Effect of Vibration Pretreatment–Microwave Curing Process Parameters on the Mechanical Performance of Resin-Based Composites

Abstract

1. Introduction

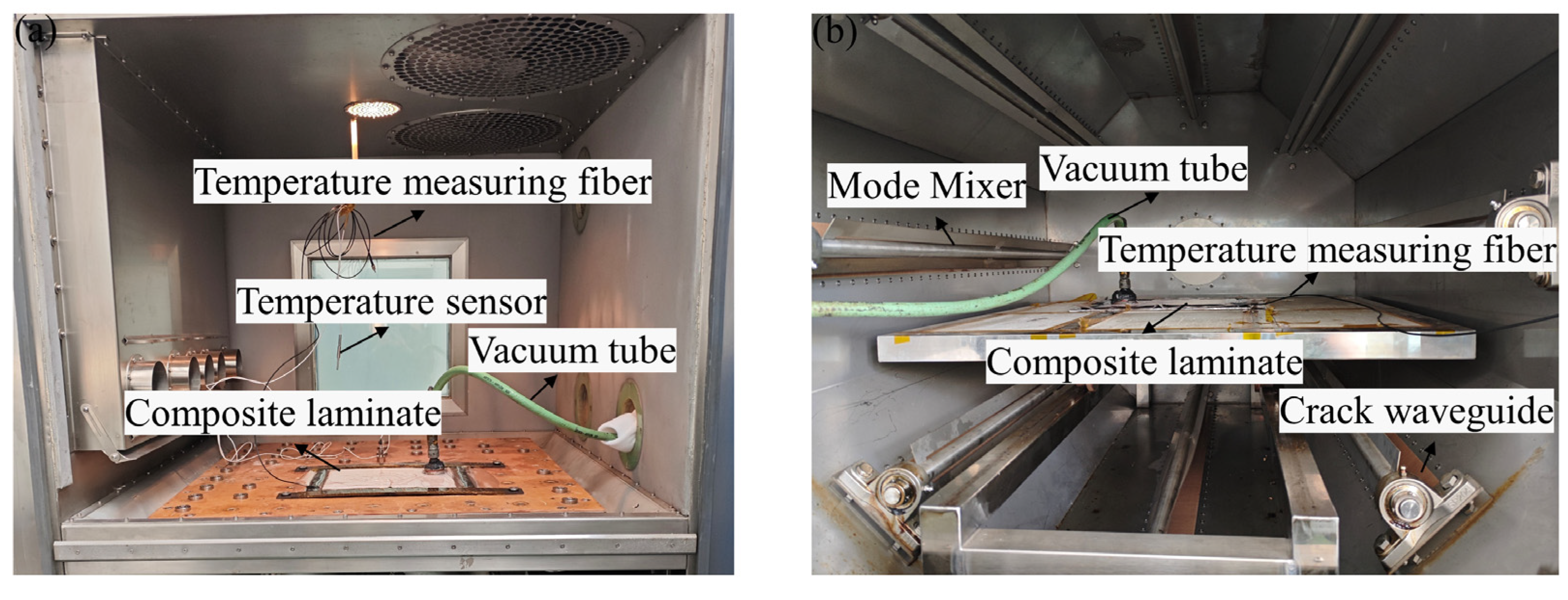

2. Materials and Methods

2.1. Materials and Equipment

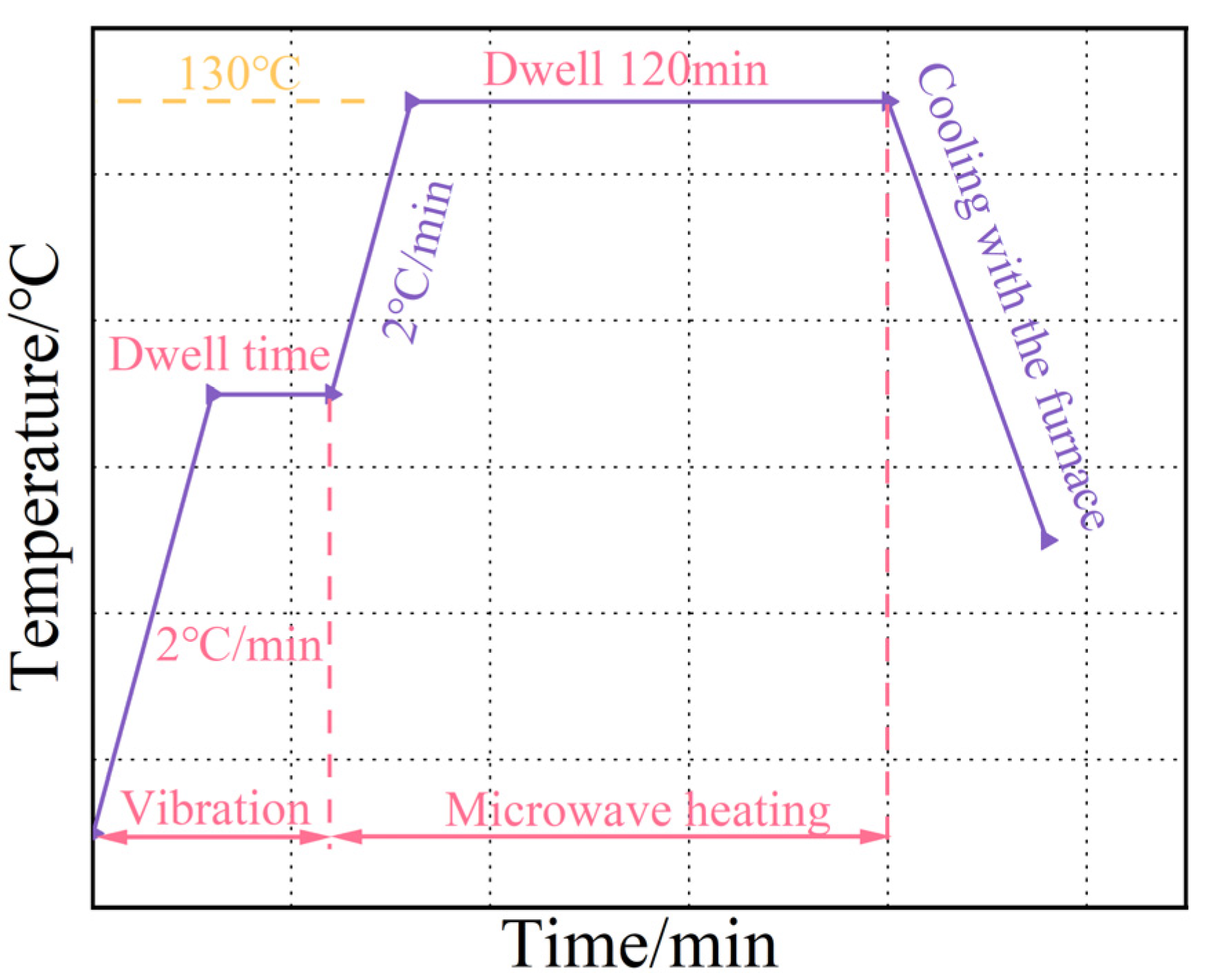

2.2. Selection of Process Parameters and Curing Process Curve

2.3. Interlaminar Shear Strength Test

2.4. Characterization of Void Morphology

2.5. Evaluation of Fiber Weight Fraction in Composite Laminates

2.6. Testing Impact Properties of Composite Laminates

3. Results and Discussion

3.1. Analysis of the Optimized Vibration Pretreatment Process Parameters

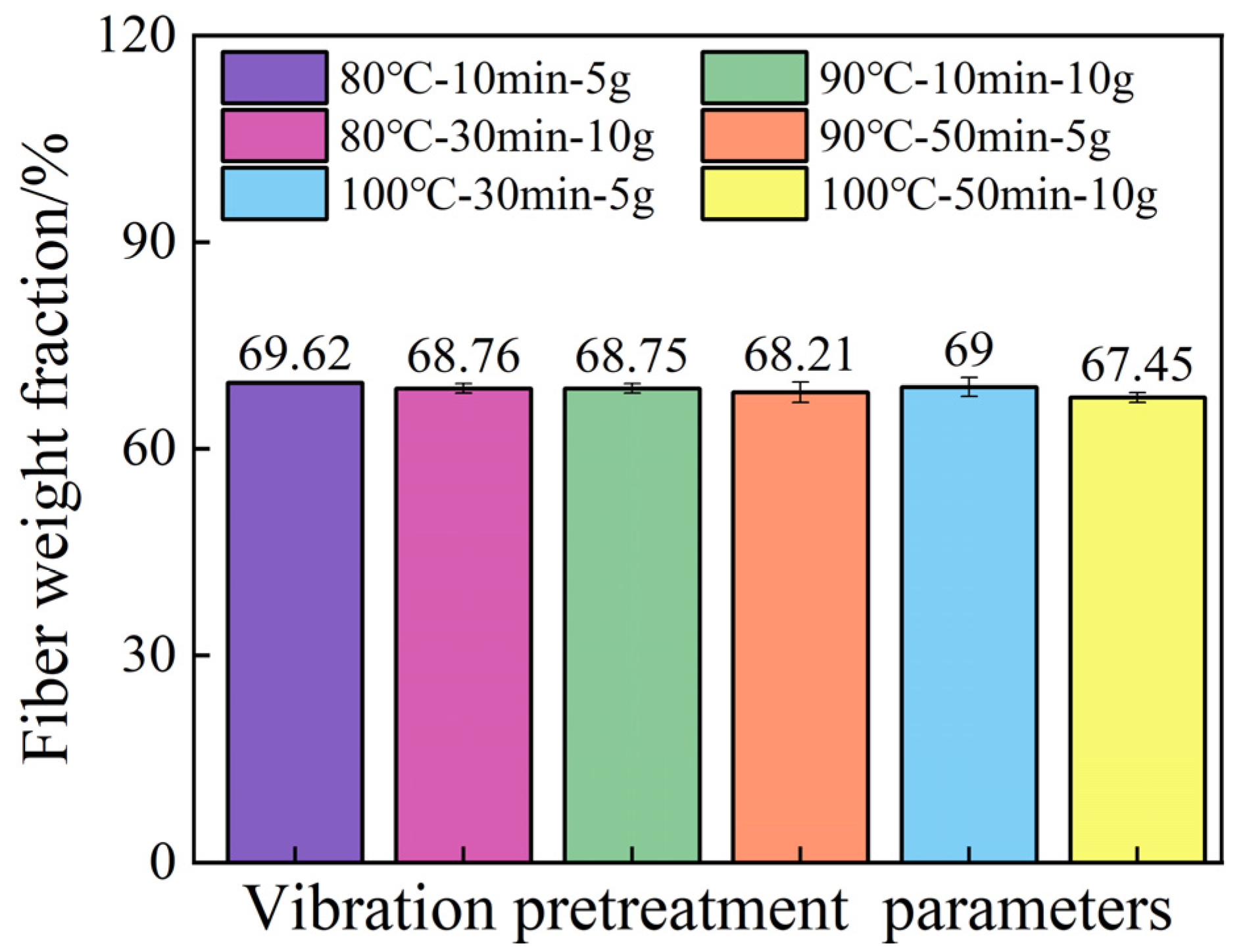

3.2. Effect of Vibration Pretreatment Process Parameters on Fiber Weight Fraction

3.3. Effect of Vibration Pretreatment Process Parameters on Void Micromorphology

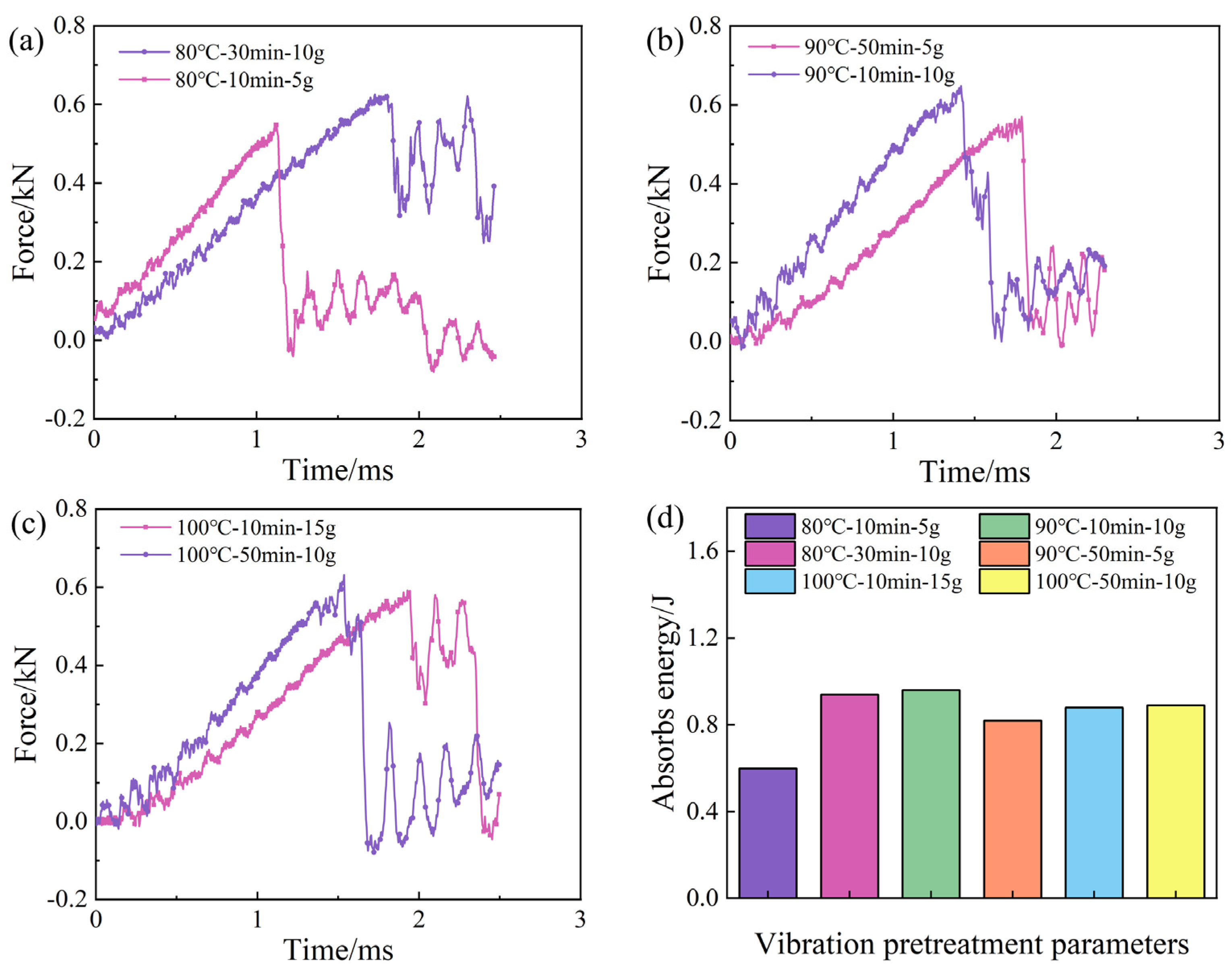

3.4. Effect of Vibration Pretreatment Process Parameters on Impact Strength

4. Conclusions

- (1)

- The order of pretreatment process parameters affecting the interlaminar shear strength of T700/TRE231 is as follows: vibration acceleration > dwell time > pretreatment temperature. The optimized parameters are a pretreatment temperature of 90 °C, a dwell time of 30 min, and a vibration acceleration of 10 g.

- (2)

- Within the range of vibration pretreatment process parameters studied in this paper, the minimum fiber weight fraction increased by 0.45% over the initial prepreg, indicating that the pretreatment process produced a compaction effect. However, the maximum range of variation in fiber weight fraction is only 2.17%. Therefore, the influence of pretreatment process parameters on the fiber weight fraction is relatively slight.

- (3)

- When the vibration energy is 5 g, large circular and elliptical voids are present in the samples. Increasing the vibration energy to 10 g caused large voids between layers to fracture into smaller voids and moved into within the layers. Further increasing the energy to 15 g reintroduces interlaminar voids, indicating that vibration acceleration can alter the escape path of voids.

- (4)

- The simply supported beam impact tests of samples treated with different process parameters revealed that samples subjected to a vibration energy of 10 g exhibited higher impact strength, mainly attributed to lower void content. Additionally, the impact strength showed a positive correlation with interlaminar shear strength.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Tian, K.; Tay, T.E.; Tan, V.B.C.; Haris, A.; Chew, E.Q.; Pham, V.N.H.; Huang, J.Z.; Raju, K.; Sugahara, T.; Fujihara, K.; et al. Improving the impact performance and residual strength of carbon fibre reinforced polymer composite through intralaminar hybridization. Compos. Part A Appl. Sci. Manuf. 2023, 171, 107590. [Google Scholar] [CrossRef]

- Kalusuraman, G.; Kumaran, S.T.; Balamurugan, K.; Sivashanmugam, N.; Sivaprakasam, P.; Kurniawan, R.; Ezhilmaran, V. Vibration studies on fiber reinforced composites—A review. J. Nat. Fibers 2023, 20, 2157361. [Google Scholar] [CrossRef]

- Ojha, S.; Bisaria, H.; Mohanty, S.; Kanny, K. Fabrication and characterization of light weight PVC foam based E-Glass reinforced polyester sandwich composites. Proc. Inst. Mech. Eng. Part C-J. Mech. Eng. Sci. 2023, 237, 5042–5051. [Google Scholar] [CrossRef]

- Nan, J.J.; Zhi, C.; Meng, J.G.; Miao, M.H.; Yu, L.J. Seawater aging effect on fiber-reinforced polymer composites: Mechanical properties, aging mechanism, and life prediction. Text. Res. J. 2023, 93, 3393–3413. [Google Scholar] [CrossRef]

- Wang, A.N.; Liu, X.G.; Yue, Q.R.; Xian, G.J. Tensile properties hybrid effect of unidirectional flax/carbon fiber hybrid reinforced polymer composites. J. Mater. Res. Technol. 2023, 24, 1373–1389. [Google Scholar] [CrossRef]

- Huang, X.H.; Su, S.Y.; Xu, Z.D.; Miao, Q.S.; Li, W.F.; Wang, L.X. Advanced composite materials for structure strengthening and resilience improvement. Buildings 2023, 13, 2406. [Google Scholar] [CrossRef]

- Jiao, J.K.; Cheng, X.Y.; Wang, J.L.; Sheng, L.Y.; Zhang, Y.M.; Xu, J.H.; Jing, C.H.; Sun, S.Y.; Xia, H.B.; Ru, H.L. A review of research progress on machining carbon fiber-reinforced composites with lasers. Micromachines 2023, 14, 24. [Google Scholar] [CrossRef]

- Zhu, T.L.; Wang, Z. Research and application prospect of short carbon fiber reinforced ceramic composites. J. Eur. Ceram. Soc. 2023, 43, 6699–6717. [Google Scholar] [CrossRef]

- Devi, G.; Nagabhooshanam, N.; Chokkalingam, M.; Sahu, S.K. EMI shielding of cobalt, red onion husk biochar and carbon short fiber-PVA composite on X and Ku band frequencies. Polym. Compos. 2022, 43, 5996–6003. [Google Scholar] [CrossRef]

- Gandhi, Y.; Minak, G. A review on topology optimization strategies for additively manufactured continuous fiber-reinforced composite structures. Appl. Sci. 2022, 12, 11211. [Google Scholar] [CrossRef]

- Liu, J.W.; Cai, M.; Guo, Y.W.; Ma, Q.H.; Sun, B.Z. The static and dynamic mechanical properties analysis of ramie/carbon fiber-reinforced composites. Polym. Compos. 2024, 45, 6575–6587. [Google Scholar] [CrossRef]

- Zhang, D.C.; Zhan, L.H.; Guan, C.L.; Guo, J.Z.; Ma, B.L.; Dai, G.M.; Yao, S.M. Optimization of vibration pretreatment microwave curing in composite laminate molding process. Polymers 2023, 15, 296. [Google Scholar] [CrossRef] [PubMed]

- Meng, Q.S.; Yang, Y.C.; Han, S.S.; Meng, F.Z.; Liu, T.Q. Preparation of high-performance bismuthene thermoelectric composites doped with graphene using UV-curing 3D printing technology. Polym. Compos. 2024, 45, 8176–8186. [Google Scholar] [CrossRef]

- Kim, C.S.; Jang, J.; Im, H.G.; Yoon, S.; Kang, D.J. Preparation and performance of alumina/epoxy-siloxane composites: A comparative study on thermal- and photo-curing process. Heliyon 2024, 10, 27580. [Google Scholar] [CrossRef] [PubMed]

- Kumar, M.; Saini, J.S.; Singh, K.; Bhunia, H. Comparison of different failure criteria in numerical modeling of electron beam cured polymer nanocomposites. J. Compos. Mater. 2024, 58, 533–545. [Google Scholar] [CrossRef]

- Kim, H.B.; Oh, S.H.; Jeong, Y.G.; Kim, H.S.; Park, B.G.; Park, J.S. Effects of heat treatment on the microstructure and flexural mechanical properties of carbon fiber reinforced composite cured by electron beam. Mater. Today Commun. 2023, 37, 107181. [Google Scholar] [CrossRef]

- Mandic, V.N.; Par, M.; Marovic, D.; Rakic, M.; Tarle, Z.; Sever, E.K. Blue laser for polymerization of bulk-fill composites: Influence on polymerization kinetics. Nanomaterials 2023, 13, 303. [Google Scholar] [CrossRef]

- Jiang, Y.; Zhao, W.W.; Yu, W.; Yu, Z.Q.; Xiao, X.Y.; Zhou, W.H.; Liu, X.Q. Free-standing laser-induced graphene heaters for efficient curing and repairing of composites. J. Mater. Sci. 2023, 58, 2604–2618. [Google Scholar] [CrossRef]

- Li, Y.G.; Cheng, L.B.; Zhou, J. Curing multidirectional carbon fiber reinforced polymer composites with indirect microwave heating. Int. J. Adv. Manuf. Technol. 2018, 97, 1137–1147. [Google Scholar] [CrossRef]

- Rao, S.; Chiranjeevi, M.C.; Prakash, M.R. Vacuum-assisted microwave processing of glass-epoxy composite laminates using novel microwave absorbing molds. Polym. Compos. 2018, 39, 1152–1160. [Google Scholar] [CrossRef]

- Guan, C.L.; Zhan, L.H.; Zhang, D.C.; Yao, S.M.; Zhong, S.C.; Wang, B. Microwave uniformity regulation and its influence on temperature field distribution of composite materials. J. Cent. South Univ. 2023, 30, 3374–3394. [Google Scholar] [CrossRef]

- Hang, X.; Li, Y.G.; Hao, X.Z.; Li, N.Y.; Wen, Y.Y. Effects of temperature profiles of microwave curing processes on mechanical properties of carbon fibre-reinforced composites. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2017, 231, 1332–1340. [Google Scholar] [CrossRef]

- Haider, I.; Gul, I.H.; Umer, M.A.; Baig, M.M. Silica-fiber-reinforced composites for microelectronic applications: Effects of curing routes. Materials 2023, 16, 1790. [Google Scholar] [CrossRef] [PubMed]

- de Vergara, U.L.; Sarrionandia, M.; Gondra, K.; Aurrekoetxea, J. Impact behaviour of basalt fibre reinforced furan composites cured under microwave and thermal conditions. Compos. Part B Eng. 2014, 66, 156–161. [Google Scholar] [CrossRef]

- Dasari, S.K.; Rangapuram, M.; Fashanu, O.; Chandrashekhara, K.; Iyyer, N.; Phan, N. Manufacturing and experimental evaluation of microwave cured carbon/epoxy composites. Appl. Compos. Mater. 2021, 28, 2087–2103. [Google Scholar] [CrossRef]

- Chen, Y.L.; Li, Y.; You, Y.Y.; Xiao, J.; Song, Q.H. Research on mechanical properties of epoxy/glass fiber composites cured by microwave radiation. J. Reinf. Plast. Compos. 2014, 13, 1441–1451. [Google Scholar] [CrossRef]

- Muric-Nesic, J.; Compston, P.; Noble, N.; Stachurski, Z.H. Effect of low frequency vibrations on void content in composite materials. Compos. Part A-Appl. Sci. Manuf. 2009, 40, 548–551. [Google Scholar]

- Guan, C.L.; Zhan, L.H.; Dai, G.M.; Wu, X.T.; Xiao, Y. A unique method for curing composite materials by introducing vibration treatment into the hybrid heating process. J. Cent. South Univ. 2021, 28, 2961–2972. [Google Scholar] [CrossRef]

- Yang, X.B.; Zhan, L.H.; Peng, Y.F.; Liu, C.; Xiong, R. Interface controlled micro- and macro-mechanical properties of vibration processed carbon fiber/epoxy composites. Polymers 2021, 13, 2764. [Google Scholar] [CrossRef]

- Xiang, Y.X.; Shen, K.; Wu, H.; He, Z.C.; Li, X.K. Preparation of fixed length carbon fiber reinforced plastic composite sheets with isotropic mechanical properties. New Carbon Mater. 2022, 36, 1188–1194. [Google Scholar] [CrossRef]

- Yang, H.L.; Li, J.; Fang, H.C.; Zhang, X.; Zhou, Z.C.; Tong, X.Y.; Ruan, J.M. Influence of FeCrAl fiber on microstructure and mechanical properties of FeCrAl(f)/HA composites. Trans. Nonferrous Met. Soc. China 2013, 23, 711–717. [Google Scholar] [CrossRef]

- Guo, L.J.; Li, H.J.; Xue, H.; Li, K.Z.; Fu, Y.W. Mechanical properties of short carbon fiber reinforced pitch-based carbon/carbon composites. New Carbon Mater. 2006, 21, 36–42. [Google Scholar]

- JC/T 773-2010; Fibre-Reinforced Plastics Composites. Determination of Apparent Interlaminar Shear Strength by Short-Beam Method. The Standardization Administration of the People’s Republic of China: Beijing, China, 2010.

- Zuo, P.Y.; Tcharkhtchi, A.; Fitoussi, J.; Shirinbayan, M.; Bakir, F. Multiscale thermal study of virgin and aged polyphenylene sulfide reinforced by glass fiber. J. Appl. Polym. Sci. 2020, 137, e49031. [Google Scholar]

- Moon, C.R.; Bang, B.R.; Choi, W.J.; Kang, G.H.; Park, S.Y. A technique for determining fiber content in FRP by thermogravimetric analyzer. Polym. Test. 2005, 24, 376–380. [Google Scholar] [CrossRef]

- Meier, R.; Kahraman, I.; Seyhan, A.T.; Zaremba, S.; Drechsler, K. Evaluating vibration assisted vacuum infusion processing of hexagonal bo-ron nitride sheet modified carbon fabric/epox composites in terms of interlaminar shear strength and void content. Compos. Sci. Technol. 2016, 128, 94–103. [Google Scholar] [CrossRef]

- GB/T 1043.1-2008; Plastics—Determination of Charpy Impact Properties—Part 1: Non–Instrumented Impact Test. AQSIQ; SAC: Beijing, China, 2008.

- Tesfay, A.G.; Kahsay, M.B.; Kumar, P.S.S. Effect of carbon and glass fillers on tensile and impact strength, water absorption, and degradation properties of sisal/polyester composites. J. Nat. Fibers 2023, 20, 2202886. [Google Scholar] [CrossRef]

- Yang, K.; Guan, J.; Numata, K.; Wu, C.G.; Wu, S.J.; Shao, Z.Z.; Ritchie, R.O. Integrating tough antheraea pernyi silk and strong carbon fibres for impact-critical structural composites. Nat. Commun. 2019, 10, 3786. [Google Scholar] [CrossRef] [PubMed]

- Yan, Y.H.; Shi, X.M.; Liu, J.G.; Zhao, T.; Yu, Y.Z. Thermosetting resin system based on novolak and bismaleimide for resin-transfer molding. J. Appl. Polym. Sci. 2002, 83, 1654–1657. [Google Scholar] [CrossRef]

- Zhu, H.Y.; Li, D.H.; Zhang, D.X.; Wu, B.C.; Chen, Y.Y. Influence of voids on interlaminar shear strength of carbon/epoxy fabric laminates. Trans. Nonferrous Met. Soc. China 2009, 19, S470–S475. [Google Scholar] [CrossRef]

- Lei, Z.; Ma, J.W.; Sun, W.; Yin, B.; Liew, K.M. Low-velocity impact and compression-after-impact behaviors of twill woven carbon fiber/glass fiber hybrid composite laminates with flame retardant epoxy resin. Compos. Struct. 2023, 321, 117253. [Google Scholar] [CrossRef]

| Factor | Pretreatment Temperature/°C | Dwell Time/min | Vibration Acceleration/g | |

|---|---|---|---|---|

| Level | ||||

| I | 80 | 10 | 5 | |

| II | 90 | 30 | 10 | |

| III | 100 | 50 | 15 | |

| Test No. | Pretreatment Temperature/°C | Dwell Time/min | Vibration Acceleration/g | Interlaminar Strength/MPa | Void Content/% |

|---|---|---|---|---|---|

| 1 | 80 | 10 | 5 | 48.52 | 0.98 |

| 2 | 80 | 30 | 10 | 58.18 | 0.57 |

| 3 | 80 | 50 | 15 | 53.89 | 0.71 |

| 4 | 90 | 10 | 10 | 59.44 | 0.44 |

| 5 | 90 | 30 | 15 | 55.82 | 0.66 |

| 6 | 90 | 50 | 5 | 48.60 | 0.80 |

| 7 | 100 | 10 | 15 | 52.23 | 0.77 |

| 8 | 100 | 30 | 5 | 51.65 | 0.78 |

| 9 | 100 | 50 | 10 | 55.58 | 0.67 |

| Level Ι | 53.53 | 53.40 | 49.59 | ||

| Level II | 54.62 | 55.22 | 57.73 | ||

| Level III | 53.15 | 52.69 | 53.98 | ||

| Extreme variance | 1.47 | 2.53 | 8.14 |

| Pretreatment Temperature/°C | Dwell Time/min | Vibration Acceleration/g | Interlaminar Strength/MPa | Absorbs Energy/J | Impact Strength/(kJ/m2) |

|---|---|---|---|---|---|

| 80 | 10 | 5 | 48.52 | 0.60 | 29.94 |

| 80 | 30 | 10 | 58.18 | 0.94 | 47.14 |

| 90 | 10 | 10 | 59.44 | 0.96 | 47.95 |

| 90 | 50 | 5 | 48.60 | 0.82 | 40.96 |

| 100 | 10 | 15 | 52.23 | 0.88 | 44.00 |

| 100 | 50 | 10 | 55.58 | 0.89 | 44.19 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, D.; Zhan, L.; Ma, B.; Guo, J.; Jin, W.; Hu, X.; Yao, S.; Dai, G. Effect of Vibration Pretreatment–Microwave Curing Process Parameters on the Mechanical Performance of Resin-Based Composites. Polymers 2024, 16, 2518. https://doi.org/10.3390/polym16172518

Zhang D, Zhan L, Ma B, Guo J, Jin W, Hu X, Yao S, Dai G. Effect of Vibration Pretreatment–Microwave Curing Process Parameters on the Mechanical Performance of Resin-Based Composites. Polymers. 2024; 16(17):2518. https://doi.org/10.3390/polym16172518

Chicago/Turabian StyleZhang, Dechao, Lihua Zhan, Bolin Ma, Jinzhan Guo, Wentao Jin, Xin Hu, Shunming Yao, and Guangming Dai. 2024. "Effect of Vibration Pretreatment–Microwave Curing Process Parameters on the Mechanical Performance of Resin-Based Composites" Polymers 16, no. 17: 2518. https://doi.org/10.3390/polym16172518

APA StyleZhang, D., Zhan, L., Ma, B., Guo, J., Jin, W., Hu, X., Yao, S., & Dai, G. (2024). Effect of Vibration Pretreatment–Microwave Curing Process Parameters on the Mechanical Performance of Resin-Based Composites. Polymers, 16(17), 2518. https://doi.org/10.3390/polym16172518