Enhancing Fatigue Resistance of Polylactic Acid through Natural Reinforcement in Material Extrusion

Abstract

1. Introduction

2. Materials and Methods

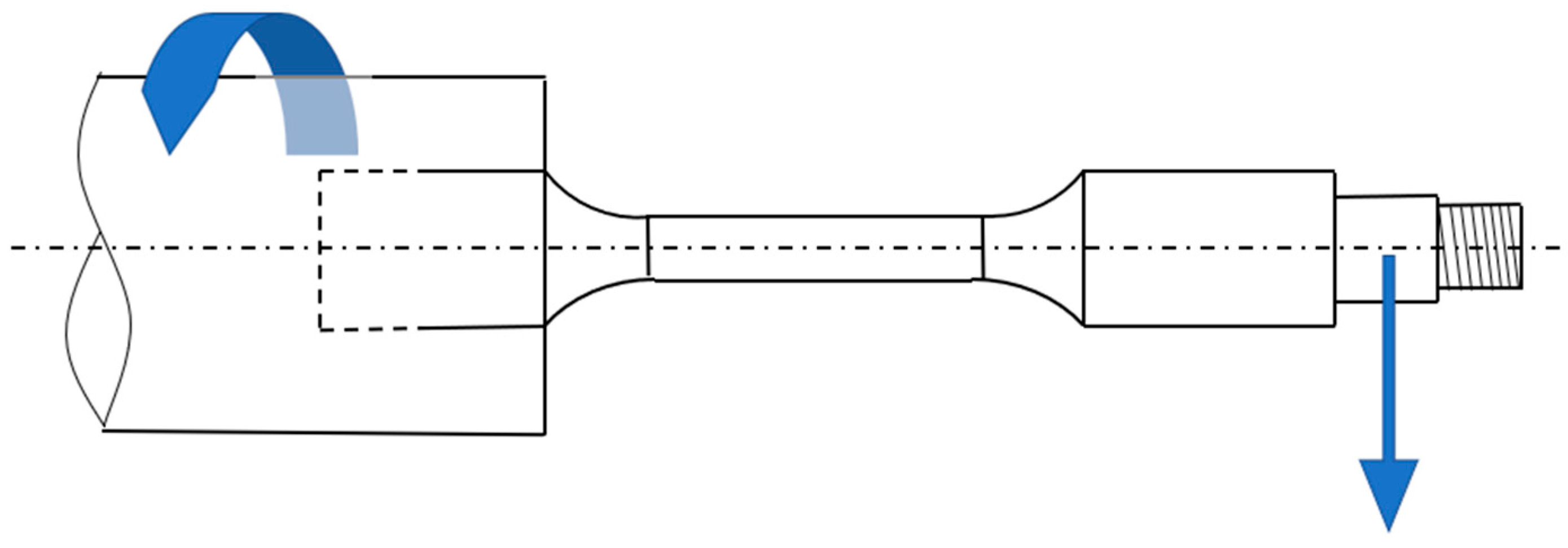

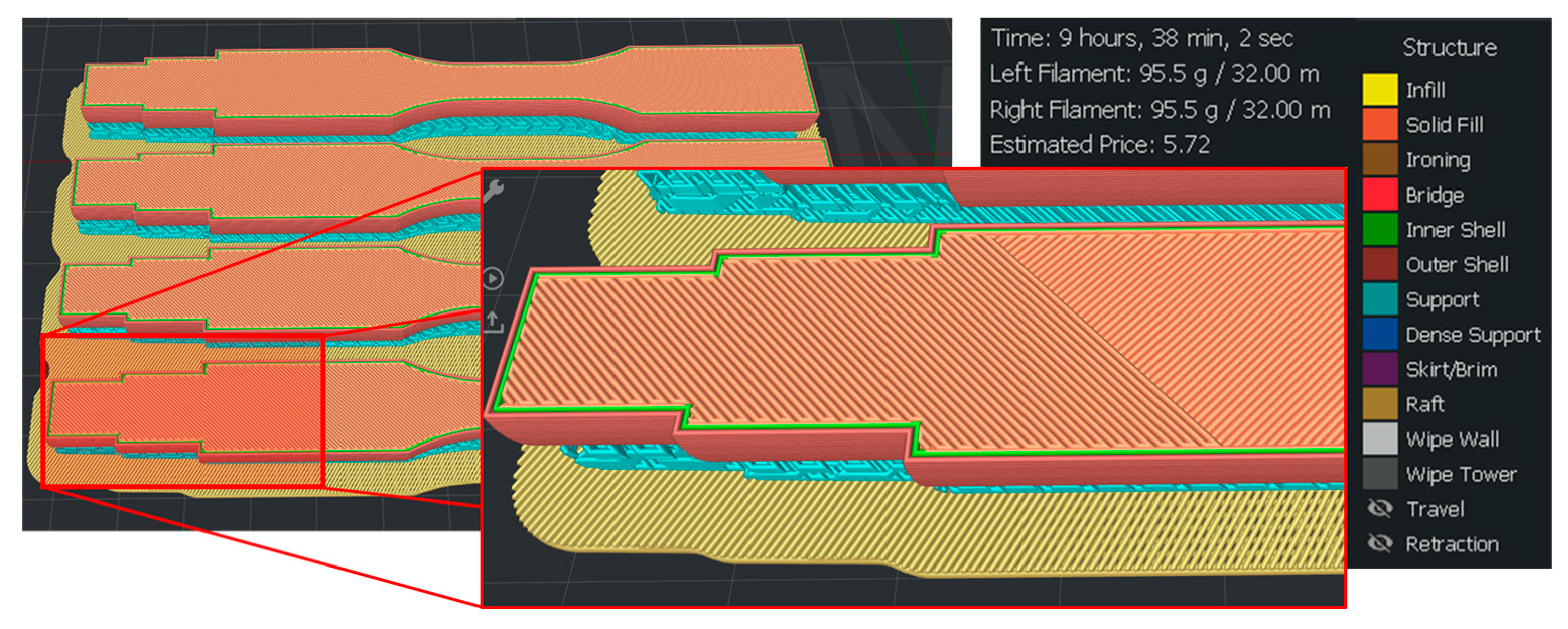

2.1. Sample Manufacture and Dimensional and Geometrical Control

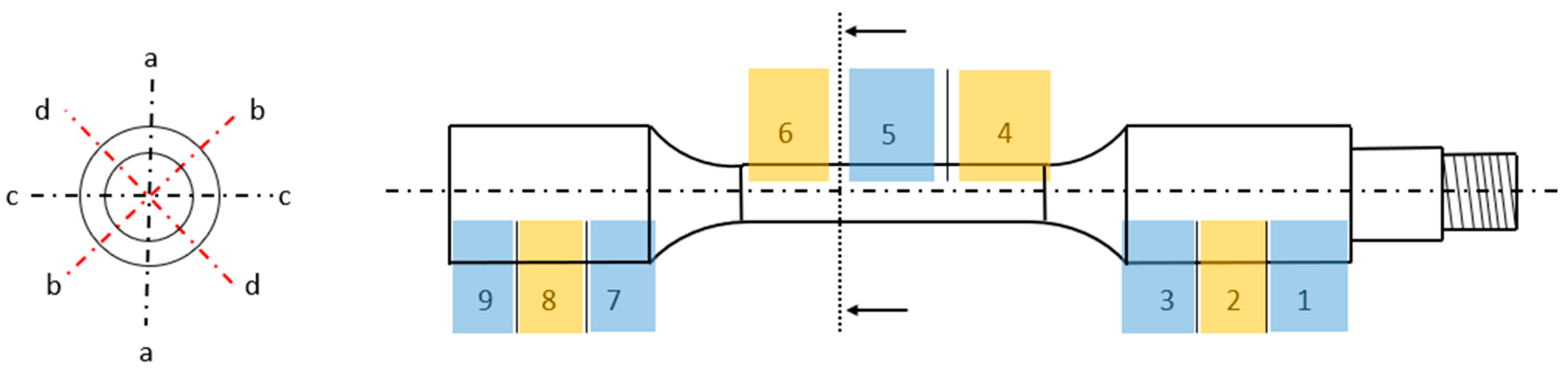

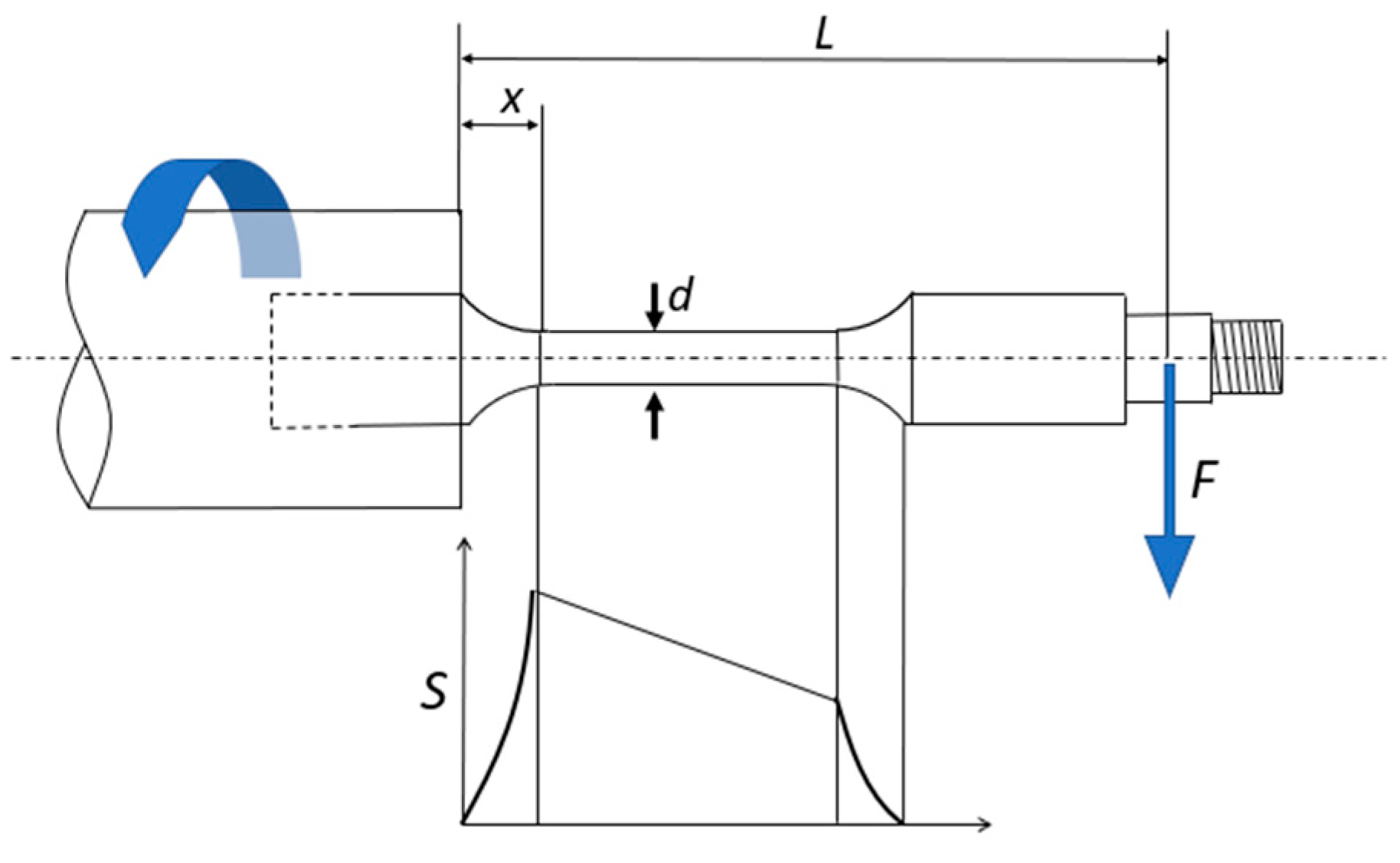

2.2. Fatigue Test

- S: stress at the fracture section (MPa).

- L: distance between the load applied section and the fixed point (mm).

- x: distance between the fixed point and the maximum stress point (mm).

- d: calibrated area diameter (mm).

- F: Load applied (N).

3. Results

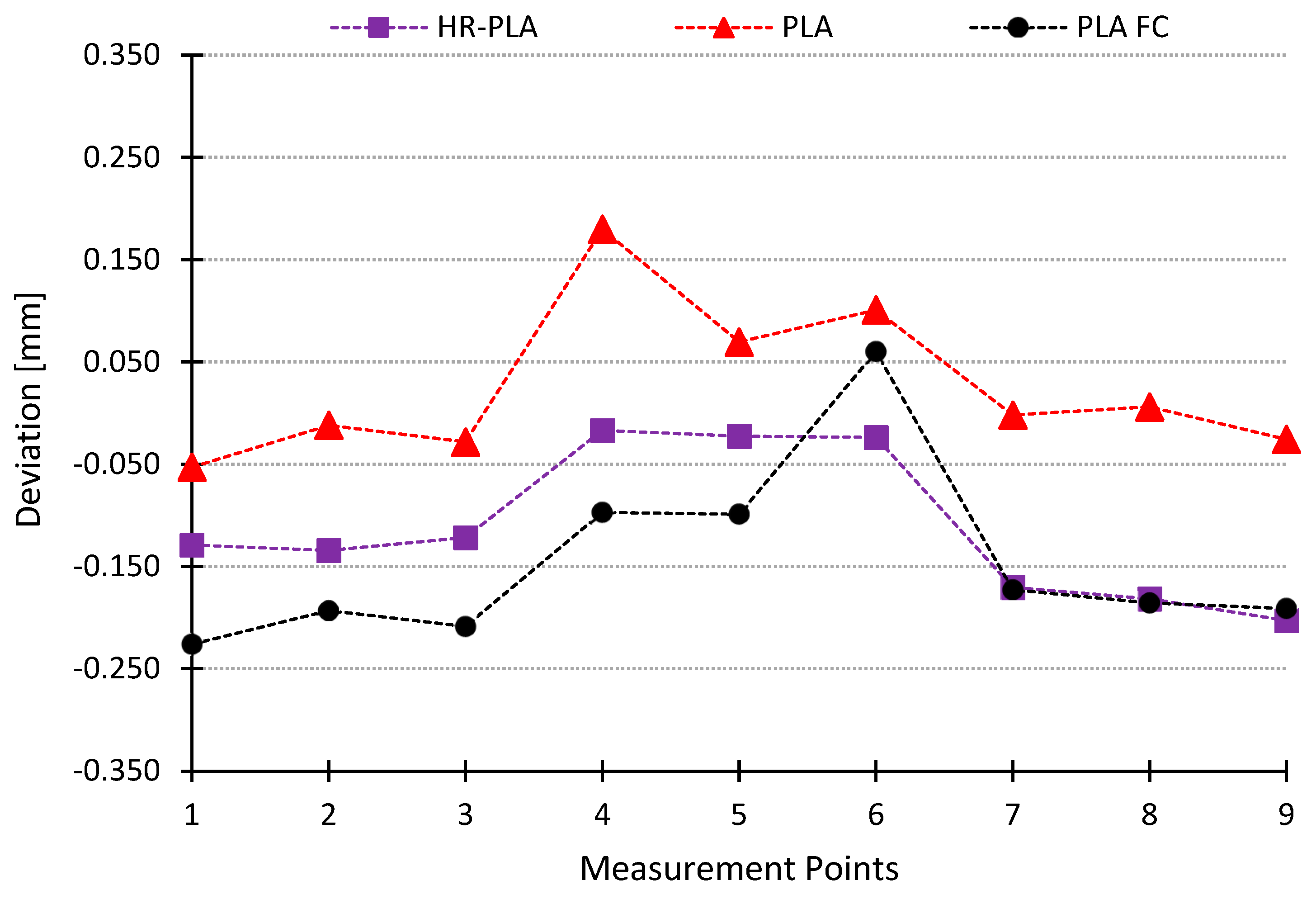

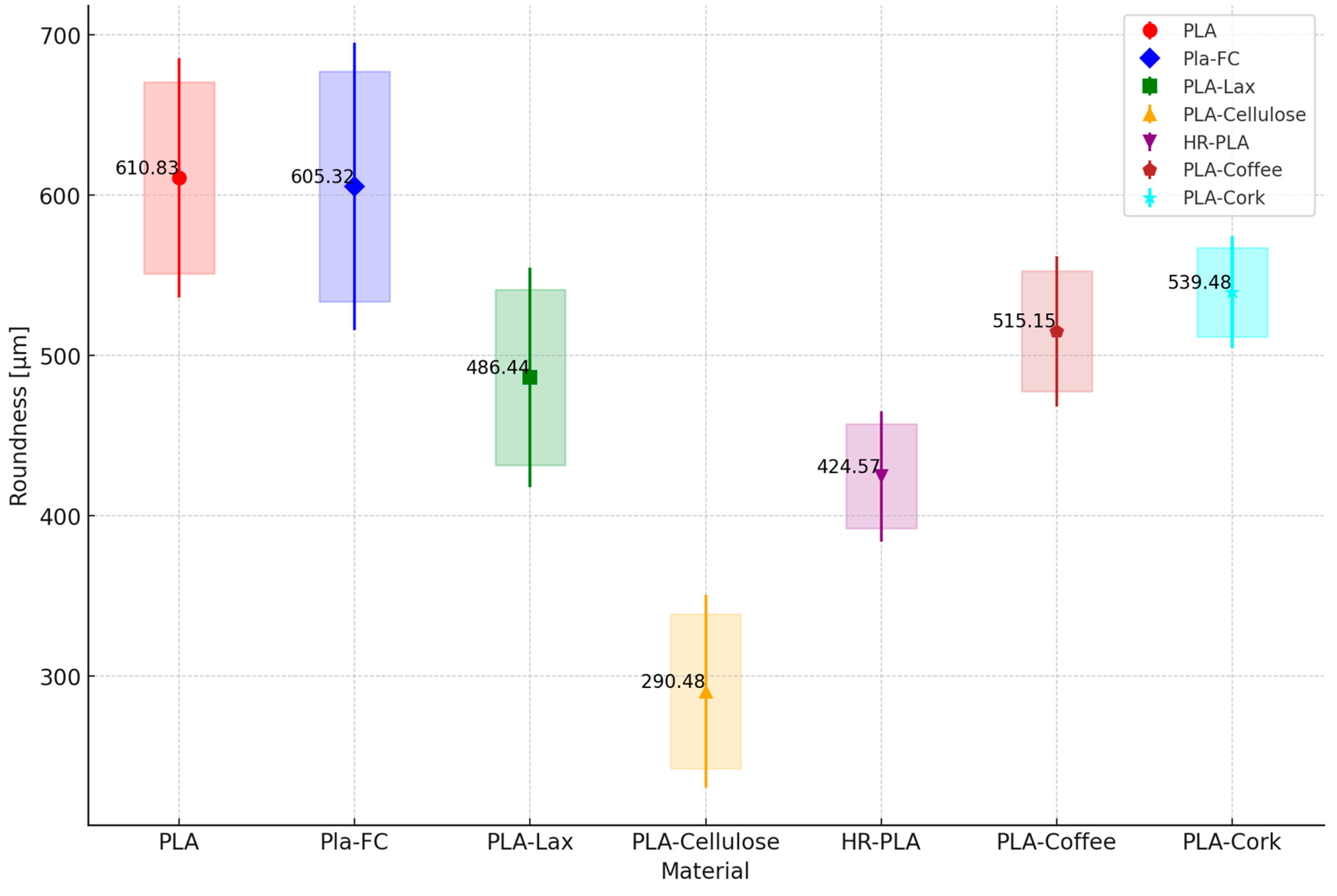

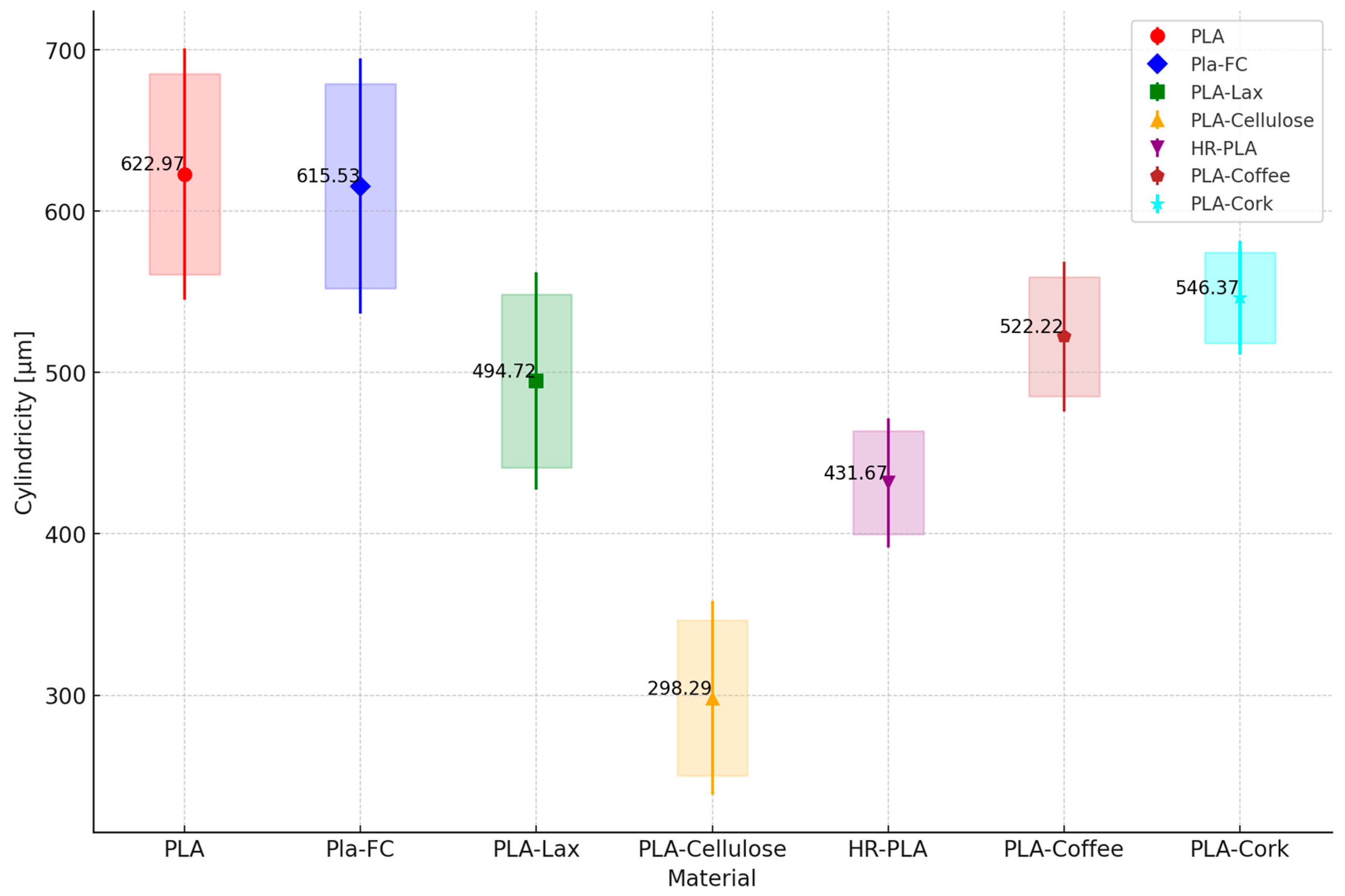

3.1. Dimensional and Geometrical Results

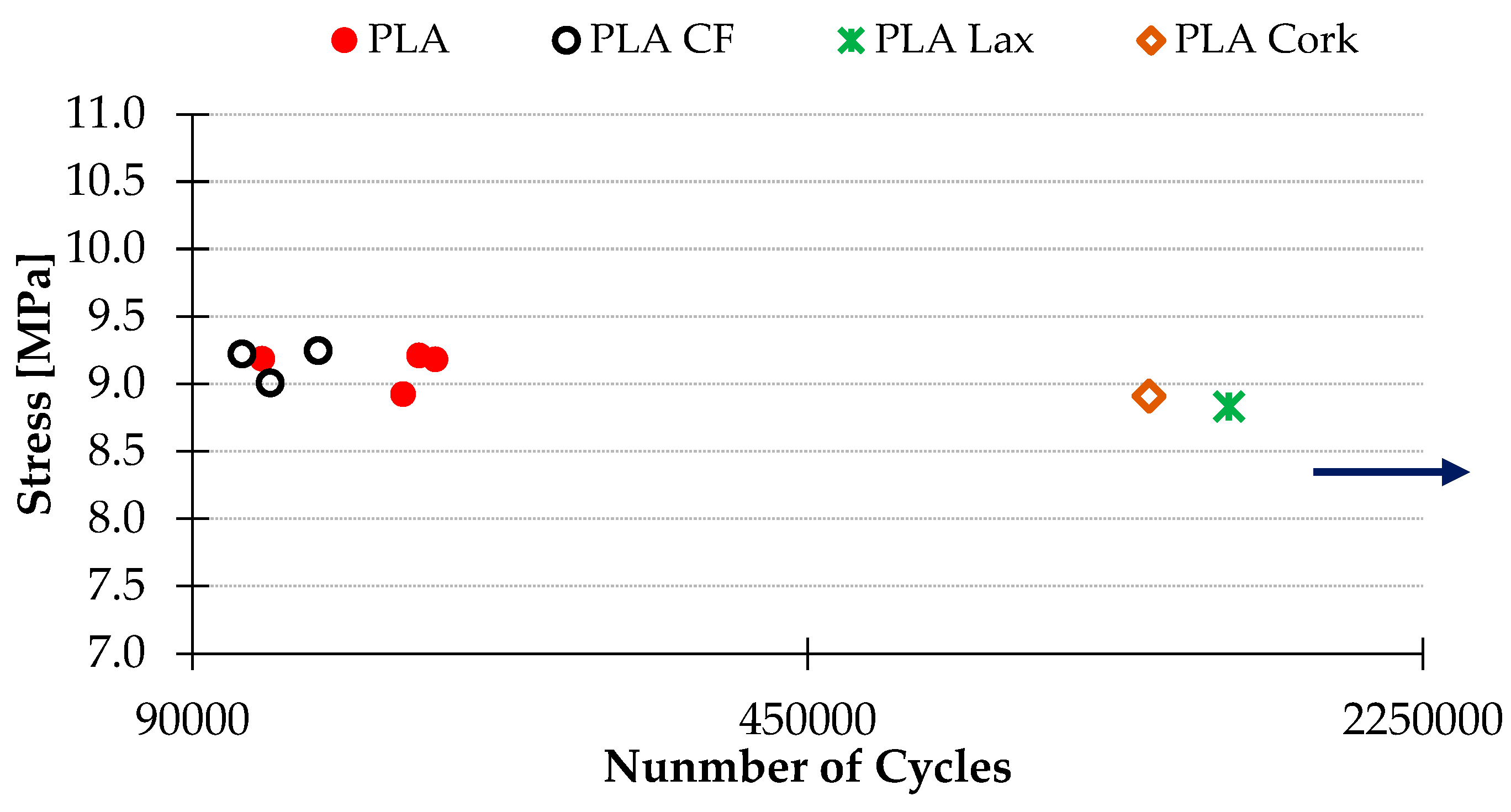

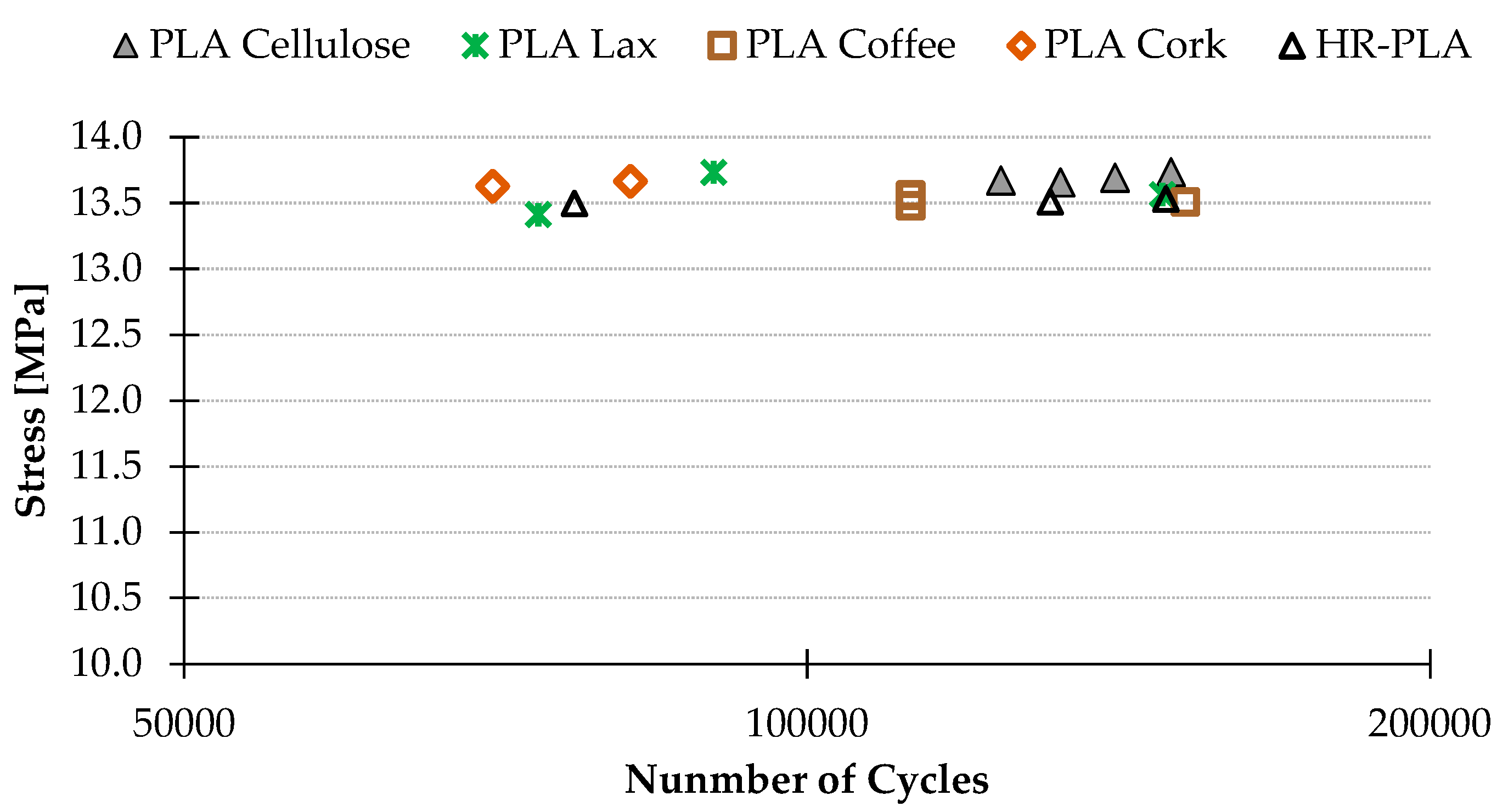

3.2. Fatigue Results

4. Conclusions

- By analyzing the dimensional deviations prior to the fatigue tests, it can be seen that these deviations not only depend on the size or diameter of the part. The reinforcement introduced also has a great influence, due to its density, its capacity to dissipate heat, or its own shrinkage capacity. In this respect, the most similar behavior to the PLA specimens is those reinforced with cellulose fibers.

- The geometrical deviations of the natural fiber reinforcement samples are lower than the samples without reinforcement or with carbon fiber. This can help when working with parts with tighter tolerances and dimensions. Also, lower geometrical deviations also improve fatigue resistance.

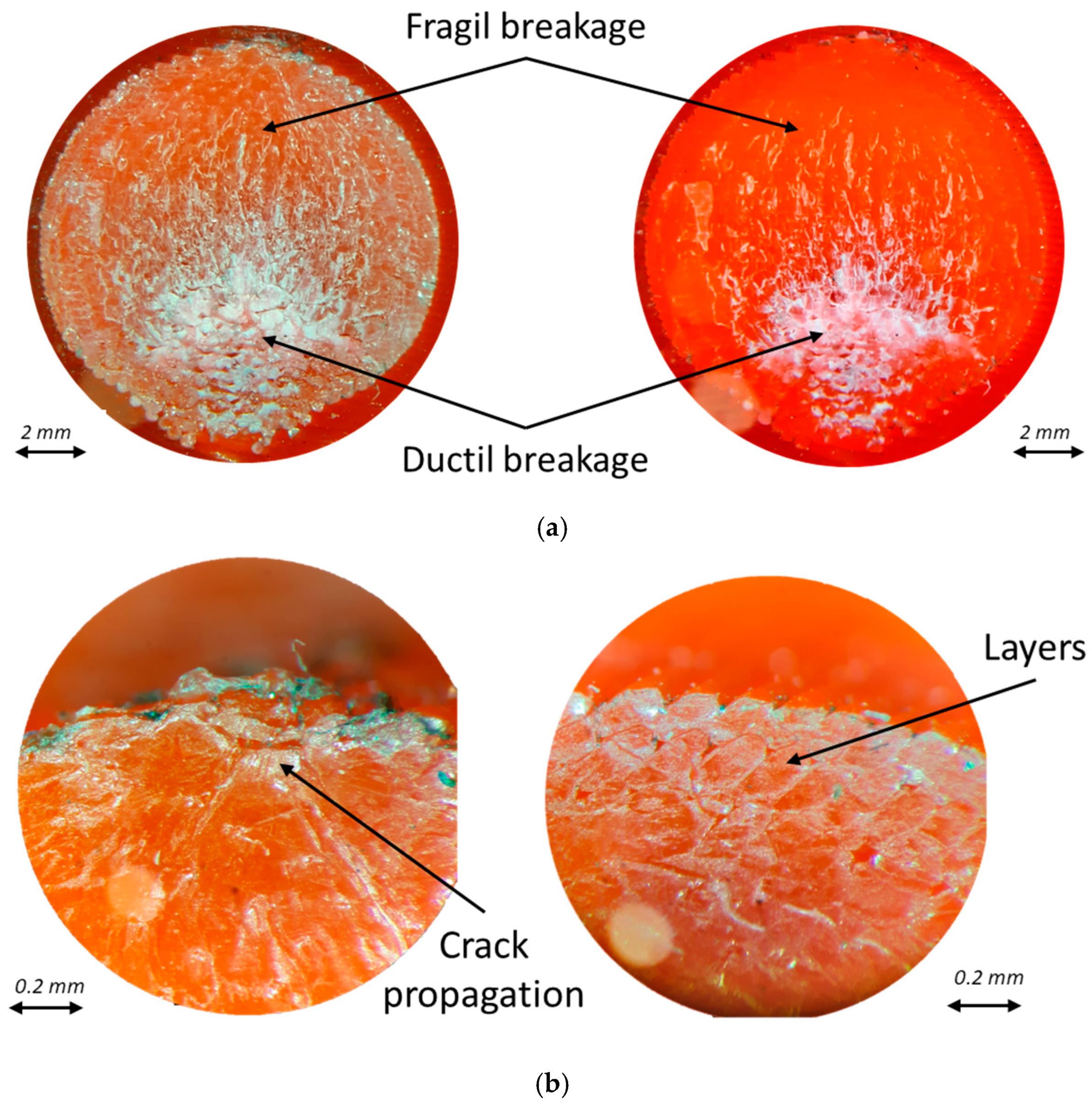

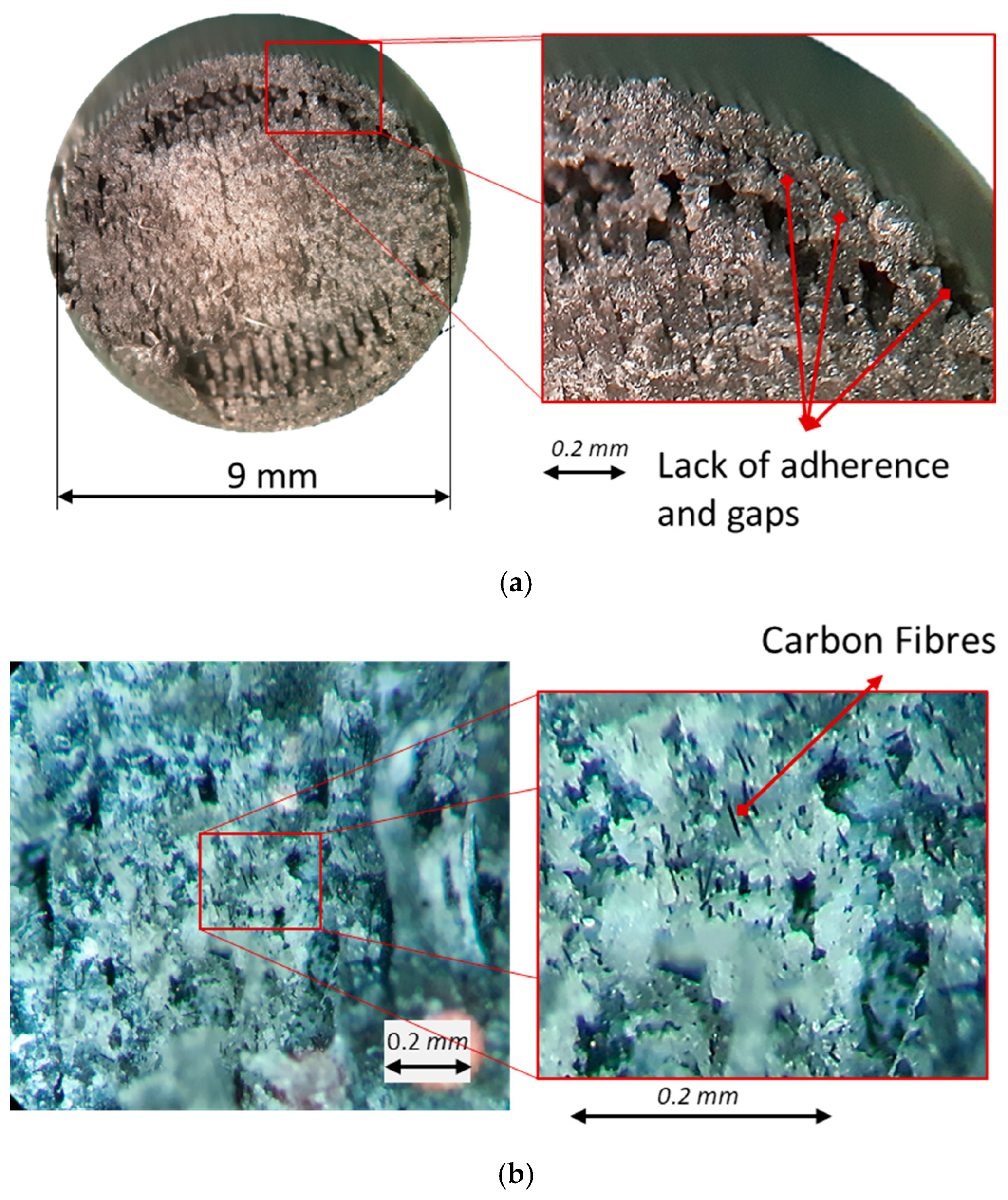

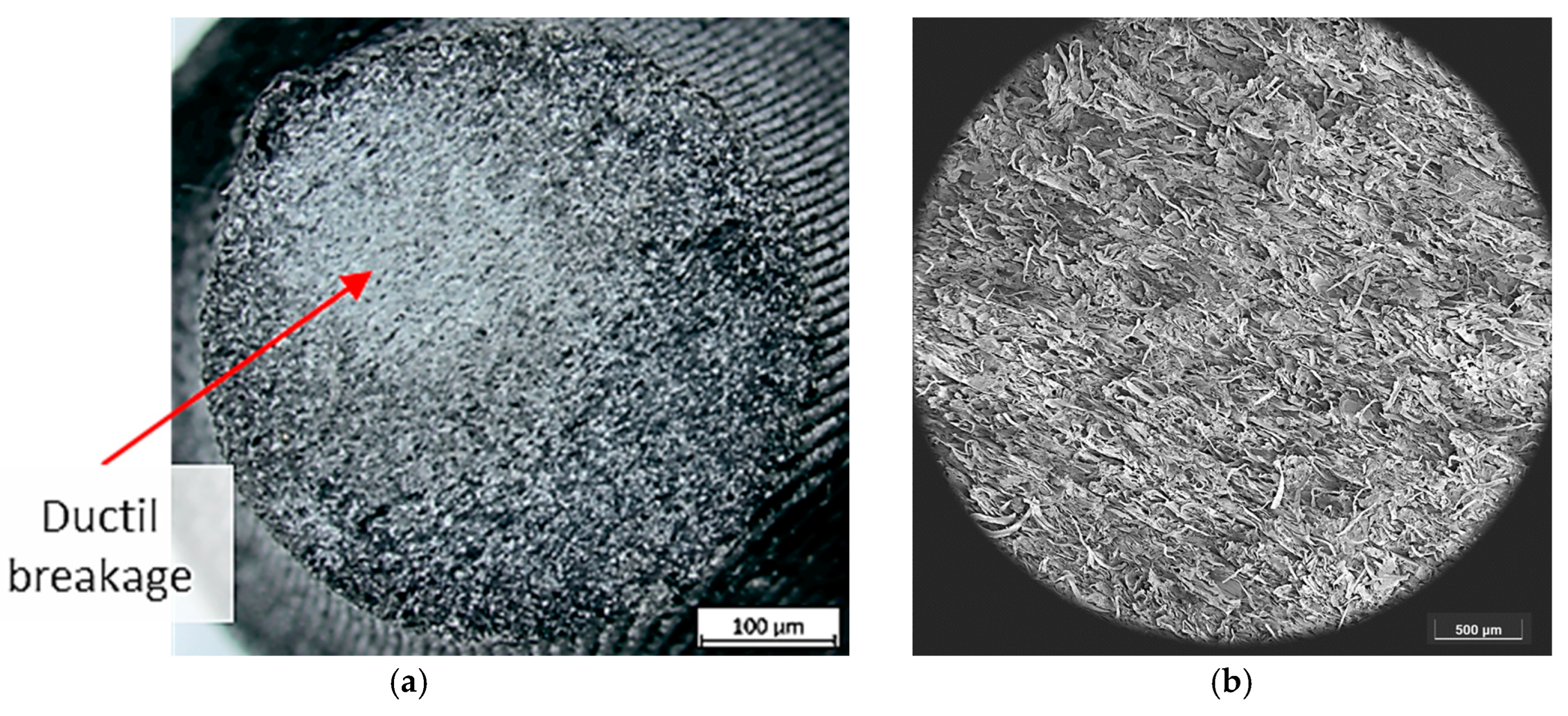

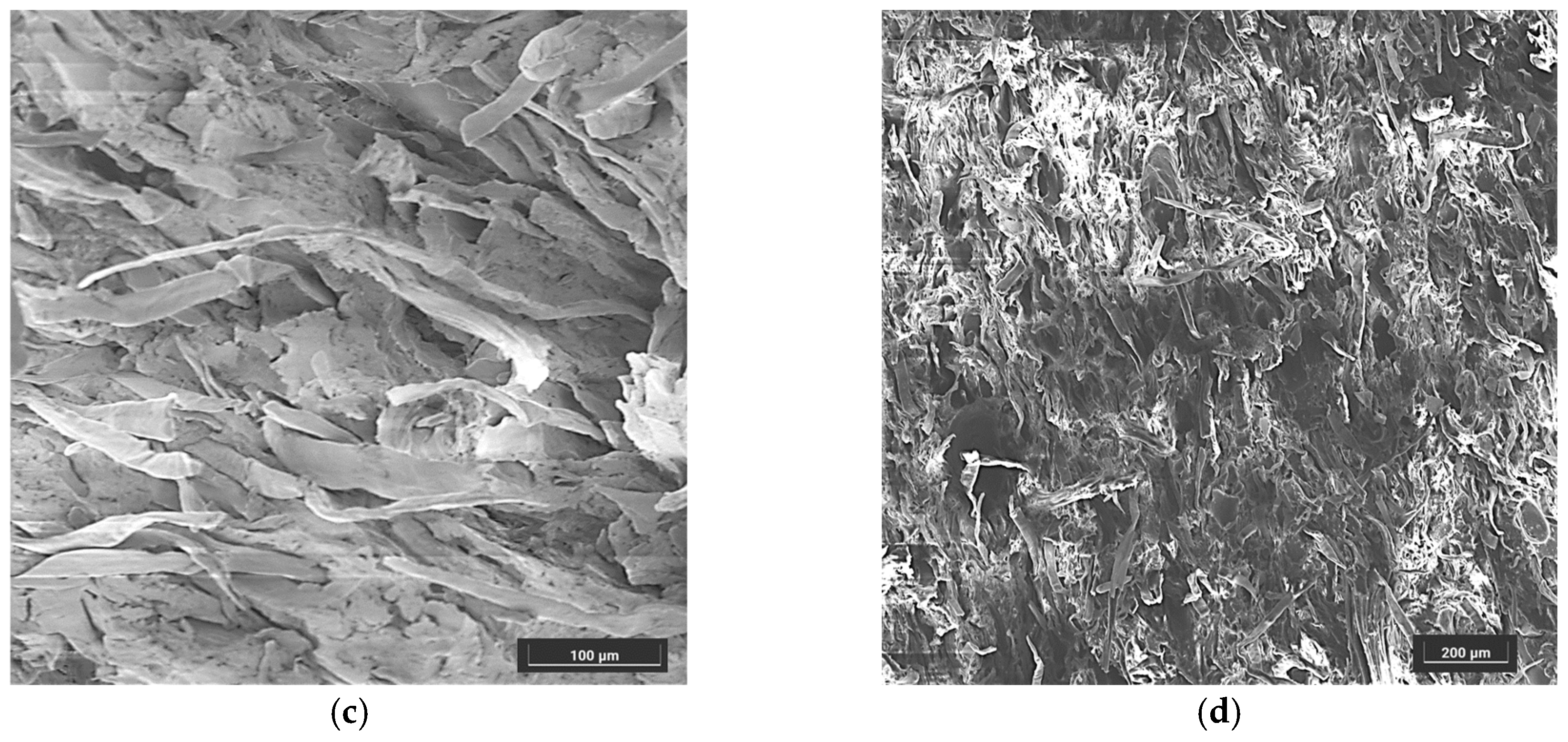

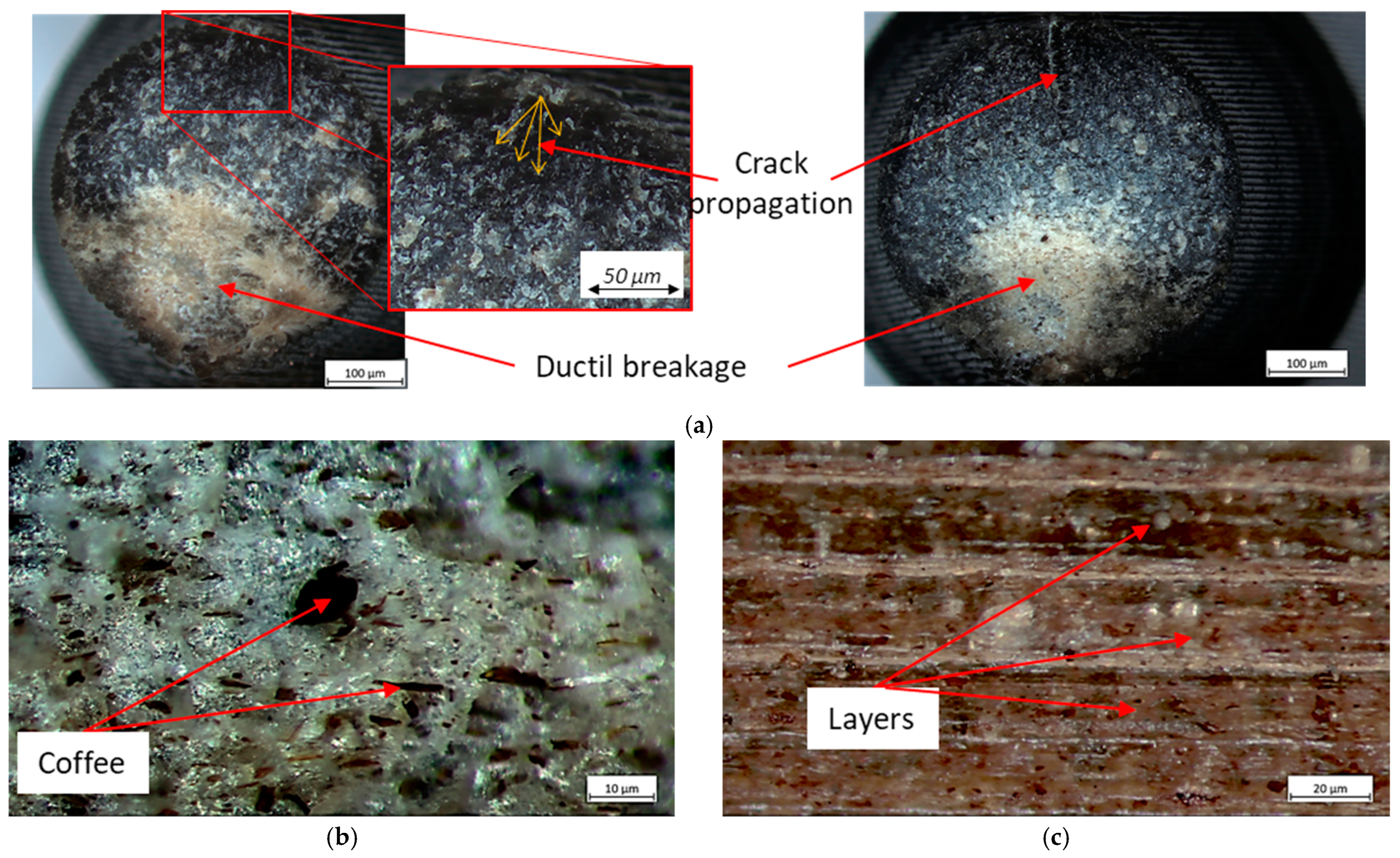

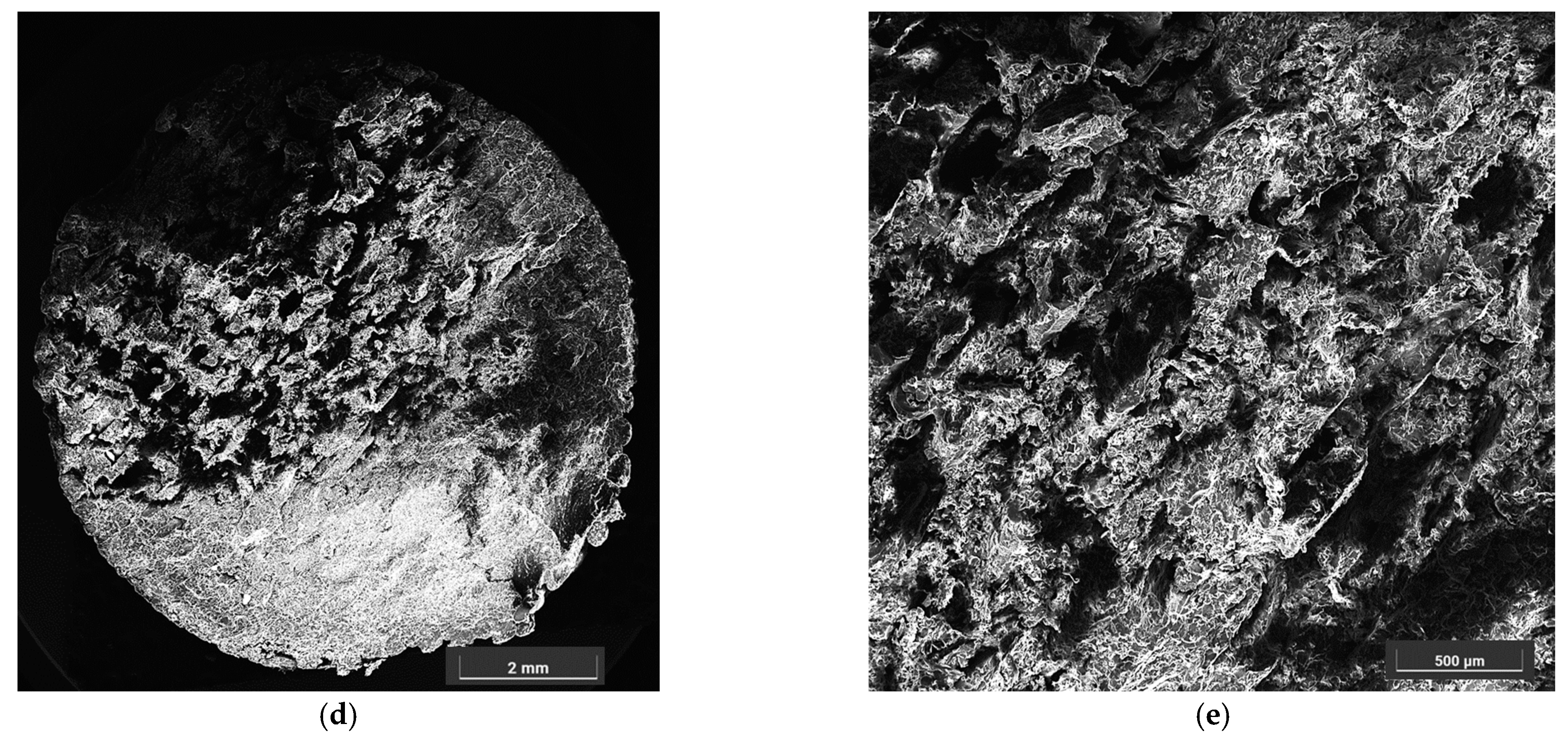

- In terms of the behavior under rotational fatigue conditions, natural fibers have a much higher potential compared to carbon fibers, improving the performance of PLA by 50%, with a similar breakage mechanism, presenting brittle and ductile breakage zones.

- Among the fibers tested, coffee and cellulose fibers performed best, with the cellulose fibers showing the best resistance. However, reduced homogeneity is observed in the cellulose specimens, with many gaps in the interior. This leads us to consider the potential of the material, improving the printing of the pieces by eliminating these voids.

- Cork and lax fibers do not present the same improvement for the higher load (1.5 kgf), but they overcome the carbon fibers under the same load (1 kgf), improving the PLA behavior.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhao, Y.; Chen, Y.; Zhou, Y. Novel Mechanical Models of Tensile Strength and Elastic Property of FDM AM PLA Materials: Experimental and Theoretical Analyses. Mater. Des. 2019, 181, 108089. [Google Scholar] [CrossRef]

- Singh, S.; Ramakrishna, S.; Singh, R. Material Issues in Additive Manufacturing: A Review. J. Manuf. Process 2017, 25, 185–200. [Google Scholar] [CrossRef]

- Caminero, M.Á.; Chacón, J.M.; García-Plaza, E.; Núñez, P.J.; Reverte, J.M.; Becar, J.P. Additive Manufacturing of PLA-Based Composites Using Fused Filament Fabrication: Effect of Graphene Nanoplatelet Reinforcement on Mechanical Properties, Dimensional Accuracy and Texture. Polymers 2019, 11, 799. [Google Scholar] [CrossRef] [PubMed]

- Wickramasinghe, S.; Do, T.; Tran, P. FDM-Based 3D Printing of Polymer and Associated Composite: A Review on Mechanical Properties, Defects and Treatments. Polymers 2020, 12, 1529. [Google Scholar] [CrossRef] [PubMed]

- Morales, A.P.; Güemes, A.; Fernandez-Lopez, A.; Valero, V.C.; de La Rosa Llano, S. Bamboo-Polylactic Acid (PLA) Composite Material for Structural Applications. Materials 2017, 10, 1286. [Google Scholar] [CrossRef]

- Salmi, M. Additive Manufacturing Processes in Medical Applications. Materials 2021, 14, 191. [Google Scholar] [CrossRef]

- Mallikarjuna, B.; Bhargav, P.; Hiremath, S.; Jayachristiyan, K.G.; Jayanth, N. A Review on the Melt Extrusion-Based Fused Deposition Modeling (FDM): Background, Materials, Process Parameters and Military Applications. Int. J. Interact. Des. Manuf. (IJIDeM) 2023, 1–15. [Google Scholar] [CrossRef]

- Osejos, J.V.M.; Sarria, C.A.; Zurita, D.B.P.; Rosero, S.G.; Jimenez, G.A.M. Mechanical Capabilities of Semi-Rigid Thermoplastics ABS and PLA from 3D Printing. Int. J. Mater. Prod. Technol. 2019, 59, 253–256. [Google Scholar] [CrossRef]

- Sandanamsamy, L.; Harun, W.S.W.; Ishak, I.; Romlay, F.R.M.; Kadirgama, K.; Ramasamy, D.; Idris, S.R.A.; Tsumori, F. A Comprehensive Review on Fused Deposition Modelling of Polylactic Acid. Prog. Addit. Manuf. 2022, 8, 775–799. [Google Scholar] [CrossRef]

- Chacón, J.M.; Caminero, M.A.; García-Plaza, E.; Núñez, P.J. Additive Manufacturing of PLA Structures Using Fused Deposition Modelling: Effect of Process Parameters on Mechanical Properties and Their Optimal Selection. Mater. Des. 2017, 124, 143–157. [Google Scholar] [CrossRef]

- Muthe, L.P.; Pickering, K.; Gauss, C. A Review of 3D/4D Printing of Poly-Lactic Acid Composites with Bio-Derived Reinforcements. Compos. Part C Open Access 2022, 8, 100271. [Google Scholar] [CrossRef]

- Huang, H.; Liu, W.; Liu, Z. An Additive Manufacturing-Based Approach for Carbon Fiber Reinforced Polymer Recycling. CIRP Ann. 2020, 69, 33–36. [Google Scholar] [CrossRef]

- Faidallah, R.F.; Hanon, M.M.; Szakál, Z.; Oldal, I. Mechanical Characterization of 3D-Printed Carbon Fiber-Reinforced Polymer Composites and Pure Polymers: Tensile and Compressive Behavior Analysis. Int. Rev. Appl. Sci. Eng. 2024. [Google Scholar] [CrossRef]

- Pertuz, A.D.; Díaz-Cardona, S.; González-Estrada, O.A. Static and Fatigue Behaviour of Continuous Fibre Reinforced Thermoplastic Composites Manufactured by Fused Deposition Modelling Technique. Int. J. Fatigue 2020, 130, 105275. [Google Scholar] [CrossRef]

- Saharudin, M.S.; Hajnys, J.; Kozior, T.; Gogolewski, D.; Zmarzły, P. Quality of Surface Texture and Mechanical Properties of Pla and Pa-Based Material Reinforced with Carbon Fibers Manufactured by Fdm and Cff 3d Printing Technologies. Polymers 2021, 13, 1671. [Google Scholar] [CrossRef]

- Najmon, J.C.; Raeisi, S.; Tovar, A. Review of Additive Manufacturing Technologies and Applications in the Aerospace Industry. In Additive Manufacturing for the Aerospace Industry; Elsevier Inc.: Amsterdam, The Netherlands, 2019; pp. 7–31. ISBN 9780128140635. [Google Scholar]

- Liu, W.; Huang, H.; Zhu, L.; Liu, Z. Integrating Carbon Fiber Reclamation and Additive Manufacturing for Recycling CFRP Waste. Compos. B Eng. 2021, 215, 108808. [Google Scholar] [CrossRef]

- Rahimizadeh, A.; Kalman, J.; Fayazbakhsh, K.; Lessard, L. Recycling of Fiberglass Wind Turbine Blades into Reinforced Filaments for Use in Additive Manufacturing. Compos. B Eng. 2019, 175, 107101. [Google Scholar] [CrossRef]

- Vidakis, N.; Petousis, M.; Tzounis, L.; Grammatikos, S.A.; Porfyrakis, E.; Maniadi, A.; Mountakis, N. Sustainable Additive Manufacturing: Mechanical Response of Polyethylene Terephthalate Glycol over Multiple Recycling Processes. Materials 2021, 14, 1162. [Google Scholar] [CrossRef] [PubMed]

- Deb, D.; Jafferson, J.M. Natural Fibers Reinforced FDM 3D Printing Filaments. Mater. Today Proc. 2021, 46, 1308–1318. [Google Scholar] [CrossRef]

- Subramani, R.; Mustafa, M.A.; Ghadir, G.K.; Al-Tmimi, H.M.; Alani, Z.K.; Rusho, M.A.; Haridas, D.; Rajan, A.J.; Kumar, A.P. Exploring the Use of Biodegradable Polymer Materials in Sustainable 3D Printing. Appl. Chem. Eng. 2024, 7, 3870. [Google Scholar] [CrossRef]

- Travieso-Rodriguez, J.A.; Zandi, M.D.; Jerez-Mesa, R.; Lluma-Fuentes, J. Fatigue Behavior of PLA-Wood Composite Manufactured by Fused Filament Fabrication. J. Mater. Res. Technol. 2020, 9, 8507–8516. [Google Scholar] [CrossRef]

- Khan, F.; Hossain, N.; Hasan, F.; Rahman, S.M.M.; Khan, S.; Saifullah, A.Z.A.; Chowdhury, M.A. Advances of Natural Fiber Composites in Diverse Engineering Applications—A Review. Appl. Eng. Sci. 2024, 18, 100184. [Google Scholar] [CrossRef]

- Colorado, H.A.; Velásquez, E.I.G.; Monteiro, S.N. Sustainability of Additive Manufacturing: The Circular Economy of Materials and Environmental Perspectives. J. Mater. Res. Technol. 2020, 9, 8221–8234. [Google Scholar] [CrossRef]

- Rajendran Royan, N.R.; Leong, J.S.; Chan, W.N.; Tan, J.R.; Shamsuddin, Z.S.B. Current State and Challenges of Natural Fibre-Reinforced Polymer Composites as Feeder in Fdm-Based 3d Printing. Polymers 2021, 13, 2289. [Google Scholar] [CrossRef] [PubMed]

- Aliotta, L.; Gigante, V.; Coltelli, M.B.; Cinelli, P.; Lazzeri, A. Evaluation of Mechanical and Interfacial Properties of Bio-Composites Based on Poly(Lactic Acid) with Natural Cellulose Fibers. Int. J. Mol. Sci. 2019, 20, 960. [Google Scholar] [CrossRef] [PubMed]

- Granda, L.A.; Espinach, F.X.; Tarrés, Q.; Méndez, J.A.; Delgado-Aguilar, M.; Mutjé, P. Towards a Good Interphase between Bleached Kraft Softwood Fibers and Poly(Lactic) Acid. Compos. B Eng. 2016, 99, 514–520. [Google Scholar] [CrossRef]

- Chalid, M.; Rahman, A.; Ferdian, R.; Nofrijon; Priyono, B. On the Tensile Properties of Polylactide (PLA)/Arenga Pinnata Ijuk Fibre Composite. In Macromolecular Symposia; Wiley-VCH Verlag: Weinheim, Germany, 2015; Volume 353, pp. 108–114. [Google Scholar]

- Travieso-Rodriguez, J.A.; Jerez-Mesa, R.; Llumà, J.; Gomez-Gras, G.; Casadesus, O. Comparative Study of the Flexural Properties of ABS, PLA and a PLA–Wood Composite Manufactured through Fused Filament Fabrication. Rapid Prototyp. J. 2021, 27, 81–92. [Google Scholar] [CrossRef]

- Jerez-Mesa, R.; Travieso-Rodriguez, J.A.; Llumà-Fuentes, J.; Gomez-Gras, G.; Puig, D. Fatigue Lifespan Study of PLA Parts Obtained by Additive Manufacturing. Procedia Manuf. 2017, 13, 872–879. [Google Scholar] [CrossRef]

- Fischer, M.; Schöppner, V. Fatigue Behavior of FDM Parts Manufactured with Ultem 9085. JOM 2017, 69, 563–568. [Google Scholar] [CrossRef]

- Lee, J.; Huang, A. Fatigue Analysis of FDM Materials. Rapid Prototyp. J. 2013, 19, 291–299. [Google Scholar] [CrossRef]

- UNE-EN ISO 527-1:2020 Plásticos. Determinación de Las Propieda. Available online: https://www.une.org/encuentra-tu-norma/busca-tu-norma/norma/?c=N0064896 (accessed on 23 November 2022).

- Petersmann, S.; Spoerk, M.; Van De Steene, W.; Üçal, M.; Wiener, J.; Pinter, G.; Arbeiter, F. Mechanical Properties of Polymeric Implant Materials Produced by Extrusion-Based Additive Manufacturing. J. Mech. Behav. Biomed. Mater. 2020, 104, 103611. [Google Scholar] [CrossRef] [PubMed]

- Azadi, M.; Dadashi, A. Experimental Fatigue Dataset for Additive-Manufactured 3D-Printed Polylactic Acid Biomaterials under Fully-Reversed Rotating-Bending Bending Loadings. Data Brief. 2022, 41, 107846. [Google Scholar] [CrossRef]

- Hassanifard, S.; Hashemi, S.M. On the Strain-Life Fatigue Parameters of Additive Manufactured Plastic Materials through Fused Filament Fabrication Process. Addit. Manuf. 2020, 32, 100973. [Google Scholar] [CrossRef]

- Parast, M.S.A.; Bagheri, A.; Kami, A.; Azadi, M.; Asghari, V. Bending Fatigue Behavior of Fused Filament Fabrication 3D-Printed ABS and PLA Joints with Rotary Friction Welding. Prog. Addit. Manuf. 2022, 7, 1345–1361. [Google Scholar] [CrossRef]

- Bagheri, A.; Aghareb Parast, M.S.; Kami, A.; Azadi, M.; Asghari, V. Fatigue Testing on Rotary Friction-Welded Joints between Solid ABS and 3D-Printed PLA and ABS. Eur. J. Mech. A/Solids 2022, 96, 104713. [Google Scholar] [CrossRef]

- ISO 1143:2021; Metallic Materials—Rotating Bar Bending Fatigue Testing. IOS: Geneva, Switzerland, 2010. Available online: https://www.iso.org/standard/79575.html (accessed on 24 November 2022).

- Bermudo Gamboa, C.; Martín Béjar, S.; Trujillo Vilches, F.J.; Sevilla Hurtado, L. Geometrical Analysis in Material Extrusion Process with Polylactic Acid (PLA)+carbon Fiber. Rapid Prototyp. J. 2022, 29, 21–39. [Google Scholar] [CrossRef]

- Martín Béjar, S.; Trujillo Vilches, F.J.; Bermudo Gamboa, C.; Sevilla Hurtado, L. Fatigue Behavior Parametric Analysis of Dry Machined UNS A97075 Aluminum Alloy. Metals 2020, 10, 631. [Google Scholar] [CrossRef]

- Montesinos, A.G.; Gamboa, C.B.; Bejar, S.M.; Hurtado, L.S. Influence of Layer Thickness on Fatigue Life of PLA+ Carbon Fiber Specimens by Additive Manufacturing; Springer International Publishing: Cham, Switzerland, 2023; pp. 401–412. [Google Scholar] [CrossRef]

- SOLIDWORKS. Available online: https://www.solidworks.com/es (accessed on 13 March 2023).

- Powerful 3D Slicer Software: IdeaMaker by Raise3D. Available online: https://www.raise3d.com/ideamaker/ (accessed on 13 March 2023).

- ISO 12107:2012; Metallic Materials—Fatigue Testing—Statistical Planning and Analysis of Data. IOS: Geneva, Switzerland, 2003. Available online: https://www.iso.org/standard/50242.html (accessed on 23 November 2022).

- Trujillo, F.J.; Martín-Béjar, S.; Bermudo, C.; Sevilla, L. Fatigue Test Bench Manufacturing by Reusing a Parallel Lathe. In Advances in Manufacturing Technology XXXII; IOS Press: Amsterdam, The Netherlands, 2018; Volume 8, pp. 15–20. [Google Scholar]

- Martín Bejar, S. Análisis Paramétrico Del Comportamiento a Fatiga de Piezas Torneadas En Seco de La Aleación UNS A97075 (Al-Zn). Ph.D. Thesis, Universidad de Málaga, Málaga, Spain, 2020. [Google Scholar]

- Gómez-Gras, G.; Pérez, M.A.; Fábregas-Moreno, J.; Reyes-Pozo, G. Experimental Study on the Accuracy and Surface Quality of Printed versus Machined Holes in PEI Ultem 9085 FDM Specimens. Rapid Prototyp. J. 2021, 27, 5183. [Google Scholar] [CrossRef]

- Buj-Corral, I.; Zayas-Figueras, E.E. Comparative Study about Dimensional Accuracy and Form Errors of FFF Printed Spur Gears Using PLA and Nylon. Polym. Test. 2023, 117, 107862. [Google Scholar] [CrossRef]

- Zayas-Figueras, E.E.; Buj-Corral, I. Comparative Study about Dimensional Accuracy and Surface Finish of Constant-Breadth Cams Manufactured by FFF and CNC Milling. Micromachines 2023, 14, 377. [Google Scholar] [CrossRef]

- Redwood, B.; Schöffer, F.; Garret, B. The 3D Printing Handbook: Technologies, Design and Applications; 3D Hubs: Amsterdam, The Netherlands, 2017; p. 304. [Google Scholar]

- Kiani, P.; Sedighi, M.; Kasaeian-Naeini, M.; Jabbari, A.H. High cycle fatigue behavior and thermal properties of PLA/PCL blends produced by fused deposition modeling. J. Polym. Res. 2023, 30, 264. [Google Scholar] [CrossRef]

- Korol, J.; Hejna, A.; Burchart-Korol, D.; Wachowicz, J. Comparative Analysis of Carbon, Ecological, and Water Footprints of Polypropylene-Based Composites Filled with Cotton, Jute and Kenaf Fibers. Materials 2020, 13, 3541. [Google Scholar] [CrossRef] [PubMed]

- Meredith, J.; Ebsworth, R.; Coles, S.R.; Wood, B.M.; Kirwan, K. Natural Fibre Composite Energy Absorption Structures. Compos. Sci. Technol. 2012, 72, 211–217. [Google Scholar] [CrossRef]

- Joshi, S.V.; Drzal, L.T.; Mohanty, A.K.; Arora, S. Are Natural Fiber Composites Environmentally Superior to Glass Fiber Reinforced Composites? Compos. Part. A Appl. Sci. Manuf. 2004, 35, 371–376. [Google Scholar] [CrossRef]

| Material PLA + | Reinforcement Percentage [%] | Brand |

|---|---|---|

| Cellulose | 10–20 | Addnorth |

| Flax | 10–20 | Nanovia |

| Coffee | <10 | 3D Fuel |

| Cork | 10–20 | ColorFabb |

| HR-PLA | - | NatureWorks |

| CF | <15 | Fillamentum |

| Normal | - | Smartfill |

| Layer Thickness e [mm] | Temperature T [°C] | Speed v [mm/s] | Filling [%] | Filling Pattern | Bed Temperature T [°C] | Shells |

|---|---|---|---|---|---|---|

| 0.2 | 215 | 40 | 100 | Grid | 55 | 2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bermudo Gamboa, C.; Martín-Béjar, S.; Bañón García, F.; Sevilla Hurtado, L. Enhancing Fatigue Resistance of Polylactic Acid through Natural Reinforcement in Material Extrusion. Polymers 2024, 16, 2422. https://doi.org/10.3390/polym16172422

Bermudo Gamboa C, Martín-Béjar S, Bañón García F, Sevilla Hurtado L. Enhancing Fatigue Resistance of Polylactic Acid through Natural Reinforcement in Material Extrusion. Polymers. 2024; 16(17):2422. https://doi.org/10.3390/polym16172422

Chicago/Turabian StyleBermudo Gamboa, Carolina, Sergio Martín-Béjar, Fermín Bañón García, and Lorenzo Sevilla Hurtado. 2024. "Enhancing Fatigue Resistance of Polylactic Acid through Natural Reinforcement in Material Extrusion" Polymers 16, no. 17: 2422. https://doi.org/10.3390/polym16172422

APA StyleBermudo Gamboa, C., Martín-Béjar, S., Bañón García, F., & Sevilla Hurtado, L. (2024). Enhancing Fatigue Resistance of Polylactic Acid through Natural Reinforcement in Material Extrusion. Polymers, 16(17), 2422. https://doi.org/10.3390/polym16172422