The Influence of Printing Speed and Temperature on the Mechanical, Absorptive, and Morphological Properties of PLA-Based Hybrid Materials Produced with an FDM-Type 3D Printer

Abstract

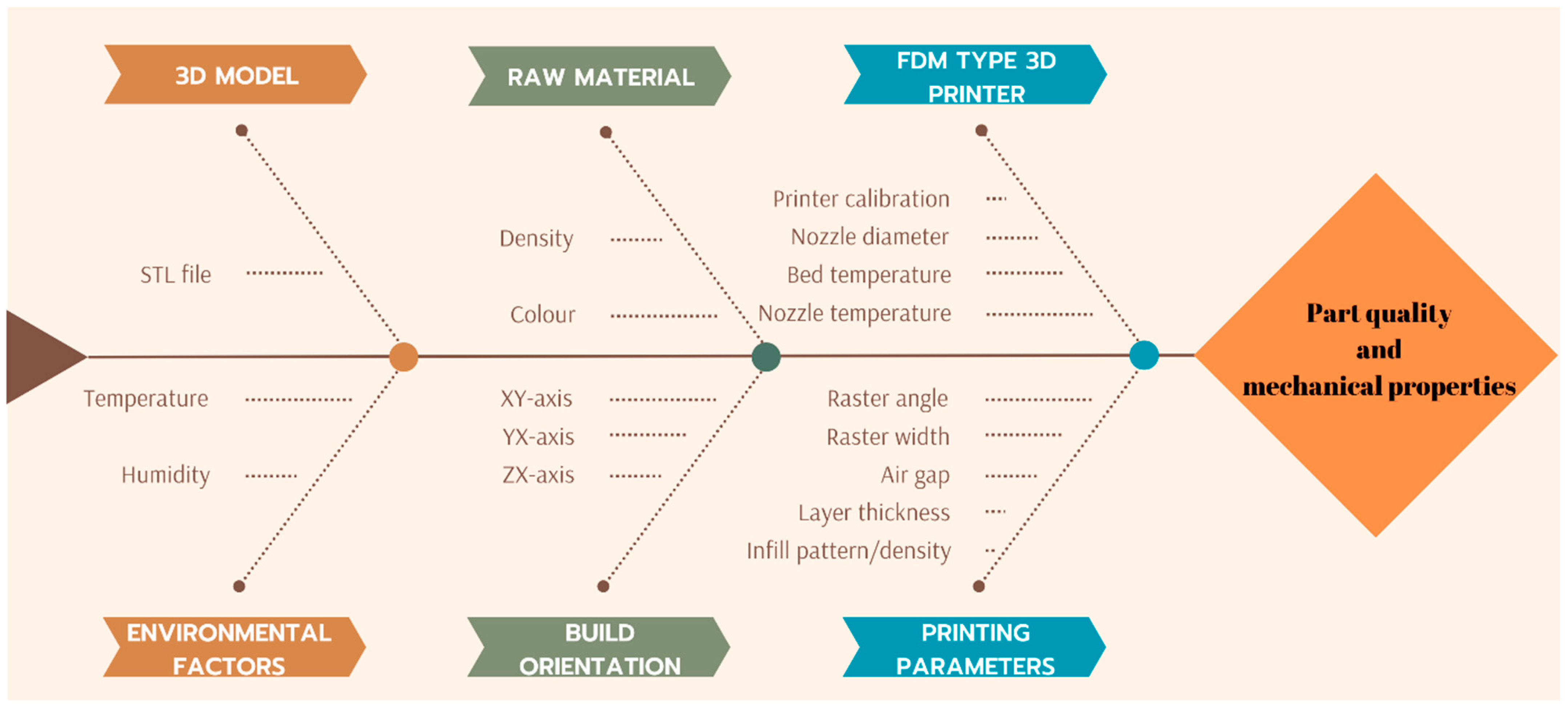

1. Introduction

2. Materials, Methods, and Specimen Preparation

2.1. FDM-Type 3D Printer Revision

2.2. Specimen Preparation

2.3. Characterisation

2.3.1. Mechanical Properties

2.3.2. Absorptive Properties

2.3.3. Morphological Properties

3. Results and Discussion

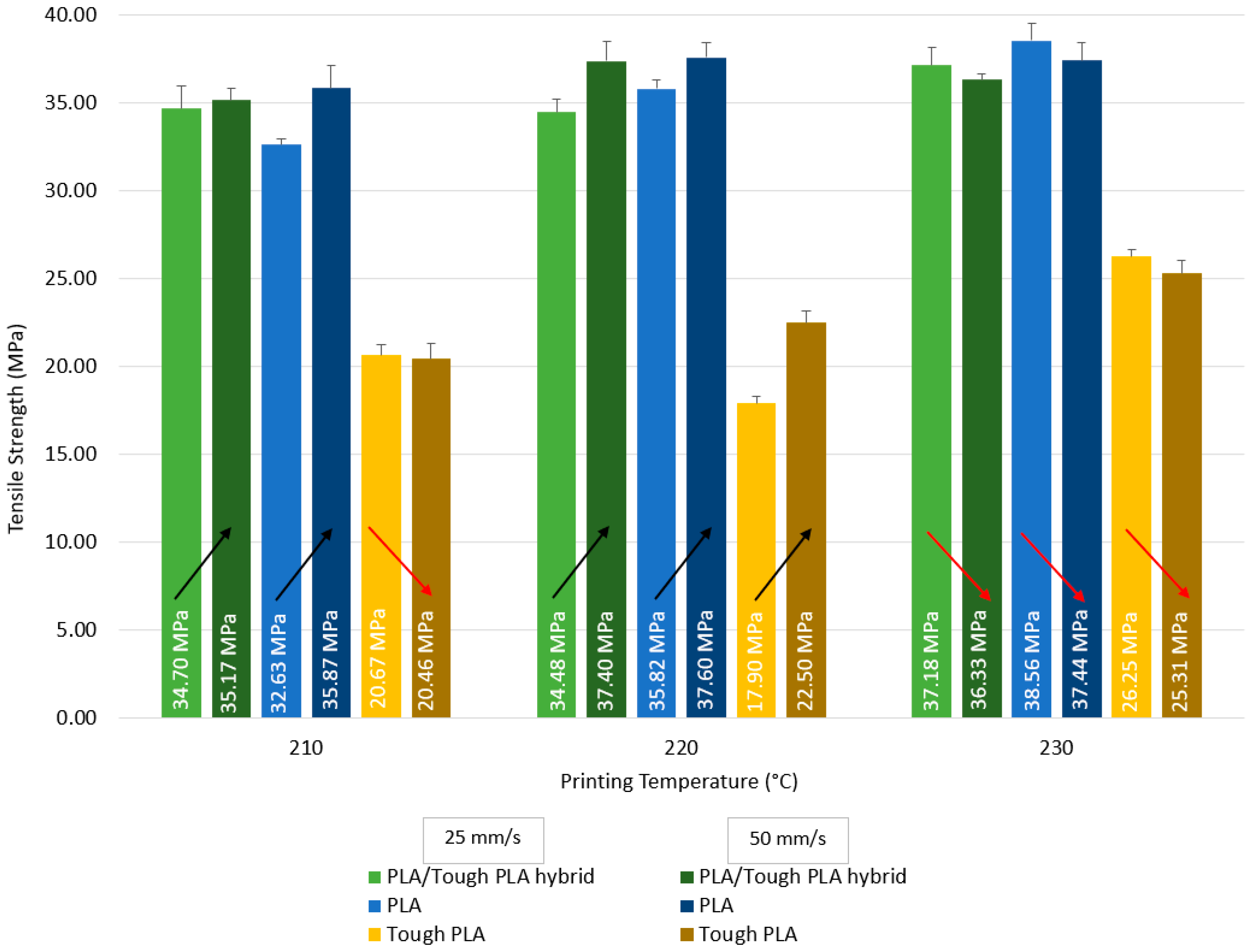

3.1. Tensile Tests

3.2. Three-Point Bending Tests

3.3. Absorptive Tests

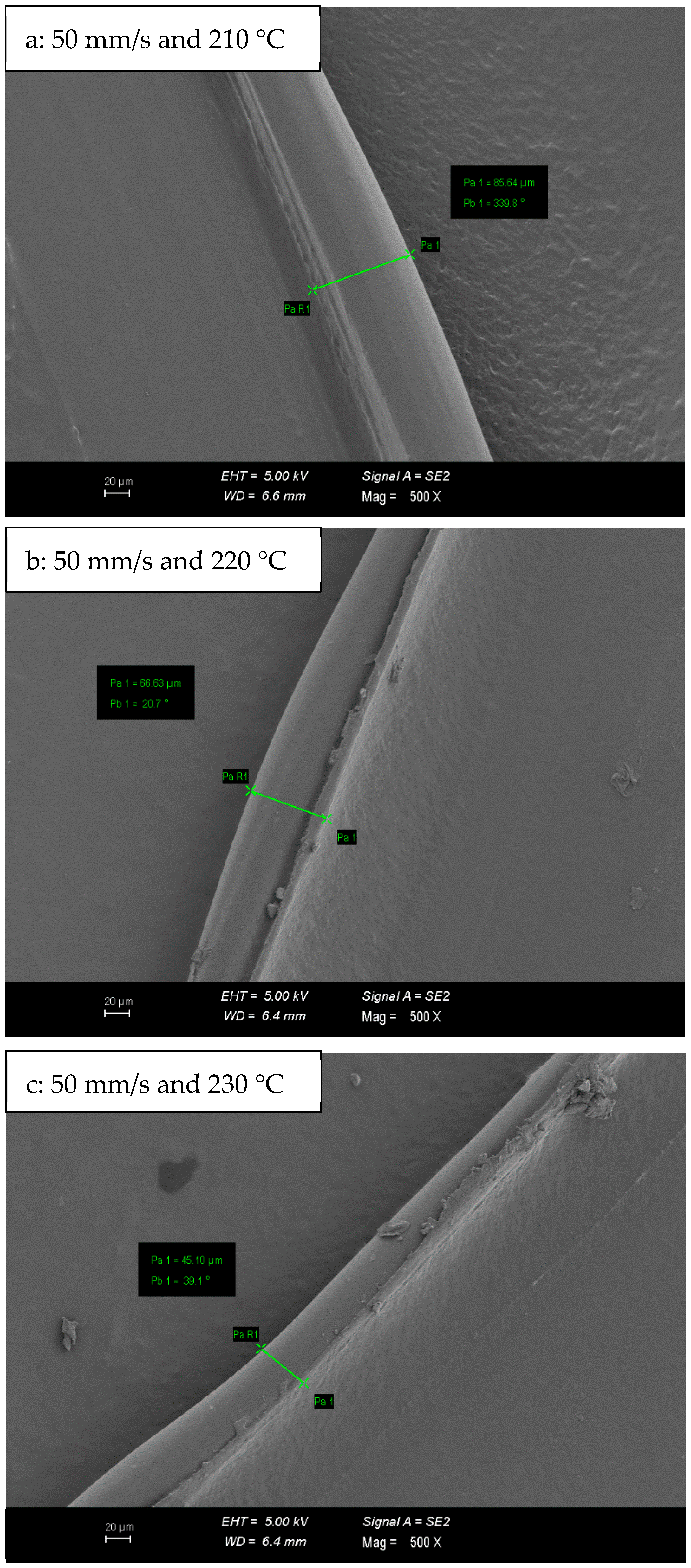

3.4. Morphological Analyses

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Kristiawan, R.B.; Imaduddin, F.; Ariawan, D.; Ubaidillah; Arifin, Z. A Review on the Fused Deposition Modeling (FDM) 3D Printing: Filament Processing, Materials, and Printing Parameters. Open Eng. 2021, 11, 639–649. [Google Scholar] [CrossRef]

- Morales, M.A.; Maranon, A.; Hernandez, C.; Michaud, V.; Porras, A. Colombian Sustainability Perspective on Fused Deposition Modeling Technology: Opportunity to Develop Recycled and Biobased 3D Printing Filaments. Polymers 2023, 15, 528. [Google Scholar] [CrossRef] [PubMed]

- Prayitno, G.; Imaduddin, F.; Ubaidillah; Arifin, Z. Recent Progress of Fused Deposition Modeling (FDM) 3D Printing: Constructions, Parameters and Processings. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1096, 012045. [Google Scholar] [CrossRef]

- Calignano, F.; Manfredi, D.; Ambrosio, E.P.; Biamino, S.; Lombardi, M.; Atzeni, E.; Salmi, A.; Minetola, P.; Iuliano, L.; Fino, P. Overview on Additive Manufacturing Technologies. Proc. IEEE 2017, 105, 593–612. [Google Scholar] [CrossRef]

- Jaisingh Sheoran, A.; Kumar, H. Fused Deposition Modeling Process Parameters Optimization and Effect on Mechanical Properties and Part Quality: Review and Reflection on Present Research. Mater. Today Proc. 2020, 21, 1659–1672. [Google Scholar] [CrossRef]

- He, F.; Khan, M. Effects of Printing Parameters on the Fatigue Behaviour of 3D-Printed ABS under Dynamic Thermo-Mechanical Loads. Polymers 2021, 13, 2362. [Google Scholar] [CrossRef]

- Vinitha, M.; Rao, A.N.; Mallik, M.K. Optimization of Speed Parameters in Burnishing of Samples Fabricated by Fused Deposition Modeling. Int. J. Mech. Ind. Eng. 2013, 2, 243–245. [Google Scholar] [CrossRef]

- Geng, P.; Zhao, J.; Wu, W.; Ye, W.; Wang, Y.; Wang, S.; Zhang, S. Effects of Extrusion Speed and Printing Speed on the 3D Printing Stability of Extruded PEEK Filament. J. Manuf. Process. 2019, 37, 266–273. [Google Scholar] [CrossRef]

- Caminero, M.A.; Chacón, J.M.; García-Moreno, I.; Rodríguez, G.P. Impact Damage Resistance of 3D Printed Continuous Fibre Reinforced Thermoplastic Composites Using Fused Deposition Modelling. Compos. Part B Eng. 2018, 148, 93–103. [Google Scholar] [CrossRef]

- Ayrilmis, N.; Kariz, M.; Kwon, J.H.; Kitek Kuzman, M. Effect of Printing Layer Thickness on Water Absorption and Mechanical Properties of 3D-Printed Wood/PLA Composite Materials. Int. J. Adv. Manuf. Technol. 2019, 102, 2195–2200. [Google Scholar] [CrossRef]

- Rahman, K.M.; Letcher, T.; Reese, R. Mechanical Properties of Additively Manufactured PEEK Components Using Fused Filament Fabrication. In Volume 2A: Advanced Manufacturing; American Society of Mechanical Engineers: Houston, TX, USA, 2015; p. V02AT02A009. [Google Scholar]

- Fatimatuzahraa, A.W.; Farahaina, B.; Yusoff, W.A.Y. The Effect of Employing Different Raster Orientations on the Mechanical Properties and Microstructure of Fused Deposition Modeling Parts. In Proceedings of the 2011 IEEE Symposium on Business, Engineering and Industrial Applications (ISBEIA), Langkawi, Malaysia, 25–28 September 2011; IEEE: Langkawi, Malaysia, 2011; pp. 22–27. [Google Scholar]

- Akderya, T. Effects of Post-UV-Curing on the Flexural and Absorptive Behaviour of FDM-3D-Printed Poly(Lactic Acid) Parts. Polymers 2023, 15, 348. [Google Scholar] [CrossRef] [PubMed]

- Fafenrot, S.; Grimmelsmann, N.; Wortmann, M.; Ehrmann, A. Three-Dimensional (3D) Printing of Polymer-Metal Hybrid Materials by Fused Deposition Modeling. Materials 2017, 10, 1199. [Google Scholar] [CrossRef] [PubMed]

- Ultrafuse® PLA—BASF FORWARD AM. Available online: https://forward-am.com/material-portfolio/ultrafuse-filaments-for-fused-filaments-fabrication-fff/standard-filaments/ultrafuse-pla/ (accessed on 30 July 2024).

- Ultrafuse® PLA PRO1—BASF FORWARD AM. Available online: https://forward-am.com/material-portfolio/ultrafuse-filaments-for-fused-filaments-fabrication-fff/engineering-filaments/ultrafuse-pla-pro1/ (accessed on 30 July 2024).

- Alsoufi, M.S.; Alhazmi, M.W.; Suker, D.K.; Alghamdi, T.A.; Sabbagh, R.A.; Felemban, M.A.; Bazuhair, F.K. Experimental Characterization of the Influence of Nozzle Temperature in FDM 3D Printed Pure PLA and Advanced PLA+. Am. J. Mech. Eng. 2019, 7, 45–60. [Google Scholar] [CrossRef]

- Wang, S.; Ma, Y.; Deng, Z.; Zhang, S.; Cai, J. Effects of Fused Deposition Modeling Process Parameters on Tensile, Dynamic Mechanical Properties of 3D Printed Polylactic Acid Materials. Polym. Test. 2020, 86, 106483. [Google Scholar] [CrossRef]

- Hsueh, M.-H.; Lai, C.-J.; Wang, S.-H.; Zeng, Y.-S.; Hsieh, C.-H.; Pan, C.-Y.; Huang, W.-C. Effect of Printing Parameters on the Thermal and Mechanical Properties of 3D-Printed PLA and PETG, Using Fused Deposition Modeling. Polymers 2021, 13, 1758. [Google Scholar] [CrossRef] [PubMed]

- ISO 527; Plastics—Determination of Tensile Properties. ISO: Geneva, Switzerland, 2012.

- ASTM D790; Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials. ASTM: West Conshohocken, PA, USA, 2017.

- ASTM D570; Standard Test Method for Water Absorption of Plastics. ASTM: West Conshohocken, PA, USA, 2010.

- ASTM E986-04; Standard Practice for Scanning Electron Microscope Beam Size Characterization. ASTM International: West Conshohocken, PA, USA, 1997.

- Kuznetsov, V.; Solonin, A.; Urzhumtsev, O.; Schilling, R.; Tavitov, A. Strength of PLA Components Fabricated with Fused Deposition Technology Using a Desktop 3D Printer as a Function of Geometrical Parameters of the Process. Polymers 2018, 10, 313. [Google Scholar] [CrossRef]

- Ning, F.; Cong, W.; Hu, Y.; Wang, H. Additive Manufacturing of Carbon Fiber-Reinforced Plastic Composites Using Fused Deposition Modeling: Effects of Process Parameters on Tensile Properties. J. Compos. Mater. 2017, 51, 451–462. [Google Scholar] [CrossRef]

- Drummer, D.; Cifuentes-Cuéllar, S.; Rietzel, D. Suitability of PLA/TCP for Fused Deposition Modeling. Rapid Prototyp. J. 2012, 18, 500–507. [Google Scholar] [CrossRef]

- Liu, X.; Li, S.; Liu, Z.; Zheng, X.; Chen, X.; Wang, Z. An Investigation on Distortion of PLA Thin-Plate Part in the FDM Process. Int. J. Adv. Manuf. Technol. 2015, 79, 1117–1126. [Google Scholar] [CrossRef]

- Valerga, A.P.; Batista, M.; Salguero, J.; Girot, F. Influence of PLA Filament Conditions on Characteristics of FDM Parts. Materials 2018, 11, 1322. [Google Scholar] [CrossRef]

- Ding, Q.; Li, X.; Zhang, D.; Zhao, G.; Sun, Z. Anisotropy of Poly(Lactic Acid)/Carbon Fiber Composites Prepared by Fused Deposition Modeling. J. Appl. Polym. Sci. 2020, 137, 48786. [Google Scholar] [CrossRef]

- Re, G.L.; Benali, S.; Habibi, Y.; Raquez, J.-M.; Dubois, P. Stereocomplexed PLA Nanocomposites: From In Situ Polymerization to Materials Properties. Eur. Polym. J. 2014, 54, 138–150. [Google Scholar] [CrossRef]

- Tian, X.; Liu, T.; Yang, C.; Wang, Q.; Li, D. Interface and Performance of 3D Printed Continuous Carbon Fiber Reinforced PLA Composites. Compos. Part A Appl. Sci. Manuf. 2016, 88, 198–205. [Google Scholar] [CrossRef]

- Sin, L.T.; Rahmat, A.R.; Rahman, W.A.W.A. Thermal Properties of Poly(Lactic Acid). In Polylactic Acid; Elsevier: Amsterdam, The Netherlands, 2013; pp. 109–141. ISBN 978-1-4377-4459-0. [Google Scholar]

- Nathaphan, S.; Trutassanawin, W. Effects of Process Parameters on Compressive Property of FDM with ABS. Rapid Prototyp. J. 2021, 27, 905–917. [Google Scholar] [CrossRef]

- Davis, C.S.; Hillgartner, K.E.; Han, S.H.; Seppala, J.E. Mechanical Strength of Welding Zones Produced by Polymer Extrusion Additive Manufacturing. Addit. Manuf. 2017, 16, 162–166. [Google Scholar] [CrossRef] [PubMed]

- Ecker, J.V.; Haider, A.; Burzic, I.; Huber, A.; Eder, G.; Hild, S. Mechanical Properties and Water Absorption Behaviour of PLA and PLA/Wood Composites Prepared by 3D Printing and Injection Moulding. Rapid Prototyp. J. 2019, 25, 672–678. [Google Scholar] [CrossRef]

- Torres, J.; Cole, M.; Owji, A.; DeMastry, Z.; Gordon, A.P. An Approach for Mechanical Property Optimization of Fused Deposition Modeling with Polylactic Acid via Design of Experiments. Rapid Prototyp. J. 2016, 22, 387–404. [Google Scholar] [CrossRef]

- Ding, S.; Zou, B.; Wang, P.; Ding, H. Effects of Nozzle Temperature and Building Orientation on Mechanical Properties and Microstructure of PEEK and PEI Printed by 3D-FDM. Polym. Test. 2019, 78, 105948. [Google Scholar] [CrossRef]

| Product Parameters | Unit | Value |

|---|---|---|

| Moulding technology | - | FDM |

| Materials | - | PLA, Tough PLA |

| Volumetric hybridisation ratio | (%) | 50/50 |

| Filament diameter | (mm) | 1.75 |

| Nozzle diameter | (mm) | 0.4 |

| Nozzle temperature | (°C) | 210, 220, 230 |

| Bed temperature | (°C) | 50 |

| Printing accuracy | (mm) | ±0.1 |

| Printing speed | (mm/s) | 25, 50 |

| Layer height | (mm) | 0.2 |

| Infill density | (%) | 100 |

| Raster angle | (°) | 45 |

| Environmental temperature | (°C) | 28 |

| Environmental humidity | (%) | 45 (±5%) |

| Young’s Modulus (GPa) | |||||||

|---|---|---|---|---|---|---|---|

| PLA/Tough PLA Hybrid | PLA | Tough PLA | |||||

| Printing Speed (mm/s) | 25 | 50 | 25 | 50 | 25 | 50 | |

| Printing Temperature (°C) | 210 | 2.58 (±0.27) | 2.56 (±0.27) | 3.04 (±0.08) | 3.32 (±0.14) | 2.35 (±0.24) | 2.33 (±0.08) |

| 220 | 2.81 (±0.47) | 3.00 (±0.20) | 2.55 (±0.61) | 2.95 (±0.16) | 2.10 (±0.07) | 2.28 (±0.13) | |

| 230 | 2.92 (±0.20) | 2.80 (±0.13) | 2.85 (±0.27) | 2.79 (±0.13) | 2.54 (±0.15) | 2.52 (±0.14) | |

| Flexural Modulus (GPa) | |||||||

|---|---|---|---|---|---|---|---|

| PLA/Tough PLA Hybrid | PLA | Tough PLA | |||||

| Printing Speed (mm/s) | 25 | 50 | 25 | 50 | 25 | 50 | |

| Printing Temperature (°C) | 210 | 2.00 (±0.17) | 1.92 (±0.17) | 2.44 (±0.12) | 2.64 (±0.19) | 1.77 (±0.12) | 1.80 (±0.21) |

| 220 | 2.05 (±0.18) | 1.93 (±0.09) | 2.32 (±0.09) | 2.44 (±0.12) | 1.88 (±0.10) | 1.89 (±0.19) | |

| 230 | 2.09 (±0.09) | 2.25 (±0.10) | 2.23 (±0.16) | 2.45 (±0.12) | 1.76 (±0.11) | 1.86 (±0.15) | |

| Increase in Weight (%) | ||||||||

|---|---|---|---|---|---|---|---|---|

| PLA/Tough PLA Hybrid | PLA | Tough PLA | ||||||

| Printing Speed (mm/s) | 25 | 50 | 25 | 50 | 25 | 50 | ||

| Printing Temperature (°C) | 210 | 3 days 1 week 2 weeks | 0.51 1.49  1.19 | 0.53 1.38  1.23 | 0.50 1.55  1.39 | 0.60 1.50  1.30 | 0.51 1.51  1.41 | 0.52 1.57  1.33 |

| 220 | 3 days 1 week 2 weeks | 0.58 1.50  1.28 | 0.55 1.47  1.25 | 0.57 1.47  1.35 | 0.58 1.61  1.39 | 0.62 1.47  1.38 | 0.59 1.48  1.25 | |

| 230 | 3 days 1 week 2 weeks | 0.53 1.43  1.29 | 0.59 1.48  1.30 | 0.70 1.49  1.41 | 0.56 1.50  1.49 | 0.60 1.44  1.48 | 0.62 1.45  1.38 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

İncesu, R.; Akderya, T. The Influence of Printing Speed and Temperature on the Mechanical, Absorptive, and Morphological Properties of PLA-Based Hybrid Materials Produced with an FDM-Type 3D Printer. Polymers 2024, 16, 2771. https://doi.org/10.3390/polym16192771

İncesu R, Akderya T. The Influence of Printing Speed and Temperature on the Mechanical, Absorptive, and Morphological Properties of PLA-Based Hybrid Materials Produced with an FDM-Type 3D Printer. Polymers. 2024; 16(19):2771. https://doi.org/10.3390/polym16192771

Chicago/Turabian Styleİncesu, Rumeysa, and Tarkan Akderya. 2024. "The Influence of Printing Speed and Temperature on the Mechanical, Absorptive, and Morphological Properties of PLA-Based Hybrid Materials Produced with an FDM-Type 3D Printer" Polymers 16, no. 19: 2771. https://doi.org/10.3390/polym16192771

APA Styleİncesu, R., & Akderya, T. (2024). The Influence of Printing Speed and Temperature on the Mechanical, Absorptive, and Morphological Properties of PLA-Based Hybrid Materials Produced with an FDM-Type 3D Printer. Polymers, 16(19), 2771. https://doi.org/10.3390/polym16192771