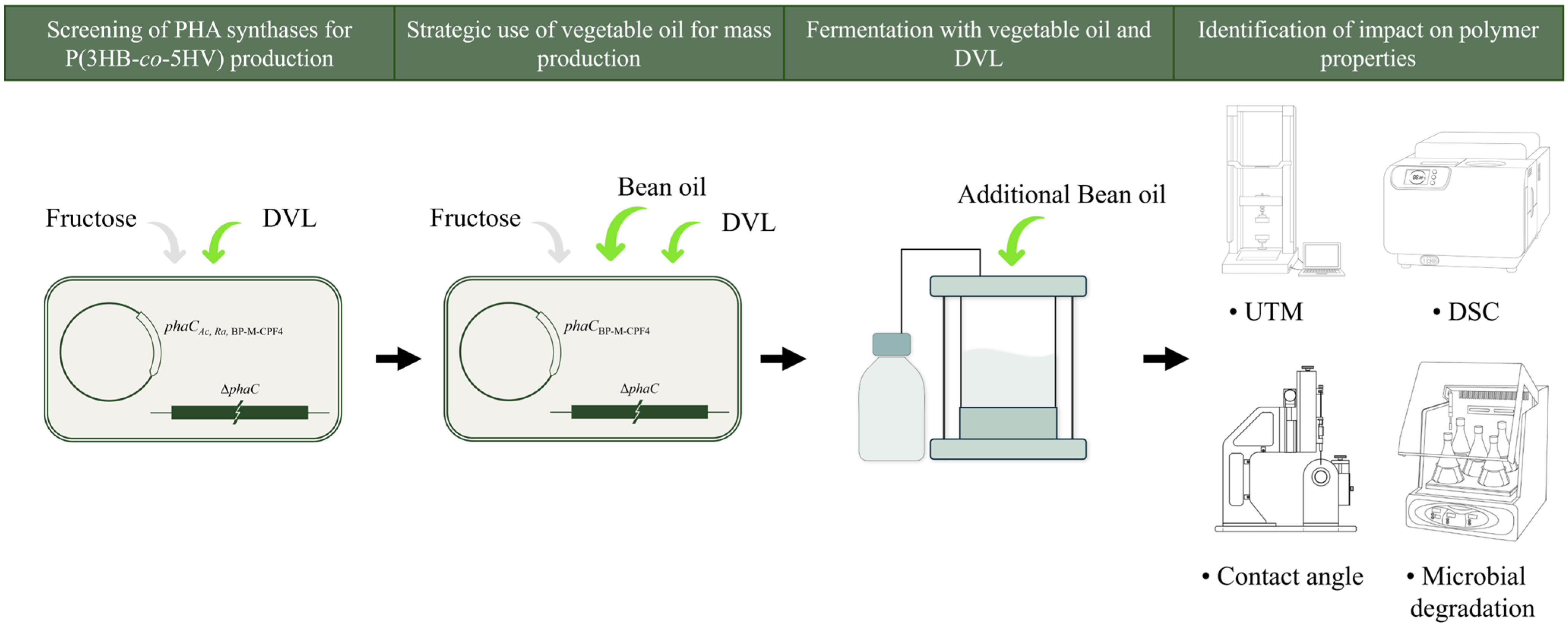

Strategic Use of Vegetable Oil for Mass Production of 5-Hydroxyvalerate-Containing Polyhydroxyalkanoate from δ-Valerolactone by Engineered Cupriavidus necator

Abstract

1. Introduction

2. Materials and Methods

2.1. Microorganisms and Culture Conditions

2.2. Analytical Methods

2.3. Gel Permeation Chromatography (GPC)

2.4. Analysis of the Physical and Thermal Characteristics

2.5. Culture Conditions for a 5-L Fermenter

3. Results

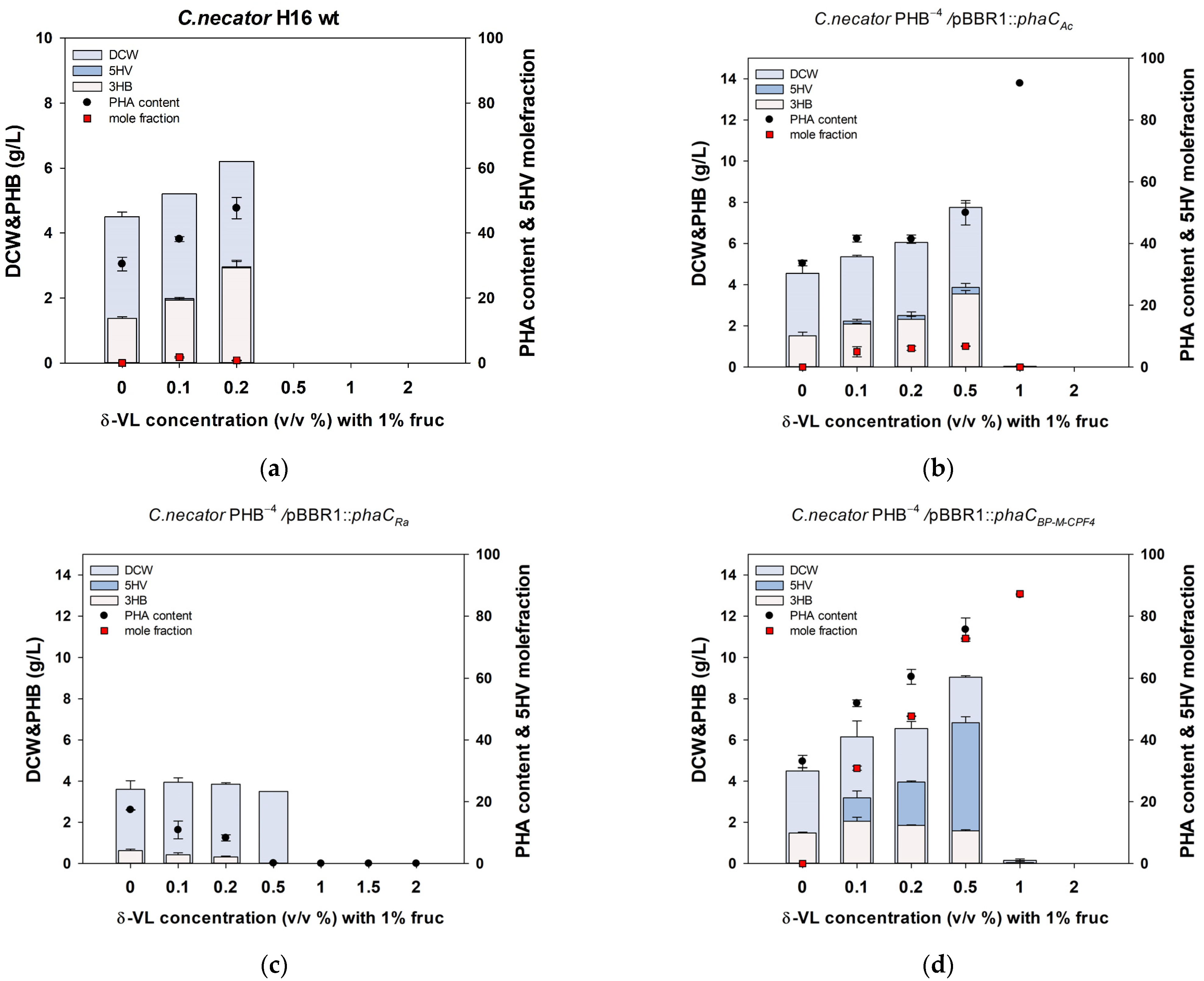

3.1. PhaC Screening for Efficient 5HV Polymerization in PHA

3.2. Validation of Plant Oil for Increased Production of PHA Containing 5HV

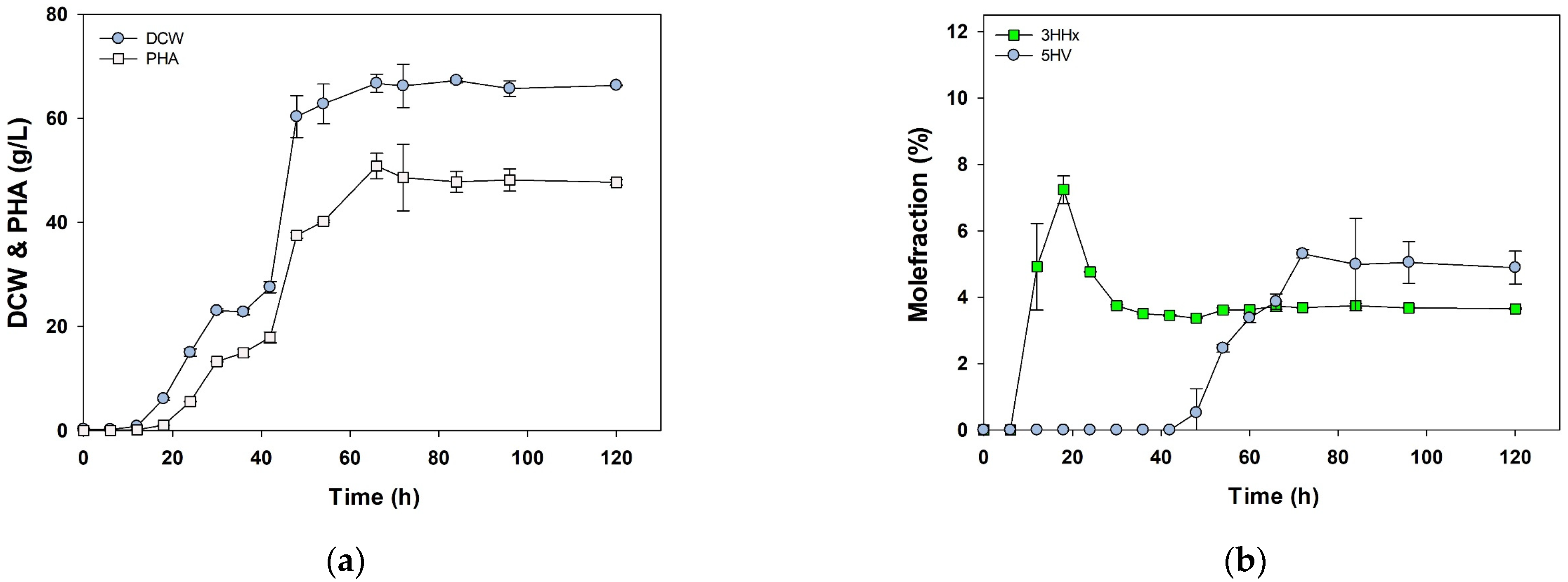

3.3. Fed-Batch Production of Poly(3HB-co-3HHx-co-5HV)

3.4. Physical and Mechanical Properties of Poly(3HB-co-3HHx-co-5HV)

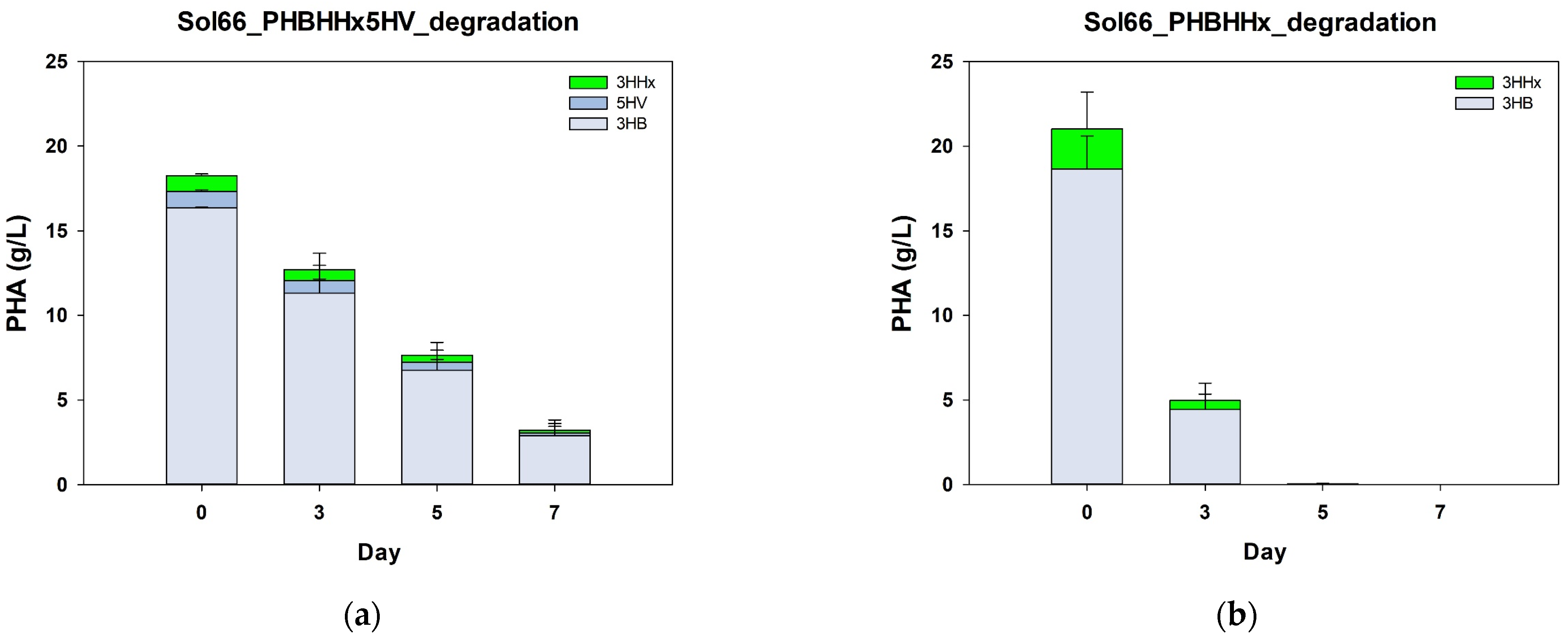

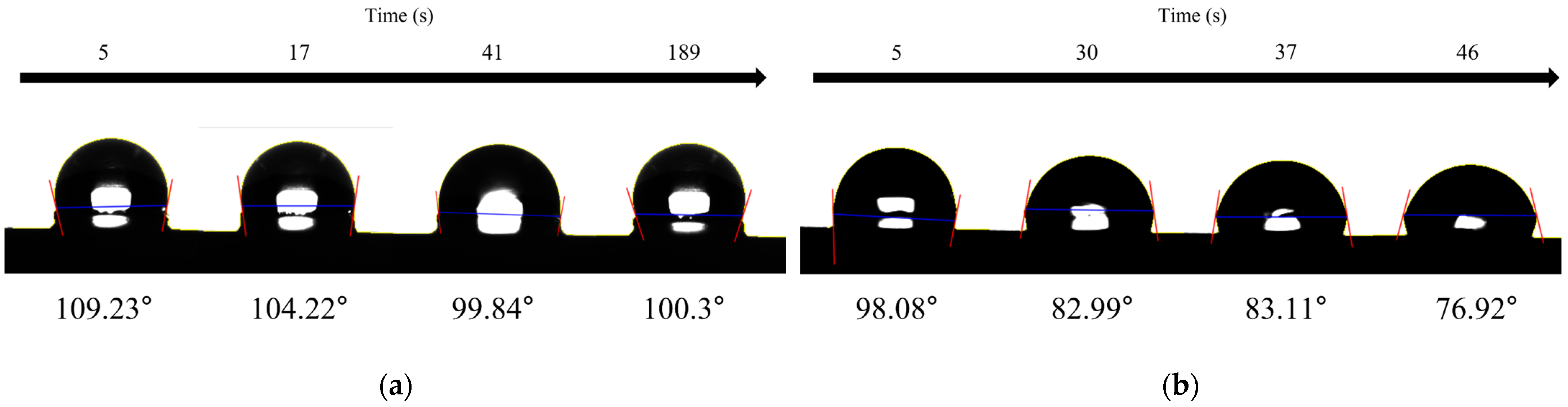

3.5. Comparison of PHBHHx5HV and Conventional PHBHHx Degradation and Contact Angle

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Rueda, E.; Gonzalez-Flo, E.; Mondal, S.; Forchhammer, K.; Arias, D.M.; Ludwig, K.; Drosg, B.; Fritz, I.; Gonzalez-Esquer, C.R.; Pacheco, S.; et al. Challenges, Progress, and Future Perspectives for Cyanobacterial Polyhydroxyalkanoate Production. Rev. Environ. Sci. Biotechnol. 2024, 23, 321–350. [Google Scholar] [CrossRef]

- Meereboer, K.W.; Misra, M.; Mohanty, A.K. Review of Recent Advances in the Biodegradability of Polyhydroxyalkanoate (PHA) Bioplastics and Their Composites. Green Chem. 2020, 22, 5519–5558. [Google Scholar] [CrossRef]

- Prados, E.; Maicas, S. Bacterial Production of Hydroxyalkanoates (PHA). Univers. J. Microbiol. Res. 2016, 4, 23–30. [Google Scholar] [CrossRef]

- Alves, M.I.; Macagnan, K.L.; Rodrigues, A.A.; De Assis, D.A.; Torres, M.M.; De Oliveira, P.D.; Furlan, L.; Vendruscolo, C.T.; Moreira, A.D.S. Poly(3-Hydroxybutyrate)-P(3HB): Review of Production Process Technology. Indus. Biotechnol. 2017, 13, 192–208. [Google Scholar] [CrossRef]

- Briassoulis, D.; Tserotas, P.; Athanasoulia, I.G. Alternative Optimization Routes for Improving the Performance of Poly(3-Hydroxybutyrate) (PHB) Based Plastics. J. Clean. Prod. 2021, 318, 128555. [Google Scholar] [CrossRef]

- Volova, T.; Kiselev, E.; Nemtsev, I.; Lukyanenko, A.; Sukovatyi, A.; Kuzmin, A.; Ryltseva, G.; Shishatskaya, E. Properties of Degradable Polyhydroxyalkanoates with Different Monomer Compositions. Int. J. Biol. Macromol. 2021, 182, 98–114. [Google Scholar] [CrossRef]

- Yan, X.; Liu, X.; Yu, L.P.; Wu, F.; Jiang, X.R.; Chen, G.Q. Biosynthesis of Diverse α,ω-Diol-Derived Polyhydroxyalkanoates by Engineered Halomonas Bluephagenesis. Metab. Eng. 2022, 72, 275–288. [Google Scholar] [CrossRef]

- Lakshmanan, M.; Foong, C.P.; Abe, H.; Sudesh, K. Biosynthesis and Characterization of Co and Ter-Polyesters of Polyhydroxyalkanoates Containing High Monomeric Fractions of 4-Hydroxybutyrate and 5-Hydroxyvalerate via a Novel PHA Synthase. Polym. Degrad. Stab. 2019, 163, 122–135. [Google Scholar] [CrossRef]

- Rehakova, V.; Pernicova, I.; Kourilova, X.; Sedlacek, P.; Musilova, J.; Sedlar, K.; Koller, M.; Kalina, M.; Obruca, S. Biosynthesis of Versatile PHA Copolymers by Thermophilic Members of the Genus Aneurinibacillus. Int. J. Biol. Macromol. 2023, 225, 1588–1598. [Google Scholar] [CrossRef]

- Myung, J.; Flanagan, J.C.A.; Waymouth, R.M.; Criddle, C.S. Expanding the Range of Polyhydroxyalkanoates Synthesized by Methanotrophic Bacteria through the Utilization of Omega-Hydroxyalkanoate Co-Substrates. AMB Express 2017, 7, 118. [Google Scholar] [CrossRef]

- Doi, Y.; Tamaki, A.; Kunioka, M.; Soga, K. Biosynthesis of Terpolyesters of 3-Hydroxybutyrate, 3-Hydroxyvalerate, and 5-Hydroxyvalerate in Alcaligenes eutrophus from 5-Chloropentanoic and Pentanoic Acids. Die Makromol. Chem. Rapid Commun. 1987, 8, 631–635. [Google Scholar] [CrossRef]

- Oh, S.J.; Kim, S.; Lee, Y.; Shin, Y.; Choi, S.; Oh, J.; Bhatia, S.K.; Joo, J.C.; Yang, Y.H. Controlled Production of a Polyhydroxyalkanoate (PHA) Tetramer Containing Different Mole Fraction of 3-Hydroxybutyrate (3HB), 3-Hydroxyvalerate (3 HV), 4 HV and 5 HV Units by Engineered Cupriavidus necator. Int. J. Biol. Macromol. 2024, 266, 131332. [Google Scholar] [CrossRef] [PubMed]

- Sohn, Y.J.; Son, J.; Jo, S.Y.; Park, S.Y.; Yoo, J.I.; Baritugo, K.A.; Na, J.G.; Choi, J.-i.; Kim, H.T.; Joo, J.C.; et al. Chemoautotroph Cupriavidus necator as a Potential Game-Changer for Global Warming and Plastic Waste Problem: A Review. Bioresour. Technol. 2021, 340, 125693. [Google Scholar] [CrossRef]

- Zhila, N.O.; Sapozhnikova, K.Y.; Kiselev, E.G.; Shishatskaya, E.I.; Volova, T.G. Biosynthesis of Poly(3-Hydroxybutyrate-Co-4-Hydroxybutyrate) from Different 4-Hydroxybutyrate Precursors by New Wild-Type Strain Cupriavidus necator IBP/SFU-1. Processes 2023, 11, 1423. [Google Scholar] [CrossRef]

- Duvigneau, S.; Dürr, R.; Behrens, J.; Kienle, A. Advanced Kinetic Modeling of Bio-Co-Polymer Poly(3-Hydroxybutyrate-Co-3-Hydroxyvalerate) Production Using Fructose and Propionate as Carbon Sources. Processes 2021, 9, 1260. [Google Scholar] [CrossRef]

- Wang, C.-T.; Sivashankari, R.M.; Miyahara, Y.; Tsuge, T. Polyhydroxyalkanoate Copolymer Production by Recombinant Ralstonia Eutropha Strain 1F2 from Fructose or Carbon Dioxide as Sole Carbon Source. Bioengineering 2024, 11, 455. [Google Scholar] [CrossRef]

- Park, S.; Roh, S.; Yoo, J.; Ahn, J.H.; Gong, G.; Lee, S.M.; Um, Y.; Han, S.O.; Ko, J.K. Tailored Polyhydroxyalkanoate Production from Renewable Non-Fatty Acid Carbon Sources Using Engineered Cupriavidus necator H16. Int. J. Biol. Macromol. 2024, 263, 130360. [Google Scholar] [CrossRef]

- Fukui, T.; Suzuki, M.; Tsuge, T.; Nakamura, S. Microbial Synthesis of Poly((R)-3-Hydroxybutyrate-Co- 3-Hydroxypropionate) from Unrelated Carbon Sources by Engineered Cupriavidus necator. Biomacromolecules 2009, 10, 700–706. [Google Scholar] [CrossRef]

- Insomphun, C.; Xie, H.; Mifune, J.; Kawashima, Y.; Orita, I.; Nakamura, S.; Fukui, T. Improved Artificial Pathway for Biosynthesis of Poly(3-Hydroxybutyrate-Co-3-Hydroxyhexanoate) with High C6-Monomer Composition from Fructose in Ralstonia eutropha. Metab. Eng. 2015, 27, 38–45. [Google Scholar] [CrossRef]

- Jo, Y.Y.; Park, S.; Gong, G.; Roh, S.; Yoo, J.; Ahn, J.H.; Lee, S.M.; Um, Y.; Kim, K.H.; Ko, J.K. Enhanced Production of Poly(3-Hydroxybutyrate-Co-3-Hydroxyvalerate) with Modulated 3-Hydroxyvalerate Fraction by Overexpressing Acetolactate Synthase in Cupriavidus necator H16. Int. J. Biol. Macromol. 2023, 242, 125166. [Google Scholar] [CrossRef]

- Obruca, S.; Marova, I.; Snajdar, O.; Mravcova, L.; Svoboda, Z. Production of Poly(3-Hydroxybutyrate-Co-3-Hydroxyvalerate) by Cupriavidus necator from Waste Rapeseed Oil Using Propanol as a Precursor of 3-Hydroxyvalerate. Biotechnol. Lett. 2010, 32, 1925–1932. [Google Scholar] [CrossRef] [PubMed]

- Oh, S.J.; Choi, T.R.; Kim, H.J.; Shin, N.; Hwang, J.H.; Kim, H.J.; Bhatia, S.K.; Kim, W.; Yeon, Y.J.; Yang, Y.H. Maximization of 3-Hydroxyhexanoate Fraction in Poly(3-Hydroxybutyrate-Co-3-Hydroxyhexanoate) Using Lauric Acid with Engineered Cupriavidus necator H16. Int. J. Biol. Macromol. 2024, 256, 128376. [Google Scholar] [CrossRef] [PubMed]

- Sato, S.; Maruyama, H.; Fujiki, T.; Matsumoto, K. Regulation of 3-Hydroxyhexanoate Composition in PHBH Synthesized by Recombinant Cupriavidus necator H16 from Plant Oil by Using Butyrate as a Co-Substrate. J. Biosci. Bioeng. 2015, 120, 246–251. [Google Scholar] [CrossRef] [PubMed]

- Lee, H.S.; Lee, S.M.; Park, S.L.; Choi, T.R.; Song, H.S.; Kim, H.J.; Bhatia, S.K.; Gurav, R.; Kim, Y.G.; Kim, J.H.; et al. Tung Oil-Based Production of High 3-Hydroxyhexanoate-Containing Terpolymer Poly(3-Hydroxybutyrate-Co-3-Hydroxyvalerate-Co-3-Hydroxyhexanoate) Using Engineered Ralstonia eutropha. Polymers 2021, 13, 1084. [Google Scholar] [CrossRef]

- Chien Bong, C.P.; Alam, M.N.H.Z.; Samsudin, S.A.; Jamaluddin, J.; Adrus, N.; Mohd Yusof, A.H.; Muis, Z.A.; Hashim, H.; Salleh, M.M.; Abdullah, A.R.; et al. A Review on the Potential of Polyhydroxyalkanoates Production from Oil-Based Substrates. J. Environ. Manag. 2021, 298, 113461. [Google Scholar] [CrossRef]

- Tang, H.J.; Neoh, S.Z.; Sudesh, K. A Review on Poly(3-Hydroxybutyrate-Co-3-Hydroxyhexanoate) [P(3HB-Co-3HHx)] and Genetic Modifications That Affect Its Production. Front. Bioeng. Biotechnol. 2022, 10, 1057067. [Google Scholar] [CrossRef]

- Ciesielski, S.; Mozejko, J.; Pisutpaisal, N. Plant Oils as Promising Substrates for Polyhydroxyalkanoates Production. J. Clean. Prod. 2015, 106, 408–421. [Google Scholar] [CrossRef]

- Sato, S.; Fujiki, T.; Matsumoto, K. Construction of a Stable Plasmid Vector for Industrial Production of Poly(3-Hydroxybutyrate-Co-3-Hydroxyhexanoate) by a Recombinant Cupriavidus necator H16 Strain. J. Biosci. Bioeng. 2013, 116, 677–681. [Google Scholar] [CrossRef]

- Santolin, L.; Waldburger, S.; Neubauer, P.; Riedel, S.L. Substrate-Flexible Two-Stage Fed-Batch Cultivations for the Production of the PHA Copolymer P(HB-Co-HHx) With Cupriavidus necator Re2058/PCB113. Front. Bioeng. Biotechnol. 2021, 9, 623890. [Google Scholar] [CrossRef]

- Wang, J.; Li, C.; Zou, Y.; Yan, Y. Bacterial Synthesis of C3-C5 Diols via Extending Amino Acid Catabolism. Korea Adv. Inst. Sci. Technol. 2020, 117, 19159–19167. [Google Scholar] [CrossRef]

- SelL, H.G. The Isolation of Mutants Not Accumulating Poly-β-Hydroxybutyric Acid. Arch. Mikrobiol. 1970, 71, 283–294. [Google Scholar]

- Raberg, M.; Voigt, B.; Hecker, M.; Steinbüchel, A. A Closer Look on the Polyhydroxybutyrate- (PHB-) Negative Phenotype of Ralstonia eutropha PHB-4. PLoS ONE 2014, 9, e95907. [Google Scholar] [CrossRef] [PubMed]

- Chek, M.F.; Hiroe, A.; Hakoshima, T.; Sudesh, K.; Taguchi, S. PHA Synthase (PhaC): Interpreting the Functions of Bioplastic-Producing Enzyme from a Structural Perspective. Appl. Microbiol. Biotechnol. 2019, 103, 1131–1141. [Google Scholar] [CrossRef] [PubMed]

- Bhatia, S.K.; Kim, J.H.; Kim, M.S.; Kim, J.; Hong, J.W.; Hong, Y.G.; Kim, H.J.; Jeon, J.M.; Kim, S.H.; Ahn, J.; et al. Production of (3-Hydroxybutyrate-Co-3-Hydroxyhexanoate) Copolymer from Coffee Waste Oil Using Engineered Ralstonia eutropha. Bioprocess Biosyst. Eng. 2018, 41, 229–235. [Google Scholar] [CrossRef]

- Wang, H.; Ye, J.W.; Chen, X.; Yuan, Y.; Shi, J.; Liu, X.; Yang, F.; Ma, Y.; Chen, J.; Wu, F.; et al. Production of PHA Copolymers Consisting of 3-Hydroxybutyrate and 3-Hydroxyhexanoate (PHBHHx) by Recombinant Halomonas bluephagenesis. Chem. Eng. J. 2023, 466, 143261. [Google Scholar] [CrossRef]

- Harada, K.; Kobayashi, S.; Oshima, K.; Yoshida, S.; Tsuge, T.; Sato, S. Engineering of Aeromonas Caviae Polyhydroxyalkanoate Synthase Through Site-Directed Mutagenesis for Enhanced Polymerization of the 3-Hydroxyhexanoate Unit. Front. Bioeng. Biotechnol. 2021, 9, 627082. [Google Scholar] [CrossRef]

- Foong, C.P.; Lakshmanan, M.; Abe, H.; Taylor, T.D.; Foong, S.Y.; Sudesh, K. A Novel and Wide Substrate Specific Polyhydroxyalkanoate (PHA) Synthase from Unculturable Bacteria Found in Mangrove Soil. J. Polym. Res. 2018, 25, 23. [Google Scholar] [CrossRef]

- Tan, H.T.; Chek, M.F.; Lakshmanan, M.; Foong, C.P.; Hakoshima, T.; Sudesh, K. Evaluation of BP-M-CPF4 Polyhydroxyalkanoate (PHA) Synthase on the Production of Poly(3-Hydroxybutyrate-Co-3-Hydroxyhexanoate) from Plant Oil Using Cupriavidus necator Transformants. Int. J. Biol. Macromol. 2020, 159, 250–257. [Google Scholar] [CrossRef]

- Tan, H.T.; Chek, M.F.; Miyahara, Y.; Kim, S.Y.; Tsuge, T.; Hakoshima, T.; Sudesh, K. Characterization of an (R)-Specific Enoyl-CoA Hydratase from Streptomyces Sp. Strain CFMR 7: A Metabolic Tool for Enhancing the Production of Poly(3-Hydroxybutyrate-Co-3-Hydroxyhexanoate). J. Biosci. Bioeng. 2022, 134, 288–294. [Google Scholar] [CrossRef]

- Lim, S.W.; Kansedo, J.; Tan, I.S.; Tan, Y.H.; Nandong, J.; Lam, M.K.; Ongkudon, C.M. Microbial Valorization of Oil-Based Substrates for Polyhydroxyalkanoates (PHA) Production—Current Strategies, Status, and Perspectives. Process Biochem. 2023, 130, 715–733. [Google Scholar] [CrossRef]

- Du, C.; Sabirova, J.; Soetaert, W.; Ki, S.; Lin, C. Polyhydroxyalkanoates Production From Low-Cost Sustainable Raw Materials. Curr. Chem. Biol. 2012, 6, 14–25. [Google Scholar]

- Surendran, A.; Lakshmanan, M.; Chee, J.Y.; Sulaiman, A.M.; Van Thuoc, D.; Sudesh, K. Can Polyhydroxyalkanoates Be Produced Efficiently from Waste Plant and Animal Oils? Front. Bioeng. Biotechnol. 2020, 8, 169. [Google Scholar] [CrossRef] [PubMed]

- Fadzil, F.I.B.M.; Tsuge, T. Bioproduction of Polyhydroxyalkanoate from Plant Oils. In Microbial Applications; Springer International Publishing: Cham, Switzerland, 2017; Volume 2, pp. 231–260. ISBN 9783319526690. [Google Scholar]

- Ng, K.S.; Ooi, W.Y.; Goh, L.K.; Shenbagarathai, R.; Sudesh, K. Evaluation of Jatropha Oil to Produce Poly(3-Hydroxybutyrate) by Cupriavidus necator H16. Polym. Degrad. Stab. 2010, 95, 1365–1369. [Google Scholar] [CrossRef]

- Budde, C.F.; Riedel, S.L.; Willis, L.B.; Rha, C.K.; Sinskey, A.J. Production of Poly(3-Hydroxybutyrate-Co-3-Hydroxyhexanoate) from Plant Oil by Engineered Ralstonia Eutropha Strains. Appl. Environ. Microbiol. 2011, 77, 2847–2854. [Google Scholar] [CrossRef]

- Shenbagarathai, R.; Saranya, V. Effect of Nitrogen and Calcium Sources on Growth and Production of PHA of Pseudomonas Sp. LDC-5 and Its Mutant. Curr. Res. J. Biol. Sci. 2010, 2, 164–167. [Google Scholar]

- Gumel, A.M.; Annuar, M.S.M.; Chisti, Y. Recent Advances in the Production, Recovery and Applications of Polyhydroxyalkanoates. J. Polym. Environ. 2013, 21, 580–605. [Google Scholar] [CrossRef]

- Satoh, K.; Kawakami, T.; Isobe, N.; Pasquier, L.; Tomita, H.; Zinn, M.; Matsumoto, K. Versatile Aliphatic Polyester Biosynthesis System for Producing Random and Block Copolymers Composed of 2-, 3-, 4-, 5-, and 6-Hydroxyalkanoates Using the Sequence-Regulating Polyhydroxyalkanoate Synthase PhaCAR. Microb. Cell. Fact. 2022, 21, 84. [Google Scholar] [CrossRef]

- Volova, T.G.; Syrvacheva, D.A.; Zhila, N.O.; Sukovatiy, A.G. Synthesis of P(3HB-Co-3HHx) Copolymers Containing High Molar Fraction of 3-Hydroxyhexanoate Monomer by Cupriavidus Eutrophus B10646. J. Chem. Technol. Biotechnol. 2016, 91, 416–425. [Google Scholar] [CrossRef]

- Chuah, J.A.; Yamada, M.; Taguchi, S.; Sudesh, K.; Doi, Y.; Numata, K. Biosynthesis and Characterization of Polyhydroxyalkanoate Containing 5-Hydroxyvalerate Units: Effects of 5HV Units on Biodegradability, Cytotoxicity, Mechanical and Thermal Properties. Polym. Degrad. Stab. 2013, 98, 331–338. [Google Scholar] [CrossRef]

- Park, S.L.; Cho, J.Y.; Kim, S.H.; Bhatia, S.K.; Gurav, R.; Park, S.H.; Park, K.; Yang, Y.H. Isolation of Microbulbifer Sp. Sol66 with High Polyhydroxyalkanoate-Degrading Activity from the Marine Environment. Polymers 2021, 13, 4257. [Google Scholar] [CrossRef]

| C-Source | PHA Type | DCW (g/L) | PHA (g/L) | Content (%) | Ref. | |

|---|---|---|---|---|---|---|

| Copolymers | fructose | P (3HB-co-2.1 mol% 3HP) | 2.5 | - | 31 | [18] |

| fructose | P (3HB-co-37.7 mol% 3HHx) | 1.42 ± 0.05 | - | 41.1 ± 3.0 | [19] | |

| fructose | P (3HB-co-64.9 mol% 3HV) | 1.5 ± 0.1 | - | 42.5 ± 3.8 | [20] | |

| fructose + ε-CL | P (3HB-co-4HB) | 7.5 | - | - | [14] | |

| waste rapeseed oil + propanol | P (3HB-co-3HV) | 14.7 ± 0.3 | 11.7 ± 0.7 | 80 | [21] | |

| P (3HB-co-3HV) * | 138 | 105 | 76 | |||

| fructose + coconut oil | P (3HB-co-3HHx) | 19 | 15 | - | [22] | |

| palm kernel oil + butyrate | P (3HB-co-3HHx) * | 153–175 | 113–138 | 73.3–78.6 | [23] | |

| Terpolymers | fructose + 4HVA + 5HVA | P (3HB-co-3HV-co-4HV-co-5HV) | 8.7 ± 0.1 | 6.3 ± 0.1 | 72 | [12] |

| fructose + GVL | P (3HB-co-3HV-co-4HV) | 8.2 ± 0.2 | - | 80 ± 2 | [14] | |

| fructose | P (3HB-co-3HV-co-3H4MV-co-3H2MP) | 1.67 ± 0.03 | 0.93 ± 0.03 | 55.9 ± 1.8 | [16] | |

| tung oil | P (3HB-co-3HV-co-3HHx) | 1.65 | 0.68 | 41.2 | [24] | |

| fructose + bean oil + DVL | P (3HB-co-3HHx-co-5HV) * | 66 | 49 | 73 | this work | |

| fructose + bean oil + DVL | P (3HB-co-3HHx-co-5HV) * | 90 | 69 | 77 | this work |

| PHA Composition | Properties | |||||||

|---|---|---|---|---|---|---|---|---|

| 3HB | 3HHx | 5HV | Tensile Strength (MPa) | Elongation at Break (%) | Young’s Modulus (MPa) | Mn (103) | Mw (103) | Dispersity |

| 91.5 | 3.6 | 4.9 | 9.03 ± 0.18 | 16.64 ± 1.36 | 112.14 ± 4.65 | 60 ± 10 | 306 ± 19 | 5.2 ± 0.5 |

| 92.9 | 7.1 | - | 6.81 ± 0.42 | 176.6 ± 18.24 | 81.71 ± 5.25 | 53 ± 3 | 354 ± 11 | 6.7 ± 0.2 |

| Tg (°C) | Tc (°C) | Tm (°C) | ΔH (mJ/mg) | |

|---|---|---|---|---|

| Poly(3HB-co-3HHx-co-5HV) | n.a. | n.a. | 151.5 ± 0.1 | 16.6 ± 0.3 |

| Poly(3HB-co-3HHx) | 2.6 ± 0.2 | 48.3 ± 0.3 | 175.5 ± 0.0 | 19.2 ± 0.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Oh, S.-J.; Shin, Y.; Oh, J.; Kim, S.; Lee, Y.; Choi, S.; Lim, G.; Joo, J.-C.; Jeon, J.-M.; Yoon, J.-J.; et al. Strategic Use of Vegetable Oil for Mass Production of 5-Hydroxyvalerate-Containing Polyhydroxyalkanoate from δ-Valerolactone by Engineered Cupriavidus necator. Polymers 2024, 16, 2773. https://doi.org/10.3390/polym16192773

Oh S-J, Shin Y, Oh J, Kim S, Lee Y, Choi S, Lim G, Joo J-C, Jeon J-M, Yoon J-J, et al. Strategic Use of Vegetable Oil for Mass Production of 5-Hydroxyvalerate-Containing Polyhydroxyalkanoate from δ-Valerolactone by Engineered Cupriavidus necator. Polymers. 2024; 16(19):2773. https://doi.org/10.3390/polym16192773

Chicago/Turabian StyleOh, Suk-Jin, Yuni Shin, Jinok Oh, Suwon Kim, Yeda Lee, Suhye Choi, Gaeun Lim, Jeong-Chan Joo, Jong-Min Jeon, Jeong-Jun Yoon, and et al. 2024. "Strategic Use of Vegetable Oil for Mass Production of 5-Hydroxyvalerate-Containing Polyhydroxyalkanoate from δ-Valerolactone by Engineered Cupriavidus necator" Polymers 16, no. 19: 2773. https://doi.org/10.3390/polym16192773

APA StyleOh, S.-J., Shin, Y., Oh, J., Kim, S., Lee, Y., Choi, S., Lim, G., Joo, J.-C., Jeon, J.-M., Yoon, J.-J., Bhatia, S. K., Ahn, J., Kim, H.-T., & Yang, Y.-H. (2024). Strategic Use of Vegetable Oil for Mass Production of 5-Hydroxyvalerate-Containing Polyhydroxyalkanoate from δ-Valerolactone by Engineered Cupriavidus necator. Polymers, 16(19), 2773. https://doi.org/10.3390/polym16192773