Abstract

A lignin modified salt-resistant branched high-performance water reducer was prepared via free radical polymerization. The water-reducing agent was identified through its NMR spectrum, elemental analysis, Fourier transform infrared analysis, thermal gravimetric analysis, and scanning electron microscopy. The experiment conducted on cement paste demonstrates that the water-reducing efficiency can reach a maximum of 44%. Additionally, the significant spatial steric hindrance of the application enhances the dispersal capability of the water-reducing agent, resulting in effective water reduction and reduced viscosity. In addition, its compressive strength is the highest after 3-day curing and 3-, 7-, 28-day standard curing, and it has the best overall performance both in water and saline water prepared systems. The application in oil cement slurry shows that it exhibits a good dispersibility in fresh water, saline water, and substitute ocean water. In the Halfaya and Missan Oilfields of Iraq, BHPWR was used in a slurry with a density of 2.28 g/cm3 for casing the salt paste layer of five wells. The cementing results exceeded expectations with 100% qualified including over 85% excellent.

1. Introduction

The water reducer is a crucial admixture in the concrete industry, which has witnessed a shift from the conventional polyelectrolyte water reducer to the polycarboxylic acid water reducer [1,2,3,4]. The comb type polycarboxylic acid water reducer, characterized by its remarkable adjustability and significant potential for achieving a high performance [5,6,7], effectively addresses concerns related to dispersibility and stability, thereby yielding exceptional application outcomes [8,9,10].

However, it is impossible to directly use seawater, saline water, and alkali water to build coastal wave-resistant dikes and saltwater lake dams due to the decreased flow ability induced by salt resistance, which requires the long-distance transportation of fresh water, increasing costs and fuel consumption during transportation.

A salt-resistant water reducer could effectively increase the flow ability of concrete slurry containing salt which could help in the direct preparation of slurry with seawater, saline water, and alkali water.

This study is still in its early stages, and there is no relevant research yet. The available salt-resistant water reducer literature is mostly about the resistance of erosion of concrete by sulfate and chloride salts after being added [11,12,13,14,15,16,17,18], rather than to improve its fluidity during construction.

Lignin and its derivates are the most abundant biomass resource due to lignin’s impressive characteristics like its high abundance, high molecular weight, oxidation resistance, bacteriostasis, and biodegradability, and they have been widely used for water treatment [19,20], as adhesive-reinforcing agents [21], water reducers [22,23], and even in hydrogen production [24].

Lignosulfonate is the predominant biomass water reducer in use currently. Although its shortcomings, such as a low water-reducing efficiency and high level of air entrainment and retardation, constrain its broader application, lignin and lignosulfonate still carry the advantages of being environmentally friendly and cost-effective.

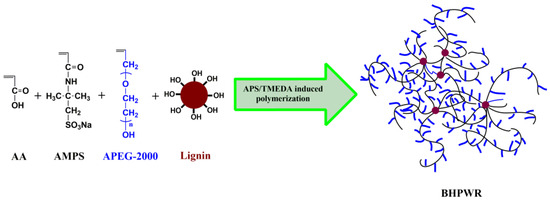

In this work, a salt-resistant branched high-performance water reducer (BHPWR) was prepared by introducing branching structures starting from the multi-hydroxyl lignin, The main chain of BHPWR contained carboxyl and sulfonic acid groups as well as long hydrophilic side chains. By utilizing the strong steric hindrance effect of lignin and polyethylene glycol monocetyl ether in the side chains, the volume dispersion and electrostatic repulsion led to strong dispersing effect which could effectively improve concrete fluidity under saline conditions. The BHPWR was experimented with by chemical analyses such as 1H-NMR, Fourier transform infrared, elemental analysis, thermogravimetric analysis, and scanning electron microscope, as well as performance analysis in concrete and cement slurry, which indicated that BHPWER performs good water-reducing rate in concrete prepared with saline water and good dispersion in cement slurry prepared by saline water. And the BHPWR-3 was used to cement a 244.5 mm salt paste layer casing for five wells in the Halfaya and Missan Oilfields in Iraq.

2. Materials and Methods

2.1. Materials

Acrylic acid (AA) was obtained from Sinopharm Chemical Reagent Co., Ltd., Shanghai, China. AMPS was obtained from Nanjing All-Plus Chemical Co., Ltd., Nanjing, China. APEG-2000 was obtained from Haian Petrochemical Plant Co., Ltd., Haian, China. Lignin was obtained from Shandong Gaotang Polymeric Lignin Co., Ltd., Liaocheng, China. Ammonium persulfate (APS) was obtained from Shandong Zhengxing New Material Co., Ltd., Zibo, China. Tetramethylethylenediamine (TMEDA) was obtained from Shandong Zhenkun New Material Co., Ltd., Liaocheng, China. Ethanol was obtained from Xi’an Dongsen Chemical Material Co., Ltd., Xi’an, China.

P·O 52.5 Cement was obtained from Jidong Cement Co., Ltd., Tangshan, China. Quartz sand ranging from 20 to 120 mesh was obtained from Hebei Huakai Mining Co., Ltd., Xingtai, China. Silica fume with a SiO2 content exceeding 94% and a specific surface area of 20 m2/g was obtained from Gansu Sanyuan Silicon Material Co., Ltd., Lanzhou, China. Class I fly ash with a density of 2200 kg/m3 was obtained from Shandong Shunke Building Materials Technology Co., Ltd., Yantai, China. Glass beads with a density of 412 kg/m3 and a particle size of approximately 0.1 mm were obtained from Xingtai Guangqing Refractory Material Distribution Co., Ltd., Xingtai, China. Steel fiber with a diameter of 0.22 mm and length ranging from 13 to 15 mm was obtained from Changzhou Tianyi Engineering Fiber Co., Ltd., Changzhou, China. Defoaming agent was obtained from Jiangsu Liqi Environmental Technology Co., Ltd., Yancheng, China. NaCl was obtained from Tianjin Changlu Haijing Group Co., Ltd., Tianjin, China.

All reagents were of industrial grade and were used without further purification. The water used was distilled three times.

2.2. Characterization

The 1H-NMR experiment was performed on a Bruker AVANCE400 NMR spectrometer, Billerica, MA, USA. D2O was used for field-frequency lock, and the observed 1H chemical shifts were reported in parts per million (ppm) relative to an internal standard (TMS, 0 ppm).

The Fourier transform infrared (FTIR) experiment was performed on Bruker Tensor 27 spectrometer with BHPWR in KBr pellets at room temperature. The spectra were recorded in the range of 4000–400 cm−1.

Elemental analysis was performed on an Elementar Vario E1 III analyzer, Rhine Main, Germany.

Thermogravimetric analysis (TGA) of the dried sample was performed using a Mettler Toledo TGA/DSC 1, Zurich, Switzerland, in the temperature range 30–700 °C with a heating rate of 10 °C/min under a nitrogen atmosphere.

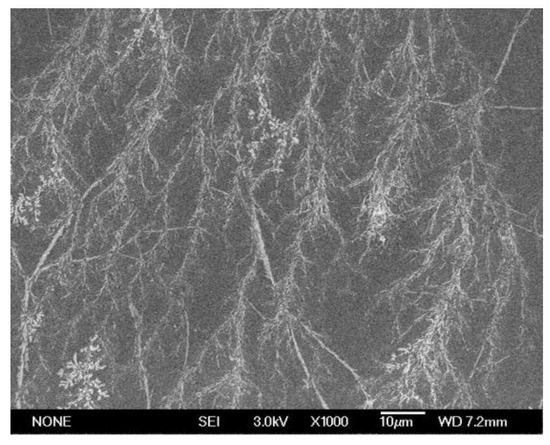

The scanning electron microscope (SEM) measurement was obtained using an JEOL JSM-7600 Thermal Field Emission Scanning Electron Microscope, Akishima, Japan, and the surface of the polymer was treated with gold spraying as previously.

The water reduction rate was tested according to GB 8076-2008 [25]. The concrete mix ratio was: m (Jidong Cement): m (sand): m (stone) = 360: 810: 990.

Concrete viscosity was tested according to T500 in JGJ/T 283-2012 [26].

The mechanical properties of concrete are tested in accordance with the GB/T 50081-2019 standard [27] through the process of standard steam curing. The specimens, after being exposed to an experimental setting for 24 h at a temperature of (20 ± 5) °C and a relative humidity above 50%, are transferred to a curing box. They are then gradually heated, not surpassing a rate of 15 °C/h, until reaching a temperature of (90 ± 1) °C. The specimens are maintained at a constant temperature for 48 h before being cooled down, again not exceeding a rate of 15 °C/h, until reaching (20 ± 5) °C.

The process of curing at the typical temperature of a room is conducted in accordance with the guidelines provided by GB/T 50081-2019 [27], which outlines the standard procedures for evaluating the mechanical properties of concrete. Samples are placed in a typical curing chamber at a temperature of (20 ± 2) °C and a relative humidity exceeding 95%.

A ZNN-D6 rotational viscometer was used to conduct the rheological test at 85 °C and atmospheric pressure, following the guidelines of SY/T 5504.3-2018 [28] “Evaluation Method for Oil Well Cement Additives Part 3 Friction Reducers”.

3. Synthesis and Characterization of BHPWR

3.1. The Synthesis of BHPWR

One linear water reducer (LWR) and six BHPWR samples were synthesized via free radical polymerization as shown in Figure 1. The compounds 2-acrylamide-2-methylpropanesulfonic acid (AMPS), acrylic acid (AA), allyl polyethylene glycol with molecular weight of 2000 g/mol (APEG-2000), lignin, and water were added in one portion and stirred to dissolve at 70 °C forming a solution with lignin and 125 g monomers and 375 g water, then the initiators APS (0.5 g, 0.0022 mol) and TMEDA (0.26 g, 0.0022 mol) were added, and the solution was kept at 70 °C for 3 h. The resulting pale yellow liquid was filtered while still hot, then precipitated by ethanol, and washed by ethanol 6 times and a mixture of water/ethanol (3/7, v/v) 3 times to remove unreacted monomers. The products were dried in a vacuum at 70 °C for 48 h.

Figure 1.

Synthesis route of BHPWR.

The composition of samples was determined by the elemental analysis. The weight percentages of carbon, hydrogen, nitrogen, and sulfur from elemental analyses of the samples could be obtained. However, we can only give the actual mole ratio of AMPS in polymer via the weight percentages of sulfur as listed in Table 1. The results indicate that the reactivity ratio of AMPS is less than that of AA and APEG-2000 in the copolymerization.

Table 1.

Characteristics of 6 samples.

3.2. The Characterization of BHPWR

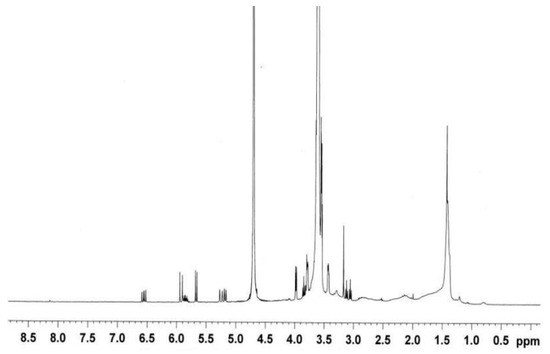

The observed 1H chemical shifts of BHPWR-5 were reported as shown in Figure 2, (a) –CH3 of AMPS and lignin appeared at 1.2–1.3 ppm, (b) –CH2 of AA, APEG-2000, and AMPS in the polymer backbone and lignin appeared at 1.3–1.6 ppm, (c) -CH of AA, APEG-2000, and AMPS in the polymer backbone, and Ar-CH3 lignin appeared at 1.9–2.3 ppm, (d) –CH2 of APEG-2000 on the side chain, on the AMPS nearing -SO3H, and –O–CH2 and –OH on lignin appeared at 3.0–4.1 ppm, (e) the double bond (–CH2=CH–) of unreacted monomers and –CH2=CH– of the benzene ring on lignin appeared at 5.1–6.7 ppm.

Figure 2.

NMR spectrum of BHPWR-5.

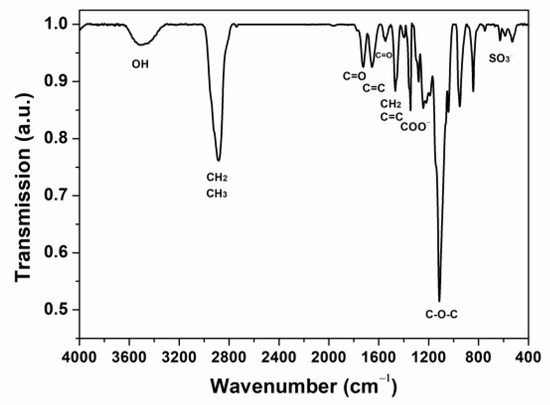

The IR spectrum of BHPWR-5 is presented in Figure 3 with the main absorption bands of BHPWR-6 assigned as follows: (a) OH stretching (H2O, APEG-2000) appeared at 3500 cm−1, (b) CH2 and CH3 stretching (AMPS, APEG-2000, lignin) appeared at 2880 cm−1, (c) C=O symmetric stretching (acrylic acid) appeared at 1720 cm−1, (d) aromatic ring skeleton stretching (lignin) appeared at 1653 cm−1 and 1467 cm−1, (e) COO-symmetric stretching (acrylic acid) appeared at 1345 cm−1, (f) C–O–C stretching (APEG-2000, lignin) appeared at 1114 cm−1, and (g) S–O bending (sulfonic acid group of AMPS) appeared at 626 cm−1.

Figure 3.

Infrared spectra of BHPWR-5.

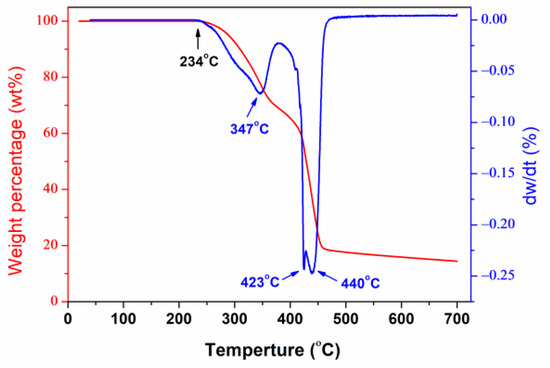

TGA and DTG curves of BHPWR-5 are shown in Figure 4. The thermogram of BHPWR-5 showed three steps during its mass loss. The first stage of 16.0% weight loss was related to the thermal decomposition of the polyethylene glycol monocetyl ether at 234–382 °C. The second stage of 36.1% weight loss was attributed to the thermal decomposition of the ether bond formed by the –OH of lignin and –CH=CH2 of monomers at 380–430 °C. The third step of 29.8% weight loss may be attributed to polymer backbone degradation at 430–470 °C. The results indicate that BHPWR exhibits a good temperature resistance.

Figure 4.

TGA and DTG curves of the BHPWR-5.

An electron microscopy test was conducted to further study the stereostructure of the water reducer in solution, using scanning electron microscopy (SEM). BHPWR-5 did not exhibit a single regular shape due to the free rotation of its main chain and side chains. Despite the adsorption of the primary chain onto the cement particle surface in the cement slurry, the secondary chain exhibits erratic movement as well. Figure 5 shows the aggregate state of the water reducer at the micrometer scale, which is a dendritic shape. The primary chain of the polymer attaches to the cement particles in the cement slurry through carboxyl and sulfonic acid groups, while the polymer’s secondary chains are long side chains that can extend without restriction when the primary chain is attached to the cement slurry. The response of water and the mechanical radius increases due to the significant molecular weight of the side chains, resulting in a substantial spatial steric hindrance. Due to this large spatial steric hindrance effect, the side chains have a strong three-dimensional dispersing ability on cement particles, which leads to a good dispersion of cement slurry and further increases its rheology.

Figure 5.

SEM of BHPWR-5.

4. Concrete and Cement Slurry Performance

4.1. Concrete Performance

Table 2 and Table 3 display the performance of concrete made with freshwater and saltwater, correspondingly. The water-reducing rate of BHPWR-3 could reach up to 45% in fresh water and 44% in saline water, and its large spatial steric hindrance improves the dispersibility of the water reducer, achieving a high water reduction and flow rate which help to reach a 500 mm slump quickly.

Table 2.

Performance of concrete prepared by fresh water 1.

Table 3.

Performance of concrete prepared by saline water 1.

In addition, its compressive strength is the highest after 3-day curing and 3-, 7-, and 28-day standard curing, and it has the best overall performance both in fresh water and saline water prepared systems.

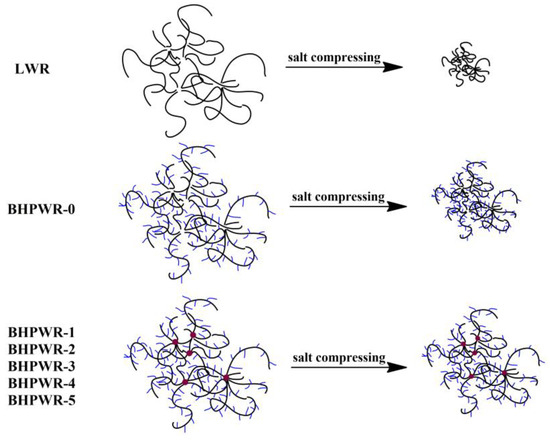

The scheme model of water reducers compressed by salt is given in Figure 6. Chains of LWR were compressed and the gyration radius of copolymer coils decreased sharply from the stretched conformation in aqueous solution when salt ions were added. The small gyration radius of copolymer coils could not disperse the cement particles. Thus, LWR could not reduce water in saline water with a high salt content. Chains of BHPWR-0, which has a long side chain but no lignin, were also compressed and the gyration radius of copolymer coils decreased sharply, less sharply than LWR, from the stretched conformation in aqueous solution when salt ions were added. The gyration radius of copolymer coils, which is bigger than LWR due to the three-dimensional dispersion effects of side chains, could partly disperse the cement particle. Thus, BHPWR-0 could reduce some water in saline water with a high salt content. When it comes to water reducers with APEG-2400 and lignin (BHPWR-1, BHPWR-2, BHPWR-3, BHPWR-4, BHPWR-5), the chains were also compressed and the gyration radius of copolymer coils decreased. However, the gyration radius of copolymer coils with side chains and a lignin structure could still maintain a larger size due to the three-dimensional dispersion effects of the side chains and impregnable lignin structure. Thus, they could effectively reduce water in saline water with a high salt content.

Figure 6.

The scheme model of the water reducers compressed by salt.

4.2. Cement Slurry Performance

BHPWR could also be used as oil cement dispersant. BHPWR-3 was added to the slurry prepared with fresh water, saline water with 36% NaCl by weight of water, and substitute ocean water which is prepared according to Designation D1141-98 (D1141-98). The dispersant underwent evaluation in accordance with SY/T 5504.3-2008 and the important indicators are the flow behavior index n and consistency index K calculated from θ300 and θ300, the reading of viscometer at the shearing rate of 100 r/min and 300 r/min. A good dispersant should result in a bigger n and lower k.

The rheology of slurries prepared with fresh water, saline water, and substitute ocean water is listed in Table 4. With the addition of 1.5% by weight of cement (BWOC), n = 0.78–0.93 and K = 0.04–0.16 Pa.sn at 52 °C and atmospheric pressure, while n = 0.73–0.92 and K = 0.16–0.19 Pa.sn at 85 °C and atmospheric pressure, which indicates that BHPWR-3 exhibits a good dispersibility in fresh water, saline water, and substitute ocean water.

Table 4.

Rheology of slurries prepared with different kinds of water 1.

5. The Application of BHPWR

The cement slurries used in Iraq’s Halfaya and Missan Oilfields were prepared by saline water with a low fluidity, significant thixotropy, and high initial consistency due to its high solid and salt content. Furthermore, the elevated temperature during the summer in Iraq speeds up the process of cement hydration, ultimately causing a decrease in the rheology of the cement slurry. Due to the persistent high ground temperature, which can reach up to 60 °C during the summer in Iraq, the cement slurry experienced significant hydration while being mixed, leading to a decrease in its fluidity as shown in Table 5 which shows θ300 unreadable at 60 °C, strong thixotropy, and a high initial consistency leading to difficulty in pumping and unstable density which seriously impacts on on-site construction safety and cementing quality. The Sector Bond Tool (SBT) results showed that the salt paste layer casing in Halfaya and Missan Oilfields was only about 60% qualified including 20–30% excellent.

Table 5.

Rheology of 2.28 g/cm3 slurry 1at different ambient temperatures.

BHPWR could enhance the flow characteristics of slurry, making it easier to mix and place. Rheology is a metric that gauges the ability to resist fluid motion and the decrease in such resistance when subjected to pressure. Upon substitution of the dispersant in Table 6 with BHPWR-3, the slurry displayed favorable rheological characteristics, with a flow behavior index of n = 0.74 and a consistency factor of K = 1.08 Pa.sn at 60 °C from which we can learn that BHPWR-3 represents good dispersant performance.

Table 6.

Rheology of 2.28 g/cm3 slurry using BHPWR-3 1 at different ambient temperatures.

To cement the 244.5 mm salt paste layer casing for five wells in the Halfaya and Missan Oilfield in Iraq, the BHPWR-3 was utilized with high-density (2.28 g/cm3) saline cement slurry under the ambient temperature of 55–58 °C. One of the wells, namely FQCS-44H, serves as a prime example, involving the sealing of the Lower Fars formation containing high-pressure saltwater zones via casing measuring 244.5 mm in diameter placed in 311.1 mm open holes, with the shoe being at 2957.7 m as opposed to the previous 339.7 mm casing at 2081.5 m. However, it is challenging to conduct cementing under these circumstances given that a higher mud weight (2.23 g/cm3) requires a denser slurry, potentially narrowing the cementing window. Despite these complications, the SBT evaluation indicates that the cementing job was 100% qualified including over 85% excellent.

6. Conclusions

BHPWR prepared via free radical polymerization with a good temperature resistance, which decomposes from 234 °C, demonstrates an excellent performance as a water reducer, with reduction rates of up to 45% in fresh water and 44% in saline water. After 3-day curing and standard curing for 3, 7, and 28 days, it shows the highest compressive strength and overall best performance in both water and saline water systems. Furthermore, it has been found to exhibit a good dispersibility in fresh water, saline water, and substitute ocean water, making it a suitable dispersant for oil cement slurries. Rheological testing of slurries prepared with BHPWR-3 showed n = 0.78–0.93 and K = 0.04–0.16 Pa.sn at 52 °C and atmospheric pressure, and n = 0.73–0.92 and K = 0.16–0.19 Pa.sn at 85 °C and atmospheric pressure. This indicates that BHPWR-3 is effective in fresh water, saline water, and substitute ocean water. In the Halfaya and Missan Oilfields of Iraq, BHPWR was used in slurry with a density of 2.28 g/cm3 for casing the 244.5 mm salt paste layer of five wells. The cementing results exceeded expectations with 100% qualified including over 85% excellent.

Author Contributions

Conceptualization, H.X.; methodology, D.G.; software, H.X.; validation, D.G.; formal analysis, H.X.; investigation, H.X.; resources, D.G.; data curation, H.X.; writing—original draft preparation, H.X.; writing—review and editing, D.G.; visualization, H.X.; supervision, D.G.; project administration, H.X.; funding acquisition, H.X. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Shanxi Province Postdoctoral Special Subsidy ‘2023 Synthesis of High-Performance Salt-Resistant Bioconcrete Water Reducer’, grant number 205521029.

Institutional Review Board Statement

Not applicable.

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Rodrigues, F.A.; Joekes, I. Water reducing agents of low molecular weight: Suppression of air entrapment and slump loss by addition of an organic solvent. Cem. Concr. Res. 1994, 24, 987–992. [Google Scholar] [CrossRef]

- Chen, J.; Li, L.; Wu, G.; Zhou, M.; Jiang, T.; Pu, Q.; Wei, M. Study on the effect of fly ash and polycarboxylic acid water reducer on the properties of recycled concrete. IOP Conf. Ser. Earth Environ. Sci. 2019, 218, 012068. [Google Scholar] [CrossRef]

- Chen, Y. Research and application of polycarboxylate water reducer for precast components. IOP Conf. Ser. Earth Environ. Sci. 2021, 621, 012112. [Google Scholar] [CrossRef]

- Pang, L.; Zhou, X. Research of polyocarboxy acid water-reducer with modified ployether and its effect on concrete’s workability. Adv. Mater. Res. 2011, 250–253, 2032–2035. [Google Scholar] [CrossRef]

- Chen, Y.; Chen, Y.; Liu, Y.; Tao, J.; Liu, R.; Li, Z.; Liu, F.; Li, M. Effect of the Alkyl Density of Acrylic Acid Ester on the Viscosity-Reducing Effect of Polycarboxylate Superplasticizer. Molecules 2023, 28, 7293. [Google Scholar] [CrossRef]

- Pang, J.; Guo, J.; Li, W.; Chang, Q. Effect of the structure of macromonomer in polycarboxylate superplasticizer on slump-retention of concrete. J. Dispers. Sci. Technol. 2023. [Google Scholar] [CrossRef]

- Zhang, J.; Ma, Y.; Wang, J.; Gao, N.; Hu, Z.; Liu, J.; Wang, K. A novel shrinkage-reducing polycarboxylate superplasticizer for cement-based materials: Synthesis, performance and mechanisms. Constr. Build. Mater. 2022, 321, 126342. [Google Scholar] [CrossRef]

- Süleyman, Ö.; Muhammet, G.; Ali, M.; Kambiz, R. Effect of main and side chain length change of polycarboxylate-ether-based water-reducing admixtures on the fresh state and mechanical properties of cementitious systems. Struct. Concr. 2021, 22, E607–E618. [Google Scholar]

- Li, C.; Feng, N.; Li, Y.; Chen, R. Effects of polyethlene oxide chains on the performance of polycarboxylate-type water-reducers. Cem. Concr. Res. 2005, 35, 867–873. [Google Scholar] [CrossRef]

- Liu, y.; Li, H.; Wang, K.; Wu, H.; Cui, B. Effects of accelerator–water reducer admixture on performance of cemented paste backfill. Constr. Build. Mater. 2020, 242, 118187. [Google Scholar] [CrossRef]

- Konzilia, J.; Matthias, E.; Jürgen, F. Experimental investigation on salt frost scaling of textile-reinforced concrete. Struct. Concr. 2022, 23, 954–969. [Google Scholar] [CrossRef]

- Brun, M.; Shpak, A.; Jacobsen, S. Shape and size of particles scaled from concrete surfaces during salt frost testing and rapid freeze/thaw in water. Nord. Concr. Res. 2021, 64, 53–68. [Google Scholar] [CrossRef]

- Kryvenko, P.; Rudenko, I.; Konstantynovskyi, O.; Boiko, O. Restriction of Cl− and SO42− ions transport in alkali activated slag cement concrete in seawater. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1164, 012066. [Google Scholar] [CrossRef]

- Wu, B.; Li, X.; Meng, X.; Zhang, Y.; Zhao, L.; Zhang, Q. An Experimental Study and Adaptability Evaluation of Chain Extender Component in Water Reducer on the Sulfate Corrosion Resistance of Ordinary Concrete. Coatings 2023, 13, 1958. [Google Scholar] [CrossRef]

- Yang, W.; Ye, X.; Li, R.; Yang, J. Effect of Stray Current on Corrosion and Calcium Ion Corrosion of Concrete Reinforcement. Materials 2022, 15, 7287. [Google Scholar] [CrossRef]

- Han, F.; Huang, K.; Wei, Y.; Han, J.; Xu, Y. The Mechanical Properties and Water-Reducing and Retarding Mechanism of a Xylonic Cement Admixture. Materials 2023, 16, 7096. [Google Scholar] [CrossRef]

- Zhang, M.; Lv, H.; Zhou, S.; Wu, Y.; Zheng, X.; Yan, Q. Study on the Frost Resistance of Composite Limestone Powder Concrete against Coupling Effects of Sulfate Freeze–Thaw. Buildings 2023, 13, 2776. [Google Scholar] [CrossRef]

- Yao, Y.; Liu, C.; Liu, H.; Zhang, W.; Hu, T. Deterioration mechanism understanding of recycled powder concrete under coupled sulfate attack and freeze-thaw cycles. Constr. Build. Mater. 2023, 388, 131718. [Google Scholar] [CrossRef]

- Wang, T.; Jiang, M.W.; Yu, X.L.; Niu, N.; Chen, L.G. Application of lignin adsorbent in wastewater Treatment: A review. Sep. Purif. Technol. 2022, 302, 122116. [Google Scholar] [CrossRef]

- Wu, W.; Li, P.; Wang, M.; Liu, H.; Zhao, X.; Wu, C.; Ren, J. Comprehensive Evaluation of Polyaniline-Doped Lignosulfonate in Adsorbing Dye and Heavy Metal Ions. Int. J. Mol. Sci. 2024, 25, 133. [Google Scholar] [CrossRef]

- Vidal-Vega, M.; Núñez-Decap, M.; Hernández-Durán, J.; Catricura-Muñoz, P.; Jara-Briones, C.; Moya-Rojas, B.; Opazo-Carlsson, C. Comparative Study of Carbon Nanotubes and Lignosulfonate as Polyvinyl Acetate (PVAc) Wood Adhesive-Reinforcing Agents. Appl. Sci. 2024, 14, 365. [Google Scholar] [CrossRef]

- Johnson, A.T.; Sosa, D.; Arredondo, R.; Li, H.; Yuan, Z.; Xu, C. Production of Bio-based Concrete Water Reducers from Renewable Resources—A Review. Biofuels Bioprod. Biorefining 2023, 17, 1425–1444. [Google Scholar] [CrossRef]

- Ruviaro, A.S.; Dos Santos Lima, G.T.; Silvestro, L.; Barraza, M.T.; Rocha, J.C.; De Brito, J.; Gleize, P.J.P.; Pelisser, F. Characterization and investigation of the use of oat husk ash as supplementary cementitious material as partial replacement of Portland cement: Analysis of fresh and hardened properties and environmental assessment. Constr. Build. Mater. 2023, 363, 129762. [Google Scholar] [CrossRef]

- Umer, M.; Brandoni, C.; Jaffar, M.; Hewitt, N.J.; Dunlop, P.; Zhang, K.; Huang, Y. An Experimental Investigation of Hydrogen Production through Biomass Electrolysis. Processes 2024, 12, 112. [Google Scholar] [CrossRef]

- GB 8076-2008; Concrete Admixtures. Standards Press of China: Beijing, China, 2008.

- JGJ/T 283-2012; Technical Specification for Application of Self-Compacting Concrete. China Architecture & Building Press: Beijing, China, 2012.

- GB/T 50081-2019; Standard for Test Methods for Physical and Mechanical Properties of Concrete. China Architecture & Building Press: Beijing, China, 2019.

- SY/T 5504.3-2018; Evaluation Method for Oil Well Cement Additives Part 3 Friction Reducers. Petroleum Industry Press: Beijing, China, 2018.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).