Development of Flexible and Partly Water-Soluble Binder Systems for Metal Fused Filament Fabrication (MF3) of Ti-6Al-4V Parts

Abstract

1. Introduction

2. Materials and Methods

2.1. Material Selection

2.2. Compounding and Extrusion

2.3. Rheological Characterization

- Temperature: 160 °C,

- Capillary length and diameter: 30 and 1 mm,

- Shear rate range: 1 to 3000 s−1.

- Temperature: 20–50 °C,

- Frequency: 0.5 Hz,

- Amplitude: 50 µm,

- Pre-force: 0.1 N.

2.4. Fused Filament Fabrication

2.5. Debinding and Sintering

2.6. Characterization of Sintered Samples

3. Results and Discussion

3.1. Materials Characterization

3.2. PVB/PEG

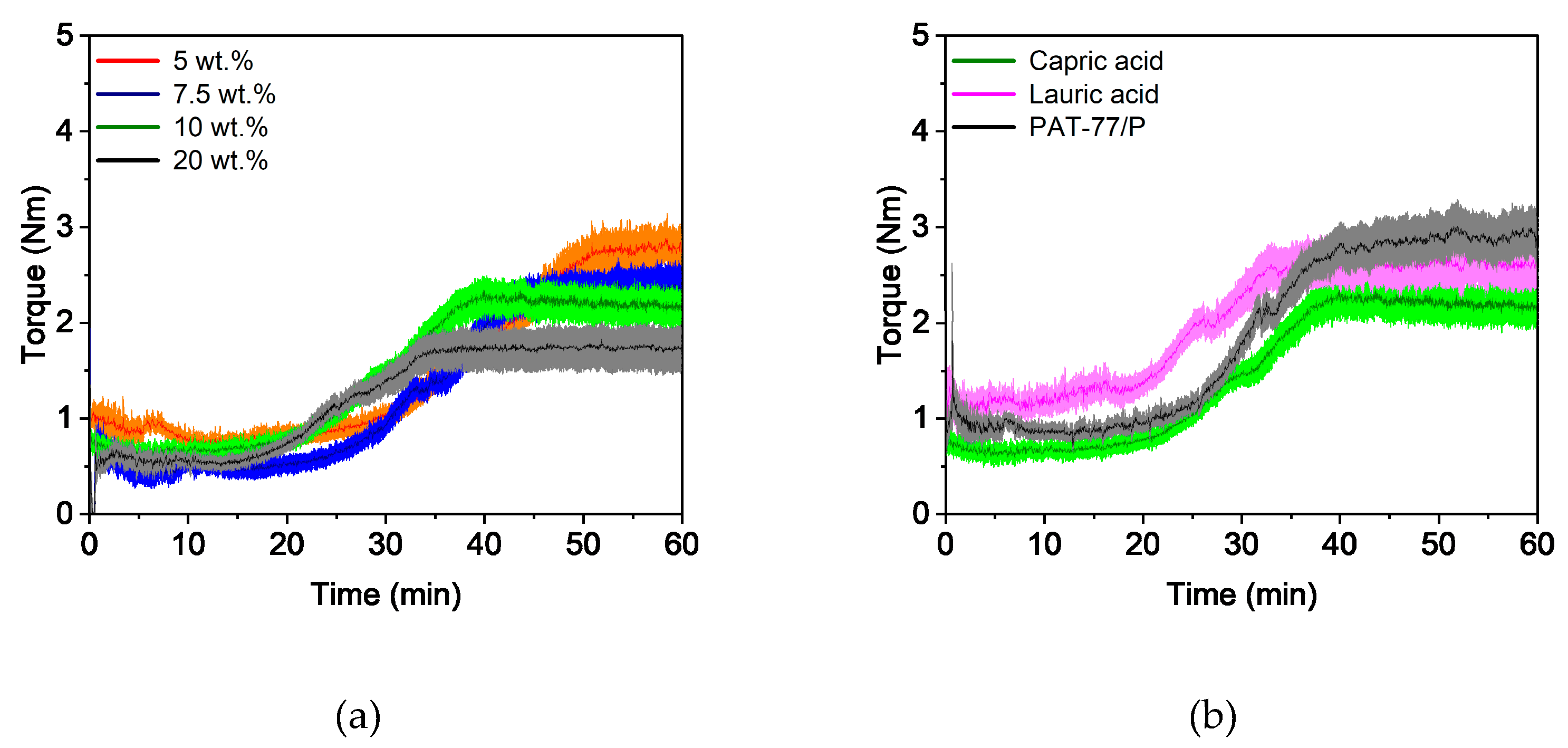

3.2.1. Compounding and Extrusion

3.2.2. Rheological Characterization

Capillary Rheology

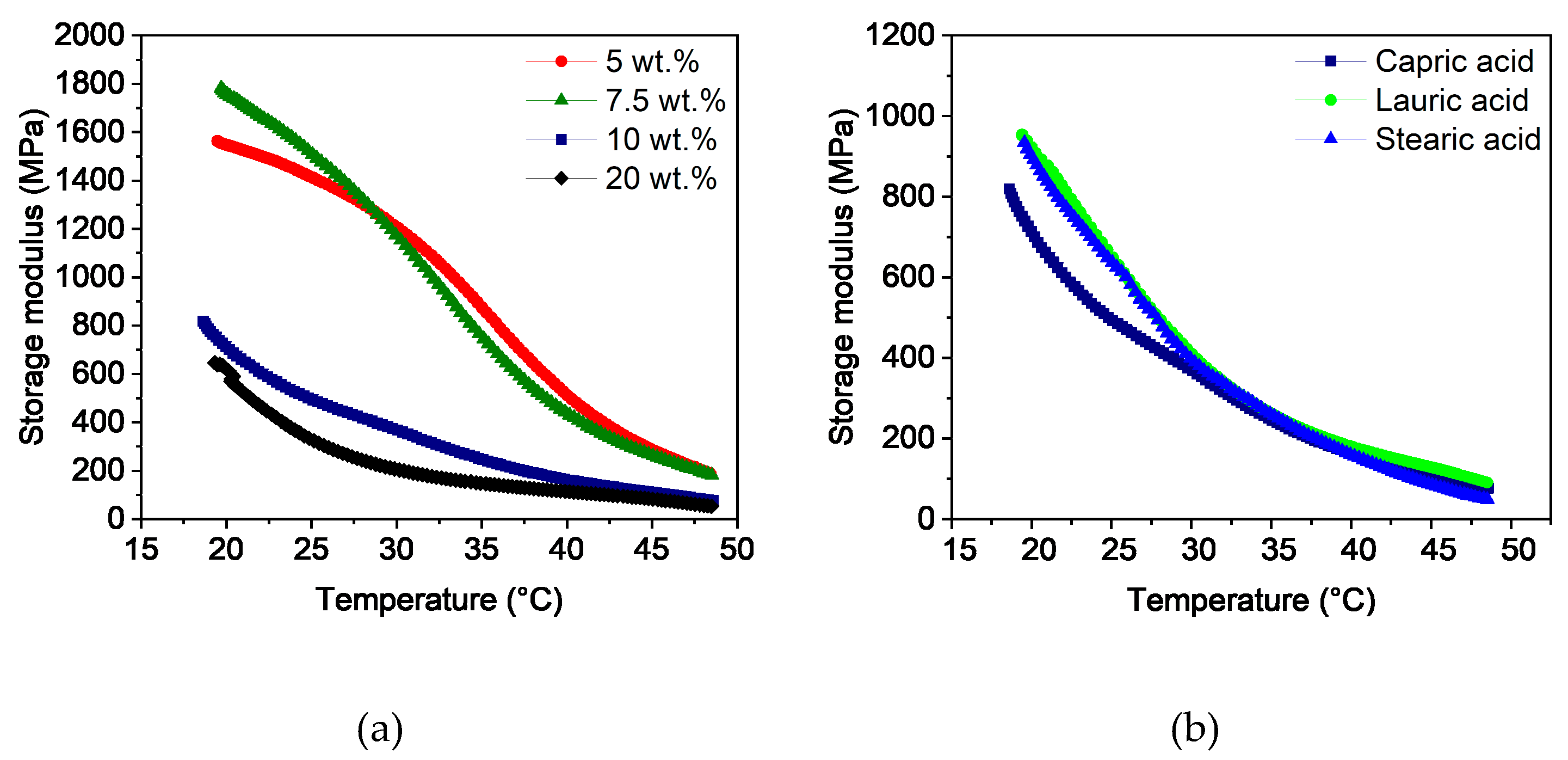

DMA

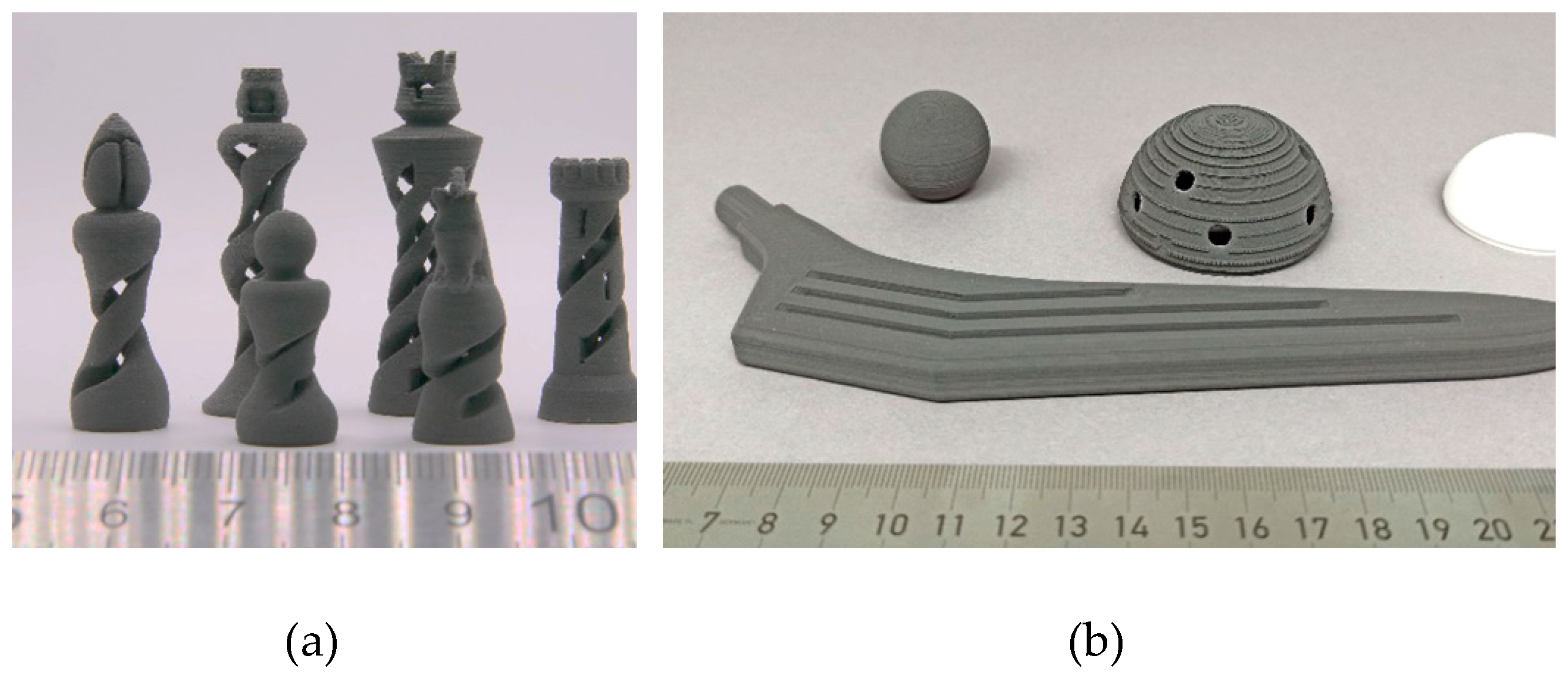

3.2.3. Fused Filament Fabrication

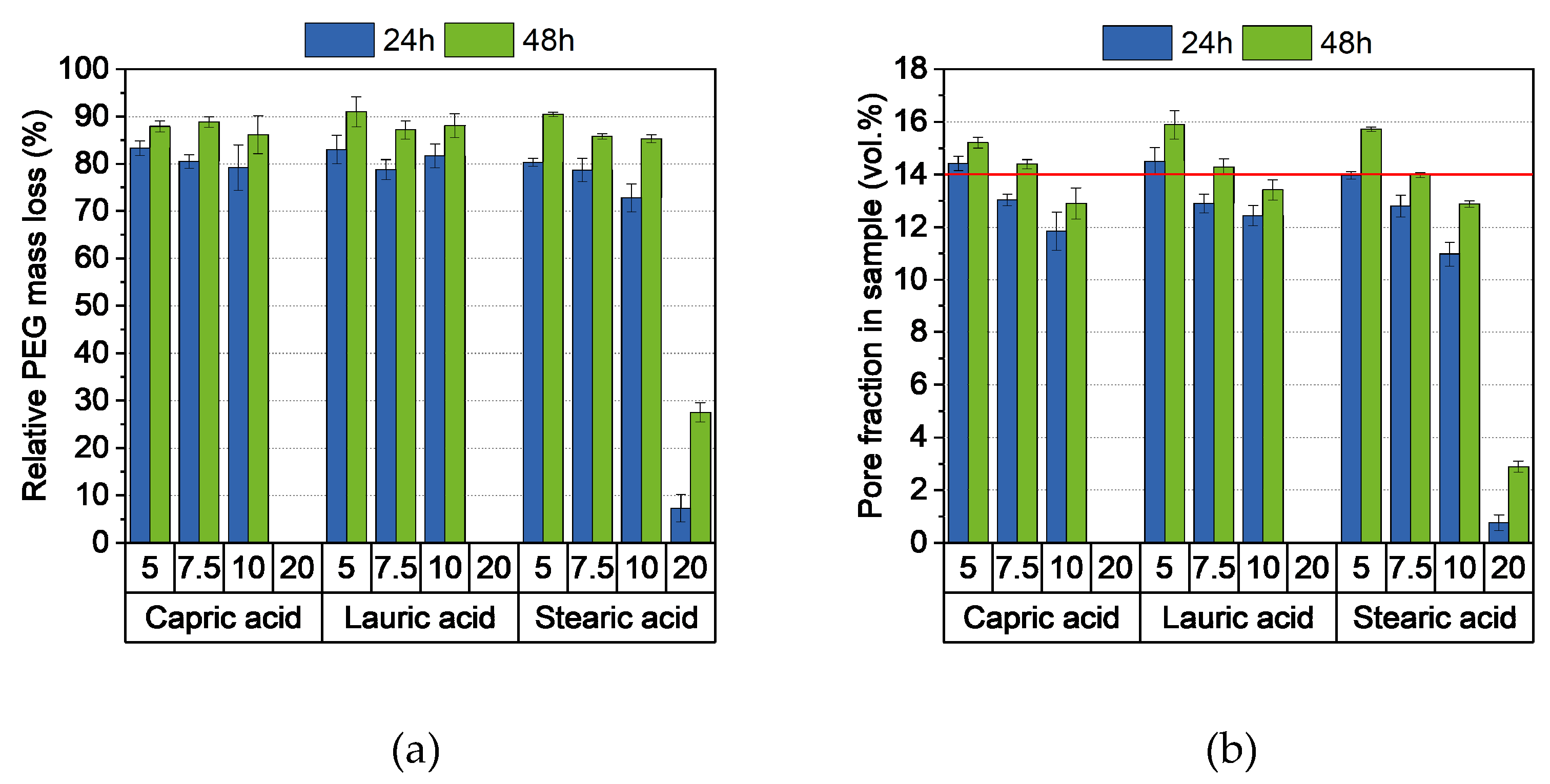

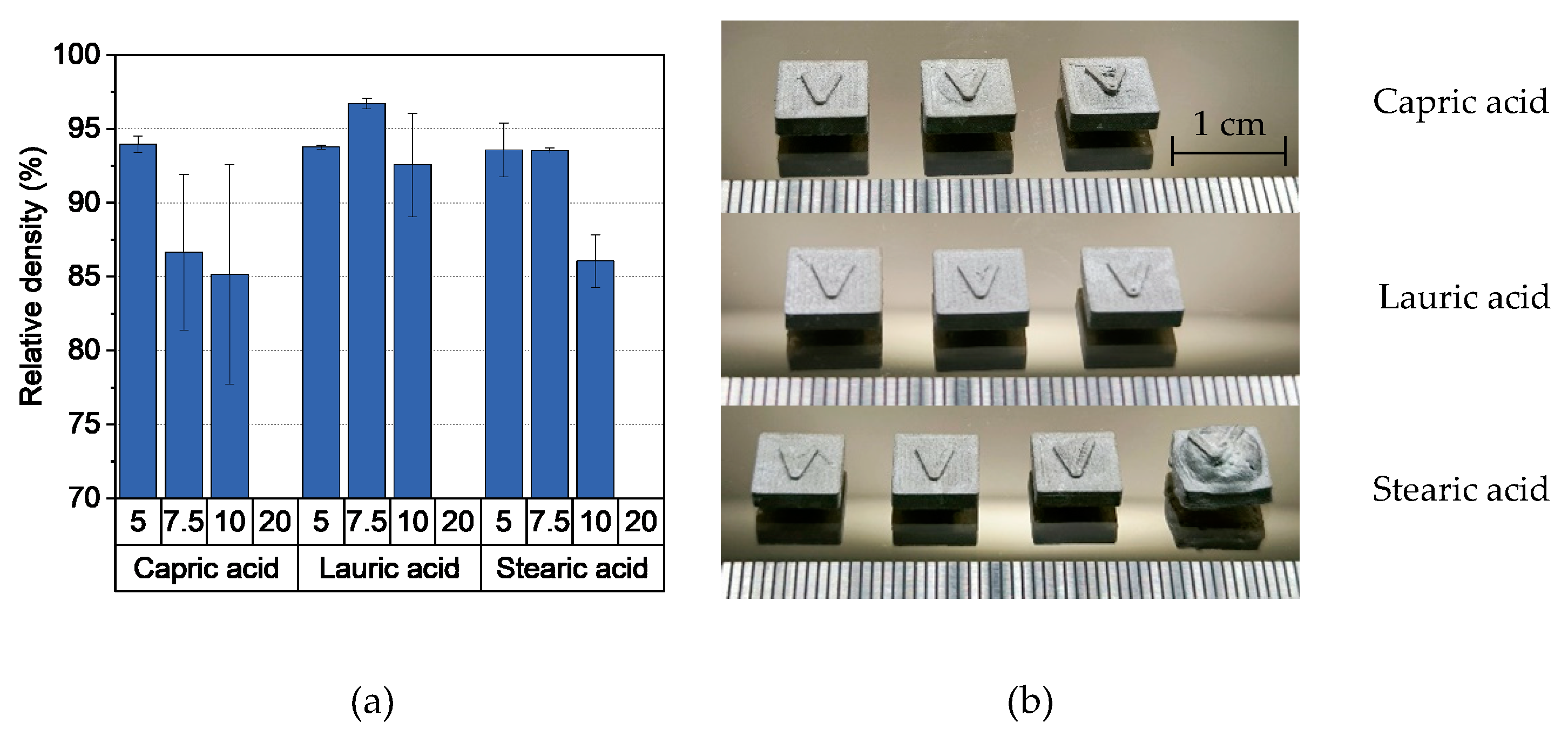

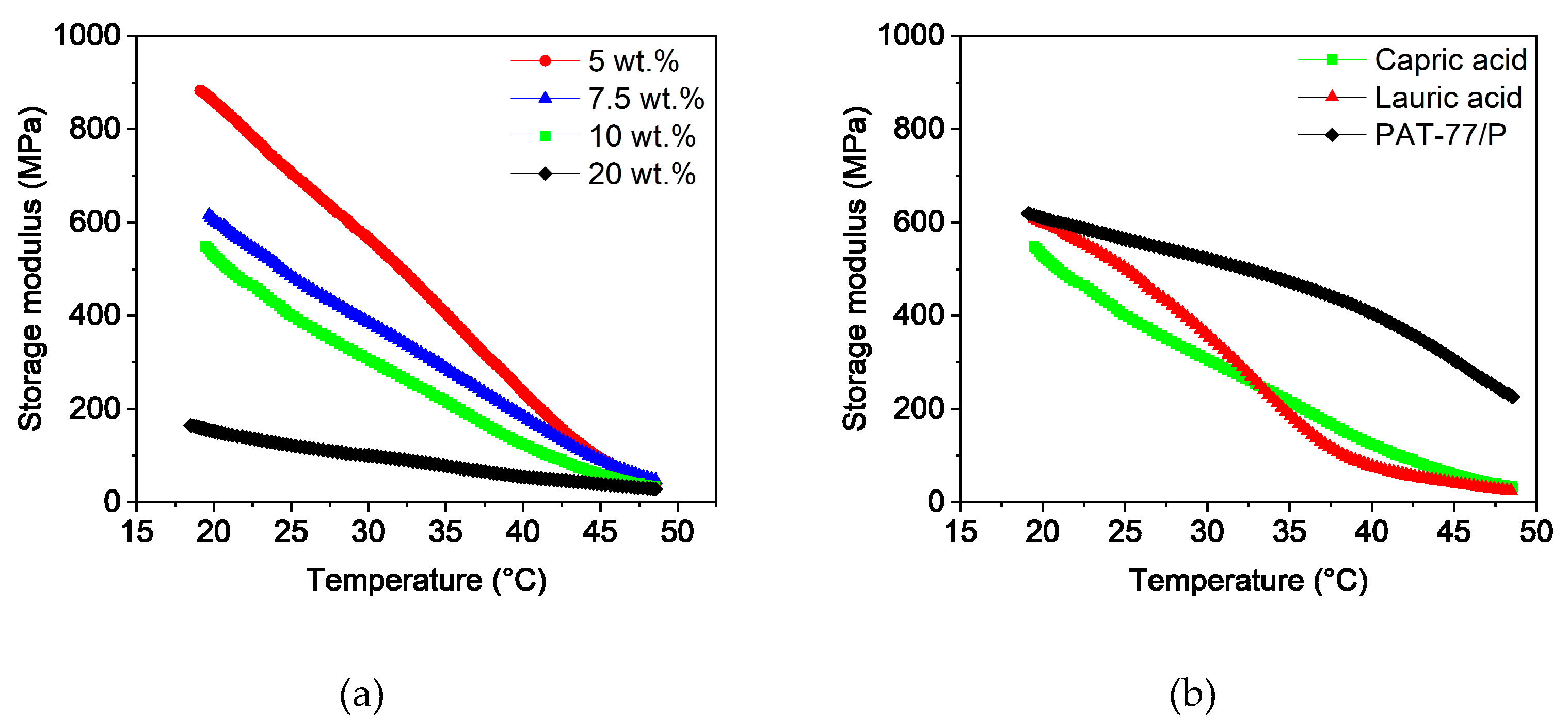

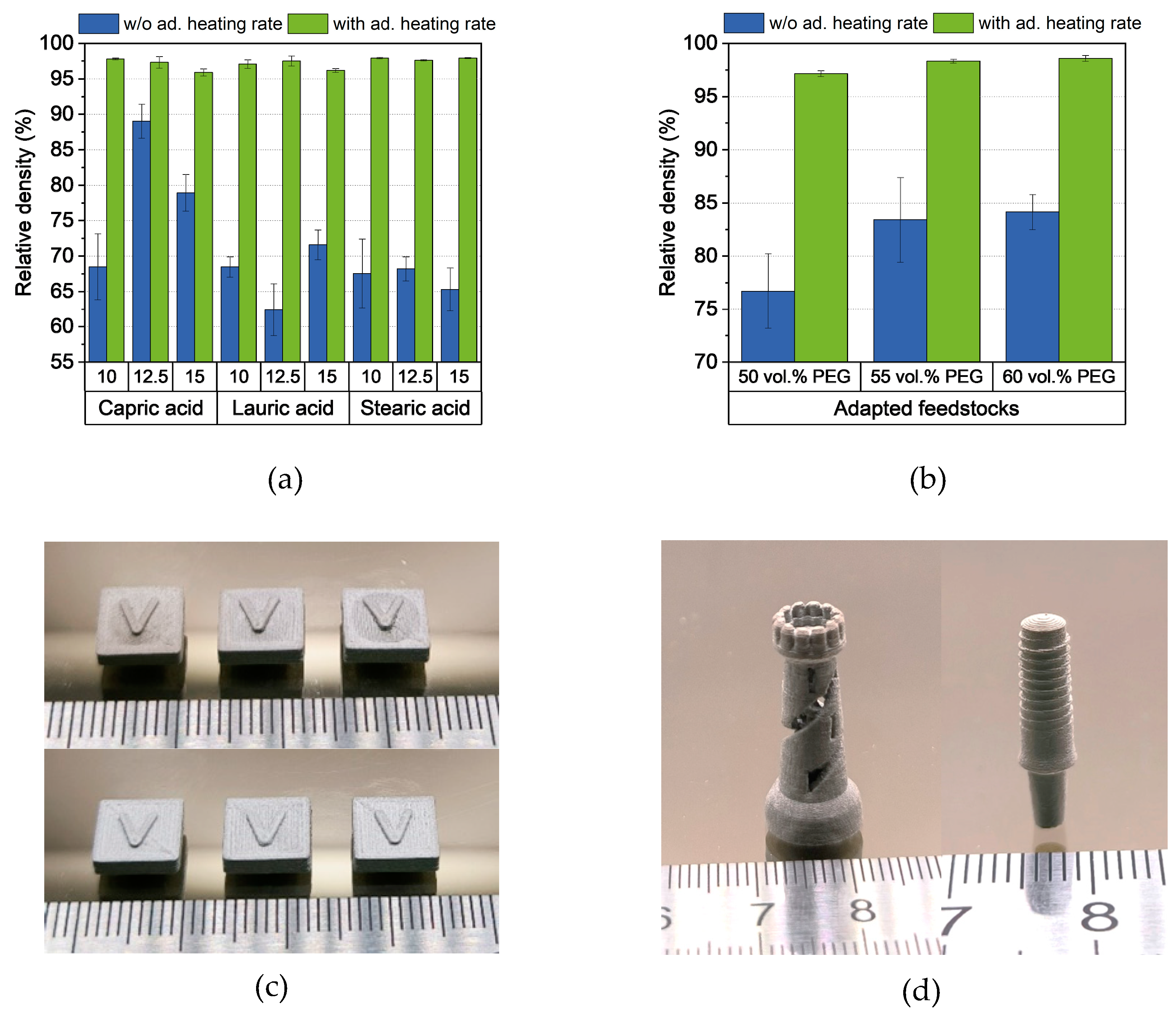

3.2.4. Debinding and Sintering

3.3. PMMA/PEG

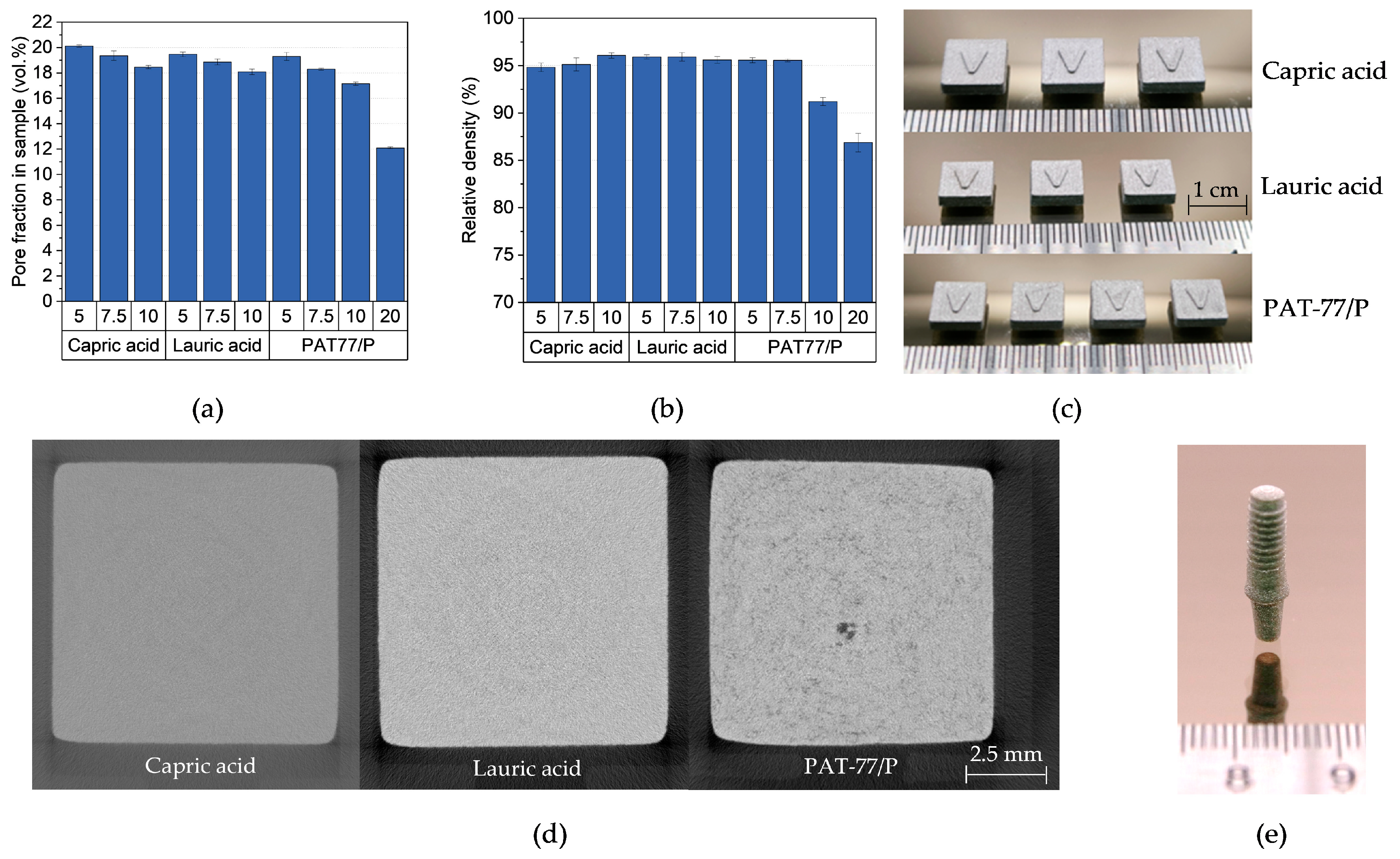

3.3.1. Compounding and Extrusion

3.3.2. Rheological Characterization

Capillary Rheology

DMA

3.3.3. Fused Filament Fabrication

3.3.4. Debinding and Sintering

3.4. PMMA/PVB/PEG

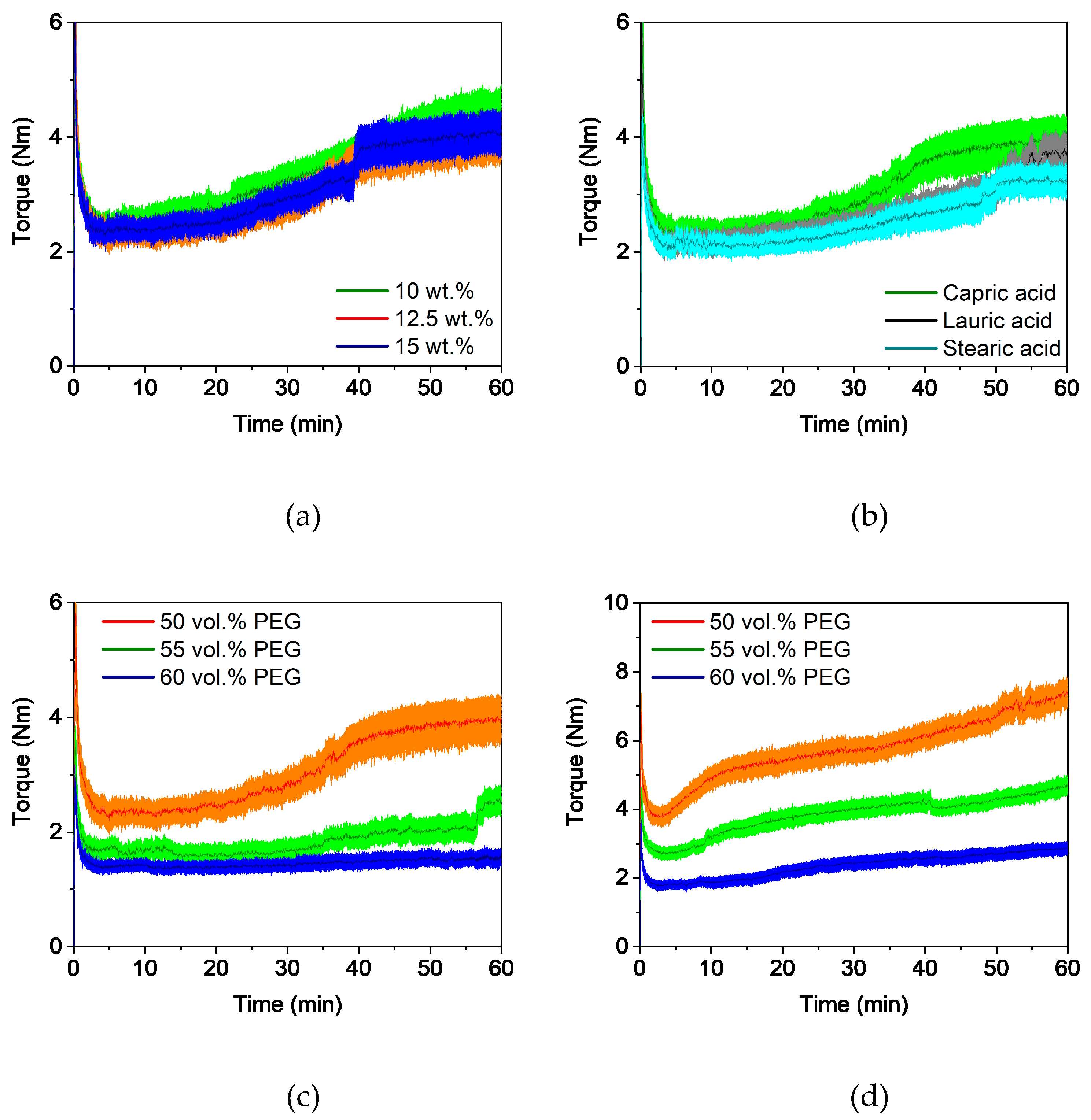

3.4.1. Compounding and Extrusion

3.4.2. Rheological Characterization

Capillary Rheology

DMA

3.4.3. Fused Filament Fabrication

3.4.4. Debinding and Sintering

4. Conclusions and Outlook

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Tebianian, M.; Aghaie, S.; Razavi Jafari, N.S.; Elmi Hosseini, S.R.; Pereira, A.B.; Fernandes, F.A.O.; Farbakhti, M.; Chen, C.; Huo, Y. A Review of the Metal Additive Manufacturing Processes. Materials 2023, 16, 24. [Google Scholar] [CrossRef] [PubMed]

- Blakey-Milner, B.; Gradl, P.; Snedden, G.; Brooks, M.; Pitot, J.; Lopez, E.; Leary, M.; Berto, F.; Du Plessis, A. Metal additive manufacturing in aerospace: A review. Mater. Des. 2021, 209, 110008. [Google Scholar] [CrossRef]

- Mohammed, M.T.; Semelov, V.G.; Sotov, A.V. SLM-built titanium materials: Great potential of developing microstructure and properties for biomedical applications: A review. Mater. Res. Express 2019, 6, 122006. [Google Scholar] [CrossRef]

- Gunasekaran, J.; Sevvel, P.; Solomon, I.J. Metallic materials fabrication by selective laser melting: A review. Mater. Today Proc. 2021, 37, 252–256. [Google Scholar] [CrossRef]

- Parenti, P.; Puccio, D.; Semeraro, Q.; Colosimo, B.M. A techno-economic approach for decision-making in metal additive manufacturing: Metal extrusion versus single and multiple laser powder bed fusion. Prog. Addit. Manuf. 2023, 9, 185–210. [Google Scholar] [CrossRef]

- Dağ, I.E.; Avar, B. Additively Manufactured Medical Implants. In Practical Implementations of Additive Manufacturing Technologies; Rajendrachari, S., Ed.; Springer: Singapore, 2024; pp. 219–250. [Google Scholar]

- Shaikh, M.Q.; Nath, S.D.; Akilan, A.A.; Khanjar, S.; Balla, V.K.; Grant, G.T.; Atre, S.V. Investigation of Patient-Specific Maxillofacial Implant Prototype Development by Metal Fused Filament Fabrication (MF3) of Ti-6Al-4V. J. Dent. 2021, 9, 109. [Google Scholar] [CrossRef]

- Nötzel, D.; Eickhoff, R.; Pfeifer, C.; Hanemann, T. Printing of Zirconia Parts via Fused Filament Fabrication. Materials 2021, 14, 5467. [Google Scholar] [CrossRef]

- Vozárová, M.; Neubauer, E.; Bača, Ľ.; Kitzmantel, M.; Feranc, J.; Trembošová, V.; Peciar, P.; Kritikos, M.; Orlovská, M.; Janek, M.; et al. Preparation of fully dense boron carbide ceramics by Fused Filament Fabrication (FFF). J. Eur. Ceram. Soc. 2023, 43, 1751–1761. [Google Scholar] [CrossRef]

- Truxova, V.; Safka, J.; Sobotka, J.; Machacek, J.; Ackermann, M. Alumina Manufactured by Fused Filament Fabrication: A Comprehensive Study of Mechanical Properties and Porosity. J. Polym. 2022, 14, 5. [Google Scholar] [CrossRef]

- Nötzel, D.; Eickhoff, R.; Hanemann, T. Fused Filament Fabrication of Small Ceramic Components. J. Mater. 2018, 11, 8. [Google Scholar] [CrossRef]

- de la Torre-Gamarra, C.; Garcia-Suelto, M.D.; Del Rio Santos, D.; Levenfeld, B.; Varez, A. 3D-printing of easily recyclable all-ceramic thick LiCoO(2) electrodes with enhanced areal capacity for Li-ion batteries using a highly filled thermoplastic filament. J. Colloid Interface Sci. 2023, 642, 351–363. [Google Scholar] [CrossRef] [PubMed]

- Valera-Jiménez, J.F.; Pérez-Flores, J.C.; Castro-García, M.; Canales-Vázquez, J. Development of full ceramic electrodes for lithium-ion batteries via desktop-fused filament fabrication and further sintering. Appl. Mater. Today 2021, 25, 101243. [Google Scholar] [CrossRef]

- Kutlu, A.C.; Nötzel, D.; Ziebert, C.; Seifert, H.J.; Ul Mohsin, I. 3D Printing of Na1.3Al0.3Ti1.7(PO4)3 Solid Electrolyte via Fused Filament Fabrication for All-Solid-State Sodium-Ion Batteries. Batter. Supercaps 2023, 7, 1. [Google Scholar] [CrossRef]

- Abel, J.; Scheithauer, U.; Janics, T.; Hampel, S.; Cano, S.; Müller-Köhn, A.; Günther, A.; Kukla, C.; Moritz, T. Fused Filament Fabrication (FFF) of Metal-Ceramic Components. JoVE 2019, 143, e57693. [Google Scholar]

- Atre, S.; Weaver, T.; German, R. Injection Molding of Metals and Ceramics; SAE Technical Paper; SAE: Warrendale, PA, USA, 1998. [Google Scholar]

- Shibo, G.; Xuanhui, Q.; Xinbo, H.; Ting, Z.; Bohua, D. Powder injection molding of Ti–6Al–4V alloy. J. Mater. Process. Technol. 2006, 173, 310–314. [Google Scholar] [CrossRef]

- Wen, G.; Cao, P.; Gabbitas, B.; Zhang, D.; Edmonds, N. Development and Design of Binder Systems for Titanium Metal Injection Molding: An Overview. Metall. Mater. Trans. A 2013, 44, 1530–1547. [Google Scholar] [CrossRef]

- Kuznetsov, V.E.; Solonin, A.N.; Tavitov, A.; Urzhumtsev, O.; Vakulik, A. Increasing strength of FFF three-dimensional printed parts by influencing on temperature-related parameters of the process. Rapid Prototyp. J. 2020, 26, 107–121. [Google Scholar] [CrossRef]

- Kennedy, Z.C.; Christ, J.F.; Fenn, M.D.; Zhong, L.; Chouyyok, W.; Arnold, A.M.; Denny, A.C.; Albrecht, A.M.; Silverstein, J.A.; Erikson, R.L.; et al. Mica filled polyetherketoneketones for material extrusion 3D printing. Addit. Manuf. 2022, 49, 102492. [Google Scholar] [CrossRef]

- Eickhoff, R.; Antusch, S.; Baumgartner, S.; Nötzel, D.; Hanemann, T. Feedstock Development for Material Extrusion-Based Printing of Ti6Al4V Parts. Materials 2022, 15, 18. [Google Scholar] [CrossRef]

- Cerejo, F.; Gatões, D.; Vieira, M.T. Optimization of metallic powder filaments for additive manufacturing extrusion (MEX). Int. J. Adv. Manuf. Technol. 2021, 115, 2449–2464. [Google Scholar] [CrossRef]

- Lotfizarei, Z.; Mostafapour, A.; Barari, A.; Jalili, A.; Patterson, A.E. Overview of debinding methods for parts manufactured using powder material extrusion. Addit. Manuf. 2023, 61, 103335. [Google Scholar] [CrossRef]

- Gonzalez-Gutierrez, J.; Cano, S.; Schuschnigg, S.; Kukla, C.; Sapkota, J.; Holzer, C. Additive Manufacturing of Metallic and Ceramic Components by the Material Extrusion of Highly-Filled Polymers: A Review and Future Perspectives. J. Mater. 2018, 11, 5. [Google Scholar] [CrossRef] [PubMed]

- Gloeckle, C.; Konkol, T.; Jacobs, O.; Limberg, W.; Ebel, T.; Handge, U.A. Processing of Highly Filled Polymer-Metal Feedstocks for Fused Filament Fabrication and the Production of Metallic Implants. Materials 2020, 13, 19. [Google Scholar] [CrossRef] [PubMed]

- Kukla, C.; Cano, S.; Kaylani, D.; Schuschnigg, S.; Holzer, C.; Gonzalez-Gutierrez, J. Debinding behaviour of feedstock for material extrusion additive manufacturing of zirconia. Powder Metall. 2019, 62, 196–204. [Google Scholar] [CrossRef]

- Thompson, Y.; Polzer, M.; Gonzalez-Gutierrez, J.; Kasian, O.; Heckl, J.P.; Dalbauer, V.; Kukla, C.; Felfer, P.J. Fused Filament Fabrication-Based Additive Manufacturing of Commercially Pure Titanium. Adv. Eng. Mater. 2021, 3, 2100380. [Google Scholar] [CrossRef]

- Hayat, M.D.; Wen, G.; Zulkifli, M.F.; Cao, P. Effect of PEG molecular weight on rheological properties of Ti-MIM feedstocks and water debinding behaviour. Powder Technol. 2015, 270, 296–301. [Google Scholar] [CrossRef]

- Zhang, H.; Hayat, M.D.; Zhang, W.; Singh, H.; Hu, K.; Cao, P. Improving an easy-to-debind PEG/PPC/PMMA-based binder. Polym. J. 2022, 262, 125465. [Google Scholar] [CrossRef]

- Chen, G.; Cao, P.; Wen, G.; Edmonds, N. Debinding behaviour of a water soluble PEG/PMMA binder for Ti metal injection moulding. Mater. Chem. Phys. 2013, 139, 557–565. [Google Scholar] [CrossRef]

- Eickhoff, R.; Antusch, S.; Nötzel, D.; Hanemann, T. New Partially Water-Soluble Feedstocks for Additive Manufacturing of Ti6Al4V Parts by Material Extrusion. Materials 2023, 16, 3162. [Google Scholar] [CrossRef]

- Ebel, T.; Milagres Ferri, O.; Limberg, W.; Oehring, M.; Pyczak, F.; Schimansky, F.P. Metal Injection Moulding of Titanium and Titanium-Aluminides. Key Eng. Mater. 2012, 520, 153–160. [Google Scholar] [CrossRef]

- F04 Committee; Specification for Metal Injection Molded Titanium-6Aluminum-4Vanadium Components for Surgical Implant Applications. 5. ASTM International: West Conshohocken, PA, USA, 2023.

- ASTM F2885-17; Specification for Metal Injection Molded Titanium-6Aluminum-4Vanadium Components for Surgical Implant Applications. ASTM International: West Conshohocken, PA, USA, 2017.

- Heldele, R. Entwicklung und Charakterisierung von Formmassen für das Mikropulverspritzgießen. Ph.D. Dissertation, Albert-Ludwigs-Universität Freiburg, Freiburg im Breisgau, Germany, 2008. [Google Scholar]

- Zurn, M.; Schrage, A.; Antusch, S.; Bohn, N.; Holzer, P.; Hanemann, T. Development of a Polyethylene Glycol/Polymethyl Methacrylate-Based Binder System for a Borosilicate Glass Filler Suitable for Injection Molding. Materials 2024, 17, 6. [Google Scholar] [CrossRef] [PubMed]

- Thompson, Y.; Gonzalez-Gutierrez, J.; Kukla, C.; Felfer, P. Fused filament fabrication, debinding and sintering as a low cost additive manufacturing method of 316L stainless steel. Addit. Manuf. 2019, 30, 100861. [Google Scholar] [CrossRef]

- Rodríguez, J.F.; Thomas, J.P.; Renaud, J.E. Mechanical behavior of acrylonitrile butadiene styrene fused deposition materials modeling. Rapid Prototyp. J. 2003, 9, 219–230. [Google Scholar] [CrossRef]

- Turner, B.N.; Gold, S.A. A review of melt extrusion additive manufacturing processes: II. Materials, dimensional accuracy, and surface roughness. Rapid Prototyp. J. 2015, 21, 250–261. [Google Scholar] [CrossRef]

- Nötzel, D. Herstellung Keramischer Bauteile Mittels Fused Filament Fabrication (FFF). Ph.D. Dissertation, Albert-Ludwigs-Universität Freiburg, Freiburg, Germany, 2023. [Google Scholar]

- Weber, O. Wasserlösliche Bindersysteme zum Minimieren von Pulver-Binder-Segregationseffekten im Mikropulverspritzguss. Ph.D. Dissertation, Albert-Ludwigs-Universität Freiburg, Freiburg, Germany, 2015. [Google Scholar]

- Hanemann, T.; Heldele, R.; Mueller, T.; Hausselt, J. Influence of Stearic Acid Concentration on the Processing of ZrO2-Containing Feedstocks Suitable for Micropowder Injection Molding. Int. J. Appl. Ceram. Technol. 2011, 8, 865–872. [Google Scholar] [CrossRef]

- Hanemann, T.; Heidele, R. Modern alchemy: Ceramic feedstock optimization by surfactant screening. In CFI-Ceramic Forum International; Goller Verlag GMBH: Baden-Baden, Germany, 2010. [Google Scholar]

- Beran, T.; Mulholland, T.; Henning, F.; Rudolph, N.; Osswald, T.A. Nozzle clogging factors during fused filament fabrication of spherical particle filled polymers. Addit. Manuf. 2018, 23, 206–214. [Google Scholar] [CrossRef]

- Desloir, M.; Benoit, C.; Bendaoud, A.; Alcouffe, P.; Carrot, C. Plasticization of poly(vinyl butyral) by water: Glass transition temperature and mechanical properties. J. Appl. Polym. Sci. 2018, 136, 12. [Google Scholar] [CrossRef]

- Hayat, M.D.; Goswami, A.; Matthews, S.; Li, T.; Yuan, X.; Cao, P. Modification of PEG/PMMA binder by PVP for titanium metal injection moulding. Powder Technol. 2017, 315, 243–249. [Google Scholar] [CrossRef]

- Chuankrerkkul, N.; Messer, P.F.; Davies, H.A. Flow and void formation in powder injection moulding feedstocks made with PEG/PMMA binders Part 1—Experimental observations. Powder Metall. 2013, 51, 66–71. [Google Scholar] [CrossRef]

- Piérard-Smeets, A.; Dembinski, L.; Abboudi, S. Experimental study of water debinding on water soluble PEG behavior for SS 316L parts printed by pellet-based additive manufacturing process. In Technological Systems, Sustainability and Safety; HAL Science: Paris, France, 2024. [Google Scholar]

- Singh, P.; Balla, V.K.; Gokce, A.; Atre, S.V.; Kate, K.H. Additive manufacturing of Ti-6Al-4V alloy by metal fused filament fabrication (MF3): Producing parts comparable to that of metal injection molding. Prog. Addit. Manuf. 2021, 11, 840. [Google Scholar] [CrossRef]

- Burkhardt, C.; Freigassner, P.; Weber, O.; Imgrund, P.; Hampel, S. Fused Filament Fabrication (FFF) of 316L Green Parts for the MIM process. In World PM2016; Sokolowski, P., Ed.; Deposition Technology Inc.: Austin, TX, USA, 2016. [Google Scholar]

- Herranz, G.; Levenfeld, B.; Várez, A.; Torralba, J.M. Development of new feedstock formulation based on high density polyethylene for MIM of M2 high speed steels. Powder Metall. 2005, 48, 134–138. [Google Scholar] [CrossRef]

- German, R.M. Progress in Titanium Metal Powder Injection Molding. Materials 2013, 6, 3641–3662. [Google Scholar] [CrossRef] [PubMed]

| Combination | Backbone Polymer | Base Polymer | Additive |

|---|---|---|---|

| PVB/PEG | PVB 30H | PEG 20,000 | Capric acid, Lauric acid, Stearic acid |

| PMMA/PEG | PMMA G7E | PEG 8000 | Capric acid, Lauric acid, PAT 77/P |

| PMMA/PVB/PEG | PMMA G7E/PVB 30H | PEG 8000 | Capric acid, Lauric acid, Stearic acid |

| Ti-6Al-4V | Density (g/cm3) | D10 (µm) | D50 (µm) | D90 (µm) | SSA (m2/g) |

|---|---|---|---|---|---|

| Measured | 4.4 | 13.2 | 28.6 | 47.3 | 0.15 |

| Component | Density (g/cm3) | MW (g/mol) | TS (°C) | TD (°C) |

|---|---|---|---|---|

| PMMA G7E | 1.18 | 159,000 V | 106 | 252 |

| PVB 30H | 1.11 | 32,000–35,000 V | 64 | 286 |

| PEG 8000 | 1.22 | 7300–9000 V | 66 | 343 |

| PEG 20,000 | 1.22 | 20,000 V | 69 | 372 |

| Capric acid | 0.89 | 172 V | 36 | 162 |

| Lauric acid | 0.95 | 200 V | 50 | 184 |

| Stearic acid | 0.92 | 284 V | 69 | 235 |

| PAT-77/P | 0.97 | n.a. | 98 | 252 |

| Additive Content | Capric Acid | Lauric Acid | Stearic Acid |

|---|---|---|---|

| 5 | 100 | 105 | 95 |

| 7.5 | 100 | 100 | 95 |

| 10 | 105 | 100 | 95 |

| 20 | 100 | 85 | 95 |

| Printing Parameter | Capric Acid | Lauric Acid | Stearic Acid |

|---|---|---|---|

| Extrusion temperature (°C) | 180–190 | 180 | 180 |

| Platform temperature (°C) | 60 | 60 | 60 |

| Printing speed (mm/s) | 8 | 8 | 8 |

| Used nozzle diameter (mm) | 0.4 | 0.25–0.8 | 0.4 |

| Additive Content | Capric Acid | Lauric Acid | PAT-77/P |

|---|---|---|---|

| 5 | 50 °C/2.8 mm | 55 °C/2.7 mm | 72 °C/2.8 mm |

| 7.5 | 50 °C/2.8 mm | 55 °C/2.7 mm | 72 °C/2.8 mm |

| 10 | 47 °C/2.8 mm | 55 °C/2.7 mm | 70 °C/2.8 mm |

| 20 | 55 °C/2.8 mm | 82 °C/2.8 mm | 95 °C/2.8 mm |

| Printing Parameter | Capric Acid | Lauric Acid | PAT77/P |

|---|---|---|---|

| Extrusion temperature (°C) | 190 | 180 | 180 |

| Platform temperature (°C) | 40 | 40 | 40 |

| Printing speed (mm/s) | 8 | 8 | 8 |

| Used nozzle diameter (mm) | 0.4 | 0.4 | 0.15–0.4 |

| Additive and PEG Content | Capric Acid | Lauric Acid | Stearic Acid |

|---|---|---|---|

| 10 wt.%/50 vol.% PEG | 63 °C/2.8 mm | 65 °C/2.7 mm | 70 °C/2.7 mm |

| 12.5 wt.%/50 vol.% PEG | 62 °C/2.7 mm | 65 °C/2.7 mm | 90 °C/2.8 mm |

| 12.5 wt.%/55 vol.% PEG | 52 °C/2.8 mm | - | - |

| 12.5 wt.%/60 vol.% PEG | 65 °C/2.7 mm | - | - |

| 15 wt.%/50 vol.% PEG | 90 °C/2.8 mm | 50 °C/2.8 mm | 65 °C/2.8 mm |

| Printing Parameter | Capric Acid | Lauric Acid | Stearic Acid |

|---|---|---|---|

| Extrusion temperature (°C) | 180–200 | 190 | 190 |

| Platform temperature (°C) | 60 | 60 | 60 |

| Printing speed (mm/s) | 2.5–20 | 8 | 8 |

| Used nozzle diameter (mm) | 0.15–0.8 | 0.4 | 0.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Eickhoff, R.; Antusch, S.; Nötzel, D.; Probst, M.; Hanemann, T. Development of Flexible and Partly Water-Soluble Binder Systems for Metal Fused Filament Fabrication (MF3) of Ti-6Al-4V Parts. Polymers 2024, 16, 2548. https://doi.org/10.3390/polym16172548

Eickhoff R, Antusch S, Nötzel D, Probst M, Hanemann T. Development of Flexible and Partly Water-Soluble Binder Systems for Metal Fused Filament Fabrication (MF3) of Ti-6Al-4V Parts. Polymers. 2024; 16(17):2548. https://doi.org/10.3390/polym16172548

Chicago/Turabian StyleEickhoff, Ralf, Steffen Antusch, Dorit Nötzel, Marcel Probst, and Thomas Hanemann. 2024. "Development of Flexible and Partly Water-Soluble Binder Systems for Metal Fused Filament Fabrication (MF3) of Ti-6Al-4V Parts" Polymers 16, no. 17: 2548. https://doi.org/10.3390/polym16172548

APA StyleEickhoff, R., Antusch, S., Nötzel, D., Probst, M., & Hanemann, T. (2024). Development of Flexible and Partly Water-Soluble Binder Systems for Metal Fused Filament Fabrication (MF3) of Ti-6Al-4V Parts. Polymers, 16(17), 2548. https://doi.org/10.3390/polym16172548