Ethylene-Propylene-Methylene/Isoprene Rubber/SiO2 Nanocomposites with Enhanced Mechanical Performances and Deformation Recovery Ability by a Combination of Synchronously Vulcanizing and Nanoparticle Reinforcement

Abstract

1. Introduction

2. Experimental Section

2.1. Materials

2.2. Sample Preparation

2.3. Characterization

2.3.1. Tensile Test

2.3.2. Equilibrium Swelling

2.3.3. Phase Contrast Microscopy (PCM)

2.3.4. Transmission Electron Microscopy (TEM)

2.3.5. Temperature Modulated Differential Scanning Calorimetry (TMDSC)

2.3.6. Dynamic Mechanical Analysis (DMA)

2.3.7. Rheological Measurement

3. Results and Discussion

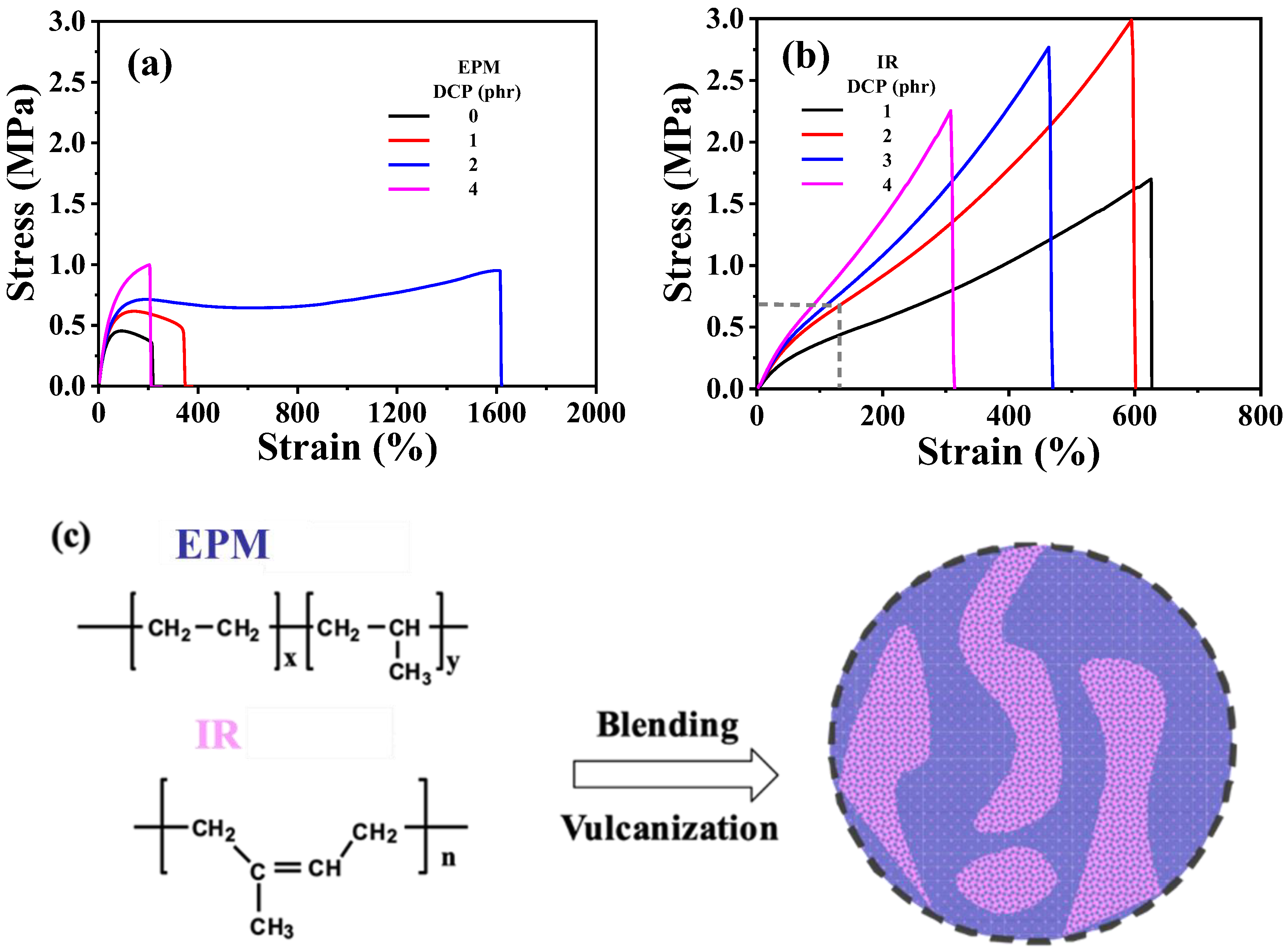

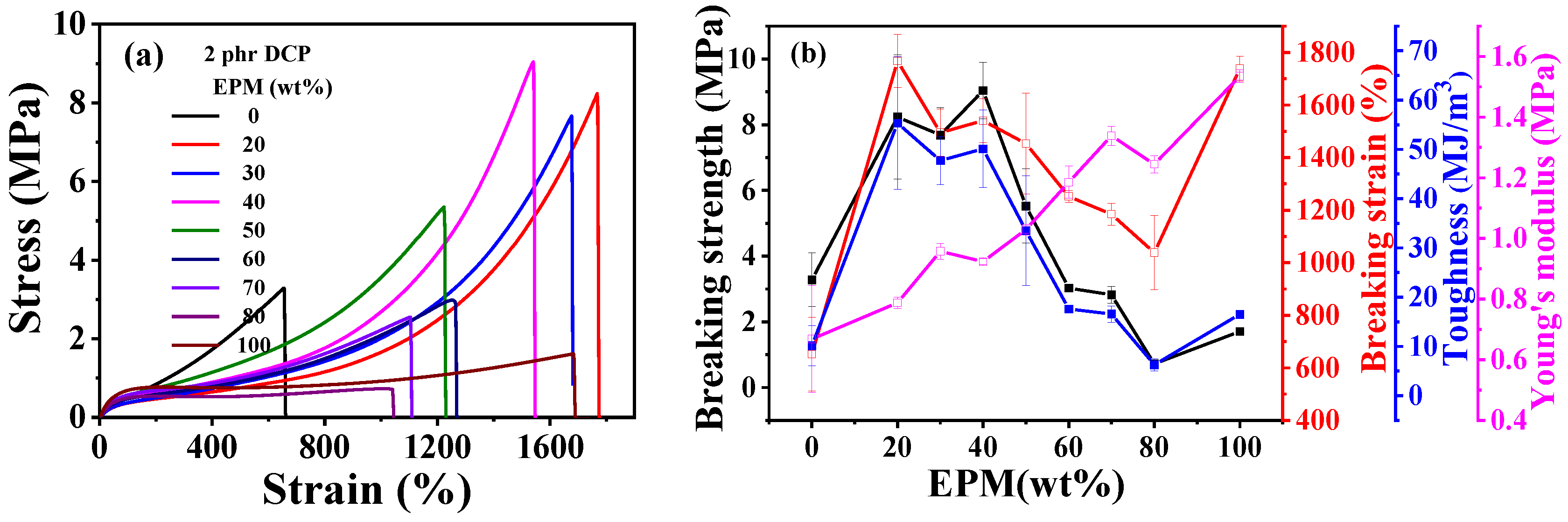

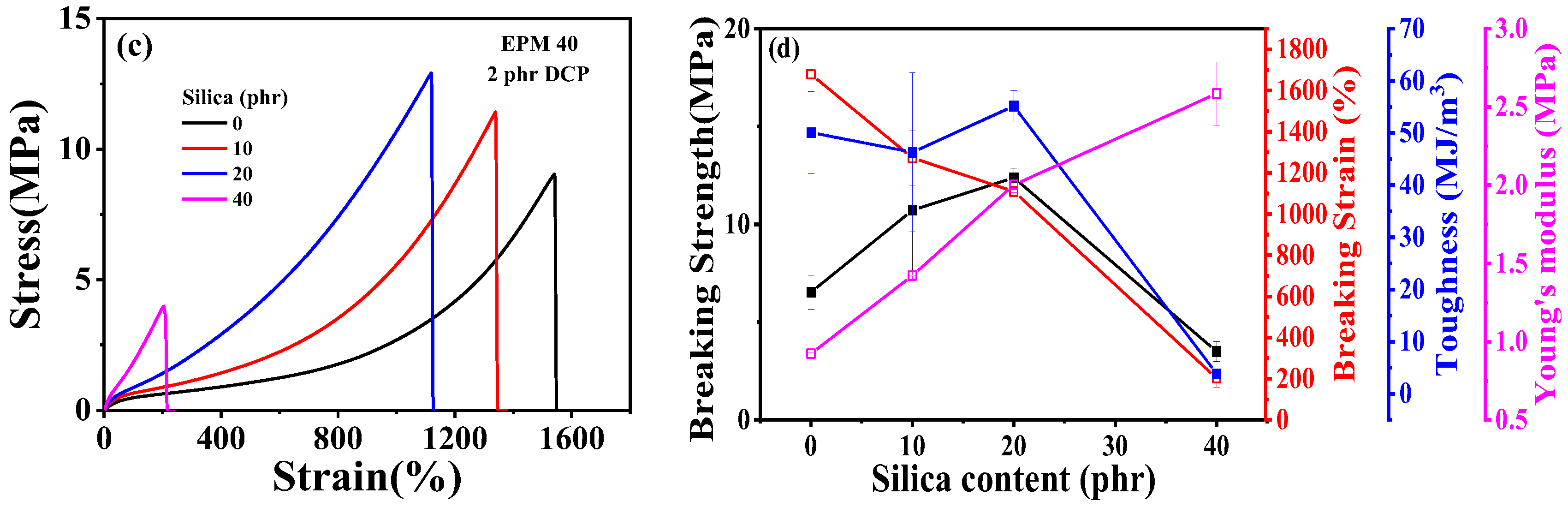

3.1. Mechanical Properties

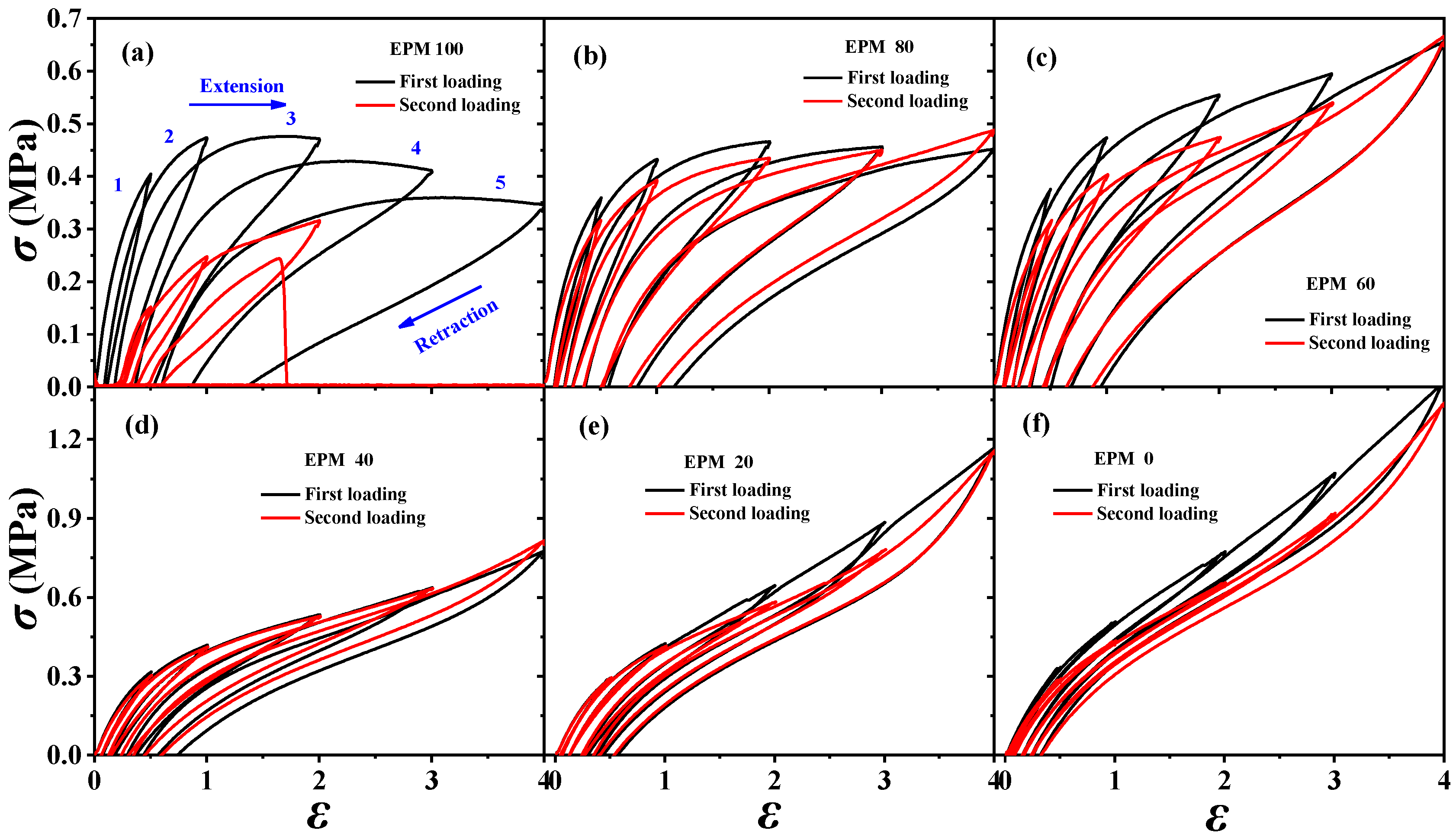

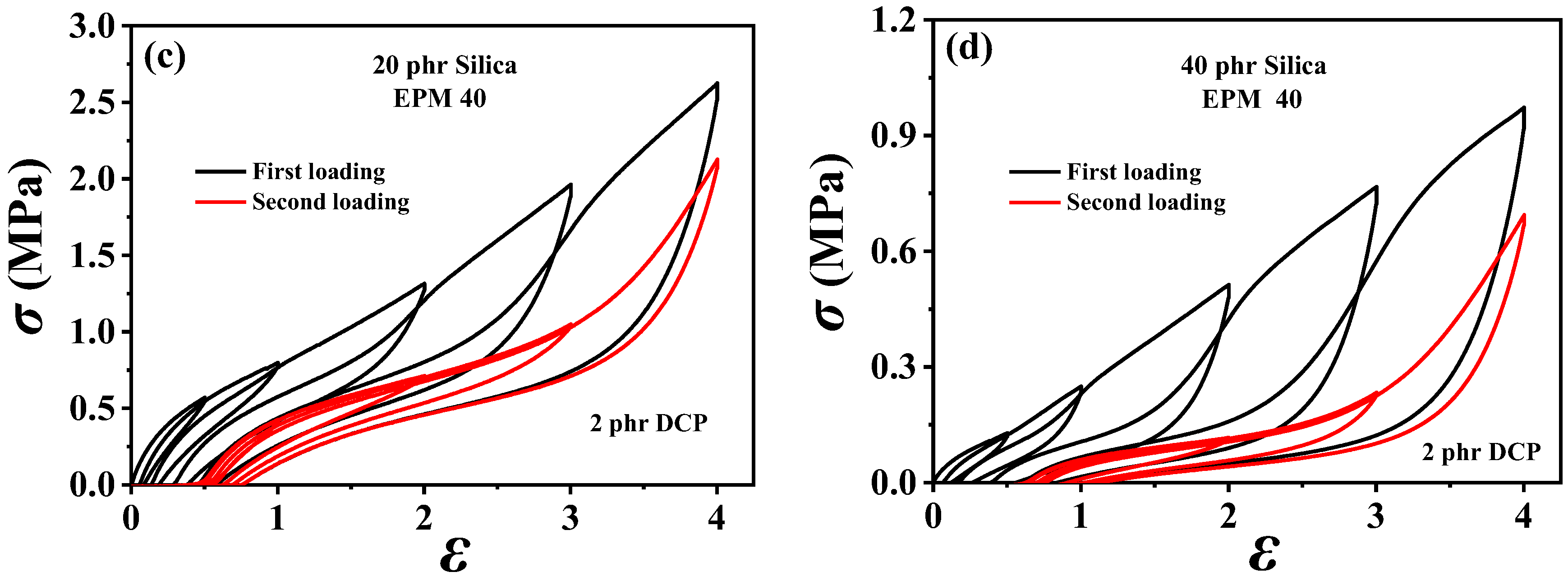

3.2. Hysteresis and Recovery Ability

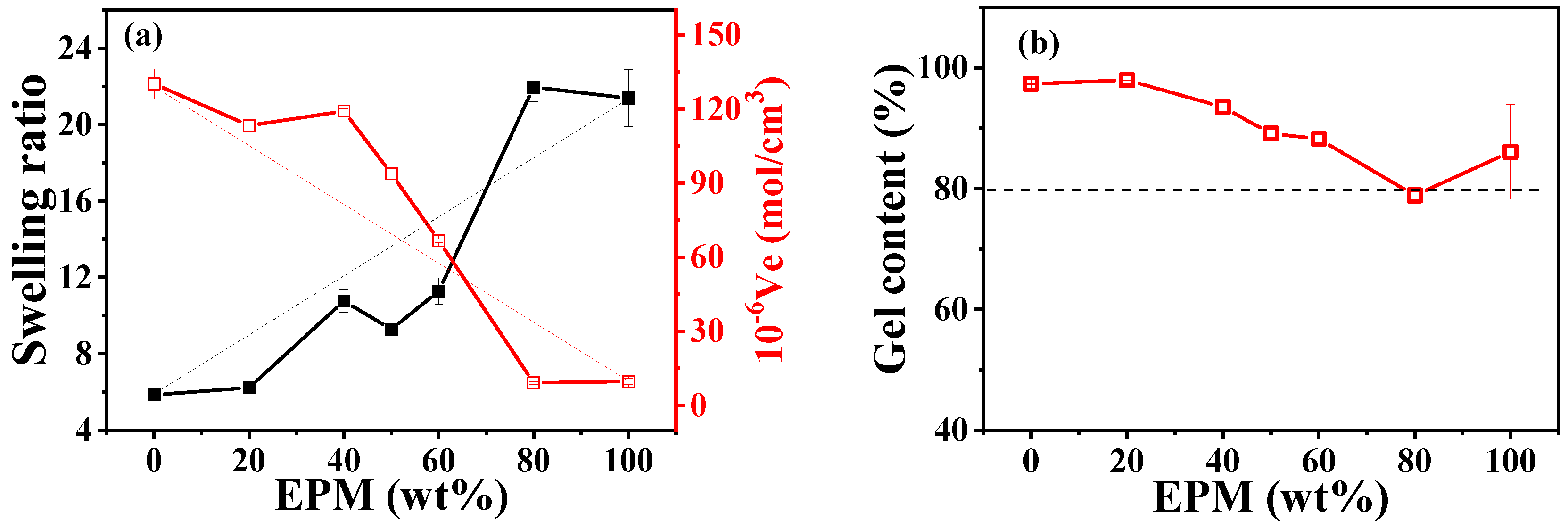

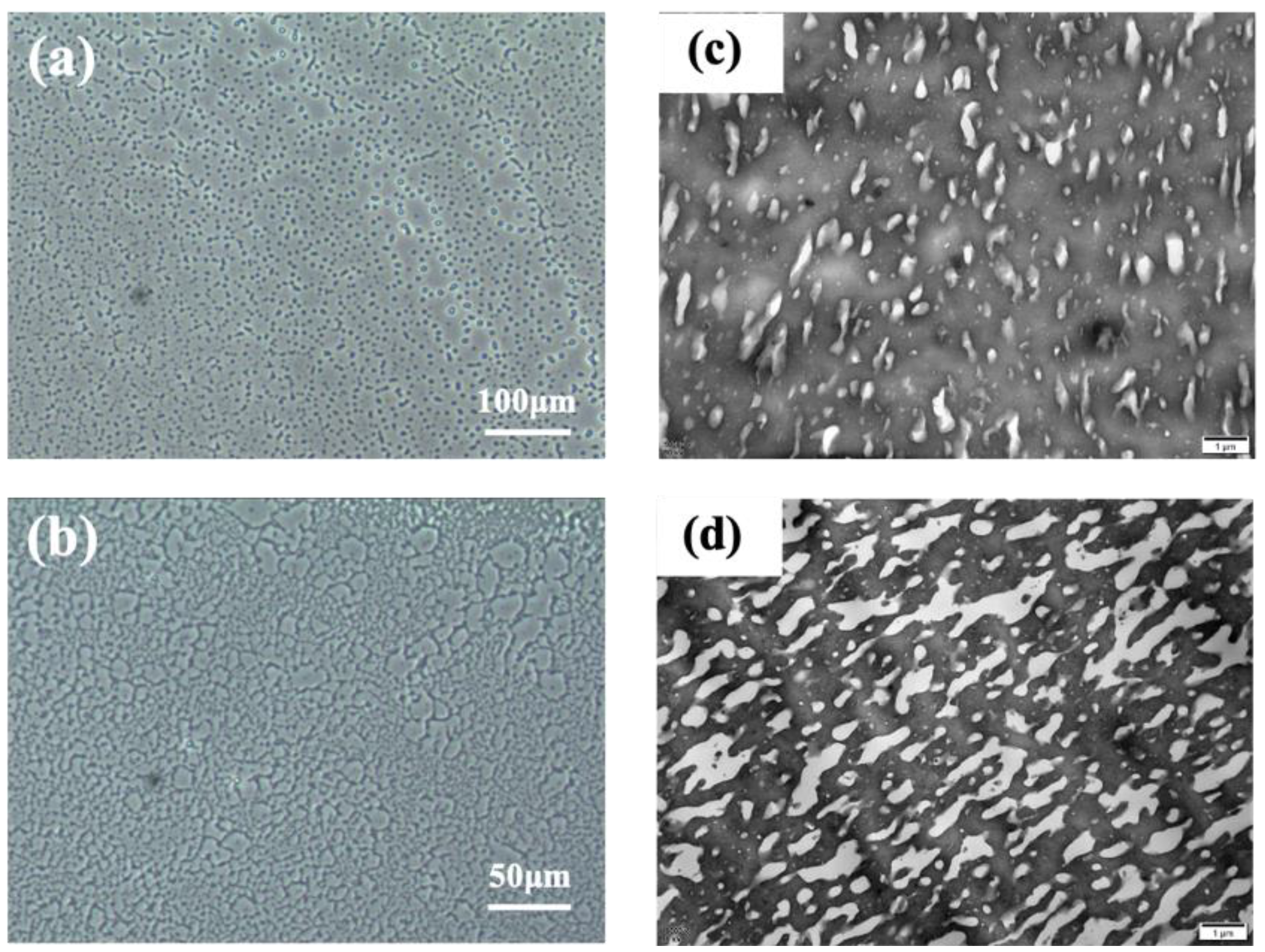

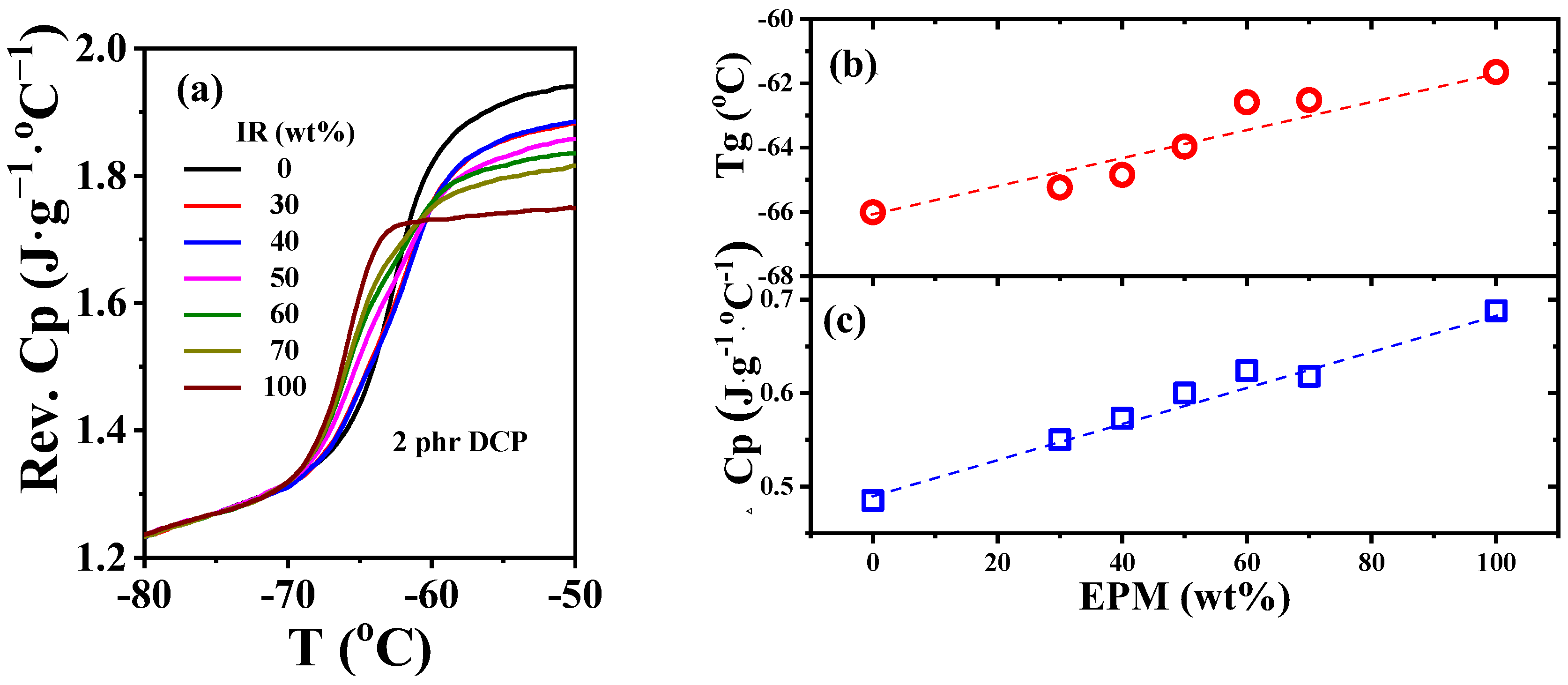

3.3. Crosslinking Structure and Microstructure

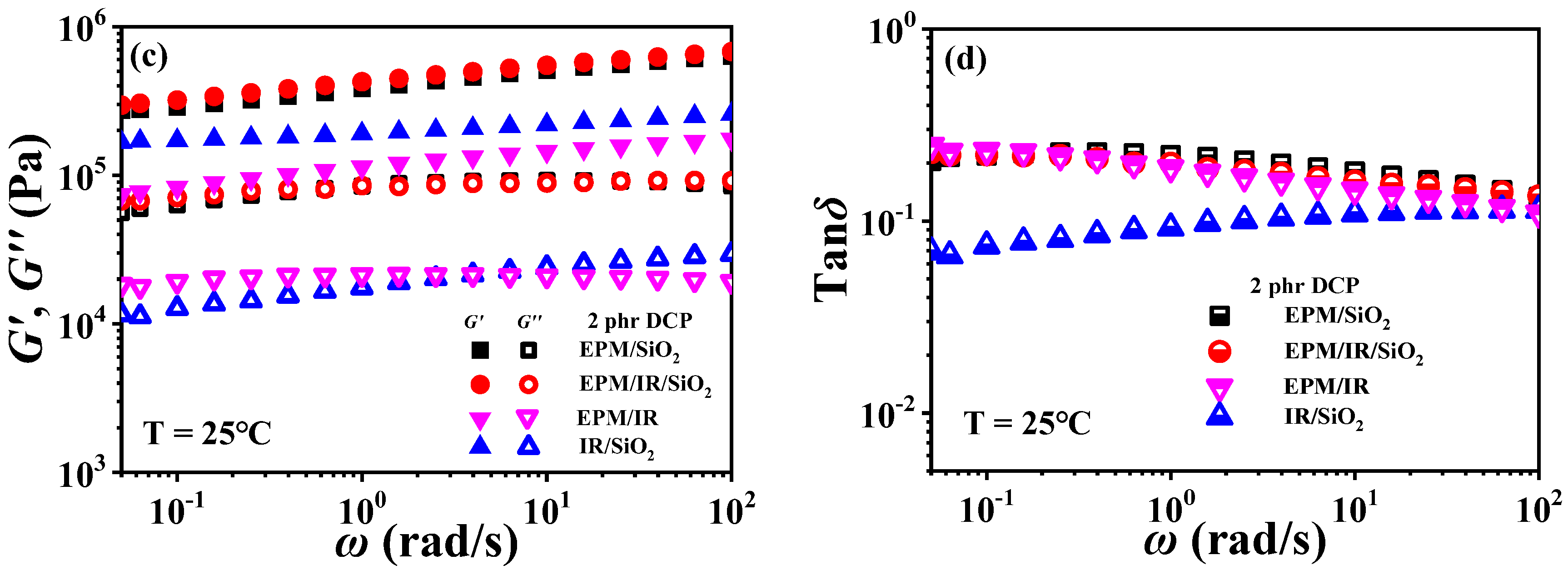

3.4. Dynamic Rheological Behavior

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ponnamma, D.; Thomas, S. Non-Linear Viscoelasticity of Rubber Composites and Nanocomposites. Springer International Publishing: Cham, Switzerland, 2014. [Google Scholar]

- Majeste, J.C.; Vincent, F. A kinetic model for silica-filled rubber reinforcement. J. Rheol. 2015, 59, 405–427. [Google Scholar] [CrossRef]

- Harwood, J.A.C.; Payne, A.R.; Whittaker, R.E. Stress-Softening and Reinforcement of Rubber. J. Macromol. Sci.-Phys. B 1971, 5, 473–486. [Google Scholar] [CrossRef]

- Merabia, S.; Sotta, P.; Long, D.R. A Microscopic Model for the Reinforcement and the Nonlinear Behavior of Filled Elastomers and Thermoplastic Elastomers (Payne and Mullins Effects). Macromolecules 2008, 41, 8252–8266. [Google Scholar] [CrossRef]

- Sodhani, D.; Reese, S. Finite Element-Based Micromechanical Modeling of Microstructure Morphology in Filler-Reinforced Elastomer. Macromolecules 2014, 47, 3161–3169. [Google Scholar] [CrossRef]

- Wu, J.; Cai, L.; Weitz, D.A. Tough Self-Healing Elastomers by Molecular Enforced Integration of Covalent and Reversible Networks. Adv. Mater. 2017, 29, 1702616. [Google Scholar] [CrossRef]

- Shangguan, Y.; Yang, J.; Zheng, Q. Rheology of nitrile rubber with hybrid crosslinked network composed of covalent bonding and hydrogen bonding. Rsc Adv. 2017, 7, 15978–15985. [Google Scholar] [CrossRef]

- Xia, X.; Wu, Z.; Wang, W.; Shangguan, Y.; Zheng, Q. A Facile and Environmentally Friendly Approach to Fabricate Hybrid Crosslinked Nitrile Butadiene Rubber with Comprehensively Improved Mechanical Performances by Incorporating Sacrificial Ionic Bonds. Polymer 2019, 161, 55–63. [Google Scholar] [CrossRef]

- Yanagisawa, Y.; Nan, Y.; Okuro, K.; Aida, T. Mechanically robust, readily repairable polymers via tailored noncovalent cross-linking. Science 2018, 359, 72–76. [Google Scholar] [CrossRef]

- Zhou, X.; Guo, B.; Zhang, L.; Hu, G. Progress in bio-inspired sacrificial bonds in artificial polymeric materials. Chem. Soc. Rev. 2017, 46, 6301–6329. [Google Scholar] [CrossRef]

- Zhang, Y.; Zuo, M.; Liu, T.; Song, Y.; Zheng, Q. Segmental dynamics and rheology of miscible poly(vinylidene fluoride)/poly(methyl methacrylate) (70/30 by weight) blend filled with titania or poly(methyl methacrylate)-grafted titania. Compos. Sci. Technol. 2016, 123, 39–48. [Google Scholar] [CrossRef]

- Song, Y.; Zheng, Q. Application of Two Phase Model to Linear Viscoelasticity of Reinforced Rubbers. Polymer 2011, 52, 593–596. [Google Scholar] [CrossRef]

- Sternstein, S.S.; Zhu, A.J. Reinforcement Mechanism of Nanofilled Polymer Melts as Elucidated by Nonlinear Viscoelastic Behavior. Macromolecules 2002, 35, 7262–7273. [Google Scholar] [CrossRef]

- Gong, L.; Yang, H.; Ke, Y.; Wang, S.; Yao, X. Investigation on vulcanization degree and residual stress on fabric rubber composites. Compos. Struct. 2019, 209, 472–480. [Google Scholar] [CrossRef]

- Liu, J.; Wang, S.; Tang, Z.; Huang, J.; Guo, B.; Huang, G. Bioinspired Engineering of Two Different Types of Sacrificial Bonds into Chemically Cross-Linked cis-1,4-Polyisoprene toward a High-Performance Elastomer. Macromolecules 2016, 49, 8593–8604. [Google Scholar] [CrossRef]

- Filippidi, E.; Cristiani, T.R.; Eisenbach, C.D.; Waite, J.H.; Israelachvili, J.N.; Ahn, B.K.; Valentine, M.T. Toughening Elastomers Using Mussel-Inspired Iron-Catechol Complexes. Science 2017, 358, 502–505. [Google Scholar] [CrossRef]

- Zhang, X.; Tang, Z.; Huang, J.; Lin, T.; Guo, B. Strikingly Improved Toughness of Nonpolar Rubber by Incorporating Sacrificial Network at Small Fraction. J. Polym. Sci. Pol. Phys. 2016, 54, 781–786. [Google Scholar] [CrossRef]

- Huang, J.; Tang, Z.; Yang, Z.; Guo, B. Bioinspired Interface Engineering in Elastomer/Graphene Composites by Constructing Sacrificial Metal-Ligand Bonds. Macromol. Rapid Commun. 2016, 37, 1040–1045. [Google Scholar] [CrossRef]

- Shin, H.; Kim, B.; Han, J.-G.; Lee, M.Y.; Park, J.K.; Cho, M. Fracture toughness enhancement of thermoplastic/epoxy blends by the plastic yield of toughening agents: A multiscale analysis. Compos. Sci. Technol. 2017, 145, 173–180. [Google Scholar] [CrossRef]

- Wang, W.; Shangguan, Y.; Zhao, L.; Yu, J.; He, L.; Tan, H.; Zheng, Q. The linear viscoelastic behaviors of nylon1212 blends toughened with elastomer. J. Appl. Polym. Sci. 2008, 108, 1744–1754. [Google Scholar] [CrossRef]

- Watanabe, H.; Matsumiya, Y.; Takada, J.; Sasaki, H.; Matsushima, Y.; Kuriyama, A.; Inoue, T.; Ahn, K.H.; Yu, W.; Krishnamoorti, R. Viscoelastic and dielectric behavior of a polyisoprene/poly(4-tert-butyl styrene) miscible blend. Macromolecules 2007, 40, 5389–5399. [Google Scholar] [CrossRef]

- Xu, Y.; Huang, C.; Yu, W.; Zhou, C. Evolution of concentration fluctuation during phase separation in polymer blends with viscoelastic asymmetry. Polymer 2015, 67, 101–110. [Google Scholar] [CrossRef]

- Huang, Q.; Liu, Y.; Li, S.; Zhu, M.; Hao, T.; Zhou, Z.; Nie, Y. Blending polar rubber with polyurethane to construct self-healing rubber with multiple hydrogen bond networks. Polymer 2022, 246, 124768. [Google Scholar] [CrossRef]

- Vijay, V.R.; Anitha, A.M.; Menon, A.R.R. Studies on blends of natural rubber and butadiene rubber containing silica—Organomodified kaolin hybrid filler systems. Polymer 2016, 89, 135–142. [Google Scholar] [CrossRef]

- Fuke, C.A.; Mahanwar, P.A.; Chowdhury, S.R. Modified ethylene-propylene-diene elastomer (EPDM)-contained silicone rubber/ethylene-propylene-diene elastomer (EPDM) blends: Effect of composition and electron beam crosslinking on mechanical, heat shrinkability, electrical, and morphological properties. J. Appl. Polym. Sci. 2019, 136, 47787. [Google Scholar] [CrossRef]

- Rehman, A.; Saeed, F.; Shuib, R.K. Characterisation and properties of polyisoprene (IR)/polybutadiene (BR) rubber blends-reinforced silanised silica nano-filler. J. Rubber Res. 2022, 25, 223–230. [Google Scholar] [CrossRef]

- Ostad-Movahed, S.; Yasin, K.A.; Ansarifar, A.; Song, M.; Hameed, S. Comparing Effects of Silanized Silica Nanofiller on the Crosslinking and Mechanical Properties of Natural Rubber and Synthetic Polyisoprene. J. Appl. Polym. Sci. 2008, 109, 869–881. [Google Scholar] [CrossRef]

- Li, J.; Lu, Y.; Jin, Z.; Zhang, L. Influence of interfacial compatibilizer, silane modification, and filler hybrid on the performance of NR/NBR blends. J. Appl. Polym. Sci. 2019, 136, 47421. [Google Scholar] [CrossRef]

- Li, J.C.; Zhang, H.S.; Zhao, X.Y.; Jian, J.G.; Wu, Y.X.; Lu, Y.L.; Zhang, L.Q.; Nishi, T. Development of high damping natural rubber/butyl rubber composites compatibilized by isobutylene-isoprene block copolymer for isolation bearing. Express Polym. Lett. 2019, 13, 686–696. [Google Scholar] [CrossRef]

- Xanthos, M.; Dagli, S.S. Compatibilization of Polymer Blends by Reactive Processing. Polym. Eng. Sci. 1991, 31, 929–935. [Google Scholar] [CrossRef]

- Yu, W.; Li, R.; Zhou, C. Rheology and phase separation of polymer blends with weak dynamic asymmetry. Polymer 2011, 52, 2693–2700. [Google Scholar] [CrossRef]

- Sun, Z.B.; Zhang, Y.F.; Shao, H.F.; He, A.H. In situ reactive compatibilization of polypropylene/trans-1,4-poly(isoprene-co-butadiene) rubber (TBIR) blends with balanced toughness and stiffness via dynamic vulcanization. React. Funct. Polym. 2019, 142, 60–68. [Google Scholar] [CrossRef]

- Zhao, R.F.; Dai, G. Mechanical property and morphology comparison between the two blends poly(propylene)/ethylene-propylene-diene monomer elastomer and poly(propylene)/maleic anhydride-ethylene-propylene-diene monomer. J. Appl. Polym. Sci. 2002, 86, 2486–2491. [Google Scholar] [CrossRef]

- Bao, S.H.; Zhu, L.H.; Wang, H.B.; Luo, H.L.; Chen, F.; Yu, W.W.; Zhang, Z.Y.; Zhuang, X.W.; Wu, Q.; Shangguan, Y.G.; et al. Synergistic effect of compound rubber and SiO2 nanoparticles on low-temperature toughening and balanced stiffness-toughness of random copolymer polypropylene nanocomposites. Compos. Sci. Technol. 2023, 242, 110210. [Google Scholar] [CrossRef]

- Jia, E.W.; Shangguan, Y.G.; Xiong, J.W.; Chen, F.; Zheng, Q. Fabrication of polypropylene blends with excellent low-temperature toughness and balanced toughness-rigidity by a combination of EPR and SEEPS. J. Appl. Polym. Sci. 2018, 135, 45714. [Google Scholar] [CrossRef]

- Kim, D.K.; Lee, S.H.; Hong, S.K.; Han, S.W.; Lee, D.H.; Yu, S. Low-Temperature-Toughened Polypropylene Blends with Highly Packed Elastomeric Domains. Acs. Appl. Polym. Mater. 2022, 4, 7834–7840. [Google Scholar] [CrossRef]

- Zhao, S.J.; Shangguan, Y.G.; Wu, Q.; Li, Z.J.; Zheng, Q. Toughening Mechanism of PP/EPR/SiO2 Composites with Superior Low-Temperature Toughness. Compos. Sci. Technol. 2021, 207, 108691. [Google Scholar] [CrossRef]

- Flory, P.J.; Rehner, J. Statistical Mechanics of Cross-Linked Polymer Networks I. Rubberlike Elasticity. J. Chem. Phys. 1943, 11, 512–520. [Google Scholar] [CrossRef]

- Benmouna, F.; Maschke, U.; Coqueret, X.; Benmouna, M. Equilibrium phase behavior of polymer and liquid crystal blends. Macromol. Theory Simul. 2000, 9, 215–229. [Google Scholar] [CrossRef]

- Albouy, P.-A.; Vieyres, A.; Perez-Aparicio, R.; Sanseau, O.; Sotta, P. The impact of strain-induced crystallization on strain during mechanical cycling of cross-linked natural rubber. Polymer 2014, 55, 4022–4031. [Google Scholar] [CrossRef]

- Toki, S.; Takagi, R.; Ito, M.; Hsiao, B.S. Rupture, orientation and strain-induced crystallization of polymer chain and network in vulcanized polyisoprene during uniaxial deformation by in-situ Electron Spin Resonance (ESR) and synchrotron X-ray analysis. Polymer 2011, 52, 2453–2459. [Google Scholar] [CrossRef]

- Che, J.; Burger, C.; Toki, S.; Rong, L.; Hsiao, B.S.; Amnuaypornsri, S.; Sakdapipanich, J. Crystal and Crystallites Structure of Natural Rubber and Synthetic cis-1,4-Polyisoprene by a New Two Dimensional Wide Angle X-ray Diffraction Simulation Method. I. Strain-Induced Crystallization. Macromolecules 2013, 46, 4520–4528. [Google Scholar] [CrossRef]

- Diani, J.; Brieu, M.; Gilormini, P. Observation and modeling of the anisotropic visco-hyperelastic behavior of a rubberlike material. Int. J. Solids Struct. 2006, 43, 3044–3056. [Google Scholar] [CrossRef]

- Hanson, D.E.; Hawley, M.; Houlton, R.; Chitanvis, K.; Rae, P.; Orler, E.B.; Wrobleski, D.A. Stress softening experiments in silica-filled polydimethylsiloxane provide insight into a mechanism for the Mullins effect. Polymer 2005, 46, 10989–10995. [Google Scholar] [CrossRef]

- Ciardelli, F.; Dossi, S.; Galanti, A.; Magri, A.; Riolo, S. Molecular evolution during dynamic vulcanization of polyolefin mixtures for lead-free thermoplastic vulcanized. Polym. Adv. Technol. 2020, 31, 864–872. [Google Scholar] [CrossRef]

- Passaglia, E.; Coiai, S.; Augier, S. Control of macromolecular architecture during the reactive functionalization in the melt of olefin polymers. Prog. Polym. Sci. 2009, 34, 911–947. [Google Scholar] [CrossRef]

- Setua, D.K.; White, J.L. Flow Visualization of the Influence of Compatibilizing Agents on the Mixing of Elastomer Blends and the Effect on Phase Morphology. Polym. Eng. Sci. 1991, 31, 1742–1754. [Google Scholar] [CrossRef]

- Setua, D.K.; Pandey, K.N.; Saxena, A.K.; Mathur, G.N. Characterization of elastomer blend and compatibility. J. Appl. Polym. Sci. 1999, 74, 480–489. [Google Scholar] [CrossRef]

- Mansilla, M.A.; Silva, L.; Salgueiro, W.; Marzocca, A.J.; Somoza, A. A Study about the Structure of Vulcanized Natural Rubber/Styrene Butadiene Rubber Blends and the Glass Transition Behavior. J. Appl. Polym. Sci. 2012, 125, 992–999. [Google Scholar] [CrossRef]

- Saad, A.L.G.; El-Sabbagh, S. Compatibility studies on some polymer blend systems by electrical and mechanical techniques. J. Appl. Polym. Sci. 2001, 79, 60–71. [Google Scholar] [CrossRef]

- Sebenik, U.; Zupancic-Valant, A.; Krajnc, M. Investigation of rubber-rubber blends miscibility. Polym. Eng. Sci. 2006, 46, 1649–1659. [Google Scholar] [CrossRef]

- Hourston, D.J.; Song, M. Quantitative characterization of interfaces in rubber-rubber blends by means of modulated-temperature DSC. J. Appl. Polym. Sci. 2000, 76, 1791–1798. [Google Scholar] [CrossRef]

- Hourston, D.J.; Song, M.; Hammiche, A.; Pollock, H.M.; Reading, M. Modulated differential scanning calorimetry.6. Thermal characterization of multicomponent polymers and interfaces. Polymer 1997, 38, 1–7. [Google Scholar] [CrossRef]

- Song, M.; Hammiche, A.; Pollock, H.M.; Hourston, D.J.; Reading, M. Modulated Differential Scanning Calorimetry.1. A Study of the Glass-Transition Behavior of Blends of Poly(Methyl Methacrylate) and Poly(Styrene-Co-Acrylonitrile). Polymer 1995, 36, 3313–3316. [Google Scholar] [CrossRef]

- Zhu, Z.Y.; Thompson, T.; Wang, S.Q.; von Meerwall, E.D.; Halasa, A. Investigating Linear and Nonlinear Viscoelastic Behavior Using Model Silica-Particle-Filled Polybutadiene. Macromolecules 2005, 38, 8816–8824. [Google Scholar] [CrossRef]

- Scholtens, B.J.R. Linear Thermoviscoelasticity and Characterization of Noncrystalline Epdm Rubber Networks. J. Polym. Sci. Pol. Phys. 1984, 22, 317–344. [Google Scholar] [CrossRef]

- Graessley, W.W.; Edwards, S.F. Entanglement Interactions in Polymers and the Chain Contour Concentration. Polymer 1981, 22, 1329–1334. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, R.; Xiao, R.; Xia, X.; Shangguan, Y.; Zheng, Q. Ethylene-Propylene-Methylene/Isoprene Rubber/SiO2 Nanocomposites with Enhanced Mechanical Performances and Deformation Recovery Ability by a Combination of Synchronously Vulcanizing and Nanoparticle Reinforcement. Polymers 2024, 16, 2809. https://doi.org/10.3390/polym16192809

Hu R, Xiao R, Xia X, Shangguan Y, Zheng Q. Ethylene-Propylene-Methylene/Isoprene Rubber/SiO2 Nanocomposites with Enhanced Mechanical Performances and Deformation Recovery Ability by a Combination of Synchronously Vulcanizing and Nanoparticle Reinforcement. Polymers. 2024; 16(19):2809. https://doi.org/10.3390/polym16192809

Chicago/Turabian StyleHu, Rongyan, Ran Xiao, Xinxin Xia, Yonggang Shangguan, and Qiang Zheng. 2024. "Ethylene-Propylene-Methylene/Isoprene Rubber/SiO2 Nanocomposites with Enhanced Mechanical Performances and Deformation Recovery Ability by a Combination of Synchronously Vulcanizing and Nanoparticle Reinforcement" Polymers 16, no. 19: 2809. https://doi.org/10.3390/polym16192809

APA StyleHu, R., Xiao, R., Xia, X., Shangguan, Y., & Zheng, Q. (2024). Ethylene-Propylene-Methylene/Isoprene Rubber/SiO2 Nanocomposites with Enhanced Mechanical Performances and Deformation Recovery Ability by a Combination of Synchronously Vulcanizing and Nanoparticle Reinforcement. Polymers, 16(19), 2809. https://doi.org/10.3390/polym16192809