Long-Service-Life Rigid Polyurethane Foam Fillings for Spent Fuel Transportation Casks

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

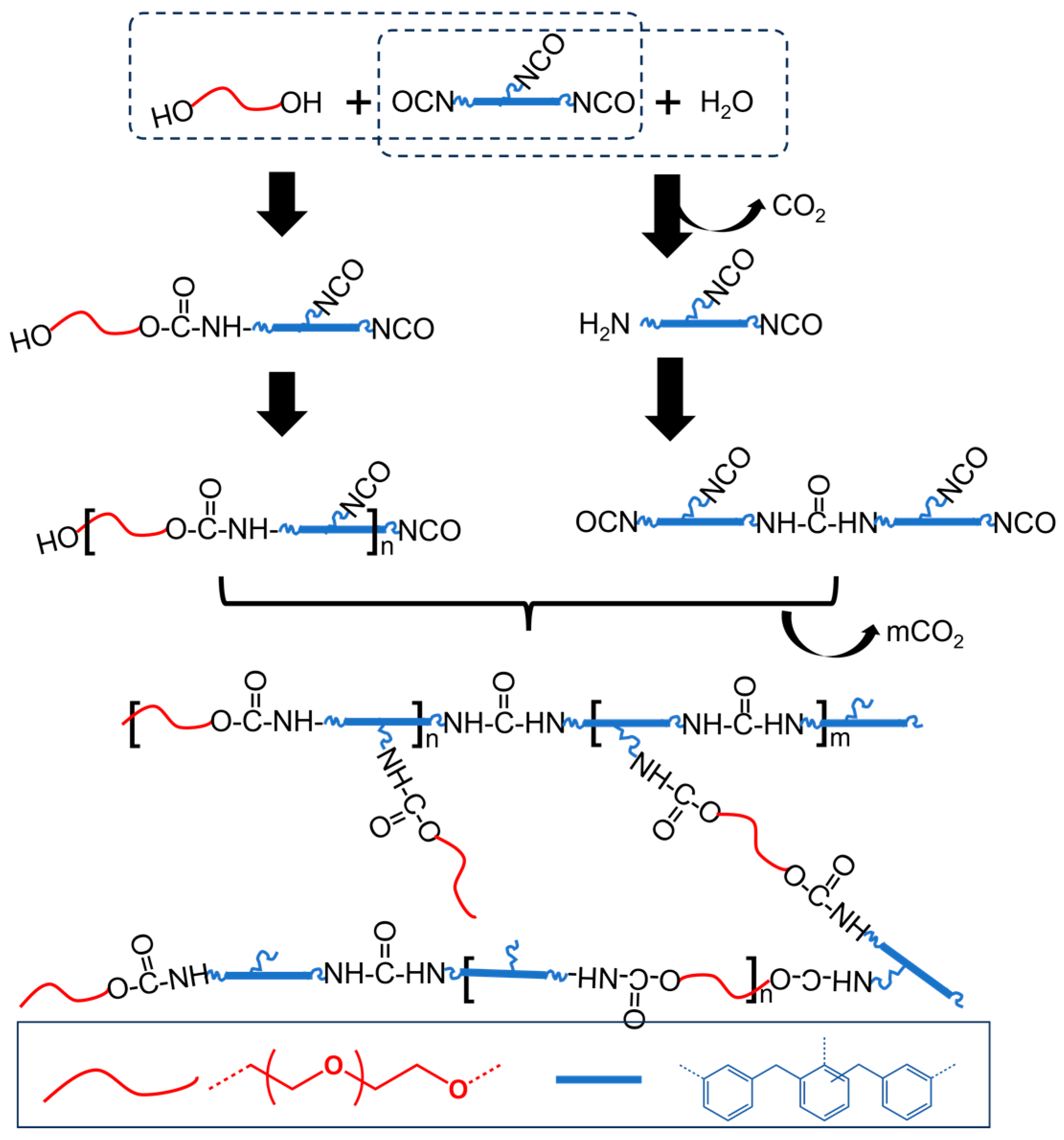

2.2. Preparation Procedure

2.3. Characterization

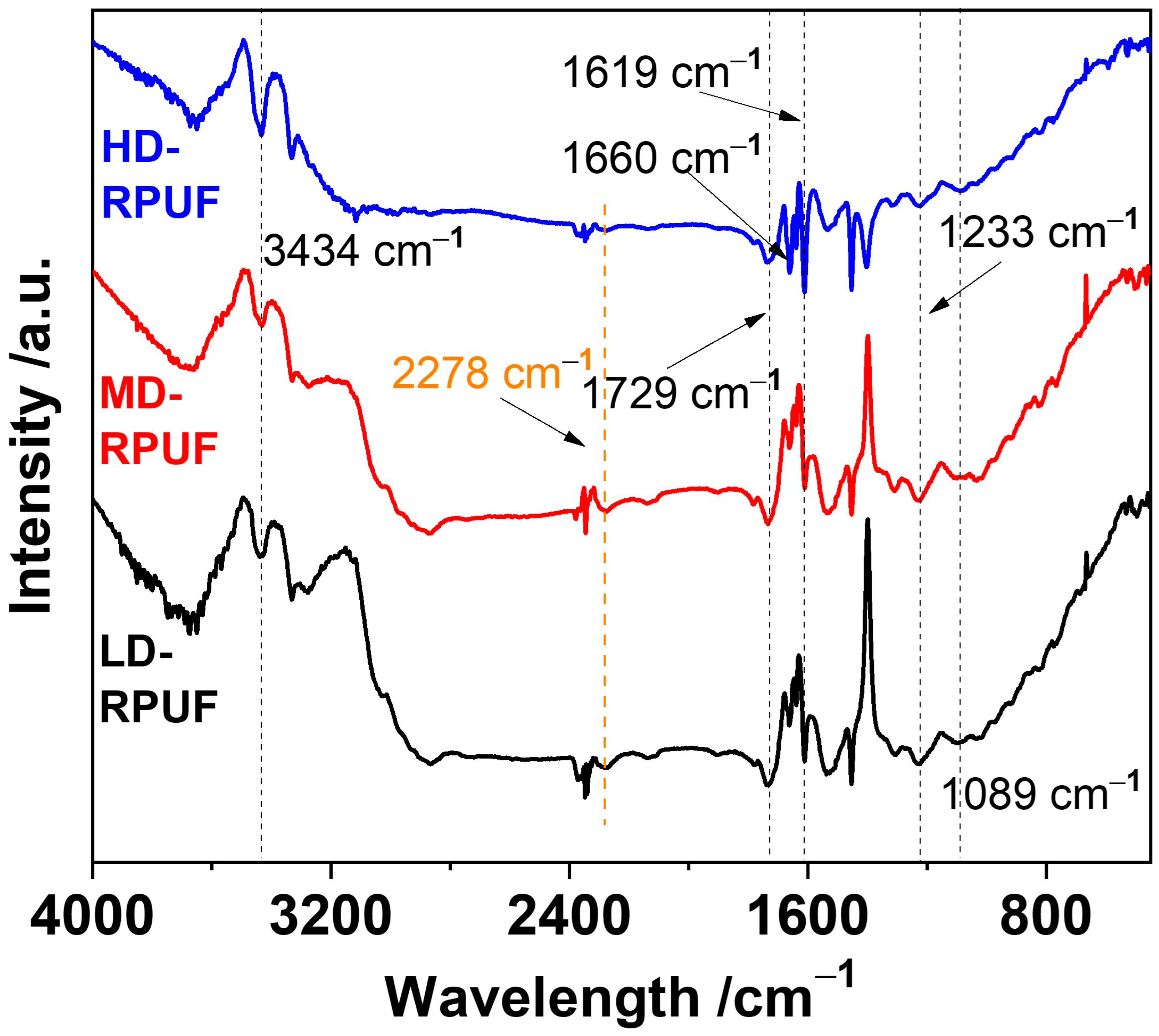

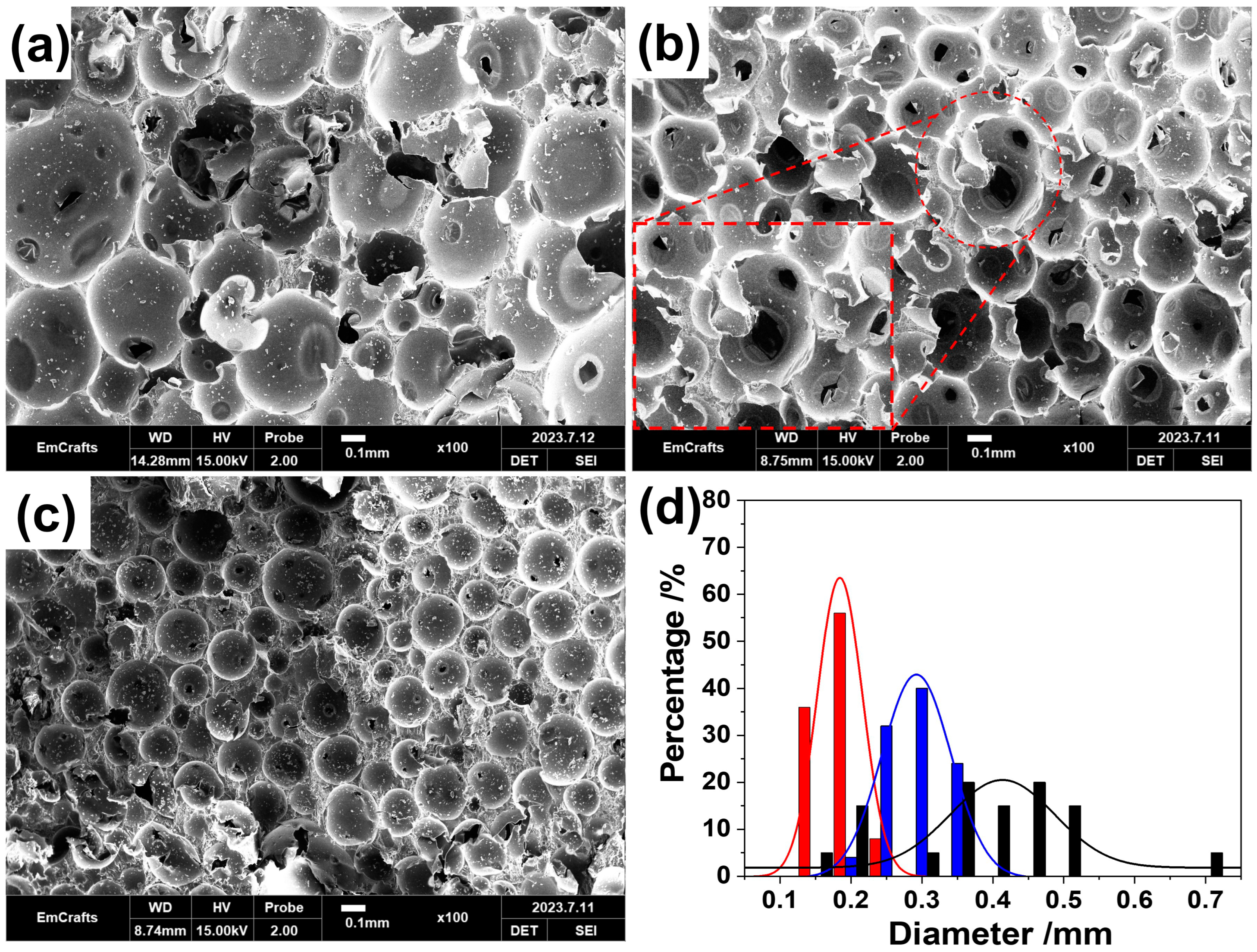

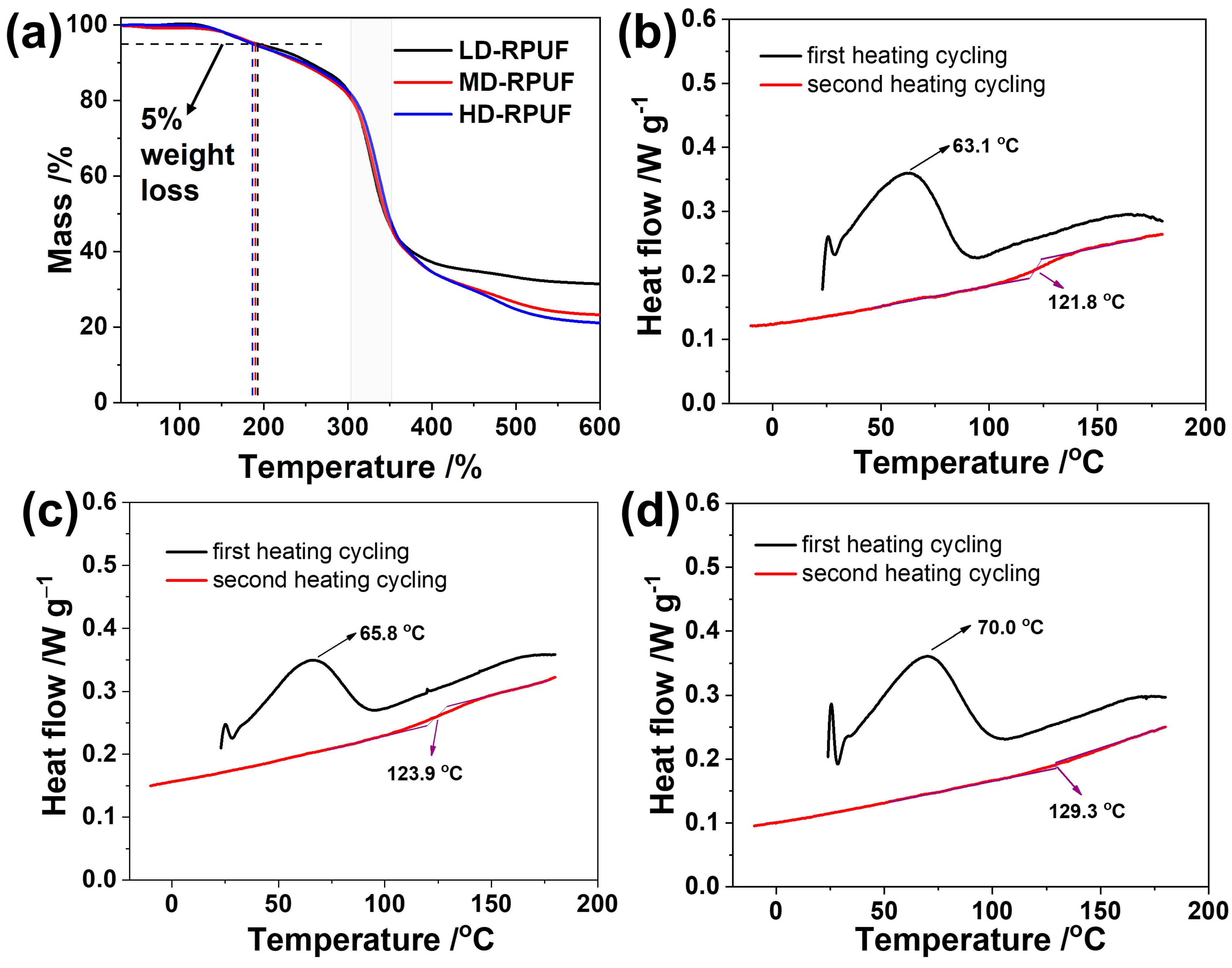

3. Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Sun, J.; Li, G.; Lim, M.K. China’s power supply chain sustainability: An analysis of performance and technology gap. Ann. Oper. Res. 2020, 1–29. [Google Scholar] [CrossRef]

- Varma, R.; Sushil. Bridging the electricity demand and supply gap using dynamic modeling in the Indian context. Energy Policy 2019, 132, 515–535. [Google Scholar] [CrossRef]

- Shellenberger, M. Nuclear power: Unexpected health benefits. Nat. Energy 2017, 2, 17058. [Google Scholar] [CrossRef]

- Horvath, A.; Rachlew, E. Nuclear power in the 21st century: Challenges and possibilities. Ambio 2016, 45, 38–49. [Google Scholar] [CrossRef] [PubMed]

- Jiang, H.; Wang, J.-A.J. Spent nuclear fuel system dynamic stability under normal conditions of transportation. Nucl. Eng. Des. 2016, 310, 1–14. [Google Scholar] [CrossRef][Green Version]

- Qi, Z.; Yang, Z.; Li, J.; Guo, Y.; Yang, G.; Yu, Y.; Zhang, J. The Advancement of Neutron-Shielding Materials for the Transportation and Storage of Spent Nuclear Fuel. Materials 2022, 15, 3255. [Google Scholar] [CrossRef]

- Tae-Man, K.; Ho-Seog, D.; Chun-Hyung, C.; Jae-Hun, K. Preliminary Shielding Analysis of the Concrete Cask for Spent Nuclear Fuel Under Dry Storage Conditions. J. Nucl. Fuel Cycle Waste Technol. 2017, 15, 391–402. [Google Scholar]

- Li, X.; Wu, J.; Tang, C.; He, Z.; Yuan, P.; Sun, Y.; Lau, W.-m.; Zhang, K.; Mei, J.; Huang, Y. High temperature resistant polyimide/boron carbide composites for neutron radiation shielding. Compos. Part B Eng. 2019, 159, 355–361. [Google Scholar] [CrossRef]

- Kim, K.; Chung, S.; Hong, J. Performance evaluation of METAMIC neutron absorber in spent fuel storage rack. Nucl. Eng. Technol. 2018, 50, 788–793. [Google Scholar] [CrossRef]

- El-Samrah, M.G.; Tawfic, A.F.; Chidiac, S.E. Spent nuclear fuel interim dry storage; Design requirements, most common methods, and evolution: A review. Ann. Nucl. Energy 2021, 160, 108408. [Google Scholar] [CrossRef]

- Weiner, R.F.; Ammerman, D.J. Spent fuel transportation risk assessment: Transportation accident analysis. Packag. Transp. Storage Secur. Radioact. Mater. 2013, 24, 147–157. [Google Scholar] [CrossRef]

- Diersch, R.; Weiss, M.; Dreier, G. Investigation of the impact behaviour of wooden impact limiters. Nucl. Eng. Des. 1994, 150, 341–348. [Google Scholar] [CrossRef]

- Aktay, L.; Johnson, A.F.; Kröplin, B.-H. Numerical modelling of honeycomb core crush behaviour. Eng. Fract. Mech. 2008, 75, 2616–2630. [Google Scholar] [CrossRef]

- Peixinho, N.; Carvalho, O.; Areias, C.; Pinto, P.; Silva, F. Compressive properties and energy absorption of metal-polymer hybrid cellular structures. Mater. Sci. Eng. A 2020, 794, 139921. [Google Scholar] [CrossRef]

- Ryu, J.; Lim, H.; Lee, S.-H.; Lee, J. Polymer filling behaviors and imprinting velocities with pressure variation rates in nanoimprint lithography. Microelectron. Eng. 2015, 140, 67–71. [Google Scholar] [CrossRef]

- Wang, C.; Kilic, K.I.; Koerner, H.; Baur, J.W.; Varshney, V.; Lionti, K.; Dauskardt, R.H. Polyimide Hybrid Nanocomposites with Controlled Polymer Filling and Polymer–Matrix Interaction. ACS Appl. Mater. Interfaces 2022, 14, 28239–28246. [Google Scholar] [CrossRef] [PubMed]

- Pearce, A.K.; O’Reilly, R.K. Polymers for Biomedical Applications: The Importance of Hydrophobicity in Directing Biological Interactions and Application Efficacy. Biomacromolecules 2021, 22, 4459–4469. [Google Scholar] [CrossRef]

- Cichosz, S.; Masek, A.; Zaborski, M. Polymer-based sensors: A review. Polym. Test. 2018, 67, 342–348. [Google Scholar] [CrossRef]

- Akindoyo, J.O.; Beg, M.D.H.; Ghazali, S.; Islam, M.R.; Jeyaratnam, N.; Yuvaraj, A.R. Polyurethane types, synthesis and applications—A review. RSC Adv. 2016, 6, 114453–114482. [Google Scholar] [CrossRef]

- Mane, J.V.; Chandra, S.; Sharma, S.; Ali, H.; Chavan, V.M.; Manjunath, B.S.; Patel, R.J. Mechanical Property Evaluation of Polyurethane Foam under Quasi-static and Dynamic Strain Rates- An Experimental Study. Procedia Eng. 2017, 173, 726–731. [Google Scholar] [CrossRef]

- ASTM D3418-2015; Standard Test Method for Transition Temperatures and Enthalpies of Fusion and Crystallization of Polymers by Differential Scanning Calorimetry. ASTM International: West Conshohocken, PA, USA, 2021.

- ASTM D695-15; Standard Test Method for Compressive Properties of Rigid Plastics. ASTM International: West Conshohocken, PA, USA, 2023.

- ASTM D412; Standard Test Methods for Vulcanized Rubber and Thermoplastic Elastomers—Tension. ASTM International: West Conshohocken, PA, USA, 2021.

- Brondi, C.; Di Maio, E.; Bertucelli, L.; Parenti, V.; Mosciatti, T. Competing bubble formation mechanisms in rigid polyurethane foaming. Polymer 2021, 228, 123877. [Google Scholar] [CrossRef]

- Burgaz, E.; Kendirlioglu, C. Thermomechanical behavior and thermal stability of polyurethane rigid nanocomposite foams containing binary nanoparticle mixtures. Polym. Test. 2019, 77, 105930. [Google Scholar] [CrossRef]

- Scholz, P.; Wachtendorf, V.; Panne, U.; Weidner, S.M. Degradation of MDI-based polyether and polyester-polyurethanes in various environments—Effects on molecular mass and crosslinking. Polym. Test. 2019, 77, 105881. [Google Scholar] [CrossRef]

- Li, J.; Jiang, S.; Ding, L.; Wang, L. Reaction kinetics and properties of MDI base poly (urethane-isocyanurate) network polymers. Des. Monomers Polym. 2021, 24, 265–273. [Google Scholar] [CrossRef] [PubMed]

- Maia, L.S.; de Bomfim, A.S.C.; de Oliveira, D.M.; Pinhati, F.R.; da Conceição, M.O.T.; Barud, H.S.; Medeiros, S.A.; Rosa, D.S.; Mulinari, D.R. Tuning of renewable sponge-like polyurethane physical-chemical and morphological properties using the pullulan as a reactive filler. J. Appl. Polym. Sci. 2023, 140, e53619. [Google Scholar] [CrossRef]

- Diaz, T.J.; Cerrutti, P.; Chiacchiarelli, L.M. In-situ thermal aging of biobased and conventional rigid polyurethane foams nanostructured with bacterial nanocellulose. J. Appl. Polym. Sci. 2022, 139, 51824. [Google Scholar] [CrossRef]

- Qiu, F.; Tu, C.; Chen, Y.; Shi, Y.; Song, L.; Wang, R.; Zhu, X.; Zhu, B.; Yan, D.; Han, T. Control of the Optical Properties of a Star Copolymer with a Hyperbranched Conjugated Polymer Core and Poly(ethylene glycol) Arms by Self-Assembly. Chem. Eur. J. 2010, 16, 12710–12717. [Google Scholar] [CrossRef]

- Olcay, H.; Kocak, E.D. The mechanical, thermal and sound absorption properties of flexible polyurethane foam composites reinforced with artichoke stem waste fibers. J. Ind. Text. 2020, 51, 8738S–8763S. [Google Scholar] [CrossRef]

- Chattopadhyay, D.K.; Webster, D.C. Thermal stability and flame retardancy of polyurethanes. Prog. Polym. Sci. 2009, 34, 1068–1133. [Google Scholar] [CrossRef]

- Ge, C.; Wang, S.; Zheng, W.; Zhai, W. Preparation of microcellular thermoplastic polyurethane (TPU) foam and its tensile property. Polym. Eng. Sci. 2018, 58, E158–E166. [Google Scholar] [CrossRef]

- Son, T.W.; Lee, D.W.; Lim, S.K. Thermal and Phase Behavior of Polyurethane Based on Chain Extender, 2,2-Bis-[4-(2-hydroxyethoxy)phenyl]propane. Polym. J. 1999, 31, 563–568. [Google Scholar] [CrossRef]

- Li, X.; Wang, G.; Yang, C.; Zhao, J.; Zhang, A. Mechanical and EMI shielding properties of solid and microcellular TPU/nanographite composite membranes. Polym. Test. 2021, 93, 106891. [Google Scholar] [CrossRef]

- Japins, G.; Kalnins, K.; Kirpluks, M.; Cabulis, U. Modeling the Effect of Foam Density and Strain Rate on the Compressive Response of Polyurethane Foams. SAE Int. J. Mater. Manf. 2018, 11, 131–138. [Google Scholar] [CrossRef]

- Takano, M.; Takamatsu, K.; Saito, H. High-Strength Heat-Elongated Thermoplastic Polyurethane Elastomer Consisting of a Stacked Domain Structure. Polymers 2022, 14, 1470. [Google Scholar] [CrossRef]

- Shuai, M.-K.; Gong, Y.; Cheng, F.; Zhang, J.; Li, R.-B.; Pan, J.; Li, N.; Xu, J.-F.; Liu, X.-Q.; Yang, X.-L.; et al. Innovation in lifetime prediction of rigid polyurethane foam through random vibration and comparison with conventional methods. Polym. Test. 2023, 125, 108122. [Google Scholar] [CrossRef]

- Doyle, C.D. Kinetic analysis of thermogravimetric data. J. Appl. Polym. Sci. 1961, 5, 285–292. [Google Scholar] [CrossRef]

- Gong, Y.; Tang, J.; Sun, B.-N.; Yang, Z.-G.; Shi, X.-Q.; Liu, X.-Q.; Xie, Y.-C.; Xu, X.-L. Comparative study on different methods for determination of activation energies of nuclear cable materials. Polym. Test. 2018, 70, 81–91. [Google Scholar] [CrossRef]

- ASTM E1641-07; Standard Test Method for Decomposition Kinetics by Thermogravimetry Using the Ozawa/Flynn/Wall Method. ASTM International: West Conshohocken, PA, USA, 2023.

- ASTM E1877; Standard Practice for Calculating Thermal Endurance of Materials from Thermogravimetric Decomposition Data. ASTM International: West Conshohocken, PA, USA, 2021.

- Plota, A.; Masek, A. Lifetime Prediction Methods for Degradable Polymeric Materials—A Short Review. Materials 2020, 13, 4507. [Google Scholar] [CrossRef]

- Zeng, F.; Men, X.; Chen, M.; Liu, B.; Han, Q.; Huang, S.; Zhao, H.; Wang, Y. Molecular-micron multiscale toughening and flame retarding for polyurethane foams. Chem. Eng. J. 2023, 454, 140023. [Google Scholar] [CrossRef]

| Sample | PEG-(OH)2 (kg) | Polymeric MDI (kg) | DMMP (kg) | Distilled Water (kg) | Et3N (kg) | Polysilane (kg) | Molar Ratio of NCO in Polymeric DMI to OH in PEG-(OH)2 |

|---|---|---|---|---|---|---|---|

| HD-RPUF | 100 | 165 | 40 | 0.6 | 2 | 0.8 | 3.70 |

| MD-RPUF | 100 | 155 | 40 | 2.6 | 2 | 0.8 | 3.47 |

| LD-RPUF | 100 | 150 | 40 | 3.4 | 10 | 0.2 | 3.36 |

| Sample | Contents of Elements (wt%) (a) | Flame Extinction Time (s) | Residual Carbons (wt%) (b) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| C | H | N | O | P | Si | Cl | Other | |||

| HD-RPUF | 61.82 | 6.04 | 7.13 | 14.7 | 1.125 | 0.078 | 0.005 | <1 | 0.88 | 96.71 ± 1.70% |

| MD-RPUF | 62.73 | 6.13 | 7.27 | 13.6 | 0.905 | 0.088 | 0.005 | <1 | 1.08 | 92.48 ± 0.77% |

| LD-RPUF | 62.51 | 6.07 | 7.36 | 13.2 | 1.736 | 0.021 | 0.004 | <1 | 1.26 | 90.64 ± 1.44% |

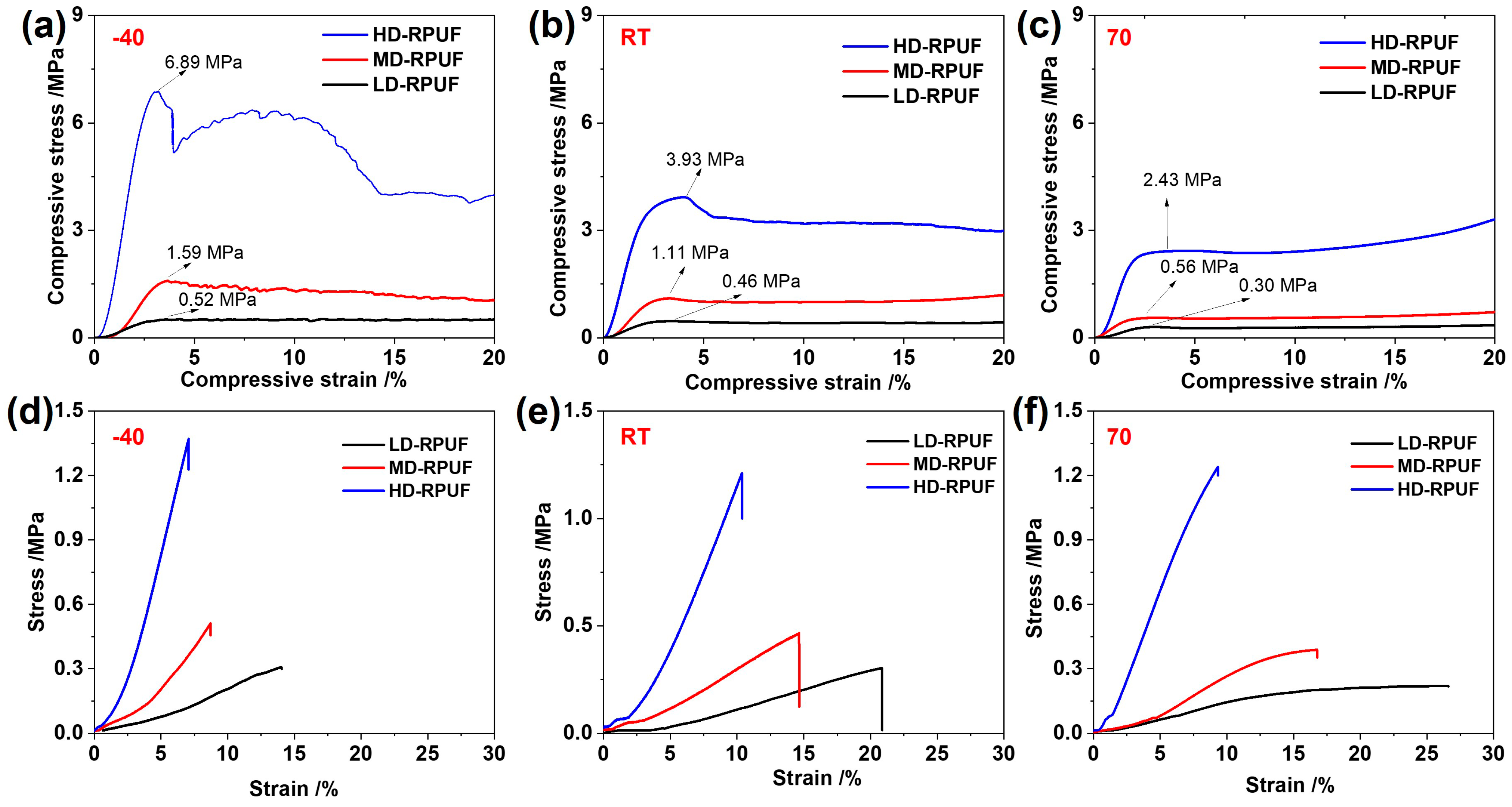

| Sample | Compression Strength (MPa) | Tensile Strength (MPa) | Strain (%) | Yong’s Modulus (MPa) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| −40 | 25 | 70 | −40 | 25 | 70 | −40 | 25 | 70 | −40 | 25 | 70 | |

| HD-RPUF | 6.89 | 3.93 | 2.43 | 1.37 | 1.24 | 1.21 | 7.06 | 9.25 | 10.32 | 19.41 | 13.48 | 11.72 |

| MD-RPUF | 1.59 | 1.11 | 0.56 | 0.51 | 0.47 | 0.39 | 8.70 | 14.58 | 16.74 | 5.86 | 3.22 | 2.33 |

| LD-RPUF | 0.52 | 0.46 | 0.30 | 0.31 | 0.31 | 0.22 | 14.01 | 20.83 | 26.57 | 2.21 | 1.49 | 0.83 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Z.; Shen, G.; Li, R.; Yuan, L.; Feng, H.; Chen, X.; Qiu, F.; Yuan, G.; Zhuang, X. Long-Service-Life Rigid Polyurethane Foam Fillings for Spent Fuel Transportation Casks. Polymers 2024, 16, 229. https://doi.org/10.3390/polym16020229

Zhang Z, Shen G, Li R, Yuan L, Feng H, Chen X, Qiu F, Yuan G, Zhuang X. Long-Service-Life Rigid Polyurethane Foam Fillings for Spent Fuel Transportation Casks. Polymers. 2024; 16(2):229. https://doi.org/10.3390/polym16020229

Chicago/Turabian StyleZhang, Zhenyu, Guangyao Shen, Rongbo Li, Lei Yuan, Hongfu Feng, Xiuming Chen, Feng Qiu, Guangyin Yuan, and Xiaodong Zhuang. 2024. "Long-Service-Life Rigid Polyurethane Foam Fillings for Spent Fuel Transportation Casks" Polymers 16, no. 2: 229. https://doi.org/10.3390/polym16020229

APA StyleZhang, Z., Shen, G., Li, R., Yuan, L., Feng, H., Chen, X., Qiu, F., Yuan, G., & Zhuang, X. (2024). Long-Service-Life Rigid Polyurethane Foam Fillings for Spent Fuel Transportation Casks. Polymers, 16(2), 229. https://doi.org/10.3390/polym16020229