A.C. Preparation and Evaluation of Thermal Properties of Composites Based on Polypropylene Reinforced with Garlic Husk Particles (GHP). J. Nat. Fibers 2023, 20, 2145409. [Google Scholar] [CrossRef]

- Chaudhary, B.U.; Lingayat, S.; Banerjee, A.N.; Kale, R.D. Development of multifunctional food packaging films based on waste Garlic peel extract and Chitosan. Int. J. Biol. Macromol. 2021, 192, 479–490. [Google Scholar] [CrossRef] [PubMed]

- Kopec, A.; Skoczylas, J.; Jedrszczyk, E.; Francik, R.; Bystrowska, B.; Zawistowski, J. Chemical Composition and Concentration of Bioactive Compounds in Garlic Cultivated from Air Bulbils. Agriculture 2020, 10, 40. [Google Scholar] [CrossRef]

- ASTM D638; Standard Test Method for Tensile Properties of Plastics. ASTM International: West Conshohocken, PA, USA, 2010.

- Flores-Hernandez, C.G.; Colin-Cruz, A.; Velasco-Santos, C.; Castano, V.M.; Rivera-Armenta, J.L.; Almendarez-Camarillo, A.; Garcia-Casillas, P.E.; Martinez-Hernandez, A.L. All Green Composites from Fully Renewable Biopolymers: Chitosan-Starch Reinforced with Keratin from Feathers. Polymers 2014, 6, 686. [Google Scholar] [CrossRef]

- Flores-Hernandez, C.G.; Colin-Cruz, A.; Velasco-Santos, C.; Castano, V.M.; Almendarez-Camarillo, A.; Olivas-Armendariz, I.; Martinez-Hernandez, A.L. Chitosan–Starch–Keratin Composites: Improving ThermoMechanical and Degradation Properties Through ChemicalModifiation. J. Polym. Environ. 2018, 26, 2182. [Google Scholar] [CrossRef]

- Patil, S.; Bharimalla, A.K.; Mahapatra, A.; Dhakane-Lad, J.; Arputharaj, A.; Kumar, M.; Raja, A.S.M.; Kambli, N. Effect of polymer blending on mechanical and barrier properties of starch-polyvinyl alcohol based biodegradable composite films. Food Biosci. 2021, 44, 101352. [Google Scholar] [CrossRef]

- Xiong, H.; Tang, S.; Tang, H.; Zou, P. The structure and properties of a starch-based biodegradable film. Carbohydr. Polym. 2008, 71, 263–268. [Google Scholar] [CrossRef]

- Sarkar, A.; Biswas, D.R.; Datta, S.C.; Dwivedi, B.S.; Bhattacharyya, R.; Kumar, R.; Bandyopadhyay, K.K.; Saha MChawla, G.; Saha, J.K.; Patra, A.K. Preparation of novel biodegradable starch/poly (vinyl alcohol)/bentonite grafted polymeric films for fertilizer encapsulation. Carbohydr. Polym. 2021, 259, 117679. [Google Scholar] [CrossRef] [PubMed]

- Biancolillo, A.; Marini, F.; D’Archivio, A.A. Geographical discrimination of red garlic (Allium sativum L.) using fast and non-invasive Attenuated Total Reflectance-Fourier Transformed Infrared (ATR-FTIR) spectroscopy combined with chemometrics. J. Food Compos. Anal. 2020, 86, 103351. [Google Scholar] [CrossRef]

- Dharmalingam, K.; Ramachandran, K.; Sivagurunathan, P. FTIR and dielectric studies of molecular interaction between alkyl methacrylates and primary alcohols. Phys. B 2007, 392, 127–131. [Google Scholar] [CrossRef]

- Agustin, M.B.; Ahmmad, B.; De Leon, E.R.P.; Buenaobra, J.L.; Salazar, J.R.; Hirose, F. Starch-based biocomposite films reinforced with cellulose nanocrystals from garlic stalks. Polym. Compos. 2013, 34, 1325–1332. [Google Scholar] [CrossRef]

- Lee, S.Y.; Mohan, D.J.; Kang, I.A.; Doh, G.H.; Lee, S.; Han, S.O. Nanocellulose reinforced PVA composite films: Effects of acid treatment and filler loading. Fibers Polym. 2009, 10, 77–82. [Google Scholar] [CrossRef]

- Reddy, J.P.; Rhim, J.W. Isolation and characterization of cellulose nanocrystals from garlic skin. Mater. Lett. 2014, 129, 20–23. [Google Scholar] [CrossRef]

- Zhang, Y.; Rempel, C.; Liu, Q. Thermoplastic starch processing and characteristics—A review. Crit. Rev. Food Sci. Nutr. 2014, 54, 1353–1370. [Google Scholar] [CrossRef]

- Garcia, P.S.; Turbiani, F.R.B.; Baron, A.M.; Brizola, G.L.; Tavares, M.A.; Yamashita, F.; Eiras, D.; Grossmann, M.V.E. Sericin as compatibilizer in starch/polyester blown fims. Polimeros 2018, 28, 5. [Google Scholar] [CrossRef]

- Ghizdareanu, A.I.; Banu, A.; Pasarin, D.; Ionita, A.; Nicolae, C.A.; Gabor, A.R.; Pătroi, D. Enhancing the Mechanical Properties of Corn Starch Films for Sustainable Food Packaging by Optimizing Enzymatic Hydrolysis. Polymers 2023, 15, 1899. [Google Scholar] [CrossRef]

- Mucha, M.; Pawlak, A. Thermal analysis of chitosan and its blends. Thermochim. Acta 2005, 427, 69–76. [Google Scholar] [CrossRef]

- Salim, M.H.; Kassab, Z.; Abdellaoui, Y.; García-Cruz, A.; Soumare, A.; Ablouh, E.H.; El Achaby, M. Exploration of multifunctional properties of garlic skin derived cellulose nanocrystals and extracts incorporated chitosan biocomposite films for active packaging application. Int. J. Biol. Macromol. 2022, 210, 639–653. [Google Scholar] [CrossRef] [PubMed]

- Saba, N.; Jawaid, M.; Alothman, O.Y.; Paridah, M.T. A review on dynamic mechanical properties of natural fibre reinforced polymer composites. Constr. Build. Mater. 2016, 106, 149–159. [Google Scholar] [CrossRef]

- Martone, A.; Formicola, C.; Giordano, M.; Zarrelli, M. Reinforcement efficiency of multi-walled carbon nanotube/epoxy nano composites. Compos. Sci. Tech. 2010, 70, 1154–1160. [Google Scholar] [CrossRef]

- Pavon, C.; Aldas, M.; López-Martínez, J.; Hernández-Fernández, J.; Arrieta, M.P. Films based on thermoplastic starch blended with pine resin derivatives for food packaging. Foods 2021, 10, 1171. [Google Scholar] [CrossRef] [PubMed]

- Castro, J.M.; Montalbán, M.G.; Martínez-Pérez, N.; Domene-López, D.; Pérez, J.M.; Arrabal-Campos, F.M.; Fernández, I.; Martín-Gullón, I.; García-Quesada, J.C. Thermoplastic starch/polyvinyl alcohol blends modification by citric acid–glycerol polyesters. Int. J. Biol. Macromol. 2023, 244, 125478. [Google Scholar] [CrossRef] [PubMed]

- Torres, F.G.; Mayorga, J.P.; Vilca, C.; Arroyo, J.; Castro, P.; Rodriguez, L. Preparation, and characterization of a novel starch–chestnut husk biocomposite. SN Appl. Sci. 2019, 1, 1158. [Google Scholar] [CrossRef]

- Taguet, A.; Huneault, M.A.; Favis, B.D. Interface/morphology relationships in polymer blends with thermoplastic starch. Polymer 2009, 50, 5733–5743. [Google Scholar] [CrossRef]

- DeFelice, J.; Lipson, J. The Influence of Additives on Polymer Matrix Mobility and the Glass Transition. Soft Matter 2021, 17, 376–387. [Google Scholar] [CrossRef]

- Liu, P.; Yu, L.; Wang, X.; Li, D.; Chen, L.; Li, X. Glass transition temperature of starches with different amylose/amylopectin ratios. J. Cereal Sci. 2010, 51, 388–391. [Google Scholar] [CrossRef]

- Raaj, E.P.; Bhuvaneshwari, K.; Lakshmipathy, R.; Devi, V.V.; Rico, I.L.R. Garlic peel surface modification and fixed-bed column investigations towards crystal violet dye. Adsorpt. Sci. Tech. 2022, 2022, 6904842. [Google Scholar] [CrossRef]

- Hernández-Varela, J.D.; Chanona-Pérez, J.J.; Benavides, H.A.C.; Sodi, F.C.; Vicente-Flores, M. Effect of ball milling on cellulose nanoparticles structure obtained from garlic and agave waste. Carbohydr. Polym. 2021, 255, 117347. [Google Scholar] [CrossRef] [PubMed]

- do Lago, R.C.; de Oliveira, A.L.M.; dos Santos, A.D.A.; Zitha, E.Z.M.; Carvalho, E.E.N.; Tonoli, G.H.D.; Boas, E.V.D.B.V. Addition of wheat straw nanofibrils to improve the mechanical and barrier properties of cassava starch–based bionanocomposites. Ind. Crops Prod. 2021, 170, 113816. [Google Scholar] [CrossRef]

- Harussani, M.M.; Sapuan, S.M.; Firdaus, A.H.M.; El-Badry, Y.A.; Hussein, E.E.; El-Bahy, Z.M. Determination of the tensile properties and biodegradability of cornstarch-based biopolymers plasticized with sorbitol and glycerol. Polymers 2021, 13, 3709. [Google Scholar] [CrossRef] [PubMed]

- Lim, H.; Hoag, S.W. Plasticizer Effects on Physical–Mechanical Properties of Solvent Cast Soluplus® Films. AAPS Pharm. Sci. Tech. 2013, 14, 903–910. [Google Scholar] [CrossRef]

- Chen, N.; Gao, H.-X.; He, Q.; Zeng, W.-C. Potential application of phenolic compounds with different structural complexity in maize starch-based film. Food Struct. 2023, 36, 100318. [Google Scholar] [CrossRef]

- Liu, B.; Zhong, F.; Yokoyama, W.; Huang, D.; Zhu, S.; Li, Y. Interactions in starch co-gelatinized with phenolic compound systems: Effect of complexity of phenolic compounds and amylose content of starch. Carbohydr. Polym. 2020, 247, 116667. [Google Scholar] [CrossRef]

| Percentage of GH Particles (% wt) | Composites Code |

|---|---|

| 0 | starch |

| 2 | SG02 |

| 4 | SG04 |

| 6 | SG06 |

| 8 | SG08 |

| 10 | SG10 |

| Sample | Young’s Modulus (MPa) | Yield Stress (MPa) | Tensile Stress at Break (MPa) | % Elongation at Break |

|---|---|---|---|---|

| Starch | 82.33 ± 10.40 | 1.04 ± 0.12 | 4.09 ± 0.23 | 22.87 ± 0.13 |

| SG02 | 91.49 ± 4.90 | 1.53 ± 0.08 | 5.58 ± 0.25 | 17.25 ± 0.14 |

| SG04 | 19.6 ± 2.48 | 0.32 ± 0.03 | 0.86 ± 0.14 | 8.86 ± 0.04 |

| SG06 | 35.84 ± 0.99 | 0.54 ± 0.00 | 1.64 ± 0.03 | 13.15 ± 0.09 |

| SG08 | 26.23 ± 2.70 | 0.44 ± 0.04 | 1.45 ± 0.13 | 14.94 ± 0.06 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Flores-Hernández, C.G.; López-Barroso, J.; Salazar-Cruz, B.A.; Saucedo-Rivalcoba, V.; Almendarez-Camarillo, A.; Rivera-Armenta, J.L. Evaluation of Starch–Garlic Husk Polymeric Composites through Mechanical, Thermal, and Thermo-Mechanical Tests. Polymers 2024, 16, 289. https://doi.org/10.3390/polym16020289

Flores-Hernández CG, López-Barroso J, Salazar-Cruz BA, Saucedo-Rivalcoba V, Almendarez-Camarillo A, Rivera-Armenta JL. Evaluation of Starch–Garlic Husk Polymeric Composites through Mechanical, Thermal, and Thermo-Mechanical Tests. Polymers. 2024; 16(2):289. https://doi.org/10.3390/polym16020289

Chicago/Turabian StyleFlores-Hernández, Cynthia Graciela, Juventino López-Barroso, Beatriz Adriana Salazar-Cruz, Verónica Saucedo-Rivalcoba, Armando Almendarez-Camarillo, and José Luis Rivera-Armenta. 2024. "Evaluation of Starch–Garlic Husk Polymeric Composites through Mechanical, Thermal, and Thermo-Mechanical Tests" Polymers 16, no. 2: 289. https://doi.org/10.3390/polym16020289

APA StyleFlores-Hernández, C. G., López-Barroso, J., Salazar-Cruz, B. A., Saucedo-Rivalcoba, V., Almendarez-Camarillo, A., & Rivera-Armenta, J. L. (2024). Evaluation of Starch–Garlic Husk Polymeric Composites through Mechanical, Thermal, and Thermo-Mechanical Tests. Polymers, 16(2), 289. https://doi.org/10.3390/polym16020289