Mechanical, Thermal and Morphological Study of Bio-Based PLA Composites Reinforced with Lignin-Rich Agri-Food Wastes for Their Valorization in Industry

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Development of PLA-Based Polymeric Materials with Agri-Food Waste through Melt Compounding

2.3. Development of PLA-Based Polymeric Materials with Commercial Lignin through Melt Compounding

2.4. Agri-Food Waste and Lignin/PLA Composite Injection Molding

2.5. Characterization Methods

2.5.1. Determination of Density

2.5.2. Determination of Shore Hardness

2.5.3. Determination of Charpy Impact Strength

2.5.4. Infrared Spectroscopy (FTIR) of Developed Composites

2.5.5. Determination of Tensile Properties

2.5.6. Determination of Melt Flow Index (MFI) Properties

2.5.7. Determination of Vicat Softening Temperature

2.5.8. Thermal Analysis

2.5.9. Morphological Analysis

3. Results and Discussion

3.1. Physicochemical Characterization

3.1.1. Determination of Density

3.1.2. Determination of Shore Hardness

3.1.3. Determination of Charpy Impact Strength

3.1.4. Infrared Spectroscopy of Developed Composites

3.1.5. Determination of Tensile Properties

3.1.6. Determination of Melt Flow Index (MFI) Properties

3.1.7. Determination of VICAT Softening Temperature

3.2. Thermal Analysis

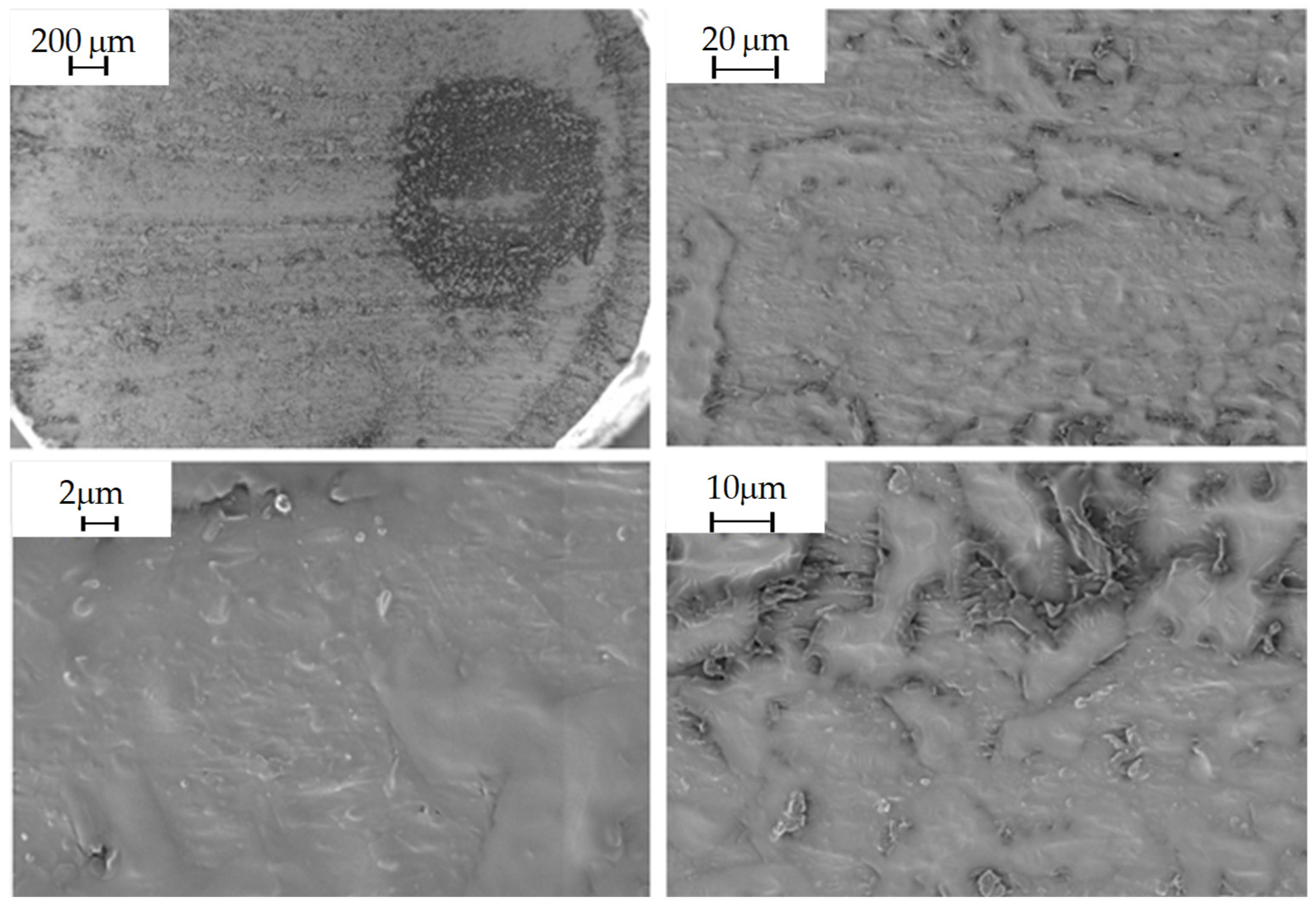

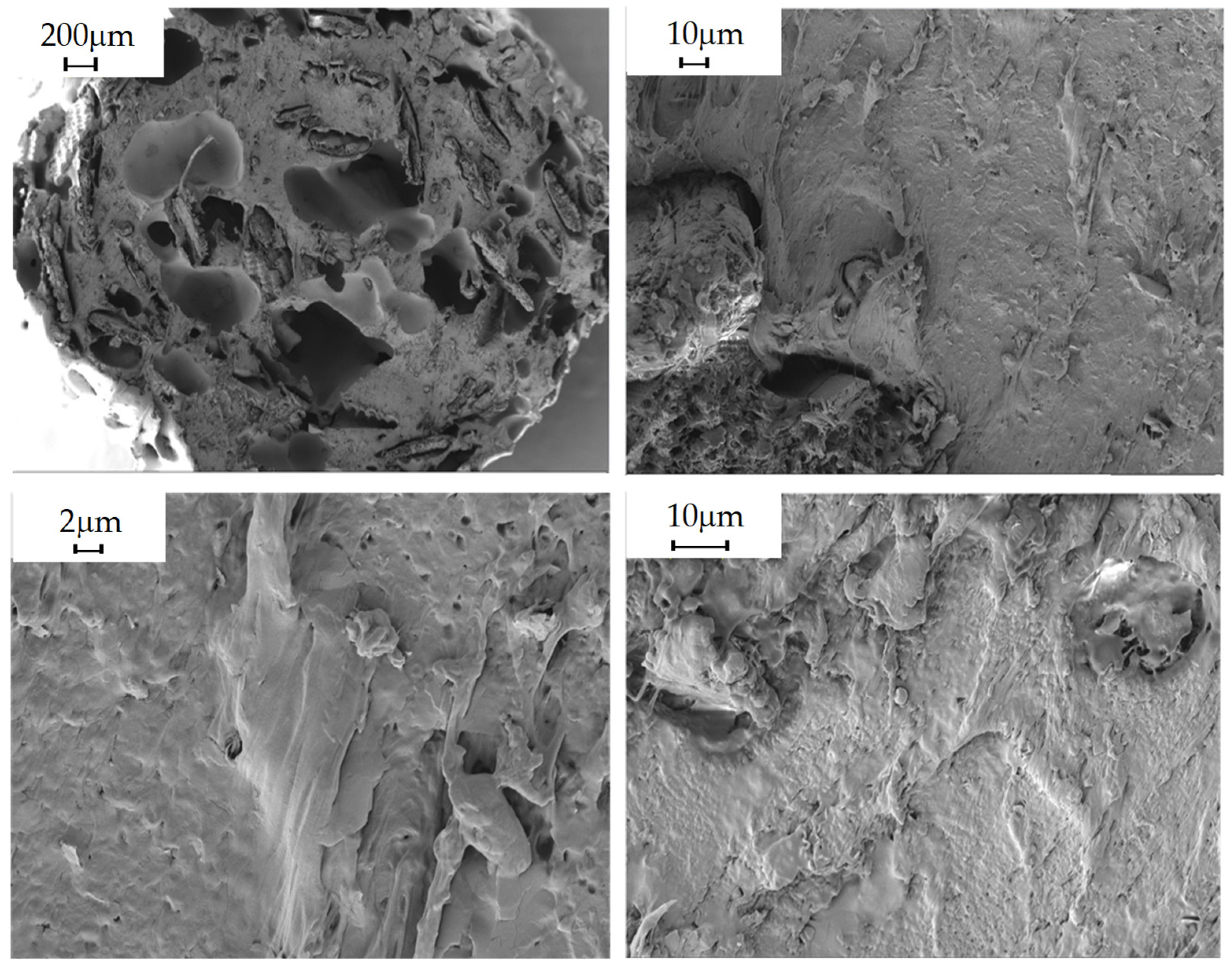

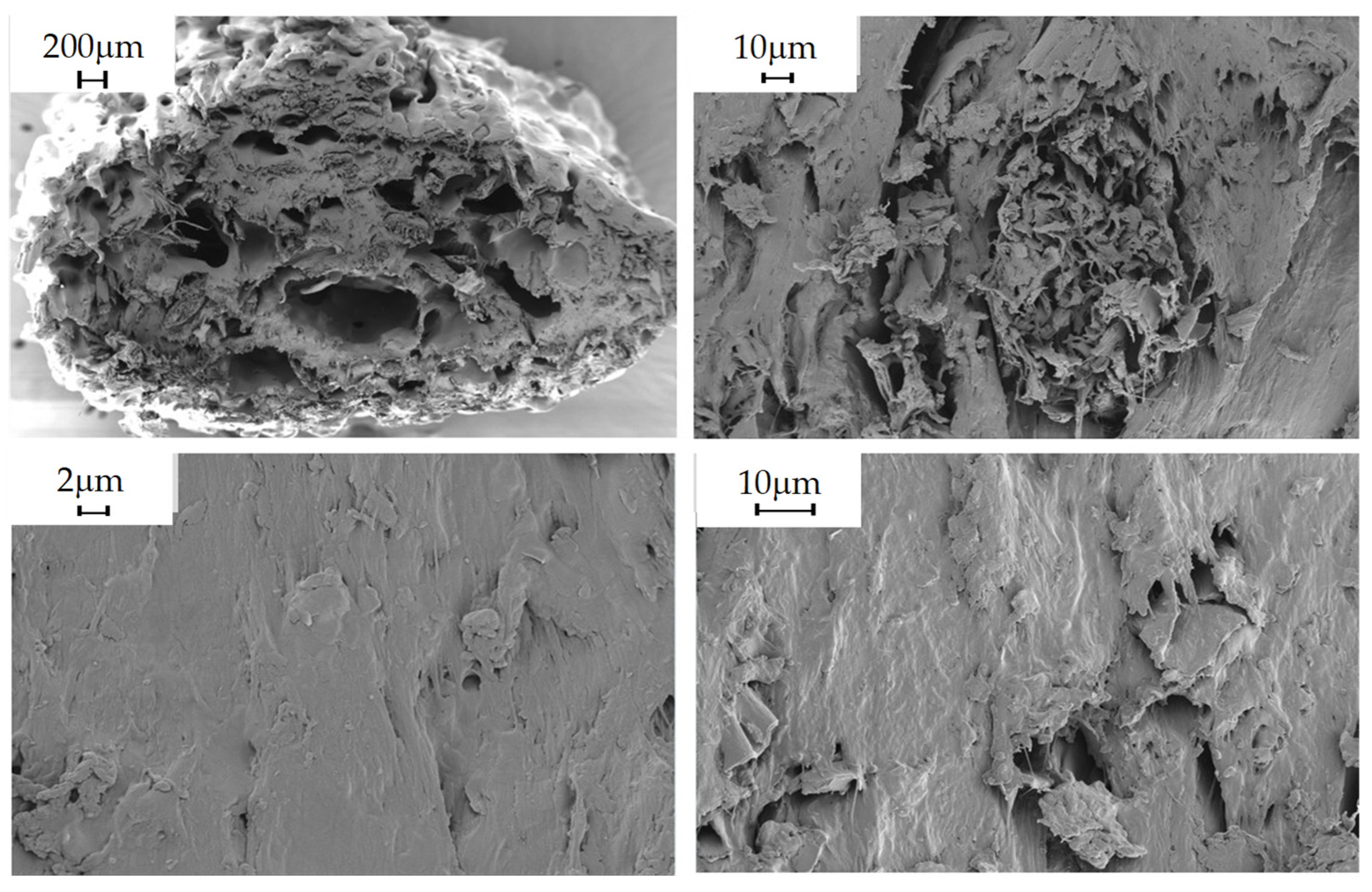

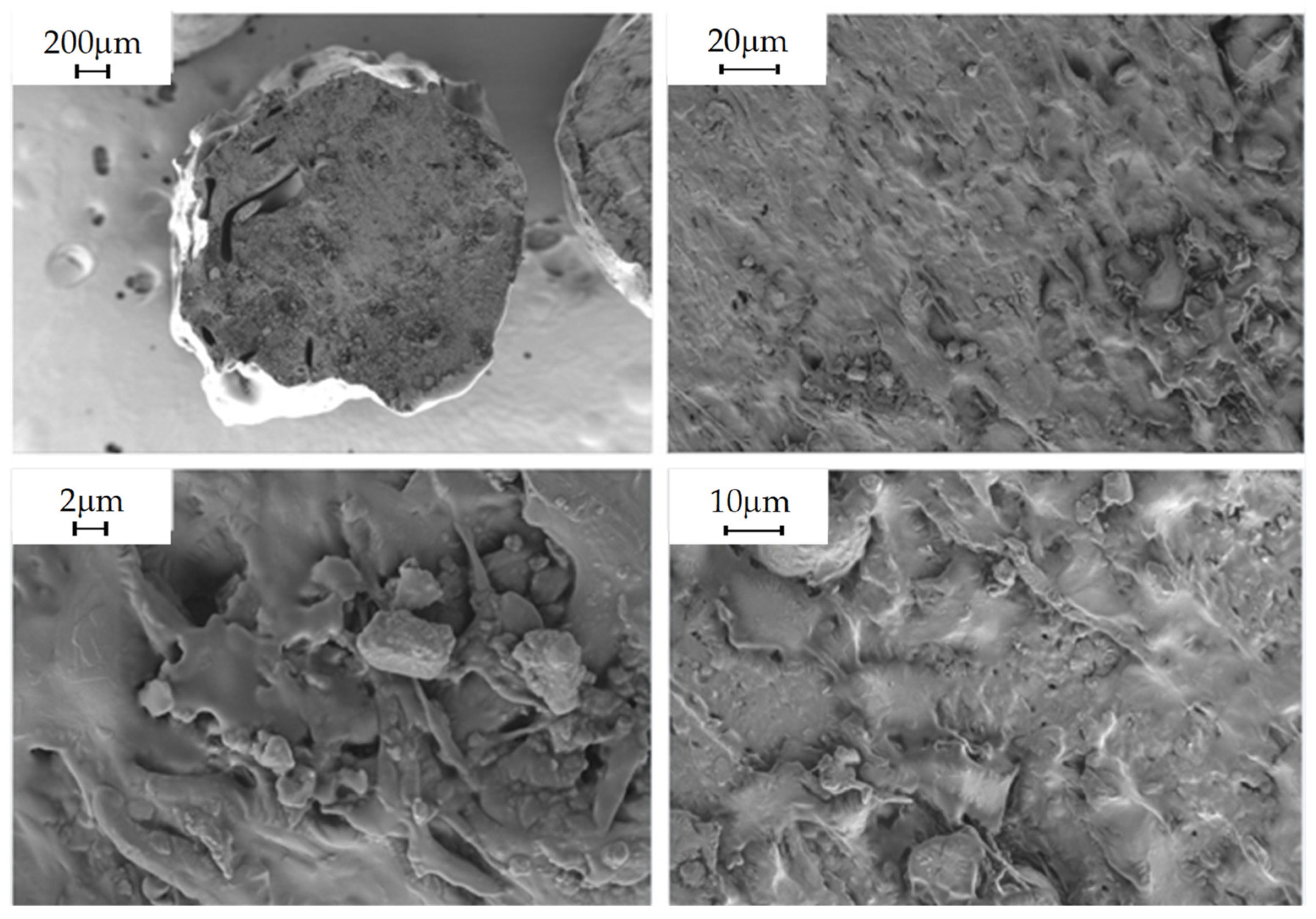

3.3. Morphological Analysis

- Virgin PLA

- PLA/20% Olive Pit

- PLA/20% Wheat Straw

- PLA/20% Rice Husk

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Rajeshkumar, G.; Arvindh, S.; Devnani, G.L.; Sanjay, M.R.; Siengchin, S.; Prakas Maran, J.; Al-Dhabi, N.A.; Karuppiah, P.; Mariadhas, V.A.; Sivarajasekar, N.; et al. Environment friendly, renewable and sustainable poly lactic acid (PLA) based natural fiber reinforced composites—A comprehensive review. J. Clean. Prod. 2021, 310, 127483. [Google Scholar] [CrossRef]

- Getme, A.S.; Patel, B. A review: Bio-fiber’s as reinforcement in composites of polylactic acid (PLA). Mater. Today Proc. 2020, 26, 2116–2122. [Google Scholar] [CrossRef]

- Bartolucci, L.; Cordiner, S.; De Maina, E.; Kumar, G.; Mele, P.; Mulone, V.; Iglinski, B.; Piechota, G. Sustainable Valorization of Bioplastic Waste: A Review on Effective Recycling Routes for the Most Widely Used Biopolymers. Int. J. Mol. Sci. 2023, 24, 7696. [Google Scholar] [CrossRef] [PubMed]

- Augé, M.-O.; Roncucci, D.; Bonnet, F.; Gaan, S.; Fontaine, G. Recent Advances on reactive extrusion of Poly(lactic acid). Eur. Polym. J. 2023, 184, 111727. [Google Scholar] [CrossRef]

- He, Z.; Wang, M. Porous lignin-based composites for oil/water separation: A review. Int. J. Biol. Macromol. 2024, 260, 129569. [Google Scholar] [CrossRef] [PubMed]

- Yan, Y.; Zhang, L.; Zhao, X.; Zhai, S.; Wang, Q.; Li, C.; Zhang, X. Utilization of lignin upon successive fractionation and esterification in polylactic acid (PLA)/lignin biocomposite. Int. J. Biol. Macromol. 2022, 203, 49–57. [Google Scholar] [CrossRef] [PubMed]

- Lendvai, L.; Omastova, M.; Patnaik, A.; Dogossy, G.; Singh, T. Valorization of Waste Flour and Rice Husk in Poly(Lactic Acid)—Based Hybrid Biocomposites. J. Polym. Environ. 2023, 31, 541–551. [Google Scholar] [CrossRef]

- Shi, K.; Liu, G.; Sun, H.; Weng, Y. Polylactic Acid/Lignin Composites: A Review. Polymers 2023, 15, 2807. [Google Scholar] [CrossRef]

- Tanase-Opedal, M.; Espinosa, E.; Rodriguez, A.; Chinga-Carrasco, G. Lignin: A Biopolymer from Forestry Biomass for Biocomposites and 3D Printing. Materials 2019, 12, 3006. [Google Scholar] [CrossRef]

- Otero, P.; Echave, J.; Chamorro, F.; Soria-Lopez, A.; Cassani, L.; Simal-Gandara, J.; Prieto, M.A.; Fraga-Corral, M. Challenges in the Application of Circular Economy Models to Agricultural By-Producs: Pesticides in Spain as a Case Study. Foods 2023, 12, 3054. [Google Scholar] [CrossRef]

- Sanjay, M.R.; Madhu, P.; Jawaid, M.; Senthamaraikannan, P.; Senthil, S.; Pradeep, S. Characterization and properties of natural Fiber Polymer composites: A comprehensive review. J. Clean. Prod. 2018, 172, 566–581. [Google Scholar] [CrossRef]

- Roostazadeh, R.; Behzad, T.; Karimi, K. Isolation and characterization of lignin-rich particles as byproducts of bioetanol production from wheat Straw to reinforce starch composite films. Ind. Crop. Prod. 2022, 186, 115175. [Google Scholar] [CrossRef]

- Makri, S.P.; Zanthopoulou, E.; Valera, M.A.; Mangas, A.; Marra, G.; Ruiz, V.; Koltsakidis, S.; Tzetzis, D.; Karathanasis, A.Z.; Deligkiozi, I.; et al. Poly(Lactic Acid) Composites with Lignin and Nanolignin Synthesized by In Situ Reactive Processing. Polymers 2023, 15, 2386. [Google Scholar] [CrossRef] [PubMed]

- Fontecha-Camara, M.A.; Delgado-Blanca, I.; Mañas-Villar, M.; Orriach-Fernández, J.; Soriano-Cuadrado, B. Extraction and Depolymerization of lignin from different agricultural and forestry wastes to obtain building blocks in a circular economy framework. Polymers 2024, 14, 1981. [Google Scholar] [CrossRef] [PubMed]

- Valvez, S.; Maceiras, A.; Santos, P.; Reis, P.N.B. Olive Stones as Filler for Polymer-Based Composites: A review. Materials 2021, 14, 845. [Google Scholar] [CrossRef]

- Koutsomitopoulou, A.F.; Bénézet, J.C.; Bergeret, A.; Papanicolaou, G.C. Preparation and characterization of olive pit powder as a filler to PLA-matriz bio-composites. Powder Technol. 2014, 255, 10–16. [Google Scholar] [CrossRef]

- Nyambo, C.; Mohanty, A.K.; Misra, M. Polylactide-Based Renewable Green Composites from Agricultural Residues and Their Hybrids. Biomacromolecules 2010, 11, 1654–1660. [Google Scholar] [CrossRef]

- Zhang, L.; Larsson, A.; Moldin, A.; Edlund, U. Comparison of lignin distribution, structure, and Morphology in wheat Straw and Wood. Ind. Crop. Prod. 2022, 187, 115432. [Google Scholar] [CrossRef]

- Barreto, G.; Restrepo, S.; Vieira, C.M.; Monteiro, S.N.; Colorado, H.A. Rice Husk with PLA: 3D Filament Making and Additive Manufacturing of Samples for Potential Structural Applications. Polymers 2024, 16, 245. [Google Scholar] [CrossRef]

- Klaai, L.; Hammiche, D.; Boukerrou, A. Valorization of Prickly Pear Seed and Olive Husk Agricultural Wastes for Plastic Reinforcement: The Influence on the Mechanical and Thermal Properties. Macromol. Symp. 2023, 409, 2200112. [Google Scholar] [CrossRef]

- Chougan, M.; Ghaffar, S.H.; Mijowska, E.; Kukulka, W.; Sikora, P. High-perfomance polylactic acid compressed strawboard using pre-treated and functionalised wheat straw. Ind. Crop. Prod. 2022, 184, 114996. [Google Scholar] [CrossRef]

- Pereira, D.F.; Branco, A.C.; Clàudio, R.; Marques, A.C.; Figueiredo-Pina, C.G. Development of Composites of PLA Filled with Different Amounts of Rice Husk Fibers for Fused Deposition Modeling. J. Nat. Fibers 2023, 20, 2162183. [Google Scholar] [CrossRef]

- Ariturk, G.; Girisken, C.; Bilge, K.; Yargici Kovanci, C.; Menceloglu, Y.Z.; Seven, S.A. Hybrid green composites of PLA incorporated with upcycled waste cellulose and vermiculite. Eur. Polym. J. 2024, 203, 112667. [Google Scholar] [CrossRef]

- Lendvai, L. Lignocellulosic agro-residue/polylatic acid (PLA) biocomposites: Rapeseed Straw as sustainable filler. Clean. Mater. 2023, 9, 100196. [Google Scholar] [CrossRef]

- Aliotta, L.; Sergi, C.; Dal Pont, B.; Coltelli, M.B.; Gigante, V.; Lazzeri, A. Sustainable 3D printed poly (lactic acid) (PLA)/Hazelnut Shell poder bio composites for design applications. Mater. Today Sustain. 2024, 26, 1000780. [Google Scholar] [CrossRef]

- Mohite, A.S.; Jagtap, A.R.; Avhad, M.S.; More, A.P. Recycling of major agriculture crop residues and its application in polymer industry: A review in the context of waste to energy nexus. Energy Nexus 2022, 7, 100134. [Google Scholar] [CrossRef]

- ISO/TC61/SC5. Physical-Chemical Properties. In UNE-EN ISO 1183-1:2019 Plastics—Methods for Determining the Density of Non-cellular Plastics—Part 1: Inmmersion Method, Liquid Pycnometer Method and Titration Method, 3rd ed.; 2019. Available online: https://www.iso.org/standard/74990.html (accessed on 1 June 2024).

- ISO/TC61/SC2. In ISO 868: 2003 Plastic and Ebonite—Determination of Indentation Hardness by Means of a Durometer (Shore Hardness), 3rd ed.; 2003. Available online: https://www.iso.org/standard/34804.html (accessed on 1 June 2024).

- ISO/TC61/SC2. In ISO 179-1: 2011 Plastics—Determination of Charpy Impact Properties—Part 1: Non-Instrumented Impact Test, 3rd ed.; 2023. Available online: https://www.iso.org/standard/84393.html (accessed on 1 June 2024).

- ISO/TC61/SC2. In ISO 527-1: 2019. Plastics—Determination of Tensile Properties—Part 1: General Principles, 3rd ed.; 2019. Available online: https://www.iso.org/standard/75824.html (accessed on 1 June 2024).

- ISO/TC61/SC5. In ISO 1133-2: 2011 Plastics—Determination of the Melt Mass-Flow Rate (MFR) and Melt Volume-Flow Rate (MVR) of thermoplastics—Part 2: Method for Materials Sensitive to Time-Temperature History and/or Moisture, 1st ed.; 2011. Available online: https://www.iso.org/standard/44274.html (accessed on 1 June 2024).

- ISO/TC61/SC2. In ISO 306:2022 Plastics—Thermoplastic Materials—Determination of Vicat Softening Temperature (VST), 6th ed.; 2022. Available online: https://www.iso.org/standard/82176.html (accessed on 1 June 2024).

- ISO/TC61/SC5. In ISO 11357-1:2023. Plastics—Differential Scanning Calorimetry (DSC)—Part 1: General Principles, 4th ed.; 2023. Available online: https://www.iso.org/standard/83904.html (accessed on 1 June 2024).

- Oliaei, E.; Kaffashi, B. Investigation of structure and Mechanical Properties of toughened poly(l-lactide)/thermoplastic poly(ester urethane) blends. J. Appl. Polym. Sci. 2016, 133, 3560–3572. [Google Scholar] [CrossRef]

- Cruz-Fabian, D.R.; Duperkova, S.; Dusankova, M.; Cisar, J.; Drohsler, P.; Elich, O.; Borkova, M.; Cechmankova, J.; Sedlarik, V. Renewable Poly(Lactic Acid) lignocellulose Biocomposites for the enhancement of the water retention capacity of the soil. Polymers 2023, 15, 2243. [Google Scholar] [CrossRef]

- Caicedo, C.; De la Cruz-Rodriguez, H.; Crespo-Delgado, L.M.; Álvarez-Jaramillo, N.A. Thermo-mechanical properties of Polypropylene: Effects during reprocessing. Ing. Investig. Tecnol. 2017, 18, 245–252. [Google Scholar] [CrossRef][Green Version]

- Hejna, A.; Korol, J. By-products from Food Industry as a Promising Alternative for the Conventional Fillers for Wood-Polymer Composites. Polymers 2021, 13, 893. [Google Scholar] [CrossRef]

- Hejna, A.; Formela, K. Processing, mechanical and thermal behavior assessments of polycaprolactone/agricultural wastes composites. Ind. Crop. Prod. 2015, 76, 725–733. [Google Scholar] [CrossRef]

- Terzopoulou, Z.; Xanthopoulou, E.; Pardalis, N.; Pappa, C.P.; Torofias, S.; Triantafyllidis, K.S.; Bikiaris, D.N. Synthesis and Characterization of Poly(Lactic Acid) Composites with Organosolv Lignin. Molecules 2022, 27, 8143. [Google Scholar] [CrossRef] [PubMed]

- Anwer, M.A.S.; Naguib, H.E.; Celzard, A.; Fierro, V. Comparison of the thermal, Dynamic Mechanical and Morphological properties of PLA-Lignin & PLA-Tannin particulate Green composites. Compos. Part B Eng. 2015, 82, 92–99. [Google Scholar] [CrossRef]

- Ferreira da Silva, T.; Menezes, F.; Montagna, L.S.; Lemes, A.P.; Passador, F.R. Effect of lignin as accelerator of the Biodegradation process of poly (lactic acid)/lignin composites. Mater. Sci. Eng. B 2019, 251, 114441. [Google Scholar] [CrossRef]

| Material | Temperature Profile (°C) | Spindle Speed (rpm) | Pelletizer Speed (rpm) |

|---|---|---|---|

| PLA | 121 130 141 145 145 145 145 | 160 | 28 |

| PLA/20% olive pit | 121 130 141 146 146 146 146 | 165 | 28 |

| PLA/20% rice husk | 121 130 141 146 146 146 146 | 165 | 28 |

| PLA/20% wheat straw | 125 135 144 149 149 150 154 | 160 | 28 |

| Material | Temperature Profile (°C) | Spindle Speed (rpm) | Pelletizer Speed (rpm) |

|---|---|---|---|

| PLA/6% lignin | 175 | 15 | 7 |

| 170 | |||

| 190 | |||

| 200 | |||

| 190 |

| Material | Injection Temperature (°C) | Mold Temperature (°C) | Heating Time (min) | Injection Pressure |

|---|---|---|---|---|

| PLA | 170 | 65 | 5 | 7 |

| PLA/20% olive pit | 170 | 65 | 5 | 7 |

| PLA/20% rice husk | 175 | 65 | 5 | 7 |

| PLA/20% wheat straw | 180 | 65 | 5 | 7 |

| Material | Density (g/cm3) |

|---|---|

| PLA | 1.252 ± 0.003 |

| PLA/6% Lignin | 1.230 ± 0.006 |

| PLA/20% Olive Pit | 1.249 ± 0.007 |

| PLA/20% Wheat Straw | 1.276 ± 0.002 |

| PLA/20% Rice Husk | 1.252 ± 0.005 |

| Material | Shore Hardness D/25 |

|---|---|

| PLA | 83.1 ± 0.39 |

| PLA/6% Lignin | 65.7 ± 0.37 |

| PLA/20% Olive Pit | 67.9 ± 0.36 |

| PLA/20% Wheat Straw | 70.1 ± 0.51 |

| PLA/20% Rice Husk | 70.2 ± 0.41 |

| Material | Charpy Impact (kJ/m2) |

|---|---|

| PLA | 20.50 ± 1.87 |

| PLA/6% Lignin | 27.50 ± 2.24 |

| PLA/20% Olive Pit | 14.70 ± 1.77 |

| PLA/20% Wheat Straw | 13.34 ± 1.16 |

| PLA/20% Rice Husk | 13.20 ± 2.26 |

| Material | Elastic Modulus (MPa) | Strain at Break (%) | Stress at Break (σb) (MPa) | Tensile Strength (σm) (MPa) |

|---|---|---|---|---|

| PLA | 2300 ± 169 | 159 ± 2.00 | 31.25 ± 0.73 | 54.85 ± 0.23 |

| PLA/6% Lignin | 1800 ± 070 | 9.55 ± 0.12 | 17.37 ± 0.54 | 23.82 ± 0.45 |

| PLA/20% Olive Pit | 2100 ± 175 | 27.40 ± 0.33 | 6.42 ± 0.66 | 9.55 ± 0.86 |

| PLA/20% Wheat Straw | 2200 ± 119 | 6.59 ± 0.39 | 9.37 ± 1.19 | 13.55 ± 0.73 |

| PLA/20% Rice Husk | 2500 ± 196 | 4.93 ± 0.81 | 10.32 ± 0.39 | 15.78 ± 0.56 |

| Material | Fluency MFI (g/10 min) |

|---|---|

| PLA | 10.26 ± 0.005 |

| PLA/6% Lignin | 32.63 ± 0.001 |

| PLA/20% Olive Pit | 32.95 ± 0.004 |

| PLA/20% Wheat Straw | 20.67 ± 0.003 |

| PLA/20% Rice Husk | 32.63 ± 0.002 |

| Material | VICAT Softening Temperature (°C) |

|---|---|

| PLA | 64.43 ± 1.4 |

| PLA/6% Lignin | 46.00 ± 1.2 |

| PLA/20% Olive Pit | 61.00 ± 1.5 |

| PLA/20% Wheat Straw | 61.00 ± 1.6 |

| PLA/20% Rice Husk | 45.00 ± 1.6 |

| Material | Tg (°C) | Tcc (°C) | ΔHcc (J/g) | Tm (°C) | ΔHm (J/g) | Xc (%) |

|---|---|---|---|---|---|---|

| Virgin PLA | 63.35 | 80.48 | 10.22 | 153.03 | 13.02 | 3 |

| PLA/6% Lignin * | 62.85 | 81.72 | 6.34 | 141.25 153.09 | 19.33 | 15 |

| PLA/20% Olive Pit | 58.62 | 122.28 | 0.82 | 152.86 | 9.16 | 11 |

| PLA/20% Wheat Straw | 62.33 | 134.03 | 0.084 | 153.64 | 7.75 | 10 |

| PLA/20% Rice Husk | 61.89 | 133.37 | 0.027 | 154.60 | 11.62 | 15 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Soriano-Cuadrado, B.; Fontecha-Cámara, M.Á.; Mañas-Villar, M.; Delgado-Blanca, I.; Ramírez-Rodríguez, M.D. Mechanical, Thermal and Morphological Study of Bio-Based PLA Composites Reinforced with Lignin-Rich Agri-Food Wastes for Their Valorization in Industry. Polymers 2024, 16, 2462. https://doi.org/10.3390/polym16172462

Soriano-Cuadrado B, Fontecha-Cámara MÁ, Mañas-Villar M, Delgado-Blanca I, Ramírez-Rodríguez MD. Mechanical, Thermal and Morphological Study of Bio-Based PLA Composites Reinforced with Lignin-Rich Agri-Food Wastes for Their Valorization in Industry. Polymers. 2024; 16(17):2462. https://doi.org/10.3390/polym16172462

Chicago/Turabian StyleSoriano-Cuadrado, Belén, Mᵃ Ángeles Fontecha-Cámara, María Mañas-Villar, Irene Delgado-Blanca, and María Dolores Ramírez-Rodríguez. 2024. "Mechanical, Thermal and Morphological Study of Bio-Based PLA Composites Reinforced with Lignin-Rich Agri-Food Wastes for Their Valorization in Industry" Polymers 16, no. 17: 2462. https://doi.org/10.3390/polym16172462

APA StyleSoriano-Cuadrado, B., Fontecha-Cámara, M. Á., Mañas-Villar, M., Delgado-Blanca, I., & Ramírez-Rodríguez, M. D. (2024). Mechanical, Thermal and Morphological Study of Bio-Based PLA Composites Reinforced with Lignin-Rich Agri-Food Wastes for Their Valorization in Industry. Polymers, 16(17), 2462. https://doi.org/10.3390/polym16172462