Laboratory Evaluation of Geosynthetic Interface Friction under Low Stress

Abstract

1. Introduction

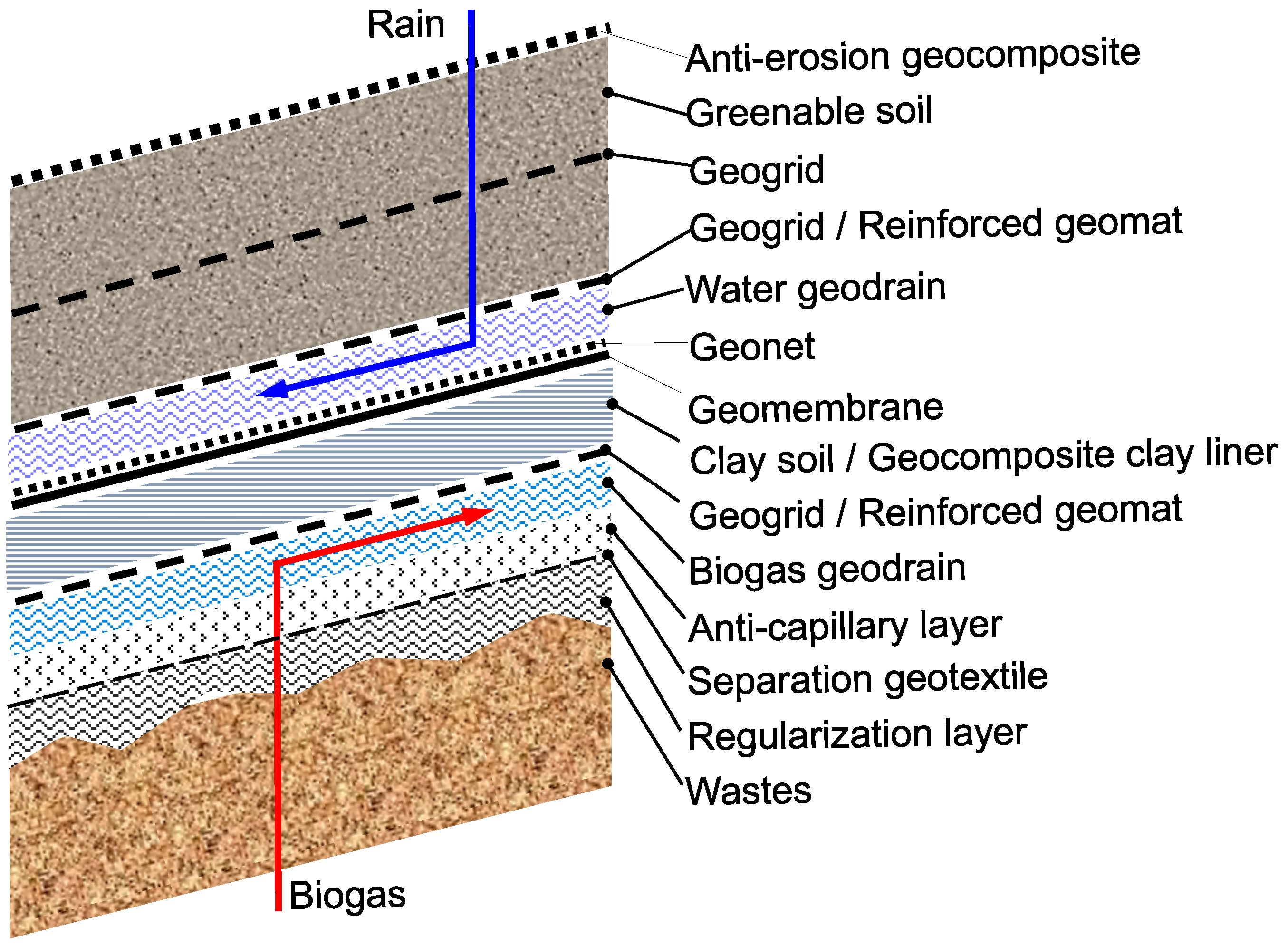

- Drainage functions are guaranteed by drainage geocomposites, which offer a continuous low-friction surface for the filtering geosynthetics. An appropriate filter opening is required in order to prevent unwanted long-term phenomena, such as blinding and clogging, both of which are capable of negating the drainage properties of the geocomposite itself.

- The waterproofing of both fluid emission and entry is achieved with the aid of a geomembrane, possibly coupled with a geocomposite clay liner or with a clay layer. To protect the geomembrane, a geonet is placed above it with the aim of avoiding possible lacerations during the subsequent phase of laying the drainage geocomposite.

- If the covering lies on a slope and/or in areas where substantial differential settlements are expected, a geogrid is inserted into the covering soil to increase strength to slippage and to relieve the induced tensile forces in the less resistant geosynthetics.

- Geocells or geomats can be placed to prevent the soil erosion exposed to atmospheric agents and also to allow for natural greening or hydro-seeding.

2. Laboratory Measurement of the Interface Strength under Low Stress

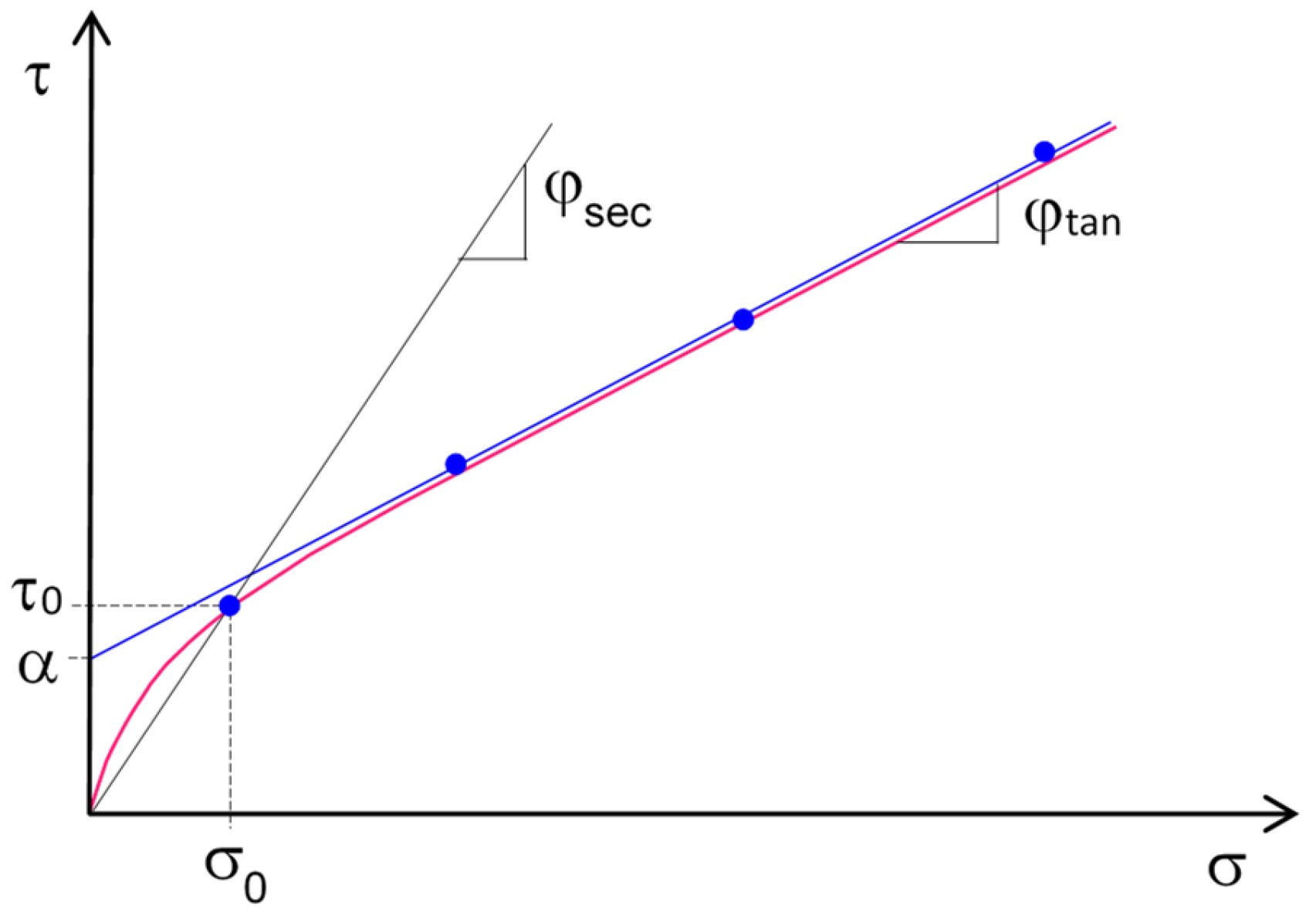

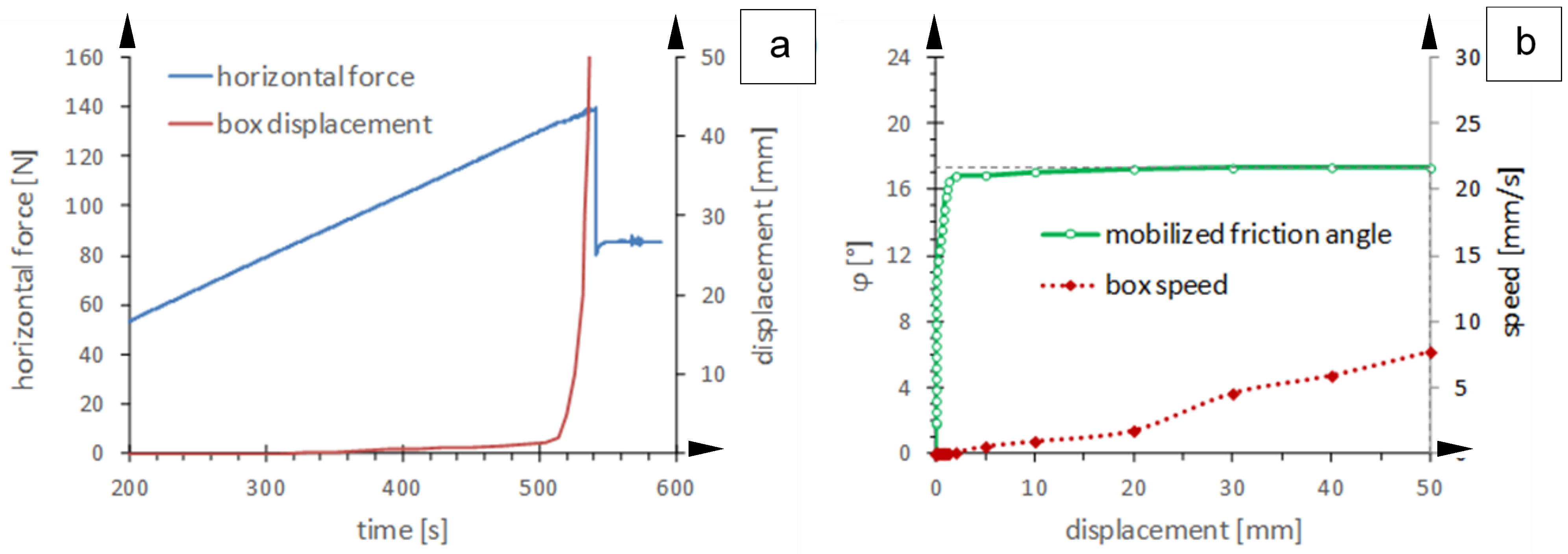

- The standard direct shear test at constant displacement speed is perhaps the most widespread in the technical literature and has been the subject of standardization [1,2]. It is performed on samples with a minimum size of 0.30 × 0.30 m, fixed horizontally to two supports, one of which remains fixed while the other can slide relative to the first. Once a predetermined normal pressure has been applied, σ0, the mobile box is made to slide during the test at a constant speed, and the shear stress, τ0, as a reaction to the impressed displacements, is measured.

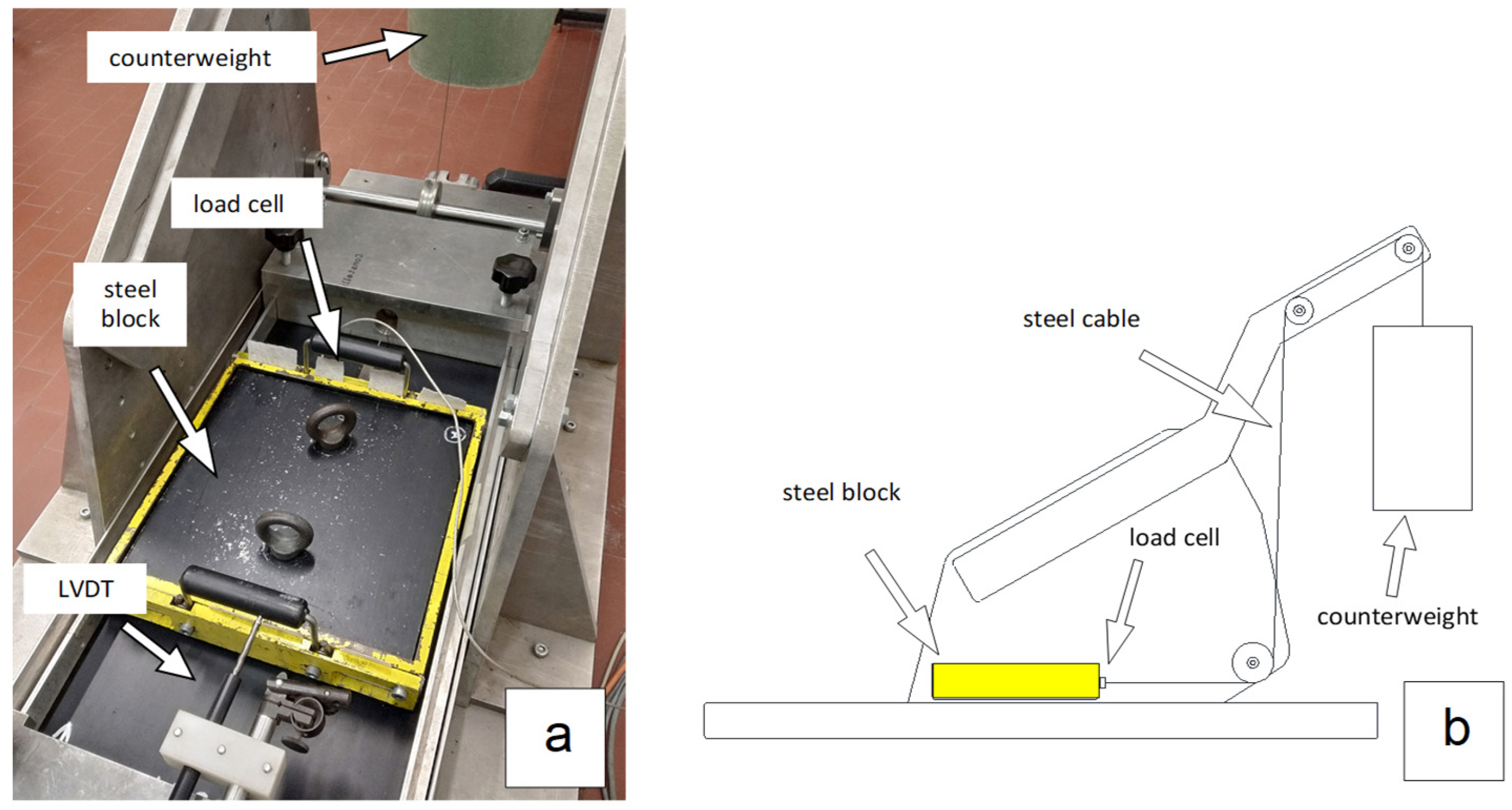

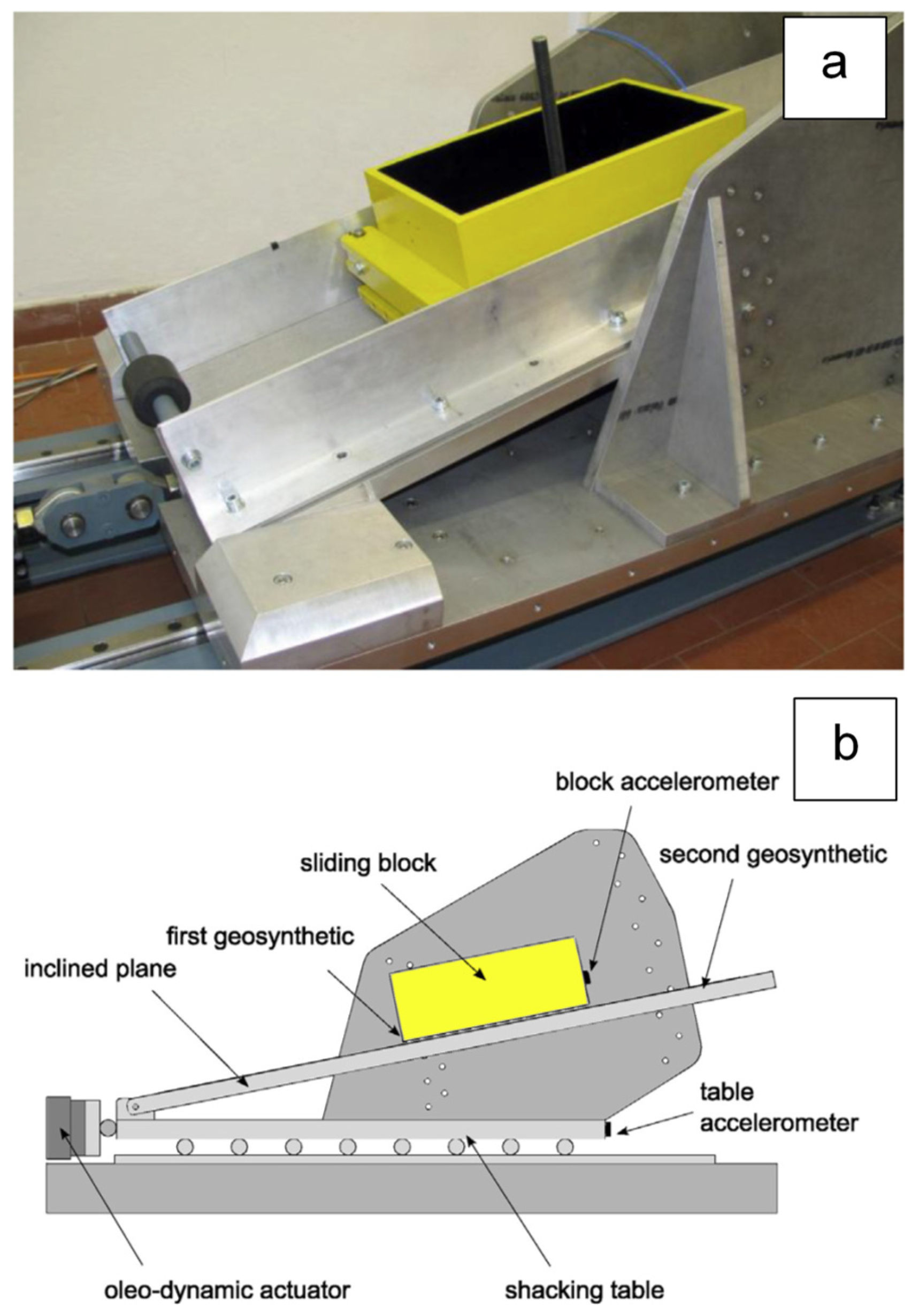

- A prototype of a direct shear device with constant speed of loading has been made at the geotechnical laboratory of the University of Padua [5,6]. Figure 3a shows a top view of the prototype, while Figure 3b shows the device’s operational scheme. It consists of a steel box with sides of 0.30 × 0.30 m placed on a horizontal plane. The first geosynthetic specimen is fixed on the base of the mobile box, while the second is fixed on the base of the device.

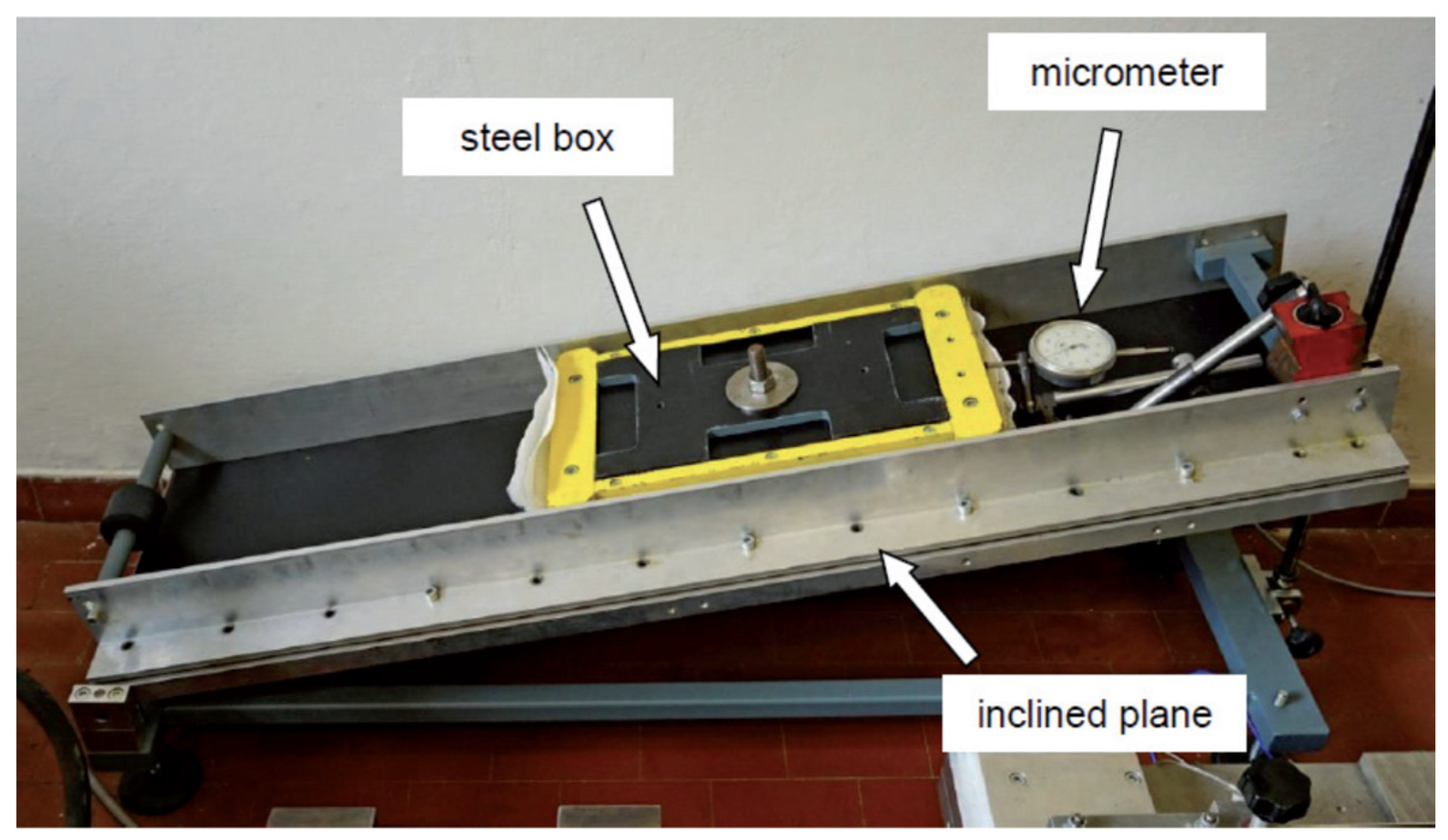

- The inclined plane test [7,8,9] has been standardized according to the European standard [10]. Strictly speaking, this standard refers only to interfaces between soil and geosynthetics, but its indications can also be easily extended to cases featuring contact between geosynthetics. The equipment made at the geotechnical laboratory of the University of Padua (Figure 5) consists of a tilting plane, above which, a steel box that is free to slide along the plane is placed. The motion of the box can be controlled via lateral guides and trolleys positioned outside the contact zone of the geosynthetics.

- -

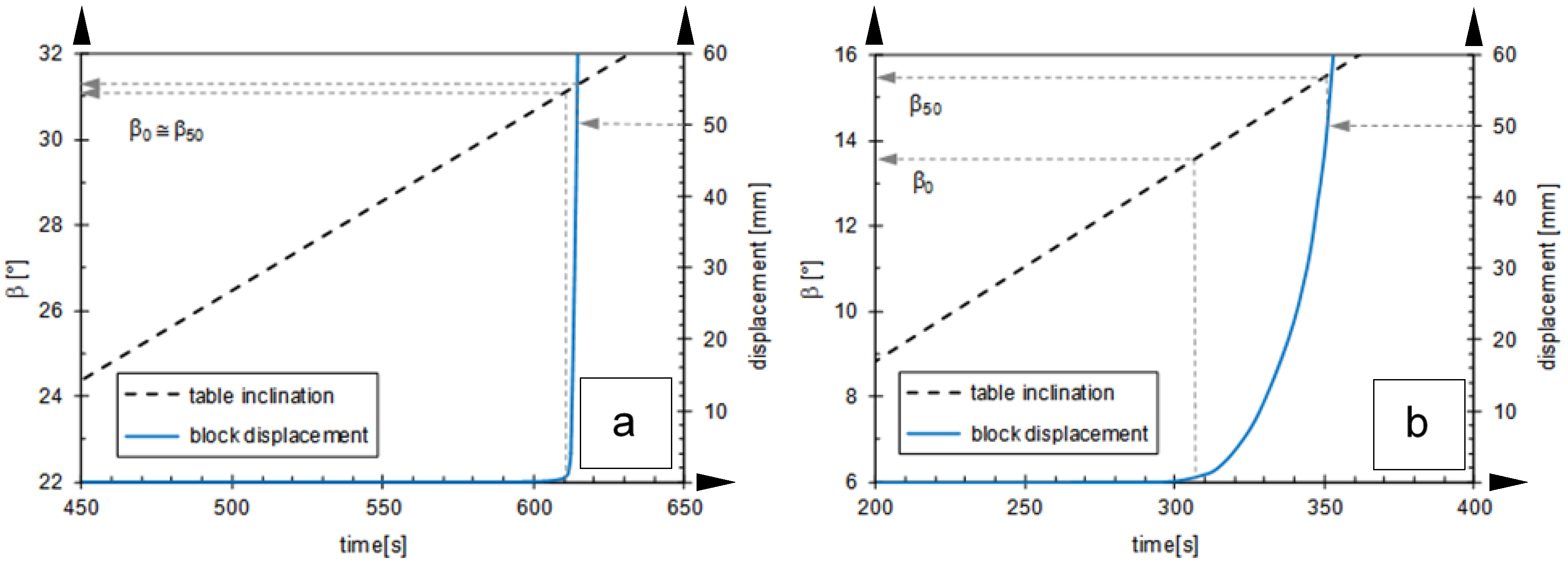

- The sudden sliding mode is defined as that for which, once φ0 is reached, the box goes forward with uniformly accelerated motion (abox = cost) and the friction strength becomes dynamic. It can be evaluated by means of the dynamic equilibrium equation, in which both the box accelerations and the gravity, g, are included:

- -

- The gradual sliding mode is defined as one in which, once φ0 is reached, the box goes forward with uniform motion (abox = 0), whose speed, v, becomes a function of the plane inclination, β(t), when the latter exceeds the value β0; in this case, a part of the reaction to the box motion, τ, comes from the viscous resistance (τ = c × v). Under the hypothesis that the speed remains constant in correspondence with the table inclination β(t), a kinematic strength angle, φkin, is provided by the following expression:

- -

- The conventional angle of interface strength, φstand, is more significant for geosynthetic interfaces showing non-uniform motion during failure. For example, a rough geomembrane in contact with the nonwoven geotextile of a drainage geocomposite can give rise to considerable displacements well beyond β50 due to the effect of interpenetration of the geotextile fibres within the roughness of the geomembrane; for these interfaces, φ0 cannot be significant. Interfaces of particular polymers and geometries can manifest irregular motion during slip, as in the case of the stick slip mode of failure. It is a kinematic phenomenon characterized by sudden accelerations and stops as soon as the abrupt transition from static to dynamic friction occurs. The resulting motion is an alternating of stick and slip phases, which do not allow for a failure point to be identified.

- -

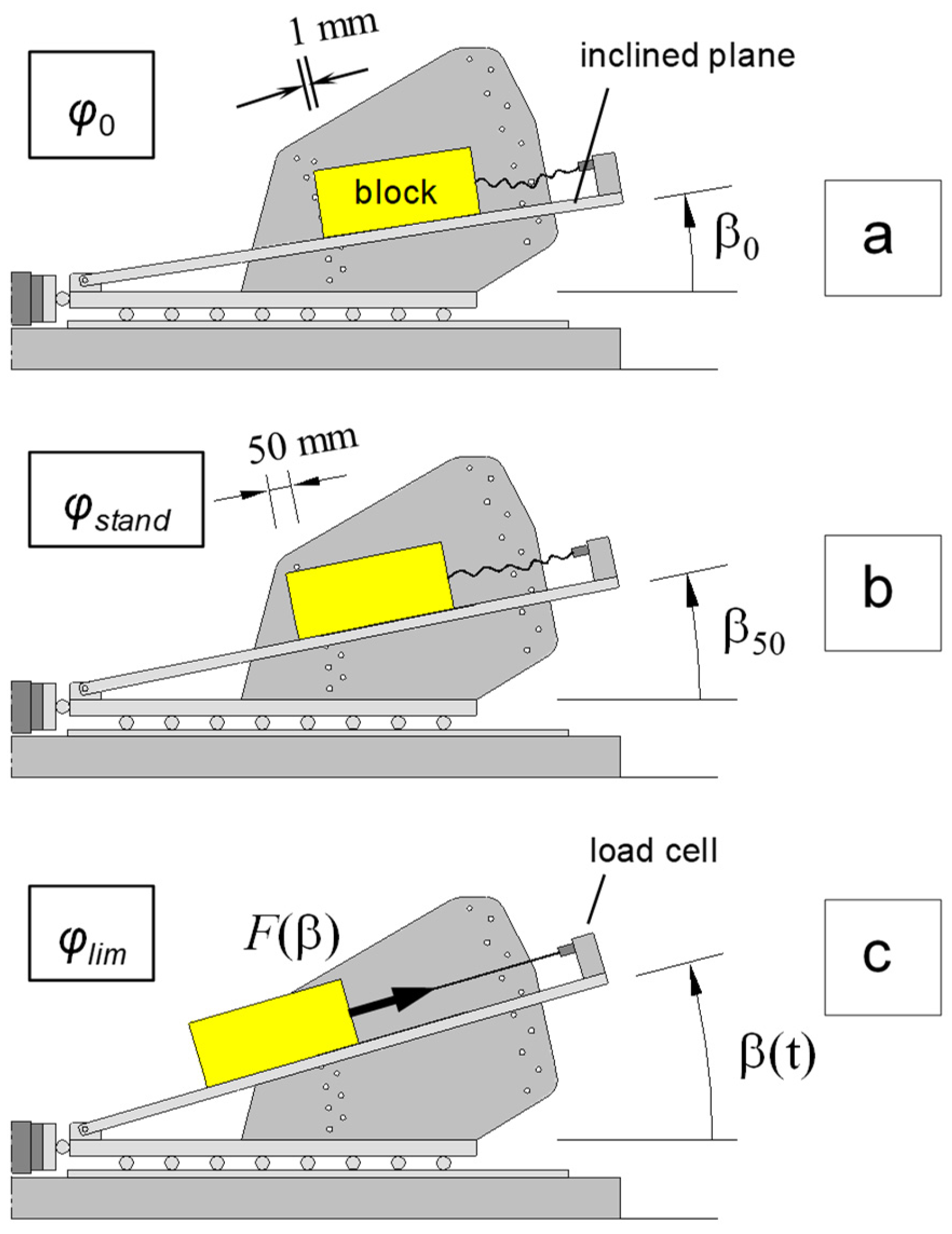

- In addition to the standard test, described earlier, the inclined plane device allows for the evaluation of the interface friction by means of a further procedure, namely the force method [13].

- -

- We would like to reiterate that, in addition to the evaluation of resistance in static conditions, there is a whole area related to dynamic conditions, such as those that can occur in seismic situations, which can be studied with tests that differ from those described up to now. Though this aspect is beyond the scope of this paper, we refer readers to the widespread research on this topic in the literature [15,16,17,18,19,20].

- -

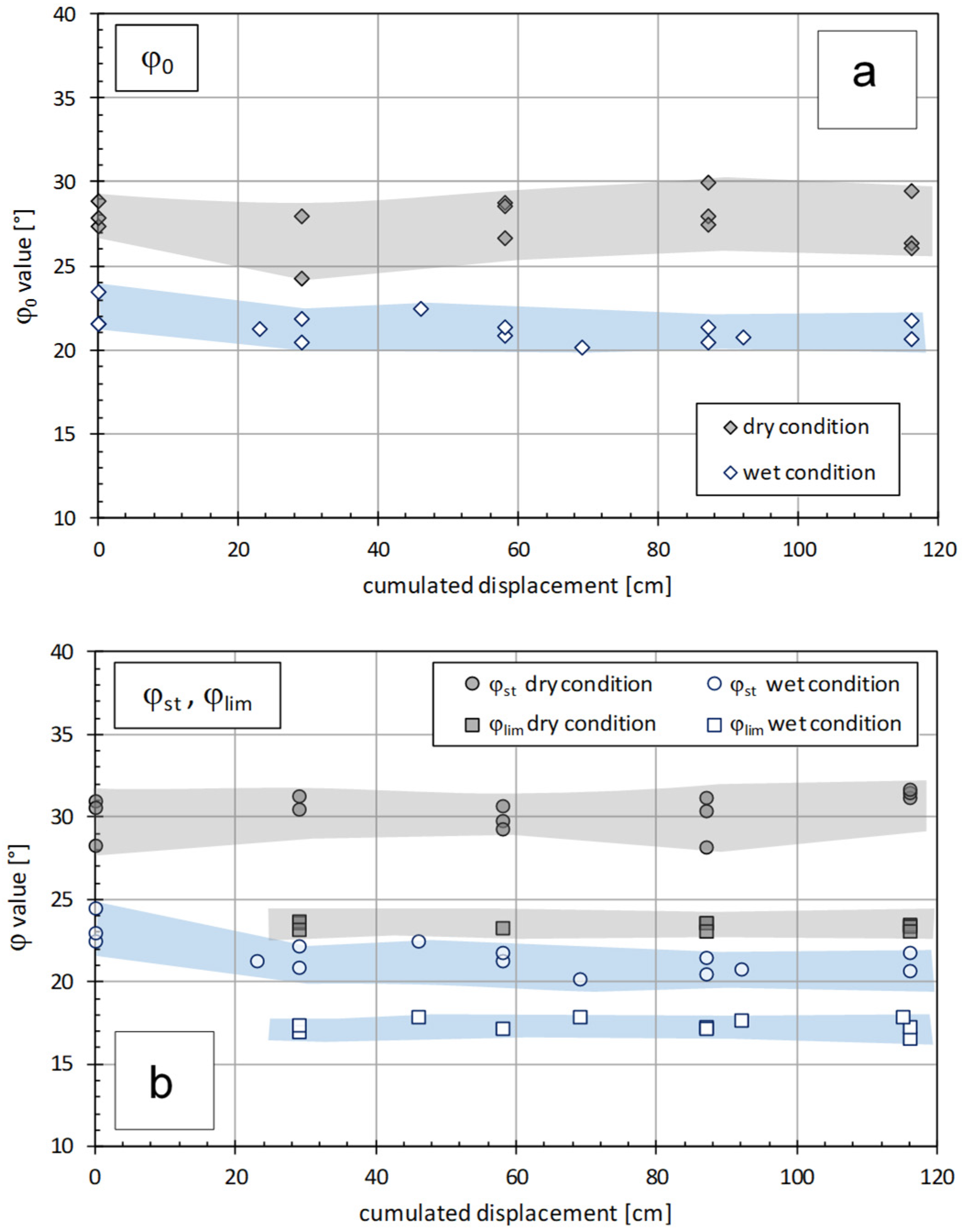

- The inclined plane tests also allow one to carry out experiments on the variation in the interface friction between geosynthetics for large relative displacements [21]. Figure 10 reports the results of inclined plane tests at large displacements for an interface between a drainage geocomposite and the woven side of a geocomposite clay liner (GCD-GCL), showing gradual sliding behaviour both in wet and dry conditions [22]. It is possible to note how the presence of fluid at the interface causes a lower frictional resistance, and it is confirmed that the parameter φlim always remains lower than the corresponding φ0 and φstand values in both the dry and wet conditions.

3. Conclusions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- ASTM D 5321/D5321M; Standard Test Method for Determining the Shear Strength of Soil-Geosynthetic and Geosynthetic-Geosynthetic Interfaces by Direct Shear. ASTM: West Conshohocken, PA, USA, 2021.

- EN ISO 12957-1; Geosynthetics—Determination of Friction Characteristics—Part 1: Direct Shear Test. European Committee for Standardization, CEN: Brussels, Belgium, 2018.

- Bacas, B.M.; Konietzky, H.; Berini, J.C.; Sagaseta, C. A new constitutive model for textured geomembrane/geotextile interfaces. Geotext. Geomembr. 2011, 29, 137–148. [Google Scholar] [CrossRef]

- Cazzuffi, D.; Recalcati, P.; Calvarano, L.S. Direct Shear and Inclined Plane Experimental Activities for Different Interfaces among Geosynthetics and Soils. In Geo-Congress 2023; ASCE: Los Angeles, CA, USA, 2023; pp. 536–544. [Google Scholar]

- Pavanello, P.; Carrubba, P.; Moraci, N. Evaluation of geosynthetic interface friction at low normal stress: Comparison between two different test procedures. Acta Sci. Pol. Archit. 2022, 21, 3–10. [Google Scholar] [CrossRef]

- Pavanello, P.; Carrubba, P.; Moraci, N. Geosynthetic interface friction at low normal stress: Two approaches with increasing shear loading. Appl. Sci. 2022, 12, 1065. [Google Scholar] [CrossRef]

- Lalarakotoson, S.; Villard, P.; Gourc, J.P. Shear strength characterization of geosynthetic interfaces on inclined planes. Geotech. Test. J. 1999, 22, 284–291. [Google Scholar] [CrossRef]

- Reyes Ramirez, R.; Gourc, J.P. Use of the inclined plane test in measuring geosynthetic interface friction relationship. Geosynth. Int. 2003, 10, 165–175. [Google Scholar] [CrossRef]

- Pitanga, H.N.; Gourc, J.P.; Vilar, O.M. Interface shear strength of geosynthetics: Evaluation and analysis of inclined plane tests. Geotext. Geomembr. 2009, 27, 435–446. [Google Scholar] [CrossRef]

- EN ISO 12957-2; Geosynthetics—Determination of Friction Characteristics—Part 2: Inclined Plane Test. European Committee for Standardization, CEN: Brussels, Belgium, 2005.

- Gourc, J.P.; Reyes Ramirez, R. Dynamics-based interpretation of the interface friction test at the inclined plane. Geosynth. Int. 2004, 11, 439–454. [Google Scholar] [CrossRef]

- Pavanello, P.; Carrubba, P.; Moraci, N. The characterisation of geosynthetic interface friction by means of the inclined plane test. Geotext. Geomembr. 2021, 49, 257–275. [Google Scholar] [CrossRef]

- Briançon, L.; Girard, H.; Gourc, J.P. A new procedure for measuring geosynthetic friction with an inclined plane. Geotext. Geomembr. 2011, 29, 472–482. [Google Scholar] [CrossRef]

- Carbone, L.; Gourc, J.P.; Carrubba, P.; Pavanello, P.; Moraci, N. Dry friction behaviour of a geosynthetic interface using inclined plane and shaking table tests. Geotext. Geomembr. 2015, 43, 293–306. [Google Scholar] [CrossRef]

- Kavazanjian, E. Current issues in seismic design of geosynthetic cover systems. In Proceedings of the 6th International Conference on Geosynthetics, Atlanta, GA, USA, 25–29 March 1998; Volume 1, pp. 219–226. [Google Scholar]

- Kavazanjian, E.; Matasovic, N.; Caldwell, J. Seismic design and performance criteria for landfills. In Proceedings of the 6th US National Conference on Earthquake Engineering, Seattle, WA, USA, 31 May–4 June 1998. Paper No. 245. [Google Scholar]

- Kavazanjian, E.; Wu, X.; Arab, M.; Matasovic, N. Development of a numerical model for performance-based design of geosynthetic liner systems. Geotext. Geomembr. 2018, 46, 166–182. [Google Scholar] [CrossRef]

- Kim, J.; Riemer, M.; Bray, J.D. Dynamic properties of geosynthetic interfaces. Geotech. Test. J. 2005, 28, 1–9. [Google Scholar] [CrossRef]

- Pavanello, P.; Carrubba, P.; Moraci, N. Dynamic friction and the seismic performance of geosynthetic interfaces. Geotext. Geomembr. 2018, 46, 715–725. [Google Scholar] [CrossRef]

- Pavanello, P.; Carrubba, P.; Moraci, N. The determination of interface friction by means of vibrating table tests. Geotext. Geomembr. 2018, 46, 830–835. [Google Scholar] [CrossRef]

- Pinho-Lopes, M.; Paula, A.M.; Lopes, M.L. Soil–geosynthetic interaction in pullout and inclined-plane shear for two geosynthetics. Geosynth. Int. 2016, 23, 331–347. [Google Scholar] [CrossRef]

- Pavanello, P.; Carrubba, P.; Moraci, N.; Pezzano, P.; Miuzzi, M. Parameters and conditions affecting friction angles in geosynthetic interfaces. In Proceedings of the Eurogeo 6, Ljubljana, Slovenia, 25–28 September 2016; pp. 563–574. [Google Scholar]

- Frost, J.D.; Lee, S.W. Microscale study of geomembrane-geotextile interactions. Geosynth. Int. 2001, 8, 577–597. [Google Scholar] [CrossRef]

- Stark, T.D.; Niazi, F.S.; Keuscher, T.C. Strength envelopes from single and multi geosynthetic interface tests. Geotech. Geol. Eng. 2015, 33, 1351–1367. [Google Scholar] [CrossRef]

- Bacas, B.M.; Cañizal, J.; Konietzky, H. Shear strength behaviour of geotextile/geomembrane interfaces. J. Rock Mech. Geotech. Eng. 2015, 7, 638–645. [Google Scholar] [CrossRef]

- Moraci, N.; Cardile, G.; Gioffré, D.; Mandaglio, M.C.; Calvarano, L.S.; Carbone, L. Soil geosynthetic interaction: Design parameters from experimental and theoretical analysis. Transp. Infrastruct. Geotechnol. 2014, 1, 165–227. [Google Scholar] [CrossRef]

- Palmeira, E.M. Soil-geosynthetic interaction: Modelling and analysis. Geotext. Geomembr. 2009, 27, 368–390. [Google Scholar] [CrossRef]

- Ferreira, F.B.; Vieira, C.S.; Lopes, M.L. Direct shear behaviour of residual soil–geosynthetic interfaces—Influence of soil moisture content, soil density and geosynthetic type. Geosynth. Int. 2015, 22, 257–272. [Google Scholar] [CrossRef]

- Ferreira, F.B.; Fernandes, J.; Vieira, C.S.; Lopes, M.L. Soil-geosynthetic interface shear behaviour: Insights from inclined plane and direct shear tests. In Proceedings of the 12th International Conference on Geosynthetics, Roma, Italy, 17–21 September 2023; pp. 418–424. [Google Scholar]

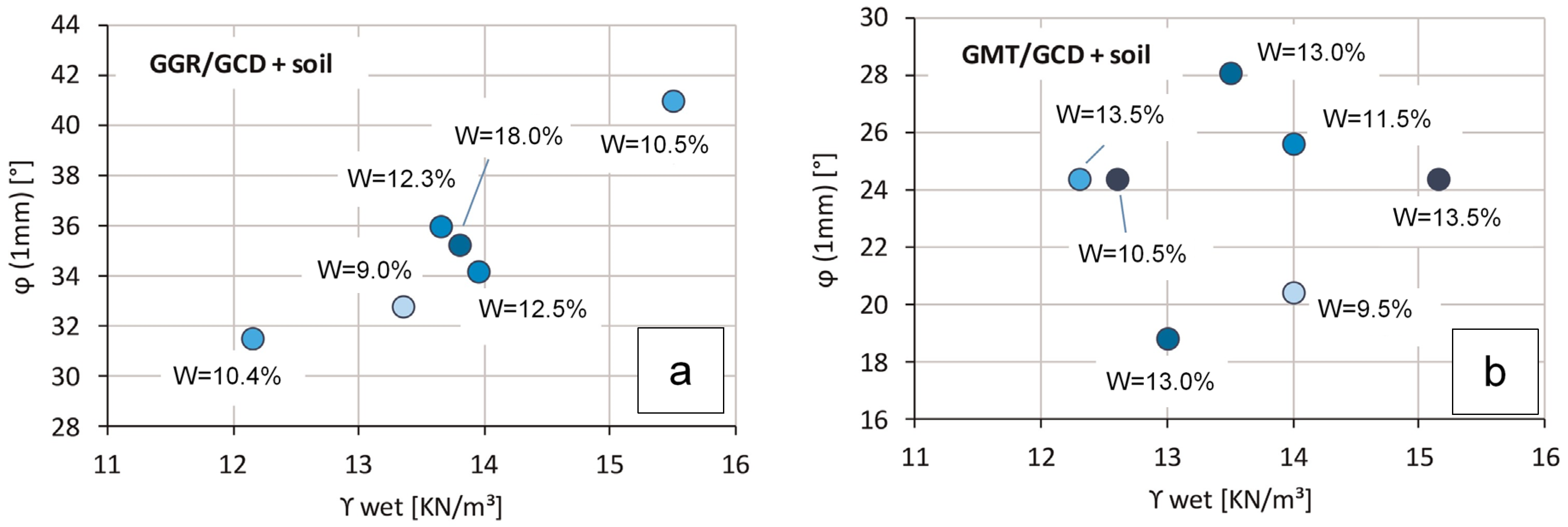

- Pavanello, P.; Carrubba, P. The effect of soil on the shear strength of geosynthetic interfaces. In Proceedings of the 12th International Conference on Geosynthetics, Roma, Italy, 17–21 September 2023; pp. 425–431. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Carrubba, P. Laboratory Evaluation of Geosynthetic Interface Friction under Low Stress. Polymers 2024, 16, 2519. https://doi.org/10.3390/polym16172519

Carrubba P. Laboratory Evaluation of Geosynthetic Interface Friction under Low Stress. Polymers. 2024; 16(17):2519. https://doi.org/10.3390/polym16172519

Chicago/Turabian StyleCarrubba, Paolo. 2024. "Laboratory Evaluation of Geosynthetic Interface Friction under Low Stress" Polymers 16, no. 17: 2519. https://doi.org/10.3390/polym16172519

APA StyleCarrubba, P. (2024). Laboratory Evaluation of Geosynthetic Interface Friction under Low Stress. Polymers, 16(17), 2519. https://doi.org/10.3390/polym16172519