Isolation and Structural Characterization of Natural Deep Eutectic Solvent Lignin from Brewer’s Spent Grains

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Materials and Chemicals

2.2. BSG Characterization

2.3. Microwave-Assisted BSG Fractionation Using NaDES

2.4. Lignin Characterization

3. Results and Discussion

3.1. BSG Chemical Composition

3.2. Thermal Behavior of NaDES

3.3. Lignin Fraction Isolation

3.3.1. Lignin Yield and Purity: Effect of Fractionation Temperature

3.3.2. Lignin Yield and Purity: Effect of Fractionation Duration

3.4. Extracted NaDES-Lignin Characterization

3.4.1. Antioxidant Activity

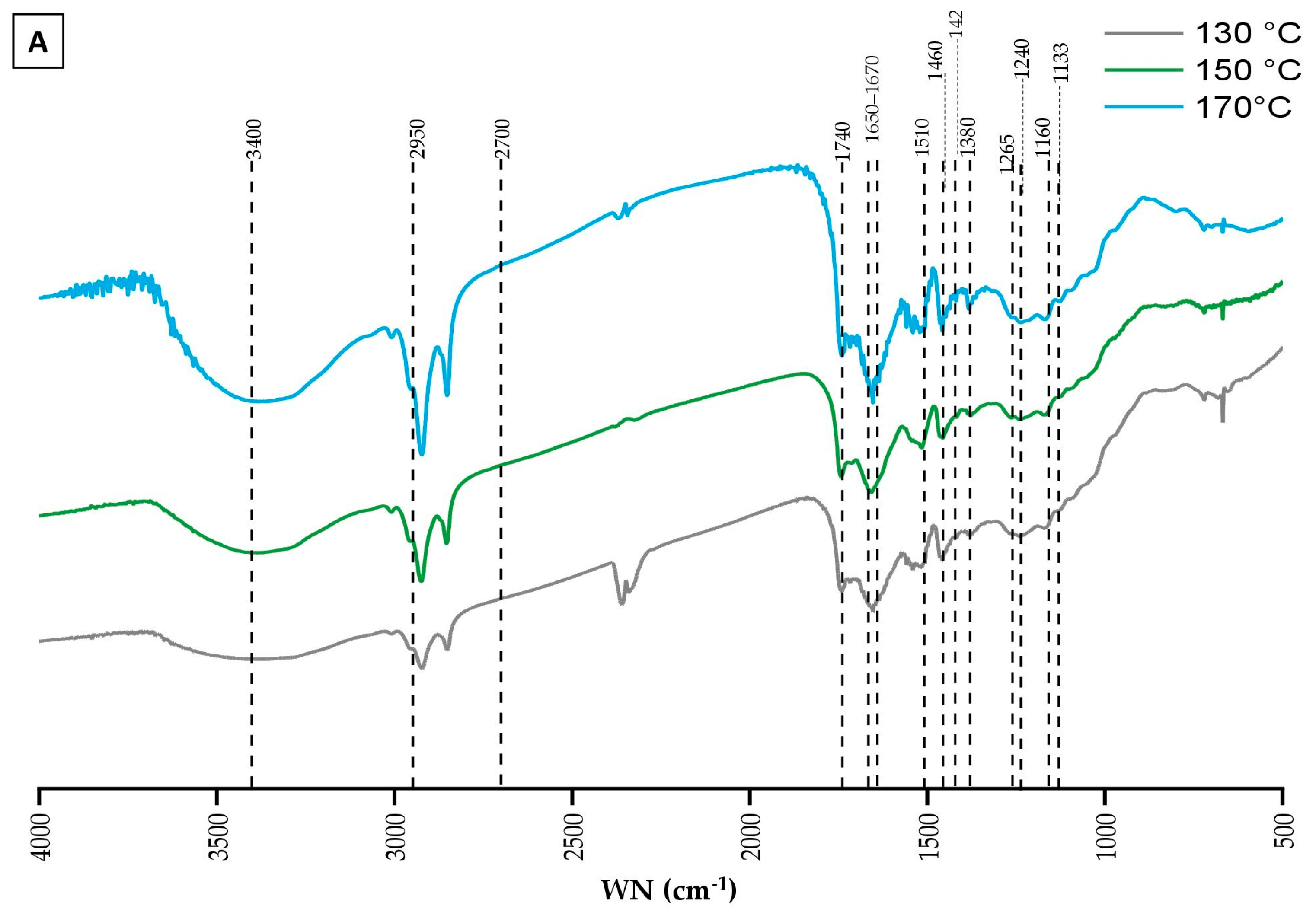

3.4.2. FTIR Lignin Characterization

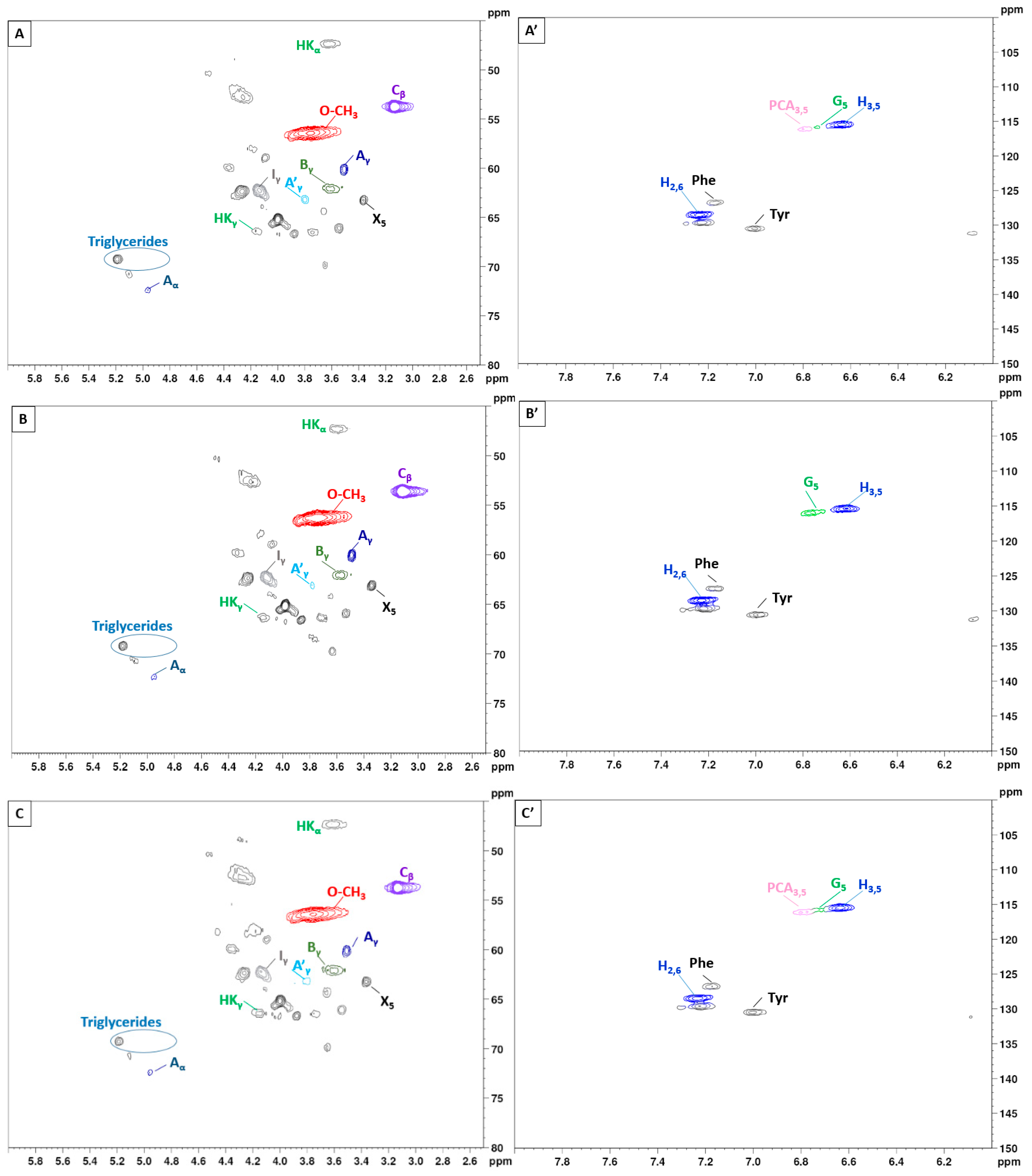

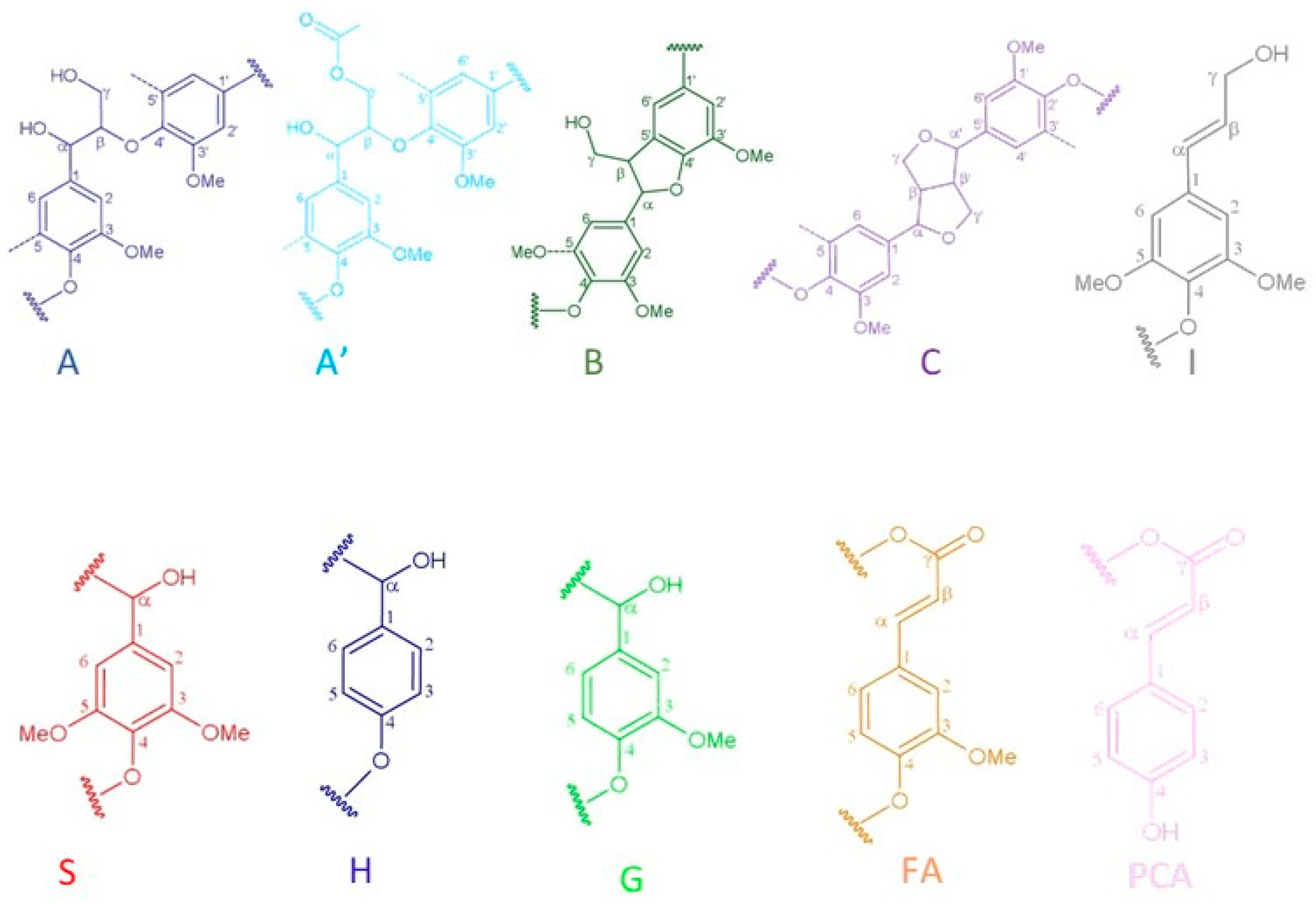

3.4.3. 2D-HSQC NMR Characterization

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Puligundla, P.; Mok, C. Recent Advances in Biotechnological Valorization of Brewers’ Spent Grain. Food Sci. Biotechnol. 2021, 30, 341–353. [Google Scholar] [CrossRef] [PubMed]

- Sanches, M.A.R.; Augusto, P.E.D.; Polachini, T.C.; Telis-Romero, J. Water Sorption Properties of Brewer’s Spent Grain: A Study Aimed at Its Stabilization for Further Conversion into Value-Added Products. Biomass Bioenergy 2023, 170, 106718. [Google Scholar] [CrossRef]

- Sanches, M.A.R.; Stochi, V.A.L.; Borges-Machado, A.L.; Augusto, P.E.D.; Polachini, T.C.; Telis-Romero, J. Valorization of Brewer’s Spent Grains (BSG) through Alkaline Hydrogen Peroxide Processing: Effect on Composition, Structure and Rheological Properties. Food Bioprod. Process. 2024, 147, 239–250. [Google Scholar] [CrossRef]

- Statista. Beer Production Worldwide from 1998 to 2022; Statista: New York, NY, USA, 2023. [Google Scholar]

- Lynch, K.M.; Steffen, E.J.; Arendt, E.K. Brewers’ Spent Grain: A Review with an Emphasis on Food and Health. J. Inst. Brew. 2016, 122, 553–568. [Google Scholar] [CrossRef]

- Akermann, A.; Weiermüller, J.; Christmann, J.; Guirande, L.; Glaser, G.; Knaus, A.; Ulber, R. Brewers’ Spent Grain Liquor as a Feedstock for Lactate Production with Lactobacillus delbrueckii Subsp. Lactis. Eng. Life Sci. 2020, 20, 168–180. [Google Scholar] [CrossRef]

- Chetrariu, A.; Dabija, A. Brewer’s Spent Grains: Possibilities of Valorization, a Review. Appl. Sci. 2020, 10, 5619. [Google Scholar] [CrossRef]

- Mitri, S.; Salameh, S.-J.; Khelfa, A.; Leonard, E.; Maroun, R.G.; Louka, N.; Koubaa, M. Valorization of Brewers’ Spent Grains: Pretreatments and Fermentation, a Review. Fermentation 2022, 8, 50. [Google Scholar] [CrossRef]

- Kavalopoulos, M.; Stoumpou, V.; Christofi, A.; Mai, S.; Barampouti, E.M.; Moustakas, K.; Malamis, D.; Loizidou, M. Sustainable Valorisation Pathways Mitigating Environmental Pollution from Brewers’ Spent Grains. Environ. Pollut. 2021, 270, 116069. [Google Scholar] [CrossRef]

- Amore, A.; Parameswaran, B.; Kumar, R.; Birolo, L.; Vinciguerra, R.; Marcolongo, L.; Ionata, E.; La Cara, F.; Pandey, A.; Faraco, V. Application of a New Xylanase Activity from Bacillus amyloliquefaciens XR44A in Brewer’s Spent Grain Saccharification. J. Chem. Technol. Biotechnol. 2015, 90, 573–581. [Google Scholar] [CrossRef]

- Nazzaro, F.; Fratianni, F.; Ombra, M.N.; d’Acierno, A.; Coppola, R. Recovery of Biomolecules of High Benefit from Food Waste. Curr. Opin. Food Sci. 2018, 22, 43–54. [Google Scholar] [CrossRef]

- Pabbathi, N.P.P.; Velidandi, A.; Pogula, S.; Gandam, P.K.; Baadhe, R.R.; Sharma, M.; Sirohi, R.; Thakur, V.K.; Gupta, V.K. Brewer’s Spent Grains-Based Biorefineries: A Critical Review. Fuel 2022, 317, 123435. [Google Scholar] [CrossRef]

- Mussatto, S.I. Brewer’s Spent Grain: A Valuable Feedstock for Industrial Applications: Brewer’s Spent Grain and Its Potential Applications. J. Sci. Food Agric. 2014, 94, 1264–1275. [Google Scholar] [CrossRef] [PubMed]

- Rencoret, J.; Prinsen, P.; Gutiérrez, A.; Martínez, Á.T.; Del Río, J.C. Isolation and Structural Characterization of the Milled Wood Lignin, Dioxane Lignin, and Cellulolytic Lignin Preparations from Brewer’s Spent Grain. J. Agric. Food Chem. 2015, 63, 603–613. [Google Scholar] [CrossRef] [PubMed]

- Aliyu, S.; Bala, M. Brewer’s Spent Grain: A Review of Its Potentials and Applications. Afr. J. Biotechnol. 2011, 10, 324–331. [Google Scholar]

- Wilkinson, S.; Smart, K.A.; Cook, D.J. Optimisation of Alkaline Reagent Based Chemical Pre-Treatment of Brewers Spent Grains for Bioethanol Production. Ind. Crops Prod. 2014, 62, 219–227. [Google Scholar] [CrossRef]

- Lisý, A.; Ház, A.; Nadányi, R.; Jablonský, M.; Šurina, I. About Hydrophobicity of Lignin: A Review of Selected Chemical Methods for Lignin Valorisation in Biopolymer Production. Energies 2022, 15, 6213. [Google Scholar] [CrossRef]

- Tobimatsu, Y.; Schuetz, M. Lignin Polymerization: How Do Plants Manage the Chemistry so Well? Curr. Opin. Biotechnol. 2019, 56, 75–81. [Google Scholar] [CrossRef]

- Huang, J.; Fu, S.; Gan, L. (Eds.) Chapter 2—Structure and Characteristics of Lignin. In Lignin Chemistry and Applications; Elsevier: Amsterdam, The Netherlands, 2019; pp. 25–50. ISBN 978-0-12-813941-7. [Google Scholar]

- Md Salleh, M.; Mohd Noor, R.; Yahya, A.; Abd-Aziz, S.; Hussin, H. Potential Applications of Lignin and Its Derivatives from Lignocellulosic Biomass—A Review. J. Teknol. 2023, 85, 43–59. [Google Scholar] [CrossRef]

- Karmanov, A.P.; Ermakova, A.V.; Raskosha, O.V.; Bashlykova, L.A.; Rachkova, N.G.; Kocheva, L.S. Structure and Biomedical Properties of Lignins (Review). Chem. Plant Raw Mater. 2023, 5–28. [Google Scholar] [CrossRef]

- Roy, S.; Priyadarshi, R.; Purohit, S.D.; Rhim, J.-W. Antimicrobial and Antioxidant Properties of Lignin and Its Composites. In Lignin-Based Materials; Joseph, K., Wilson, R., George, G., Appukuttan, S., Eds.; The Royal Society of Chemistry: Piccadilly, London, UK, 2023; pp. 106–129. ISBN 978-1-83916-535-1. [Google Scholar]

- Radotić, K.; Spasojević, D.; Zmejkoski, D. Lignin-Based Materials for Biomedical Applications: Basic Requirements and Properties. In Lignin-Based Materials; Joseph, K., Wilson, R., George, G., Appukuttan, S., Eds.; The Royal Society of Chemistry: Piccadilly, London, UK, 2023; pp. 85–105. ISBN 978-1-83916-535-1. [Google Scholar]

- Mishra, M. Lignin as a Biomaterial for Bioimaging. In Lignin-Based Materials; Joseph, K., Wilson, R., George, G., Appukuttan, S., Eds.; The Royal Society of Chemistry: Piccadilly, London, UK, 2023; pp. 223–246. ISBN 978-1-83916-535-1. [Google Scholar]

- Sipponen, M.H.; Liu, L. Advances in Preparation and Applications of Lignin Nanoparticles. In Lignin Chemistry; Liao, Y., Sels, B.F., Eds.; Wiley: Hoboken, NJ, USA, 2024; pp. 369–400. ISBN 978-3-527-35107-7. [Google Scholar]

- Bajpai, P. Depolymerization of Lignin to Produce Value Added Chemicals, 1st ed.; Wiley: Hoboken, NJ, USA, 2023; ISBN 978-1-394-19163-5. [Google Scholar]

- Nawaz, H.; Zhang, X.; Chen, S.; Li, X.; Zhang, X.; Shabbir, I.; Xu, F. Recent Developments in Lignin-Based Fluorescent Materials. Int. J. Biol. Macromol. 2024, 258, 128737. [Google Scholar] [CrossRef]

- Arif Hakimi Saadon, S.Z.; Osman, N.B.; Yusup, S. Pretreatment of Fiber-Based Biomass Material for Lignin Extraction. In Value-Chain of Biofuels; Elsevier: Amsterdam, The Netherlands, 2022; pp. 105–135. ISBN 978-0-12-824388-6. [Google Scholar]

- Perna, F.M.; Vitale, P.; Capriati, V. Deep Eutectic Solvents and Their Applications as Green Solvents. Curr. Opin. Green. Sustain. Chem. 2020, 21, 27–33. [Google Scholar] [CrossRef]

- López-Linares, J.C.; García-Cubero, M.T.; Lucas, S.; González-Benito, G.; Coca, M. Microwave Assisted Hydrothermal as Greener Pretreatment of Brewer’s Spent Grains for Biobutanol Production. Chem. Eng. J. 2019, 368, 1045–1055. [Google Scholar] [CrossRef]

- Singh, V.; Mittal, N.; Dhukia, S.; Atri, A.K.; Singh, V. Novel Ternary Based Natural Deep Eutectic Solvents (NADES) for Sustainable Extraction of Lignin Nanoparticles from Waste Pinus Roxburghii Needles: A Green Approach. Sustain. Chem. Pharm. 2024, 39, 101518. [Google Scholar] [CrossRef]

- Beaucamp, A.; Muddasar, M.; Amiinu, I.S.; Moraes Leite, M.; Culebras, M.; Latha, K.; Gutiérrez, M.C.; Rodriguez-Padron, D.; Del Monte, F.; Kennedy, T.; et al. Lignin for Energy Applications—State of the Art, Life Cycle, Technoeconomic Analysis and Future Trends. Green. Chem. 2022, 24, 8193–8226. [Google Scholar] [CrossRef]

- Meraj, A.; Singh, S.P.; Jawaid, M.; Nasef, M.M.; Alomar, T.S.; AlMasoud, N. A Review on Eco-Friendly Isolation of Lignin by Natural Deep Eutectic Solvents from Agricultural Wastes. J. Polym. Environ. 2023, 31, 3283–3316. [Google Scholar] [CrossRef]

- Grillo, G.; Calcio Gaudino, E.; Rosa, R.; Leonelli, C.; Timonina, A.; Grygiškis, S.; Tabasso, S.; Cravotto, G. Green Deep Eutectic Solvents for Microwave-Assisted Biomass Delignification and Valorisation. Molecules 2021, 26, 798. [Google Scholar] [CrossRef]

- Chen, Z.; Ragauskas, A.; Wan, C. Lignin Extraction and Upgrading Using Deep Eutectic Solvents. Ind. Crops Prod. 2020, 147, 112241. [Google Scholar] [CrossRef]

- Yue, X.; Suopajärvi, T.; Mankinen, O.; Mikola, M.; Mikkelson, A.; Ahola, J.; Hiltunen, S.; Komulainen, S.; Kantola, A.M.; Telkki, V.-V.; et al. Comparison of Lignin Fractions Isolated from Wheat Straw Using Alkaline and Acidic Deep Eutectic Solvents. J. Agric. Food Chem. 2020, 68, 15074–15084. [Google Scholar] [CrossRef]

- Han, H.; Chen, L.; Zhao, J.; Yu, H.; Wang, Y.; Yan, H.; Wang, Y.; Xue, Z.; Mu, T. Biomass-Based Acidic Deep Eutectic Solvents for Efficient Dissolution of Lignin: Towards Performance and Mechanism Elucidation. Acta Phys. Chim. Sin. 2023, 39, 2212043. [Google Scholar] [CrossRef]

- Chen, H.; Wang, A.; Yan, C.; Liu, S.; Li, L.; Wu, Q.; Liu, Y.; Liu, Y.; Nie, G.; Nie, S.; et al. Study on the Solubility of Industrial Lignin in Choline Chloride-Based Deep Eutectic Solvents. Sustainability 2023, 15, 7118. [Google Scholar] [CrossRef]

- Li, C.; Huang, C.; Zhao, Y.; Zheng, C.; Su, H.; Zhang, L.; Luo, W.; Zhao, H.; Wang, S.; Huang, L.-J. Effect of Choline-Based Deep Eutectic Solvent Pretreatment on the Structure of Cellulose and Lignin in Bagasse. Processes 2021, 9, 384. [Google Scholar] [CrossRef]

- Kohli, K.; Katuwal, S.; Biswas, A.; Sharma, B.K. Effective Delignification of Lignocellulosic Biomass by Microwave Assisted Deep Eutectic Solvents. Bioresour. Technol. 2020, 303, 122897. [Google Scholar] [CrossRef] [PubMed]

- Chio, C.; Sain, M.; Qin, W. Lignin Utilization: A Review of Lignin Depolymerization from Various Aspects. Renew. Sustain. Energy Rev. 2019, 107, 232–249. [Google Scholar] [CrossRef]

- Liu, L.-Y.; Patankar, S.C.; Chandra, R.P.; Sathitsuksanoh, N.; Saddler, J.N.; Renneckar, S. Valorization of Bark Using Ethanol–Water Organosolv Treatment: Isolation and Characterization of Crude Lignin. ACS Sustain. Chem. Eng. 2020, 8, 4745–4754. [Google Scholar] [CrossRef]

- Liu, Y.; Chen, W.; Xia, Q.; Guo, B.; Wang, Q.; Liu, S.; Liu, Y.; Li, J.; Yu, H. Back Cover: Efficient Cleavage of Lignin–Carbohydrate Complexes and Ultrafast Extraction of Lignin Oligomers from Wood Biomass by Microwave-Assisted Treatment with Deep Eutectic Solvent (ChemSusChem 8/2017). ChemSusChem 2017, 10, 1857. [Google Scholar] [CrossRef]

- Zhang, C.-W.; Xia, S.-Q.; Ma, P.-S. Facile Pretreatment of Lignocellulosic Biomass Using Deep Eutectic Solvents. Bioresour. Technol. 2016, 219, 1–5. [Google Scholar] [CrossRef]

- Dean, J.R. Extraction Techniques for Environmental Analysis, 1st ed.; Wiley: Hoboken, NJ, USA, 2022; ISBN 978-1-119-71904-5. [Google Scholar]

- Ferrara, D.; Beccaria, M.; Cordero, C.E.; Purcaro, G. Microwave-assisted Extraction in Closed Vessel in Food Analysis. J. Sep. Sci. 2023, 46, 2300390. [Google Scholar] [CrossRef]

- Foong, S.Y.; Liew, R.K.; Yang, Y.; Cheng, Y.W.; Yek, P.N.Y.; Wan Mahari, W.A.; Lee, X.Y.; Han, C.S.; Vo, D.-V.N.; Van Le, Q.; et al. Valorization of Biomass Waste to Engineered Activated Biochar by Microwave Pyrolysis: Progress, Challenges, and Future Directions. Chem. Eng. J. 2020, 389, 124401. [Google Scholar] [CrossRef]

- Mao, Y.; Gerrow, A.; Ray, E.; Perez, N.D.; Edler, K.; Wolf, B.; Binner, E. Lignin Recovery from Cocoa Bean Shell Using Microwave-Assisted Extraction and Deep Eutectic Solvents. Bioresour. Technol. 2023, 372, 128680. [Google Scholar] [CrossRef]

- Małachowska, E.; Dubowik, M.; Boruszewski, P.; Łojewska, J.; Przybysz, P. Influence of Lignin Content in Cellulose Pulp on Paper Durability. Sci. Rep. 2020, 10, 19998. [Google Scholar] [CrossRef]

- Provost, V.; Dumarcay, S.; Ziegler-Devin, I.; Boltoeva, M.; Trébouet, D.; Villain-Gambier, M. Deep Eutectic Solvent Pretreatment of Biomass: Influence of Hydrogen Bond Donor and Temperature on Lignin Extraction with High β-O-4 Content. Bioresour. Technol. 2022, 349, 126837. [Google Scholar] [CrossRef] [PubMed]

- Afessa, G.; Saka, A.; Tesfaye, J.L.; Nagaprasad, N.; Shanmugam, R.; Dwarampudi, L.P.; Venkatesh, S.; Badassa, B.; Krishnaraj, R. Synthesis of Plant-Derived Khat Waste for Environmental Application. J. Nanomater. 2022, 2022, 1094798. [Google Scholar] [CrossRef]

- Sluiter, A.; Bartolomé, B.; Ruiz, R.; Scarlata, C.; Sluiter, J.; Templeton, D.; Crocker, D. Determination of Structural Carbohydrates and Lignin in Biomass; Laboratory Analytical Procedure (LAP), National Renewable Energy Laboratory: Golden, CO, USA, 2005.

- Kim, J.-Y.; Johnston, P.A.; Lee, J.H.; Smith, R.G.; Brown, R.C. Improving Lignin Homogeneity and Functionality via Ethanolysis for Production of Antioxidants. ACS Sustain. Chem. Eng. 2019, 7, 3520–3526. [Google Scholar] [CrossRef]

- Fărcaș, A.C.; Socaci, S.A.; Chiș, M.S.; Martínez-Monzó, J.; García-Segovia, P.; Becze, A.; Török, A.I.; Cadar, O.; Coldea, T.E.; Igual, M. In Vitro Digestibility of Minerals and B Group Vitamins from Different Brewers’ Spent Grains. Nutrients 2022, 14, 3512. [Google Scholar] [CrossRef] [PubMed]

- Ivanova, K.; Bakalov, I.; Shopska, V.; Nedyalkov, P.; Kostov, G. Phytochemical Composition of Brewers’ Spent Grains. Acta Univ. Cibiniensis. Ser. E Food Technol. 2020, 24, 139–145. [Google Scholar] [CrossRef]

- Zeko-Pivač, A.; Tišma, M.; Žnidaršič-Plazl, P.; Kulisic, B.; Sakellaris, G.; Hao, J.; Planinić, M. The Potential of Brewer’s Spent Grain in the Circular Bioeconomy: State of the Art and Future Perspectives. Front. Bioeng. Biotechnol. 2022, 10, 870744. [Google Scholar] [CrossRef]

- Kemppainen, K.; Rommi, K.; Holopainen, U.; Kruus, K. Steam Explosion of Brewer’s Spent Grain Improves Enzymatic Digestibility of Carbohydrates and Affects Solubility and Stability of Proteins. Appl. Biochem. Biotechnol. 2016, 180, 94–108. [Google Scholar] [CrossRef]

- López-Linares, J.C.; Lucas, S.; García-Cubero, M.T.; Jiménez, J.J.; Coca, M. A Biorefinery Based on Brewer`s Spent Grains: Arabinoxylans Recovery by Microwave Assisted Pretreatment Integrated with Butanol Production. Ind. Crops Prod. 2020, 158, 113044. [Google Scholar] [CrossRef]

- Jackowski, M.; Niedźwiecki, Ł.; Jagiełło, K.; Uchańska, O.; Trusek, A. Brewer’s Spent Grains—Valuable Beer Industry By-Product. Biomolecules 2020, 10, 1669. [Google Scholar] [CrossRef]

- Castro, L.E.N.; Colpini, L.M.S. All-around Characterization of Brewers’ Spent Grain. Eur. Food Res. Technol. 2021, 247, 3013–3021. [Google Scholar] [CrossRef]

- Guido, L.F.; Moreira, M.M. Techniques for Extraction of Brewer’s Spent Grain Polyphenols: A Review. Food Bioprocess. Technol. 2017, 10, 1192–1209. [Google Scholar] [CrossRef]

- Bravi, E.; Francesco, G.D.; Sileoni, V.; Perretti, G.; Galgano, F.; Marconi, O. Brewing By-Product Upcycling Potential: Nutritionally Valuable Compounds and Antioxidant Activity Evaluation. Antioxidants 2021, 10, 165. [Google Scholar] [CrossRef]

- Sun, W.; Zhang, Z.; Li, X.; Lu, X.; Liu, G.; Qin, Y.; Zhao, J.; Qu, Y. Production of Single Cell Protein from Brewer’s Spent Grain through Enzymatic Saccharification and Fermentation Enhanced by Ammoniation Pretreatment. Bioresour. Technol. 2024, 394, 130242. [Google Scholar] [CrossRef] [PubMed]

- Rojas-Pérez, L.C.; Narváez-Rincón, P.C.; Rocha, M.A.M.; Coelho, E.; Coimbra, M.A. Production of Xylose through Enzymatic Hydrolysis of Glucuronoarabinoxylan from Brewers’ Spent Grain. Bioresour. Bioprocess. 2022, 9, 105. [Google Scholar] [CrossRef] [PubMed]

- Tan, Y.T.; Ngoh, G.C.; Chua, A.S.M. Effect of Functional Groups in Acid Constituent of Deep Eutectic Solvent for Extraction of Reactive Lignin. Bioresour. Technol. 2019, 281, 359–366. [Google Scholar] [CrossRef]

- Hou, X.-D.; Li, A.-L.; Lin, K.-P.; Wang, Y.-Y.; Kuang, Z.-Y.; Cao, S.-L. Insight into the Structure-Function Relationships of Deep Eutectic Solvents during Rice Straw Pretreatment. Bioresour. Technol. 2018, 249, 261–267. [Google Scholar] [CrossRef]

- Allegretti, C.; Bellinetto, E.; D’Arrigo, P.; Griffini, G.; Marzorati, S.; Rossato, L.A.M.; Ruffini, E.; Schiavi, L.; Serra, S.; Strini, A.; et al. Towards a Complete Exploitation of Brewers’ Spent Grain from a Circular Economy Perspective. Fermentation 2022, 8, 151. [Google Scholar] [CrossRef]

- Ceaser, R.; Rosa, S.; Montané, D.; Constantí, M.; Medina, F. Optimization of Softwood Pretreatment by Microwave-Assisted Deep Eutectic Solvents at High Solids Loading. Bioresour. Technol. 2023, 369, 128470. [Google Scholar] [CrossRef]

- Mankar, A.R.; Pandey, A.; Modak, A.; Pant, K.K. Pretreatment of Lignocellulosic Biomass: A Review on Recent Advances. Bioresour. Technol. 2021, 334, 125235. [Google Scholar] [CrossRef]

- Mankar, A.R.; Pandey, A.; Pant, K.K. Microwave-Assisted Extraction of Lignin from Coconut Coir Using Deep Eutectic Solvents and Its Valorization to Aromatics. Bioresour. Technol. 2022, 345, 126528. [Google Scholar] [CrossRef]

- Yaakob, M.N.A.; Salim, N.; Mustapha, S.N.H.; Misnon, I.I.; Rahim, M.H.A.; Roslan, R. Efficient Lignin Extraction from Oil Palm Empty Fruit Bunches Using Guanidine-Based Deep Eutectic Solvents under Microwave Assistance. Ind. Crops Prod. 2024, 218, 118968. [Google Scholar] [CrossRef]

- Wu, M.; Zhao, D.; Pang, J.; Zhang, X.; Li, M.; Xu, F.; Sun, R. Separation and Characterization of Lignin Obtained by Catalytic Hydrothermal Pretreatment of Cotton Stalk. Ind. Crops Prod. 2015, 66, 123–130. [Google Scholar] [CrossRef]

- Deshpande, R.; Sundvall, L.; Grundberg, H.; Lawoko, M.; Henriksson, G. Lignin Carbohydrate Complex Studies during Kraft Pulping for Producing Paper Grade Pulp from Birch. Tech. Assoc. Pulp Pap. Ind. J. 2020, 19, 447–460. [Google Scholar] [CrossRef]

- Lou, R.; Ma, R.; Lin, K.; Ahamed, A.; Zhang, X. Facile Extraction of Wheat Straw by Deep Eutectic Solvent (DES) to Produce Lignin Nanoparticles. ACS Sustain. Chem. Eng. 2019, 7, 10248–10256. [Google Scholar] [CrossRef]

- Yimtrakarn, T.; Kaveevivitchai, W.; Lee, W.-C.; Lerkkasemsan, N. Study of Lignin Extracted from Rubberwood Using Microwave Assisted Technology for Fuel Additive. Polymers 2022, 14, 814. [Google Scholar] [CrossRef]

- Boarino, A.; Klok, H.-A. Opportunities and Challenges for Lignin Valorization in Food Packaging, Antimicrobial, and Agricultural Applications. Biomacromolecules 2023, 24, 1065–1077. [Google Scholar] [CrossRef]

- Li, K.; Zhong, W.; Li, P.; Ren, J.; Jiang, K.; Wu, W. Recent Advances in Lignin Antioxidant: Antioxidant Mechanism, Evaluation Methods, Influence Factors and Various Applications. Int. J. Biol. Macromol. 2023, 251, 125992. [Google Scholar] [CrossRef]

- Lu, X.; Gu, X.; Shi, Y. A Review on Lignin Antioxidants: Their Sources, Isolations, Antioxidant Activities and Various Applications. Int. J. Biol. Macromol. 2022, 210, 716–741. [Google Scholar] [CrossRef]

- Wu, Y.; Liu, Z.; Ma, L.; Guo, Z.; Yang, Q.; Wang, X.; Hui, L. Structural Characterization and Evaluation of the Antioxidant Activity of DES-Lignin Isolated from Cunninghamia Lanceolata. Wood Sci. Technol. 2021, 55, 1041–1055. [Google Scholar] [CrossRef]

- Patil, V.; Adhikari, S.; Cross, P.; Jahromi, H. Progress in the Solvent Depolymerization of Lignin. Renew. Sustain. Energy Rev. 2020, 133, 110359. [Google Scholar] [CrossRef]

- Lu, Q.; Liu, W.; Yang, L.; Zu, Y.; Zu, B.; Zhu, M.; Zhang, Y.; Zhang, X.; Zhang, R.; Sun, Z.; et al. Investigation of the Effects of Different Organosolv Pulping Methods on Antioxidant Capacity and Extraction Efficiency of Lignin. Food Chem. 2012, 131, 313–317. [Google Scholar] [CrossRef]

- Wagner, E.; Pería, M.E.; Ortiz, G.E.; Rojas, N.L.; Ghiringhelli, P.D. Valorization of Brewer’s Spent Grain by Different Strategies of Structural Destabilization and Enzymatic Saccharification. Ind. Crops Prod. 2021, 163, 113329. [Google Scholar] [CrossRef]

- Ravindran, R.; Jaiswal, S.; Abu-Ghannam, N.; Jaiswal, A.K. A Comparative Analysis of Pretreatment Strategies on the Properties and Hydrolysis of Brewers’ Spent Grain. Bioresour. Technol. 2018, 248, 272–279. [Google Scholar] [CrossRef] [PubMed]

- Xu, G.; Shi, Z.; Zhao, Y.; Deng, J.; Dong, M.; Liu, C.; Murugadoss, V.; Mai, X.; Guo, Z. Structural Characterization of Lignin and Its Carbohydrate Complexes Isolated from Bamboo (Dendrocalamus sinicus). Int. J. Biol. Macromol. 2019, 126, 376–384. [Google Scholar] [CrossRef] [PubMed]

- Liu, W.; Ning, C.; Li, Z.; Li, X.; Wang, H.; Hou, Q. Revealing Structural Features of Lignin Macromolecules from Microwave-Assisted Carboxylic Acid-Based Deep Eutectic Solvent Pretreatment. Ind. Crops Prod. 2023, 194, 116342. [Google Scholar] [CrossRef]

- Karmanov, A.P.; Kocheva, L.S.; Raskosha, O.V.; Moskalev, A.A. Investigation of the Structure and Properties of Lignins of Some Agricultural Plants. Biocatal. Agric. Biotechnol. 2023, 53, 102848. [Google Scholar] [CrossRef]

- Wang, L.; Li, X.; Jiang, J.; Zhang, Y.; Bi, S.; Wang, H.-M. Revealing Structural and Functional Specificity of Lignin from Tobacco Stalk during Deep Eutectic Solvents Deconstruction Aiming to Targeted Valorization. Ind. Crops Prod. 2022, 180, 114696. [Google Scholar] [CrossRef]

- Mainka, H.; Täger, O.; Körner, E.; Hilfert, L.; Busse, S.; Edelmann, F.T.; Herrmann, A.S. Lignin—An Alternative Precursor for Sustainable and Cost-Effective Automotive Carbon Fiber. J. Mater. Res. Technol. 2015, 4, 283–296. [Google Scholar] [CrossRef]

- Karlen, S.D.; Zhang, C.; Peck, M.L.; Smith, R.A.; Padmakshan, D.; Helmich, K.E.; Free, H.C.A.; Lee, S.; Smith, B.G.; Lu, F.; et al. Monolignol Ferulate Conjugates Are Naturally Incorporated into Plant Lignins. Sci. Adv. 2016, 2, e1600393. [Google Scholar] [CrossRef]

- Wang, H.-M.; Wang, B.; Wen, J.-L.; Yuan, T.-Q.; Sun, R.-C. Structural Characteristics of Lignin Macromolecules from Different Eucalyptus Species. ACS Sustain. Chem. Eng. 2017, 5, 11618–11627. [Google Scholar] [CrossRef]

- Fernández-Costas, C.; Gouveia, S.; Sanromán, M.A.; Moldes, D. Structural Characterization of Kraft Lignins from Different Spent Cooking Liquors by 1D and 2D Nuclear Magnetic Resonance Spectroscopy. Biomass Bioenergy 2014, 63, 156–166. [Google Scholar] [CrossRef]

- Kirui, A.; Zhao, W.; Deligey, F.; Yang, H.; Kang, X.; Mentink-Vigier, F.; Wang, T. Carbohydrate-Aromatic Interface and Molecular Architecture of Lignocellulose. Nat. Commun. 2022, 13, 538. [Google Scholar] [CrossRef] [PubMed]

- Del Río, J.C.; Rencoret, J.; Gutiérrez, A.; Elder, T.; Kim, H.; Ralph, J. Lignin Monomers from beyond the Canonical Monolignol Biosynthetic Pathway: Another Brick in the Wall. ACS Sustain. Chem. Eng. 2020, 8, 4997–5012. [Google Scholar] [CrossRef]

- Audu, I.G.; Brosse, N.; Winter, H.; Hoffmann, A.; Bremer, M.; Fischer, S.; Laborie, M.-P. Acetyl Groups in Typha Capensis: Fate of Acetates during Organosolv and Ionosolv Pulping. Polymers 2018, 10, 619. [Google Scholar] [CrossRef] [PubMed]

- Alper, K.; Tekin, K.; Karagöz, S.; Ragauskas, A.J. Sustainable Energy and Fuels from Biomass: A Review Focusing on Hydrothermal Biomass Processing. Sustain. Energy Fuels 2020, 4, 4390–4414. [Google Scholar] [CrossRef]

- Martínez, Á.T.; Rencoret, J.; Marques, G.; Gutiérrez, A.; Ibarra, D.; Jiménez-Barbero, J.; Del Río, J.C. Monolignol Acylation and Lignin Structure in Some Nonwoody Plants: A 2D NMR Study. Phytochemistry 2008, 69, 2831–2843. [Google Scholar] [CrossRef]

- Zhao, C.; Huang, J.; Yang, L.; Yue, F.; Lu, F. Revealing Structural Differences between Alkaline and Kraft Lignins by HSQC NMR. Ind. Eng. Chem. Res. 2019, 58, 5707–5714. [Google Scholar] [CrossRef]

- Prinsen, P.; Rencoret, J.; Gutiérrez, A.; Liitiä, T.; Tamminen, T.; Colodette, J.L.; Berbis, M.Á.; Jiménez-Barbero, J.; Martínez, Á.T.; Del Río, J.C. Modification of the Lignin Structure during Alkaline Delignification of Eucalyptus Wood by Kraft, Soda-AQ, and Soda-O2Cooking. Ind. Eng. Chem. Res. 2013, 52, 15702–15712. [Google Scholar] [CrossRef]

- Wang, W.; Gu, F.; Zhu, J.Y.; Sun, K.; Cai, Z.; Yao, S.; Wu, W.; Jin, Y. Fractionation of Herbaceous Biomass Using a Recyclable Hydrotropic p–Toluenesulfonic Acid (p–TsOH)/Choline Chloride (ChCl) Solvent System at Low Temperatures. Ind. Crops Prod. 2020, 150, 112423. [Google Scholar] [CrossRef]

- Jastrzebski, R.; Constant, S.; Lancefield, C.S.; Westwood, N.J.; Weckhuysen, B.M.; Bruijnincx, P.C.A. Tandem Catalytic Depolymerization of Lignin by Water-Tolerant Lewis Acids and Rhodium Complexes. ChemSusChem 2016, 9, 2074–2079. [Google Scholar] [CrossRef]

- Iram, A.; Cekmecelioglu, D.; Demirci, A. Optimization of Dilute Sulfuric Acid, Aqueous Ammonia, and Steam Explosion as the Pretreatments Steps for Distillers’ Dried Grains with Solubles as a Potential Fermentation Feedstock. Bioresour. Technol. 2019, 282, 475–481. [Google Scholar] [CrossRef] [PubMed]

- Foltanyi, F.; Hawkins, J.E.; Panovic, I.; Bird, E.J.; Gloster, T.M.; Lancefield, C.S.; Westwood, N.J. Analysis of the Product Streams Obtained on Butanosolv Pretreatment of Draff. Biomass Bioenergy 2020, 141, 105680. [Google Scholar] [CrossRef]

- Kim, H.; Padmakshan, D.; Li, Y.; Rencoret, J.; Hatfield, R.D.; Ralph, J. Characterization and Elimination of Undesirable Protein Residues in Plant Cell Wall Materials for Enhancing Lignin Analysis by Solution-State Nuclear Magnetic Resonance Spectroscopy. Biomacromolecules 2017, 18, 4184–4195. [Google Scholar] [CrossRef] [PubMed]

- Junttila, M.H. Extraction of Brewers’ Spent Grain in near Subcritical Conditions: A Method to Obtain High Protein Contents Extracts. J. Agric. Food Res. 2022, 10, 100378. [Google Scholar] [CrossRef]

| BSG Mass Content (%, DRY Weight Basis) a | Zeko-Pivač et al. (%, Dry Weight Basis) [56] | Ribeiro-Sanches et al. (%, Dry Weight Basis) [3] | ||

|---|---|---|---|---|

| Extractives | 6.8 ± 0.7 | nr b | 7.99 ± 0.06 | |

| Protein (Kjeldahl) | 17.5 ± 0.5 | 20.93 ± 2.38 | 21.26 ± 0.12 | |

| Klason lignin | 15.8 ± 0.3 | 11.41 ± 6.76 | 16.81 ± 0.14 | |

| Monosaccharides | Glucose | 21.42 ± 4.81 | 17.50 ± 0.05 | 21.7 ± 1.4 |

| Xylose | nr | 24.82 ± 0.29 | 13.6 ± 0.8 | |

| Rhamnose and arabinose | 10.37 ± 10.17 | 4.81 ± 0.01 | 5.6 ± 0.4 | |

| Galactose | nr | nr | nr | |

| Mannose | nr | nr | nr | |

| Elemental analysis | C | nr | nr | nr |

| N | nr | nr | nr | |

| H | nr | nr | nr | |

| Protein (elemental analysis) | 20.0 | nr | nr | |

| Duration of Microwave-Assisted Fractionation (min) | |||||

|---|---|---|---|---|---|

| 10 | 15 | 20 | 25 | 30 | |

| Lignin yield (%) | 22.13 ± 1.13 | 16.10 ± 0.85 | 17.51 ± 0.82 | 19.68 ± 0.78 | 16.28 ± 0.35 |

| Klason lignin (%) | 74.03 ± 1.99 | 79.03 ± 0.16 | 77.14 ± 0.12 | 84.62 ± 3.17 | 87.96 ± 1.22 |

| Pure lignin yield (%) a | 16.38 ± 0.95 | 12.72 ± 0.67 | 13.51 ± 0.63 | 16.65 ± 0.91 | 14.32 ± 0.37 |

| Acid-soluble lignin (%) | 5.75 ± 0.29 | 3.38 ± 0.18 | 4.00 ± 0.19 | 3.03 ± 0.12 | 1.96 ± 0.04 |

| Glucose (%) | 0.20 ± 0.04 | 0.10 ± 0.01 | 0.24 ± 0.02 | 0.09 ± 2.49 × 10−3 | 0.03 ± 0.01 |

| Xylose (%) | 0.07 ± 0.01 | 0.03 ± 2.10 × 10−3 | 0.06 ± 0.01 | 0.02 ± 1.74 × 10−3 | <0.01 |

| Rhamnoe and arabinose (%) | 0.04 ± 0.01 | 0.02 ± 1.37 × 10−3 | 0.03 ± 2.10 × 10−3 | <0.01 | <0.01 |

| Galactose (%) | 0.05 ± 0.01 | 0.04 ± 2.48 × 10−3 | 0.04 ± 3.17 × 10−3 | 0.02 ± 4.14 × 10−3 | <0.01 |

| Mannose (%) | <0.01 | <0.01 | <0.01 | <0.01 | <dl c |

| Carbohydrates (%) b | 0.36 | 0.19 | 0.37 | 0.13 | 0.03 |

| Label | δC/δH | Assignement |

|---|---|---|

| OCH3 | 55.6/3.73 | C−H in methoxyls |

| Aγ | 59.4/3.40–3.72 | Cγ−Hγ in β-O-4′ substructures (A) |

| A′γ | 63.8/3.83–4.30 | Cγ−Hγ in γ acetylated β-O-4′ substructures (A′) |

| Bγ | 62.5/3.66 | Cγ−Hγ in β-5′ phenylcoumaran substructures (B) |

| Aα | 71.8/4.86 | Cα−Hα in β-O-4′substructures (A) |

| Iγ | 61.4/4.10 | Cγ−Hγ in p-hydroxycinnamyl alcohol end groups (I) |

| Cβ | 53.5/3.05 | Cβ−Hβ in β-β′resinol substructures (C) |

| X5 | 62.6/3.40–3.72 | C5-H5 in β-D xylopyranoside |

| HKα | 47.4/3.62 | α-protons in Hibbert ketone (HK) structure |

| HKγ | 66.2/ 4.2 | γ-protons in Hibbert ketone (HK) structure |

| G5 | 114.9/6.77 | C5−H5 in guaiacyl units (G) |

| H3,5 | 114.5/6.62 | C3,5−H3,5 in p-hydroxyphenyl units (H) |

| H2,6 | 128.3/7.22 | C2,6−H2,6 in p-hydroxyphenyl units (H) |

| PCA3.5 | 115.8/6.83 | C3,5–H3,5 in p-coumarate (PCA) |

| Phe | 126.9/7.16 | Phenylalanine (residual proteins) |

| Tyr | 130.5/7.0 | Tyrosine (residual proteins) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Antoun, K.; Tabib, M.; Salameh, S.J.; Koubaa, M.; Ziegler-Devin, I.; Brosse, N.; Khelfa, A. Isolation and Structural Characterization of Natural Deep Eutectic Solvent Lignin from Brewer’s Spent Grains. Polymers 2024, 16, 2791. https://doi.org/10.3390/polym16192791

Antoun K, Tabib M, Salameh SJ, Koubaa M, Ziegler-Devin I, Brosse N, Khelfa A. Isolation and Structural Characterization of Natural Deep Eutectic Solvent Lignin from Brewer’s Spent Grains. Polymers. 2024; 16(19):2791. https://doi.org/10.3390/polym16192791

Chicago/Turabian StyleAntoun, Karina, Malak Tabib, Sarah Joe Salameh, Mohamed Koubaa, Isabelle Ziegler-Devin, Nicolas Brosse, and Anissa Khelfa. 2024. "Isolation and Structural Characterization of Natural Deep Eutectic Solvent Lignin from Brewer’s Spent Grains" Polymers 16, no. 19: 2791. https://doi.org/10.3390/polym16192791

APA StyleAntoun, K., Tabib, M., Salameh, S. J., Koubaa, M., Ziegler-Devin, I., Brosse, N., & Khelfa, A. (2024). Isolation and Structural Characterization of Natural Deep Eutectic Solvent Lignin from Brewer’s Spent Grains. Polymers, 16(19), 2791. https://doi.org/10.3390/polym16192791